Abstract

Due to complications in describing and analysing the behaviour of earth materials resulting from alteration of rocks, detailed laboratory and empirical studies of their geochemical, geological, and mechanical properties are very essential and require great attention. In this work, geochemical indices have been used as an important tool in characterising tropical clays and mechanical behaviour has been predicted using different techniques. This was achieved by using a scanning electron microscope equipped with an electron dispersive spectrometer and conducting statistical analysis on tropical clays, materials that are frequently encountered by practising engineers. The mechanical behaviour considered were inherent (in situ specific volume), compression (compression index and intercept), and strength (uniaxial compressive strength), and the indices used were physical (e.g. fines content), mineralogical (e.g. quartz), and chemical indices (e.g. silica-to-alumina ratio). Tropical clay can be characterised by relating chemical indices with both depth and in situ specific volume, and the most appropriate chemical indices are alumina-titania index (ATI), silica-titania index (STI), and silica-to-alumina ratio (SA). The in situ specific volume will be satisfactorily predicted by the coefficient of uniformity (Cu), ATI, STI, and SA. The fines content (Fc), Cu, quartz, and the SA are the most suitable predictor for the compression behaviour. The strength will be successfully predicted by Fc. Physical, mineralogical, and chemical indices can be used to predict mechanical behaviour, and they are recommended for practitioners working on these materials depending on the properties required.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A deep understanding of elemental behaviour is necessary to establish the importance of chemical indices in engineering geology study as applied to characterize the geomaterials. Also, studying chemical indices is very important because quantitative chemical indices are essentially possible to investigate the chemistry of geomaterials (rocks and soils) through geological ages (e.g. Nesbitt and Young 1982; Harnois and Moore 1988; Li et al. 1995). The geochemical indices, which combine major elemental oxides and also called chemical weathering indices, are commonly used for characterising the extent of weathering and weathering profiles (e.g. Chigira 1990; Chigira and Sone 1991; Irfan 1996, 1999; Chigira and Oyama 1999; Ng et al. 2001; Duzgoren-Aydin et al. 2002; Price and Velbel 2003; Adams et al. 2011; Momeni et al. 2015; Udagedara et al. 2016b; Okewale 2020a; El Desoky et al. 2019, 2020; Heikal et al. 2019), analysis of soil for distributions of chemical oxides, and predicting weathering changes (e.g. Harnois 1988), ground investigation (e.g. Duzgoren-Aydin et al. 2002), quantifying soil development and fertility (e.g. Delvaux et al. 1989; Heidari and Raheb 2020) and analysing, predicting, and describing the behaviour of geomaterials (e.g. Hodder and Hetherington 1991; de jayawardena J and Izawa 1994; Gupta and Rao 2000, 2001; Ng et al. 2001; Udagedara et al. 2016a; Okewale and Coop 2018b; Okewale and Grobler 2021b).

However, the majority of the studies on the geochemistry of clays were on sedimentary clays, and investigation on tropical clays is still a debate. Clays are abundant in tropical and subtropical areas of the world, and these materials are encountered by practising engineers and geologists in their daily activities, and investigations, designs, analyses, and constructions are made in and/or on them. Therefore, a study of geochemistry of these materials is very essential due to the nature of their formation which is majorly from geological processes (weathering).

Also, another problem associated with these materials is the complications in analysing their mechanics of behaviour for engineering design compared with sedimentary geomaterials, which have been exhaustively studied (e.g. Burland 1990; Cotecchia and Chandler 2000). Although the behaviour of geomaterials resulting from decomposed rocks has been studied (e.g. Udagedara et al. 2016a; Rocchi et al. 2017; Okewale 2017: Okewale and Coop 2017), and different approaches have been used by Okewale and Coop (2018b) to predict the behaviour of decomposed geomaterials, similar studies on tropical clays are very few (e.g. Okewale and Grobler 2020b: Okewale 2020b). Okewale (2020b) investigated compressibility and the effects of structure on the compression behaviour of tropical clays and found that the intrinsic behaviour is consistent with fines content, plasticity, and clay minerals. However, this study did not present geochemical indices and suitable predictors for the mechanical behaviour of the geomaterials.

This paper addressed the geochemistry of tropical clays in an attempt to provide suitable geochemical indices that can be applied for characterisation in them and also investigates different approaches that can be used to predict the mechanical parameters (compression, strength) required for engineering design, analysis, and construction. A similar study on tropical clay is much more limited to the best knowledge of the authors. This study is new and novel in the way different indices were systematically used to predict engineering parameters required in the design and analysis of engineering structures.

Materials used

The samples used were tropical clays. They were collected as block samples from Ire Ekiti, southwest Nigeria. The collected samples’ location is well verified (Fig. 1). Geologically, they were underlain by the Precambrian basement complex and overlaid by a small layer of loamy soil and vegetation (Okewale 2020b). They were collected from four different locations and at different depths. Locations (A and B) have been studied by Okewale (2020b), and the other two locations (C and D) are new. The studied weathered samples were taken horizontally and vertically based on their formation and likely heterogeneity, which is a common signature of weathering processes (Okewale and Coop 2018b, 2020; Okewale 2019a, 2019b, 2019c; Okewale and Grobler 2020a2020, 2021b). The details of sample collection have been reported by Okewale (2020b) and characterized in Table 1. The details of other studies investigated are also provided in Table 1. The samples analysed from other studies were from different regions and countries. For clarity, acronyms are used for the samples. In the acronym, the letter stands for the location and the number represents the point of retrieving sample based on the depth starting from the top.

Methodology

The geochemistry and predictability of tropical clay behaviour were achieved by conducting geochemical analysis using a scanning electron microscope (SEM) equipped with electron dispersive spectrometer (EDS), analysing data from several relevant studies and performing statistical analyses. Although parts of materials used by Okewale (2020b) were used, several new physical and mechanical tests were conducted to estimate mechanical parameters and indices.

From the engineering point of view, geochemical indices were related with depth which is a typical approach, and the indices were related to engineering parameters needed for design and analyses. The indices considered were physical indices (e.g. fines content Fc, coefficient of uniformity Cu, plasticity index Ip), mineralogical indices (e.g. quartz Q, clay Cl) and chemical indices (e.g. silica to alumina SA, silica-titania index STI, alumina titania index ATI). The mechanical parameters used were uniaxial compressive strength (UCS) which stands for strength, compression index (Cc), the intercepts of one-dimensional normal compression line (N) which represents compression behaviour, and the in situ specific volume (v) which represents the in situ state of geomaterials. This study is very important due to the usefulness and applications of these geomaterials in massive and rapid infrastructural projects.

The coefficient of uniformity (Cu) and fines content (Fc) were estimated from grading curves (Fig. 2) (Okewale and Grobler 2021e) determined using wet sieving and sedimentation methods. The curves are for samples from different locations and depths. The same colour schemes are used for samples from the same location and different lines and symbols are used for samples from different depths. The demarcations represent clay fraction (particle diameter < 0.002 mm) and silt fraction (particle diameter between 0.002 and 0.063 mm) based on British standard (BSI 1990). The liquid limit (LL), plastic limit (PL), and plasticity index (Ip) were determined through Atterberg limit tests.

modified from Okewale 2020b)

Grading curves of the samples (

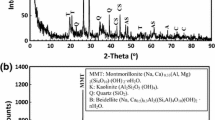

The mineralogy of the samples was studied using a Shimadzu XDS 2400H diffractometer equipped with JCPDFWIN software. The equipment operated at 40 kV and 55 mA, and the minerals were identified in the range of 5° ≤ 2θ ≤ 70° with Cu-Kα radiation. The samples were scanned at an interval of 0.02°/0.30 s, and the samples were analysed in powder form. The quantitative geochemical analysis of the samples was conducted using a Phenom ProX SEM equipped with an energy-dispersive spectrometer (EDS). The samples were air-dried, pulverised, placed in a sample holder, and then pushed into the machine for the EDS analysis. The chemical indices were calculated in molecular proportions of major elemental oxides. Thirteen chemical indices were evaluated, similar to other studies (e.g. Duzgoren-Aydin et al. 2002; Price and Velbel 2003; Udagedara et al. 2016a, 2016b; Okewale and Coop 2018b; Okewale 2020a), and the details of formulae and references are given in Table 2. The details of descriptions and definitions of these chemical indices have been reported by Udagedara et al. (2016a), Okewale and Coop (2018b), and Okewale (2020a).

The specific volume, which is similar to void ratio and porosity, is very important because it is directly related to in situ behaviour of geomaterials, in conjunction with stress level. Therefore, it must be accurately calculated in order to describe the behaviour of the samples. The in situ specific volume (v = 1 + e, where e is a void ratio) were calculated using different measurements. Several methods were used to improve the confidence using the methods highlighted by similar studies (e.g. Okewale and Coop 2017, 2018a; Rocchi et al. 2015, 2017; Okewale 2019b). The initial dimensions, water content, and sample weight were used to estimate initial v and final measurements and water content were used for verification by back-calculating the initial v employing the volumetric strains determined in the tests. Different equations similar to other studies were used (e.g. Okewale and Coop 2018b, 2020; Okewale 2019a, 2019c, 2020b; Okewale and Grobler, 2020b, 2020c,2021d, 2021a).

The compression parameters used were the compression index (Cc), which is the slope of the normal compression line (NCL) in v: logσʹv plane and the intercept of NCL (N). In other words, Cc is defined in terms of vertical stress and N was taken as the specific volume at vertical stress of 1 kPa in this study. They were obtained from one-dimensional compression tests in which the details have been discussed by Okewale (2020b). The NCLs were assumed to be straight lines within the range of stress tested. The uniaxial compressive strength was used as a strength parameter and they were taken as the peak strength from laboratory tests. The details of uniaxial compression tests have been discussed by Okewale (2020b).

Results and discussions

Geochemical analysis

In order to present the usefulness of chemical indices for tropical clays in a qualitative and quantitative manner, they are related with depth. The relationships are represented by regression lines and statistics. In this work, the relationships between mechanical parameters and indices are generally represented by regression statistics. The statistics properties used are correlation coefficient (r) and p value. While the correlation coefficient presents the quantitative strength between chemical indices and depth or mechanical parameters and other indices, p value shows the probability of a true relationship between chemical indices and depth or mechanical parameters and other indices. A relationship is said to be statistically significant if the correlation coefficient is high, and p value is low.

The correlation coefficients are classified based on the study of Okewale and Coop (2018b). The regression statistics are classified as follows; the r values between 0 and 0.19 are classified as very weak, those between 0.20 and 0.39 are classified weak, those between 0.40 and 0.59 are classified as moderate, those between 0.60 and 0.79 are classified as strong and finally, and those between 0.80 and 1.00 are classified as very strong. In this study, only the relationships that are statistically significant are presented in the figures. The figures are shown in the order of reducing regression statistics.

Figure 3 reveals a variation of chemical indices with depth. This is very essential in characterising materials resulting from weathered rock in order to highlight the trend along with vertical profiles (Okewale and Coop 2018b; Okewale 2020a; Okewale and Grobler 2021c). In the figures, open black and coloured symbols are used for samples tested, and open and filled grey symbols are used for data analysed from relevant studies. However, these symbol schemes are used throughout this work. The trends and relationships are presented using linear regression lines and the regression statistics (r and p values) are shown in each plot. As stated earlier, the figures are shown for chemical indices with meaningful regression statistics. However, the details of the statistics are given in Table 3. The chemical indices give regression statistics ranging from very weak to very strong correlations (Table 3). Figure 3a presents the variation of ATI with depth. This was developed for weathered metamorphic rocks. This shows the relationship between oxides of aluminium, titanium, and silicon. The ATI is increasing with depth, and the regression statistics are very strong (r = 0.95, p value = 1.94E − 06). The material is a product of weathering and the intensity is expected to reduce with depth thereby increasing the ATI. This indicates that the ATI is useful and can be applied in characterising tropical clays similar to other geomaterials (e.g. de Jayawardena and Izawa 1994).

For comparison, the data analysed from related studies are presented in Fig. 3a. The depths for the data are chosen arbitrarily because the depths at which samples were retrieved were not stated. The ATI values vary for different materials, and the values for samples tested are within the range obtained for other samples. This can be attributed to the heterogeneity of the samples. It can be seen that even samples from the same area have different values (e.g. Dah-Traore et al. 2018; Seynou et al. 2016; Chukwujike and Igwe 2016; Folorunso et al. 2012; OlaOlorun and Oyinloye 2010). Also, the ATI values are within the values reported for residual soils from metamorphic rocks (de Jayawardena and Izawa 1994) and igneous rocks (Gupta and Rao 2001; Okewale 2020a; Okewale and Coop 2018b).

Figure 3b presents the variation of STI with depth. This index shows the relationship between oxides of silicon, aluminium, and titanium. The STI increases with depth similar to ATI with very strong correlation statistics (r = 0.85, p value = 0.0003). At very shallow depth, the weathering intensity is high, and the STI reduces. This shows that this index can be used to characterise tropical clays, similar to other studies (e.g. de Jayawardena and Izawa 1994). While values from Dah-Traore et al. (2018), Seynou et al. (2016), Chukwujike and Igwe (2016), and Folorunso et al. (2012) seem relatively higher, others are within the values obtained for tested samples.

Figure 3c shows the variation of silica to alumina ratio (SA) with depth. This index is also called the Ruxton ratio. The SA is reducing with depth, and the statistics are very significant with r = 0.84 and p value of 0.0005. Weathering increases the formation of aluminium oxide which consequently reduces SA. The SA gives a very good relationship with depth, and this shows that it can be used to characterise tropical clay. The SA has also been found to be suitable for the applicability in some weathered geomaterials (e.g. de Jayawardena and Izawa 1994). Comparing the samples, the data are within the values obtained for tested samples. Again, The SA values are within the values reported for residual soils from igneous rocks (Gupta and Rao 2001; Okewale 2020a; Okewale and Coop 2018b).

The weathering product index (PI) that measures nonmobile elemental oxides, weathering index of Parker (WIP) that considers some mobile elements and quantifying cations, Vogt’s residual index (VRI) that measures the maturity of residual sediments, and residual contents (Rc) that relates the combination of oxides of iron and aluminium to mobile elemental oxides have very weak correlation statistics (Table 3), and they cannot be used in the characterisation of tropical clays. For the tropical clays studied, the values vary, but they are comparable.

The chemical index of alteration (CIA) that measures alteration of feldspars into clays, chemical index of weathering (CIW) which is different from CIA with the removal of oxide of potassium from the formula, plagioclase index of alteration (PIA) which is an alternative to CIW, leaching coefficient (Lc) that relates silica to mobile elemental oxides, S/SAF which is similar to PI but without oxide of titanium and CALMAG which was formulated based on the correlation found between CaO and MgO are statistically insignificant with weak correlations (Table 3), and this shows that they cannot be used to characterise tropical clays.

Attempts are made to determine the overall performance of the significant indices. In order to achieve this, a criterion (r ≥ 0.60) is set based on the classification used by Okewale and Coop (2018b) and Okewale (2020a). This means that only indices with strong and very strong correlations are used to quantify the overall performance. For the variation of chemical indices with depth, the ATI, STI, and SA are used. The average values of regression statistics (r and p) for the variations of chemical indices with depth for the best chemical indices are 0.88 and 0.0002, respectively.

In situ specific volume (v) is another index that has been found to be a good indicator for characterising geomaterials (e.g. Okewale 2020a). This is because in situ v provides direct in situ behaviour of materials resulting from decomposed rocks. In this way, the specific volume will serve as an independent measurement to characterise weathered geomaterials. Figure 4 presents the variation of chemical indices with in situ specific volume. Data from Okewale (2020a) are shown for comparisons. Again, the plots are shown for the indices with significant correlations, but the details of all the indices are given in Table 4. The regression statistics vary from very weak to very strong correlations. The relationships between the indices and specific volume are represented by regression lines and both r and p value are included in each figure.

Figure 4a presents a variation of ATI with specific volume. The ATI increases with a specific volume, and the relationship is very strong as represented by regression statistics (r = 0.86, p value = 0.0002). Since this material results from the decomposition of rocks, the geological processes will lead to the formation of oxides of aluminium and hence, an increase in in situ specific volume. The STI increases with specific volume with strong relationship as depicted by regression statistics (r = 0.77, p value = 0.002) (Fig. 4b). The trend is similar to ATI and gives direct similarity with depth. The variation of SA with specific volume is shown in Fig. 4c. The SA reduces with specific volume with very strong regression statistics (r = 0.73, p value = 0.006). Due to weathering processes, aluminium oxides are higher than silicon oxides, and this invariably leads to a low ratio that reduces with increasing in situ v. It is interesting to see that some indices show a strong relationship with specific volume similar to the related study (Okewale 2020a).

The PI, WIP, CIA, CIW, PIA, VRI, Lc, and Rc have a very weak relationship with specific volume as shown by correlation statistics (Table 4). The relationship of some of these indices is similar to the related study (e.g. Okewale 2020b). The S/SAF and CALMAG show a weak relationship with specific volume as presented in Table 4. In considering in situ specific volume as an indicator for characterising tropical clay using chemical indices, the best indices are ATI, STI, and SA. To estimate the overall performance of indices similar to that of the depth, the average correlation coefficient r and p value are 0.78 and 0.002, respectively.

Comparisons are made between the two approaches that can be applied in characterising tropical clay. These are vertical profile (depth) and inherent property (in situ specific volume). Figures 3 and 4 in combination with Tables 3 and 4 are used for the comparisons. The ATI, STI, and SA are the best for both depth and specific volume in that order. The ATI has a very strong correlation for both depth and specific volume. The STI has a very strong correlation for depth and a strong correlation for a specific volume. The SA has very strong and strong correlations for depth and specific volume respectively. Comparing the average values of regression statistics (r and p value) of the suitable indices, the values differ, and the depth approach is better. To characterise tropical clay using chemical indices, plotting chemical indices versus both depth and specific volume can be applied.

Prediction of mechanical behaviour using different techniques

Estimation of mechanical parameters needed for engineering design and analysis is very essential especially at the early stage of the project where data availability may be limited. Doing this will reduce the cost and save time, but this should not be misconstrued as an alternative to suitable field and quality laboratory testing. However, it will serve as a guide for practising engineers and geologists to suggest probable values at the start of design in order to interpolate and extrapolate between the data available for other sites. In this study, attempts are made to investigate suitable approaches using different indices that can be used as a predictor for mechanical parameters required for engineering design and analysis. The indices considered are physical, mineralogical, and chemical indices. Again, regression statistics are used to provide the relationships between mechanical parameters and the indices.

Physical indices

The physical indices used in this work are engineering grading descriptors (fines content Fc and coefficient of uniformity Cu) and index property (plasticity index Ip). The relationships are represented by regression lines. The figures herein are shown for the valuable indices, that is, those with good correlations. In each plot, the equation representing the relationship and correlation coefficient are included. Figure 5 presents a variation of in situ specific volume with a coefficient of uniformity. The in situ v increases with Cu with very strong correlation statistics (Table 5). As the samples become well-graded, the in situ v increases. This shows that Cu can be used to predict the inherent behaviour of tropical clay using the empirical equation shown in Fig. 5. The in situ v has a weak relationship with fines content and plasticity index (Table 5). This indicates that they cannot be used as a predictor for in situ v.

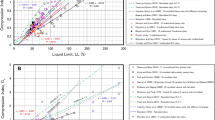

The variation of compression index Cc with fines content Fc is presented in Fig. 6a. The Cc reduces with fines content with strong regression statistics. This shows that as the samples become finer, the compressibility reduces. Fines content can be used to predict the compressibility of tropical clay by employing the equation in the figure. The Cc has a weak and moderate correlation with the coefficient of uniformity and plasticity index, respectively (Table 5), and they are not a suitable predictor for the compression behaviour of tropical clay. Figure 6b shows the relationship between compression line intercept N and coefficient of uniformity. The relationship is statistically significant (r = 0.68, p value = 0.009). The compressibility parameter increases with Cu, and it can be used to predict the compression behaviour. The N has a weak and moderate correlation with Fc and Ip, respectively (Table 5), and they are not a suitable predictor for compression behaviour of tropical clay.

The variation of uniaxial compressive strength with fines content is presented (Fig. 7). The strength reduces with fines content as expected and the relationship is statistically significant (r = 0.97, p value = 8.98E − 09). This shows that the finer the samples, the lower the strength, similar to compression behaviour. Fines content can be used to predict the strength of tropical clay using the equation presented in Fig. 7. This is similar to what has been found for other studies but uses different strength parameters (e.g. Okewale and Coop 2018a). However, strength has very weak correlations with both plasticity index and coefficient of uniformity (Table 5) which indicate their unsuitability for use as a predictor in this material.

The overall performance as discussed earlier is estimated using two methods. The first method combines the indices together for particular mechanical parameters, and the second method considers the performance of the individual index with mechanical parameters. To determine overall indices for physical indices, the average r and p value are 0.76 and 0.009, respectively. Since two parameters are used for compression behaviour, the average correlation statistics are r = 0.64 and p value = 0.01. Fines content is good for both compression and strength, and the average r and p value are 0.78 and 0.01, respectively. Comparing each physical index, fines content is the best and can be used for both compression and strength. This is followed by the coefficient of uniformity which is best for in situ specific volume and compression behaviour. If practising engineers and geologists require the prediction of mechanical behaviour using physical indices, consideration could be given to strength followed by in situ behaviour and then compression behaviour.

Mineralogical index-based approach

Quartz and clay are the minerals considered in this study, and again, the relationships are represented by regression lines. The plots are shown for the indices with reasonable regression statistics. Figure 8 presents a variation of compression behaviour with quartz content. The compression index Cc reduces with quartz, and the regression statistics are strong (r = 0.66, p value = 0.01). This shows that the compressibility reduces with quartz. The direct similarity is observed in the relationship between compression intercept N and quartz but with slightly different correlations (r = 0.53, p value = 0.05). The compression behaviour of the sample can only be predicted using Cc as shown in the equation presented in Fig. 8. The in situ specific volume has a weak relationship with quartz as shown by regression statistics (Table 5). Also, the relationship between the strength and quartz is poor, and in situ behaviour and strength cannot be meaningfully predicted using quartz content.

The in situ v shows a very poor relationship with clay minerals as shown by regression statistics. The Cc has a fair relationship with clay as represented by moderate correlation, and the N has a moderate relationship with clay minerals (Table 5). The relationship between strength and clay mineral is weak with insignificant statistics as shown in Table 5. The overall performance of the mineralogical index is r = 0.66 and p value = 0.01.

Chemical index-based approach

All the chemical indices discussed earlier are considered to predict the mechanical behaviour of the sample. Figure 9 presents the variation of in situ specific volume with chemical indices. The regression statistics vary from very weak to very strong correlations. The relationships are represented by regression line and empirical equation. Figure 9a shows the variation of in situ v with ATI. It increases with ATI with very strong regression statistics (r = 0.86, p value = 0.001). The ATI is very suitable for predicting in situ behaviour of tropical clay using the equation given in Fig. 9a. Figure 9b presents a variation of in situ v with STI, and the trend is similar to that of ATI with strong correlation statistics (r = 0.77, p value = 0.002). The in situ v can be predicted by STI using the relationship given in Fig. 9b. The relationship between in situ v and SA is presented in Fig. 9c, and it reduces with SA with strong regression statistics (r = 0.73, p value = 0.006). The SA will be a good predictor of in situ v with the regression equation shown in Fig. 9c.

The in situ v has weak correlations with the S/SAF and CALMAG. The relationships between in situ v and PI, WIP, CIA, CIW, PIA, VRI, Lc, and Rc are very weak as shown by regression statistics in Table 5. The best chemical indices for predicting in situ v are ATI, STI, and SA in that order. To determine the overall performance of chemical indices that can be used to predict in situ v, the average r and p values are determined. The values are 0.78 and 0.003 for r and p value respectively.

Figure 10 presents the variation of compression behaviour with chemical indices. Again, the indices with meaningful statistics are shown and the relationships are represented by regression lines and equations. The compression intercept reduces with SA with strong correlation statistics (r = 0.60, p value = 0.04). However, compression intercept has very weak correlations with CIA, CIW, PIA, VRI, Rc, Lc, S/SAF, and CALMAG. The N has weak correlations with PI (Table 5). There is a moderate relationship between WIP, STI, and ATI. The Cc has weak and moderate relationships with PI and WIP, respectively (Table 5). However, Cc has very poor correlations with other indices. Based on the set criteria, only one chemical index can be successfully used for predicting compression behaviour, and the average values of r and p are 0.60 and 0.04.

The strength does not have a strong relationship with chemical indices as shown in Table 5. The strength shows a moderate relationship with ATI, VRI, Lc, Rc, and CALMAG, and the relationships with WIP, SA, CIA, CIW, and PIA are weak. A very weak relationship exists between strength and PI, STI, and S/SAF. This indicates that the strength cannot be successfully predicted using chemical indices. The chemical indices are most suitable for predicting in situ v, followed by compression based on overall performance. Apart from relating indices with mechanical properties, practising engineers may need these indices, and this can be achieved by cross-correlation. Figure 11 presents cross-correlations of mineralogical and chemical indices. In Fig. 11a, Q increases with SA, and the relationship is statistically significant (r = 0.64, p value = 0.002). Also, Q reduces with ATI with strong regression statistics (Fig. 11b). This shows that the indices can be predicted depending on what is needed.

Conclusions

Detailed experimental and statistical studies have been conducted into the geochemistry and predictability of mechanical behaviour of tropical clay using different techniques. Geochemistry allows the characterisation of tropical clay using chemical indices, and the tools investigated were physical, mineralogical, and chemical indices. This was achieved by the combination of elemental oxides determined by SEM equipped with EDS and extensive statistical analyses for samples from different locations and depths. In other to characterise geomaterials using chemical indices, they are commonly plotted against depth and using this approach the ATI, STI, and SA are the best for the characterisation of tropical clay.

Another indicator has been used here for the characterisation of this material and can also be used instead of the usual depth approach. The in situ specific volume (v) defines the inherent behaviour of materials, and in considering in situ v as an indicator for characterising tropical clay using chemical indices, the best indices are ATI, STI, and SA. It is interesting to recognise that the same indices are the best for the two approaches. Comparing the depth and in situ v for characterising tropical clay. The performances of the two approaches are good, but the depth approach is better, and both can be used by practitioners working on the geomaterials.

Physical indices and chemical indices are the best approaches for predicting in situ v. The physical index is the coefficient of uniformity and the chemical indices are SA, STI, and ATI. However, chemical indices are the most suitable approach for in situ v. For the compression behaviour, physical indices and chemical index are also the best approaches, and the physical indices are fines content and coefficient of uniformity, and the chemical index is SA. The physical indices are the most suitable predictors for compression behaviour. Physical index only is the best approach for strength, and the physical index is fines content, and the fines content is the only suitable index for predicting strength.

The mineralogical index-based approach is only suitable for predicting the compressibility of tropical clay. Considering the overall performance of the indices, physical indices are the most successful for strength, followed by in situ v and then the compression behaviour. In addition, chemical indices are best suited for in situ v, followed by the compression behaviour. Although some chemical indices are suitable for mechanical parameters, overall, physical indices are the best for predicting the mechanical behaviour of tropical clay. The empirical equations developed can serve as a guide and can be used by practitioners to estimate engineering properties needed for geological and geotechnical engineering design and analysis particularly at the early stage of the project when data availability may be a problem.

Abbreviations

- ATI:

-

Alumina-titania index

- Cc:

-

Compression index

- CF:

-

Clay fraction

- CIA:

-

Chemical index of alteration

- CIW:

-

Chemical index of weathering

- Cl:

-

Clay

- C u :

-

Coefficient of uniformity

- D 50 :

-

Mean particle size

- Fc:

-

Fines content

- Fe:

-

Feldspar

- Ip:

-

Plasticity index

- Lc:

-

Leaching coefficient

- LL:

-

Liquid limit

- N:

-

NCL intercept at 1 kPa

- PI:

-

Weathering product index

- PIA:

-

Plagioclase index of alteration

- PL:

-

Plastic limit

- Q:

-

Quartz

- Rc:

-

Residual coefficient

- SA:

-

Silica-to-alumina ratio

- STI:

-

Silica-titania index

- UCS:

-

Uniaxial compressive strength

- v :

-

In situ specific volume

- VRI:

-

Vogt’s residual index

- WIP:

-

Weathering index of Parker

References

Adams JS, Kraus MJ, Wing SL (2011) Evaluating the use of weathering indices for determining mean annual precipitation in the ancient stratigraphic record. Palaeogeogr Palaeoclimatol Palaeoecol 309:358–366

BSI (1990) Methods of test for soils for civil engineering purposes. British Standard Institution, London, UK.

Burland JB (1990) On the compressibility and shear strength of natural soils. Geotechnique 40:329–378. https://doi.org/10.1680/geot.1990.40.3.329

Chigira M (1990) A mechanism of chemical weathering of mudstone in a mountainous area. Eng Geol 29(119):138

Chigira M, Sone K (1991) Chemical weathering mechanisms and their effects on engineering properties of soft sandstone and conglomerate cemented by zeolite in a mountainous area. EngGeol 30:195–219

Chigira M, Oyama T (1999) Mechanisms and effect of weathering of sedimentary rocks. EngGeol 55:3–14

Chukwujike IC, Igwe IO (2016) Extender properties of some Nigerian clays. Journal of Minerals and Materials Characterization and Engineering 4:279–291. https://doi.org/10.4236/jmmce.2016.45025

Cotecchia F, Chandler RJ (2000) A general framework for the mechanical behaviour of clay. Geotechnique 50:431–447. https://doi.org/10.1680/geot.2000.50.4.431

Dah-TraoreY ZL, Seynou M, Ouedraogo R (2018) Mechanical, microstructural and mineralogical analyses of porous clay pots elaborated with rice husks. J Miner Mater Charact Eng 6:257–270. https://doi.org/10.4236/jmmce.2018.63019

de Jayawardena US, Izawa E (1994) A new Chemical Index of Weathering for metamorphic silicate rocks in tropical regions: a study from Sri Lanka. Eng Geol 36:303–310. https://doi.org/10.1016/0013-7952(94)90011-6

Delvaux B, Herbillon AJ, Vielvoye L (1989) Characterization of a weathering sequence of soils derived from volcanic ash in Cameroon. Taxonomic, mineralogical and agronomic implications. Geoderma 45:375–388

Duzgoren-Aydin NS, Aydin A, Malpas J (2002) Re-assessment of chemical weathering indices: case study of pyroclastic rocks of Hong Kong. Eng Geol 63:99–119. https://doi.org/10.1016/S0013-7952(01)00073-4

El Desoky H, Farouk S, Heikal M, El Mahallawy M, Wahid A (2019) Geochemical and technical investigation on some clay materials in the Bahariya Oasis, Western Desert, Egypt: implication in the vitrified clay pipes industry. J Afr Earth Sci 160:103612

El Desoky H, .Farouk S, Heikal M, El Mahallawy M, Wahid A (2020) Egyptian Cretaceous Clay Deposits: Insights on Mineralogy, Geochemistry and Industrial uses. Arab J Geosci 13(3):556

Folorunso DO, Aribo S, Olubambi PO, Borode JO (2012) Hydrometallurgical purification of some clay deposits for high temperature applications. JMMCE 5:461–469

Gupta AS, Rao KS (2000) Weathering effects on strength and deformational behaviour of crystalline rocks under uniaxial compression. Eng Geol 56:257–274

Gupta AS, Rao KS (2001) Weathering indices and their applicability for crystalline rocks. Bull Eng Geol Env 60:201–221

Harnois L (1988) The CIW index: a new Chemical Index of Weathering. Sed Geol 55:319–322

Harnois L, Moore JM (1988) Geochemistry and origin of the Ore Chimney Formation. A Transported Paleoregolith in the Grenville Province of Southeastern Ontario. Canada Chem Geo 69:267–289. https://doi.org/10.1016/0009-2541(88)90039-3

Heidari A, Raheb A (2020) Geochemical indices of soil development on basalt rocks in arid to sub-humid climosequence of Central Iran. J Mt Sci 17:1–18. https://doi.org/10.1007/s11629-019-5862-4

Heikal MThS, Khedr Mohamed Z, Abd El Monsef M, Gomaa S (2019) Petrogenesis and geodynamic evolution of albite granite, Central Eastern Desert of Egypt: petrological and geochemical constraints. J. African Earth Sci 158:103518

Hill IG, Worden RH, Meighan IG (2000) Yttrium: the immobility mobility transition during basaltic weathering. Geology 28:923–926

Hodder APW, Hetherington JR (1991) A quantitative study of the weathering of greywacke. Eng Geol 31:353–368

Irfan TY (1996) Mineralogy, fabric properties and classification of weathered granite in Hong Kong. Q J Eng Geol 29:5–25. https://doi.org/10.1144/GSL.QJEGH.1996.029.P1.02

Irfan TY (1999) Characterisation of weathered volcanic rocks in Hong Kong. Q J Eng Geol 32:317–328. https://doi.org/10.1144/GSL.QJEG.1999.032.P4.03

Jock AS, Ayeni FA, Ahmed AS, Sullayman UA (2013) Evaluation of the refractory properties of Nigerian Ozanagogo clay deposit. Journal of Minerals and Materials Characterization and Engineering 1:321–325. https://doi.org/10.4236/jmmce.2013.16048

Li WD, Wang WB, Cheng ZF, Zhou HM (1995) Geochemistry of lateritization process and the possibility of forming lateritic type gold deposits in southern China. Geological Press (In Chinese with English abstract).

Momeni AA, Khanlari GR, Heidari M et al (2015) New engineering geological weathering classifications for granitoid rocks. Eng Geol 185:43–51

Nesbitt HW, Young GM (1982) Early Proterozoic climates and plate motions inferred from major element chemistry of lutites. Nature 299:715–717. https://doi.org/10.1038/299715a0

Ng CWW, Guan P, Shang YJ (2001) Weathering mechanisms and indices of the igneous rocks of Hong Kong. Q J Eng Geol Hydro 34:133–151. https://doi.org/10.1144/qjegh.34.2.133

Nordt LC, Driese SD (2010) New weathering index improves paleorainfall estimates from Vertisols. Geology 38:407–410

Okewale IA (2017) Geotechnical and geological characterisation of decomposed volcanic rocks from Hong Kong. PhD Dissertation, City University of Hong Kong

Okewale IA, Coop MR (2017) A study of the effects of weathering on soils derived from decomposed volcanic rocks. Eng Geol 222:53–71. https://doi.org/10.1016/j.enggeo.2017.03.014

Okewale IA, Coop MR (2018a) On the effects of weathering on the compression behaviour of decomposed volcanic rocks. TuniRock 2018, Hammamet, Tunisia, 85–90.

Okewale IA, Coop MR (2018b) Suitability of different approaches to analyze and predict the behavior of decomposed volcanic rocks. J Geotech Geoenviron Eng 144:1–14. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001944

Okewale IA (2019a) Influence of fines on the compression behaviour of decomposed volcanic rocks. Int J GeoEng 10:1–17. https://doi.org/10.1186/s40703-019-0101-y

Okewale IA (2019b) Effects of weathering on the stiffness characteristics and the small strain behaviour of decomposed volcanic rocks. J GeoEng 14:97–107. https://doi.org/10.6310/jog.201906_14(2).5

Okewale IA (2019c) On the intrinsic behaviour of decomposed volcanic rocks. Bull Eng Geol Env 79:1311–1322. https://doi.org/10.1007/s10064-019-01643-7

Okewale IA (2020a) Applicability of chemical indices to characterize weathering degrees in decomposed volcanic rocks. CATENA 189:1–13. https://doi.org/10.1016/j.catena.2020.104475

Okewale IA (2020b) Compressibility and the effects of structure of tropical clay in incremental loading oedometer tests. Geotech Geol Eng 38:5355–5371. https://doi.org/10.1007/s10706-020-01369-4

Okewale IA, Coop MR (2020) A study of completely decomposed volcanic rocks with transitional mode of behaviour. Bull Eng Geol Env 79:4035–4050

Okewale IA, Grobler H (2020) A study of dynamic shear modulus and breakage of decomposed volcanic soils. J GeoEng 15:53–66

Okewale IA, Grobler H (2021a) Mechanics of compression in talc considering sample quality. Arab J Geosci 14(441):1–13. https://doi.org/10.1007/s12517-021-06836-7

Okewale IA, Grobler H (2021b) Inherent complexities in weathered rocks: a case of volcanic rocks. Rock Mechanics and Rock Engineering 1–22. https://doi.org/10.1007/s00603-021-02569-x

Okewale IA, Grobler H (2021c) Influence of fabric and mineralogy on the mechanics of dolomitic rocks. Int. J. Min. Geo-Eng. Accepted.

OlaOlorun O, Oyinloye A (2010) Geology and geotechnical appraisal of some clay deposits around Ijero-Ekiti Southwestern Nigeria: implication for industrial uses. Pak J Sci Ind Res 53(3):127–135

Price JR, Velbel MA (2003) Chemical weathering indices applied to weathering profiles developed on heterogeneous felsic metamorphic parent rocks. Chem Geol 202:397–416. https://doi.org/10.1016/j.chemgeo.2002.11.001

Rocchi I, Coop MR, Maccarini M (2017) The effects of weathering on the physical and mechanical properties of igneous and metamorphic saprolites. Eng Geol 231:56–67

Rocchi I, Okewale IA, Coop MR (2015) The behaviour of Hong Kong volcanic saprolites in one-dimensional compression. Volcanic rocks and soils. Balkema, Rotterdam, pp 281–287

Seynou M, Millogo Y, Zerbo L, Sanou I, Ganon F, Ouedraogo R, Kabore K (2016) Production and characterization of Pozzolan with raw clay from Burkina Faso. JMMCE 4:195–209. https://doi.org/10.4236/jmmce.2016.43018

Udagedara DT, Oguchi CT, Gunatilake JK (2016a) Combination of chemical indices and physical properties in the assessment of weathering grades of sillimanite-garnet gneiss in tropical environment. Bull Eng Geol Environ 76:145–157

Udagedara DT, Oguchi CT, Gunatilake JK (2016b) Evaluation of geomechanical and geochemical properties in weathered metamorphic rocks in tropical environment: a case study from Samanalawewa hydropower project, Sri Lanka. Geosci J 21:441–452

Yami AM, Umaru S (2007) Characterization of some Nigerian clays as refractory materials for furnace lining. Continental J Engineering Sciences 2:30–35

de Jayawardena US, Izawa E (1994) A new Chemical Index of Weathering for metamorphic silicate rocks in tropical regions: a study from Sri Lanka. Eng Geol 36:303-310.https://doi.org/10.1016/0013-7952(94)90011-6.

Okewale IA, Grobler H (2020b) The effects of structure of Nigeria clay in one dimensional compression. The 2020 World Congress on Advances in Civil, Environmental, & Materials Research (ACEM20) 25-28, August, 2020, GECE, Seoul, Korea, pp 1-10.

Okewale IA, Grobler H (2020c) Mechanics of compression behaviour in shale. The 2020 World Congress on Advances in Civil, Environmental, & Materials Research (ACEM20) 25-28, August, 2020, GECE, Seoul, Korea, pp 1-10.

Okewale IA, Grobler H (2021d) Influence of Fabrics on Compression Mechanics of Iron Tailings. The International Conference Series on Geotechnics, Civil Engineering and Structures (CIGOS 2021), Lecture Notes in Civil Engineering 203, Springer pp 1-8. https://doi.org/10.1007/978-981-16-7160-9_113.

Okewale IA, Grobler H (2021e) Investigations into Grading Characteristics of Tailings. The International Conference Series on Geotechnics, Civil Engineering and Structures (CIGOS 2021), Lecture Notes in Civil Engineering 203, Springer pp 1-7. https://doi.org/10.1007/978-981-16-7160-9_114.

Acknowledgements

The authors would like to thank the National Research Foundation (NRF) of South Africa for the award of fellowship which led to this paper. The authors would like to appreciate Mr Akerele C. for his assistance in the laboratory in the course of conducting this research. Special thanks to Prof. Mohamed Th. S. Heikal, Prof. of Mineralogy and Petrology, Tanta University, Egypt, for his critical comments and suggestions that strongly improved the present article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Domenico M. Doronzo

Rights and permissions

About this article

Cite this article

Okewale, I.A., Grobler, H. Geochemistry and predictability of tropical clay behaviour using different techniques. Arab J Geosci 14, 2209 (2021). https://doi.org/10.1007/s12517-021-08596-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08596-w