Abstract

A field experiment was conducted from 2016 to 2018 at the ICAR-Indian Institute of Sugarcane Research, Lucknow, Uttar Pradesh, India, to study the effect of integration of bio-products and inorganic fertilizers on soil quality parameters, growth and yield of sugarcane and also to assess the possibilities of reduction in inorganic fertilizers doses, if any through the integration of bio-products with inorganic fertilizers. Eight treatments of various bio-products in different combinations were applied on sugarcane plant and ratoon crops. These treatments were replicated three times in randomized block design. Inclusion of dharmarut (DHA), diamond (DIA), sugar factory kit (SF kit), and bio NPK kit with a recommended dose of fertilizers (RDF) improved about 18.4% soil organic carbon (SOC) in sugarcane ratoon crop (13.37 Mg/ha). However, a 40% reduction in NPK could also improve SOC by 7.9% over the control (11.29 Mg/ha). Application of SF kit and bio NPK kit with RDF improved available N content in soil by 15.5% over the control. SF and bio NPK kits and NPK also improved available P in soil significantly over the control. Integration of DHA, DIA, SF kit, and bio NPK kit with 100% RDF improved 11.41% available K in the soil as compared to control plot (289 kg/ha). However, reduction in NPK with similar bio-products improved 15.6% available K after harvesting of ratoon crop compared to control plot. Mean available K content in soil (305.5 kg/ha) after harvesting ratoon crop was recorded higher by 43.6 kg/ha than after harvesting of plant crop. Integrated use of DHA, DIA, SF kit, and bio NPK kit along with 100% RDF improved sugarcane yield by 38.58% and 30.0% in sugarcane (plant) and ratoon crops, respectively, over the control (RDF). Such improvements in sugarcane yield also improved sugar yield by 30.4% and 26.4% in plant and ratoon crops, respectively, over the recommended NPK through chemical fertilizers alone. Integrated use of these bio-products with 60% RDF also resulted in an improvement of 16.65% and 19.0% cane yield in plant and ratoon crops, respectively, over the RDF. Such improvement in yield could contribute additional sugar production by 9% and 18.5% in sugarcane plant and ratoon crops, respectively, over the recommended dose of NPK (RDF). Thus, the integration of bio-products with NPK holds great promise for various sugarcane growing regions and categories of farmers to harness sustainable yield increases in sugarcane-based systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane is grown in more than ninety countries globally and occupies about 26.26 m ha area with production of 1907.0 m tones at 72.59 t/ha productivity (FAO 2018). India ranks second after Brazil in the area (5.11 m ha) and total sugarcane production (400.16 m tones) at 78.3 t ha−1 productivity level (DAC 2019). Response of organics has been reported by several research workers on the growth and yields of sugarcane at various places (Shukla et al. 2008). Sugarcane is a vegetatively propagated crop, and the organics increased the response of added nutrients inorganic sources (Shukla et al. 2012). The importance of rhizospheric environment influencing root and plant growth has also been researched by several scientists (Shukla et al. 2008; Yadav et al. 2009a and b). Several physicals, chemical, and biological factors in the rhizospheric environment affect sugarcane crop growth, yield, and sugar recovery (Shukla et al. 2011). Sugarcane crop produces about 10–12 tonnes/ha of trash in one ha area. Its application in subsequent ratoon crops conserves soil moisture, controls weed growth, and adds organic carbon after decomposition (Yadav et al. 2009a).

The importance of microbes in modern agriculture is increasing because of the declining trend in factor productivity and soil organic carbon content (Dawe et al. 2003). Sustainability in agriculture has always been considered a critical issue while feeding the growing population of the country and world (Benbi and Brar 2009). Nowadays, high cropping intensity, minimum use of organics because of their unavailability, and higher use of chemical fertilizers in intensive agriculture are causing imbalanced nutrients to use and resulting in deficiencies of several other macro- and micronutrients (Raihanna et al. 2017). Soil microbes and their functions related to C transformation and turnover are influenced by N application (Compton et al. 2004). Microbes also play an important role in decomposition processes, including lignin and cellulose degradation and soil carbon turnover (Lei et al. 2018; Mele and Crowley 2008; Sun et al. 2017). Gluconacetobacter diazotrophicus is an endophytic bacteria that survive under anaerobic conditions in plant roots, rhizomes, stalk, and sugarcane leaves (Hallmann et al. 1997). Pseudomonas fluorescens acts as a P solubilizer and improves the solubility of P by converting PO4−3 to HPO4−2 and H2PO4−1 (Alori et al., 2017; Satyprakash et al. 2017). Increasing P content in sugarcane juice is essential for better crystallization of sugar during crushing.

The role of Trichoderma in growth production and inhibition of plant pathogens is well known (Singh et al. 2010; Yadav et al. 2009a). Several researchers have also reported various nitrogen, phosphorus, and K supplying microorganisms. These microorganisms/bioagents improved the growth of crops through nutritional enrichment of soil (Yadav et al. 2009a; Shukla et al. 2009a; Shukla and Yadav 2011). Several experiments have been conducted on various types of organisms such as trash mulching, FYM, press mud cake, and biofertilizer, especially N and P (Shukla et al. 2009a). However, the efficacy of various spp of biofertilizers at several places behaved differently. Thus, the focus is required to determine the potential microbes and integrate microbial consortia in the sugarcane-based system to harness maximum sustainable crop yields. However, very little information is available on the subject.

Keeping above points in view, our central hypothesis was that "application of bioproducts may have an impact on the rhizospheric environment of crop and creates good physical, chemical, and biological conditions. These bio-products may produce various compounds required to break down complex organic compounds. Thus, nutrient availability could be increased. Enhanced nutrient availability will influence crop growth and sugarcane yield in a sustainable manner. Therefore the present experiment was taken up with the two objectives (i) to study the effect of integration of bio-products containing several bio-agents and inorganic fertilizers on soil quality parameters, growth and yield of sugarcane in sugarcane (plant)-ratoon system (ii) to find out the possibilities of reduction in inorganic fertilizers doses if any through the integration of bio-products with inorganic fertilizers.

Material and Methods

A field experiment was conducted from 2016 to 2018 at the ICAR-Indian Institute of Sugarcane Research, Lucknow, Uttar Pradesh, India, geographically located at 111 m above mean sea level in the subtropical region. The soil of the experimental field was loam (48% sand, 35% silt, and 17% clay) of the Indo Gangetic alluvial region. Before the start of field experiment, initial soil physical and chemical parameters viz., bulk density (1.35 Mg/m3), pH (7.8), electrical conductivity (0.22 ds/m), soil organic carbon (12.5 Mg/ha), available N (279 kg/ha), available P (10.5 kg/ha) and available K (277.9 kg/ha) were determined.

Sugarcane was planted on 16th October 2016 at 90 cm row spacing. Furrows were opened at 90 cm apart through a tractor-drawn furrow opener at a depth of about 15–20 cm. About 1/3rd N and a total dose of P and K were applied before placement of setts in furrows. Three bud sets of cane were planted at the end-to-end placement in-furrow. Thus about 45,000 three bud setts were required for planting of one ha area. All the treatments (Table 1) were applied while raising sugarcane and ratoon crops. The recommended dose of NPK (150, 26, 50 kg/ha) for sugarcane plant crops and other bio-products was given in different treatments as per the schedule. In the sugarcane ratoon crop, a 25% higher dose of NPK (187.5 kg N, 32.5 kg P, and 62.5 kg K/ha) was applied. Sugarcane plant crop was harvested on 16th December 2017, and another ratoon crop was initiated. Sugarcane ratoon crop was harvested on 10th December 2018. Sugarcane early maturing variety ‘CoPK 05,191’ recommended for the region was grown in the experiment.

Treatments

Eight treatments of various bio-products in different combinations were applied on sugarcane plant and ratoon crops (Tables 1 and 2). These treatments were replicated three times in randomized block design (RBD). The minimum plot size (7.2 m × 6 m) was kept in the experiment. Thus, eight rows of sugarcane with 6-m length were taken in each plot. The schedule of treatments applied is given in Table 2. All the treatments were applied on the plant (first crop) and ratoon crops. Thus, the effect of treatments on soil properties and crop growth was recorded in the sugarcane (plant)-ratoon system.

Soil and Plant Studies

Soil sampling at 0–15 cm depth was done for determination of organic carbon (Walkley and Black method-Walkley and Black 1934), available N (KMnO4 method), available P (0.5 M NaHCO3, pH 8.5, extractable P), and NH4OAc extractable K, following Jackson (1973). Sugarcane tillers were counted from April to September. Growth and yield attributes were determined at the harvest. At the time of harvesting the crop, five canes were selected for determining juice quality parameters. (Brix, sucrose (%) juice, and purity) in each plot. After crushing of cane in Motor operated Crusher, sugarcane juice was extracted. °Brix, sucrose, and juice purity were determined in the laboratory through Auto Pol. Individual cane length, diameter, and weight of these canes were also recorded. Sugarcane yield was determined by harvesting net plots (four sugarcane rows leaving one border row and one sample row on each side). Commercial cane sugar was calculated through a formula given by Meade and Chen (1977). Sugar yield was calculated after multiplying CCS (%) and sugarcane yield.

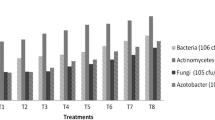

Polynomial equation fitted well in tiller population achieved with the advancement of the growth phase and depicted in Figs. 1 and 2. A regression equation was also worked out through excel software. The data of various soil and crop parameters in plant and ratoon crops were statistically analyzed. Critical difference (CD) was computed to determine statistically significant differences among multiple treatments and draw a valid conclusion.

where VE: Error variance; r is the number of replications t5%: t value at error d.f. MSTAT software was used for statistical analysis.

Results and Discussion

Soil Quality Parameters

Soil organic carbon (SOC) and available N, P, and K/ha were recorded after harvesting sugarcane (plant) and ratoon crops (Table 3). Initial soil organic carbon, available N, P, and K recorded low soil organic carbon (12.5 Mg/ha), low available N (279 kg/ha), medium available P (10.5 kg/ha), and available K (277.9 kg/ha) contents. About 9.8% improvement in SOC content was recorded with applying bio-products viz., DHA, DIA, SF kit, bio NPK kit, and recommended NPK in sugarcane plant crop over the control (12.18 mg/ha). Available N content in soil was also improved by 8.4% with applying these bio-products and 100% NPK over the control (Table 3). Application of SF kit and bio NPK kit with 100% NPK improved about 13.0% available N over the use of PCO and PSD (T1). Available P content in the soil also increased with the integration of bio-products with NPK. However, the highest available P (11.56 kg/ha) was analyzed using RDF + DHA + DIA + SF kit and bio NPK kit (T4), which resulted in a 31.7% increase over RDF alone. Reduction in NPK and integration of similar bio-products also increased the available P content @ 21.5% in the soil after harvesting of sugarcane plant crop as compared to control. Integration of SF kit and bio NPK kit improved 20% higher available P content as compared to PCO + PSD. 1

Higher SOC using DHA, DIA, SF kit, and bio NPK kit with RDF over recommended NPK alone was recorded due to better crop growth and a higher rate of leaf fall and their decomposition through bio-agents (Shukla et al. 2012, 2020). Available N also increased due to integrating these bioagents/bio-product with chemical fertilizers. However, the rate of change of SOC and available N was higher in ratoon cane. It was due to the decomposition of trash and improved rhizospheric environment due to bioproducts + NPK as compared to NPK alone (Yadav et al. 2009a and b).

Soil quality parameters after harvesting sugarcane ratoon crop indicated that mean SOC changed marginally and available N content declined by 10.5 kg/ha. Available P and K contents in soil increased to the tune of 0.4 kg/ha and 27.6 kg/ha, respectively. Inclusion of DHA, DIA, SF kit, and bio NPK kit with recommended NPK level improved about 18.4% SOC in sugarcane ratoon crop (13.37 Mg/ ha). However, a 40% reduction in NPK could also improve SOC by 7.9% over the control (11.29 Mg/ha). Inclusion of SF kit with recommended NPK improved SOC content about 13.11% over the control. Other treatments could not produce tangible differences in SOC content. Applying bio-products (T4) also improved available N content in soil by 20.78% (285.9 kg/ha) over the control. Reduction in NPK (T5) also enhanced it by 15.5% over the control (236.7 kg/ha). Application of SF kit and bio NPK kit with RDF improved available N content in soil by 15.5% over the control. SF and bio NPK kits and NPK also improved available P in soil significantly over the control. Bioproducts also improved available K content in the soil after harvesting ratoon crops over the control. Integration of DHA, DIA, SF kit, and bio NPK kit with 100% RDF improved 11.41% available K in the soil as compared to control plot (289 kg/ha). However, reduction in NPK with similar bio-products improved 15.6% available K after harvesting of ratoon crop compared to control plot. Mean available K content in soil (305.5 kg/ha) after harvesting ratoon crop was recorded higher by 43.6 kg/ha than after harvesting of plant crop. However, it was also higher in the tune of 27.6 kg/ha as compared to the initial value of available K.

Application of bioproducts increased availability of fixed K and made available to crops and showed higher exchangeable K after harvesting plant and ratoon crops. Although after harvesting of plant crop about 25.8 kg K/ha was decreased application of trash in sugarcane ratoon and integration of bioproducts increased K availability at higher rates (Yadav et al. 2009a; Shukla et al. 2008, 2012). The mean available N after harvesting of sugarcane plant crop was increased by 20 kg/ha as compared to the initial level (279 kg/ha). The use of bioproducts released several acids, phytohormones and growth-promoting substances. These affect microbial populations and plant growth-promoting bacteria. Inclusion of organic compounds released unavailable nutrients available in the soil, and several complex mixtures such as phytin, phospholipids, lignin, cellulose, and hemicellulose were decomposed through the integration of these bioproducts with chemical fertilizers, resulting in increased nutrients availability (Alori et al., 2017; Dong et al. 2012; Salim et al. 2015; Satyaprakash et al. 2017).

Tillering Pattern

Mean tiller population in sugarcane plant crop (Fig. 1) increased up to June (356,300/ha). The mean tiller population during April was counted as 199,400/ha. Since July, the tiller population decreased, and the declining trend continued until September (163,200/ha). Tiller population in sugarcane increased at higher temperatures and low humidity (summer season) and decreased when relative humidity increased (rainy season). Various treatments significantly influenced tiller emergence in sugarcane crops. During the month of September, integration of DHA, DIA, SF kit, and bio NPK kit along with a recommended dose of fertilizers (RDF) increased 12.97% tiller population in plant crop (174,220/ha). However, the application of RDF along with these bioproducts could increase 6.3% tiller population. Although from April to August, tiller population showed increment due to various bioproducts applied along with NPK. However, in the month of September, due to mortality of tillers, it showed improvement in the range of 5.1–12.97%. Inclusion of SF and bio NPK kits with recommended NPK also showed a 5% increment in the tiller population over the recommended NPK. Polynomial equation (Y = − 28.71 X2 + 203.1 X + 5.834 (R2 = 0.916) in sugarcane plant crop at the RDF + DHA, DIA, SF kit, and Bio NPK kit showed the higher degree of positive correlation in tiller population with the advancement of the crop growth period. However, the similar pattern was followed with the control.

also (T8; Y = − 24.16 X2 + 158.7 X + 68.9; R2 = 0.959). This showed that various bioproducts with NPK almost maintained the tiller emergence pattern as obtained in control. The gap between the two lines (Fig. 1: T4 and T1) showed an increasing trend till August and comparatively decreased in September after attaining a peak in July.

The mean tiller population in the sugarcane ratoon crop during the month of April (Fig. 2) was counted as 158,100/ha, which could increase up to 259,200/ha in June and further decline to the level of 183,400/ha in the month of September. Integration of DHA, DIA, SF kit, and bio NPK kit along with RDF improved 13.65% tiller population in April (166,440/ha), which could be increased to the level of 42.8% in September (215,560/ha) over RDF alone. Application of 60% RDF and these bioproducts also improved 23.12% tiller population in sugarcane ratoon over the control (158,890/ha). However, only the SF kit with RDF increased 21.65% tiller population in September compared to the RDF. This showed that various bio-products with NPK improved tiller emergence significantly in different proportions. Reduction in NPK through chemical fertilizers and bio-product application was also found beneficial over the control. Thus, maximization and optimization in growth could be possible due to the integration of these bioproducts along with NPK fertilizers at recommended and reduced levels.

Mean tiller population is sugarcane plant and ratoon crops increased till June. It was due to high temperature and low humidity (summer season). Tillering decreased after attaining monsoon in sugarcane plant and ratoon crops (Shukla 2007) because of higher temperature and high humidity. Tiller mortality in sugarcane is a standard feature. More than 40–60% of tillers die and do not possess the ability to become millable canes (Verma et al. 1996; Shukla 2007; Shukla et al. 2009b). However, in our experiment, the tiller mortality was comparatively reduced in ratoon crop compared to sugarcane plant crop. Autumn planting received the maximum period for tillering in subtropical India and produced a higher number of tillers. Besides, the integration of bio-products with NPK also produced vigorous tillers and resulted in lower tiller mortality at a higher rate in ratoon crop as compared to plant crop (Shukla et al. 2008, 2012).

Polynomial equation (Fig. 2) on tiller population in sugarcane ratoon crop during the growth period fitted well. Integration of bio-products viz., DHA, DIA, SF kit & bio NPK kit along with recommended NPK showed an equation viz., Y = − 14.77 X2 + 105.6 X + 94.19 (R2 = 0.765). Polynomial equation for control plot (Y = − 13.89 X2 + 94.07 X + 76.44; R2 = 0909) also followed similar trend. The gaps between these two regression lines could be increased with the increasing period from April to September. This showed that the effect of these bio-products with chemical fertilizers produced a consistent effect on the tiller population. It was reflected that tiller mortality percentage could be reduced with the application of these bioproducts, which was mainly due to vigorous tillers. These vigorous tillers contributed to a large number of millable canes having higher individual cane length and weight. Thus, sugarcane ratoon yield was affected to a greater extent due to the integration of bioproducts with chemical fertilizers.

Growth and Yield Attributes, Sugar Yield in Plant and Ratoon Crops

About 21.14% higher number of millable canes (135,200/ha—Table 4) was counted with the application of 100% recommended dose of fertilizer (RDF) + dharamrut (DHA) + diamond (DIA) + platinum comprehensive (PCO) + platinum shakti drip (PSD)- T1) than T2 (60% RDF along with all these bio-products applied in T1). Application of 100% RDF with DHA + DIA + sugar factory kit (SF kit) and bio NPK kit (T4) improved 23.65% number of millable canes as compared to RDF (T8). However, the application of 60% RDF (T5) with all these bio-products as applied in T4 increased the number of millable canes by 13.17% (104,800/ha) over the recommended NPK (T8). However, a reduction in the dose of chemical fertilizer reduced the number of millable canes significantly (Table 4). Individual cane length increased with the integration of bio-products with the inorganic source of fertilizers. The highest individual cane length (275.8 cm) was recorded with T4 (100% RDF + DHA + DIA + SF kit and bio NPK kit). Mean particular cane length was improved by 25.14% over recommended NPK (T8). Reduced NPK (60%) and application of these bioproducts also improved individual cane length significantly (262.5 cm) over recommended NPK through chemical fertilizers. The higher mean cane diameter (2.67 cm) was recorded with 100% RDF + DHA + DIA + SF kit + bio NPK kit. The improvement in individual cane length and diameter affected particular cane weight. Thus, the highest mean cane weight (1572 g) was recorded with T4 (100% RDF + DHA + DIA + SF kit and bio NPK kit). Various treatments did not affect juice quality parameters (°brix, sucrose in juice, and purity). Sugarcane yield was significantly affected by different treatments. About 12.35% increment in sugarcane yield (121.9 t/ha) was recorded with the application of 100% RDF + DHA + DIA + PCO + PSD (T1) over 60% NPK along with these bio-products. However, 100% RDF + DHA + DIA + SF kit + bio NPK kit improved sugarcane yield by 38.58% (136.5 t/ha) over the control (RDF). Reduction in NPK by 40% (T5) with the application of these bio-agents also produced higher yields (16.65%) than recommended NPK (T8). Although, the application of bio-products along with recommended NPK further improved sugarcane and sugar yields significantly. Sugar yield also followed a similar pattern with sugarcane yield. However, about a 30.4% increment in commercial cane sugar (CCS) was recorded due to the application of recommended NPK + DHA + DIA + SF kit + bio NPK kit (T4) over recommended NPK alone (T8).

The effect of bio-products was also recorded in the sugarcane ratoon crop (Table 5). The highest number of millable canes (161,300/ha) was recorded with T4 (100% DHA + DIA + SF kit + bio NPK kit). Application of SF kit and bio NPK kit with recommended NPK also produced about 19% higher number of millable canes (156,900/ha) than recommended NPK alone (T8). Inclusion of DHA + DIA with bio NPK and SF kit and recommended NPK through the inorganic source (T4) improved 22.38% number of millable canes than recommended NPK alone (T8-131,800/ha). The highest cane length (269.4 ha) in the ratoon crop was recorded with T4 with an improvement of 20.2% over recommended NPK (T8). Improvement in individual cane diameter was also recorded through the integration of bio-products with NPK. Integration of DHA, DIA, SF, and bio NPK kits with recommended NPK (T4) improved individual cane diameter by 13.6% over recommended NPK (2.2 cm). Ratoon cane weight was the product of individual cane length and diameter. Increased length and diameter improved the mean individual cane weight (1217.9 g) to the highest level with the application of DHA, DIA, SF kit & bio NPK kit + RDF for ratoon crop. About 50.8% increment in individual cane weight was recorded through these bio-products along with recommended NPK over the RDF alone (807.5 g). However, a 40% reduction in RDF and application of these bio-products improved 31.4% higher individual cane weight. Inclusion of SF kit and bio NPK kit with RDF also increased about 15.97% higher cane weight than the application of DHA, DIA, PCO and PSD with NPK. Juice quality parameters of ratoon cane were not significantly affected by different treatments. The highest sugarcane ratoon yield (134t/ha) was recorded with the integration of DHA, DIA, SF kit, and Bio NPK kit along with NPK supplied through inorganic sources (T4). Thus about 30.1% increment in sugarcane ratoon yield was registered with T4 over the control (RDF-103 t/ha). However, a 40% reduction in NPK also improved ratoon cane yield by 19% over the control. Inclusion of DHA, DIA, PCO, and PSD with NPK also improved about 22.2% sugarcane ratoon yield (125.9 t/ha) over the control (T8). Sugar yield was the product of sugarcane ratoon yield and sucrose (%) juice. Sugar yield also showed a similar pattern as ratoon cane yield because of the insignificant effect of treatments on juice quality parameters. The highest sugar yield (15.95 t/ha) to the tune of 26.4% was recorded with T4 (100% NPK + DHA + DIA + SF kit + bio NPK kit) as compared to RDF alone. Reduction in doses of NPK by 40% also increased about 8.5% sugar yield over the control (12.62 t/ha) in the ratoon crop.

Integration of bio-products with recommended NPK increased the millable canes, individual cane length, and cane diameter significantly over NPK supplied through chemical fertilizers alone (Shukla et al. 2008). Increased length and diameter positively affected cane weight. The higher number of tillers contributed to a higher number of millable canes (Shukla et al. 2009b). The yield of sugarcane plant and ratoon crops increased due to the higher number of millable canes and individual cane weight. The highest cane yield was achieved due to the integration of DHA, DIA, SF kit, and bio NPK kit with recommended NPK in sugarcane plant and ratoon crops. Bioproducts increased the availability of NPK and promoted crop growth attributes which resulted in higher cane yield (Shukla et al. 2012, 2017, 2019). Sugar yield in plant and ratoon crops increased due to higher tonnage obtained with the integration of bioproducts. Although, reduction in NPK showed higher cane yield than RDF alone supplied through chemical fertilizers. However, at 100%, the NPK response of bioproducts increased, and significantly higher sugarcane and sugar yields could be obtained. Several researchers reported a positive response of microbial consortia on sugarcane and sugar yields (Yadav et al. 2009a and b; Shukla et al. 2019; Shukla et al. 2020).

Conclusion

After 2 years of experimentation on sugarcane plants and ratoon crops in a sequential cropping system following conclusions could be drawn.

-

1.

Integrated use of DHA, DIA, SF kit, and bio NPK kit along with 100% RDF improved sugarcane yield by 38.58% and 30.0% in sugarcane (plant) and ratoon crops, respectively, over the control (RDF). Such improvements in sugarcane yield also resulted in sugar yield improvement by 30.4% and 26.4% in both the crops, respectively, over the recommended NPK through chemical fertilizers alone.

-

2.

Integrated use of these bio-products with 60% RDF (NPK) also resulted in an improvement of 16.65% and 19.0% cane yield in plant and ratoon crops, respectively, over the 100% RDF. Such improvement in yield could contribute to additional sugar production by 9% and 18.5% in sugarcane plant and ratoon crops, respectively.

-

3.

Bio-products viz., DHA, DIA, SF kit, bio NPK kit, and recommended NPK in sugarcane plant crop improved about 9.8% SOC over the control (12.18 mg/ha).

-

4.

Thus integration of bio-products with NPK fertilizers holds great promise for harnessing sustainable yield increases in the sugarcane-based system.

References

Alori, E.T., B.R. Glick, and O.O. Babalola. 2017. Microbial phosphorus solubilization and its potential for use in sustainable agriculture. Frontiers in Microbiology 8: 971. https://doi.org/10.3389/fmicb.2017.00971.

Benbi, D.K., and J.S. Brar. 2009. A 25-year record of carbon sequestration and soil properties in intensive agriculture. Agronomy for Sustainable Development 29: 257–265.

Compton, J.E., L.S. Watrud, L.A. Porteous, and S. Degrood. 2004. Response of soil microbial biomass and community composition to chronic nitrogen additions at Harvard forest. Forest Ecology and Management 196: 143–158. https://doi.org/10.1016/s0378-1127(04)00197-5.

DAC. 2019. Agricultural Statistics at a Glance. Published by Ministry of Agriculture and Farmers Welfare, GOI, Deptt. of Economics and Statistics, New Delhi. p126.

Dawe, D., A. Dobermann, J.K. Ladha, R. Yadav, B. Lin, R. Gupta, P. Lal, G. Panaullah, O. Sairam, Y. Singh, A. Swaroop, and Q.X. Zhen. 2003. Do organic amendments improve yield trends and profitability in intensive rice systems? Field Crops Research 83: 191–213. https://doi.org/10.1016/S0378-4290(03)00074-1.

Dong, W., X. Zhang, H. Wang, X. Dai, X. Sun, W. Qiu, and F. Yang. 2012. Effect of different fertilizer applications on the soil fertility of paddy soils in the red soil region of southern China. Plus One 7: e44504. https://doi.org/10.1371/journal.pone.0044504.

FAO. 2018. Crop Statistics. http://www.fao.org/faostat/en/#data/QC

Hallmann, J., A. Quadt-Hallmann, W.F. Mahaffee, and J.W. Klopper. 1997. Bacterial endophytes in agricultural crops. Canadian Journal of Microbiology 43: 895–914.

Jackson, M.L. 1973. In: Soil Chemical Analysis. Pub. Prentice-Hall of Indian Pvt. Ltd, New Delhi.

Lei, L., W. Xiao, L. Zeng, J. Zhu, Z. Huang, R. Cheng, R.S. Gao, and M. Li. 2018. Thinning but not understory removal increased heterotrophic respiration, and total soil respiration in Pinus massoniana stands. Science of the Total Environment 621: 1360–1369. https://doi.org/10.1016/j.scitotenv.2017.10.092.

Meade, G.P., and J.C.P. Chen. 1977 In: Cane Sugar Hand Book, (10th) Wiley Inter-Science. John Wiley and Sons, New York, p 882–885.

Mele, P.M., and D.E. Crowley. 2008. Application of self-organizing maps for assessing soil biological quality. Agricultural Ecosystems and Environment 126: 39–152. https://doi.org/10.1016/j.agee.2007.12.008.

Raihana, K., D.L. Ahmad, and P. Sabah. 2017. Problems and prospects of secondary and micronutrients management in India. SKUAST Journal of Research 19: 29–52.

Salim, M., P. Kumar, M.K. Gupta, and S. Kumar. 2015. Variation in some chemical characteristics of the soil under different land uses of Jhilmil Jheel wetland, Haridwar-Uttrakhand, India. International Journal of Scientific and Research Publications 5: p10.

Satyaprakash, M., T. Nikitha, E.U.B. Reddi, B. Sadhana, and S. Satyavani. 2017. A Review on phosphorous and phosphate solubilizing bacteria and their role in plant nutrition. International Journal of Current Microbiology and Applied Sciences 6: 2133–2144. https://doi.org/10.20546/ijcmas.2017.604.251.

Shukla, S.K. 2007. Growth, yield, and quality of high sugarcane (Saccharum officinarum) genotypes as influenced due to planting seasons and fertility levels. Indian Journal of Agricultural Sciences 7: 569–573.

Shukla, S.K., S. Shee, S.K. Maity, S.K. Awasthi, and A. Gaur. 2020. Growth, nutrient accumulation, and crop yields as influenced by crop residue recycling and Trichoderma inoculation in rice-wheat and sugarcane-ratoon-wheat cropping systems in subtropical India. Indian Journal of Agronomy 65: 58–66.

Shukla, S.K., S. Shee, S.K. Maity, S. Solomon, S.K. Awasthi, A. Gaur, A.D. Pathak, and V.P. Jaiswal. 2017. Soil carbon sequestration and crop yields in rice-wheat and sugarcane-ratoon–wheat cropping systems through crop residue management and inoculation of Trichoderma viride in subtropical India. Sugar Tech 19: 347–358.

Shukla, S.K., P.N. Singh, and R.S. Chauhan. 2011. Effect of organic wastes amended with Trichoderma and Gluconacetobacter on physicochemical properties of soil and sugarcane ratoon yield in udic ustochrept. Indian Journal of Agronomy 56: 254–259.

Shukla, S.K., P.N. Singh, R.S. Chauhan, and R.L. Yadav. 2012. Recycling of organic wastes amended with Trichoderma and Gluconacetobacter for sustenance in soil health and sugarcane ratoon yield in udic ustochrept. Communications in Soil Science and Plant Analysis 43: 1073–1097.

Shukla, S.K., S. Solomon, L. Sharma, V.P. Jaiswal, A.D. Pathak, and P. Singh. 2019. Green technologies for improving cane sugar productivity and sustaining soil fertility in sugarcane-based cropping systems. Sugar Tech 21: 186–196.

Shukla, S.K., and R.L. Yadav. 2011. Improving growth and yield of winter initiated sugarcane (Saccharum spp hybrid complex) ratoon through bio-agents amended press mud cake in subtropical India. Indian Journal of Agricultural Sciences 81: 1184–1186.

Shukla, S.K., R.L. Yadav, P.N. Singh, and I. Singh. 2009b. Potassium nutrition for improving stubble bud sprouting, dry matter partitioning, nutrient uptake, and winter initiated sugarcane (Saccharum spp. hybrid complex) ratoon yield. European Journal of Agronomy 30: 27–33. https://doi.org/10.1016/j.eja.2008.06.005.

Shukla, S.K., R.L. Yadav, A. Suman, and P.N. Singh. 2008. Improving rhizospheric environment and sugarcane ratoon yield through bioagents amended farmyard manures in udic ustochrept soil. Soil and Tillage Research 99: 158–168.

Shukla, S.K., A. Suman, A. K. Singh, R.L. Yadav, and M. Lal. 2009a. Organic nutrition for sustaining soil health, improving the rhizospheric environment, and sugarcane yield in India. In: Sugar Beet Crops: Growth, Fertilization, and Yield. Editor Claus T Hertburg ISBN ISBN: 978-1-60741-491-9 © 2009a Nova Science Publishers, Inc.

Singh, V., P.N. Singh, R.L. Yadav, S.K. Awasthi, B.B. Joshi, R.K. Singh, R.J. Lal, and S.K. Dutta Majumder. 2010. Increasing the efficacy of Trichoderma harzianum for nutrient uptake and control of red rot in sugarcane. Journal of Horticulture and Forestry 2: 66–71.

Sun, S., H. Zhao, F. Xing, Z. Bai, Y. Gao, Y. Dong, J. Zhou, Y. Wu, and Y. Yang. 2017. Response of soil microbial community structure to increased precipitation and nitrogen addition in a semiarid meadow steppe. European Journal of Soil Science 68: 524–536. https://doi.org/10.1111/ejss.12441.

Verma, R.S., S.K. Shukla, G.B. Singh, and L.J. Verma. 1996. Agrotechniques to enhance sugarcane productivity of mid-late varieties for early crushing. Indian Journal of Sugarcane Technology 11: 38–41.

Walkley, A.J., and I.A. Black. 1934. Estimation of soil organic carbon by the chromic acid titration method. Soil Science 37: 29–38.

Yadav, R.L., S.K. Shukla, A. Suman, and P.N. Singh. 2009a. Trichoderma inoculation and trash management effects on soil microbial biomass, soil respiration, nutrient uptake, and yield of ratoon sugarcane under subtropical conditions. Biology and Fertility of Soils 45: 461–468.

Yadav, R.L., D.V. Yadav, and S.K. Shukla. 2009b. Bio intensive agronomy: A paradigm shift in agronomic research. Indian Journal of Agronomy 54: 105–112.

Acknowledgements

Authors acknowledge the funding and support provided by Gujarat Eco Microbial Technologies Pvt. Ltd, B/5 Madhur Milan Society, High Tension Line Rd, Subhanpura, Vadodara 390023 for sponsoring Contract research project on Bioproducts. The assistance provided by the Director, ICAR-IISR, Lucknow for extending the facilities is greatly acknowledged. The help rendered by staff members of SWAPAM Lab is also duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors do not have any conflict of interest in presenting the data in current research paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shukla, S.K., Jaiswal, V.P., Sharma, L. et al. Integration of Bio-products and NPK Fertilizers for Increasing Productivity and Sustainability of Sugarcane-Based System in Subtropical India. Sugar Tech 25, 320–330 (2023). https://doi.org/10.1007/s12355-022-01182-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01182-8