Abstract

This study introduced modified biochar to enhance the adesorption isotherms of hexavalent chromium in a calcareous soil. Almond soft husk and rice husk biochars as precursor reagents were applied to prepare the modified biochars with abundant amino groups for heavy metal removal. For this purpose, biochars included levels zero (without biochar or control) and 4 wt% (unmodified biochar and modified biochar). Biochars were modified separately with Fe3O4, NaOH, KOH, H2SO4, and HNO3 and four levels of potassium dichromate (0–150 mg/kg soil) were used. Sampling from the treated soil was carried out 5 months after the contamination of soil with chromium. All treatments (5 g) were extracted with 25 mL of a 0.01 M EDTA solutions. The suspensions were shaken for different time periods (5 to 2880 min) at 150 rpm. Concentration of Cr was analyzed in each extract by atomic absorption spectrophotometer. The results indicated that adding rice husk and almond soft husk biochars to the soil resulted in a decrease in Cr uptake at all extraction times compared to control, whereas the rice husk biochar showed a lower reduction in Cr removal than the control compared to the almond soft husk biochar. Based on the determination coefficient and standard error, the best two-constant rate equations are considered the best predictor of the chromium release kinetics trend in the studied soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals are naturally found in the distributed form in rock formations; however, with rapid industrialization, their concentration is tremendously increasing in the environment (Muhammad et al. 2019; Ullah and Muhammad 2020; Khan et al. 2020). One of the main problems related to heavy metals is that unlike organic contaminants, they cannot be degraded or quite removed from the environment (Bharagava and Mishra 2018). Large amounts of these metals unloaded from different sources are constantly introducing into food chains and therefore seriously affecting the metabolism, resulting in finally the death of microorganisms, herbs, and animals (Theriault and Nkongolo 2016; Fernando et al. 2016). A lot of these wastes are enriched with different heavy metals, for example, hexavalent chromium (Cr(VI)) which creates a damaging influence on environmental health. The 21st most abounding metallic element is chromium found in the environment (Sarkar et al. 2011). Chromium (Cr) is entered into the aquatic and earthly environments via discarding of indiscriminate wastes from different industries such as leather tanning, electroplating, pulp production, timber treatment, and petroleum refining (Zhitkovich 2011). Trivalent chromium (Cr(III)) and hexavalent chromium (Cr(VI)) are the two most common species of chromium that they can be found in most of the industrial superfluous materials. Cr(III) can be sorbed by soil particles and it forms precipitates with less solubility, which prevents its leaching into soil profile, and groundwater as well as its absorption by plants (Yang et al. 2007; Reale et al. 2016; Ashraf et al. 2017; Van Ginkel et al. 2011). Cr(VI) is one of the eight most toxic chemical materials to human health and it is universally identified as one of the most carcinogenic elements (Jin et al. 2016). In addition, Cr(VI) anion known as chromate is highly soluble, and weakly adsorbed by soil particles which allow plants to uptake it simply from the soil, and also expose it to release into the groundwater (Rajapaksha et al. 2013). Therefore, Cr(VI) is highly active in soil and water, and it has the potential to be stored and perseveres in the long term due to its non-biodegradability (Antoniadis et al. 2018; Jobby et al. 2018). In comparison with Cr(III), Cr(VI) is about 100 times toxic to living organisms, so that it enables to cause mutagenicity, teratogenicity, and carcinogenicity; accordingly, the health hazard owing to Cr is essentially attributable to Cr(VI) (Saha et al. 2011). Usually, very poisonous Cr(VI) can be reduced to less poisonous Cr(III) by applying different biowastes including dairy manure, poultry manure, and biosolids (Singh and Rattan 2014).

Biochar, a carbonaceous material, is commonly produced as a by-product of the pyrolysis of organic biomass under limited oxygen conditions at low temperatures (Ahmad et al. 2014). In recent years, biochar soil modification has served to increase product yields via improved soil structure, modified microbial activity, and enhanced soil nutrient supply (Liu et al. 2018). The multipurpose function of biochar includes options is as follows: (i) possible carbon sequestration factor in soil; (ii) macro and micronutrient sink in soil, therefore decreasing their leaching losses; (iii) adsorbent of heavy metals in aqueous solution and soil; and (iv) soil productivity and fertility enhancer (Novak et al. 2016). Biochar features, such as great specific surface area, porous structure, the presence of efficient functional groups (containing oxygen), and high adesorption isotherms capacity, cause the unique capability for removing pollutants in soil and water (Inyang et al. 2015).

The biochar engineering is the modified or activated state of biochar (Ok et al. 2015). In order to engineer biochar, the pristine biochars are modified by chemical, biological, and physical techniques to increase their chemical, biological, and physical properties such as porosity, specific surface area, surface functional group, pH, and cation exchange capacity. In comparison to physical modification, chemical modification can change the surface chemistry of biochar, therefore resulting in an increased adesorption isotherms capacity after the modification process (Usman et al. 2016). Biochars can be activated by applying airflow or steam (Trakal et al. 2014); they can be chemically modified by utilizing acid and alkaline compounds (Regmi et al. 2012) as well as magnetic nanoparticles (Devi and Saroha 2014). The suitable choice of biochar oxidation can provide biochar with abundant carboxyl functional groups for heavy metal removal in contaminated water and soils (Uchimiya et al. 2012). Acid modification exhibited a high increase in the BET surface area of bur cucumber plant biochar, which might be owing to the increase in porosity (Vithanage et al. 2015). The oxidation with nitric acid and sulfuric acid can remarkably increase the extent of surface acidic groups on the biochar and improve its surface hydrophilicity, decrease the pH value, and create the collapse in the biochar structure and the reduction of surface area, which can notably influence the biochar adesorption isotherms efficiency of metal ions (Vithanage et al. 2015). NaOH modification can enhance the percent of surface graphitic carbon and other oxygen-containing compounds (Fan et al. 2010). The porous structure of biochar was adjusted by a chemical modification process using KOH (Dehkhoda et al. 2016).

Magnetic biochar composites have not only the high adesorption isotherms capacity but also the magnetic compounds under the operation of an external magnet and it is separated easily. Magnetic biochar has a broad application in purification, adesorption isotherms, and environmental remediation. Generally, magnetic compounds connected with biochar are commonly iron or iron oxides, i.e., Fe (0), Fe3O4, γ-Fe2O3, CoFe2O4, etc. (Reddy and Lee 2014).

Therefore, according to the above, the purpose of this study is to stabilize heavy metals using inexpensive methods which seems to be absolutely necessary, because rice husk and almond soft husk are available in abundance and at very low prices. At the same time, its accumulation around agricultural lands and gardens causes environmental pollution and unfavorable conditions in these areas. In this study, we investigated the effect of rice husk and almond soft husk modified biochars with Fe3O4, NaOH, KOH, H2SO4, and HNO3 on the chromium desorption kinetics in contaminated calcareous soils. These modified compounds were used to remove chromium(VI) in the soil.

Materials and methods

Material and instruments

Sulfuric acid (H2SO4, 98%), nitric acid (HNO3, 65%), sodium hydroxide (NaOH, 97%), potassium hydroxide (KOH, 85%), ferric chloride hexahydrate (FeCl3·6H2O, 97%), ferrous chloride tetrahydrate (FeCl2·4H2O, 98%), ammonium hydroxide solution (NH4OH, 28%), and other used materials were purchased from Sigma and Merck companies.

Fourier-transform infrared (FTIR) spectra of the compounds were performed using AVATAR spectrometer (Thermo, IET company, USA). X-ray diffraction (XRD) patterns of prepared compounds were obtained using a Philips diffractometer with monochromated high-intensity CuKα (Philips company, Netherlands). The field emission scanning electron microscopy (FESEM) was used to surface images of prepared materials by using the MIRA III microscope (TESCAN company, Czechia). The surface area of the prepared materials was obtained by a single-point BET method using a BELSORP MINI II (BEL company, Thailand). The samples were degassed at 150 °C for 2 h before adsorbing the N2 gas.

Soil sampling

The soil sample was obtained from the 0–30-cm layer of a field at the Faculty of Agriculture, Kerman University, Iran. The samples were air-dried and passed via a 2-mm mesh sieve and kept in polyethylene bags prior to use. The physical and chemical properties of the selected soil were shown in Table 1. Particle size was measured by the hydrometer method (Bouyoucos 1962); soil pH was obtained in the saturated extract of soil utilizing a combination electrode (Thomas 1996); electrical conductivity (EC) in the soil saturated extract was measured by applying a conductometer (Rhoades et al. 1996); organic matter (OM) content was obtained by dichromate oxidation (Nelson and Sommers 1996); CEC was determined by saturation with 1 M ammonium acetate (NH4OAc) at pH = 7 (Sumner et al. 1996); calcium carbonate (CaCO3) was measured by titration (Loeppert and Suarez 1996); accessible phosphorus (P) was determined based on the Olsen method (Olsen et al. 1954); total nitrogen was obtained by Bremner (1996) method; extractable potassium was determined by ammonium acetate molar (Chapman and Pratt 1982) and zinc (Zn), iron (Fe), manganese (Mn), and copper (Cu) concentrations were extracted by DTPA and after that determined by atomic absorption spectrophotometer (AAS) (Lindsay and Norvell 1978). Total chromium with a mixture of four acids HF, HCLO4, HNO3, and H2SO4 (Ma and Uren 1997) was measured and determined by atomic absorption spectrophotometer. This research was a factorial design based on a completely randomized design with four levels of potassium dichromate (K2Cr2O7) (0, 50, 100, and 150 mg/kg soil) and biochars (almond soft husk and rice husk) included levels zero (without biochar or control) and 4 wt% (unmodified biochar and modified biochar). Biochars were modified with Fe3O4, NaOH, KOH, H2SO4, and HNO3.

Biochar production

In order to prepare the biochar and residues, the almond soft husk was prepared from the almond garden in Shiraz and rice husk was prepared from rice factory in Kamfirouz (Fars province). The residues were packed after air-drying and milling in aluminum sheets to limit the oxygenation during the pyrolysis process. Then, they were placed in the oven at 500 °C for 4 h to produce the biochar (Hall et al. 2008). After grinding the biochars and residues (almond soft husk and rice husk) and passing through 0.5-mm sieve, some investigated chemical and physical properties were measured (Tables 2 and 3). One (1 g) of residues and biochars (almond soft husk and rice husk) was placed in an electric furnace for 4 h at 550 °C for ashing. The residues and biochars were dissolved in 2 N HCl. Then it was passed through filter paper. Zinc (Zn), iron (Fe), manganese (Mn), copper (Cu), and chromium (Cr) concentrations were measured by atomic absorption spectrophotometer. The pH was determined in 1:5 water to residue and biochar suspension. The EC was measured in 1:5 water to residue and biochar suspension by conductivity meter, and P was obtained by Chapman and Pratt (1961), and total nitrogen by the Kjeldahl method (Bremner 1996).

Preparation the modified biochar

To modify the prepared biochars (rice husk biochar and almond soft husk biochar), 0.5 g of biochar was added to 130 mL of water and sonicated for 15 min. Then 1.5 g of FeCl3·6H2O and 0.5 g of FeCl2·4H2O were added to the above mixture and stirred for 30 min. The temperature was then brought to 60 °C, and under nitrogen atmosphere, 11 mL of NH4OH was added to it. This mixture was stirred at 60 °C for 1 h and then separated by a magnet and washed several times with distilled water and finally dried at room temperature.

To prepare biochar modified with H2SO4 (HNO3, NaOH, and KOH), 1.0 g of biochar was added to 100 mL of distilled water and then 10 mL of concentrated acid (or 10.0 g of alkali) was added to it. The mixture was stirred at 60 °C for 24 h. It was finally filtered using a centrifuge and washed several times with distilled water to neutralize PH. The resulting powder was dried at 70 ° C for 24 h.

Incubation assay

To perform the test, a kilogram of soil was poured into pots, then treatments almond soft husk residues, rice husk residues, and biochars were added to the soil of each pot and mixed completely. And they were placed in the greenhouse under humid conditions at 25 ± 5 °C for 1 month. After 1 month of incubation, 50, 100, and 150 mg/kg of potassium dichromate was added to the soil of each pot and mixed completely. Then, they were maintained in the same conditions as before (humidity conditions at 25 ± 5 °C) for another 5 months. Soil chromium desorption kinetics was studied 5 months after incubation. The study changes in chromium desorption kinetics over a period of 5 months after incubation, all treatment soil (5 g) were extracted with 25 mL of a 0.01 M EDTA solutions. The suspensions were shaken for different time periods (5, 15, 30, 60, 120, 240, 480, 960, 1440, and 2880 min) at 150 rpm. These samples were then centrifuged at 3000 rpm for 15 min and filtered using Whatman no. 42 filter paper. Concentration of Cr was analyzed in each extract by atomic absorption spectrophotometer (Dang et al. 1994). The zero order, first order, second order, third order, Parabolic diffusion, Elovich, and two-constant equations were used to describe the kinetics of desorption of the mentioned elements. Equations that have the highest determination coefficient and the least standard error were selected as the best predictor of chromium desorption kinetics in soil. Then the coefficients of the equations with high predictive power were calculated and the mean of these coefficients was compared between different treatments (Table 4).

The standard error was obtained using the following equation:

where Mt is the amount of metal released (mg/kg) at time t (s), Mt* the estimated metal value (mg/kg) of velocity equations at time t (s), and n is the number of observations (Table 5).

Results and discussion

Characterization of materials

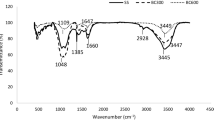

FTIR spectra

Figure 1 showed the FTIR spectra of prepared samples. Figure 1(c, h) indicated the FTIR spectra of the magnetic nanoparticle–modified rice husk biochar and almond soft husk biochar, respectively. In fact, according to biochar peaks that appear in wavenumber 1091 cm−1 for C–O groups and about 2850 cm−1 for C–H, this indicates a higher biochar presence in the nanocomposites. But in the spectrum (h), the dominant peak is related to Fe3O4 in the region of about 570 cm−1, which indicates a high percentage of Fe3O4 than biochar. So, spectrum (c) has good magnetic properties. It can be a better adsorbent because it has higher biochar content. But it should be borne in mind that the lower the number of Fe3O4 nanoparticles, the lower the magnetic properties of the resulting nanocomposite will eventually be, so it cannot be a good adsorbent. Finally, experimental observations are needed for the adsorbent. The spectra of (d) and (e), which are in the acidic treatments of sulfuric acid and nitric acid respectively, show that in acidic conditions, the oxidation is higher than that in the basic treatment. According to the intensity of C–O peaks in the 1100 cm−1 region, it can be inferred to sodium hydroxide and potassium hydroxide, respectively, in relation to basic conditions in Fig. 1(f, g), respectively. In fact, the rate of oxidation of rice husk biochar in acidic conditions is higher than that of basic. The higher the oxidation, the higher the functional groups that can adsorb the analyte sample.

FTIR spectra of (a) unmodified almond soft husk biochar, (b) unmodified rice husk biochar, (c) rice husk biochar modified with Fe3O4, (d) rice husk biochar modified with H2SO4, (e) rice husk biochar modified with HNO3, (f) rice husk biochar modified with NaOH, (g) rice husk biochar modified with KOH, (h) almond soft husk biochar modified with Fe3O4

XRD patterns

Figure 2 shows the X-ray diffraction patterns of the prepared samples. A comparison of the diffraction patterns of unmodified rice husk and almond soft husk biochars shows that both compounds are amorphous and disordered. The figures show that rice husk biochar is slightly more regular than almond soft husk biochar. After modifying the two biochars with Fe3O4 nanoparticles, the crystalline structure of the biochars improved and the peaks of the Fe3O4 nanoparticles appeared at angles of 30.1°, 35.6°, 43.7°, 54.2°, 57.8°, 63.5°, and 75.1°. In addition, rice husk biochar was also modified with two acids (HNO3 and H2SO4) and two bases (NaOH and KOH). The results show that acid modification does not cause much change in the amorphous structure of biochar. But the amorphous structures of biochar modified with two bases are changed and the extra peak places in these modified patterns.

XRD patterns of (a) unmodified almond soft husk biochar, (b) unmodified rice husk biochar, (c) rice husk biochar modified with Fe3O4, (d) rice husk biochar modified with H2SO4, (e) rice husk biochar modified with HNO3, (f) rice husk biochar modified with NaOH, (g) rice husk biochar modified with KOH, (h) almond soft husk biochar modified with Fe3O4

FESEM Images

The FESEM images are shown in Fig. 3. As can be seen from the figures, the unmodified rice husk and almond soft husk biochars have an almost porous structure and the biochars are amorphous in accordance with their XRD patterns. By modifying biochars with Fe3O4 nanoparticles, the nanoscale Fe3O4 particles on the biochar are distributed almost spherically and uniformly.

FESEM images of a unmodified almond soft husk biochar, b unmodified rice husk biochar, c rice husk biochar modified with Fe3O4, d rice husk biochar modified with H2SO4, e rice husk biochar modified with HNO3, f rice husk biochar modified with NaOH, g rice husk biochar modified with KOH, h almond soft husk biochar modified with Fe3O4

Figures of biochar of rice modified with two acids and two bases show that both have increased the number of cavities in biochar and this increase is more in biochars modified with alkali compounds, especially KOH.

Therefore, it can be concluded that the amount of cavities created in rice husk biochar is higher in the presence of potassium hydroxide alkaline composition and may indicate that this modified biochar structure can remove the desired contaminants than acid-modified biochars.

N2 adesorption isotherms and desorption studies

The adesorption isotherms and desorption isotherms for nitrogen for the prepared samples are shown in Fig. 4. The surface area of unmodified almonds soft husk and rice husk was 1.92 and 20.42 m2/g, respectively. After modification of these biochars with Fe3O4 nanoparticles, the surface area of both biochars has increased dramatically, so it can be said that by modifying the biochar surface with Fe3O4 nanoparticles, it can be theoretically stated that the ability to adsorb pollutants increases.

Adsorption/desorption isotherms of a unmodified almond soft husk biochar, b unmodified rice husk biochar, c rice husk biochar modified with Fe3O4, d rice husk biochar modified with H2SO4, e rice husk biochar modified with HNO3, f rice husk biochar modified with NaOH, g rice husk biochar modified with KOH, h almond soft husk biochar modified with Fe3O4

On the other hand, biochar modification of rice husk with nitric acid and sulfuric acid reduced the surface area compared to unmodified biochar but its pore diameter almost doubled. In addition, biochar modification of rice husk with sodium hydroxide and potassium hydroxide showed that the surface area increased very dramatically, reaching from 20.42 to 101.17 and 81.6 m2/g for KOH and NaOH, respectively, which is consistent with FESEM images (Table 6). Here, the diameter of the pores has not changed, but the volume of the pores has almost five times.

Desorption kinetics of chromium in soil

Figures 5, 6, 7, 8, 9, and 10 show the effect of adding almond soft husk and rice husk biochar to the soil on Cr uptake at different extraction times compared to control. Changes caused by several time periods (5, 15, 30, 60, 120, 240, 480, 960, 1440, and 2880 min) on chromium desorption in the treated soil are 150 days after incubation.

In all figures, the amount of chromium desorbed by the extractant in the studied soil increased cumulatively over time (5 to 2880 min). The rate of desorption was rapid at first and early times (first 2 h) and then with desorption time slower (8 h) and finally, equilibrium was observed in the treated and control samples. Adding rice husk and almond soft husk biochar to the soil resulted in a decrease in Cr uptake at all extraction times compared to control, whereas the rice husk biochar compared to almond soft husk biochar caused a significant decrease in the amount of Cr desorption compared to the control soil. The highest amount of chromium desorption is related to soil without biochar treatment. The highest chromium desorption was in untreated soil with rice husk and almond soft husk biochar (control), while the lowest desorption rate of chromium in soil with rice husk and almond soft husk modified biochar with NaOH was at 4 wt%. However, rice husk biochar had a better effect than almond soft husk biochar. The results showed the application of rice husk and almond soft husk modified with NaOH in the treatment of 50 mg/kg, and chromium contamination compared to the control soil in the period of 5 months after incubation, and the amount of chromium desorption after 8 h of in soil was reduced by 46% and 44%, respectively. Also in the treatment of 100 mg/kg, the amount of chromium desorption was reduced by 46.52% and 46.11%, respectively, while this reduction in the 150 mg/kg treatment was 32.72% and 32.36%. However, the modified biochars showed more efficient Cr(VI) reduction compared to the untreated biochars because of the presence of effective oxygen-containing surface functional groups (Mandal et al. 2016). The adsorptive removals of chloramphenicol (CAP) on the renewable bioresource of biochar (BC) and modified bamboo charcoal were investigated and compared. The adesorption isotherms of CAP on BC and H2SO4-modified BC was very slight, but on NaOH-modified BC was greatly increased. It was found that NaOH treatment increased the percentage of surface graphitic carbon and other oxygen-containing functional groups. The increased adesorption isotherms on BC–NaOH was ascribed to the enhanced π–π interaction between the adsorbent and adsorbate. It is proposed that NaOH-modified BC was effective for the adesorption isotherms of CAP in wastewater (Fan et al. 2010). Engineered biochar was obtained through the slow pyrolysis of hickory wood and then further modified with NaOH. After modification, biochar’s surface area, cation exchange capacity, and thermal stability were significantly improved. The modified biochar exhibited much larger (2.6–5.8 times) metal adesorption isotherms capacities than the pristine biochar. Competitive batch adesorption isotherms of mixed metal ions (Pb2+, Cd2+, Cu2+, Zn2+, and Ni2+) showed preferential adesorption isotherms of Pb2+ and Cu2+ onto the modified biochar. The alkali-modified biochar in a fixed-bed column also showed a strong ability to filter heavy metals from aqueous solutions. The alkali-modified biochar thus can serve as an alternative adsorbent for heavy metals. This work showed that alkali (NaOH) modification greatly increased the surface area, oxygen-containing surface functional groups, and CEC of biochar derived from hickory wood. As a result, the modified biochar showed much higher sorption of heavy metal ions (i.e., Pb2+, Cd2+, Cu2+, Zn2+, and Ni2+) than the original one in both single-metal and mixed-metal systems. In addition, a fixed-bed column packed with the modified biochar showed good filtration of heavy metal ions and preferentially removed Pb2+ and Cu2+ out of the mixed-metal solution. The spent column was flushed with a 0.2 M HCl solution, which desorbed all of the metal ions with Pb2+ desorption efficiency of 100.6%. The regenerated column effectively removed Pb2+ from aqueous solution and most of the retained Pb2+ could be released by the acid solution. Findings from this work indicated that the alkali modification method can be applied to biochar to enhance its heavy metal removal ability and the resulting modified biochar has great potential as an alternative adsorbent for environmental remediation (Ding et al. 2016).

Comparison of the kinetics of chromium desorption equations

The values of the determination coefficient (R2) and standard error of estimation (SE) were obtained by fitting the chromium desorption data to the kinetic equations for soil 5 months after incubation under the effects of treatments; the results are shown in Tables 7, 8, 9, 10, 11, and, 12. Determination of the best kinetic equations is usually according to the R2 and SE; in other words, equations that have a high R2 and a low SE are selected as equations that best describe the rate of chromium desorption. The results obtained from these equations were investigated for the period of 5 months after incubation under treatments rice husk and almond soft husk modified biochar. The kinetic equations of zero, first, second, and third order due to the low the values of the determination coefficient cannot predict chromium desorption in soil samples. Fitting the chromium desorption data from the soils with the parabolic diffusion equation showed that due to the low R2 and the relatively high SE, this equation cannot be a suitable equation for describing chromium desorption from the studied soils. Based on the values obtained from the R2 and SE, two-constant rate equations were introduced as the best equation for chromium desorption kinetics (Tables 7–12). Although the Elovich equation has determination coefficient of determination similar to two-constant rate equations, but due to the high standard error of estimation, it could not be used as an appropriate equation for the investigation of chromium desorption kinetics. The values of the velocity constants αs and βs of the Elovich equation in the soil show many variations (Tables 7–12). Increasing the value of βs and decreasing the value of αs indicate a decrease in chromium desorption rate; with increasing βs, the rate of desorption decreases; αs value is lower in soils with less desorption. The αs constant is a useful parameter to predict the availability of elements in the soil. These results indicate that the application of higher levels of biochar in the soil reduces the availability of chromium in the soil. Also the use of modified biochar with NaOH and KOH reduced the desorption kinetics of chromium in the soil compared to the application of other modified biochars. Coefficients in the two-constant rate equations using modified biochars were reduced compared to the control, so the rate of chromium desorption in soil was also reduced. In the two-constant rate equations with the application of modified biochars, the coefficient a decreased compared to the control, which indicates a decrease in the rate of chromium desorption in the soil. The values of kp and q0 constants of the parabolic diffusion equation were decreased compared to the control, indicating a decrease in chromium desorption in the modified biochar samples compared to the control treatment.

Conclusion

In general, the mechanisms of adesorption isotherms of heavy metals by biochar include electrostatic interactions, ion exchange, chemical deposition, and formation of complexes with functional groups at the biochar surface. Biochar has organic functional groups on its surface (hydroxyl, carboxyl, and carbonyl), which can increase the cation exchange capacity of the soil and increase the formation of complexes with heavy metals. According to the results of this study, the amount of chromium extracted by EDTA at different times showed that the amount of desorbed chromium decreased in soils treated with biochar. The highest chromium desorption was in untreated soil with rice husk and almond soft husk biochar (control), while the lowest desorption rate of chromium in soil with modified biochar (rice husk and almond soft husk) with NaOH was at 4 wt%. However, rice husk biochar showed a greater reduction compared to almond soft husk biochar. It can be stated that rice husk biochar has been more successful than soft almond peel biochar due to its more porous structure and cation exchange capacity. Due to the above, it can be possible to recommend the use of biochar as a modifier in soils contaminated with this element. Evaluation of chromium desorption data from studied soil with different kinetic equations showed that chromium desorption data had fits good with two-constant rate equations. In this study, it can be reported that two-constant rate equations are introduced as the best descriptive equation for desorption of chromium in soil samples 5 months after incubation.

References

Ahmad M, Rajapaksha AU, Lim JE, Zhang M, Bolan N, Mohan D, Vithanage M, Lee SS, Ok YS (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere. 99:19–33. https://doi.org/10.1016/j.chemosphere.2013.10.071

Antoniadis V, Zanni AA, Levizou E, Shaheen SM, Dimirkou A, Bolan N, Rinklebe J (2018) Modulation of hexavalent chromium toxicity on Origanum vulgare in an acidic soil amended with peat, lime, and zeolite. Chemosphere. 195:291–300. https://doi.org/10.1016/j.chemosphere.2017.12.069

Ashraf A, Bibi I, Niazi NK, Ok YS, Murtaza G, Shahid M, Mahmood T (2017) Chromium (VI) sorption efficiency of acid-activated banana peel over organomontmorillonite in aqueous solutions. Int J Phytorem 19:605–613. https://doi.org/10.1080/15226514.2016.1256372

Bharagava RN, Mishra S (2018) Hexavalent chromium reduction potential of Cellulosimicrobium sp. isolated from common effluent treatment plant of tannery industries. Ecotoxicol Environ Saf 147:102–109. https://doi.org/10.1016/j.ecoenv.2017.08.040

Bouyoucos GJ (1962) Hydrometer method improved for making particle size analyses of soils. Agron J 54:464–465

Bremner JM (1996) Nitrogen total. In: Sparks DL et al (eds) Methods of Soil Analysis, Part 3. American Agronomy Society, Madison, pp 1085–1122

Chapman HD, Pratt PF (1961) Methods of analysis for soils, plants and waters. Division of Agricultural Sciences, University of California, Berkeley, pp 60–68

Chapman HD, Pratt PE (1982) Methods of analysis for soil, plants, and waters. University of California Publication, Berkely, California, p 4034

Dang YP, Dalal RC, Edwards DG, Tiller KG (1994) Kinetics of zinc desorption from vertisols. Soil Sci Soc Am J 58:1392–1399. https://doi.org/10.2136/sssaj1994.03615995005800050016x

Dehkhoda AM, Ellis N, Gyenge E (2016) Effect of activated biochar porous structure on the capacitive deionization of NaCl and ZnCl2 solutions. Microporous Mesoporous Mater 224:217–228. https://doi.org/10.1016/j.micromeso.2015.11.041

Devi P, Saroha AK (2014) Synthesis of themagnetic biochar composites for use as an adsorbent for the removal of pentachlorophenol from the effluent. Bioresour Technol 169:525–531. https://doi.org/10.1016/j.biortech.2014.07.062

Ding Z, Hu X, Wan Y, Wang S, Gao B (2016) Removal of lead, copper, cadmium, zinc, and nickel from aqueous solutions by alkali-modified biochar: batch and column tests. J Ind Eng Chem 33:239–245. https://doi.org/10.1016/j.jiec.2015.10.007

Fan Y, Wang B, Yuan S, Wu X, Chen J, Wang L (2010) Adsorptive removal of chloramphenicol from wastewater by NaOH modified bamboo charcoal. Bioresour Technol 101:7661–7664. https://doi.org/10.1016/j.biortech.2010.04.046

Fernando VA, Weerasena J, Lakraj GP, Perera IC, Dangalle CD, Handunnetti S, Premawansa S, Wijesinghe MR (2016) Lethal and sub-lethal effects on the Asian common toad Duttaphrynus melanostictus from exposure to hexavalent chromium. Aquat Toxicol 177:98–105. https://doi.org/10.1016/j.aquatox.2016.05.017

Hall G, Woodborne S, Scholes M (2008) Stable carbon isotope rations from archaeological charcoal as palaeo-environmental indicators. Chem Geol 247:384–400. http://hdl.handle.net/10204/2255. Accessed 30 Jan 2008

Inyang MI, Gao B, Yao Y, Xue Y, Zimmerman A, Mosa A, Pullammanappallil P, Ok YS, Cao X (2015) A review of biochar as a low-cost adsorbent for aqueous heavy metal removal. Crit Rev Environ Sci Technol 46:1–28. https://doi.org/10.1080/10643389.2015.1096880

Jin W, Du H, Zheng SL, Zhang Y (2016) Electrochemical processes for the environmental remediation of toxic Cr (VI): a review. Electrochim Acta 191:1044–1055. https://doi.org/10.1016/j.electacta.2016.01.130

Jobby R, Jha P, Yadav AK, Desai N (2018) Biosorption and biotransformation of hexavalent chromium [Cr (VI)]: a comprehensive review. Chemosphere. 207:255–266. https://doi.org/10.1016/j.chemosphere.2018.05.050

Khan SA, Muhammad S, Nazir S, Shah FA (2020) Heavy metals bounded to particulate matter in the residential and industrial sites of Islamabad, Pakistan: implications for non-cancer and cancer risks. Environ Technol Innov 21:100822. https://doi.org/10.1016/j.eti.2020.100822

Lindsay WL, Norvell WA (1978) Development of a DTPA soil test for zinc, iron, manganese, and copper. Soil Sci Soc Am J 42:421–428. https://doi.org/10.2136/sssaj1978.03615995004200030009x

Liu Y, Yang S, Lu H, Wang Y (2018) Effects of biochar on spatial and temporal changes in soil temperature in cold waterlogged rice paddies. Soil Tillage Res 181:102–109. https://doi.org/10.1016/j.still.2018.04.008

Loeppert RH, Suarez DL (1996) Carbonate and gypsum. In: Sparks DL (ed) Methods of Soil Analysis, Part 3, 3rd edn. Soil Science Society of America and American Society of Agronomy, Madison, pp 437–474

Ma YB, Uren NC (1997) The fate and transformations of zinc added to soils. Aust J Soil Res 35:727–738. https://doi.org/10.1071/S96102

Mandal S, Sarkar B, Bolan N, Sik Ok Y, Naidu R (2016) Enhancement of chromate reduction in soils by surface modified biochar. J Environ Manag 186:1–8. https://doi.org/10.1016/j.jenvman.2016.05.034

Muhammad S, Ullah R, Jadoon IA (2019) Heavy metals contamination in soil and food and their evaluation for risk assessment in the Zhob and Loralai valleys, Baluchistan province, Pakistan. Microchem J 149:103971. https://doi.org/10.1016/j.microc.2019.103971

Nelson DW, Sommers LE (1996) Total carbon, organic carbon, and organic matter. In: Sparks DL et al (eds) Methods of Soil Analysis. Part 3-chemical methods and microbiological properties, 3rd edn. Soil Science of America and American Society of Agronomy, Madison, pp 961–1010

Novak J, Ro K, Ok YS, Sigua G, Spokas K, Uchimiya S, Bolan N (2016) Biochars multifunctional role as a novel technology in the agricultural, environmental, and industrial sectors. Chemosphere. 142:1–3. https://doi.org/10.1016/j.chemosphere.2015.06.066

Ok YS, Chang SX, Gao B, Chung HJ (2015) SMART biochar technology-A shifting paradigm towards advanced materials and healthcare research. Environ Technol Innov 4:206–209. https://doi.org/10.1016/j.eti.2015.08.003

Olsen SR, Cole CV, Watanabe FS, Dean LA (1954) Estimation of available phosphorous in soils by extraction with sodium bicarbonate, USDA.Cir. Washing ton, DC: US Government printing Office, p 939

Rajapaksha AU, Vithanage M, Ok YS, Oze C (2013) Cr (VI) formation related to Cr (III)-muscovite and birnessite interactions in ultramafic environments. Environ Sci Technol 47:9722–9729. https://doi.org/10.1021/es4015025

Reale L, Ferranti F, Mantilacci S, Corboli M, Aversa S, Landucci F, Venanzoni R (2016) Cyto-histological and morpho-physiological responses of common duckweed (Lemna minor L.) to chromium. Chemosphere 145:98–105. https://doi.org/10.1016/j.chemosphere.2015.11.047

Reddy DH, Lee SM (2014) Magnetic biochar composite: facile synthesis, characterization, and application for heavy metal removal. Colloids Surf A Physicochem Eng Asp 454:96–103. https://doi.org/10.1016/j.colsurfa.2014.03.105

Regmi P, Garcia Moscoso JL, Kumar S, Cao X, Mao J, Schafran G (2012) Removal of copper and cadmium from aqueous solution using switchgrass biochar produced via hydrothermal carbonization process. J Environ Manag 109:61–69. https://doi.org/10.1016/j.jenvman.2012.04.047

Rhoades JD, Sparks DL, Page AL, Helmke PA, Loeppert RH, Soltanpour PN, Sumner ME (1996) Salinity: Electrical conductivity and total dissolved solids. Methods of Soil Analysis: Part 3 Chemical Methods 5:417–35

Saha R, Nandi R, Saha B (2011) Sources and toxicity of hexavalent chromium. J Coord Chem 64:1782–1806. https://doi.org/10.1080/00958972.2011.583646

Sarkar B, Megharaj M, Xi Y, Naidu R (2011) Structural characterisation of Arquad 2HT-75 organobentonites: surface charge characteristics and environmentalapplication. J Hazard Mater 195:155–161. https://doi.org/10.1016/j.jhazmat.2011.08.016

Singh H, Rattan V (2014) Comparison of hexavalent chromium adesorption isotherms from aqueous solutions by various biowastes and granulated activated carbon. Indian Chem Eng 56:12–28. https://doi.org/10.1080/00194506.2014.881002

Sumner ME, Miller WP, Sparks DL, Page AL, Helmke PA, Loeppert RH, Johnston CT (1996) Cation exchange capacity and exchange coefficients. In: Sparks DL (ed) Methods of Soil Analysis, Part 3 (Chemical Methods), 3rd edn. Soil Science Society of America and American Society of Agronomy, Madison, pp 1201–1229

Theriault G, Nkongolo K (2016) Nickel and copper toxicity and plant response mechanisms in White Birch (Betula papyrifera). Bull Environ Contam Toxicol 97:171–176. https://doi.org/10.1007/s00128-016-1842-3

Thomas GW (1996) Soil pH and soil acidity. Methods of Soil Analysis: Part 3 Chemical Methods 5:475–90

Trakal L, Bingöl D, Pohořelý M, Hruška M, Komárek M (2014) Geochemical and spectroscopic investigations of Cd and Pb sorption mechanisms on contrasting biochars: engineering implications. Bioresour Technol 171:442–451. https://doi.org/10.1016/j.biortech.2014.08.108

Uchimiya M, Bannon DI, Wartelle LH (2012) Retention of heavy metals by carboxyl functional groups of biochars in small arms range soil. J Agric Food Chem 60:1798–1809. https://doi.org/10.1021/jf2047898

Ullah R, Muhammad S (2020) Heavy metals contamination in soils and plants along with the mafic-ultramafic complex (Ophiolites), Baluchistan, Pakistan: Evaluation for risk and phytoremediation potential. Environ Technol Innov:100931. https://doi.org/10.1016/j.eti.2020.100931

Usman ARA, Ahmad M, El-Mahrouky M, Al-Omran A, Ok YS, Sallam AS, El-Naggar AH, Al-Wabel MI (2016) Chemically modified biochar produced from conocarpus waste increases NO3 removal from aqueous solutions. Environ Geochem Health 38:511–521. https://doi.org/10.1007/s10653-015-9736-6

Van Ginkel SW, Hassan SH, Ok YS, Yang JE, Kim Y-S, Oh S-E (2011) Detecting oxidized contaminants in water using sulfur-oxidizing bacteria. Environ Sci Technol 45:3739–3745. https://doi.org/10.1021/es1036892

Vithanage M, Rajapaksha AU, Zhang M, Thiele-Bruhn S, Lee SS, Ok YS (2015) Acid-activated biochar increased sulfamethazine retention in soils. Environ Sci Pollut Res 22:2175–2186. https://doi.org/10.1007/s11356-014-3434-2

Yang J, Kim J, Ok Y, Yoo K (2007) Mechanistic evidence and efficiency of the Cr (VI) reduction in water by different sources of zerovalent irons. Water Sci Technol 55:197–202. https://doi.org/10.2166/wst.2007.062

Zhitkovich A (2011) Chromium in drinking water: sources, metabolism and cancer risks. Chem Res Toxicol 24:1617–1629. https://doi.org/10.1021/tx200251t

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Amjad Kallel

Rights and permissions

About this article

Cite this article

Dianat Maharlouei, Z., Fekri, M., Mahmoodabadi, M. et al. Chromium desorption kinetics influenced by the rice husk and almond soft husk modified biochar in a calcareous soil. Arab J Geosci 14, 38 (2021). https://doi.org/10.1007/s12517-020-06269-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-06269-8