Abstract

Hydraulic fracturing technologies revolutionize the way petroleum industries drill the conventional and unconventional formations by the purpose for oil recovery enhancement. Multi-criteria decision-making (MCDM) methods are always considered as the preferable techniques in organizational and industrial operational performances that some of them are being widely administered for numerous purposes. The objective of this comprehensive study is to conduct an investigation about the considerable influence of five important criteria on the hydraulic fracturing techniques and select the best technology regarding enhancing oil recovery factor. Fuzzy Analytic Hierarchy Process (FAHP) and Fuzzy Technique for Order Preference by Similarity to Ideal Solution (FTOPSIS) analyses are applied to compare each criterion. Consequently, among the five fundamental criteria for selecting and operating hydraulic fracturing, in situ stress-strain with the score weight of 0.421 is the most important selectivity criteria. Furthermore, after analyzing the results derived from FAHP and FTOPSIS methods, hydra-jet fracturing and zipper fracturing techniques with the normalized weights of 0.186 and 0.194, and relative closeness coefficients of 0.69 with a 0.66 are considered respectively as the best and optimum techniques of hydraulic fracturing. Last but not least, the cavitation hydro-vibration fracturing and explosive fracturing are the least preferable methods among hydraulic fracturing techniques.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hydraulic fracturing has been considered as one of the preferable technologies in petroleum industries for several decades by the purpose of hydro-carbon well stimulation to recover a huge volume of oil and gas since the 1940s (King and Durham 2017; Shahbazi et al. 2017; Sutra et al. 2017; L. Thomas et al. 2019; Davarpanah and Mirshekari 2019). Hence, the industrial utilization of hydraulic fracturing techniques is catapulted in petroleum industries to enhance the oil recovery factor. The treatments of hydraulic fracturing were extraordinarily applicable rather than the conventional fracturing processes in the year 1968, and after that, other techniques of hydraulic fracturing have taken into consideration among petroleum industries (Cheremisinoff and Davletshin 2015; Li et al. 2015; Davarpanah 2018b). The considerable influence of hydraulic fracturing in the multi-layers’ formation and its combination with the directional drilling procedures of a well especially in horizontal wells due to the high contact level with reservoir fluids has become the substantially progress role in the modeling analysis and operational processes (Dustin et al. 2018; Ebadati et al. 2019a; Lei et al. 2017). However, numerical modeling of hydraulic fracturing facilitated the contemporary advancement of harnessing technologies, and managing the challenges of fluid mechanics characterization phenomena is still considered as the pressing concern of petroleum companies. Hence, modeling and estimation techniques give petroleum industries the chance to overcome the squanders vast sums of money (Davarpanah 2018a; Edwards et al. 2017; Kiran et al. 2017; Kirane et al. 2017; Klejment et al. 2018). The factors which severely affect the procedures of hydraulic fracturing are in situ stress and strain, rock heterogeneity, fractures that existed from the previous processes or induced naturally (pre-existed fractures), sidewall pressure, and geometry of the injected section (Bandara et al. 2018; Krietsch et al. 2018; Yin et al. 2019; Davarpanah et al. 2018). The effects of each parameter are illustrated briefly as the following descriptions to espouse the importance of them on hydraulic fracturing appropriately (Cheremisinoff and Davletshin 2015; Hagström and Adams 2012; Li et al. 2015; Meyer and Bazan 2011; Ebadati et al. 2019b).

In situ stress-strain effect on the hydraulic fracturing procedures has played a substantial role in the creation of hydraulic fractures at several locations and could control the propagation rate. Rock heterogeneity effect on the hydraulic fracturing procedures related to the variation of reservoir characteristics especially rock properties entailing porosity, permeability, and Young’s modulus has exerted a profound impact on the hydraulic fracturing procedures. Thereby, the fluctuation of these parameters might be affected by the location and data sets of the selected area. Formations initially have fractures and cracks from the original base of creating the formation which most of them are several far from the created fractures during the process. Therefore, these natural fractures might be significant influences due to their induced connectivity during hydraulic fracturing which is called as pre-existed fracture effect on the hydraulic fracturing procedures. In addition, sidewall pressure and geometry of the injected section effect on the hydraulic fracturing procedures are considered as the crucial parameters which should be taken into consideration (Daneshy 2009; Pak and Chan 2008; Thomas et al. 2017; Vengosh et al. 2017; Zhang et al. 2017; Davarpanah 2018c).

In the coming decades, petroleum industries have tended to utilize harnessing technologies and recent advancements to find the optimum method with the current reservoir characteristics. The following techniques, which are used in this study, are the preferable ones who have applied for decades and engineers have tried to improve them by recreating or administering modern facilities to obtain more volume of oil and gas. Zipper fracturing entails the simultaneous stimulation between two wells which they are located parallel in the horizontal axis. Hence, fractures that are created in each section propagate in front of other sections (Rafiee et al. 2012; Yu and Sepehrnoori 2013).

Moreover, this method is preferably used in shallow formations. In cavitation hydro-vibration fracturing, by simultaneous operation of pressurized water pulse, the rock is fractured. Regardless the use of any chemical treatment, this technology is considered as the green technology. Hydra-jet fracturing is a combination of hydraulic fracturing and hydro-jetting by running a specific jetting tool to start hydraulic fracturing. Thereby, dynamic fluid energy is the primary force to create fractures on the determined locations (East Jr et al. 2004; Gokdemir et al. 2013; McDaniel and Surjaatmadja 2009). Exothermic hydraulic fracturing is a combination of mechanical and thermal fracturing processes by generating gas and heat from the injected chemical treatment in a specific location (Al-Nakhli et al. 2013). In explosive fracturing, any utilization of fluids seemingly appears in the process, and it operated as the induced dynamic loadings by locating the explosives at the bottom surface of a well or administration of electrical fracturing near the sidewall of the formation (Zhong et al. 2018). Other hydraulic fracturing techniques are hydraulic fracturing with foam-based fluids, hydraulic fracturing with oil-based fluids, hydraulic fracturing with acid-based fluids, hydraulic fracturing with alcohol-based fluids, and hydraulic fracturing with emulsion-based fluids. Although each of the mentioned techniques has its privileges due to the reservoir characteristics and the compatibility of injected fluid to the formation, petroleum engineers try to operate new techniques such as plasma stimulation and fracturing technology (PSF) and enhanced bacterial methanogenesis to improve the oil recovery factor in exceptional circumstances (Ma and Ruggiero 2018; Sumner and Plata 2018; Zhu et al. 2018).

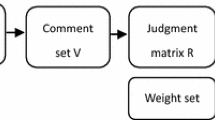

The basic definition of decision-making could be explained as the clarification and selection of a specific alternative from a collection of alternatives categorized by the preferences and criteria that managers or decision makers responded to answer correctly. These criteria are entailed the problem statement and how to choose the appropriate method by experts to achieve the optimum method of selection. Due to the increasing demand for selecting optimum ways and methods in every aspect of human life, decision-making techniques would be the preferred choice to adapt to a world accelerating technological change regarding divergent views and experiences. On the contrary, decision makers have encountered a blizzard of attributes in the selection of decision-making criteria and method for their purposes, and this is why they would try to improve the current methods to be more adapted with their system (Laureiro-Martínez and Brusoni 2018; Toth and Vacik 2018). For numerical evaluation of criteria and alternatives in the decision-making methods, three sequential steps are being administered as the following statement to obtain the best results:

-

i.

Specify the properly relevant alternatives and criteria

-

ii.

Combine the numerical measurements with the most relative criteria and spouse the significant importance of each alternative

-

iii.

Evaluate the numerical investigation to identify the best ranking for each analysis

Decision-making criteria techniques are categorized as the following techniques which everyone has its privileges in each circumstance. These techniques are Analytic Hierarchy Process (Panahpoori et al. 2018), Fuzzy Analytic Hierarchy Process (FAHP), Analytic Network Process (ANP), Simple Additive Weighted (Zhu et al. 2015), Linear-Programming for Multi-dimensional Analysis of Preference (LINMAP), Fuzzy Technique for Order Preference by Similarity to Ideal Solution (FTOPSIS), Elimination et Choice in Translating to Reality (ELECTRE), Preference Ranking Organization Method for Enrichment Evaluations (PROMETHEE), and Simple Multi-Attribute Ranking Technique (SMART) (Amin and Rajhans 2016; Amini et al. 2016; Hsu et al. 2017; Qin et al. 2017; Triantaphyllou 2000; Wangen 2017; Yazdani et al. 2016).

Although all of the decision-making techniques are widely reported in literature and numerous studies are being done to improve the recent analysis and offer the best preferable solutions in different industrial purposes, in this comprehensive study, the utilization of FAHP and FTOPSIS techniques is applied to conduct an investigation into the hydraulic fracturing methods in order to enhance oil recovery from the hydro-carbon reservoirs and select the optimum fracturing technique which is more adaptable to the reservoir characteristics. Consequently, among the five fundamental criteria, in situ stress-strain criteria are the most important selectivity criteria. Furthermore, by the analysis of FAHP and FTOPSIS methods, it indicates that hydra-jet fracturing with the normalized weight of being considered as the best and optimum techniques of hydraulic fracturing respectively.

Decision-making criteria techniques

Numerical analysis of FAHP

In this technique, the possibility of investigating quantitative and qualitative criteria is simultaneously provided and formulated the problem definition by the hierarchy processing as one of the principles of the FAHP technique. Moreover, the utilization of fuzzy procedures in the decision-making activities is more preferred by the experts in their judgments. One of the significant drawbacks of this technique is the inappropriate pairing comparison and the heterogeneity scales in the judgments. Thereby, experts are often would not be able to demonstrate their opinions properly about the priorities regarding the fuzzy nature of pairing comparisons (Aslani and Aslani 2012; Khanaposhtani et al. 2016). The steps of process are being explained by the following principles with the purpose of investigating the hydraulic fracturing methods (Amin and Rajhans 2016; Amini et al. 2016; Hsu et al. 2017; Qin et al. 2017; Triantaphyllou 2000; Wangen 2017; Yazdani et al. 2016);

-

Set up the analytic hierarchy process structure. In this step, the purpose of the decision including causes and effects of making the decision is demonstrated. The first level entails the general goal of the decision, and the second level is related to the general criteria which decisions are based on. At the final level, decision criteria selections according to the eleven hydraulic fracturing techniques are proposed.

As is seen in Fig. 1, Cs are the criteria and Fs are the fracturing methods.

-

Create pairing comparison matrix A regarding the application of fuzzy numbers; pairing comparison matrix is according to the following matrix:

Also, the matrix included the following fuzzy numbers.

-

Calculation of Si for each of matrix rows for pairing comparison matrix as follows:

wherein this matrix i indicates row number and j indicates column number. And \( {M}_{gi}^j \) is the triangular fuzzy numbers of pairing comparison matrix. The other parameters are defined as follows:

where li, mi, ui are the triangular Fuzzy numbers for the three components.

-

Determine the maximum Si

Generally, M1 = (l1, m1, u1) and M2 = (l2, m2, u2) are the fuzzy numbers; therefore, increasing ratio of M1 than M2 is

-

Calculation of criteria and alternatives weight in the pairing comparison matrix

To do this, the normalized weight vector is calculated by

-

Calculation of final weight vector

To do this, equation eight should be normalized again as the following equation:

The fuzzy triangular numbers are described in Table 1.

Numerical analysis of FTOPSIS

Yoon and Hwang firstly proposed this technique as an alternative to the ELECTRE technique. The principle concept of this technique is that the alternative which was selected by experts should have the smallest distance from the ideal solution and the farthest solution from the negative ideal solutions. The FTOPSIS steps are considered as the following steps (Amin and Rajhans 2016; Amini et al. 2016; Hsu et al. 2017; Nazari et al. 2018; Qin et al. 2017; Triantaphyllou 2000; Wangen 2017; Yazdani et al. 2016):

-

Build the normalized decision matrix

In this step, the dimensions of different criteria are converted into the non-dimensional criteria. An element rij of the normalized decision matrix R is thus calculated as follows:

-

Build the weighted normalized decision matrix

In this step, the normalized matrix crossed to the weights to generate the normalized decision matrix.

-

Specify the ideal and non-ideal solutions

The F∗ and F− are the ideal and non-ideal solutions respectively.

-

Calculate the separation measure

The distances of each ideal and non-ideal solution are as follows:

where \( {S}_i^{\ast } \) and \( {S}_i^{-} \) are the alternative distances of ideal and non-ideal solutions respectively.

-

Calculate the relative closeness to the ideal solution

The relative closeness for each of Fi is calculated from the following equation:

\( {C}_i^{\ast }=\frac{S_i^{-}}{S_i^{-}+{S}_i^{\ast }}\kern4em 0<{C}_i^{\ast }<1 \) and i = 1,2, 3, …, m, \( {C}_i^{\ast }=\frac{S_i^{-}}{S_i^{-}+{S}_i^{\ast }}\kern0.50em \ \kern0.50em \ \kern0.50em \ \kern0.50em \ \kern0.50em \ \ 0<{C}_i^{\ast }<1\ \kern0.2em and\;i=1,2,3,\dots, m, \)

It is assumed that \( {C}_i^{\ast }=1 \) if Fi = F∗

-

Prioritize the preferences ordering

Finally, the relative closeness’s are ranked in the descending wise. Thereby, the best alternative is those that have the shortest distance to the ideal solution.

Results and discussion

FAHP analysis

In the first part of the analysis, the significant parameters which have played a substantial role in the hydraulic fracturing are being calculated according to the pairing comparison matrix. Thereby, due to the experts’ judgment, the weighted normalized criteria are derived in Table 2.

As is seen in Table 2, the most significant criteria regarding expert’s judgment are related to the in situ stress and strain criterion with the score weight of 0.421. Since then, rock heterogeneity and sidewall pressure with the score weight of 0.325 and 0.294 respectively are in the sequential orders. The least criteria are related to the pre-existed fractures and geometry of the injected section; in respect of the way, an overwhelming majority of the experts subscribe to the theory that these two criteria are less important than other criteria. In the second part of the analysis, the selected criteria by utilization of pairing comparison matrix for the eleven hydraulic fracturing techniques are analyzed, and the normalized weight is calculated for each technique.

As is seen in Table 3, zipper fracturing and hydra-jet fracturing with the normal weight of 0.194 and 0.186 respectively are considered as the best method of hydraulic fracturing among eleven techniques. Also, hydraulic fracturing with emulsion-based fluids, hydraulic fracturing with oil-based fluids, and exothermic hydraulic fracturing are in the middle ranking. Next, explosive fracturing and cavitation hydro-vibration fracturing are the least applicable techniques to oil recovery enhancement.

FTOPSIS analysis

In this part, the following steps are done to calculate the relative closeness and then prioritize the preferences:

-

i.

Build the normalized decision matrix

-

ii.

Build the weighted normalized decision matrix

-

iii.

Specify the ideal and non-ideal solutions

-

iv.

Calculate the separation measure

-

v.

Calculate the relative closeness to the ideal solution

-

vi.

Prioritize the preferences ordering

The results of these six-step calculations are statistically demonstrated in Table 4.

After prioritizing the normal weigh for each technique is statistically categorized in Table 5.

As is seen in Table 5, hydra-jet fracturing and zipper fracturing with the normal weight of 0.69 and 0.66 respectively are considered as the best method of hydraulic fracturing among eleven techniques. Also, hydraulic fracturing with oil-based fluids, hydraulic fracturing with foam-based fluids, and hydraulic fracturing with acid-based fluids are in the middle ranking. Next, exothermic hydraulic fracturing and cavitation hydro-vibration fracturing are the least applicable techniques in order to oil recovery enhancement.

Conclusion

Hydraulic fracturing is the procedure where the rocks are ruptured by fluid injection under high pressure, and it is considered one of the significant processes in order to improve the oil recovery from reservoirs. Regarding the utilization of the decision-making techniques in numerous studies to improve the recent analysis and offer the best preferable solutions in different industrial purposes, in this extensive study, the utilization of FAHP and FTOPSIS techniques is applied to select the optimum hydraulic fracturing methods in order to enhance oil recovery from the hydro-carbon reservoirs which is more adaptable to the reservoir characteristics. To do this, the five important criteria in the hydraulic fracturing are analyzed by the decision-making procedures, i.e., FAHP and FTOPSIS. Among the five crucial criteria for selecting and operating hydraulic fracturing, in situ stress and strain criteria with the score weight of 0.421 are the most important criteria. According to the results derived from both FAHP and FTOPSIS, hydra-jet fracturing and zipper fracturing techniques are considered the best and optimum techniques of hydraulic fracturing. Hydra-jet fracturing and zipper fracturing techniques with the normalized weights of 0.186 and 0.194 and relative closeness coefficients of 0.69 with 0.66 are considered respectively as the best and optimum techniques of hydraulic fracturing. Moreover, the cavitation hydro-vibration fracturing and explosive fracturing are the least preferable methods among hydraulic fracturing techniques.

References

Al-Nakhli AR, Abass HH, Al-Ajwad HA, Kwak HT, Al-Harith AM, & Al-Otaibi A (2013). Unconventional gas stimulation by creating synthetic sweetspot. Paper presented at the SPE Unconventional Gas Conference and Exhibition

Amin SS, & Rajhans MN (2016). Application of integrated AHP and TOPSIS method for prioritization and selection of suppliers: case study in automotive industry

Amini M, Chang S, & Malmir B (2016). A fuzzy MADM method for uncertain attributes using ranking distribution. Paper presented at the Proceedings of the Industrial and Systems Engineering Research Conference

Aslani A, Aslani F (2012) Application of fuzzy AHP approach to selection of organizational structure with consideration to contextual dimensions. Organizacija 45(5):246–254

Bandara K, Ranjith P, Rathnaweera T, Perera M, Kumari W (2018) Thermally-induced mechanical behaviour of a single proppant under compression: insights into the long-term integrity of hydraulic fracturing in geothermal reservoirs. Measurement 120:76–91

Cheremisinoff NP, & Davletshin A (2015). Hydraulic fracturing operations: handbook of environmental management practices: John Wiley & Sons

Daneshy AA (2009). Factors controlling the vertical growth of hydraulic fractures. Paper presented at the SPE Hydraulic Fracturing Technology Conference

Davarpanah A (2018a) Feasible analysis of reusing flowback produced water in the operational performances of oil reservoirs. Environ Sci Pollut Res 25(35):35387–35395

Davarpanah A (2018b) A feasible visual investigation for associative foam >⧹ polymer injectivity performances in the oil recovery enhancement European Polymer Journal 105:405–411. https://doi.org/10.1016/j.eurpolymj.2018.06.017

Davarpanah A (2018c) The feasible visual laboratory investigation of formate fluids on the rheological properties of a shale formation International Journal of Environmental Science and Technology. https://doi.org/10.1007/s13762-018-1877-6

Davarpanah A, Mirshekari B, Jafari Behbahani T, Hemmati M (2018) Integrated production logging tools approach for convenient experimental individual layer permeability measurements in a multi-layered fractured reservoir Journal of Petroleum Exploration and Production Technology 8:743–751. https://doi.org/10.1007/s13202-017-0422-3

Davarpanah A, Mirshekari B (2019) Mathematical modeling of injectivity damage with oil droplets in the waste produced water re-injection of the linear flow Eur Phys J Plus 134(4):180. https://doi.org/10.1140/epjp/i2019-12546-9

Dustin, M. K., Bargar, J. R., Jew, A. D., Harrison, A. L., Joe-Wong, C., Thomas, D. L., ..., Maher, K. (2018). Shale kerogen: hydraulic fracturing fluid interactions and contaminant release. Energy Fuel, 32(9), 8966–8977

East Jr LE, Grieser W, McDaniel B, Johnson B, Jackson R, & Fisher K (2004). Successful application of hydrajet fracturing on horizontal wells completed in a thick shale reservoir. Paper presented at the SPE Eastern Regional Meeting

Ebadati, A., Davarpanah, A., Shahhoseini, A., & Ahmadi, P. (2019a). An experimental study to measure the required fresh water and treated water for drilling an unconventional shale reservoir. Int J Environ Sci Technol, 1–8

Ebadati, A., Akbari, E., & Davarpanah, A. (2019b). An experimental study of alternative hot water alternating gas injection in a fractured model. Energy Exploration & Exploitation, 37(3), 945–959. https://doi.org/10.1177/0144598718815247

Edwards RW, Doster F, Celia MA, Bandilla KW (2017) Numerical modeling of gas and water flow in shale gas formations with a focus on the fate of hydraulic fracturing fluid. Environ Sci Technol 51(23):13779–13787

Gokdemir OM, Liu Y, Qu H, Cheng K, & Cheng Z (2013). New technique: multistage hydra-jet fracturing technology for effective stimulation on the first U-shape well in Chinese coal bed methane and case study. Paper presented at the Offshore Technology Conference

Hagström EL, Adams JM (2012) Hydraulic fracturing: identifying and managing the risks. Environ Claims J 24(2):93–115. https://doi.org/10.1080/10406026.2012.674414

Hsu C-H, Chang A-Y, Luo W (2017) Identifying key performance factors for sustainability development of SMEs–integrating QFD and fuzzy MADM methods. J Clean Prod 161:629–645

Khanaposhtani HF, Nikabadi MS, Eftekhari H, Aslani A (2016) A new decision making model based on factor analysis (FA), F-ANP, and F-ARAS for selecting and ranking maintenance strategies. Int J Bus Anal (IJBAN) 3(4):41–63

King GE, & Durham D (2017). Chemicals in drilling, stimulation, and production Advances in Chemical Pollution, Environmental Management and Protection (Vol. 1, pp. 47–61): Elsevier

Kiran R, Teodoriu C, Dadmohammadi Y, Nygaard R, Wood D, Mokhtari M, Salehi S (2017) Identification and evaluation of well integrity and causes of failure of well integrity barriers (a review). J Nat Gas Sci Eng 45:511–526

Kirane K, Gosavi S, Ning J, & Sanz P (2017). Numerical modeling of the step rate test using fully coupled hydraulic fracturing capabilities. Paper presented at the 51st US Rock Mechanics/Geomechanics Symposium

Klejment P, Foltyn N, Kosmala A, & Dębski W (2018). Discrete element method as the numerical tool for the hydraulic fracturing modeling. Interdisciplinary approaches for sustainable development goals (pp. 217–235): Springer,

Krietsch H, Gischig V, Evans K, Doetsch J, Dutler NO, Valley B, Amann F (2018) Stress measurements for an in situ stimulation experiment in crystalline rock: integration of induced seismicity, stress relief and hydraulic methods. Rock Mech Rock Eng 52:517–542 1–26

Laureiro-Martínez D, Brusoni S (2018) Cognitive flexibility and adaptive decision-making: evidence from a laboratory study of expert decision makers. Strateg Manag J 39(4):1031–1058

Lei Q, Latham J-P, Tsang C-F (2017) The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput Geotech 85:151–176

Li Q, Xing H, Liu J, Liu X (2015) A review on hydraulic fracturing of unconventional reservoir. Petroleum 1(1):8–15

Ma X, Ruggiero P (2018) Practical aspects of suspension plasma spray for thermal barrier coatings on potential gas turbine components. J Therm Spray Technol 27(4):591–602

McDaniel BW, & Surjaatmadja JB (2009). Hydrajetting applications in horizontal completions to improve hydraulic fracturing stimulations and improve ROI. Paper presented at the SPE Eastern Regional Meeting

Meyer BR, & Bazan LW (2011). A discrete fracture network model for hydraulically induced fractures-theory, parametric and case studies. Paper presented at the SPE Hydraulic Fracturing Technology Conference

Nazari MA, Aslani A, Ghasempour R (2018) Analysis of solar farm site selection based on TOPSIS approach. Int J Social Ecol Sustain Dev (IJSESD) 9(1):12–25

Pak A, Chan D (2008) Numerical modeling of hydraulic fracturing in oil sands. Scientia Iranica 15(5):516–535

Panahpoori D, Dehdari B, Riazi M, & Parsaei R (2018). Visualization experiments on the impact of surfactant and nanoparticle on EOR potential of foam injection. Paper presented at the Saint Petersburg 2018

Qin J, Liu X, Pedrycz W (2017) A multiple attribute interval type-2 fuzzy group decision making and its application to supplier selection with extended LINMAP method. Soft Comput 21(12):3207–3226

Rafiee M, Soliman MY, & Pirayesh E (2012). Hydraulic fracturing design and optimization: a modification to zipper frac. Paper presented at the SPE Annual Technical Conference and Exhibition

Shahbazi K, Abdideh M, Hadipoor M (2017) Modelling hydraulic fracturing process in one of the Iranian southwest oil reservoirs. Appl Earth Sci 126(3):108–117. https://doi.org/10.1080/03717453.2017.1322395

Sumner AJ, Plata DL (2018) Halogenation chemistry of hydraulic fracturing additives under highly saline simulated subsurface conditions. Environ Sci Technol 52(16):9097–9107

Sutra E, Spada M, Burgherr P (2017) Chemicals usage in stimulation processes for shale gas and deep geothermal systems: a comprehensive review and comparison. Renew Sust Energ Rev 77:1–11. https://doi.org/10.1016/j.rser.2017.03.108

Thomas, L., Tang, H., Kalyon, D. M., Aktas, S., Arthur, J. D., Blotevogel, J., ..., Young, M. H. (2019). Toward better hydraulic fracturing fluids and their application in energy production: a review of sustainable technologies and reduction of potential environmental impacts. J Pet Sci Eng, 173, 793–803. doi: https://doi.org/10.1016/j.petrol.2018.09.056

Thomas, M., Pidgeon, N., Evensen, D., Partridge, T., Hasell, A., Enders, C., ..., Bradshaw, M. (2017). Public perceptions of hydraulic fracturing for shale gas and oil in the United States and Canada. Wiley Interdiscip Rev Clim Chang, 8(3):e450

Toth W, Vacik H (2018) A comprehensive uncertainty analysis of the analytic hierarchy process methodology applied in the context of environmental decision making. J Multi-Criteria Decis Anal 25(5–6):142–161

Triantaphyllou, E. (2000). Multi-criteria decision making methods. Multi-criteria decision making methods: a comparative study (pp. 5–21): Springer

Vengosh A, Kondash A, Harkness J, Lauer N, Warner N, Darrah TH (2017) The geochemistry of hydraulic fracturing fluids. Procedia Earth Planet Sci 17:21–24

Wangen M (2017) A 2D volume conservative numerical model of hydraulic fracturing. Comput Struct 182:448–458

Yazdani M, Zavadskas EK, Ignatius J, Abad MD (2016) Sensitivity analysis in MADM methods: application of material selection. Eng Econ 27(4):382–391

Yin S, Xie R, Wu Z, Liu J, Ding W (2019) In situ stress heterogeneity in a highly developed strike-slip fault zone and its effect on the distribution of tight gases: a 3D finite element simulation study. Mar Pet Geol 99:75–91

Yu W, Sepehrnoori K (2013) Optimization of multiple hydraulically fractured horizontal wells in unconventional gas reservoirs. J Pet Eng 2013:1–16

Zhang Q, Huang W, Hu Z, Zhou H, Lu X, Lin K, Xia X (2017) Study of the effects of hydraulic fracturing at different dip angles for the development of coalbed methane: a case study in the southeast part of Qinshui Basin, China. Int J Oil Gas Coal Technol 14(1–2):186–200

Zhong Z, Deng R, Lv L, Fu X, Yu J (2018) Fracture mechanism of naturally cracked rock around an inverted U-shaped opening in a biaxial compression test. Int J Rock Mech Min Sci 103:242–253

Zhu C, Takaya J, Iwasawa N (2015) Use of formate salts as a hydride and a CO2 source in PGeP-palladium complex-catalyzed hydrocarboxylation of allenes. Org Lett 17(7):1814–1817

Zhu Q, He W, Zhu J, Zhou Y, Chen L (2018) Investigation on interfacial fracture toughness of plasma-sprayed TBCs using a three-point bending method. Surf Coat Technol 353:75–83

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial handling: Liang Xiao

Electronic supplementary material

ESM 1

(DOCX 137 kb)

Rights and permissions

About this article

Cite this article

Davarpanah, A., Shirmohammadi, R., Mirshekari, B. et al. Analysis of hydraulic fracturing techniques: hybrid fuzzy approaches. Arab J Geosci 12, 402 (2019). https://doi.org/10.1007/s12517-019-4567-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-019-4567-x