Abstract

Clear understanding of thermal and compositional properties of shales is important as it is directly linked to gas-flow properties (such as porosity and permeability) that would benefit shale gas development for CO2 storage. This study aims to investigate the effect of temperature on thermal degradation of shales using thermal techniques. In this work, thermal degradation of four gas shale samples from Marcellus formation, USA at a heating rate of 5, 10, and 20 ℃/min were examined by thermogravimetry (TG) coupled with X-ray powder diffraction (XRD) and Rock–Eval techniques. The result obtained using TGA is also analyzed by THINKS thermokinetic software, to determine and compare the kinetic parameters at different heating rates. Kinetic analysis is conducted under the second-order reaction. The TGA curve obtained in pyrolysis exhibits peaks having substantial mass loss primarily associated with decomposition of kerogen in the temperature range of 400–600 ℃ for all three heating rates. More than one-tenth of weight loss in the range of 350–650 ℃ is contributed by the minerals. The Rock–Eval analysis suggests that all four selected shales are rich in organic matter with TOC values ranging from 9.3 to 13.5% and are dominated by Type II and Type III kerogen. X-ray diffraction contributed further to mineralogical characterization where illite (5–35%) and kaolinite (7–26%) are found to be dominant clay minerals present in shale samples. In kinetic analysis of TGA data, the activation energy is found to be increasing with heating rate. The value of activation energy is found between 70 and 110 kJ/mol for all the samples. Using the activation energy values, it is inferred that physisorption is a prevalent mechanism for gas storage in the selected shales.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent times, CO2 concentrations in the atmosphere have been increasing remarkably, adding to overall greenhouse gases. In 2019, the eruption was 34,169 million tons, an increment of 0.5% over 2018 level (BPC 2020). By 2030, CO2 emissions will have grown by 63% from 2004 level, which is about 90% higher than 1990 levels (UNEP 2020). Although the main cause of CO2 is the burning of fossil fuels, currently it is challenging to move from fossil fuels to renewable energy sources such as wind, solar, nuclear power, etc. This is because alternative power sources are inadequate to satisfy the global energy requirement. Therefore, researchers have largely focused on various CO2 capture and storage techniques. If CO2 storage and sequestration technologies are developed and used efficiently, it is predicted that there will be a 45% CO2 release decline from the total 32 Gt of carbon dioxide flow (IEA 2004). Capture and geological storage has the potential to decrease global carbon dioxide discharges significantly if the technologies are utilized efficiently (Dashti et al. 2015). While the foundation for extraction of shale gas exists or is currently under development, integration of geological storage of CO2 with gas recovery from these formations contributes unique opportunities for reduction of CO2 discharges. CO2 can be permanently stored in depleted shale gas reservoirs as shale plays could act as impermeable barriers and prevent CO2 leakage. The abundance of shale deposits around the world as well as higher adsorption affinity of CO2 for shale shows the extra substantial storage potential of shale reservoirs as opposed to many alternatives (Merey and Sınayuç 2013). This CO2 storage in shale gas plays can also benefit in enhanced recovery of methane. Shale resources development may aid CO2 storage due to the innovations involved that can be directly transferable, particularly those related to shale composition (both organic and inorganic) as it is correlated to porosity and thermal properties which is directly linked to improving permeability.

Shale is a fine-grained sedimentary rock, containing organic and inorganic constituents. Dispersed organic portion in shale is categorized into soluble organic solvents and insoluble organic solvents. The insoluble portion is known as “kerogen” and the soluble portion is termed as “bitumen'”. The inorganic part in shale comprises clay minerals (illite, smectite, montmorillonite and kaolinite) and non-clay minerals (quartz, carbonates, feldspar, sulphides and sulfates) (Abdullayev and Muslimova 2010). Usually within shale formations, methane produced is stored as a free phase in the fractures and porous matrix and also as adsorbed phase on kerogen (organic part) and clays (inorganic part). Previous studies have extensively studied advanced procedures that are utilized for determining the inorganic and organic parts of shale (Lafargue et al. 1998; Jarvie et al. 2001; Gips 2014; Hazra et al. 2021). However, the determination of chemical structure of inorganic parts and organic parts remains a challenge and is a vital component for the shale gas development study. Therefore, further investigation of shales of various organic matter types is done in this work that is separated finely within the inorganic mineral matter that aids in complexity during analysis. Pyrolysis reaction of shales is affected by inhibition quality of silicates and catalytic influence of carbonates (Behar et al. 2001). The inorganic components in shale impact the conversion of kerogen and gas release during shale gas production (Lafargue et al. 1998). It is important to note that the hydrocarbon portion is kept in the kerogen fraction and bitumen fraction of shales. Utilization of thermal analysis method to the study of shale would give data on the change in mass of hydrocarbons. Thermal methods can effectively estimate organic matter in fine-grained rocks like gas shale and are useful in distinguishing the reactions occurring during heating treatment in both air and nitrogen atmosphere.

Rock–Eval pyrolysis and thermogravimetric analysis (TGA) are two thermal analysis methods applied in characterizing shale composition involving the pyrolysis process in this work. Rock–Eval has a few key limitations, such as inability to estimate water saturation or distinguishing the nature of hydrocarbons present. TGA is effective in determining the temperature range at which different types of hydrocarbons are volatilized. TGA has been widely applied to oil shales for determination of kinetic parameters and temperature dependency of devolatilization (Jarvie et al. 2001; Rietveld 1967; Langford and Blanc-Valleron 1990). Other benefits of TGA involve its ability to measure free fluid volumes in the sample and its effectiveness in learning organic and mineral properties when combined with Rock–Eval and XRD techniques, respectively. DTG (Derivative Thermogravimetric) curves can be applied to restrict the maximum temperature from the pyrolysis peak and thermal maturity of organic matter already in the shale sample. Several researchers also used TGA to examine relationships existing between degradation with pyrolysis temperature and heating rate in oil shales (Jarvie et al. 2001; Langford and Blanc-Valleron 1990). Accurate evaluation of kinetic parameters in the whole temperature range is crucial in predicting the thermal degradation of hydrocarbons present in shale. The heterogeneity in the composition of shale, mainly kerogen, and an extensive variety of minerals (clay and non-clay minerals) causes errors in the calculation of kinetic parameters using TGA. The hydrocarbons existing in shale undergo a wide range of reactions that TGA can only translate as a curve of weight loss vs. temperature. Several methods are available for the determination of activation energy and frequency factor from TGA data for the thermal decomposition of a sample. Thermogravimetric analysis can be used in discovering activation energy and discovering different stages of shale pyrolysis.

In this study, four shale samples were pyrolyzed using TGA under room temperature at three different heating rates (5, 10, and 20 °C min−1). TGA is combined with Rock–Eval Pyrolysis and XRD to interpret the organic and inorganic properties of the four gas shale samples. The present study attempts to understand thermal and compositional properties of shales as it is directly linked to gas-flow for CO2 storage in shale gas plays. This study aims to investigate the effect of temperature on the thermal degradation of shales using TGA. The kinetic simulation using THINKS thermokinetic software was used to analyze and compare the pyrolysis kinetic parameters for shales.

Materials and methods

Materials

In the present investigation, four shale samples were collected from the outcrops in the form of bigger size chunks of the Marcellus formation, USA. All the samples were crushed, powdered, oven-dried, and then weighed in stainless steel crucibles in the range of 10–50 mg for analysis. All the bulk samples were stored in a desiccator and crushed samples were sealed. Shale samples were prepared in the as-received basis (without any pre-treatment as suggested by Bakshi et al. (2018)).

Rock–Eval pyrolysis

The shale samples were subjected to pyrolysis using a Rock–Eval pyrolysis instrument, enabling the determination of TOC content, free hydrocarbons (S1), hydrocarbon generative potential (S2), and temperature (Tmax) at the maximum of the S2 peak. Sample of three different forms were pyrolyzed at the heating rates of 5 °C/min, 10 °C/min and 20 °C/min. For better observation, samples in different forms were subjected to same apparatus and experimental conditions.

At first in the pyrolysis stage, the sample is exposed to 573 K for release of free hydrocarbons from the sample. This is followed by heating the samples to 923 K for cracking of kerogen present in the sample. Details of performing Rock–Eval analysis are discussed extensively in the literature (Lafargue et al. 1998; Behar et al. 2001; Bakshi et al. 2018; Hazra et al. 2020). Vitrinite reflectance values were determined using the method suggested by Jarvie et al. (2001).

X-ray diffraction analysis

X-ray diffraction was used to determine the phase composition of shales. Bruker D8 Advanced instrument was used to perform a semi-quantitative study of minerals present in the shale samples. The measurements were performed using powdered samples with diffraction patterns being recorded for 2θ values in the range of 7–70° using Copper Kα radiation. With the help of basal spacing (d) and 2θ values for Cu K-α radiation, clay and non-clay mineral peaks were easily distinguished. Eventually, the minerals were quantified by the Rietveld technique utilizing the software Topas (Rietveld 1967).

TG analysis

Thermal analysis was conducted using thermogravimetry (TG) and differential thermogravimetry (DTG) technique with RIGAKU THERMO MASS PHOTO® equipment. The temperatures estimated in the TGA were calibrated using the melting point of indium as a standard. TG is a method in which the mass of a sample is determined concerning temperature while the sample is subjected to a controlled temperature program. TG analysis cannot directly show the water removal behavior and water content in the shale. However, TG analysis can help to understand the composition; thus, the thermal weight loss behavior of shale was studied by TG analysis. DTG is the first derivative of the TG graph and measures ‘Dm’ (weight loss or weight increase) per unit temperature/time. In the present study, TGA analysis was carried out with 3 different heating rates, i.e. 5 °C/min, 10 °C/min, and 20 °C/min over the temperature range of ambient to 800 °C using nitrogen. The powdered samples were charged into alumina (Al2O3) crucibles in amounts of about 15 mg. During the pyrolysis process, sample weight loss and heat flow were continuously recorded as a function of temperature and time. In the course of entire experiment, TG measurements were recorded every second.

Kinetic modeling

Kinetic predictions from the TGA data were conducted using open source thermokinetic code THINKS (Muravyev, 2016), which includes various estimation methods including Vyazovkin (2020), Friedman (2007), Flynn–Wall–Ozawa (FWO) (1965), Starink (2003), combined kinetic analysis (CKA) (Pérez-Maqueda et al. 2006), and model-fitting procedures, kinetic deconvolution (Muravyev et al. 2017; Sánchez-Jiménez et al. 2010) and formal kinetic analysis (Opfermann 2000; Burnham and Dinh 2007). Muravyev et al. (2019) discovered that the model-fitting method for activation energy estimation by THINKS was determined to be more useful for the complex process reaction. The main benefit of Flynn–Wall–Ozawa is to get a model-free evaluation of activation energy (Opfermann and Kaisersberger 1992). For examining the partially overlapping thermal events, the statistical peak separation technique, i.e., mathematical deconvolution (Perejón et al. 2011) was used. The fundamentals of these kinetic calculation methods are built as per the ICTAC Kinetic committee recommendation. Extensive literature is available on utilization of the above method for kinetic analysis (Garn 1975; Agrawal 1986; Koga 1994). In this study, THINKS software used the TGA data to determine activation energy and Arrhenius constant for all the four samples (SM05, SQ13, SQ14 and SQ15) at heating rate of 5 °C/min, 10 °C/min, and 20 °C/min.

Results and discussion

Rock–Eval pyrolysis

The Rock–Eval analysis was conducted on four Marcellus shales as shown in Table 1. The TOC values are ranging from 9.3 to 13.5% appear to exhibit shales rich in organic matter content and TOC values are also greater than 5% implying all four selected samples are carbonaceous shales. With the advances in reservoir engineering, organic-rich carbonaceous shales can be exploited for methane recovery and such advances also arises the possibility for using carbonaceous shales as promising CO2 storage reservoirs.

Generation potential of the source rock is identified using the data obtained from pyrolysis analysis (S1 and S2). The S1 (free hydrocarbon) values range from 0.06 to 0.17 mg HC/g rock (milligram hydrocarbon/g of rock) (Table 1). S2 values of the shale samples are varying in a wide range from 0.13 to 0.65 mg HC/g rock. The HI values are ranging widely from 1.25 to 6.35 mg HC/g TOC indicating that the organic fraction of shale samples is dominated by Type II and Type III kerogen. Due to the lower quantity of hydrocarbons produced through thermal cracking, lower values of HI were observed. The HI results imply that SM05 and SQ13 are oil-prone and SQ14 and SQ15 are gas-prone at moderate levels of Tmax (Al-Farraji 2017). Tmax values are ranging from 604 to 609 °C suggesting shales to be in the post-mature phase. Higher Tmax values result from the dominance of recycled kerogen in coarse-grained and organic-rich rocks. The vitrinite reflectance values are varying in a narrow range of 3.7–3.8% and it places all four samples in the initial stage of gas window.

X-ray diffraction analysis

The mineralogy of selected shales is quantified using X-ray diffraction and listed in Table 2. Carbonaceous shales tend to exhibit a wide variation in the composition of inorganic fractions. Illite (5–35%) and kaolinite (7–26%) are found to be the dominant clay minerals present in shale samples. The shales also have a certain amount of quartz content (2–9%). Other minerals present are calcite, siderite, feldspar, pyrite, chlorite, and dolomite in varying amounts. In the SM05 sample, a mixed layer of illite–smectite (I/S) is present in significant quantities with small amounts of illite and kaolinite. Calcite is the dominant carbonate mineral phase in SM05 shale. In the case of SQ13 and SQ14 shales, chlorite is an abundant mineral.

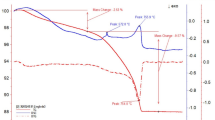

TG analysis

Thermogravimetric analysis is carried out on shale samples at three different heating rates (5, 10, and 20 °C/min) and in the temperature range of 22 to 800 °C. TG and derivative (first) of TG (DTG) plots for SM05, SQ13, SQ14, and SQ15 shales were obtained to depict the mass loss of sample and the rate of change in mass respectively as shown in Fig. 1. All the TG/DTG plots in Fig. 1 suggests minor differences in weight loss with heating rate at a lower temperature, but at a temperature range of 400–600 °C significant differences can be seen. Even in temperature range of 600 to 800 °C, weight loss difference with varying heating rates decreases but is still distinct. The TG curves of all the samples show three distinct areas of weight loss. In the DTG curves for most cases, several distinct volatilization reactions occur in the temperature region of 400–600 °C. The thermoanalytical plots of selected shales exhibit similar profiles except for SM05 shale (Fig. 1A). In the case of the SM05 sample, mass loss was initially < 1 wt.% (in the range of 155–200 °C) and a small peak can also be seen indicating release of free fluid at lower temperatures. This small peak also represents the release of clay-bound fluid and residual producible hydrocarbons in a combination that has a significantly higher boiling point (155 °C approx.). A small peak is seen at 505 °C indicating degradation of clay (illite and kaolinite) involving crystalline water loss or dehydroxylation or water dehydration of interstices (Wang et al. 2011; Cheng et al. 2010; Ptáček et al. 2010). The inflection point at around 500 °C is also indicative of organics volatilization. With the further rise in temperature from 580 to 698 °C, degradation of illite and smectite can be observed, followed by volatilization and the beginning of carbonate (dolomite or calcite) peak. In most cases, these minerals (illite and smectite) tend to lose weight between 600–700 °C rather than at 500 °C (Earnest 1991). Sharp peak at around 750 °C is indicative of carbonates with traces of occurrence of other events such as simultaneous organic matter combustion. The organics combustion is too small to account for all the weight loss in this temperature range. Sometimes, at these temperatures, clay transitions also occur but are not usually accompanied by weight loss (Al-Farraji 2017).

In the case of SQ13 and SQ14 samples, TGA plots have a smaller peak at a lower temperature (120 °C approx.) signifying loss of free fluid and interlayer fluid found in clay minerals (Fig. 1(B) and (D)). The weight loss amount is quite small at a temperature below 200 °C (ranging between 0.81 and 0.87%) as shown in Table 3. In the range of 200–300 °C, kerogen decomposition is noticed specifically for aliphatic compounds (Ashida et al. 2005). The two shales exhibit multiple-stage decomposition of hydrocarbon material in the range of 415–650 °C involving conversion of kerogen to bitumen and other products (gas, oil, char) occurring simultaneously. This also involves numerous complex reactions occurring in parallel. Past studies have reported single and two-stage decomposition of hydrocarbon material for oil shales (Ampomah et al. 2017; Behar et al. 2001; Lafargue et al. 1998). Further heating beyond 650 °C, displays inflection suggesting carbonate degradation (Alcázar-Vara et al. 2021). The SQ14 shale showed higher weight loss at around 700 °C, whereas the SQ13 shale shows a small rate of weight loss. This is due to the smaller amounts of carbonate minerals present in SQ13 shale as shown in Fig. 2 and Table 2. Figure 2 shows the TGA and DTG plots for SQ13 shale which acts as a representative highlighting the multiple events that occur during thermal treatment of shale.

Lastly, for SQ15 sample (Fig. 1(D)), a tiny peak is identified at 126 °C suggesting clay bound fluid and residual producible hydrocarbons with a higher boiling point that begins usually at around 100 °C. A further rise in temperature displays an inflection in the range of 418–440 °C. This extends ahead to separate peaks that lie in the range of 464–560 °C signifying various events comprising kerogen volatilization which tends to occur over longer time-scales. The decomposition of carbonate minerals (basic dolomite) can be identified by a small inflection point at a temperature above 650 °C as significant amounts of dolomite are found in SQ15 shale (Table 2) (Wang et al. 2011). Higher peak size for lower temperature suggests that low TOC samples (such as SQ13, SQ14, and SQ15) lose more mass at low temperature during pyrolysis than shales with higher TOC.

Comparing TG data with XRD

At different temperatures, weight loss (%) for selected shale samples is shown in Table 3. In the low-temperature region, i.e. below 200 °C, weight loss is extremely low with 1.12% being highest for SQ15 shale sample at a heating rate of 20 °C/min. This is attributed to moisture loss and as a result of loss of structural/interlayer water in clay minerals. However, in the temperature region of 200–620 °C, 16.1% of weight loss is found due to the loss of moisture from clay minerals. Grim (1968) stated that loss of structural water from clay minerals occurs over temperature extending up to 550 °C. The SQ15 shale has a higher amount of siderite (24%) as seen in XRD results (Table 2) and its decomposition occurs in the temperature region of 425–520 °C (Hurst et al. 1993). This would lead to a loss of about 7 wt.% in the total weight of the SQ15 sample and account for a much steeper slope of the DTG curve for temperature ranging between 400 and 500 °C (Luo et al. 2016; El-Bellihi 2010). It implies a much lower loss of organic matter for the SQ15 sample in this temperature range than for other samples (Chakraborty et al. 2021; Raghuvanshi et al. 2020). In this region, its weight loss percentage is higher at all three heating rates (15–16% approx.) compared to the SQ13 sample. In the range of 200–620 °C, although weight loss is lower for SQ13 and SQ14 samples as compared to SQ15 shale, the difference is not much (2–4% approx.) which may be due to the presence of significant amounts of chlorite in both the samples. The chlorite decomposition takes place in the temperature region of 585–625 °C that falls in the range of 200–620 °C (Villiéras et al. 1993).

The quartz content of all four samples is less compared to other minerals and its contribution to weight loss is insignificant. Clay minerals present in four shales identified from XRD results are kaolinite, illite, and illite–smectite mixed layers that loose moisture at a temperature below 200 °C (Santos and Gupta 1997). The crystalline-bound water is released at considerably higher temperatures.

Out of four samples, three samples (SQ13, SQ14, and SQ15) exhibit almost similar weight loss at different temperature regions. This behavior is due to quite similar TOC content for three samples (i.e. lying between 9.3 and 10.4%). It can be implied that more than one-tenth of the weight loss at 350–650 °C is contributed by the minerals. Higher weight loss contributed by kerogen decomposition in the temperature range of 450–550 °C tends to mask the weight loss due to the decomposition of minerals (such as siderite) in this range.

An important observation can be made from Table 3 that except for the SM05 sample, weight loss in the temperature region of 200–620 °C is high and significant for the rest of the shales. SM05 shale exhibits the highest weight loss in the temperature region of 620–800 °C. Kerogen decomposition for the SM05 sample is two to three times higher at 620–800 °C than the amount decomposed at 200–620 °C. Higher weight loss for SM05 shale at higher temperatures is due to the dominance of calcite which decomposes at a higher temperature above 700 °C. The presence of a significant amount of illite–smectite in the SM05 sample is also an important indicator of higher weight loss occurring in the range of 620–800 °C temperature region as smectite decomposes in the range of 700–800 °C (Gips 2014).

Overall, qualitatively it can be inferred that weight loss due to pyrolysis of organic content occurs in the entire temperature region of 200–800 °C. Although the amount of weight loss varies in each temperature region, it also depends on the sample type. The weight loss region of organic matter is wider and gets interfered at various stages by the decomposition of inorganic matter (basically minerals).

Kinetic analysis

The TGA data for 5, 10, and 20 °C/min heating rates were applied for kinetic analysis. In Table 4, the TGA data shows maximum weight loss in the range of 200–800 °C. In Table 4, the nomenclature used in the present study is described in terms of temperature rise in the lateral direction as Tmax1, Tmax2, Tmax3, and Tmax4 for shale samples used in this study. Accordingly, the maximum weight loss rate is also shown in Table 4 as Rmax-1, Rmax-2, Rmax-3, and Rmax-4 respectively. The weight loss rate increases with the heating rate from 5 to 20 °C/min for almost all shale samples. Similar behavior was reported in the past for oil shales showing a lateral shift in the rate of weight loss with an increase in heating rates (Rajeshwar 1981; Herrell and Arnold 1976; Drescher et al. 1983; Thakur and Nuttall 1987). This shift to higher temperatures of degradation is attributed to variation in the rate of heat transfer to shale with the change in heating rate (Doǧan and Uysal 1996). Few studies also suggest that the shift in temperature of degradation is due to collective behaviors of heat transfer with variation in heating rates. Eventually, this kinetics of degradation leads to delayed degradation (Drescher et al. 1983; Thakur and Nuttall 1987). An important parameter to be considered is the temperature difference existing between the inner and outer surface of shales. The temperature difference value would be insignificant at lower temperatures but with the rise in temperature (with an increase in heating rate) this temperature difference would tend to be more distinct. In the inner surface of particles at low temperatures, preliminary reactions occur due to the temperature difference thereby generating oil and gas (Lin et al. 2017). As the temperature passes through a higher range, secondary reactions occur. Subsequently, there would be delayed heat transfer from the heating kiln to the sample initially but it will increase later with an increase in heating rate. This variation in temperature results in change in the pyrolysis parameters. Thakur and Nuttall (1987) reported that the rate of weight loss is related to the final temperature for oil shale samples from Morocco. It was explained that with increasing final temperature, there is an increase in weight loss and also the rate of weight loss.

In Table 4, the SM05, SQ13, and SQ15 samples exhibit two major regions of weight loss for different heating rates. However, for SQ14 and SQ15 shales, additional regions (Tmax3 and Tmax4) of weight loss are noticed at different heating rates. The SQ14 shale shows three main regions of weight loss for all the heating rates. The characteristic temperature Tonset denotes initiation temperature and Tmax (Tmax1, Tmax2, Tmax3, and Tmax4) temperatures indicate maximum weight loss at respective characteristic temperatures. The initial weight loss of 1% approx. occurs within 200 °C. The first distinct weight loss is noticed in the temperature range of 415–542 °C, releasing volatiles that are thermally stable. Furthermore, in the case of the SM05 sample maximum weight loss occurs in the last temperature range of 752–796 °C that generates products such as residual char occurring due to secondary reactions involving thermal cracking. However, for SQ13, SQ14, and SQ15 samples the next principal weight loss occurs in the temperature range of 445–523 °C as an additional release of volatiles takes place that continues further because of pyrolysis in later stages until the final temperature is reached.

Kinetic modeling

Using the THINKS software, TGA data were analyzed for different heating rates and different models were compared to get the best-fit scenario. In the case of non-linear regression models, best fit was observed when the kinetic model in the software was set to simple reaction types with order of reaction being second. Also no over-fitting of data was observed in case of the second order simple kinetic model. Therefore, for the calculation of activation energy the order of reaction used was second than other rates due to its best fit. Nonlinear regression is carried out for fitting the calculated data to the experimental data giving the optimized kinetic parameters activation energy (Ea) and log k (where k is the frequency factor) along with the residual sum of squares (RSS) for each sample (Table 5). The mathematical method used in the determination of TG-derived kinetics communicates to the generally used integral method of analysis. The kinetic analysis of the TGA data using the iso-conversional methods is supported by the kinetic committee of ICTAC. The second reaction which accounts for the calculation of Ea and log k, are described below:

where \(\alpha\) is indicated below

\(\alpha\) is conversional degree for the overall reaction based on the initial mass (Wo), mass at t time (Wt) and the final mass of sample (Wf). k is second order rate constant for the reaction. The kinetic calculations have been performed with THINKS software in second order reaction. The software used the Euler method to solve differential equations and generate results.

The activation energy depends on the heating rate as shown in Table 5. It increases with higher heating rate and falls in the range of 70 kJ/mol to 111 kJ/mol. These values are in near close conjunction with those described by 73–77 kJ/mol at about 4 °C/min and 79.6 kJ/mol at 100 °C/min for Jordanian oil shale samples by previous studies (Khraisha 2000; Haddadin and Tawarah 1980). Two-stage breakdown was noticed for oil shale from Turkey with 25 kJ/mol in a lower temperature range and breakdown at main-stage was reported to be 43 kJ/mol (Doǧan and Uysal 1996). This could be ascribed to the combined effects of heat exchange at different heating rates and kinetics of kerogen reactions, performing in breaking of heavy molecular weight hydrocarbons to smaller segments which are distinguished by high activation energy. Physisorption mechanisms appear to be prevalent in gas shales involving weak forces leading to lower activation energies. Higher activation energy with a rise in heating rate can be related to kerogen breakdown requiring lower activation energy than that of demineralization. Decomposition undergoes three-stages of drying, pyrolysis and mineral disintegration. In the drying zone, activation energy is lowest as gas shale weight loss is attributed to moisture release and lighter organic matter is not volatilized. This requires minimal energy as compared to rest of the zones. Activation energy is an important parameter in pyrolysis stage and activation energy is in an intermediate-range than that of two zones. Here, gas shale weight loss is mainly attributed to hydrocarbons lost. Activation energy value is highest in the mineral decomposition stage as carbonate minerals undergo decomposition to release carbon dioxide. Presence of CaCO3 and SiO2 in selected shales is confirmed from inorganic mineralogy (Table 2) where decomposition of calcium carbonate occurs and is effective at higher temperatures i.e. more than 700 °C (Elder and Ready 1986). Lower activation energy values in gas shale can be due to presence of kerogen that characterizes complex heterogeneous structure. The higher weight loss for SM05 samples (Table 3) results in larger activation energy variation compared to rest of samples. The residual standard error for all samples falls within the range of 0.03 to 0.90. The smaller value of residual sum of squares indicates higher accuracy in model fitting during kinetics calculation.

Conclusion

In the present study, an attempt is made to understand thermal and compositional (organic and inorganic) properties of shales as it is directly related to gas flow mechanism within a shale gas reservoir. This in turn would aid in shale resources development for CO2 storage as well as enhanced gas recovery. Thermal decomposition of Marcellus shales are analyzed by TG/DTG methods ranging from room temperature up to 800 °C with varying heating rates at 5, 10, and 20 °C/min. In order to examine correlations between thermal and compositional properties, TGA results are integrated with experimental data obtained from X-ray powder diffraction (XRD) and Rock–Eval techniques. TGA curves exhibit substantial mass loss peaks primarily associated with kerogen decomposition in the temperature range of 400–600 ℃ for all three heating rates. The weight loss region of organic matter is wider (200–800 °C) and is interfered at various stages by the decomposition of minerals. Shale samples are found to be dominated by Type II and Type III kerogen with TOC values ranging between 9.3 and 10.4%. More than one-tenth of weight loss in the range of 350–650 ℃ is contributed by the minerals. Illite, kaolinite, and mixed-layer illite–smectite are common clay minerals noticed in selected shales. Activation energy values are increasing with higher heating rate and are in the range of 70 kJ/mol to 111 kJ/mol. Higher activation energy with a rise in heating rate can be related to kerogen breakdown requiring lower activation energy than that of demineralization. The physisorption mechanism is prevalent in the selected gas shales that usually involve weak forces leading to lower activation energies.

References

Abdullayev E, Muslimova Y (2010) Mineralogical Content of Productive Series Shales of Western Portion of South Caspian (Example, Bulla-Daniz Area), Oral presentation at AAPG European Region Annual Conference, Kiev, Ukraine

Agrawal RK (1986) On the compensation effect. J Therm Anal Calorim 31:73–86

Alcázar-Vara LA, Guerrero-Hernández J, Cortés-Monroy IR (2021) Thermal Analysis of Shale from a Mexican Deepwater Gas Field. Arab J Sci Eng. https://doi.org/10.1007/s13369-021-06281-4

Al-Farraji A (2017) Chemical engineering and reactor design of a fluidised bed gasifier, Doctoral dissertation, Cardiff University

Ampomah W, Balch R, Cather M, Will R, Gunda D, Dai Z, Soltanian M (2017) Optimum design of CO2 storage and oil recovery under geological uncertainty. Appl Energy 195:80–92

Ashida R, Painter P, Larsen JW (2005) Kerogen Chemistry 4. Thermal Decarboxylation of Kerogens. Energy Fuels 19(5):1954–1961

Bakshi T, Prusty B, Pathak K, Pal S (2018) Pore characteristics of Damodar valley shale and their effect on gas storage potential. J Petrol Sci Eng 162:725–735

Behar F, Beaumont V, Penteado HDB (2001) Rock-Eval 6 technology: performances and developments. Oil Gas Sci Technol 56(2):111–134

British Petroleum Company (2020) BP Statistical Review of World Energy. British Petroleum Company

Burnham AK, Dinh LN (2007) A comparison of isoconversional and model-fitting approaches to kinetic parameter estimation and application predictions. J Therm Anal Calorim 89(2):479–490

Chakraborty P, Hazra B, Sarkar P, Singh AK, Singh PK, Kumar S (2021) Thermal behavior of some Indian coals: inferences from simultaneous thermogravimetry–calorimetry and rock–eval. Nat Resour Res 30(3):2161–2177

Cheng H, Liu Q, Yang J, Frost RL (2010) Thermogravimetric analysis of selected coal-bearing strata kaolinite. Thermochim Acta 507–508:84–90

Dashti H, Zhehao Yew L, Lou X (2015) Recent advances in gas hydrate-based CO2 capture. J Nat Gas Sci Eng 23:195–207

Doǧan M, Uysal B (1996) Non-isothermal pyrolysis kinetics of three Turkish oil shales. Fuel 75(12):1424–1428

Drescher EA, Bassil CA, Rolinski EJ (1983) The kinetics of the thermal decomposition of Green River oil- shale by thermogravimetric analysis. In: Veziroglu TN (ed) Alternative energy sources V, Part D: biomass/hydrocarbons/hydrogen. Elsevier Science Publishers, Amsterdam

Earnest CM (1991) Thermal analysis of selected illite and smectite clay minerals. Part II. Smectite clay minerals. In: Smykatz-Kloss W, Warne SSJ (eds) Thermal Analysis in Geosciences, Lecture Notes in Earth Sciences, vol 38. Springer, Berlin, Heidelberg

El-Bellihi AA (2010) Kinetics of thermal decomposition of iron carbonate. Egypt J Chem 53(6):871–884

Elder JP, Ready VB (1986) The kinetics of the thermal degradation of calcium carbonate. J Therm Anal Calorim 31(2):395–405

Friedman HL (2007) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C: Poly Symp 6(1):183–195

Garn PD (1975) An examination of the kinetic compensation effect. J Therm Anal Calorim 7:475–478

Gips JP (2014) Shale characterization using TGA, Py-GC-MS, and NMR, MS Thesis, The University of Texas at Austin

Grim RE (1968) Clay Mineralogy (McGraw-Hill International Series in the Earth and Planetary), 2nd edn. McGraw-Hill Companies

Haddadin RA, Tawarah KM (1980) DTA derived kinetics of Jordan oil shale. Fuel 59(7):539–543

Hazra B, Sarkar P, Chakraborty P, Mahato A, Raghuvanshi G, Singh PK, Mukherjee A (2020) Coal combustion analysis using Rock-Eval: importance of S4-T peak. Arab J Geosci 13(12):1–10

Hazra B, Singh DP, Chakraborty P, Singh PK, Sahu SG, Adak AK (2021) Using rock-eval S4Tpeak as thermal maturity proxy for shales. Mar Petrol Geol 127:104977

Herrell AY, Arnold C (1976) Preliminary studies on the recovery of oil from chattanooga shale. Thermochim Acta 17(2):165–175

Hurst HJ, Levy JH, Patterson JH (1993) Siderite decomposition in retorting atmospheres. Fuel 72(6):885–890

IEA (2004) Prospects for CO2 Capture and Storage. IEA/OECD, Paris, France. Retrieved from (accessed on 20.01.16.). http://ccs-info.org/onewebmedia/iea_oecd_ccs_prospects.pdf

Jarvie DM, Claxton BL, Henk F, Breyer JT (2001) Oil and Shale Gas from the Barnett Shale, Ft. Worth Basin, Texas. Talk presented at the AAPG National Convention, June 3–6, 2001, Denver, CO. American Association of Petroleum Geologists Bulletin A, 100

Khraisha YH (2000) Retorting of oil shale followed by solvent extraction of spent shale: experiment and kinetic analysis. Energy Sources 22(4):347–355

Koga N (1994) A review of the mutual dependence of Arrhenius parameters evaluated by the thermoanalytical study of solid state reactions: the kinetic compensation effect. Thermochim Acta 244:1–20

Lafargue E, Marquis F, Pillot D (1998) Rock-Eval 6 Applications in hydrocarbon exploration, production, and soil contamination studies. Revue De L’institut Français Du Pétrole 53(4):421–437

Langford FF, Blanc-Valleron MM (1990) Interpreting Rock-Eval pyrolysis data using graphs of pyrolizable hydrocarbons vs. total organic carbon (1). AAPG Bull 74(6):799–804

Lin L, Lai D, Shi Z, Han Z, Xu G (2017) Distinctive oil shale pyrolysis behavior in indirectly heated fixed bed with internals. RSC Adv 7(35):21467–21474

Luo Y, Zhu D, Pan J, Zhou X (2016) Thermal decomposition behaviour and kinetics of Xinjiang siderite ore. Min Process Extract Metall 125(1):17–25

Merey Ş, Sınayuç Ç (2013) Experimental analysis of adsorption capacities and behaviours of shale samples, 19th International Petroleum and Natural Gas Congress and Exhibition of Turkey

Muravyev NV, Koga N, Meerov DB, Pivkina AN (2017) Kinetic analysis of overlapping multistep thermal decomposition comprising exothermic and endothermic processes: thermolysis of ammonium dinitramide. Phys Chem Chem Phys 19(4):3254–3264

Muravyev NV, Pivkina AN, Koga N (2019) Critical appraisal of kinetic calculation methods applied to overlapping multistep reactions. Molecules 24(12):2298. https://doi.org/10.3390/molecules24122298

Muravyev NV (2016) THINKS – thermokinetic software, Moscow

Opfermann J (2000) Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J Therm Anal Calorim 60(2):641–658

Opfermann J, Kaisersberger E (1992) An advantageous variant of the Ozawa-Flynn-Wall analysis. Thermochim Acta 203:167–175. https://doi.org/10.1016/0040-6031(92)85193-y

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38(11):1881–1886

Perejón A, Sánchez-Jiménez PE, Criado JM, Pérez-Maqueda LA (2011) Kinetic analysis of complex solid-state reactions. A new deconvolution procedure. J Phys Chem B 115(8):1780–1791

Pérez-Maqueda LA, Criado JM, Sánchez-Jiménez PE (2006) Combined kinetic analysis of solid-state reactions: a powerful tool for the simultaneous determination of kinetic parameters and the kinetic model without previous assumptions on the reaction mechanism. J Phys Chem A 110(45):12456–12462

Ptáček P, Kubátová D, Havlica J, Brandštetr J, ŠOukal, F., & Opravil, T. (2010) The non-isothermal kinetic analysis of the thermal decomposition of kaolinite by thermogravimetric analysis. Powder Technol 204(2–3):222–227

Raghuvanshi G, Chakraborty P, Hazra B, Adak AK, Singh PK, Singh AK, Singh V (2020) Pyrolysis and combustion behavior of few high-ash Indian coals. Int J Coal Prep Util 1–21

Rajeshwar K (1981) The kinetics of the thermal decomposition of green river oil shale kerogen by non-isothermal thermogravimetry. Thermochim Acta 45(3):253–263

Rietveld HM (1967) Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr A 22(1):151–152

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM (2010) A new model for the kinetic analysis of thermal degradation of polymers driven by random scission. Polym Degrad Stab 95(5):733–739

Santos H, Gupta HA (1997) Application of Thermal Analysis to Characterize Clay-Rich Formations, Presented at the Petroleum Conference of the South Saskatchewan Section of the Petroleum Society of CIM, Regina, SK, Canada. 19–22 October

Starink M (2003) The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta 404(1–2):163–176

Thakur DS, Nuttall HE (1987) Kinetics of pyrolysis of Moroccan oil shale by thermogravimetry. Ind Eng Chem Res 26(7):1351–1356

United Nations Environment Programme (2020) Emissions Gap Report 2020 - Executive summary. Nairobi

Villiéras F, Yvon J, François M, Maurice Cases J, Lhote F, Uriot JP (1993) Micropore formation due to thermal decomposition of hydroxide layer of Mg-chlorites: interactions with water. Appl Clay Sci 8(2–3):147–168

Vyazovkin S (2020) Kissinger method in kinetics of materials: things to beware and be aware of. Molecules 25(12):2813

Wang H, Li C, Peng Z, Zhang S (2011) Characterization and thermal behavior of kaolin. J Therm Anal Calorim 105(1):157–160

Funding

The authors wish to express their gratitude to PETRONAS for supporting this research through the PETRONAS Research Fund (PRF) grant awarded to Eswaran Padmanabhan. Authors further acknowledge Universiti Teknologi PETRONAS for granting the access to use analytical facilities.

Author information

Authors and Affiliations

Ethics declarations

Conflict of interest

The author(s) declare that they have no competing interests.

Additional information

Responsible Editor: François Roure

Highlights

• Effect of temperature on degradation of shale is studied using thermogravimetry.

• Pyrolysis characterization of shale is conducted under different heating rates.

• Kinetic modeling of shale yields activation energy in the range of 70–110 KJ/mol.

• Physisorption mechanism is prevalent in the selected gas shales.

Rights and permissions

About this article

Cite this article

Rani, S., Saksham, S., Sharma, J. et al. Characterizing pyrolysis behavior and kinetic parameters of shale using thermogravimetry. Arab J Geosci 15, 123 (2022). https://doi.org/10.1007/s12517-021-09389-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-09389-x