Abstract

Development of the concept of electroporation opened new perspectives for promising applications in food technology. Treatment of foods with pulsed electric fields (PEFs) allows facilitation of different food transformation operations (extraction, expression, osmotic treatment, drying, and freezing) with minimal energy consumptions and better retention of flavor, color, and preservation of nutritional properties of foods. This work shortly reviews the effects of PEF on the biological cells and food products and gives the examples of PEF-assisted techniques. The PEF protocol, power consumption, and existing small- and large-scale electroporation systems are presented. Some examples of PEF-assisted processing of meat, fish, and fat frying are discussed. The main principles of PEF-assisted cooking and kitchen operations are also discussed. The variants of PEF-assisted non-thermal cooker and PEF/ohmic thermal cooker are presented. It is speculated that PEF allows more homogeneous treatment of foods as compared to the conventional methods of thermal cooking. The PEF-assisted cooking can be faster and more effective for nutrient retention and sensory qualities of foods. Moreover, the PEF treatment can be used for producing the types of the products of fresh/natural quality and new tastes. The recent examples of PEF-assisted processing of meat and fish, assistance of frying, and commercial-scale processing are also presented and discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A cooking is the art of food preparing for consumption with the use of heat [1]. The various methods of heating are used in the cooking: baking, roasting, frying, grilling, barbecuing, smoking, boiling, steaming, braising, and microwaving. The heating is rather expensive and always needs the high energy consumption (typically, more than 100 kJ/kg). The cooking is aimed toward the blanching, sterilization, moisture content manipulation, and preparation of foods with good taste and quality.

The applications of electrical current (static or alternative) in cooking have a rather long history. There exist the old reports on use of electricity for cooking and heating [2, 3]. The practical examples on use of alternating electric currents in the cooking of fruits, vegetables, and meats, and for killing of bacteria were demonstrated [4]. The electrically based technologies, like ohmic cooking [5, 6] or microwave cooking [7], have become rather popular lately.

In recent decades, the new ideas have been actively introduced in food science and modern kitchen operations [8]. A cross-disciplinary concept of “molecular gastronomy” has been developed at the interface between physical, biological, food, and chemical sciences [9,10,11,12,13,14]. The molecular gastronomy is considered as a science supporting innovative kitchen [15].

The fine regulation of food properties can be achieved using the treatment by pulsed electric fields (PEFs). Application of short electric pulses with high amplitude can affect the cell membrane permeability or even destroy cell membrane. This effect has been discovered more than 50 years ago [16] and called as an electroporation [17]. The food applications of PEF-assisted techniques have been extensively reviewed [18,19,20,21,22,23,24,25,26]. Commonly, the PEF techniques require moderate energy consumption, allow better retention of flavor and color, and preserve nutritional properties of foods. A possibility of large-scale industrial implementations has been also demonstrated [27].

This review discusses recent efforts and perspectives of PEF application for the cooking of foods. The basic effects of PEF on biological cells in food, the typical PEF instrumentations and protocols, recent examples of PEF-assisted processes with food materials, and existing commercial-scale PEF apparatus are briefly discussed.

Brief Consideration on the PEF Effects in Biological Materials

Recent experiments provided many evidences for disintegration of membrane in biological tissues with pulsed electric fields having the strength and duration of order of E = 100–1000 V/cm and t PEF = 10 μs–0.1 s, respectively. Commonly, this disintegration is selectively applied to the membranes without significant impact on the cell walls and other constituents of the tissues. The transmembrane potential on the surface of spherical cell can be estimated using the Schwan’s equation [28],

where R is a radius of the cell, θ is the angle between the electric field direction and radius vector connected to the cell center with the actual point on the cell surface, and f e (≤1) is the dimensionless electroporation factor (it is a function reflecting the electrical and geometrical properties of the cell). So, the transmembrane potential u m is proportional to the values of E and R, and it is maximal on the cell poles.

A structure of membrane is affected when transmembrane voltage exceeds some critical value \( {u}_m^c \) (typically, \( {u}_m^c \) ≈ 1 V) [17, 29]. The critical value of \( {u}_m^c \) can be affected by a temperature, additive of surfactant, pH of medium, and other factors. For example, for cells of Valonia utricalis, the estimated values of \( {u}_m^c \) were ≈1.15 V at T = 3.2 °C and ≈0.7 V at T = 28.8 °C [30].

The electroporation has been experimentally detected for different biological systems (see, e.g., [29,30,31]), and various approaches, accounting for pore formation (electroporation), electric field-induced instabilities (mechanical, hydrodynamic, viscous-elastic, thermal, and osmotic), chemical imbalances, and overheating of the membrane surface, have been proposed for the description of these phenomena [17, 32,33,34,35].

The disintegration index Z (0–1) defined as [36, 37]

is typically used for estimation of electroporation efficiency. Here, σ is the electrical conductivity measured at low frequency (≈1–10 kHz) and indexes “i” and “d” refer to the conductivities of intact and completely electroporated tissue, respectively. Application of Eq. 2 gives Z = 0 for an intact tissue and Z c = 1 for a maximally damaged material.

The electroporation efficiency increases with increasing of the electric field strength E and the total time of PEF treatment t PEF (t PEF = t i n is the product of a pulse duration, t i , and a total number of pulses, n). Commonly, it can also depend on the other details of PEF protocol, e.g., on the pulse shape; pulse duration, t i ; and distance between pulses, Δt [27].

The different pulses with exponential, nearly square wave, and sinusoidal shapes were tested for electroporation of the biological systems. Application of the pulses with certain shape may have some advantages and disadvantages [19]. The square-wave generators (monopolar or bipolar) are more expensive and more complex than the other types of generators. However, the square-wave generators have better energy efficiency than the exponential or sinusoidal ones, and they demonstrated a higher disintegrating efficiency for inactivation of the microbial cells [38]. Commonly, the profiles of the electric strength E(t) and current I(t) are rectangular only approximately [39]. Moreover, these profiles can change in the course of the PEF treatment owing to the increase in the material electrical conductivity (effects of an electroporation and the changes in temperature [40, 41]). In general, the bipolar pulses can be more advantageous than the monopolar ones. The monopolar pulses can concentrate the ions near the electrodes, and this polarization acts against the applied voltage. Moreover, the bipolar pulses can cause an additional stress on the membrane structure and increase damage efficiency. It was also reported that bipolar pulses offer minimum energy consumption with reduced dissolution of the electrodes and decreased electrolysis [42, 43].

Existing experiments have clearly demonstrated the influence of pulse duration t i (10–1000 μs) on the efficiency of PEF treatment of grapes, apples, and potatoes [20, 44, 45]. Longer pulses were more effective, particularly at room temperature and moderate electric fields (E = 100–300 V/cm).

The distance between pulses Δt (or pulse repetition rate f = 1/Δt) can also affect the PEF electroporation efficiency [46,47,48,49]. For example, the PEF experiments with Δt = 5 s and Δt = 0.01 s for the apple tissue have been performed [46]. The protocol with longer Δt between pauses (5 s) at fixed values of E and t PEF displayed more accelerated kinetics of disintegration of the apple tissue. The obtained results were explained accounting for the moisture diffusion processes inside the cellular structure. A cell permeabilization of an onion tissue was significantly higher above the critical distance between pulses, Δt = 1 s [47]. It was suggested that at low frequencies, convection and cytoplasmic streaming play a significant role in distributing more conductive fluid throughout the tissue [48]. It has been also reported that the inactivation of Escherichia coli may be affected by the interpulse distance Δt [49].

The power consumption, required for effective electroporation of cells in the fruits and vegetables, typically lies in the interval of 1–16 kJ/kg, and it is noticeably smaller as compared with other methods of tissue disintegration like mechanical (w = 20–40 kJ/kg), enzymatic (w = 60–100 kJ/kg), and heating or freezing/thawing (w > 100 kJ/kg) [50]. Note that there exists some optimum value of electric field strength E ≈ E 0, which corresponds to minimum power consumption [37]. For vegetable and fruit tissues, the typical values of E 0 lie in the interval between 200 and 700 V/cm. The increase of E above E o can result in a progressive increase of the energy consumption without additional electroporation effect. In general case, the power consumption can be rather complex function of the size, shape of the cells, electrical properties of materials, and the PEF treatment protocol [51]. During the intensive PEF treatment, the ohmic heating of material may be also significant [39]. Note that the superposition of the PEF treatment and heating can give synergetic effects for enhancement of electroporation [52].

Existing Electroporation Systems

High-voltage pulse generator is the most important part of an electric circuit that forms the electric pulses in the treatment chamber. Electric pulses produced by the pulse generator pass to the processed material (liquids or solid-liquid mixtures) through the electrodes. The treatment chamber should be homogenously filled by the treated material to assure a good contact with electrodes. Maximally homogeneous electric field inside material is desirable, and air bubbles should be reduced to minimum [53]. Generation of PEF needs fast discharge of electric energy within a short period of time. Preparing and forming the pulse is performed in a special part of the pulse generator, the pulse-forming network. This part consists of one or more power sources, capacitors of high capacity up to the highest values of voltage (in range of tens kV), and quick switches of different types (ignitrons, thyratrons, tetrodes, spark gaps, semiconductor circuits, etc.), coils of inductance (tens mH), and resistors [54]. The pulse shape is controlled by the electric parameters of the circuit’s components. The different techniques for generation of the electric field pulses have been proposed [54].

The small-scale systems specifically designed to produce the precise voltage amplitudes and pulse lengths have been developed for study of electroporation of both eukaryotic and prokaryotic cells, bacteria, fungi, and yeast on a laboratory scale [55,56,57]. The typical electroporation cuvettes have rather small volumes, ≈100–800 μl.

In industrial applications, the different commercial-scale devices have been developed for PEF processing of fluid and solid foods [22]. These devices have been also used in many laboratories for testing of the electroporation effects [40, 41, 45, 53, 58].

The CoolPure™ process for PEF treatment of the pumpable products (milk, liquid eggs, emulsions, and fruit juices) was proposed in 1996 [59]. The electric field pulses with strengths of 20–80 kV/cm and duration of 1–10 μs were typically used. The treatment parameters can be controlled to minimize the temperature increase, and the system included heat exchangers and temperature control to cool a product after treatment. A 200-l/h continuous flow CoolPure™ Laboratory Pilot System was operated at PurePulse Technologies in San Diego, CA, a subsidiary of Maxwell Laboratories. The benefits of CoolPure™ low-temperature pasteurization included better retention of flavor, color, and nutritional properties; improved protein functionalities; eliminating damage to emulsions; increase in shelf life; reduced pathogen levels; and better control of fermentations.

The company Diversified Technologies (DTI), Inc., Bedford, MA, produces high-voltage and high-power pulse generators [60]. The first commercial-scale PEF system with co-field flow chamber was constructed in Ohio State University DTI [61]. The different commercial systems operating at 30–35 kV with co-field flow treatment chambers capable of up to 200-l/h throughput were described [62, 63]. The PEF treatment permitted extraction of the algal oil (28–44%) into a water solution without the use of other solvents or preliminary drying. Moreover, PEF-assisted processing can reduce the overall biomass drying cost by nearly 50% [62].

The company German Institute of Food Technologies (DIL)/ELEA (Quakenbrück, Germany) manufactures a large-scale Elea PEF machineries and generators suitable for treatment of a wide range of food types (e.g., microalgae, nutrient media, enzyme solutions, foods, dairy products, protein concentrates, seafood and fish marinades, sauces, and dressings) [64].

The company Steri-Beam Systems GmbH (Kehl, German) fabricates a small-scale generator suitable for disinfection of fluid products (juices, milk, etc.) as well as for sanitation of jellies and jams and extraction of nutrients/colors from plant cells [65]. The generator produces bipolar and monopolar pulses with operational pulse voltage u = 2–20 kV, pulse duration t i = 2.5–20 μs, maximum electric current I m = 150 A, pulse repetition rate f = 1–100 Hz, and maximum pulse power W = 2 kW.

The company KEA–TEC GmbH (Waghaeusel-Kirrlach, Germany) fabricates industrial-scale electroporation equipment [66]. KEA–TEC GmbH produces a mobile experimental plant (trailer) with dimensions 5.5 × 2 × 2.4 m and electrical power 21 kW. BLIZZAR technology for the electroporation of whole or sliced fruiting bodies with a capacity of up to 20,000 kg/h was developed by KEA–TEC GmbH [67]. Successful application of this technology was demonstrated for the production of French fries. The following advantages of BLIZZAR were marked out: it replaces thermal blanching, prevents damage of cell, and gelatinization of starch granules; the dissoluble sugars can be washed out; it reduces wear and tear on the cutting device and extends the lifetime of the cutting blade; it noticeably reduces consumption of energy and minimizes product loss; it serves as an additional washing stage; and it positively influences crispness in the fried product.

The company CoolWave Processing (Wageningen, Netherlands) introduces different PurePulse systems for PEF-assisted processing of fluid foods (fresh juices, sauces, or milk). PurePulse is a non-thermal preservation technology [68]. The PurePulse systems allow extending the shelf life of fresh juices (just “freshly squeezed”) with preserving their entire flavor, colors, aroma, vitamins, and other goodness. PurePulse is available for large-scale (600–2.000 l/h) and small-scale (350 l/h) production. It gives the opportunity for the different scales of investment.

The company Arc Aroma Pure AB (Lund, Sweden) proposed closed environmental PEF treatment (CEPT) technology that can be applied for cold pasteurization, juice extraction, extraction of olive oil, ballast water treatment, and purification of water [69]. CEPT® pretreatment unit (10,000 l/h) for biogas production is available for purchase. This pretreatment improves the methane production by 15–50%. OptiFreeze AB approach based on the application of vacuum technology along with PEF treatment was used to maintain the food flavor, texture, and quality throughout the freezing and thawing processes.

The company Scandinova Systems AB (Uppsala, Sweden) fabricates different PEF generators (with pulse voltage of 16–600 kV, pulse duration up to 3 ms, and pulse current 0.1–10 kA) for applications within the food industry [70]. They are suitable for PEF treatment of different foods (e.g., potatoes, olive oil, and fruit juices).

The company EnergyPulse Systems, Lda (Lisboa–Carnide, Portugal) fabricates the high-performance pulse generators, based on semiconductor transformerless Marx generator topologies [71]. For example, EPULSUS®-PM1–10 and EPULSUS®-PM1–25 systems deliver up 10 kV/240 A and 25 kV/250 A square-wave bipolar pulses, with 500-ns rise time, flexible frequency, and variation of pulse width, respectively. The PEF equipment can be used for bacterial inactivation; juice, olive, and grape processing; enzyme inactivation; and assistance of drying of foods.

The company Basis EP (Saint Quentin, France) fabricates generators of PEF (with pulse voltage 5–18 kV, pulse current up to 1600 A, and power up to 250 kW) for different applications in sugar and other industries (sugar beet cossettes, apple mash, juices…) [72]. This society fabricates also high-voltage electrical discharge (HVED) generators (50–100 kV, 100 kA, 10 Hz) for the treatment of different types of biomass suspensions (microalgae, yeast, seeds, etc.) using electric arc discharges.

The company Pulsemaster (Bladel, the Netherlands) produces PEF systems for the food and beverage industries [73]. The typical average power range of PEF systems is up to 80 kW; the systems for cell disintegration allow processing capacities of 1 to 50 t/h. The capacity of the systems for microbial inactivation of liquids varies from 50 up to 5000 l per hour per system.

The first commercial production of juices pasteurized by PEF was started in 2005 by Genesis Juice Corp. (Portland, USA) [74]. The label on the bottle states that the product is “processed by pulsed electric field.” The large-scale continuous commercial PEF treatment system (1500 l/h juice, field strength of 20 kV/cm, energy input of ≈120 kJ/kg, initial and final temperatures of 40 °C and 60 °C, respectively) for preservation of fluid foods was also started in 2009 in DIL [22].

Finally, Table 1 summarizes the different producers of PEF generators along with their web addresses.

PEF Effects on Properties of Foods and Examples of PEF-Assisted Processes

Traditional cooking by heat treatment can affect basic properties of foods at relatively high temperatures (60–70 °C). For example, the fundamental changes in texture and electrical conductivity of potatoes heated above ≈60 °C have been observed [75]. The electroporation of cell membranes can lead to the fundamental changes in basic properties of foods for PEF treatment even at room temperatures. These changes are mainly due to the loss of cell turgor and much easier transport of water and cellular components through the tissue [20]. Commonly, the PEF treatment noticeably affects the microstructure of tissue, size of the cells, electrical conductivity, diffusion coefficient, texture (firmness and relaxation characteristics), porosity, and solid–liquid expression characteristics of food tissues [27]. The PEF treatment at room temperature accompanied with weakening of texture and increasing in electrical conductivity of potatoes, apples, carrots, and other tissues [39, 76, 77]. For example, for PEF treatment (at E = 600 V/cm and t i = 10 ms) at room temperature, the noticeable changes in texture (50% decrease of elastic module tested by dynamic mechanical analysis (DMA)) and electrical parameters (35% decrease of the real component of electric impedance tested by dielectric thermal analysis (DETA)) were observed for carrot tissue [76]. Supplementary traditional heating at temperatures above 70 °C resulted in further thermal destruction. Both the disintegration procedures can be termed as cooking with the PEF as the first step (at T < 70 °C) and traditional heating as the second step (at T > 70 °C).

The PEF-induced changes in properties of foods allowed to assist, improve, and modify the different existing operations in food industry, such as

-

“Cold” and selective extraction (sucrose, betalain, inulin, phenolics, carotenoids, vitamins, proteins, and other useful components [78]),

-

Drying (convective, oven [27]),

-

Vacuum freeze-drying [85],

-

Partial dehydration before freezing (dehydrofreezing) [78, 86],

-

Osmotic treatment [86] and osmotic treatment by cryoprotectants [87,88,89].

PEF treatments have been reported to cause less modification in the texture, colors, content of vitamins, phenolic compounds, colorants, fatty and amino acids, and vitamins when compared to conventional heating processing treatments [27]. PEF treatment can also prevent the biochemical changes in materials (such as Maillard reactions, protein denaturation, and thermal degradation of compounds) [90] and positively affects the bioavailability and bioaccessibility of valuable food compounds [27]. The existing PEF-assisted food operations have been mainly developed for industrial-scale purposes in order to produce high and “fresh” quality final products and reduce energy consumption [91]. The obtained laboratory experience may be useful for future development of PEF-assisted cooking and kitchen operations.

Perspective of PEF-Assisted Cooking and Kitchen Operations

So far, very few studies have been performed on PEF-assisted cooking and kitchen operations and the first commercial E-cooker from the company IXL BV (Schalkwijk, Netherlands) are already on the market [92, 93]. Here, we have collected some examples of PEF-assisted processing of meat, fish, and fat frying. The main principles of PEF-assisted, non-thermal and thermal cooking and kitchen operations are also formulated.

Processing of Meat and Fish

Meat and fish products have complex structure with different parts such as fibrous muscles, fat globules, and blood cells. The PEF has a potential to cause physical disruption of animal tissues. The PEF-induced changes in the texture and sensorial properties of a product can be positive (e.g., enhanced tenderization, improved functional properties) and negative (e.g., increased lipid oxidation, decreased nutritional quality and safety [94]).

The first PEF studies on meats and/or animal muscles had been reported more than 15 years ago [95]. In this study, the effects of PEF and combination of PEF and high pressure (200–300 MPa) on the microstructure of lumpfish roes, salmon, and chicken were investigated [95]. The lumpfish roes can tolerate relatively strong electric pulses (up to 18.6 kV/cm) without visible damage. However, the noticeable effects of PEF on the salmon and chicken microstructure were visually observed even at low field strength (less than 2 kV/cm and 20–40 pulses with duration of 2 μs). For the chicken meat, the PEF treatment induced a reduction in size of the cells but without visible gap between the cells. In contrast to chicken muscle, the PEF treatment produced also gaping in salmon samples [95]. So, the greater effect of PEF for salmon than for chicken samples was observed. Combination of PEF treatment (at 0.35 kV/cm and 60 pulses) and high pressure (at 200 MPa) on chicken meat and salmon samples was also studied. It was shown that combination of both treatments had more detrimental effect on the microstructure than PEF treatment alone. Moreover, the effects were dependent on order of treatment. For example, for the salmon sample, application of PEF treatment first (PEF + pressure) decreased the cell size more than if the reverse order (pressure + PEF) was applied.

The PEF treatment has been applied in studies of cell permeation, meat tenderization, and product safety [50, 96]. Structure modifications in muscle foods after PEF treatment have a particular interest. The PEF technology can accelerate the release of Ca ions as well as stimulate the glycolysis process. The improved water binding due to the interaction between protein/salt/phosphate during cooked ham processing and a more porous tissue structure in cod was observed after the PEF application [50].

Advantage of PEF for the meat treatment has been recently demonstrated [97]. No effect of PEF treatment (1.1–2.8 kV/cm, 5–200 Hz, 10–200 kJ/kg) on the tenderness of beef was observed. The PEF treatment can induce a moderate temperature rises (∆T ≈ 22 °C), and the slight changes in the cell membrane can lead to more water loss. The synergistic thermo-electric effect could affect the physical characteristics of the meat. A positive role of PEF treatment on pork salting has been also reported [98]. A significant weight loss as a result of PEF treatment was observed. Beef muscle has been used to evaluate the effect of PEF treatments (1.4 kV/cm, 10 Hz, 20 μs, 300 and 600 pulses) on different meat quality attributes (weight loss, color, cook loss, and texture) [99]. Batch PEF treatments applied at different times postmortem (2, 10, 18, and 26 days) showed a tendency toward reducing toughness of beef samples during the beef aging. However, the application of PEF did not affect the tenderization process.

The effects of various PEF treatments on the quality attributes of turkey breast meat have been studied [94]. Samples were treated in a batch PEF chamber (≤3 kV/cm, 5 Hz, 20 μs, 300 pulses). Under conditions examined, PEF treatments did not induce differences in weight loss, cook loss, lipid oxidation, texture, and color (raw and cooked) either on fresh or frozen samples. The authors noted possible impact of more severe PEF processing conditions (such as higher electric field strengths) on muscle tenderization.

The role of PEF in aging of different beef muscles have been studied [100,101,102,103]. Most of experiments were done with low PEF (below 1 kV/cm), and loss of water and decrease of shear strength (usually about 20%) was observed. Tenderization was not regularly observed if higher PEF was used (stochastic application of 5 and 10 kV at frequencies 20, 50, and 90 Hz on specimens with dimensions 5 × 8 × 13 cm [103]). The effects of PEF and aging (3–21 days) on the shear force, protein profile, and postmortem proteolysis were also investigated. The PEF treatment decreased the shear force of muscles by up to 19%, and in some cases, the dependence on PEF frequency was observed. The PEF-treated beef loins showed increased proteolysis. Even if all effects of PEF on meat processing are not still known, the potential role of PEF for the improving of meat quality was shown.

Effects of freezing as a pretreatment prior to PEF treatment (1.4 kV/cm, 20 μs, 50 Hz, 250 kJ/kg) on the quality traits of beef semitendinosus muscle have been studied [104, 105]. Note that this muscle is rather resistant to thermal, mechanical, chemical, and enzymatic interventions. The applied PEF conditions and sample pretreatment (fresh or frozen-thawed) determined the effect of PEF on meat tenderization. The PEF caused significant microstructural changes of meat tissue compared to freezing and increased purge loss. However, the cooking loss was not observed, and free fatty acid profile of beef samples was unaffected by PEF treatment.

Finally, the different effects of PEF application on the texture and sensorial properties of meat and fish products have been reported. The positive effects of PEF on product structure modifications, tenderization, safety, and improved water binding can be particularly interesting for cooking operation. However, the effects of PEF are rather controversial in dependence on the type of products and applied PEF protocols. Each specific product requires thorough adaptation of PEF-assisted cooking operation. That is why, the cooking ability of PEF-assisted operations in application to animal tissues are still in the stage of basic research and/or discussions.

Assistance for Frying

In several works, the application of PEF for food frying have been also discussed [90, 106, 107]. The process of fat frying includes many complex heat and mass transfer mechanisms. The water evaporation on the surface of product results in formation of a water vapor bubble barrier against the oil [108]. The electroporation makes the diffusion of water inside the tissue easier. It is expected that more intensive evaporation of water and formation of the thicker water vapor bubble barrier on the surface of electroporated tissue can reduce dehydration and fat uptake.

The PEF treatment of food raw materials is an effective tool to assist in removing of sugars and amino acids [90]. These substances participate in the formation of harmful Maillard reaction compounds (e.g., acrylamid) spontaneously formed during the food cooking and frying. In processing of French fries, PEF permitted to accelerate sugar release during blanching and to increase enzymes (glucose oxidase or asparaginase) infusion for enzymatic conversion of the substrate [90].

Potential of PEF treatment for the production of low-fat French fries has been demonstrated [106]. Potato slices (1.5–2 mm in thickness × ∼5 cm in length) were treated by electric field strength E = 1.5–5 kV/cm with 100–400-μs exponential pulses. PEF application leads to a distinct reduction of fat content after deep fat frying. The PEF treatment was applied to facilitate blanching of potatoes intended for deep-fat frying [107]. The potato cubes were submitted to 18.9-kJ/kg PEF treatments at E = 0.75 and 2.50 kV/cm. After that, to simulate industrial production of par-fried potatoes, the samples were par-fried, frozen, and stored at −20 °C for 7 days. Finally, the potato cubes were finish-fried and analyzed for texture, color, and oil content. The PEF-treated potato cubes showed a lower oil uptake upon frying than blanched and water-dipped controls. In general, the application of PEF allows excluding the chemical (sulfites) addition, reducing the process time, and decreasing the water and energy consumption. Moreover, impact of PEF treatment on the tissue softening can be positive for improving cutting and/or slicing operations and extending knife duration [107].

Cooking and Kitchen Operations Assisted by PEF

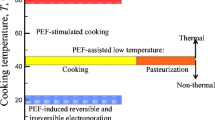

In cooking operations, the PEF treatment can cause the electroporation of cells and accelerate the diffusion processes inside the treated food, and at the same time, the PEF treatment can cause the heating of the food. Depending on the PEF protocols, the different PEF-assisted, non-thermal and thermal cooking and kitchen operations can be marked out (Fig. 1).

The electroporation is more effective during application of short pulses of high intensity. The low-temperature (non-thermal) electroporation technologies are usually limited by the temperature about 42 °C. Below this limit temperature, the rate of protein denaturation is low [109] and the living cells remain rather stable. The area of the non-thermal treatment contains several different PEF-assisted processes: low-temperature kitchen operations and pasteurization. The cold extraction, expression, and drying can be also performed with assistance of electroporation [27]. The PEF-induced electroporation can be used as a pretreatment technique to different cooking and kitchen operations.

At moderate temperatures and relatively high electric fields (E > 10 kV/cm), the PEF-assisted microbial killing, preservation, and pasteurization technologies may be effectively applied to the liquid food products [26, 110]. The treatment of foods at temperatures higher than ≈42 °C by combination of PEF and ohmic heating cannot be classified as a pure non-thermal process. This combined treatment can lead to changes in texture characteristics, composition of proteins, and certain degradation of biologically active components [27]. The foods cooked with PEF at temperatures above 80 °C can have nearly the same quality as ones cooked without PEF at the same temperature [111]. However, the PEF-induced electroporation results in increase of electrical conductivity of a product and acceleration of heat and mass transfer processes. It can enhance the efficiency of ohmic heating treatment and related suppression of pathogens. So, the better thermal efficiency of PEF-assisted cooking in comparison with standard methods of cooking is expected.

The First Commercial E-Cooker

The company IXL BV (Schalkwijk, Netherlands) has developed the first commercial Nutri-Pulse® E-cooker [92, 93]. The food product is subjected to the low field strength of 10–180 V/cm; with pulse duration of 1–20,000 μs; number of pulses of 1–2,000,000; and total cooking of 0.5–1000 s. The food product, and, if present, the surrounding liquid, has an electric conductivity of 0.01–10 S/m. The producer states that E-cooker can be used for fast preparation of food products like fish, meat, and vegetables. In E-cooker, electric field strength (10–180 V/cm) is rather low [93]. This PEF treatment may be considered as moderate. However, electroporation can be effectively developed even at relatively low electric field strength during the ohmic heating of foods [112]. So, it can be speculated that the E-cooker could partly operate as a PEF-stimulated cooker at low temperatures and PEF thermally stimulated electroporation upon heating above 40–50 °C. Such cooking synergistically combines PEF and thermal treatments along with homogeneous heating. It allows better conservation of the original nutritive value and reduction of energy used for cooking. Application of E-cooker allows rapid cooking (just a few minutes) and opens up opportunities for the preparation of fresh foods with desirable changes of taste and smell and development of new dishes [111, 113].

Evaluation of Safety, Regulatory Aspects, and Economics

There is a potential risk of toxicological changes in the PEF-treated products because of direct contact between the electrodes and products. However, for different tested PEF-assisted processes, the potential of generating undesirable changes in foods was estimated as insignificant. For example, US Food and Drug Administration (FDA) had issued a letter of no objection for the use of CoolPure™ for the treatment of foods [59]. The commercial PEF installation for fruit juice preservation by Genesis Juice Corp in the Portland was also approved by the FDA in 2006 [74]. The 5-log reduction of the total bacteria count in orange juice was obtained using large-scale continuous commercial PEF treatment system in DIL [22] that is a key requirement for US FDA approval. Regulatory aspects of PEF-induced changes for mild pasteurization of orange juice were also evaluated with regard to the European Novel Food Legislation [114, 115]. The process-induced changes were stated as insignificant (P ≤ 0.05). Nowadays, the PEF-treated fruit juices are present on the markets in Germany, the Netherlands, and the UK [61, 110]. It is important that PEF apparatus can provide the highest standard of food hygiene and good condition to prevent contamination of food. A conservative estimate of CoolPure™ treatment costs, including equipment amortization, electricity, and maintenance, is less than 0.004 USD/l [59]. More recent estimation have shown that juice pasteurization requires the total processing costs, including investment and operation in a range of 0.02 to 0.03 USD/l of product [50]. For cell disintegration of potatoes, Pulsemaster has estimated total costs as 0.1 Eurocent per kg [73].

Conclusions and Future Trends

In general, the PEF-assisted cooking seems to be very promising for future applications in kitchen operation. It can be faster, effective for sensorial quality retention, and more homogeneous compared to the conventional methods of cooking. Synergetic combination of electroporation effects and the PEF-induced ohmic heating may be also promising in prevention of pathogen growth. Commonly, the PEF-induced electroporation results in increase of electrical conductivity of a product and acceleration of heat and mass transfer processes. It can enhance the efficiency of ohmic heating treatment and related suppression of pathogens.

The meat, fish, poultry, and different fruits and vegetables can be successfully cooked using the PEF. Our analysis shows that two types of PEF-assisted cookers can be developed for standard kitchen operation: non-thermal PEF-assisted cooker (NTPEFC) and thermal PEF/ohmic heating-assisted cooker (TPEFC) (Fig. 2).

The NTPEFC device assumes a presence of intensive electroporation and ohmic heating without noticeable increase of temperature (up to 40–50 °C). The field intensity may be rather high (up to 1–5 kV/cm) with small time of PEF treatment (up to 0.1 s) and moderate overall treatment time (up to 1–2 min). The NTPEFC device should be able to compress/fix pieces of the product between electrodes and prepare them using PEF application. Moreover, this device should be able to process different fruits and vegetables before eating and/or juicing, animal and plant products before drying, and meat or fish slices before further cooking or storing. This technology is non-thermal and allows preserving the fresh quality of the products.

The TPEFC device assumes presence of simultaneous stimulation of electroporation and ohmic heating at more elevated temperatures. This device can work at low voltages with field intensities similar to those of Nutri-Pulse® E-cooker (E = 10–180 V/cm), and the process requires longer time of PEF treatment (several minutes). The efficiency of electroporation for this device strongly depends on the values of E and temperature T. At small values of E (<50 V/cm) and T (<50 °C), the TPEFC device cannot work in the electroporation mode. However, simultaneous (and synergetic) ohmic heating, electroporation, and rapid thermal plasmolysis can be useful for replacement of big amount of processes that are made in the traditional kitchen by the standard gas and electric cookers. This technology is not truly non-thermal. However, it allows fast and gentle cooking at moderate temperatures below 100 °C.

It is also interesting to note that the both NTPEFC and TPEFC devices can be used for the preparing of foods having fresh/natural quality and new tastes. However, more investigations are needed to select the proper operation conditions for different products and cooking techniques.

References

Richardson K (2014) Basic cookery for foundation learning. Hodder Education, Carmelite House, London, UK

Crompton RE (1894) 18th meeting: the use of electricity for cooking and heating. RSA J 43:511

Fleming JA (1910) The applications of electric heating. RSA J 59:885

Sater LE (1935) Passing an alternating electric current through food and fruit juices. 1. Design and use of suitable equipment. 2. Cooking food and sterilizing fruit juices. Research bulletin, information systems division. National Agricultural Library N 181:275–312

Sastry S (2008) Ohmic heating and moderate electric field processing. Food Sci Technol Int 14:419–422

Yildiz-Turp G, Sengun IY, Kendirci P, Icier F (2013) Effect of ohmic treatment on quality characteristic of meat: a review. Meat Sci 93:441–448

Vollmer M (2004) Physics of the microwave oven. Phys Educ 39:74–81

Kurti N, This-Benckhard H (1994) Chemistry and physics in the kitchen. Sci Am 270:44–51

This H (2011) Molecular gastronomy in France. J Culinary Sci Technol 9:140–149

Liberman V (2014) Molecular gastronomy. In: Thompson PB, Kaplan DM (eds) Encyclopedia of food and agricultural ethics. Springer, Dordrecht, pp 1382–1387

Der Linden E, McClements DJ, Ubbink J (2008) Molecular gastronomy: a food fad or an interface for science-based cooking? Food Biophys 3:246–254

Barham P, Skibsted LH, Bredie WLP et al (2010) Molecular gastronomy: a new emerging scientific discipline. Chem Rev 110:2313–2365

Barham P (2013) Physics in the kitchen. Flavour 2:1–4

Vilgis TA (2015) Soft matter food physics—the physics of food and cooking. Rep Prog Phys 78:124602

Vega C, Ubbink J (2008) Molecular gastronomy: a food fad or science supporting innovative cuisine? Trends Food Sci Technol 19:372–382

Stämpfli R (1958) Reversible electrical breakdown of the excitable membrane of a Ranvier node. Annals of Academia Brasileira de Ciencias 30:57–63

Weaver JC, Chizmadzhev YA (1996) Theory of electroporation: a review. Bioelectrochem Bioenerg 41:135–160

Knorr D, Geulen M, Grahl T, Sitzmann W (1994) Food application of high electric field pulses. Trends Food Sci Technol 5:71–75. doi:10.1016/0924-2244(94)90240-2

Vorobiev EI, Lebovka NI Electrotechnologies for extraction from food plants and biomaterials. Springer, New York

Vorobiev E, Lebovka N (2010) Enhanced extraction from solid foods and biosuspensions by pulsed electrical energy. Food Eng Rev 2:95–108

Toepfl S, Heinz V, Knorr D (2005) Effect of high-intensity electric field pulses on solid foods. In: Sun D-W (ed) Overview of pulsed electric field processing for food. Academic Press, London, pp 69–97

Toepfl S (2012) Pulsed electric field food processing: industrial equipment design and commercial applications. Stewart Postharvest Rev 8:1–7. doi:10.2212/spr.2012.2.4

Toepfl S, Siemer C, Saldana-Navarro G, Heinz V (2014) Overview of pulsed electric fields processing for food. In: Sun D-W (ed) Emerging Technologies for Food Processing. Academic Press, London, pp 93–114

Mahnič-Kalamiza S, Vorobiev E, Miklavčič D (2014) Electroporation in food processing and biorefinery. J Membr Biol 247:1279–1304

Kotnik T, Frey W, Sack M et al (2015) Electroporation-based applications in biotechnology. Trends Biotechnol 33:480–488. doi:10.1016/j.tibtech.2015.06.002

Barbosa-Cánovas GV, Sepúlveda D (2005) Present status and the future of PEF technology. In: Barbosa-Cánovas GV, Tapia MS, Cano MP (eds) Novel food processing technologies. CRC Press, Boca Raton, pp 1–44

Barba FJ, Parniakov O, Pereira SA et al (2015) Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res Int 77:773–798

Schwan HP (1957) Advances in biological and medical physics. In: Tobias A (ed) Lawrence JH. Academic Press, New York, pp 147–209

Tsong TY (1991) Electroporation of cell membranes. Biophys J 60:297–306. doi:10.1016/S0006-3495(91)82054-9

Coster HGL, Zimmermann U (1975) The mechanism of electrical breakdown in the membranes of Valonia utricularis. J Membr Biol 22:73–90. doi:10.1007/BF01868164

Fincan M, Dejmek P (2002) In situ visualization of the effect of a pulsed electric field on plant tissue. J Food Eng 55:223–230

Ho SY, Mittal GS (1996) Electroporation of cell membranes: a review. Crit Rev Biotechnol 16:349–362

Chen C, Smye SW, Robinson MP, Evans JA (2006) Membrane electroporation theories: a review. Med Biol Eng Comput 44:5–14

Dimitrov DS, Sowers AE (1990) Membrane electroporaton—fast molecular exchange by electroosmosis. Biochimica et Biophysica Acta (BBA)-Biomembranes 1022:381–392

Coster HGL (2003) The physics of cell membranes. J Biol Phys 29:363–399

Lebovka NI, Bazhal MI, Vorobiev E (2002) Estimation of characteristic damage time of food materials in pulsed-electric fields. J Food Eng 54:337–346

Bazhal M, Lebovka N, Vorobiev E (2003) Optimisation of pulsed electric field strength for electroplasmolysis of vegetable tissues. Biosyst Eng 86(3):339–345

Zhang Q, Monsalve-González A, Qin B-L et al (1994) Inactivation of Saccharomyces cerevisiae in apple juice by square-wave and exponential-decay pulsed electric fields. J Food Process Eng 17:469–478. doi:10.1111/j.1745-4530.1994.tb00350.x

Blahovec J, Kouřím P, Kindl M (2015) Low-temperature carrot cooking supported by pulsed electric field—DMA and DETA thermal analysis. Food Bioprocess Technol 8:2027–2035. doi:10.1007/s11947-015-1554-4

Campbell D, Harper J, Natham V, et al (2008) A compact high voltage nanosecond pulse generator. In: Proceedings of ESA (Electrostatics Society of America) Annual Meeting on Electrostatics, Paper H3, 12 pp. pp 1–12

Flisar K, Meglic SH, Morelj J et al (2014) Testing a prototype pulse generator for a continuous flow system and its use for E. coli inactivation and microalgae lipid extraction. Bioelectrochemistry 100:44–51. doi:10.1016/j.bioelechem.2014.03.008

Wouters PC, Smelt JPPM (1997) Inactivation of microorganisms with pulsed electric fields: potential for food preservation. Food Biotechnol 11:193–229. doi:10.1080/08905439709549933

Qin B-L, Zhang Q, Barbosa-Cánovas GV et al (1994) Inactivation of microorganisms by pulsed electric fields of different voltage waveforms. IEEE Trans Dielectr Electr Insul 1:1047–1057. doi:10.1109/94.368658

Ben Ammar J (2011) Etude de l’effet des champs electriques pulses sur la congelation des produits vegetaux, PhD Thesis, Compiegne: Universite de Technologie de Compiegne, France. PhD Thesis, Compiegne: Universite de Technologie de Compiegne, France

De Vito F, Ferrari G, Lebovka NI, Shynkaryk NV, Vorobiev E (2008) Pulse duration and efficiency of soft cellular tissue disintegration by pulsed electric fields. Food Bioprocess Technol 1:307–313

Lebovka NI, Bazhal MI, Vorobiev E (2001) Pulsed electric field breakage of cellular tissues: visualisation of percolative properties. Innovative Food Sci Emerg Technol 2:113–125. doi:10.1016/S1466-8564(01)00024-8

Asavasanti S, Ristenpart W, Stroeve P, Barrett DM (2011) Permeabilization of plant tissues by monopolar pulsed electric fields: effect of frequency. J Food Sci 76(1):E96–E111

Asavasanti S, Stroeve P, Barrett DM et al (2012) Enhanced electroporation in plant tissues via low frequency pulsed electric fields: influence of cytoplasmic streaming. Biotechnol Prog 28:445–453

Evrendilek GA, Zhang QH (2005) Effects of pulse polarity and pulse delaying time on pulsed electric fields-induced pasteurization of E. coli O157:H7. J Food Eng 68:271–276

Toepfl S (2006) Pulsed electric fields (PEF) for permeabilization of cell membranes in food- and bioprocessing. Applications, process and equipment design and cost analysis. PhD Thesis, Berlin University of Technology, Germany

Ben Ammar J, Lanoiselle J-L, Lebovka NI et al (2011) Effect of a pulsed electric field and osmotic treatment on freezing of potato tissue. Food Biophys 5(3):247–254. doi:10.1111/j.1750-3841.2010.01893.x

Lebovka N, Vorobiev E (2011) Food and biomaterials processing assisted by electroporation. In: G PA, Miklavcic D, Markov MS (eds) Advanced electroporation techniques in biology and medicine. CRC Press, pp 463–490

Cortese P, Dellacasa G, Gemme R et al (2011) A pulsed electric field (PEF) bench static system to study bacteria inactivation. Nucl Phys B Proc Suppl 215:162–164. doi:10.1016/j.nuclphysbps.2011.03.165

Pourzaki A, Mirzaee H (2008) Pulsed electric field generators in food processing. In: 18-th National Congress on Food Technology in Mashhad (Iran). pp 1–7

BTX/Harvard Apparatus (2016) Electroporation & electrofusion products, http://www.btxonline.com.

Eppendorf Multiporator® System (2016) Eppendorf Multiporator® System, Multitalent for transfection and cell fusion http://www.eppendorf.com.

Bio-Rad (2016) Electroporation System http://www.bio-rad.com.

Mohamed MEA, Eissa AHA (2012) Structure and function of food engineering. In: Eissa AHA (ed). Academic Press, London, pp 275–306

Dunn J (1996) Pulsed light and pulsed electric field for foods and eggs. Poult Sci 75:1133–1136

Diversified Technologies I (2016) Food and wastewater processing, http://www.divtecs.com/food-and-wastewater-processing.

Kempkes MA, Tokusoglu O (2015) Improving food quality with novel food processing technologies. In: Tokusoglu O, Swanson BG (eds). CRC Press, Taylor & Francis LLC, pp 427–453

Kempkes M, Roth I, Reinhardt N (2012) Enhancing industrial processes by pulsed electric fields. In: Proceedings of Euro-Asian Pulsed Power Conference. Karlsruhe, Germany, pp 1–4

Kempkes M, Simpson R, Roth I (2016) Removing barriers to commercialization of PEF systems and processes. In: Proceedings of 3rd School on Pulsed Electric Field Processing of Food. Institute of Food and Health, University College Dublin, Dublin, pp 1–6

DIL/ELEA (2016) Pulsed electric field technology. The Science of Food-Physics™, http://www.elea-technology.com.

SteriBeam Systems GmbH (2016) SteriBeam Systems GmbH, Fully-automatic bench-top PEF R&D sterilization systems, http://www.steribeam.com.

KEA-TEC GmbH (2016) Industrial electroporation plants, http://www.kea-tec.de.

Haferkamp R (2016) BLIZZAR made by KEA-TEC GmbH, http://www.blizzar.eu.

CoolWave Processing (2016) How does PurePulse work? http://www.purepulse.eu/.

Arc Aroma Pures (2016) Arc Aroma Pures—CEPT®—closed environment PEF treatment, http://www.arcaromapure.se.

ScandiNova Systems AB (2016) Excellence in pulsed power, http://www.scandinovasystems.com.

EnergyPulse Systems Lda (2016) EPULSUS®, high performance pulse generators, http://energypulsesystems.pt.

Basis EP (2016) Energies pulsées, http://www.arcaromapure.se/.

Pulsemaster (2016) Pulsed electric field processing for the food industry, https://www.pulsemaster.us.

Clark JP (2006) Pulsed electric field processing. Food Technol 60:66–67

Personius CJ, Sharp PF (1938) Permeability of potato-tuber tissue as influenced by heat. J Food Sci 3:525–538. doi:10.1111/j.1365-2621.1938.tb17088.x

Blahovec J, Kouřím P (2016) Combined mechanical (DMA) and dielectric (DETA) thermal analysis of carrot at temperatures 30–90 °C. J Food Eng 168:245–250. doi:10.1016/j.jfoodeng.2015.07.044

Lebovka NI, Praporscic I, Vorobiev E (2004) Effect of moderate thermal and pulsed electric field treatments on textural properties of carrots, potatoes and apples. Innov Food Sci Emerg Technol 5:9–16

Vorobiev E, Lebovka N (2011) Pulse electric field-assisted extraction. In: Lebovka N, Vorobiev E, Chemat F (eds) Enhancing Extraction Processes in the Food Industry. CRC Press, Taylor & Francis LLC, pp 25–83

Bazhal MI, Lebovka NI, Vorobiev E (2001) Pulsed electric field treatment of apple tissue during compression for juice extraction. J Food Eng 50:129–139

Praporscic I, Shynkaryk MV, Lebovka NI, Vorobiev E (2007) Analysis of juice colour and dry matter content during pulsed electric field enhanced expression of soft plant tissues. J Food Eng 79:662–670

Shynkaryk MV, Lebovka NI, Vorobiev E (2008) Pulsed electric fields and temperature effects on drying and rehydration of red beetroots. Dry Technol 26:695–704

Jalte M, Lanoiselle J-L, Lebovka NI, Vorobiev E (2009) Freezing of potato tissue pre-treated by pulsed electric fields. LWT Food Sci Technol 42:576–580

Wiktor A, Schulz M, Voigt E et al (2015) The effect of pulsed electric field treatment on immersion freezing, thawing and selected properties of apple tissue. J Food Eng 146:8–16

Phoon PY, Galindo FG, Vicente A, Dejmek P (2008) Pulsed electric field in combination with vacuum impregnation with trehalose improves the freezing tolerance of spinach leaves. J Food Eng 88:144–148

Parniakov O, Bals O, Lebovka N, Vorobiev E (2016) Pulsed electric field assisted vacuum freeze-drying of apple tissue. Innovative Food Sci Emerg Technol 35:52–57

Donsi F, Ferrari G, Pataro G (2010) Applications of pulsed electric field treatments for the enhancement of mass transfer from vegetable tissue. Food Eng Rev 2:109–130

Shayanfar S, Chauhan OP, Toepfl S, Heinz V (2013) The interaction of pulsed electric fields and texturizing—antifreezing agents in quality retention of defrosted potato strips. Int J Food Sci Technol 48:1289–1295

Shayanfar S, Chauhan OP, Toepfl S, Heinz V (2014) Pulsed electric field treatment prior to freezing carrot discs significantly maintains their initial quality parameters after thawing. Int J Food Sci Technol 49:1224–1230

Parniakov O, Lebovka NI, Bals O, Vorobiev E (2015) Effect of electric field and osmotic pre-treatments on quality of apples after freezing-thawing. Innovative Food Sci Emerg Technol 29:23–30

Jaeger H, Janositz A, Knorr D (2010) The Maillard reaction and its control during food processing. The potential of emerging technologies [la reaction de Maillard et son controle pendant la fabrication des aliments. Le potentiel des nouvelles technologies]. Pathol Biol 58:207–213

Sack M, Sigler J, Frenzel S et al (2010) Research on industrial-scale electroporation devices fostering the extraction of substances from biological tissue. Food Eng Rev 2:147–156. doi:10.1007/s12393-010-9017-1

IXL Netherlands B.V. (2016) The Nutri-Pulse® “cooks” with electric pulses, www.innovation-xl.com.

Erfinder, Van Oord G, Roelofs JTM(2016) Low field strength PEF cooking, Patent EU WO 2016008868 A1.

Arroyo C, Eslami S, Brunton NP et al (2015) An assessment of the impact of pulsed electric fields processing factors on oxidation, color, texture, and sensory attributes of turkey breast meat. Poult Sci pev097:1–8

Gudmundsson M, Hafsteinsson H (2001) Effect of electric field pulses on microstructure of muscle foods and roes. Trends Food Sci Technol 12:122–128. doi:10.1016/S0924-2244(01)00068-1

Toepfl S, Heinz V (2007) Application of pulsed electric fields to improve mass transfer in dry cured meat products. Fleischwirtschaft Int J Meat Prod Meat Process 22:62–64

O’Dowd LP, Arimi JM, Noci F et al (2013) An assessment of the effect of pulsed electrical fields on tenderness and selected quality attributes of post rigour beef muscle. Meat Sci 93:303–309. doi:10.1016/j.meatsci.2012.09.010

McDonnell CK, Allen P, Chardonnereau FS, et al (2014) The use of pulsed electric fields for accelerating the salting of pork. LWT—food science and technology 59:1054–1060. doi: 10.1016/j.lwt.2014.05.053

Arroyo C, Lascorz D, O’Dowd L et al (2015) Effect of pulsed electric field treatments at various stages during conditioning on quality attributes of beef longissimus thoracis et lumborum muscle. Meat Sci 99:52–59. doi:10.1016/j.meatsci.2014.08.004

Bekhit AE-DA, Hopkins D (2014) Enhancement of meat quality by pulsed electric field application. Project A.MQA.0005. Level 1, 40 Mount Street, North Sydney NSW 2060

Bekhit AE-DA, Carne A, Ha M, Franks P (2014) Physical interventions to manipulate texture and tenderness of fresh meat: a review. Int J Food Prop 17:433–453. doi:10.1080/10942912.2011.642442

Faridnia F, Bekhit AE-DA, Niven B, Oey I (2014) Impact of pulsed electric fields and post-mortem vacuum ageing on beef longissimus thoracis muscles. Int J Food Sci Technol 49:2339–2347. doi:10.1111/ijfs.12532

Suwandy V, Carne A, Van de Ven R et al (2015) Effect of pulsed electric field on the proteolysis of cold boned beef M. longissimus lumborum and M. semimembranosus. Meat Sci 100:222–226. doi:10.1016/j.meatsci.2014.10.011

Faridnia F (2015) The impact of pulsed electric field (PEF) processing on solid food materials. PhD Thesis, University of Otago, New Zealand

Faridnia F, Ma QL, Bremer PJ et al (2015) Effect of freezing as pre-treatment prior to pulsed electric field processing on quality traits of beef muscles. Innovative Food Sci Emerg Technol 29:31–40

Janositz A, Noack A-K, Knorr D (2011) Pulsed electric fields and their impact on the diffusion characteristics of potato slices. LWT-Food Sci Technol 44:1939–1945

Ignat A, Manzocco L, Brunton NP et al (2015) The effect of pulsed electric field pre-treatments prior to deep-fat frying on quality aspects of potato fries. Innovative Food Sci Emerg Technol 29:65–69

Totosaus A, De Lourdes Pérez-Chabela M (2004) Poultry: poultry nuggets. In: Smith JS, Hui YH (eds) Food Processing: Principles and Applications. Blackwell Publishing, pp 433–438

Garret RH, Grisham CM (2010) Biochemistry, 4th edn. Brooks/Cole, Cengage Learning, Boston

Buckow R, Ng S, Toepfl S (2013) Pulsed electric field processing of orange juice: a review on microbial, enzymatic, nutritional, and sensory quality and stability. Compr Rev Food Sci Food Saf 12:455–467

Lelieveld H, Mastwijk H, Oord G, et al (2011) Cooking in seconds with PEF. More nutrients—better taste, http://www.innova-uy.info.

Lebovka NI, Praporscic I, Ghnimi S, Vorobiev E (2005) Does electroporation occur during the ohmic heating of food? J Food Sci 70:E308–E311

Goettsch C, Roelofs H (2014) Stew cooked in minutes. The sustainable breakthrough in food preparation. Voedingsindustrie 2:8–9

Timmermans RAH, Mastwijk HC, Knol JJ et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part I: impact on overall quality attributes. Innovative Food Sci Emerg Technol 12:235–243

Vervoort L, Der Plancken I, Grauwet T et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice: part II: impact on specific chemical and biochemical quality parameters. Innovative Food Sci Emerg Technol 12:466–477

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

In this review, principles of ethical and professional conduct have been followed. This study does not involve research on human participants and/or animals.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

This article was previously published in Volume 9, Issue 2 due to an error. It is being reprinted here as originally intended.

Rights and permissions

About this article

Cite this article

Blahovec, J., Vorobiev, E. & Lebovka, N. Pulsed Electric Fields Pretreatments for the Cooking of Foods. Food Eng Rev 9, 226–236 (2017). https://doi.org/10.1007/s12393-017-9170-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-017-9170-x