Abstract

Nano-surfactant of sodium dodecyl sulfate (SDS) was synthesized to be evaluated as a new chemical enhanced oil recovery agent for the application in an Iranian carbonate oil reservoir. Particle size analysis showed that the nano-SDS emulsions with 0.3 and 0.45 wt% concentrations contain particles smaller than 100 nm. SDS nano-surfactant in the form of emulsion was relatively more stable than those of the conventional SDS, detected by the zeta potential measurements. Also, nano-SDS was slightly more effective in lowering crude oil–aqueous phase interfacial tension, compared to the conventional SDS. The results of wettability studies indicated that the SDS emulsions, either in the form of surfactant or nano-surfactant, could similarly modify the wettability of the oil-wet rock surfaces (in the forms of both slice and powder) toward water-wet conditions. The spontaneous imbibition experiments on the reservoir limestone core samples at 50 °C resulted in up to 6% percent incremental oil recovery. The maximum incremental oil recovery happened as the SDS nano-surfactant was imbibed into the core samples at the second stage, after the formation brine.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last half-century, chemical enhanced oil recovery (EOR) methods have been widely studied in literature and applied in different oil fields (Gbadamosi et al. 2019). These methods include injection of polymer/gel (Akhlaghi Amiri et al. 2014; Kamal et al. 2017), to improve volumetric sweep efficiency and injection of surfactant (Sheng 2015), alkaline (Sheng 2019), foam (Shokrollahi et al. 2014), ionically modified water (Kilybay et al. 2017) etc., to improve displacement sweep efficiency. Since the 1970s, the application of the surfactants as EOR agents has been widely considered due to their significant influence on the interfacial tension (IFT) and the reservoir wetting properties (Samanta et al. 2012).

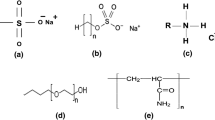

Among different studied surfactants, dodecyl trimethylammonium bromide (CTAB), a cationic surfactant, and sodium dodecyl sulfate (SDS), an anionic surfactant, have been more popular for application in the carbonate oil reservoirs (Chegenizadeh et al. 2017). The carbonate rocks (e.g., limestone, dolomite, and chalk), which contain almost half of the world’s oil reserves, are normally highly fractured and oil- or mixed-wet (Zaeri et al. 2018). The presence of an active aquifer or application of waterflooding (as a secondary method) in such reservoirs normally result in a situation in which the tight oil-saturated rock matrices are surrounded by the brine in the fracture network. It is found that the major remedy to release the oil in the rock matrices is activating the spontaneous imbibition process (Rokhforouz and Akhlaghi Amiri 2017), which may be achieved by the rock surface wettability alteration (Hatiboglu et al. 2005). Austad and his colleagues (Austad and Milter 1997; Standnes and Austad 2000; Austad and Standnes 2003) performed spontaneous imbibition tests on oil-wet chalk cores using cationic surfactants, including C12TAB. They showed that the cationic surfactants, with sufficient concentration, are quite effective in altering the wettability of the carbonate rock surfaces toward water-wet. In their studies, the rate of water imbibition decreased with connate water saturation and increased with temperature. Mohanty and his coworkers (Adibhatla and Mohanty 2008; Gupta and Mohanty 2011), on the other hand, reported that dilute non-ionic and anionic surfactant solutions can result in an oil recovery as much as 60% of originally oil-in-place (OOIP), from oil-wet carbonate cores. They suggested that in such a gravity-driven process, the surfactant molecules are diffused into the matrix from the fractures by changing surface wettability and reducing water–oil IFT. Abhijit et al. (2011) explored the capability of SDS surfactant in reducing water–oil IFT and enhancing oil recovery by performing core flooding experiments. Their study showed that the formation of an oil bank, resulted by IFT reduction, considerably increased the oil recovery factor. Vatanparast et al. (2011) evaluated different types of surfactants — including anionic, cationic, and anionic-cationic surfactant blends — in their effect on wettability in low-permeable carbonate cores, using spontaneous imbibition experiments. They found that C12TAB, at high concentrations, can lead to remarkable oil production through wettability alteration followed by capillary imbibition of water, in a counter-current flow regime. However, combining anionic and cationic surfactants ruined the performance of the cationic surfactant. Using glass micromodels, Razmi et al. (2012) conducted a series of studies to observe the effects of the surfactant type/concentration and the fracture length, orientation, and density on displacement performance. SDS surfactant resulted in 20% higher oil recovery compared to alkyl benzene sulfonate, due to its lower IFT with the crude oil. SDS and C16TAB were compared in a study on carbonate reservoir rocks (Ghojavand and Nourmohammad 2014), and it was concluded that the cationic surfactants are more effective in enhancing oil recovery in such reservoirs. Nguyen et al. (2014) used anionic, zwitterionic, non-ionic, cationic, and surfactant mixtures from 0.1 to 0.2 wt% in spontaneous imbibition tests on carbonate outcrops and revealed that cationic and anionic surfactants recovered up to 38% and 48% of the OOIP, respectively.

During recent years, there has been an increasing interest in the application of different nanomaterials for EOR, because of their larger surface area and higher activity (Sun et al. 2017). For example, CuO nanoparticle was evaluated to enhance heavy oil recovery, when subjected to gas injection (Shah 2009). Hydrophilic silica nanoparticles (Hendraningrat et al. 2012) and lipophobic and hydrophilic polysilicon nanoparticles (Ju and Fan 2009; Roustaei et al. 2012) were also studied as EOR agents with focus on wettability alteration and IFT reduction. Zargartalebi et al. (2014) studied the ability of hydrophilic and slightly hydrophobic silica nanoparticles to improve the SDS performance, by evaluation of IFT and adsorption properties. Water-dispersible polymer-silica nanocomposite was another nanomaterial which was synthesized to improve water sweep efficiency (Ponnapati et al. 2011). Ogolo et al. (2012) investigated different types of nanoparticles, including oxides of Al, Zn, Mg, Fe, Ni, and Sn, dispersed in different fluids for EOR applications. However, surfactant nanoparticles, which comprise the advantages of both surfactants and nanoparticles, have not been paid enough attention in the literature. Dehaghani and Badizad (2018) studied the effect of CTAB nano-surfactant, before and after treatment by the magnetic field, on the water–oil IFT and oil recovery factor. They found that increasing temperature and surfactant concentration results in a lower IFT. In this work, the SDS nano-surfactant was synthesized to be investigated as a new agent for EOR application in an Iranian carbonate (limestone) oil reservoir. The results of different studies on the SDS nano-surfactant were compared with those of the conventional SDS surfactant.

Experimental section

In this section, the used materials and the experimental procedures are described.

Materials

Sodium dodecyl sulfate (SDS), as an anionic surfactant, was prepared with a purity of 99% from Merck. NaCl (used for brine preparation), kerosene, and n-heptane (used for core cleaning) were provided from Sigma-Aldrich. Crude oil and reservoir core samples from an Iranian carbonate oil reservoir were provided by the National Iranian South Oil Company (NISOC). The reservoir crude oil density was 0.85 \(\frac{g}{{cm}^{3}}\) (34°API). The reservoir crude oil was centrifuged and filtered before the tests. The carbonate reservoir core samples were mostly composed of limestone with physical properties listed in Table 1.

Methods

To prepare the emulsions with the SDS concentrations of 0.3 wt% and 0.45 wt%, solid surfactant powder was added to distilled water and left to stir on a magnetic stirrer. In order to make nano-emulsions with nano-scale particles, a Hielscher ultrasonic homogenizer was employed. In this way, all the premixed samples were agitated for 90 min by applying acoustic waves with 20 kHz frequency (Dehaghani and Badizad 2018). Finally, to adjust the salinity, NaCl, with 3 wt% concentration, was dissolved in the prepared emulsions.

The particle size of the emulsions was determined using VASCO KIN™ particle size analyzer. In order to examine the effects of salinity and temperature, the particle size measurements were done before and after addition of salt and also at 25 and 50 °C (kept for 48 h). Zeta potential measurements were performed using Zeta Compact device to evaluate the electrophoretic mobility of the components, as evidence for emulsion stability. For this purpose, 10 ml of the SDS emulsion/nano-emulsion was put in the test tube and kept in an oil bath at 50 °C for 48 h; then it was analyzed.

The IFT between crude oil and the prepared samples was measured using a KRÜSS K-100 tensiometer through ring method under ambient conditions. Brine, with 3 wt% of NaCl, was used as the reference sample for the IFT measurements. Wettability studies were also done on the carbonate rock powders. Five ml of the aqueous samples (0.3 wt% surfactant/nano-surfactant emulsions) were added to the vials containing 2.5 g of the rock powders. The mixtures were agitated on a magnetic stirrer for 24 h. Afterward, 5 ml of the crude oil was added and stirred for 48 h. The vials were then placed on a flat surface for 3 days for equilibrium. The variation of the height of the water column (between solid surface and the oil interface) was investigated. Contact angles of the crude oil drops in the presence of different aqueous phases (brine and the SDS/nano-SDS emulsions) were measured on the carbonate core slices (24.5 mm diameter and 0.5 mm thickness). The core slices were carefully polished to get a smooth and flat surface, and then they were aged in the crude oil for 2 weeks. All the measurements were carried out using DSA 100 KRÜSS apparatus at room temperature and atmospheric pressure.

For the spontaneous imbibition tests, the cores were first mildly cleaned in Soxhlet extractors using kerosene and n-heptane, respectively, to remove the organic contaminations; then the salt contaminations were removed using distilled water. The cores were dried at 90 °C, and then were completely saturated with the crude oil by vacuum desiccator. They were aged in crude oil for 14 days at 50 °C. The spontaneous imbibition experiments were done using glass Amott cells at 50 °C. The spontaneous imbibition oil recovery was measured during the test by reading along the graduated tube.

Results and discussion

In this section, the obtained experimental results and the related discussion are presented.

Particle size analysis

Figure 1 shows the particle size distributions of the prepared emulsions with 0.3 wt% and 0.45 wt% SDS (Fig. 1a and b) and nano-SDS (Fig. 1c and d) under the effect of salinity and temperature (25 and 50 °C). SDS emulsion, in both concentrations (Fig. 1a and b), had a peak in particle size at the range of 200 to 800 nm. SDS particle sizes were slightly increased by salinity and temperature, maybe due to the molecular collisions and interactions between the sodium chloride ions and the SDS particles. The thickness of the electrically permeable layer at the presence of salt may also be reduced with increasing electrolyte concentration in the solution (Esmaeeli Azadgoleh et al. 2014). As depicted in Fig. 1c and d, the peak of nano-SDS particle size happened in the range of 50 nm, due to the homogenizing process, which confirms the nano-scale size of the particles in the synthesized emulsions. Nano-SDS samples, with different concentrations, were composed of particles which more than 90% of them were smaller than 100 nm. In the case of 0.3 wt% SDS nano-emulsion (Fig. 1c), the average particle size was in the range of 49 nm, while it was increased to 58 nm for 0.45 wt% nano-SDS emulsion (Fig. 1d). In the presence of salt and at 50 °C, the size of the particles in nano-SDS emulsions was less affected, compared to SDS emulsions. Due to the smaller particle sizes, the electrostatic forces and the molecular interactions are less pronounced in the case of the nano-SDS emulsions.

Zeta potential analysis

The results of the zeta potential measurements for SDS and nano-SDS emulsions are depicted in Fig. 2 at different surfactant concentrations. The charge of the particles, whether negative or positive, corresponds to the negative or positive zeta potential. So, the negative sign of the measured zeta potentials confirms the anionic nature of the SDS surfactant (Mcelfresh et al. 2012). In the case of 0.3 wt% SDS emulsion, the mean zeta potential value was − 25 mV, while for the 0.45 wt% SDS emulsion, it was slightly changed to − 19 mV. It is probably due to the rising of spatial inhibition by increasing the surfactant concentration (Zhao et al. 2018). Also, in the case of the nano-emulsion, the absolute zeta potential value was decreased from − 47 to − 36 mV, by increasing the concentration from 0.3 to 0.45 wt%. As it is clear in Fig. 2, the absolute zeta potential values in the SDS nano-emulsions are considerably higher than those of the SDS emulsions. It could be attributed to the influence of gravity that becomes negligible on nanoparticles; thus, the dispersion stability and the absolute zeta potential were increased.

IFT measurements

According to Fig. 3, the IFT between the crude oil and the surfactant emulsions (containing NaCl) was decreased by increasing concentration of both surfactant and nano-surfactant. The IFT between the crude oil and the pure brine was 26.2 mN/m. The addition of SDS surfactant at 0.3 and 0.45 wt% considerably decreased this value to 0.24 and 0.21 mN/m, respectively. The lower the tensile force at interfacial of an oil-in-water emulsion, the easier the movement of the molecules present at the oil surface and thus the easier the oil droplet to deform (Olajire 2014). Using nano-SDS, the IFT was even more decreased to 0.18 and 0.14 mN/m, for emulsions with 0.3 and 0.45 wt%, respectively. Higher surface area and thus more surface activities of the SDS nano-surfactant, compared to SDS, is a possible reason for this IFT behavior (Sun et al. 2017).

Wettability tests

The modification of the electrical load of the charged surfaces may result in the surface wettability alteration as well as variation in attraction/repulsion forces between the rock surface and the oil. The surface of the carbonate rock is normally positively charged in the pH ranges of the formation. The crude oil, which normally contains acidic carboxylic groups, is negatively charged. In an oil reservoir, as the three phases of crude oil, brine, and rock (CBR) reach equilibrium, the water film on the rock surface is limited to the water–oil and the water–rock interfaces. If these interfaces possess opposite electric charges, electrostatic attraction thins the water column and creates an oil-wet system (Derkani et al. 2018). By addition of a surfactant to the brine, the charge balance in the CBR system is disturbed; hence, the wettability may be changed. Figure 4 shows the results of the wettability tests on the rock powders in contact with reservoir crude oil and different aqueous phases (including brine, SDS, and nano-SDS emulsions) at ambient temperature. The water column was thickened by adding SDS and nano-SDS to the brine, as an indication of the existence of fewer repulsion forces between interfaces of water/oil and water/rock. In other words, SDS emulsion/nano-emulsion made the rock surface less positively charged, compared to the brine, through the ion-pair mechanism due to opposite charge interaction between them. However, the water column was slightly thinner in the presence of the SDS nano-surfactant compared to the SDS surfactant. This can be attributed to the nanoparticle’s higher tendency toward the aqueous phase, compared to the normal SDS, based on the zeta potential measurements.

Figure 5 presents the contact angle values of the crude oil droplets on the carbonate rock surface at the presence of different aqueous phases and under different aging conditions. Description of the test conditions is presented in Table 2. The oil contact angles lower than 90° indicate oil-wet condition, while the contact angles higher than 90° indicate water-wet situation. Tests A and B were done similarly using pure brine (without surfactant). Despite test A, the core slice was aged using the reservoir crude oil in case B for 2 weeks at 50 °C. As shown in Fig. 6, the measured contact angles were 143° and 60° for the non-aged (case A) and the aged (case B) slices, respectively. This confirms the surface wettability alteration toward oil-wetting condition by the aging process, which possibly happened due to the adsorption of the oil acidic components on the positively charged carbonate surface. It is important to note that the remaining tests (C to F) were conducted using the aged core slices. Figure 5 indicates that, in general, the SDS and nano-SDS surfactants considerably increased the oil drop contact angle, hence altering the wettability of the oil-wet surface toward water-wetting conditions. As an example, SDS surfactant with 0.3 and 0.45 wt% (tests C and E) resulted in contact angles of 121 and 126°, respectively, which are much higher than that of the brine at the aged mode (test B). For both SDS and nano-SDS, increasing concentration resulted in a higher contact angle, which is due to involvement of a greater number of molecules in the wettability alteration process. It is observed that the SDS emulsions were relatively more successful in changing the wettability, compared to the nano-SDS samples. This observation is in agreement with those observed in the wettability analysis with rock powders (Fig. 4).

Measured crude oil contact angle on the rock slices in the presence of different aqueous phases under conditions A to F (described in Table 2)

The images taken from the oil droplets (for contact angle measurements) on the rock slices in the presence of the pure brine for cases a A (non-aged) and b B (aged) described in Table 2

Spontaneous imbibition experiments

Table 3 shows the processes of the spontaneous imbibition experiments performed on the aged saturated cores. All the tests were done at 50 °C and initiated with the synthetic pure brine at the first stage, followed by the other surfactant/nano-surfactant emulsions (as described in Table 3). Figure 7 presents the oil recovery factor as a function of time for cases I to V. As shown in Fig. 7, in all the imbibition tests, the oil recovery factor at the first stage (pure brine imbibition) for core no. 2 (cases II, IV, and V) was slightly higher than that of core no. 1 (I and III). This is attributed to the differences in the cores’ structures and properties. In the next two stages, the cores were successively imbibed by the other aqueous phases, depending on the test process (described in Table 3).

Oil recovery factor (%) as a function of time (day) for the spontaneous imbibition recovery tests (described in Table 3) on the reservoir core samples

Comparison of the recovery profiles in Fig. 7 for cases I and III (both on the core 1) reveals that increasing the SDS emulsion concentration resulted in a slightly higher oil recovery factor at the second stage. The same trend is observed for cases II and IV (both on the core 2) using nano-SDS at the second stage. However, it is evident that using nano-SDS at the second stage of imbibition (case II) resulted in considerably (almost 2.5%) higher oil recovery than that of the conventional SDS (case V). A reason for this observation is the lower IFT of the SDS nano-emulsions compared to that of the SDS emulsions, at the same concentrations. In addition, SDS nanoparticles are considerably smaller than SDS particles; so, they can easily penetrate the pore channels of the porous medium and, hence, displace a higher amount of the trapped oil. Similar trends of the oil recovery profiles for cases I and V (with different core samples but the same sequence of the imbibing fluids) confirmed that the recovery results in the second and the third stages are independent of the cores’ characteristics.

In the third stage of all the tests, the SDS emulsions were replaced by the nano-emulsion at the same concentration and vice versa. According to the results shown in Fig. 7, the incremental oil recovery was almost negligible at this stage. However, just in case IV, an incremental oil recovery was observed in core no. 2, where the nano-surfactant emulsion was replaced by the normal SDS one. The greater effect of the SDS surfactant on the carbonate surface wettability (pronounced at higher concentrations), as shown in Figs. 4 and 5, may lead to this incremental recovery. As a conclusion, it is found that the nano-SDS surfactants are more effective on oil recovery as applied in the second stage of the imbibition process, prior to the SDS emulsion. Pore blockage, caused by larger SDS surfactants in the second stage, may lead to lower nano-SDS efficiency in the third stage.

Conclusion

In this study, sodium dodecyl sulfate (SDS) nano-surfactant with concentrations of 0.3 and 0.45 wt% were prepared to be studied, in comparison with the conventional SDS surfactant, as enhanced oil recovery agents for application in an Iranian carbonate oil reservoir. The experimental results led to the following concluding remarks:

-

The prepared SDS nano-surfactant emulsions at 0.3 wt% and 0.45 wt% were mostly composed of particles smaller than 100 nm.

-

Addition of SDS surfactant to the pure NaCl brine considerably decreased the crude oil–water IFT from 26 to about 0.2 mN/m. Using nano-SDS, the IFT was even more decreased.

-

Zeta potential analysis showed that the anionic SDS nano-surfactants were more stable than the conventional SDS surfactants.

-

Both conventional and nano-SDS surfactants successfully modified the wettability of the aged carbonate surface — in the form of the crushed core powder — from oil-wet to water-wet.

-

Crude oil in water contact angle measurements on the polished rock slices confirmed the wettability alteration by SDS conventional and nano-surfactant.

-

The spontaneous imbibition tests on the saturated carbonate core samples showed that, in the best scenario, the nano-SDS emulsion can result in incremental oil recovery up to 6% when it is applied at the second stage after brine. In the third stage, by changing the fluid type from surfactant to nano-surfactant and vice versa, the incremental oil recovery for all the fluids was negligible.

The results of this study confirmed the abilities of the SDS nano-surfactant as an EOR agent for application in carbonate oil reservoirs. However, complete screening evaluations — including stability, adsorption, and phase behavior studies — are required for such applications.

References

Abhijit S, Keka O, Ashis S, Ajay M (2011) Surfactant and surfactant–polymer flooding for enhanced oil recovery. Can Res Dev Cent Sci Cult. https://doi.org/10.3968/j.aped.1925543820110201

Adibhatla B, Mohanty KK (2008) Oil recovery from fractured carbonates by surfactant-aided gravity drainage: laboratory experiments and mechanistic simulations. SPE Res Eval Eng 11:119–130. https://doi.org/10.2118/99773-PA

Akhlaghi Amiri HA, Hamouda AA, Roostaei A (2014) Sodium silicate in porous media applied for in-depth profile modifications. Energies 7:2004–2026. https://doi.org/10.3390/en7042004

Austad T, Milter J (1997) Spontaneous imbibition of water into low permeable chalk at different wettabilities using surfactants. SPE 37236 Present. Int Symp OilfieldChemistry. https://doi.org/10.2118/37236-MS

Austad T, Standnes D (2003) Spontaneous imbibition of water into oil-wet carbonates. J Pet Sci Eng 39:363–376. https://doi.org/10.1016/S0920-4105(03)00075-5

Chegenizadeh N, Saeedi A, Quan X (2017) Most common surfactants employed in chemical enhanced oil recovery. Petroleum 3:197–211. https://doi.org/10.1016/j.petlm.2016.11.007

Dehaghani AHS, Badizad MH (2018) Effect of magnetic field treatment on interfacial tension of CTAB nano-emulsion: developing a novel agent for enhanced oil recovery. J Mol Liq 261:107–114. https://doi.org/10.1016/j.molliq.2018.03.111

Derkani MH, Fletcher AJ, Abdallah W, Sauerer B, Anderson J, Zhang Z (2018) Low salinity waterflooding in carbonate reservoirs: review of interfacial mechanisms. Colloids Interfaces 2(2):20. https://doi.org/10.3390/colloids2020020

EsmaeeliAzadgoleh J, Kharrat R, Barati N, Sobhani A (2014) Stability of silica nanoparticle dispersion in brine solution: an experimental study. Iran J Oil Gas Sci Technol 3:26–40. https://doi.org/10.22050/IJOGST.2014.7485

Gbadamosi AO, Junin R, Manan MA, Agi A, Yusuff AS (2019) An overview of chemical enhanced oil recovery: recent advances and prospects. Int Nano Lett 9:171–202. https://doi.org/10.1007/s40089-019-0272-8

Ghojavand H, Nourmohammad A (2014) Enhanced oil recovery from low permeability carbonated rocks by imbibitions of surfactant solutions. Iran J Chem Chem Eng 32:69–78

Gupta R, Mohanty KK (2011) Wettability alteration mechanism for oil recovery from fractured carbonate rocks. Transp Porous Media 87:635–652. https://doi.org/10.1007/s11242-010-9706-5

Hatiboglu CU, Karaaslan U, Akin S (2005) Spontaneous imbibition in low permeability carbonates. Energy Sources 27:839–846. https://doi.org/10.1080/00908310490450926

Hendraningrat L, Engeset O, Torsater B, Suwarno S (2012) Improved oil recovery by nanofluids flooding: an experimental study. SPE Kuwait Int Pet Conf Exhib. https://doi.org/10.2118/163335-MS

Ju B, Fan T (2009) Experimental study mathematical model of nanoparticle transport in porous media. Powder Technol 192:195–202. https://doi.org/10.1016/j.powtec.2008.12.017

Kamal MS, Adewunmi AA, Sultan AS, Al-Hamad MF, Mehmood U (2017) Recent advances in nanoparticles enhanced oil recovery: rheology, interfacial tension, oil recovery, and wettability alteration. J Nanomater: 1–15. https://doi.org/10.1155/2017/2473175

Kilybay A, Ghosh B, Chacko Thomas N (2017) A review on the progress of ion-engineered water flooding. J Pet Eng: 1–9. https://doi.org/10.1155/2017/7171957

Mcelfresh PM, Wood M, Ector D (2012) Stabilizing nano particle dispersions in high salinity, high temperature downhole environments. SPE Int Oilfield Nanotechnol Conf Exhib. https://doi.org/10.2118/154758-MS

Nguyen D, Wang D, Oladapo A (2014) Surfactant preflood to improve waterflooding performance in shale formations. SPE Improv Oil Recover Symp. https://doi.org/10.2118/169519-MS

Ogolo NA, Olafuyi OA, Onyekonwu MO (2012) Enhanced oil recovery using nanoparticles. SPE Saudi Arab Section Tech Symp Exhib. https://doi.org/10.2118/160847-MS

Olajire AA (2014) Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: prospects and challenges. Energy 77:963–982. https://doi.org/10.1016/j.energy.2014.09.005

Ponnapati R, Karazineir O, Dao E, Ng R, Mohanty K, Krishnamoorti R (2011) Polymer-functionalized nanoparticles for improving waterflood sweep efficiency: characterization and transport properties. Ind Eng Chem Res 50:13030–13036. https://doi.org/10.1021/ie2019257

Razmi R, Sedaghat MH, Janamiri R, Hatampou A (2012) Application of SDS/LABS in recovery improvement from fractured models. Int J Chem Mol Eng 6. 10.5281/ZENODO.1085323

Rokhforouz MR, Akhlaghi Amiri HA (2017) Pore-level influence of wettability on counter-current spontaneous imbibition, 79th EAGE Conference & Exhibition, Paris, France. https://doi.org/10.3997/2214-4609.201701510

Roustaei A, Moghadasi J, Bagherzadeh H, Shahrabadi A (2012) An experimental investigation of polysilicon nanoparticles’ recovery efficiencies through changes in interfacial tension and wettability alteration. SPE Int Oilf Nanotechnol Conf Exhib. https://doi.org/10.2118/156976-MS

Samanta A, Bera A, Ojha K, Mandal A (2012) Comparative studies on enhanced oil recovery by alkali–surfactant and polymer flooding. J Pet Explor Prod Technol 2:67–74. https://doi.org/10.1007/s13202-012-0021-2

Shah RD (2009) Application of nanoparticle saturated injectant gases for EOR of heavy oils. SPE Annu Tech Conf Exhib. https://doi.org/10.2118/129539-STU

Sheng JJ (2019) Status of alkaline flooding technology. J Pet Eng Technol 5:44–50. https://doi.org/10.37591/jopet.v5i1.2073

Sheng JJ (2015) Status of surfactant EOR technology. Petroleum 1:97–105. https://doi.org/10.1016/j.petlm.2015.07.003

Shokrollahi A, Ghazanfari MH, Badakhshan A (2014) Application of foam floods for enhancing heavy oil recovery through stability analysis and core flood experiments. Can J Chem Eng 92:1975–1987. https://doi.org/10.1002/cjce.22044

Standnes DC, Austad T (2000) Wettability alteration in chalk: 2. Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J Pet Sci Eng 28:123–143. https://doi.org/10.1016/S0920-4105(00)00084-X

Sun X, Zhang Y, Chen G, Gai Z (2017) Application of nanoparticles in enhanced oil recovery: a critical review of recent progress. Energies 10:345. https://doi.org/10.3390/en10030345

Vatanparast H, Alizadeh AH, Bahramian A, Bazdar H (2011) Wettability alteration of low-permeable carbonate reservoir rocks in presence of mixed ionic surfactants. Pet Sci Technol 29:1873–1884. https://doi.org/10.1080/10916461003610389

Zaeri MR, Hashemi R, Shahverdi H, Sadeghi M (2018) Enhanced oil recovery from carbonate reservoirs by spontaneous imbibition of low salinity water. Pet Sci 15:564–576. https://doi.org/10.1007/s12182-018-0234-1

Zargartalebi M, Kharrat R, Barati N (2014) Enhancement of surfactant flooding performance by the use of silica nanoparticles. Fuel 143:21–27. https://doi.org/10.1016/j.fuel.2014.11.040

Zhao M, Lv W, Li Y, Dai C, Zhou H, Song X, Wu Y (2018) A Study on Preparation and Stabilizing Mechanism of Hydrophobic Silica Nanofluids. Materials (Basel) 11(8):1385. https://doi.org/10.3390/ma11081385

Acknowledgements

The authors gratefully acknowledge the National Iranian South Oil Company (NISOC) for providing the required rock core and fluid samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Santanu Banerjee

Rights and permissions

About this article

Cite this article

Abuzaryan, M., Akhlaghi Amiri, H.A., Ahmadpour, A. et al. Evaluation of SDS nano-surfactant for EOR application in a carbonate oil reservoir. Arab J Geosci 14, 2217 (2021). https://doi.org/10.1007/s12517-021-08625-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08625-8