Abstract

Coalbed methane (CBM), as an unconventional natural gas resource, is an important part of China’s natural gas resources. A detailed description of the characteristics of coal reservoirs and CBM is conducive to the exploration and development of CBM and is of great significance to the realization of China’s peak carbon dioxide emissions and carbon neutrality goals. In this paper, the C25 coal seam of the Guxu colliery, located in the South Sichuan coalfield, is depicted in detail by the experimental results of low-temperature liquid nitrogen, high-pressure mercury injection, and isothermal adsorption experiments and geological data. The C25 coal seam is likely anthracite with medium to high ash contents, and a pore fissure system is present. The pore size distribution includes unimodal and bimodal pores, and the pore shapes include airtight pores with one closed end, open air permeable pores, and ink bottle-shaped pores. The coal seam has a strong adsorption capacity, high Langmuir volume, and scattered reservoir pressure distribution. Combined with the gas composition and carbon and hydrogen isotope data of CBM, the genesis of CBM is mainly thermal, and some secondary biogas may be present.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Commercial exploitation of coalbed methane (CBM) resources has been established in many countries around the world, including the USA, Australia, China, India and Canada (Moore 2012; Tao et al. 2019b). CBM can be preserved in many forms, including adsorbed gas on the surfaces of micropores (< 2 nm diameter), retained gas in coal matrix pores, free gas in cracks (the cleavage system), and dissolved gas in coal seam water (Bustin and Clarkson 1998; Tao et al. 2018; Ye et al. 2022; Zou et al. 2019). CBM exploration and development have the following advantages: (1) CBM resources are a clean energy source; (2) the exploitation of CBM can greatly reduce the danger of coal mine gas outbursts, thereby promoting safe coal mining; and (3) the utilization of CBM can reduce greenhouse gas emissions (Flores 1998; Karacan et al. 2011). Geological factors affecting the enrichment of CBM include coal seam development (Fu et al. 2017; Lu et al. 2021; Zou et al. 2022), coal reservoir characteristics (Chalmers and Marc Bustin 2007; Keshavarz et al. 2017; Men et al. 2021; Scott et al. 2007; Teng et al. 2017), tectonic conditions (Groshong et al. 2009; Pashin and Groshong, 1998; Zhang et al. 2021b), and hydrogeological conditions (Chen et al. 2022; Lamarre 2003; Li et al. 2015; Scott 2002; Yao et al. 2014).

China contains abundant CBM resources, and the geological resources of CBM in 42 major gas-bearing basins with a shallow depth of 2000 m reach 331.55 billion m3, ranking third in the world (Tao et al. 2019a). However, at present, the sustainable growth of proven reserves and the source of CBM in China mainly depend on several CBM industrial bases, including the southern Qinshui Basin and the eastern margin of the Ordos Basin (Li et al. 2015; Tao et al. 2014; Tao et al. 2012). Therefore, searching for strategic replacement areas for exploration and development is urgent. The development and utilization of CBM can optimize China’s energy structure and reduce greenhouse gas emissions (Tang et al. 2021). To achieve China’s 2060 carbon neutrality goal, China’s CBM development scale urgently needs to be upgraded. Following the successful development of Carboniferous-Permian CBM in the Qinshui and Ordos Basins, the exploration and development of late Permian CBM in the southern Sichuan Basin has also achieved rapid development (Yin et al. 2019).

The Guxu colliery is one of the important mining areas in the South Sichuan coalfield and one of the thirteen national coal bases in Yunnan and Guizhou Provinces. Further exploration and development of CBM in Sichuan Province by strengthening studies on CBM reservoir characteristics in this area is beneficial. Although predecessors have discussed the development and distribution characteristics of coal reservoirs in this area, as well as the macroscopic and microscopic types, coal quality, rocks surrounding coal reservoirs, and correlation between the material basis of coal reservoirs and CBM enrichment (Bao et al. 2020; Tang et al. 2021; Yin 2009; Yin et al. 2019), the exploration and development of CBM in the Guxu colliery has not experienced a breakthrough mainly because much controversy remains about the reasons for the changes in CBM contents, reservoir properties of coal reservoirs, causes of CBM, and accumulation model.

Based on the geological data in the study area, this paper describes the spatial characteristics of coal-rock reservoirs and the genetic types of CBM according to the genetic CBM chart and optimizes the favorable areas and target horizons of CBM to provide a theoretical basis for further clarifying the direction of CBM exploration and development in this area.

Geological background

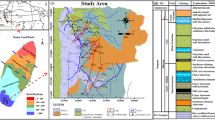

The study area is located in the transition zone between the Sichuan Basin and Yunnan-Guizhou Plateau. The Guxu colliery is surrounded by the Shiping-Dacun ore section to the northeast, the Yangtze plate to the west, the Gulin compound anticline to the south, and the margin of the Sichuan Basin to the east (Fig. 1). The latest exposed stratum is the Middle Jurassic Upper Shaximiao Formation (J2s), and the oldest stratum is the Silurian Hanjiadian Formation (S2h). Coal-bearing strata reside within the upper Permian Longtan Formation (P3l), which contains alternating land and sea facies (Fig. 2), and the thickness of the coal are 65.60 ~ 118.05 m, with a mean of 82.97 m. The Longtan Formation contains more than 20 layers, of which 3–10 layers are recoverable and locally recoverable, the average total thickness of the recoverable coal seam is 9.36 m, and C19 and C25 are the main mining seams. The C25 coal seam is located at the bottom of the upper Permian Longtan Formation. The coal seam structure is generally simple, and the condition of the coal seam is good, indicating a relatively stable to stable coal seam.

Samples and methods

Sample collection

All samples were collected from the Guxu colliery of the South Sichuan coalfield, and the sampling engineering points are shown in Fig. 1. All samples were collected from the Longtan Formation, which is the main lower Permian coal-bearing strata.

Methods

Industrial analysis and maximum vitrinite reflectance

According to the national standard GB/T212—2008, the moisture content (Mad), ash yield (Ad), volatile matter yield (Vd), and fixed carbon content (FCd) of air-dried coal samples were determined (Table 1). A microphotometer (Leica DM4P) fitted with a 50 × oil immersion objective lens and 10 × ocular lens was used to determine the vitrinite reflectance (Ro) according to China National Standards GB/T 6948 − 2008. The vitrinite reflectance was determined using 25 mm × 25 mm polished pellets. The reported reflectance was the mean value of 250 measurements. Detailed information on some typical parameters of the samples is listed in Table 2.

Low-temperature liquid nitrogen adsorption

The specific surface area, pore volume, and pore structure distribution of adsorption pores were determined by low-temperature liquid nitrogen (LTLN) adsorption experiments. All samples were crushed and sieved to 0.18–0.25 mm (60–80 mesh and dried for 48 h), and then tested at low temperature (77 K) with NOVA-2000e and GB/T 21,650.2–2008 was followed. The theoretical range of the detectable aperture of this method was 2 ~ 200 nm, and the specific surface area values were 0.1 ~ 3500.0 m2/g. The Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda (BJH) models were used to calculate the specific surface area and total pore volume, respectively (Heister 2014; Villarroel-Rocha et al. 2014).

High-pressure mercury injection

The physical properties of the powder and solid were measured via a mercury injection experiment. The fracture characteristics of pores and cracks were analyzed by mercury intrusion method, which is suitable for pore diameters of approximately 3 to 1000 nm. According to the National Standard SY/T 5346–2005, Micromeritics auto pore IV 9500 was used.

Scanning electron microscopy

Scanning electron microscopy (FE-SEM S4800) was used to observe the coal pore structure of the natural section of the coal sample, according to the Chinese petroleum industry standard SY/T 5162—1997.

Compositional analysis

A compositional test of the CBM sample was completed by the national geological testing center according to the GB/T 13,610–2020 compositional analysis of natural gas with gas chromatography: a 7890b gas chromatograph was used to determine the gas composition.

Isotopic compositions

The carbon and hydrogen isotopic compositions of CBM were determined by a Finnigan mat 253 mass spectrometer. The δ 13C and δ D measurements were corrected relative to the Vienna PeeDee Belemnite (VPDB) and Vienna standard mean ocean water (VSMOW) standards, and the standard deviations were ± (0.1 ~ 0.3 ‰) and ± (1 ~ 2 ‰), respectively.

Characteristics of coal-bearing strata

Coal seam developmental characteristics

The distances from the C25 coal seam to the C24 coal seam are 3.05 ~ 21.08 m, with an average of 10.42 m, and the distances from the top boundary of the Maokou Formation are 0.20 ~ 9.48 m, with an average of 3.19 m. The Guxu colliery exhibits an irregular rectangular shape with a surface coverage of approximately 46.47 km2. The coal mining thicknesses are 0.64 ~ 7.88 m, with an average of 2.15 m, and medium-thick coal seams dominate. The structure of the coal seam is relatively simple; the seam occasionally contains 1 ~ 2 layers of dirt bands and 4 layers of dirt bands in individual drill holes. The seam is black and dominantly has a diamond luster. The streaks are dark black. Stepped and jagged fractures are the main fractures, followed by conchoidal fractures. Both internal and external fractures are well developed, and the surfaces of external fractures are often filled with calcite. The dirt bands are dark gray and dark gray mudstone containing carbon, and the thicknesses of the dirt bands are 0.01 ~ 0.40 m. The direct roof of the coal seam is mudstone, sandy mudstone, and argillaceous siltstone, and the main roof is lithic siltstone and fine sandstone. The floor is mudstone, carbonaceous mudstone, and argillaceous siltstone and contains plant root fossils.

Coal quality characteristics

The characteristics of coal have an important influence on the physical properties of coal reservoirs, gas content characteristics, later form of fracturing and prediction of CBM development potential.

According to the Chinese national standard GB/T 212–2008, 11 coal samples were analyzed by air drying and industrial methods (Table 1). The ash contents of C25 coal range from 8.9 to 32.7%, indicating medium–high ash coal. The C25 coal seam contains more vitrinite, irregular fine ~ medium banding, linear and lenticular features, and smoother carbon lenses. The coal seam is composed of semibright coal.

According to China National Standards GB/T 6948–2008 and GB/T 8899–2013, the average vitrinite reflectance (Ro) of the same polished part of the coal sample was measured and analyzed by a Leitz MPV-3 photometer microscope (Table 2). The Ro, max values of the C25 coal seam area are between 2.36 and 2.81%, with an average of 2.63%, indicating anthracite. The microscopic components are mainly organic microscopic components of vitrinite, followed by inertinite. The vitrinite contents range from 55.1 to 91.2% and are mainly homogeneous vitrinite and matrix vitrinite, and the inertinite contents range from 1.8 to 40.5% and are mainly filamentary. The inorganic macerals range from 2.2 to 21.1% and are mainly clay, with a dotted and finely dispersed pattern; the remaining sulfides are mostly flaky and dotted pyrite; the small carbonate amounts are fragmented calcite; and silica is scattered with a small number of quartz particles.

Reservoir characteristics

Pore characteristics

Morphological characteristics and surface topography are identified by SEM. The cracks in the DC-4–1 coal sample are well developed, and the crack widths are mostly 1–5 μm (Fig. 3). Large amounts of pore filling are present in the DC-5–1 coal sample (Fig. 4). Overall, coal microfractures and pores which contribute to the exploration of CBM, are present, but some fractures are filled with clay minerals or calcite.

Pore and fissure development and filling characteristics of DC-5–1. a Filamentous illite and carbonaceous particles fill the intergranular pores. b Filamentous illite fills the pores, and quartz is also present. c Calcite and illite fill the organic joint pores. d Calcite joints and cracks are developed, and illite is attached to the surface

Pore structure characterization

In unconventional coal seam reservoirs, pore-fracture system development is rather complicated. The pore-fracture structural characteristics of the C25 coal seam were characterized by low-temperature liquid nitrogen (LTLN) and high-pressure mercury injection (HPMI) experiments.

-

(1)

LTLN adsorption experiment

Pores in coal are divided into four categories: macropores > 1 μm, 0.1 μm < mesopores < 1 μm, 0.01 μm < transitional pores < 0.1 μm, and micropores < 0.01 μm (Zhang et al. 2021a; Zou et al. 2020). As shown in Table 3, the average pore diameters of the C25 coal seam in the study area are 12.84–20.57 nm, classifying them as transitional pores. The BET specific surface area values are 0.14–4.67 m2/g, and the total pore volumes of the BJH model are 0.001–0.015 ml/g. As the average pore size of the coal samples decreases, the BET specific surface area tends to increase.

Combined with the International Union of Pure and Applied Chemistry (IUPAC) isotherm classification, the LTLN adsorption–desorption curve of the C25 coal seam mainly has two distribution forms (Fig. 5), as follows.

In type I, the adsorption–desorption curve represented by DC-4–2 produces a desorption loop, but there is no inflection point G, which indicates that no ink bottle-shaped hole is present. At low relative pressures (P/P0 < 0.5), the adsorption and desorption curves coincide, which indicates that the pore shape in the smaller pore size range is mostly airtight with one closed end. At high relative pressures (P/P0 > 0.5), a certain desorption loop occurs, which indicates that there are open air-permeable holes, but at the same time, airtight holes with one closed end may be present.

In type II, the adsorption–desorption curve represented by DC-5–4 has an abrupt decreasing inflection point, and the pore structure is relatively complex. At low relative pressures (P/P0 < 0.5), the adsorption–desorption curves coincide, which indicates that there is a closed airtight hole in a small pore size range. At a high relative pressures (P/P0 > 0.5), an adsorption loop appears with an obvious inflection point G, which indicates that thin-necked bottle-shaped (ink bottle-shaped) pores are developed, and open air permeable pores and closed airtight pores at one end may also be present.

-

(2)

HPMI experiment

According to Table 4, the peak pore diameter of the C25 coal seam in the study area is > 1 μm. The peak pore diameter indicates macropores with average pore diameters of 0.18–0.95 μm. Mesopores occur when the median pore diameters are within 25.17–40.25 μm. Macropores occur when the specific surface area values are 2.56–15.96 m2/g and the porosity values are 14.29–20.49%. Moreover, combined with the pore size distribution curve, the pore size distribution of the C25 coal seam can be roughly divided into two curve forms: the single peak pore size distribution represented by DC-4–2 and the double peak pore size distribution represented by DC-5–4 (Fig. 6). Both of these forms are in the pore size range of 10–100 μm and have an aperture peak. The difference is that in the curve represented by DC-5–4, the second peak is wide and is present at approximately 1 μm. This result suggests that the pore structure is more complex, and the specific surface area of DC-5–4 is larger than that of DC-4–2.

Isothermal adsorption characteristics

Studying the adsorption–desorption performance of coal reservoirs is of great significance for the gas-bearing characteristics of coal seams and the exploration and development of CBM (Li et al. 2019; Meng et al. 2014). The Langmuir volumes (the saturated adsorption capacity of raw coal) of the C25 coal seam in the Guxu colliery are within 21.33–32.57 cm3/g, indicating that the adsorption capacity of the C25 coal seam is strong, which is conducive to CBM enrichment; the Langmuir pressure values are within 0.99–1.59 MPa (Table 5). The methane adsorption capacity of the C25 coal seam near the DC-1 well is greater than that of the DC-4 and DC-5 wells. An obvious positive correlation is present between the Langmuir volume and Langmuir pressure of the C25 coal seam in the Guxu colliery (Fig. 7). This kind of reservoir is conducive to the development of CBM.

Genetic analysis of CBM

Gas-bearing distribution characteristics of CBM

Under the influence of multistage tectonic movement after coal formation in the study area, all coal and overlying strata are folded, and the exposed surface is weathered and denuded. In the shallow part, along the coal seam outcrop zone and structural failure zone, the formation pressure decreases, and the CBM begins to desorb and dissipate and can be preserved and enriched in the deep part. As a result, the shallow part of this area is mostly methane-poor (gas contents < 4 m3/t) and methane-containing (gas contents from 4 to 8 m3/t), and the burial depths are more than 250 ~ 300 m, with a mostly methane-rich part (gas contents > 8 m3/t). The burial depth is more than 300 m, and the average CBM content is generally approximately 20 m3/t.

Compositional characteristics of CBM

The gas composition of CBM varies significantly within different regions and coal seam metamorphic degrees; the composition is mainly CH4, N2, CO2 and C2 ~ C6 (heavy hydrocarbon gas), and sometimes contains trace H2S, Co, He, Ar, Hg, etc. (Villarroel-Rocha et al. 2014; Zhang et al. 2015, 2016). The C25 coal seam gas is mainly composed of CH4, with volume fractions of 86.04–97.45% and an average of 93.15% (Table 6). The second highest composition is N2, with volume fractions of 0.07–9.05% and an average of 4.37%. The volume fractions of CO2 are 0.14–5.48%, with an average of 1.91%. C2 ~ C6 range from 0.07 to 2.93%, with an average of 0.57%. The study area shows obvious dry gas characteristics.

The fitting trends of the N2, CO2, C2 ~ C6 and CH4 volume fractions reveal that the N2 and CO2 volume fractions of the C25 coal seam in the study area have a good negative correlation with the CH4 volume fraction, showing multiple changes and indicating the transformational role of the atmosphere in the process of CBM accumulation (Fig. 8). The volume fraction of C2 ~ C6 is small and does not change significantly compared to the volume fraction of CH4. According to previous studies, when the volume fraction of CO2 reaches more than 60%, it is mainly inorganic; when the volume fraction of CO2 is less than 15%, it is mainly organic (Dai et al. 2001). The volume fraction of CO2 is 0.14 ~ 5.48%, with an average of 1.91%. Therefore, CO2 is less affected by CO2 from inorganic sources, such as mantle and carbonate mineral dissolution, and most of the CO2 is organic in origin, such as from the decarboxylation reaction of organic macromolecules in coal and the bacterial decomposition of organic matter.

Genesis of CBM

According to previous works, methane carbon isotope δ13C (CH4) values are within − 55 ~ − 50 ‰, indicating biogenic gas (Ahmed and Smith 2001; Walsh and Haggerty 2019; Zhang et al. 2016), and the carbon isotopes of methane in thermogenic gas are δ13C (CH4) > − 50 ‰ (Feng et al. 2016), the carbon isotopes of methane are δ 13C (CH4) and are within − 45.1 ~ − 30.2 ‰, with an average value of − 34.78 ‰ (Table 7). These results suggest that thermogenic is the main factor according to the carbon isotope analysis.

The biogas methane hydrogen isotope δD (CH4) values are within − 400 ~ − 170 ‰ (Whiticar 1999), and for the C25 CBM in the study area, the δ D (CH4) values are within − 196.5 ~ − 154.9 ‰ (Table 7). Thus, biogenic gas may be distinguished by the δ13C (CH4) – D (CH4) diagram (Milkov and Etiope 2018; Whiticar 1999). The CBM of the Guxu colliery is mainly thermogenic gas, while the Molikv chart shows that it contains some secondary biogas (Fig. 9).

Regarding the origin of CO2 in CBM, many scholars use δ 13C (CO2) analysis. Dai et al. (2001) believed that CO2 is of organic origin when δ 13C (CO2) < − 10 ‰ and of inorganic origin when δ 13C (CO2) > − 8‰; Whitecar (1999) proposed that the thermal degradation of organic matter occurs when CO2 δ 13C (CO2) is − 25 ~ − 5 ‰ and that CO2 is related to secondary biogas when δ 13C (CO2) is − 40 ~ + 20 ‰.

In the study area, δ 13C (CO2) C25 CBM values range from − 34.2 to 27 ‰, with a mean of − 30.46 ‰ (Table 7). Combined with the isotope results, the CBM of C25 from the Guxu colliery is a thermogenic gas, and the Molikv chart further suggests that it is an early mature thermogenic gas (Fig. 10).

Conclusions

In this paper, the reservoir developmental characteristics and physical properties of the C25 coal seam in the Guxu colliery in the South Sichuan coalfield are described, and the genesis of CBM is analyzed.

-

(1)

The C25 coal seam in the Guxu colliery is a relatively stable medium to thick coal seam with a simple structure, mainly semibright coal. Coal microfractures and pores, which contribute to the exploration of CBM, are present, but some fractures are filled with clay minerals or calcite. According to HPMI and LTLN experiments, the reservoir develops airtight holes that are closed at one end, and some ink bottle-shaped holes, resulting in an increase in the specific surface area of the reservoir, which is conducive to the preservation of CBM.

-

(2)

The Langmuir volumes of the C25 coal seam are 21.33–32.57 cm3/g, and the Langmuir pressure values are 0.99–1.59 MPa. Low-pressure and high-pressure reservoirs present great differences. There is an obvious positive correlation among the reservoir pressure and the pressure gradient and burial depth.

-

(3)

The CBM of C25 is mainly composed of CH4, followed by N2, CO2 and C2 ~ C6 in sequence. The volume fractions of N2 and CO2 have a good negative correlation with the volume fraction of CH4, indicting the transformational role of the atmosphere in the process of CBM accumulation. CBM in the Guxu colliery mainly originates from thermogenic gas and may contain mixed secondary biogas, according to the cross-plot of δ13C(CH4)-δD(CH4) and δ13C(CH4)-δ13C(CO2).

References

Ahmed M, Smith JW (2001) Biogenic methane generation in the degradation of eastern Australian Permian coals. Org Geochem 32(6):809–816. https://doi.org/10.1016/S0146-6380(01)00033-X

Bao Y et al (2020) Constraints of methane absorbability in the Upper Permian Longtan Formation of Well DC-5 in Guxu mine area of southern Sichuan Coalfield. Nat Gas Geosci 31(01):93–99. https://doi.org/10.11764/j.issn.1672-1926.2019.10.011

Bustin RM, Clarkson CR (1998) Geological controls on coalbed methane reservoir capacity and gas content. Int J Coal Geol 38(1):3–26. https://doi.org/10.1016/S0166-5162(98)00030-5

Chalmers GRL, Marc Bustin R (2007) On the effects of petrographic composition on coalbed methane sorption. Int J Coal Geol 69(4):288–304. https://doi.org/10.1016/j.coal.2006.06.002

Chen H, Tian W, Chen Z, Zhang Q, Tao S (2022) Genesis of coalbed methane and its storage and seepage space in Baode Block, Eastern Ordos Basin. Energies 15(1):81. https://doi.org/10.3390/en15010081

Dai J, Shi X, Wei Y (2001) Summary of the abiogenic origin theory and the abiogenic gas pools (fields). Acta Petrolei Sinica 22(6):5–10. https://doi.org/10.3321/j.issn:0253-2697.2001.06.002

Feng Z et al (2016) Carbon isotopic composition of shale gas in the Silurian Longmaxi Formation of the Changning area. Sichuan Basin Petroleum Exploration and Development 43(5):769–777. https://doi.org/10.1016/S1876-3804(16)30092-1

Flores RM (1998) Coalbed methane: from hazard to resource. Int J Coal Geol 35(1):3–26. https://doi.org/10.1016/S0166-5162(97)00043-8

Fu H et al (2017) Preliminary research on CBM enrichment models of low-rank coal and its geological controls: a case study in the middle of the southern Junggar Basin, NW China. Mar Pet Geol 83:97–110. https://doi.org/10.1016/j.marpetgeo.2017.03.007

Groshong RH, Pashin JC, McIntyre MR (2009) Structural controls on fractured coal reservoirs in the southern Appalachian Black Warrior foreland basin. J Struct Geol 31(9):874–886. https://doi.org/10.1016/j.jsg.2008.02.017

Heister K (2014) The measurement of the specific surface area of soils by gas and polar liquid adsorption methods—Limitations and potentials. Geoderma 216:75–87. https://doi.org/10.1016/j.geoderma.2013.10.015

Karacan CÖ, Ruiz FA, Cotè M, Phipps S (2011) Coal mine methane: a review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int J Coal Geol 86(2):121–156. https://doi.org/10.1016/j.coal.2011.02.009

Keshavarz A, Sakurovs R, Grigore M, Sayyafzadeh M (2017) Effect of maceral composition and coal rank on gas diffusion in Australian coals. Int J Coal Geol 173:65–75. https://doi.org/10.1016/j.coal.2017.02.005

Lamarre RA (2003) Hydrodynamic and stratigraphic controls for a large coalbed methane accumulation in Ferron coals of east-central Utah. Int J Coal Geol 56(1):97–110. https://doi.org/10.1016/S0166-5162(03)00078-8

Li B, Yang K, Ren C, Li J, Xu J (2019) An adsorption-permeability model of coal with slippage effect under stress and temperature coupling condition. J Nat Gas Sci Eng 71:102983. https://doi.org/10.1016/j.jngse.2019.102983

Li Y, Tang D, Xu H, Elsworth D, Meng Y (2015) Geological and hydrological controls on water coproduced with coalbed methane in Liulin, eastern Ordos basin. China AAPG Bulletin 99(2):207–229. https://doi.org/10.1306/07211413147

Lu YY et al (2021) Current status and effective suggestions for efficient exploitation of coalbed methane in China: a review. Energy Fuels 35(11):9102–9123. https://doi.org/10.1021/acs.energyfuels.1c00460

Men X, Tao S, Liu Z, Tian W, Chen S (2021) Experimental study on gas mass transfer process in a heterogeneous coal reservoir. Fuel Process Technol 216:106779. https://doi.org/10.1016/j.fuproc.2021.106779

Meng Y et al (2014) Division of coalbed methane desorption stages and its significance. Pet Explor Dev 41(5):671–677. https://doi.org/10.1016/S1876-3804(14)60080-X

Milkov AV, Etiope G (2018) Revised genetic diagrams for natural gases based on a global dataset of >20,000 samples. Org Geochem 125:109–120. https://doi.org/10.1016/j.orggeochem.2018.09.002

Moore TA (2012) Coalbed methane: a review. Int J Coal Geol 101:36–81. https://doi.org/10.1016/j.coal.2012.05.011

Pashin JC, Groshong RH (1998) Structural control of coalbed methane production in Alabama. Int J Coal Geol 38(1):89–113. https://doi.org/10.1016/S0166-5162(98)00034-2

Scott AR (2002) Hydrogeologic factors affecting gas content distribution in coal beds. Int J Coal Geol 50(1):363–387. https://doi.org/10.1016/S0166-5162(02)00135-0

Scott S, Anderson B, Crosdale P, Dingwall J, Leblang G (2007) Coal petrology and coal seam gas contents of the Walloon Subgroup — Surat Basin, Queensland Australia. Int J Coal Geol 70(1):209–222. https://doi.org/10.1016/j.coal.2006.04.010

Tang S, Tang J, Shi Y, Lyu D (2021) Heat-hydrocarbon generating history and gas origin of Longtan Formation in Guxu mining area in South Sichuan coalfield. Journal of xi’an University of Science and Technology 41(2):298–306. https://doi.org/10.13800/j.cnki.xakjdxxb.2021.0214

Tao S, Chen S, Pan Z (2019a) Current status, challenges, and policy suggestions for coalbed methane industry development in China: a review. Energy Sci Eng 7(4):1059–1074. https://doi.org/10.1002/ese3.358

Tao S et al (2018) Material composition, pore structure and adsorption capacity of low-rank coals around the first coalification jump: a case of eastern Junggar Basin, China. Fuel 211:804–815. https://doi.org/10.1016/j.fuel.2017.09.087

Tao S, Pan Z, Tang S, Chen S (2019b) Current status and geological conditions for the applicability of CBM drilling technologies in China: a review. Int J Coal Geol 202:95–108. https://doi.org/10.1016/j.coal.2018.11.020

Tao S, Tang D, Xu H, Gao L, Fang Y (2014) Factors controlling high-yield coalbed methane vertical wells in the Fanzhuang Block, Southern Qinshui Basin. Int J Coal Geol 134–135:38–45. https://doi.org/10.1016/j.coal.2014.10.002

Tao S et al (2012) Dynamic variation effects of coal permeability during the coalbed methane development process in the Qinshui Basin, China. Int J Coal Geol 93:16–22. https://doi.org/10.1016/j.coal.2012.01.006

Teng J, Mastalerz M, Hampton L (2017) Maceral controls on porosity characteristics of lithotypes of Pennsylvanian high volatile bituminous coal: example from the Illinois Basin. Int J Coal Geol 172:80–94. https://doi.org/10.1016/j.coal.2017.02.001

Villarroel-Rocha J, Barrera D, Sapag K (2014) Introducing a self-consistent test and the corresponding modification in the Barrett, Joyner and Halenda method for pore-size determination. Microporous Mesoporous Mater 200:68–78. https://doi.org/10.1016/j.micromeso.2014.08.017

Walsh KB, Haggerty JH (2019) I’d do it again in a heartbeat: coalbed methane development and satisfied surface owners in Sheridan County. Wyoming the Extractive Industries and Society 6(1):85–93. https://doi.org/10.1016/j.exis.2018.08.014

Whiticar MJ (1999) Carbon and hydrogen isotope systematics of bacterial formation and oxidation of methane. Chem Geol 161(1):291–314. https://doi.org/10.1016/S0009-2541(99)00092-3

Yao Y, Liu D, Yan T (2014) Geological and hydrogeological controls on the accumulation of coalbed methane in the Weibei field, southeastern Ordos Basin. Int J Coal Geol 121:148–159. https://doi.org/10.1016/j.coal.2013.11.006

Ye J et al (2022) Characteristics of methane adsorption/desorption heat and energy with respect to coal rank. J Nat Gas Sci Eng 99:104445. https://doi.org/10.1016/j.jngse.2022.104445

Yin Z (2009) A discussion on CBM exploration target in Guxu mining area, South Sichuan Coalfield. Coal Geology of China 21(2):24–27. https://doi.org/10.3969/j.issn.1674-1803.2009.02.006

Yin Z, Jiang Q, Xiong J, Luo Y, Ju Y (2019) Longtan Formation coal measures argillutite gas and CBM association mode and joint exploitation prospect analysis in Southern Sichuan coalfield. Coal Geology of China 31(05):30–35. https://doi.org/10.3969/j.issn.1674-1803.2019.05.06

Zhang G, Ranjith PG, Fu X, Li X (2021a) Pore-fracture alteration of different rank coals: implications for CO2 sequestration in coal. Fuel 289:119801. https://doi.org/10.1016/j.fuel.2020.119801

Zhang S, Tang S, Li Z, Guo Q, Pan Z (2015) Stable isotope characteristics of CBM co-produced water and implications for CBM development: the example of the Shizhuangnan block in the southern Qinshui Basin, China. J Nat Gas Sci Eng 27:1400–1411. https://doi.org/10.1016/j.jngse.2015.10.006

Zhang S, Tang S, Li Z, Pan Z, Shi W (2016) Study of hydrochemical characteristics of CBM co-produced water of the Shizhuangnan Block in the southern Qinshui Basin, China, on its implication of CBM development. Int J Coal Geol 159:169–182. https://doi.org/10.1016/j.coal.2016.04.003

Zhang Z, Qin Y, You Z, Yang Z (2021b) Distribution characteristics of in situ stress field and vertical development unit division of CBM in Western Guizhou. China Nat Resour Res 30(5):3659–3671. https://doi.org/10.1007/s11053-021-09882-w

Zou G et al (2020) Two-dimensional SEM image-based analysis of coal porosity and its pore structure. Int J Coal Sci Technol 7(2):350–361. https://doi.org/10.1007/s40789-020-00301-8

Zou G, Zeng H, Peng S, Zhou X, Satibekova S (2019) Bulk density and bulk modulus of adsorbed coalbed methane. Geophysics 84(2):K11–K21. https://doi.org/10.1190/geo2018-0081.1

Zou G et al (2022) Influence of geological factors on coal permeability in the Sihe coal mine. Int J Coal Sci Technol 9(6):1–13. https://doi.org/10.1007/s40789-022-00475-3

Acknowledgements

We gratefully acknowledge the detailed and constructive comments of the two anonymous reviewers, who considerably improved the manuscript.

Funding

This work is sponsored by the National Key Research and Development Program of China (Grant No. 2018YFC0807803) and Open Fund of State Key Laboratory of Coal Resources and Safe Mining (Grant No. SKLCRSM20KFA07).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Santanu Banerjee

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhou, W., Liu, Y. et al. Physical characteristics and gas genesis of the C25 coal reservoir in the Guxu colliery in the South Sichuan coalfield. Arab J Geosci 15, 852 (2022). https://doi.org/10.1007/s12517-022-10144-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-10144-z