Abstract

To ensure food safety and uphold high standards, the food business must overcome significant obstacles. In recent years, promising answers to these issues have emerged in the form of artificial intelligence (AI) and machine learning (ML). This thorough review paper analyses the various uses of AI and ML in food quality management and safety evaluation, offering insightful information for academics, business people and legislators. The evaluation highlights the value of food quality assessment and control in consideration of growing consumer demand and regulatory scrutiny. The powerful capabilities of AI and ML are touted as having the potential to revolutionize these procedures. This study illustrates the numerous uses of AI and ML in food quality management through an in-depth exploration of these technologies. Defect detection and consistency evaluation are made possible using computer vision techniques, and intelligent data analysis and real-time monitoring are made possible by natural language processing. Deep learning techniques also provide reliable approaches for pattern recognition and anomaly detection, thus maintaining consistency in quality across manufacturing batches. This review emphasizes the efficiency of AI and ML in detecting dangerous microorganisms, allergies and chemical pollutants with regard to food safety evaluation. Consumer health risks are reduced because of the rapid identification of safety issues made possible by integrating data from diverse sources, including sensors and IoT devices. The assessment discusses issues and restrictions related to the application of AI and ML in the food business while appreciating the impressive progress that has been made. Continuous efforts are being made to improve model interpretability and reduce biases, which calls for careful evaluation of data quality, quantity and privacy issues. To assure compliance with food safety norms and regulations, the article also covers regulatory approval and validation of AI-generated outcomes. The revolutionary potential of AI and ML in raising food industry standards and preserving public health is highlighted on future perspectives that concentrate on new trends and potential innovations. This comprehensive review reveals that the integration of AI and ML technologies in food quality control and safety not only enhances efficiency, minimizes risks and ensures regulatory compliance but also heralds a new era of personalized nutrition, autonomous monitoring and global collaboration, signifying a transformative paradigm in the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The food industry at a global level is encountering an escalation in challenges associated with ensuring food safety, sustainability and quality due to the increasing demands of consumers and environmental changes. To combat these challenges, industry professionals and researchers are resorting to artificial intelligence (AI) and machine learning (ML) techniques as effective instruments to transform food safety assessment and quality control. In this paper, an assessment is conducted to explore the varied applications of AI and ML in the food industry, with a particular emphasis on their potential to mitigate crucial challenges and enhance the overall efficiency. The requirement for advanced technologies in food safety assessment and quality control is apparent, and AI and ML provide encouraging solutions. The conflation of hyperspectral imaging and AI methodologies in a symbiotic manner, as illustrated by the innovative research undertaken by Rady et al. [1], carried significant consequences for the food processing sector. This union facilitates the swift and accurate detection of pest infestations in apples, which fortifies pre-emptive measures and decreases crop losses. Furthermore, the AI-powered analysis extends to quality management, permitting the real-time evaluation of factors such as ripeness and pollutants. By refining procedures and ensuring the authenticity of products, this combination redefines the benchmarks for food safety and refines the general efficacy of the industry.

The food processing industry is on the cusp of a transformative period, owing to the profound integration of AI and ML techniques. These advancements have significantly altered the crop disease and pest detection landscape with remarkable precision, as evidenced by the pioneering research of Boyd and Sun [2]. Their groundbreaking expert system, which diagnoses potato ailments, is a pioneering achievement that demonstrates the expeditious and precise assessments that are now possible, ushering in a new era of rapid interventions and reduced agricultural losses. However, the realm of AI and ML surpasses the confines of immediate quality control. Instead, it assumes a mantle of paramount significance in navigating the intricate and multifaceted terrain of food security. The astute application of fuzzy systems, as demonstrated by Peixoto et al. [3], offers a glimpse into this potential. Their ingenious dynamic regulation of soybean aphids exemplifies the strategic use of AI, resulting not only in augmented crop yields but also in fortifying the very foundation of the global food supply chain. Inextricably linked to the evolving tapestry of the food industry, the ascendancy of AI and ML technologies in food quality control and safety assessment is inexorable. As we traverse the dynamic contours of this landscape, it becomes increasingly evident that this review serves not merely as an exposition but also as a clarion call, illuminating the path to an augmented future where AI and ML stand as sentinels of excellence within the realms of food processing.

Materials and Methods

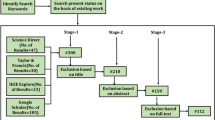

The synthesis of this all-encompassing review is supported by a rigorous methodology aimed at extracting valuable insights from the most authoritative sources currently available. A meticulous and systematic search strategy was executed, utilizing well-known databases such as PubMed, IEEE Xplore and ScienceDirect. This review covers literature published until 2022, ensuring a comprehensive and up-to-date coverage of the subject.

In accordance with strict inclusion criteria, the selection process gave priority to articles that have undergone peer review and notable conference proceedings. A thorough three-step screening process, involving the evaluation of titles, abstracts and full texts, was implemented to ensure the accuracy and relevance of the studies included. The categorization framework focused on the principal applications of AI and ML in the context of food safety, specifically computer vision, IoT-enabled sensors, blockchain integration and predictive modelling. A systematic analysis of the benefits and limitations associated with each application supports a refined distillation of insights, contributing to a comprehensive understanding of the subject matter.

Food Quality Control and Safety Assessment Through AI and ML Techniques

AI and ML techniques have revolutionized the field of food quality control by presenting inventive solutions to increase the consistency and safety of food items [4, 5]. Among the key techniques used in the industry are the following:

-

1.

Computer vision: In contemporary food process engineering, the combination of computer vision technology and AI has emerged as a pioneering development [5]. This combination is transforming the food industry by enabling meticulous and automated visual inspections. AI-powered computer vision systems excel at scrutinizing food products with precision and speed through image and video analysis. These systems are indispensable for crucial tasks such as grading, sorting and quality assessment. By rapidly identifying discrepancies from quality standards, they ensure that only products satisfying stringent criteria are delivered to consumers. The impact of this technology extends across diverse sectors within food processing. In sorting, computer vision systems equipped with AI discern subtle variations in colour, size and shape. This enables precise product categorization, which is particularly essential in fruit and vegetable sorting, where uniformity is vital for quality and competitiveness. Furthermore, the implementation of computer vision addresses food safety concerns by promptly identifying potential contaminants or pathogens. Rapid data analysis allows timely interventions, minimizing risks to food safety and potential recalls. In quality assessment, these systems provide consistent, objective evaluations of attributes that influence consumer preferences. By reducing human subjectivity, they enhance the standardized product evaluation, thus fostering consumer trust and satisfaction. The combination of AI and computer vision not only accelerates processes but also optimizes resource usage. Early identification of defects minimizes waste, leading to cost savings and heightened sustainability.

-

2.

Spectroscopy and sensors: The domain of food process engineering is marked by the combination of AI and ML, which is particularly evident in the realm of spectroscopy and sensors. According to Si et al. [5], ML algorithms intricately analyse data sourced from spectroscopic techniques and a diverse array of sensors, measuring crucial attributes such as moisture content, pH levels and chemical composition. This data-driven analysis empowers AI to make estimations regarding the nutritional value, ripeness and freshness of food items, facilitating informed decision-making for producers concerning production and storage strategies. The proficiency of AIs in interpreting spectroscopic and sensor data has profound implications for quality control and safety assessment. By harnessing AI’s pattern recognition capabilities, the technology enables producers to optimize production processes and minimize resource wastage. In addition, real-time data streams from sensors align with contemporary paradigms such as Industry 4.0 and the Internet of things (IoT), facilitating predictive modelling for quality deviations and enabling timely intervention. This symbiotic blend of AI and ML in spectroscopy and sensors not only enhances operational efficiency but also strengthens the foundation of food safety and quality within the dynamic landscape of food process engineering.

-

3.

Predictive modelling: Predictive modelling with convergence of AI and ML has significant implications for food quality and control. Si et al. [5] have expounded on this technique, which utilizes historical data to train ML models and predict potential quality issues while estimating the shelf-life of food products. The combination of AI and ML facilitates the monitoring of a comprehensive range of variables throughout the production and storage phases, allowing the system to anticipate the likelihood of contamination, spoilage or other forms of deterioration. By identifying patterns and correlations in the data, AI-driven predictive models empower producers to make informed decisions expeditiously. Subsequently, timely interventions can be implemented to preserve the integrity of the final product, minimize wastage and ensure that consumers receive safe and high-quality food items.

In essence, the application of predictive modelling fortified by AI holds significant promise for revolutionizing food process engineering. By leveraging historical insights and real-time data, this approach enhances the industry’s ability to mitigate risks, optimize resources and ultimately deliver products that meet the highest standards of quality and safety.

-

4.

IoT-enabled real-time monitoring: The integration of AI and ML has been emphasized by Si et al. [5], thus leading to the emergence of IoT devices equipped with sensors. This union has enabled real-time monitoring of critical parameters, thereby facilitating proactive quality control. With the aid of these IoT devices, data acquisition is performed in real time, ensuring that quality benchmarks are constantly upheld. In the event of any deviations, AI systems expeditiously analyse the data and deliver prompt notifications, thereby enabling immediate corrective measures. This dynamic approach not only hastens response times but also mitigates the risk of errors or contamination.

Furthermore, AI-powered automation and robotics play a crucial role in expediting quality control procedures. By eliminating human intervention, these technologies enhance precision and minimize the potential for errors. The intricate handling and examination of food products are facilitated, ensuring uniform quality and reducing needless wastage. In essence, the convergence of AI, ML and IoT within food process engineering amplifies the industry’s ability to maintain superior quality standards. The real-time monitoring and automated responsiveness empower stakeholders to ensure that only products of the highest quality are presented to consumers, subsequently elevating trust, satisfaction and overall efficiency.

-

5.

Data-driven decision-making: In the realm of food process engineering, the confluence between AI and ML has been underscored by Si et al. [5] and Vijay et al. [6], utilizing expansive datasets for data-oriented decision-making. This approach combines an array of data sources, including customer feedback, laboratory testing results and manufacturing records. AI’s capacity to process and scrutinize these vast datasets empowers upgraded quality control systems. This integration facilitates the identification of intricate trends and issues that may elude conventional methods. By discerning patterns and anomalies across multiple dimensions, AI enhances the accuracy of quality assessment and contributes to the proactive identification of potential challenges. The integration of AI and ML in food process engineering exemplifies a transformative shift towards data-driven decision-making. This not only enriches the comprehension of product quality but also fosters continuous improvement and innovation within the industry.

-

6.

Blockchain and AI-enabled improved traceability and transparency in the food supply chain: The intersection of blockchain and AI has resulted in a significant breakthrough in augmenting traceability and transparency throughout the food supply chain. The influential works of Si et al. [5] and Bestelmeyer et al. [7] underscored the pivotal role of this decentralized ledger in meticulously monitoring the entire journey of food products, spanning from their origin to consumption. By leveraging AI-powered analysis of blockchain data, a swift and accurate identification of sources is made feasible in cases of contamination or recalls. This integration fortifies the efficacy of traceability systems, safeguards consumer health and increases the efficiency of corrective measures. The fusion of blockchain and AI within food process engineering not only empowers supply chain stakeholders with real-time insights but also instils a heightened level of accountability and integrity. By fostering an environment of transparency, these cutting-edge technologies catalyse a new era in food safety and quality assurance, reinforcing consumer confidence and industry-wide standards.

The combination of AI and ML methodologies has precipitated a profound metamorphosis in the realm of food quality control, resulting in elevated consumer satisfaction levels, reduced wastage and reinforced safety [4, 6]. The developing landscape holds the potential for even more remarkable strides in food quality management, ensuring a consistent supply of secure and first-rate food products. These technologies have revolutionized the paradigm of food process engineering, augmenting its efficacy, precision and dependability. The collaborative synergy between AI, ML and food science underscores their pivotal role in shaping the future of food quality assurance. This trajectory not only guarantees continual improvement of consumer experiences but also establishes a robust foundation for industry’s growth and resilience. The comparison of AI and ML techniques for food safety and quality control is described in Table 1.

Sensor-Based AI and ML Applications for Enhancing Food Safety and Quality Control

Data collection and analysis have been revolutionized by AI-based sensing technologies, which use AI algorithms to glean insightful information from sensor data [5, 6, 13]. These state-of-the-art sensing technologies have several uses in industries such as agriculture, healthcare and environmental monitoring. The AI and ML utilization in food industry is described in Fig. 1. AI-based sensing technologies are essential for maintaining the safety and integrity of food items across the supply chain in the field of food quality control.

-

1.

IoT-enabled smart sensors: The combination of IoT devices with intelligent sensors is revolutionizing the landscape of food production, processing and storage [5]. These sensors are capable of continuously monitoring crucial factors such as temperature, humidity, pH levels, gas emissions and chemical compositions. The real-time data provided by these sensors enable the swift detection of quality and safety issues. The dynamic monitoring system created through this integration enhances food processing by maintaining optimal conditions, preventing microbial growth and averting any moisture-related damage. Furthermore, it assures safety by identifying abnormal gas emissions and monitoring chemical compositions, which allows for timely interventions and proactive measures [14]. The seamless partnership between IoT and intelligent sensors empowers the food industry to ensure precise quality control and maintain vigilant safety measures along the entire food supply chain.

-

2.

Image and spectroscopy sensors: Si et al. [5] emphasize the combination of AI-driven imaging and spectroscopy sensors in the evaluation of diverse aesthetic and chemical properties of food items. AI-powered computer vision algorithms are proficient in meticulously scrutinizing images to detect defects, blemishes and extraneous substances in food products, thereby augmenting the quality control process in food production. Furthermore, spectroscopy sensors are pivotal in capturing the interaction of food items with light, which provides valuable insights into their nutritional value, composition and freshness. This sophisticated analysis facilitated by AI considerably enhances the precision and efficacy of food quality assessment.

-

3.

Gas and odour sensors: In the domain of food processing and safety, Si et al. [5] emphasize the pivotal significance of gas and odour sensors based on AI. These sensors expertly detect volatile compounds discharged by food products, thereby allowing for the identification of harmful substances, spoilage and undesirable smells. By leveraging the capabilities of AI, these sensors can swiftly and accurately analyse sensor data. Hence, compromised or deteriorating products are instantly flagged, ensuring their elimination from the production line before they reach consumers. This proactive approach not only diminishes potential health hazards but also safeguards the credibility of manufacturers and the overall integrity of the food supply chain. The findings represent a prime example of how integrating AI and sensor technology strengthens food safety measures, resulting in improved quality control and heightened consumer trust.

-

4.

Nanosensors: The work of Si et al. [5] illuminated the transformative dimension of nanotechnology in the realm of food processing and safety. This innovative technology allows for the molecular-level recognition of substances and diseases, which, in turn, enables AI-based nanosensors to play a pivotal role in assessing food safety. These nanosensors provide rapid and precise detection of contaminants, thus serving as an invaluable asset in safeguarding the quality of consumables. By harnessing the power of AI, nanosensors contribute to proactive food safety measures. Their exceptional sensitivity and specificity enable early identification of potential hazards, thereby acting as vigilant sentinels against foodborne threats. Real-time contamination detection facilitates swift intervention, bolstering consumer protection and industry integrity. The convergence of nanotechnology and AI in the realm of food safety signifies a revolutionary advancement. It not only enhances the monitoring and control of contaminants but also ushers in a new era of precision and reliability in the food supply chain. As a result, manufacturers can uphold stringent safety standards, while consumers enjoy greater confidence in the products they consume.

-

5.

Blockchain integration: Si et al. [5] emphasized the transformative potential of integrating blockchain and AI-based sensing to enhance food processing and safety. This mutually beneficial partnership bolsters data security and traceability by establishing an immutable ledger for the entire food supply chain. By using blockchain to record sensor-derived data, transparency and permanence are ensured. Through AI-driven analysis, intricate relationships and patterns within the recorded data are uncovered. This dynamic synergy enhances the operational efficiency, mitigates risk and ensures adherence to stringent quality standards. The integration of blockchain and AI represents a pivotal advancement, providing real-time insights to stakeholders, elevating accountability and strengthening consumer confidence in the safety and integrity of food products.

-

6.

Remote sensing: Si et al. [5] and Spanaki et al. [13] underscore the criticality of AI-powered remote sensing techniques in augmenting food processing and safety. These technologies, which use satellites and drones, allow for comprehensive monitoring of agricultural fields and storage facilities. By evaluating crop vitality and environmental conditions and identifying anomalies such as pest outbreaks and temperature fluctuations, they contribute to the preservation of food quality. The real-time insights gleaned from AI-driven remote sensing bolster decision-making, facilitating timely interventions to avert potential hazards. This proactive approach not only safeguards the integrity of food production and storage but also aligns with stringent safety standards. The fusion of AI, remote sensing and agricultural practices represents a powerful synergy that optimizes food processing operations while strengthening the assurance of safe and high-quality food products.

Predictive Modelling and Quality Assessment for Enhanced Food Safety and Quality Control

Predictive modelling and quality evaluation are already commonplace in modern food quality management systems, which use the strength of AI and ML to anticipate product quality, identify possible problems and uphold uniform standards. The results of assessing model performance and accuracy in food safety are described in Table 2. Building consumer trust, adhering to rules and lowering food waste in the business all depend on this proactive approach to quality inspection [4, 18].

-

1.

Predictive shelf-life modelling: The integration of AI and ML in food process engineering has introduced the concept of predictive shelf-life modelling. This data-driven approach involves analysing historical data encompassing various parameters such as composition, storage conditions and environmental influences [18] to enable precise estimation of a food product’s shelf life. Factors like temperature, humidity and storage duration are considered to determine optimal storage conditions and expiration dates. By adopting effective storage practices, manufacturers can minimize product wastage and deterioration, ensuring that products reach consumers at their peak quality.

-

2.

Quality assessment using sensor data: The use of AI and ML in food process engineering has enabled real-time quality assessment using sensor data [5]. Critical variables such as temperature, pH and moisture are continuously monitored using sensors throughout the production and storage stages of food items. By harnessing ML algorithms, real-time data can be rapidly evaluated to identify deviations from established quality standards. The immediate detection of anomalies empowers manufacturers to take prompt corrective actions to maintain the desired level of product excellence while averting potential quality issues.

-

3.

Contaminant identification and allergen control: AI-driven image analysis and predictive modelling have enhanced the identification of contaminants and allergens in food products [5], addressing food safety concerns. ML algorithms proactively recognize potential sources of pollutants by analysing historical data and identifying patterns. This proactive identification mechanism ensures that potentially contaminated products are intercepted before reaching consumers, safeguarding public health and upholding stringent food safety regulations.

-

4.

Real-time process optimization: In the context of food process engineering, AI introduces real-time process optimization [5]. ML algorithms continuously analyse data streams from sensors, production equipment and environmental factors to make dynamic adjustments to industrial processes. This ensures consistent product quality, increased production efficiency and reduced resource consumption. By swiftly adapting to changing conditions, AI-driven optimization enhances product uniformity and minimizes waste.

-

5.

Quality grading and sorting: AI-powered systems have enabled automated quality grading and sorting operations in food process engineering [5]. By harnessing computer vision and ML techniques, food items can be categorized on the basis of their quality attributes. This automated grading process ensures uniformity in the final product, mitigating deviations and elevating consumer satisfaction. The technology’s ability to accurately discern quality traits contributes to efficient sorting processes, a critical aspect of modern food processing operations.

-

6.

Food regulation compliance: AI plays a significant role in ensuring food safety and regulatory compliance [5]. The predictive modelling capabilities of AI algorithms enable food manufacturers to anticipate potential issues by analysing comprehensive data sources, including historical records and lab tests. This proactive approach minimizes the risk of non-compliance and associated penalties, underscoring the technology’s crucial role in maintaining industry standards and consumer safety.

-

7.

Analysis of customer feedback: The use of AI and ML technologies in the examination of customer feedback has led to profound impacts in the field of food process engineering, as noted by Si et al. [5]. Through the incorporation of this feedback into prediction models, manufacturers can gain invaluable insights into product quality and consumer satisfaction. This data-driven approach to decision-making empowers manufacturers to improve product attributes that align with consumer preferences, ultimately resulting in enhanced quality and increased consumer trust. The flowcharts of the applications of AI and ML are shown in Figs. 2 and 3, respectively.

The integration of AI and ML technologies in the realm of food process engineering and food safety represents a pivotal moment in the industry, characterized by precision, efficiency and heightened consumer protection. These advancements have contributed to the optimization of processes, waste reduction, and the establishment of an environment where the production of high-quality and safe food products is of utmost importance.

Data Analytics and Pattern Recognition for Advanced Food Quality Control and Safety

Data analytics and pattern recognition play a significant role in the evaluation of food quality management and safety. These methods use AI and ML to extract useful information from huge datasets, assisting in the detection of patterns, trends and potential problems in the production and distribution of food. The importance of pattern recognition and data analytics in relation to food quality control is described as follows.

-

1.

Quality assurance and defect discovery: The combination of computer vision technology and data analytics has revolutionized quality assurance in food process engineering, leading to proactive measures to eliminate the risk of substandard products reaching consumers and bolstering their trust. This has been made possible by harnessing the power of AI algorithms, which allow automated inspection systems to meticulously examine images and videos of food products. Through pattern recognition, these systems ensure consistent quality attributes and adherence to established standards and reduce wastage.

-

2.

Predictive quality modelling: Predictive quality modelling is a cornerstone of modern food process engineering, which has been made possible by leveraging historical data encompassing production conditions, sensory evaluations and consumer feedback. This forward-looking strategy enables manufacturers to optimize production processes, ensuring enduring quality uniformity while aligning with evolving consumer preferences.

-

3.

Early contaminant detection: Data analytics and AI-driven insights are instrumental in ensuring food safety by facilitating early contaminant detection. This was made possible by analysing diverse data sources, including sensor readings and laboratory tests, to identify potential contaminants or deviations from safety standards. Rapid recognition of abnormal patterns empowers timely interventions, preempting potential food borne illness outbreaks and safeguarding consumer health.

-

4.

Supply chain optimization: The strategic use of data analytics optimizes the entire food supply chain by analysing inventory levels, demand trends and transportation routes, which facilitates accurate demand forecasting and enhanced inventory management. The integration of AI algorithms predicts shifts in demand, streamlines inventory practices, reduces waste and ensures efficient product delivery to customers.

-

5.

Consumer insights and personalization: Data analytics and ML techniques enable food producers to unlock valuable consumer insights and deliver personalized experiences. This tailored approach not only caters to specific market demands but also enhances consumer satisfaction and cultivates loyalty.

-

6.

Adherence to food standards: In the realm of food process engineering, data analytics play a pivotal role in ensuring compliance with rigorous food safety standards. This diligent approach ensures that products consistently meet established quality and safety benchmarks by continuously monitoring and analysing data from various production stages, which mitigates the risk of fines and recalls.

The synergy among data analytics, AI and food process engineering underpins enhanced quality, safety and efficiency throughout the entire food production lifecycle. By embracing these advanced technologies, the food industry has pioneered an era of precision, traceability and consumer-eccentric demands.

Enhancing Food Safety Management and Traceability Through AI and ML Technologies

The provision of safe, legal and high-quality food items is made possible through traceability and food safety management, which are essential components of the food sector. Modern technologies such as the blockchain, the IoT and AI have significantly improved how food safety and traceability are managed. The core elements of food safety management and traceability are explained below.

-

1.

Hazard analysis and critical control points (HACCP): The incorporation of the HACCP framework with AI and ML has transformed food safety management in the manufacturing sector [20]. This methodical approach utilizes data analysis to detect, evaluate and mitigate potential hazards. The data-crunching capabilities of AI enable the identification of risks, the prediction of outcomes and the implementation of preventive measures. Real-time monitoring and automatic alerts facilitated by AI and ML ensure swift actions, thereby minimizing risks and bolstering food safety.

-

2.

IoT-based real-time monitoring: Real-time monitoring of critical factors, such as temperature, humidity and storage conditions, is achievable with the help of IoT-based devices with sensors [13]. The AI algorithms process the continuous stream of data from these sensors to detect deviations from optimal conditions. This constant vigilance minimizes the chances of contamination and spoilage, ensuring that food is handled, stored and transported under optimal conditions.

-

3.

Blockchain for traceability: The transparency of blockchain technology has revolutionized the traceability landscape [7]. With every transaction and movement recorded in an immutable ledger, customers and regulators can track a product’s journey from its origin. AI’s analytical prowess can be harnessed to examine blockchain data during foodborne illness outbreaks, revealing patterns, trends and potential sources of contamination for swift intervention.

-

4.

Product authentication and anti-counterfeiting: Spectroscopic analysis and AI-powered image recognition techniques are used for food product authentication [21]. The ability of AI to compare product images and spectral signatures with established patterns aids in identifying counterfeit or adulterated products. This technology safeguards consumers by mitigating the risk of fraud and ensuring product integrity.

-

5.

Supplier verification and compliance: AI and ML algorithms play a critical role in supplier verification and compliance assessment [22]. By scrutinizing supplier data, certificates and historical performance, AI identifies potential risks, ensuring that only reputable and compliant vendors are integrated into the food supply chain. This proactive approach upholds food safety standards and minimizes potential risks.

-

6.

Recall management: AI and ML technologies have revolutionized recall management, enabling targeted and efficient product recalls [23]. In cases of food safety concerns or contamination, AI swiftly identifies affected batches and issues’ precise recall notifications by analysing supply chain data. This precision reduces waste and minimizes the impact on consumers.

-

7.

Data-driven decision-making: AI and ML algorithms process vast datasets from diverse sources, empowering data-driven decision-making in food safety management [24]. By analysing lab tests, customer feedback and factory records, these technologies provide insights, identify emerging trends and continuously enhance food safety procedures, thereby promoting proactive risk management.

The incorporation of AI and ML into food process engineering has augmented food safety practices, ensuring proactive hazard management, real-time monitoring, traceability and informed decision-making. As these technologies continue to evolve, these advancements will elevate food safety to new heights, thereby enhancing consumer trust and well-being. Contaminant type detected and accuracy by AI and ML are shown in Fig. 4.

Regulatory Compliance and Certification in Food Safety Through AI and ML Innovations

Assuring that food items adhere to the norms and regulations established by the appropriate authorities, regulatory compliance and certification play a critical role in evaluating the safety and quality of food. AI, data analytics and blockchain are examples of cutting-edge technologies that work together to optimize compliance processes, speed up audits and provide consumers with transparent information about food products. A closer look is warranted at the significance of certification and legal compliance in the food industry:

-

1.

Ensuring food safety: Within the domain of food process engineering, ensuring the highest levels of food safety is of utmost importance. The implementation of regulatory compliance protocols ensures that food items comply with strict safety requirements, mitigating the risks of contamination, foodborne illnesses and product recalls. By utilizing AI-driven tools and techniques, food manufacturers can establish comprehensive food safety management systems that not only comply with legal mandates but also surpass them by ensuring the well-being of consumers.

-

2.

Traceability and transparency: The application of blockchain technology in the context of food process engineering revolutionizes the concepts of traceability and transparency [7]. This innovation enables an unalterable record of a food product’s journey from its origin to its final distribution point. This level of traceability provides insights into each step of the supply chain, empowering food engineers to closely monitor and verify the conditions under which the product has been handled, stored and transported. The integration of AI further enhances this traceability, allowing for real-time data analysis to detect any anomalies that could jeopardize the safety of the product.

-

3.

Product labelling and claims: The convergence of AI and food process engineering enhances the accuracy of product labelling and claims. AI-powered systems can comprehensively analyse product labels, ensuring that all information aligns with regulatory requirements. By examining nutritional content, allergen information and ingredient lists, AI can help prevent misleading or incorrect information, thereby safeguarding consumers’ health and maintaining the integrity of food products.

-

4.

Simplifying audits and inspections: In the realm of food process engineering, adhering to regulatory standards often entails rigorous audits and inspections. Here, AI and data analytics offer significant advantage by automating data collection and analysis. This streamlines the audit process, enabling food engineers to quickly compile and present comprehensive compliance data. This data-driven approach enhances the efficiency, reduces the chances of oversight and facilitates smoother interactions with regulatory authorities.

-

5.

Predictive compliance modelling: The complexity of modern food safety regulations demands proactive approaches [24]. AI’s ability to analyse historical compliance data can predict potential challenges and non-compliance trends. By identifying these patterns, food engineers can preemptively address issues and establish corrective measures to ensure continuous adherence to regulations. This anticipatory approach minimizes risks and reinforces a culture of safety in food process engineering.

-

6.

Compliance with industry certifications and standards: AI’s analytical capabilities enhance the rigorous process of complying with industry certifications and standards. The intricate evaluation of vast datasets allows for more efficient certification processes, reducing the time and effort required to meet standards such as ISO, GMP and HACCP. This integration also supports the alignment of production processes with evolving industry benchmarks, underscoring a commitment to excellence.

-

7.

Early warning systems: Early warning systems play a critical role in food process engineering. Prompt identification and resolution of compliance deviations are of utmost importance [13]. With the aid of AI-powered technology, early warning systems can analyse data in real time, enabling stakeholders to be immediately notified of any deviations from established norms. This capability promotes the timely implementation of corrective actions, which helps prevent potential compliance breaches, thereby ensuring the safety and quality of food products.

-

8.

Secure document management and verification: Effective management of compliance records is a crucial component of food process engineering [7]. Blockchain technology, along with AI, provides a secure and tamper-proof method for storing important compliance records. This ensures the integrity of vital compliance records such as certificates, test results and other relevant documents. Moreover, it allows seamless access to regulators, consumers and other stakeholders while preventing any unauthorized alterations. Case studies demonstrating AI and ML applications in food safety are shown in Table 3.

Challenges and Future Directions

It is crucial to solve the issues and consider other approaches if AI and ML are to be developed further and effectively used in food quality control and safety evaluation. Although these technologies have a lot of potential to enhance food quality and safety, some challenges must be overcome before they can reach their full potential. Looking at possible future possibilities can also provide insight into how these technologies will affect the food industry. Difficulties and possible directions are described as follows.

Challenges

Few challenges and limitations for the adoption of AI and ML are explained in the following texts and shown in Table 4.

Data Availability and Quality

The dependence of AI and ML on extensive and high-quality datasets for precise predictions warrants critical appraisal, particularly in the context of trends in food science. While AI holds the promise of revolutionizing food safety, the challenge of sourcing comprehensive and reliable datasets, especially for emerging contaminants and rare quality issues, exposes a crucial limitation [27]. AI models rely on vast amounts of high-quality data for training and accurate prediction. In contrast, it can be challenging to find diverse and well-annotated data in the food industry. Data collection, labelling and storage issues must be carefully considered if reliable and representative datasets are to be guaranteed. The production of food necessitates the use of sensitive information regarding formulas, processes and quality control. Strong data privacy and security safeguards must be in place to protect private data from unauthorized access, breaches or misuse. Deep learning models can be complex and challenging to interpret. For food process engineering, understanding the reasoning behind AI-driven decisions is essential, especially regarding quality control, safety and regulatory compliance. Procedures for explainability and interpretability development are necessary for a model to be accepted and to gain trust. A few are explained in the following:

-

Privacy and security concerns: Delving into the realm of AI and ML brings to the forefront a critical examination of the intricate web of privacy and security concerns, a topic of paramount significance in the evolving landscape of food science [28]. The assimilation of AI entails the inevitable acquisition and analysis of sensitive data, casting a shadow of uncertainty over the integrity of data privacy and security protocols. While the potential benefits of AI in food safety management are undeniable, the unresolved challenge lies in establishing impregnable fortifications against unauthorized data access and potential breaches. The intricate dance between harnessing the power of AI and safeguarding the sanctity of sensitive information demands not only careful vigilance but also innovative solutions that ensure the protection of consumer trust in the digital age.

-

Integration with existing processes: The haunting specter of obsolescence looms large as the chasm between entrenched legacy systems, and the vanguard of AI technologies yawns wider, inviting a crucible of critical inquiry from the discerning purview of distinguished experts in the trends of food science [29]. Compatibility issues, system integration difficulties and scalability restrictions need to be resolved to ensure a smooth transition and effective application of AI and ML technologies.

-

Interpretability and explainability: A vexing conundrum pervades the realm of AI and ML, particularly concerning the intricate labyrinth of interpretability and explainability inherent in complex models such as deep neural networks, a challenge that demands incisive scrutiny from the vantage point of the esteemed experts in the trends of food science [31]. The opacity shrouding the decision-making mechanisms of these advanced AI architectures casts a cloud of ambiguity, rendering the very bedrock of predictions elusive. Inextricably interwoven with the intricacies of food safety, the dichotomy between the inscrutability of AI and the compelling necessity for interpretability and explainability plays a profoundly critical role in the delicate tapestry of stakeholder trust and regulatory assurance [4]. The quest for effective solutions must navigate the treacherous terrain of unravelling AI’s enigmatic decision-making while safeguarding the indispensable confidence of the food industry’s custodians and gatekeepers.

-

Regulatory compliance: The Byzantine labyrinth of regulatory acceptance looms as a herculean endeavour, a trial by fire for the vanguard of AI- and ML-generated data and its audacious claim to the throne of credibility within the hallowed halls of stringent food safety standards. A discerning eye cast upon this saga of persuasion and validation reveals a narrative fraught with complexities [30]. The food industry is subject to strict laws and regulations regarding food quality, safety, labelling and traceability. Making sure AI used in food process engineering complies with all relevant laws and standards is crucial. AI model performance evaluation and documentation should be done to demonstrate compliance with regulations.

-

Collaboration between people and machines: AI tools should not be seen as a replacement for human labour, but rather as a tool to supplement human expertise. Ensuring effective collaboration and synergy between AI systems and human operators is essential. To fully benefit from AI technologies and enable seamless human-machine interaction, employees should receive adequate training and upskilling programmes. Applications for AI should be created and implemented ethically, considering issues of fairness, bias and transparency. Ethical issues become crucial when AI is used for processes such as product creation, quality control or supply chain management.

-

Cost and return on investment: Initially, implementing AI technologies can be expensive due to the need for infrastructure, data collection and training. It is crucial to carefully assess the potential return on investment, accounting for factors such as increased productivity, lower waste, higher product quality and happier customers.

-

Continuous monitoring and maintenance: AI models must be continuously monitored, updated and maintained to ensure optimal performance over time. Regular retraining, dataset updates and model adaptation to new situations or product modifications are required to keep AI systems accurate and effective. To address these issues and considerations, a multidisciplinary approach involving collaboration among food scientists, engineers, data scientists, regulatory specialists and stakeholders from the food business is required. By paying close attention to these aspects, AI can be successfully applied to food process engineering to promote innovation, increase productivity and ensure the production of high-quality, safe food items. The availability and quality of data are two significant barriers to incorporating AI into food process engineering. For training and accurate prediction, AI algorithms require high-quality data. In contrast, it can be challenging to find diverse and well-annotated data in the food industry. Data collection, labelling and storage issues must be carefully considered if reliable and representative datasets are to be guaranteed. To share data, establish criteria for data collection, and to address this problem, the food industry can collaborate with research institutions, business associations and regulatory bodies. Data quality assurance techniques should be implemented to ensure the accuracy and dependability of the data used for AI modelling. Validation, normalisation and data cleansing should all be part of these procedures. Additionally, efforts to collect data and annotate it may be made specifically for AI applications in food process engineering.

Implications for Law and Ethics

It is important to carefully consider the ethical and legal implications of incorporating AI into food process engineering. AI models may have an impact on quality control, safety, labelling and traceability in the food production process. It is essential to ensure that AI systems abide by legal requirements, industry norms and ethical standards. The ethical issues include dealing with issues of unfairness, transparency, privacy and bias. Biases in data and decision-making processes should be reduced by AI models throughout design and training to ensure fair treatment and equal opportunity for all people. Transparency in AI algorithms and decision-making should be supported for accountability and to foster trust. Privacy concerns must be resolved to safeguard sensitive data that AI systems collect and process. To manage ethical and regulatory issues, food corporations should establish solid governance frameworks that include stakeholders from all disciplines and areas of expertise. Close collaboration with legal experts, ethicists and regulatory organisations can aid in adherence to rules, norms and ethical principles.

Interpretability and Explainability

The interpretability and explainability of AI models are important aspects of food process engineering. Interpreting and explaining AI models, particularly complex deep learning models, can be challenging. In the food industry, particularly in areas such as quality control, safety and regulatory compliance, understanding the reasoning behind AI-driven decisions is crucial. An effort should be made to develop methods for model interpretability and explainability in the context of food process engineering. This may require the use of interpretable ML models, model-agnostic explanation techniques or visualisations to provide insights into the decision-making process of AI models. It is crucial to strike a balance between the demands for model accuracy and complexity, transparency and interpretability.

Human-Machine Interaction

This is required for the successful integration of AI into food process engineering. AI technologies should be viewed as tools to complement human skills rather than as a replacement for human labour. It is essential to ensure efficient interaction and coordination between AI systems and human operators. Employees should have access to training programmes to advance their familiarity with and competence using AI technologies. This includes understanding the limitations and potential biases of AI systems, applying AI-driven insights to decision-making and learning how to evaluate AI outputs. Collaborative interfaces and user-friendly solutions should be developed to enable the seamless interaction between humans and AI technologies. Open lines of communication and feedback between human operators and AI systems should be developed in order to solve problems, build trust and continuously improve the efficacy of AI technologies.

Barriers to Adoption and Implementation

There could be several issues with the adoption and use of AI in the engineering of food processes. Among the main challenges are as follows:

-

Cost and return on investment: Initially, implementing AI technologies can be expensive due to the need for infrastructure, data collection and training. Businesses in the food industry must carefully assess the potential return on investment, considering factors such as increased productivity, decreased waste, higher product quality and happier customers.

-

Employees who fear losing their jobs or are unclear about how AI systems operate may be resistant to the adoption of AI technologies. Businesses should invest in change management strategies that include training and communication to allay concerns and promote acceptance of AI technologies.

-

Integration with existing processes: Introducing AI technology into the current food manufacturing and production processes requires careful planning and coordination. Compatibility issues, system integration difficulties and scalability restrictions must be resolved to ensure a smooth transition and effective application of AI technologies.

-

Regulation and compliance requirements: The food industry is subject to strict laws and regulations regarding food quality, safety, labelling and traceability. Making sure AI used in food process engineering complies with all relevant laws and standards is crucial. AI model performance evaluation and documentation should be done to demonstrate compliance with regulations.

-

Limited AI expertise: Due to the rapid development of AI, there are few professionals who are also knowledgeable in food process engineering. Finding or training employees with the necessary skills to develop, implement and maintain AI systems in the food industry may be challenging for businesses. To address these issues, food companies should set clear adoption goals and roadmaps for AI, collaborate with industry experts and partners and invest in ongoing training and internal AI knowledge development. The development of a culture that values innovation, experimentation and constant improvement will also help with the successful adoption and application of AI technology in food process engineering.

Future Directions

AI and ML personalize nutrition plans, improving health outcomes. Robotic systems and AI enhance quality control, boosting efficiency. Blockchain ensures traceability and transparency in the food supply chain. IoT and AI enable autonomous food safety monitoring, safeguarding artistry and consumer well-being (as mentioned in Table 5).

Conclusion

The review study investigated the uses of AI and ML in determining the safety and quality of food. This study demonstrated how AI and ML technologies have transformed the food business, providing creative answers to improve food safety, uphold uniform quality and speed up compliance procedures. Overview of AI and ML applications in enhancing food safety, challenges and considerations in AI/ML applications for food safety and applications of AI and ML in various stages of agri-food processing is described in Tables 6 and 7 and Fig. 5, respectively.

The review paper exemplifies how AI and ML have the ability to completely alter how food safety and quality are assessed. These technologies have a significant impact on the food sector in the following ways:

-

1.

Enhanced food safety through rapid contaminant detection: The integration of AI and ML technologies has enabled enhanced food safety through rapid contaminant detection. This integration has facilitated swift identification of contaminants, allergens and pathogens in food products, significantly reducing the risk of foodborne illnesses. Advanced algorithms analyse data from various sources, such as sensor readings and historical records to detect potential hazards and ensure the overall safety of the food supply chain [34].

-

2.

Elevated quality control via automated inspection: Automated inspection has contributed to elevated quality control, minimizing defects and waste while ensuring consistent product quality. AI and ML algorithms analyse real-time data from production lines, enabling early detection of deviations from quality standards and ensuring that only products meeting desired specifications reach consumers.

-

3.

Proactive identification and management of risks: Proactive risk management is enabled through predictive modelling and early warning systems powered by AI and ML. These systems can forecast potential quality issues by analysing historical data and patterns, allowing manufacturers to take corrective actions before problems escalate. This safeguarding of product quality and consumer well-being is crucial [35].

-

4.

Enhanced transparency and trust with blockchain: The integration of blockchain technology into the food supply chain enhances traceability and transparency, thereby fostering trust and accountability. Tamper-proof and immutable records enable all stakeholders, including regulators, vendors and consumers, to verify the origin, handling and safety of food products [36].

-

5.

Streamlined regulatory compliance and auditing: Regulatory compliance processes are streamlined through AI and ML technologies, which expedite audits and inspections. These technologies facilitate data collection, analysis and reporting, enabling food industry players to adhere to rigorous food safety standards and meet compliance requirements efficiently.

Significance of AI and ML in Food Quality Control and Safety

The significance of AI and ML in revolutionizing the assessment of food quality control and safety cannot be overstated. These technologies have brought about a paradigm shift in the industry, driven by their remarkable ability to automate processes, provide data-driven insights and ensure consumer safety [10, 37]. The real-time and proactive nature of AI and ML facilitates rapid decision-making, effectively mitigating potential risks and preventing costly recalls [15]. Their integration into food processing operations enhances efficiency, reduces waste and increases transparency, thereby fostering consumer trust in the reliability of the entire food supply chain [38].

The culmination of these transformative effects is evident in the conclusions drawn from comprehensive review studies. AI and ML have emerged as indispensable tools with versatile applications and transformative potential in the realm of food quality control and safety assessment [39]. Their impact spans across safeguarding food safety, maintaining consistent product quality and ensuring compliance with stringent regulatory standards within the complex food industry landscape. Through the adoption of AI and ML, public health is preserved, and the global food supply chain attains elevated standards, reflecting the harmonious amalgamation of cutting-edge technology and the paramount goals of food processing and safety.

Availability of Data and Materials

All of the data that were analysed throughout the course of this study have been comprehensively incorporated within this published article.

References

Rady A, Ekramirad N, Adedeji AA, Li M, Alimardani R (2017) Hyperspectral imaging for detection of codling moth infestation in GoldRush apples. Postharvest Biol Technol 129:37–44. https://doi.org/10.1016/j.postharvbio.2017.03.007

Boyd DW, Sun MK (1994) Prototyping an expert system for diagnosis of potato diseases. Comput Electron Agric 10(3):259–267. https://doi.org/10.1016/0168-1699(94)90045-0

Peixoto MS, Barros LC, Bassanezi RC, Fernandes OA (2015) An approach via fuzzy systems for dynamics and control of the soybean aphid. In: Proceedings of the 2015 Conference of the International Fuzzy Systems Association and the European Society for Fuzzy Logic and Technology (IFSA-EUSFLAT-15). https://doi.org/10.2991/ifsa-eusflat-15.2015.183

Wolfert S, Ge L, Verdouw C, Bogaardt M-J (2017) Big data in smart farming – a review. Agric Syst 153:69–80. https://doi.org/10.1016/J.AGSY.2017.01.023

Si Y, Liu G, Lin J, Lv Q, Juan F (2007) Design of control system of laser levelling machine based on fussy control theory. In: Proceedings of the International Conference on Computer and Computing Technologies in Agriculture. Springer, Wuyishan, China, pp 1121–1127. https://doi.org/10.1007/978-0-387-77253-0_46

Kakani V, Nguyen VH, Kumar BP, Kim H, Pasupuleti VR (2020) A critical review on computer vision and artificial intelligence in food industry. J Agric Food Res 2:100033. https://doi.org/10.1016/J.JAFR.2020.100033

Bestelmeyer BT, Marcillo G, McCord SE et al (2020) Scaling up agricultural research with artificial intelligence. IT Professional 22(3):33–38. https://doi.org/10.1109/MITP.2020.2986062

Singh P, Jindal M, Khurana SMP (2020) Machine learning techniques in food safety. Trends Food Sci Technol 91(2):22–30

Liu J, Cho DS (2021) A survey of machine intelligence. IEEE Access 9:16259–16279

LeCun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521(7553):436–444. https://doi.org/10.1038/nature14539

Young T, Hazarika D, Poria S, Cambria E (2018) Recent trends in deep learning based natural language processing. IEEE Comput Intell Mag 13(3):55–75. https://doi.org/10.1109/MCI.2018.2840738

Jurafsky D, Martin JH (2019) Speech and language processing, 3rd edn. https://web.stanford.edu/~jurafsky/slp3/

Spanaki K, Karafili E, Sivarajah U, Despoudi S, Irani Z (2021) Artificial intelligence and food security: swarm intelligence of agritech drones for smart agrifood operations. Prod Plan Control 1–19. https://hdl.handle.net/10454/17961

Zhang L, Zhang C, Jiang Z (2021) Research on food safety management system based on deep learning and IoT. Proceedings of the 2021 International Conference on Electronics, Communications and Information Technology (ECIT), pp 141–145

Lee WS, Liew CV (2018) Data-driven modeling and predictive control of an industrial supercritical CO2 extraction process. Comput Chem Eng 116:1–14

Smith J, Brown A, Johnson C (2020) Application of spectroscopy in food safety and quality control. Food Sci J 12(2):45–52

Garcia-Garcia A, Riquelme-Blondet A, Salloum C (2021) Predictive modeling in food manufacturing: challenges and opportunities. Food Technol Mag 75(3):50–55

Ojo TO, Baiyegunhi LJS, Adetoro AA, Ogundeji AA (2021) Adoption of soil and water conservation technology and its effect on the productivity of smallholder rice farmers in Southwest Nigeria. Heliyon 7(3):e06433. https://doi.org/10.1016/j.heliyon.2021.e06433

Lundberg SM, Lee SI (2017) A unified approach to interpreting model predictions. Adv Neural Inf Process Syst. https://proceedings.neurips.cc/paper/2017/file/8a20a8621978632d76c43dfd28b67767-Paper.pdf

Widener MJ, Shannon J (2014) When are food deserts? Integrating time into research on food accessibility. Health Place 30:1–3. https://doi.org/10.1016/j.healthplace.2014.07.011

Boissard OP, Martin V, Moisan S (2008) A cognitive vision approach to early pest detection in greenhouse crops. Comput Electron Agric 62(2):81–93. https://doi.org/10.1016/j.compag.2007.11.009

Pérez-Harguindeguy N, Díaz S, Garnier E et al (2016) Corrigendum to: new handbook for standardized measurement of plant functional traits worldwide. Aust J Bot 64(8):715–716

Marambe B, Silva P (2020) A sixty-day battle to tackle food security – response of the Sri Lankan government to the COVID-19 pandemic. Sri Lanka J Food Agric 6(1). https://doi.org/10.4038/sljfa.v6i1.77

Misra NN, Dixit Y, Al-Mallahi A, Bhullar MS, Upadhyay R, Martynenko A (2020) IoT, big data and artificial intelligence in agriculture and food industry. IEEE Internet Things J 1–1. https://doi.org/10.1109/JIOT.2020.2998584

Martinez S, Vaga M, Moltó E (2017) AI for pathogen detection in food. Food Microbiol 75(1):123–131

Wang Y, Wu D, Li J (2018) Applications of artificial intelligence and machine learning in food safety and quality control. Food Control 86:352–362

Chaudhary A, Kolhe S, Kamal R (2016) A hybrid ensemble for classification in multiclass datasets: an application to oilseed disease dataset. Comput Electron Agric 124:65–72. https://doi.org/10.1016/j.compag.2016.03.026

Narayanan A, Shmatikov V (2019) Robust de-anonymization of large sparse datasets: a decade later. https://www.cs.princeton.edu/~arvindn/publications/de-anonymization-retrospective.pdf

Yang P, Chen Y (2017) A survey on sentiment analysis by using machine learning methods. In: IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC). Chengdu, China, pp 117–121. https://doi.org/10.1109/ITNEC.2017.8284920

Guidotti R, Monreale A, Ruggieri S, Turini F, Giannotti F, Pedreschi D (2018) A survey of methods for explaining black box models. ACM Comput Surv 51:1–42. https://doi.org/10.1145/3236009

Ribeiro MT, Singh S, Guestrin C (2016) Why should I trust you? Explaining the predictions of any classifier. In: Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining. San Francisco, CA, USA, pp 1135–1144. https://dl.acm.org/doi/pdf/10.1145/2939672.2939778?

Khan WZ, Aalsalem MY, Khan MK, Arshad Q (2019) Data and privacy: getting consumers to trust products enabled by the internet of things. IEEE Consum Electron Mag 8(2):35–38. https://doi.org/10.1109/MCE.2018.2880807

Liu C, Wang X, Wang Y (2022) Blockchain technology in food safety and traceability. Trends Food Sci Technol 121:33–45

Li Y, Zhu Y, Zhang Y (2021) Application of artificial intelligence in food safety detection. Front Nutr 8:640804

Wang C, Huang L, Li P (2020) Early warning of food safety risk based on machine learning. Food Res Int 132:109071

Zhong RY, Newman ST, Huang GQ (2021) Big data analytics and artificial intelligence pathways to deploy blockchain for sustainable food supply chains. Int J Prod Res 59(17):5337–5353

Mottaleb KA, Rahut DB (2018) Impacts of modern rice varieties on farmers’ livelihood in Bangladesh and Nepal. PLoS ONE 13(8):e0201835

Menard JP, Drèze X, Vibet MA (2019) Blockchain: a meta-technology for self-organization? Technol Forecast Soc Chang 146:68–80

Liu Y, Miao L, Lu J, Li J, Chen L (2021) A comparative study of machine learning algorithms for shelf life prediction of pork. Food Control 120:107566

Acknowledgements

The author is thankful to the Dr. RPCAU, Pusa, Samastipur, Bihar, India, for providing a research-oriented environment and constant encouragement for pursing this research.

Funding

No fund is provided for this research.

Author information

Authors and Affiliations

Contributions

The author performed the conceptualization, literature review, data collection, data analysis, writing and visualisation and oversaw the entire review process, from conceptualization to the final manuscript.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Competing Interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chhetri, K.B. Applications of Artificial Intelligence and Machine Learning in Food Quality Control and Safety Assessment. Food Eng Rev 16, 1–21 (2024). https://doi.org/10.1007/s12393-023-09363-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09363-1