Abstract

The article describes how current risk assessment of pressure mining using the “water inrush coefficient method” based on the Down Three Zones Theory is relatively inconsistent with the facts in practice. Based on the Down Three Zones Theory, the intact aquiclude is divided into a water pressure-free zone and a water pressure zone, and four kinds of mining discriminant models containing pressure are summarized by analyzing the influence of the confined groundwater on the intact aquiclude, according to the effect on its spatial characteristics. The relationship between the ratio of water head loss and permeability coefficient in the process of confined water conduction is obtained by building laboratory experiment model, and the height of water pressure zone is determined. The discriminant models are verified using the 81004 working face of the Caozhuang mine field in the Feicheng coalfield. The discriminant model results agree with the actual situation in the field and can be used to evaluate whether a coal seam can be safely mined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The existence of an aquiclude in a coal seam floor can reduce the times required for and the amount of water inrush from the floor (Sammarco 1986; Motyka and Pulido-bosch 1985; Kuznetsov and Trofimov 2002; Wolkersdorfer and Bowell 2004; Munirathinam and Yinling 1994; Kuscer 1991; Shi et al. 2019a, b, c, d). As more coal is mined, the complexity of geological and hydrological conditions in Chinese coal mines is gradually becoming clearer. To ensure the safe operation of coal mines, Chinese researchers have proposed a series of methods to predict water inrush from the floor (Qu et al. 2019; Shi et al. 2019a, b, c, d; Gao et al. 2019; Wang and Shi 2019; Wang et al. 2019), such as the Down Three Zones Theory and the Down Four Zones Theory (Li 1999; Shi and Han 2005; Wang et al. 2017; Shi et al. 2019a, b, c, d; Wang et al. 1991), In situ Cracking and Zero-Destruction Theory (Wang et al. 1994), Key Layer Theory for a Thin-Plate Model (Zhang and Liu 1990; Li et al. 1995), Theory of “Progressive Advancement” (Wang et al. 1996), Theory of Catastrophe (Bai et al. 1997; Wang and Song 2002), and the Water Bursting Coefficient (Liu et al. 2011; Qiao et al. 2009; Yang et al. 2011). All these theories take aquiclude of the floor as a key factor, which plays a positive role in the safe exploitation of coal seams. The Water Inrush Coefficient Method based on the Down Three Zones Theory can quantitatively evaluate if a coal seam can be safely mined. With a simple and practical formula, the evaluation indicators are easily obtained, making this method widely used in practice. The water inrush coefficient is represented by the ratio of the groundwater pressure to the thickness of the effective aquiclude, that is, \( {T}_s=\frac{P}{M-{h}_1-{h}_3} \), where Ts is the water inrush coefficient (MPa/m); P is the groundwater pressure (MPa); M is the thickness of the aquiclude (m); h1 is broken depth of the floor caused by underground pressure (m); and h3 is the original rising zone height of confined water (m). According to statistics from water bursting in the 1960s in mining areas in Fengfeng, Handan, and Jiaozuo in China, the critical value of Ts is 0.06 MPa/m, which is written into relevant regulations. That is, coal seams can be mined safely if Ts < 0.06 MPa/m. Otherwise, there is a risk of water inrush from the floor. According to the statistical data at that time, the critical value of water inrush coefficient has two obvious shortcomings. First, the data comes from the mining of shallow coal seam; second, there are not enough data samples due to limited mining area. With the increase of mining depth and mining range, the water inrush coefficient method gradually becomes inapplicable (Yu et al. 2017; Yin et al. 2018; Shi et al. 2015, 2019a, b, c, d; Zhang et al. 2013). For example, in the 91002 working face of the Chazhuang coal mine in Feicheng coalfield, the water inrush coefficient of the Ordovician limestone aquifer is 0.158 MPa/m, which is far beyond the critical value of the water inrush coefficient. According to the rules, water inrush accidents from floor will happen. However, there has been no water inrush accident during coal mining. On the contrary, the water inrush coefficients of the Ordovician limestone aquifer in many coal mines are all less than 0.06 MPa/m, such as in the Taoyang Coal Mine 9903 working face and the Yangzhuang Coal Mine 9305 working face in Feicheng coalfield, the Liangzhuang Coal Mine 51101 working face in Xinwen coalfield, etc. These working faces should be mined safely according the rules, but water inrush accidents have occurred in these working faces. One of the reasons is that the Water Inrush Coefficient Method ignores the influence of the mechanical strength of the aquiclude although considers the thickness of an aquiclude. The groundwater pressure will decrease the strength of the aquiclude, cause cracks to expand and extend, and affect the risk analysis of water inrush from the floor. Therefore, it is often inaccurate to judge whether water inrush from floor will occur according to the critical value of water inrush coefficient. In order to overcome the inaccuracy of the water inrush coefficient method, we divide the intact aquiclude zone in the Down Three Zones Theory into the water-free pressure zone and the water pressure zone and evaluate the risk of water inrush from floor in combination with the water pressure and permeability of the aquifer.

Theory on the division of the aquiclude zones

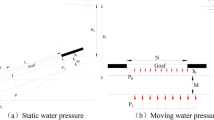

Before the coal seam is mined, the floor aquifer is in equilibrium under the combined action of overlying strata and underlying water pressure. In the underground pressure of coal seam mining, the equilibrium state of floor aquifer is broken. According to the Down Three Zones Theory (Fig. 1), the thickness (h) of the strata between the coal seam and the aquifer is divided into three zones: damage zone of the floor caused by underground pressure (h1), the intact aquiclude zone (h2), and the original rising zone height of confined water (h3). As the head loss of confined water moving along the fracture in the original rising zone is very small, the water pressure in the original rising zone is the same as that of the aquifer. The confined water has two important effects on the intact aquiclude zone: one is softening, that is, the confined water penetrates into the intact aquiclude, which reduces the compressive strength of the aquiclude under the coupling effect of water and rock; the other is destructive, that is, under the action of water pressure, the micro fissures in the intact aquiclude are expanded, which destroys the integrity of the rock stratum. Based on the two important effects on the intact aquiclude zone, the intact aquiclude is further divided into two zones: the water pressure-free zone (h21) and the water pressure zone (h22) (Fig. 1).

-

(1)

Water pressure-free zone (h21): The rock stratum in this zone is not affected by the mine pressure and the pressure water pressure. It retains the state before coal mining and has strong water separation ability. It is the key zone to prevent water inrush from floor.

-

(2)

Water pressure zone (h22): Before coal mining, the gravity of the overlying strata and the rising pressure of the confined water in the underlying aquifer are in equilibrium in this zone. After coal mining, the pressure of the overlying strata in this zone is greatly reduced, which leads to the destruction of the original mechanical balance and the formation of obvious seepage pressure of confined water in this zone. Under the action of the seepage pressure, the water original rising zone continues to rise in the zone until the seepage pressure drops to zero. It is worth noting that this zone is significantly different from the original rising zone. That is to say, the pressure of confined water has significant head loss in this zone, but not in the original guide belt. Obviously, the loss of head of confined water in this zone is closely related to the permeability of the strata in this zone.

Mining discriminant models in the “water pressure-free zone”

According to the floor zoning from coal seam to aquifer, four kinds of discriminant models to describe water inrush risks from floor are proposed based on the spatial existing status of a broken zone in the floor (h1), the water pressure-free zone (h21), the water pressure zone (h22), and the original rising zone (h3). The judgment basis is as follows.

-

(1)

If h1 + h3 ≥ h, water inrush from floor occurs. The floor broken zone enters the original rising zone, or the latter enters the former, and there is no intact rock zone. During coal mining, the floor-confined water enters the working face along cracks and causes water inrush from floor (Fig. 2a).

-

(1)

If h1 + h3 < h, there are three situations:

-

① If h22 > h2, water inrush from floor occurs. The water pressure zone and the floor broken zone are interlinked with each other, and there is no water pressure-free zone. Due to the influence of the underground pressure and confined water, water inrush from floor easily occurs (Fig.2(b)).

-

② If h22 = h2, water inrush from floor may occur. The water pressure zone and the floor broken zone are interlinked with each other, and there is no water pressure-free zone. Due to the influence of the underground pressure and confined water, crack water inrush may happen (Fig. 2c).

-

③ If h22 < h2, there is no water inrush from floor. There is no water pressure-free zone that has better water blocking ability between the water pressure zone and the floor broken zone. In that case, there is no risk of water inrush from floor (Fig. 2d).

In mining discriminant models of the “water pressure-free zone,” water pressure-free zone is the key to determine whether floor water inrush occurs. At present, there are many methods to predict and measure the depth of the floor broken zone, such as theoretical formulas, empirical formulas, numerical simulations, and actual measurements, which have mature theories or advanced means and can obtain highly precise values. The cracks formed by the geological tectonic movement are the basis of the formation of the original rising zone, and the wedge splitting and stress dissolution of the confined water are the driving forces of its expansion. There are original rising zones with different scales that develop in the strong flowing zone in the North China coalfield. The different sizes of the top borders vary greatly. An original rising zone may not exist in some coalfields or areas. The existence of this zone can be determined by geophysical exploration or drilling in production practice. The calculation of the height of water pressure zone is the key in the discrimination models of the water pressure-free zone. In this article, the relationship between permeability coefficient of floor rock and loss rate of pressure water pressure is obtained by means of laboratory experiment model, and the height of water pressure zone is determined.

Determination of height water pressure zone

When the confined water in the aquifer intrudes into the overlying aquiclude, it must overcome the resistance of the aquiclude, which will cause head loss until equalization. As the confined water seeps up along the floor of the aquiclude, the cracks expand gradually under the influence of water pressure. Through field observations, the structural properties and relationships of the surrounding rock of the coal seam are summarized, and a laboratory physical simulation model is established. The relationship between the permeability coefficient of the floor rock and the wastage rate of the confined water pressure is also simulated when the floor aquiclude is affected by the confined water. Laboratory experiment model is established to explore the relationship between permeability coefficient of floor aquifer and the ratio of water head loss.

Experimental model and principle

The experimental model consists of a physical simulation model consisting of a high-pressure aquifer, a low-permeability resistive aquifer, and a residual hydraulic pressure measuring instrument in a high-pressure water intrusion zone, a hydraulic loading system, and a hydraulic pressure stabilization system (Fig. 3). After the model is built, a certain amount of prestressing force is added to the prestressing loading system, and then prestressing water pressure to the aquifer in the model through the water adding, pressurizing and stabilizing system, respectively, and keeping the water pressure in the aquifer stable. By changing the head pressure in the aquifer, the information of the same water-resisting material on the water intrusion and uplift in different aquifers is obtained. After that, the water-resisting materials in the model are replaced to repeat the above experiments, and the relevant information of different water-resisting materials on the intrusion and uplift of different hydraulic aquifers is obtained. Through the experimental data, we can understand and grasp the control factors and laws of confined water conduction.

Experimental materials and plan designing

The low-permeability models are made using sand, white powder, and cement in different proportions. These materials are loaded with certain prestresses via a loading system. The experiment is conducted with a priming apparatus, pressure device, and pressurizer. The pressures of the water at different heights are recorded by observing the pressure gage in this model. Water blocking rules for the floor rocks in the coal seam are summarized by simulation experiments and data collation to study the pressure distribution characteristics of the highly confined underground water in different positions of overlying water in the blocking rock flowing crevice zone and at residual water pressures at the destination. The experimental plan is shown in Table 1.

Main experimental results

The following conclusions are drawn from the results of the experiment:

-

(1)

In the same medium, the rate of water head loss is faster as the current’s height increases (Fig. 4):

-

(2)

In the same medium, when the initial head pressure is low, the decrease in the head pressure differs. The higher the head pressure is, the more the head loss occurs, and the head loss and their decay rates tend to increase progressively. The higher the initial head pressure is, the faster the rate is (Fig. 5).

-

(3)

During the confined water rising process, the layer with a lower permeability will decrease the water pressure. The pressure head loss will decrease as the permeability coefficient increases (Table 2) (Hu et al. 2008; Bian and Yang 2016). The relationship between the permeability coefficient and the ratio of water head loss is set according to the experimental data (Fig. 6).

Table 2 Relationship between permeability coefficient and ratio of water head loss

where η is the ratio of water head wastage (head pressure wastage per unit thickness of rock), MPa/m; k is the permeability coefficient, m/d.

By analyzing the experimental data, we see that the influence of low-permeability rocks on head loss during the rising of floor-confined water mainly comes from the rock properties of the aquiclude, the mechanical properties of the rock, the permeability of the aquiclude, and the head pressure of the aquiclude and the aquifer. However, during the process, the most influential factor affecting head loss is the permeability of the aquiclude. Therefore, the height of the water pressure zone can be determined according to Formula 1.

Application examples

General state of the research area

Caozhuang mine field is a typical North China type coalfield; the main stable mining coal seams are the 3rd coal seam in Shanxi Formation of Permian and the 7th coal seam, 8th coal seam, 9th coal seam, and 10th coal seam in Taiyuan of Carboniferous. At present, the main mining seam is the 8th coal seam, and the distance between Ordovician limestone aquifer and floor is 61.7 m (Fig. 7).

The 81004 working face is located in the second section of the west wing of the − 480 m horizontal level in the Caozhuang coal mine. The east side is the downhill track of the mining area, the west side is the F2 fault waterproof coal pillar, and the south side is the 8812 and 81002 working faces that have been mined. The working face elevation is − 330.3 ~ − 358.2 m, and the length of working face is 88 ~ 138 m. The average thickness from coal seam to Ordovician limestone is 61.7 m, and the floor is composed of clay rock, siltstone, coal seam, and thin limestone such as No. 5 limestone. Before mining in the working face, 15 drainage drill holes were constructed for the No. 5 limestone and 1 drainage drill hole was constructed for the Ordovician limestone. Three tests to drain away water were performed in this working face. In every stable state of draining, the largest water inrush coefficient is no more than 0.06 MPa/m. According to the experimental results, the working face can be mined with reducing water pressure by drainage. During mining, the holes which may be destroyed in coal mining were grouted and sealed according to standards before the working face is advanced 30 m away from the drill holes such as the 156th drill hole, 155th drill hole, 154th drill hole, 153rd drill hole, and 151st drill hole (Fig. 8). The Ordovician pressure was measured at 2.4 MPa. The floor broken depth is 10.99 m measured by a “double end-sealing leak detector.” The measured height of the original rising zone is 10 m. The water inrush coefficient is 0.058 MPa/m calculated by the formula in relevant regulations. As this value is less than 0.06 MPa/m, the face can be safely mined.

On the other hand, using the field pumping test, the permeability coefficient of h22 is 0.0532 m/d. Based on Formula 1, the rate of water head loss is 0.044 MPa/m. Using the formula, we get h2 = 54.54 m. From this, h2 = 61.7 − h1 − h3 = 40.71 m, meaning that h22 > h2. According to discriminant models for coal mining with water pressure, water inrush accidents may easily occur. In fact, when the working face advanced 360 m, there was a water inrush accident from the floor.

From the above analysis, we can see that:

-

(1)

In the process of coal seam mining, confined water will rise along the aquifer which resulted in the destruction of water isolating.

-

(2)

Water pressure-free zone in aquifer is the key to ensure coal layer safely mining. In 81004 working face, there is no water pressure-free zone, which leads to the communication between floor failure depth and water pressure zone, and causes the floor water inrush.

-

(3)

Before mining, many water control measures were conducted on the 81004 working face. According to the calculation results of water inrush coefficient method, it is judged that safe mining under pressure can be carried out, which is not consistent with the facts. Conversely, the results from the discriminant model of the water pressure-free zone are consistent with the facts.

Based on the theory of Down Three Zones and analyzing effects of confined water pressure on aquiclude, we give the mining discriminant models in the water pressure-free zone. Through the analysis, it can be seen that the water pressure-free zone is the key to determine whether water inrush occurs from floor in the actual production. These discriminant models can be used to guide the work of mine water prevention and control.

Conclusions

-

(1)

The intact aquiclude is divided into a water pressure-free zone and a water pressure zone according to the influence of the confined water pressure on the intact aquiclude. The discriminant models for water inrush from floor are proposed.

-

(2)

The influencing factors of confined head loss are found out through laboratory experimental model, and the formula for calculating the ratio of water head loss and permeability coefficient is obtained, from which the height of water pressure zone is calculated.

-

(3)

It is proved by the example that the discriminant model of pressure-free zone is simple and practical and has dependable theoretical basis and good field application value.

References

Bai CHG, Li LJ, Yu XF (1997) Cusp catastrophe model for instability of key stratum in floor with water inrush. J China Coal Soc 22(2):149–154

Bian K, Yang ZHB. (2016) Orthogonal test of the influential factors of confined water-conducting zone in coal floor. Coal Geology & Exploration 44(1):74–78

Gao WF, Shi LQ, Zhai PH (2019) Water detection within the working face of an underground coal mine using 3D electric resistivity tomography (ERT). J Environ Eng Geophys 24(3):497–505

Hu WY, Tian G, Li KK (2008) The resistant mechanism and control factors of coal seam floor aquiclude to high pressure water intrusion. Coal Geology & Exploration 36(6):38–41

Kuscer D (1991) Hydrological regime of the water inrush into the Kotredez coal mine (Slovenia, Yugoslavia). Mine Water Environ 10:93–101

Kuznetsov S, Trofimov V (2002) Hydrodynamic effect of coal seam compression. J Min Sci 38(3):205–212

Li BY (1999) “Down Three Zones” in the prediction of the water inrush from coalbed floor aquifer-theory, development and application. J Shandong Inst Min Technol (Nat Sci) 18(4):11–18

Li LJ, Qian MG, Wen Q, Meng YP (1995) Relationship between the stability of floor structure and water-inrush from floor. J China Univ Min Technol 4:18–23

Liu Q, Sun YJ, Xu ZM (2011) Application of modified water inrush coefficient method to evaluation of water inrush from mine floor. Coal Sci Technol 39(8):107–109

Motyka J, Pulido-bosch A (1985) Karstic phenomena in calcareous-dolomitic rocks and their influence over the inrushes of water in lead-zinc mines in Olkusz region (South of Poland). Int J Mine Water 4(2):1–11

Munirathinam M, Yinling JC (1994) A review of computer-based truck dispatching strategies for surface mining. Reclam Environ 8:1–15

Qiao W, Li WP, Zhao CX (2009) Water inrush coefficient-unit inflow method for water inrush evaluation of coal mine floor. Chin J Rock Mech Eng 28(12):2466–2474

Qu XY, Qiu M, Liu JH, Niu ZC, Wu XS (2019) Prediction of maximal water bursting discharge from coal seam floor based on multiple nonlinear regression analysis. Arab J Geosci 12:567

Sammarco O (1986) Spontaneous inrushes of water in underground mines. Int J Mine Water 5(3):29–41

Shi LQ, Han J (2005) Theory and practice of dividing coal mining area floor into fore-zone. J China Univ Min Technol 34(1):16–23

Shi LQ, Tan XP, Wang J, Ji XK, Niu CH, Xu DJ (2015) Risk assessment of water inrush based on PCA_Fuzzy_PSO_SVC. J China Coal Soc, 2015 40(1):167–171

Shi LQ, Wang Y, Qiu M, Gao WF, Zhai PH (2019a) Application of three-dimensional high-density resistivity method in roof water advanced detection during working stope mining. Arab J Geosci 12:464

Shi LQ, Wang Y, Qiu M, Han L, Zhao YP (2019b) Research on the required width of a fault waterproof coal pillar based on underground pressure control theory. Arab J Geosci 12:480

Shi LQ, Wang Y, Qiu M, Wang M (2019c) Assessment of water inrush risk based on the groundwater modeling system—a case study in the Jiaojia Gold Mine Area, China. Arab J Geosci 12:807

Shi LQ, Xu DJ, Wang Y, Qiu M, Hao J (2019d) A novel conceptual model of fracture evolution patterns in the overlying strata during horizontal coal seam mining. Arab J Geosci 12(10):1–9

Wang DD, Shi LQ (2019) Source identification of mine water inrush: a discussion on the application of hydrochemical method. Arab J Geosci 12(2):58

Wang LG, Song Y (2002) Study on the self-organized critical character for water burst from coal floor. Chin J Rock Mech Eng 21(2):1205–1208

Wang Z, Liu H (1994) Analysis and calculation of ultimate hydraulic resistance of residual intact rock mass in floor space. Chinese Journal of Rock Mechanics and Engineering (04):319–326

Wang ZY, Liu HQ, Wang PY, Yu SHC (1991) Theory and practice of coal mining discipline on confined water. J China Coal Soc 19(1):40–48

Wang JM, Ge JD, Wu YH (1996) Mechanism on progressive intrusion of pressure water under coal seams into protective aquiclude and application in prediction of water inrush. J China Univ Min Technol 2(2):9–15

Wang XY, Wang TT, Wang Q, Liu XM, Li RZ, Liu BJ (2017) Evaluation of floor water inrush based on fractal theory and an improved analytic hierarchy process. Mine Water Environ 36(1):87–95

Wang XY, Yang G, Wang Q, Wang JZ, Zhang B, Wang JW (2019) Research on water-filled source identification technology of coal seam floor based on multiple index factors. Geofluids 2019:5485731 9 pages

Wolkersdorfer C, Bowell R (2004) Contemporary reviews of mine water studies in Europe. Mine Water Environ 23(4):161

Yang TH, Liu HL, Zhu WC, Meng ZP, Wang R (2011) Modification and application of critical water outburst coefficient in coal mine based on the concept of effective stress. Chin J Rock Mech Eng 30(sup.2):4011–4018

Yin HY, Zhou WF, La Moreaux JW (2018) Water inrush conceptual site models for coal mines of China. Environ Earth Sci 77:746

Yu XG, Han J, Shi LQ, Wang Y, Zhao YP (2017) Application of a BP neural network in predicting destroyed floor depth caused by underground pressure. Environ Earth Sci 76:353

Zhang JC, Liu TQ (1990) On depth of fissured zone in seam floor resulted from coal extraction and its distribution characteristics. J China Coal Soc 15(2):46–54

Zhang WQ, Zhang GP, Li W et al (2013) A model of Fisher’s discriminant analysis for evaluating water inrush risk from coal seam floor. J China Coal Soc 38(10):1832–1836

Acknowledgments

The authors would like to thank the workers of the Department of Geology in the Feicheng coal mine for their field test and data collection.

Funding

This research was financially supported by the National Science Foundation (51778351), SDUST Research Fund (No.2018TDJH101), Scientific Research Development Plan of Colleges and Universities in Shandong Province, and Taishan Scholars Construction Projects Funded by Special Funds.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Shi, L., Qu, X., Yu, X. et al. Theory and practice on the division of the “water pressure-free zone” in a mining coal seam floor. Arab J Geosci 13, 1079 (2020). https://doi.org/10.1007/s12517-020-06067-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-06067-2