Abstract

The sugar industries and ethanol distilleries have been rapidly expanding globally since bioethanol emerged as a renewable bioenergy source. However, these industries generate large volumes of wastewater with high levels of organic matter, nutrients, and metal contents, which are discharged into the nearby environment without adequate treatment. This industrial pollution may have an adverse effect on aquatic and terrestrial ecosystems. Hence, this study aimed at investigating the physicochemical properties and metal constituents of sugar industry and ethanol distillery wastewater and its adverse effect on the environment. The study also assessed the legal framework of industrial wastewater management in the sugar–ethanol industry. The wastewater samples were collected from Metahara sugar factory and ethanol distillery using time-composite sampling techniques. The laboratory analyses of physicochemical parameters and metal constituents of the wastewater were performed using standard methods. Results show that the physicochemical properties of the sugar industry’s wastewater (mg/L) were pH 7.6 ± 0.5, total solids (TS): 3050 ± 628, 5 days biochemical oxygen demand (BOD5): 1052 ± 560, chemical oxygen demand (COD): 1752 ± 433.0, NO3− N: 0.4 ± 0.3, PO −34 : 3.5 ± 1.5, SO −24 : 30 ± 9.0 and Cl−: 45 ± 10.4, whereas the ethanol distillery parameters (mg/L) were pH 3.9 ± 0.1, TS: 150,300 ± 9200, BOD5: 40,271 ± 3014, COD: 132,445 ± 6655, NO3− N: 3.2 ± 1.0, PO −34 : 21.2 ± 2.7, SO −24 : 4502 ± 69 and Cl−: 6722 ± 873. The metal constituents of the sugar industry and ethanol distillery wastewater were, respectively: Na: 61.1–113.4, 207.6–263.0 mg/L; K: 87–161, 1143.9–2987.0 mg/L; Mg: 274.2–341.0, 816.3–927.6 mg/L; Ca: 376.9–468, 1787.4–3389.8 mg/L; Cr: 0.01–0.06, 0.8–2.3 mg/L; Cu: 0.2–0.7, 1.1–1.5 mg/L; Zn: 1.3–3.5, 1.4–2.8 mg/L; Fe: 3.2–4.3, 13.8–19.6 mg/L; Ni: not detected, 0.13–2.7 mg/L and Mn: 1–1.5, 1.5–6.6 mg/L. All except one bivariate correlation between concentrations of the metals were strong (r > 0.5). The BOD5/COD (biodegradability index) of the sugar industry was 0.60, whereas the ethanol distillery was 0.25. Analysis of variance showed the concentrations of metals in the two industries were statistically significant (p < 0.05). Most of the parameters in this study were beyond the maximum permissible discharging limits, possibly interfering with physicochemical and biological processes in the natural environment. Hence, for the benefits of the environmental safeguards and sustainable water use of the sector, we recommend that the two wastewaters be treated using integrated approaches through blending using the biological method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The global environmental crisis, particularly environmental pollution, is a growing concern. For instance, the quality of freshwater is deteriorating and the quantity is being depleted as a result of industrialization (Latif et al. 2011). On other the hand, industrialization is the foundation that contributes significantly to economic growth and human welfare (Poddar and Sahu 2017). However, in many developing countries, industrial wastes are not properly managed, resulting in their disposal in the ambient environment (Nath et al. 2007). For instance, only 8% of all the wastewater generated in low-income countries is treated and over 80% of the wastewater generated worldwide is discharged without adequate treatment (UN-Water 2017). Industrial wastewater management is one of the greatest challenges worldwide because industrial processes create a variety of pollutants that are difficult and expensive to treat (Kadam and Upadhyay 2012). Furthermore, the industrial demand for water and the generation of wastewater are increasing at an alarming rate and the huge volume of effluent is difficult to treat and dispose of with available resources, especially in developing countries (Kumar and Chopra 2012).

Sugarcane production is increasing exponentially to satisfy the growing demand for sugar and bioethanol. The sugar industry is one of the most important agricultural-based industries, making a significant contribution to national economies of many developing countries, including Ethiopia. In tropical and subtropical developing countries, sugarcane is a source of cost-effective renewable bioenergy obtained through ethanol production (Martinelli et al. 2013). Additionally, one of the universal features of sugar production is the need for large amounts of water for different unit operations. The sugar industry generates about 1000 L of wastewater for every ton of sugarcane crushed (Hampannavar and Shivayogimath 2010). Furthermore, sugar factories annexed with ethanol distilleries produce, on average, 155 L spent wash (wastewater), 250 kg bagasse, 95 kg sugar and 12 L ethanol from one ton of sugarcane (Siddiqui and Waseem 2012). Many studies reported large amounts of pollutants in sugar industry wastewater, such as 5 days biochemical oxygen demand, (BOD5 1090 mg/L), chemical oxygen demand (COD 3682 mg/L), total solids (1287 mg/L) chloride (377 mg/L), sulfate (430 mg/L), nitrogen (1300 mg/L), calcium (393 mg/L) and magnesium (299 mg/L) (Wei and Jin 2004; Saranraj and Stella 2012; Sahu 2017). Usually, sugar industry wastewater contains large amounts of organic and particulate matters which are above environmental discharge standards.

Globally, the number of molasses-based ethanol distilleries is rapidly increasing in order to satisfy the growing demand for sustainable and renewable biofuel, particularly bioethanol (David et al. 2015). The amount of global demand for bioethanol in 2020 is estimated to increase above 1.2 × 1011 L (Arimi et al. 2015). However, distillery waste accounts for 88–95% of the total volume, and ethanol for only 5–12% of the raw materials (Pant and Adholeya 2007). The ever-increasing generation of molasses spent wash, an unwanted residual liquid waste, poses a serious threat to the water quality and soil properties in several areas worldwide (Mohana et al. 2009). On average, 10–15 L of spent wash is generated for every liter of ethanol produced (Christofoletti et al. 2013). Furthermore, distillery spent wash is classified as “Red Category” due to its polluting properties (Basu et al. 2015). The dark brown color-causing pigments of molasses spent wash were reported to contain COD of 110,000–190,000 mg/L, BOD5 50,000–60,000 mg/L, dissolved solids 90,000–150,000 mg/L, temperature 70–80 °C, and low acidity (pH 3.0–4.5) (Mohana et al. 2009; Kazemi et al. 2015). Spent wash is a very complex and eco-toxic agro-industrial wastewater, rendering its disposal into the environments unsafe. Thus, the removal of the pollutants from distillery spent wash using different treatment technologies is urgently needed prior to discharge (Nure et al. 2017).

Metals and their compounds play indispensable and extensive roles in the industrial and agricultural development of many nations (Akpomie et al. 2015). Currently, industrial wastewater containing various metals, including Cr, Cd, Cu, Ni, Fe, Hg, Mn, Pb, and Zn, is being discharged into the environment in developing countries (Salehzadeh 2013; Renu et al. 2017). These unsafe disposals cause the accumulation of heavy metals in water bodies, soils, food webs and living organisms. The noxious effects of the metals are of growing public health concerns (Mirbagheri et al. 2014). Metals are a group of environmental chemicals that are ubiquitous and non-biodegradable. Some of them are suspected to cause cancer, birth and immune system defects, mental retardation, behavioral abnormalities, immunotoxicity, low fertility, altered sex hormone balance, and altered metabolism (Wu et al. 2016). Many research reports show the presence of high metal concentrations in sugar industry wastewater, particularly in ethanol distillery spent wash (Srivastava and Jain 2010; Damodharan and Reddy 2012; Perovano Filho et al. 2016; Poddar and Sahu 2017). When these heavy metals are released into water bodies, they will be hydrated and become highly toxic, disrupting the normal enzymatic functions of biota (flora and fauna) and enhance the absorption process of biota (Barakat 2011; Carolin et al. 2017). Industrial metals pollution is a serious threat to the survival of terrestrial and aquatic life also because toxic metals act slowly and persist for long periods in biotic systems due to their non-biodegradability (Salehzadeh 2013). Generally, due to their potentially hazardous effects, biomagnification, bioaccumulation, and toxicity, the remediation of heavy metals is challenging for the scientific community. The toxicity of metals in different environments depends on several factors, including the dose, route of exposure, and chemical species, as well as the age, gender, genetics, and nutritional status of exposed individuals.

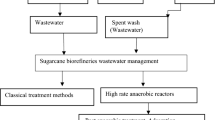

Notable achievements have been made in combating severe pollution during the period of high economic growth following the environmental principles set forth by the Basel Convention, the “polluter pays” principle, and the “precautionary” principle taken in consideration in national legislation, proclamations, policies, and regulations governing waste management. In Ethiopia, the development of environmental policy and its legal manifestation can be traced back to three core policy discourses which have been dominant in the Ethiopian policy debate over recent decades. These are the Green Revolution discourse to overcome food shortage, the environmental rehabilitation discourse to ameliorate degradation of natural resources, and a participatory natural resource management discourse (Ruffeis et al. 2010). Additionally, in many developing countries, environmental protection is generally underdeveloped, largely because nations are facing numerous other socioeconomic and environmental issues. Hence, environmental protection in these countries is lagging behind the rapidly increasing volume of pollutant emissions. However, the increasing awareness of the need for environmental protection has encouraged the development of new treatment technologies for wastewater that will work efficiently and economically (Mohana et al. 2009). Thus, sugar industry and ethanol distillery wastewater have to be treated prior to discharge into the natural environment to prevent water pollution and ecological impacts. Normally, the wastewater characteristics and the levels of pollutants vary significantly from industry to industry and change over time which impedes the selection of appropriate technologies and treatment methods. Therefore, the selection of a particular wastewater treatment technique depends on a variety of factors such as wastewater type and pollutant concentrations (Rajasulochana and Preethy 2016). In line with this, in wastewater management practice, the measurement of physical, chemical, and biological characteristics of the wastewater will be a crucial part of identifying any existing pollution problem or to estimate any emerged environmental problem in the future.

Among physicochemical treatment methods, biological treatment has emerged as an alternative and more attractive option than the existing physicochemical technologies for treating industrial wastewater containing high organic materials (Gopi Kiran et al. 2017). Additionally, biological treatment is advocating because of the major drawbacks in chemical treatment processes (Akpor et al. 2014). These biological treatment processes are employed for the removal of pollutants from various industrial wastewaters to safeguard the health of living organisms and for environmental sustainability. The mechanism of biochemical reactions and detoxification of the heavy metals by microbial degradation is a complex process but the application of the bioremediation for industrial wastewater management fluctuates over time. Particularly, the major mechanisms of the removal of heavy metals, such as intracellular accumulation, extracellular precipitation and chemical transformations by microbial enzymatic actions such as oxidation and reduction are increasingly being applied (Kulbat et al. 2003). However, biological wastewater treatment is a complex process which does not only depend on biochemical reactions, but also on the wastewater quality status (Chipasa 2003). Even though, this technology is very is easy and not complex but the biochemical reaction that takes place in bioreactor using microorganisms for wastewater treatment is complex because the biological process is very sensitive and complicated process to understand and controlled like the chemical and physical processes. The investigation of proper physicochemical properties of the wastewater and the quality status are fundamental to estimating environmental wastewater pollution burden and the implementation of wastewater management practice through the selection of proper treatment technologies for sustainable water uses. Furthermore, the sugar industry and ethanol distillery wastewater treatments are mainly focused on either the removal of organic matter or the nutrient constituents but many studies also found large metal concentrations, especially in ethanol distillery spent wash (Perovano Filho et al. 2016). Therefore, the aim of this study is to investigate the physicochemical properties and metal constituents of sugar industry wastewater and ethanol distillery spent wash and adverse effects of the pollutant loads on the environment. The study also focuses on the role of the environmental legal framework for industrial wastewater management, particularly for the sugar and ethanol industries.

Materials and Methods

Description of the Sampling Sites

Metahara sugar factory and ethanol distillery are located on the Awash River floodplains in the Rift Valley, about 200 km east of Addis Ababa, in Oromiya Regional State, at the geographical coordinates 8°54′0″N and 39°55′0″E (Fig. 1). The area has a semi-arid climate, with mean maximum and minimum temperatures of 32.8 °C and 17.5 °C, respectively. The factory is at an altitude of 940 m and has an average annual rainfall of about 600 mm. The average relative humidity, sunshine hours, and wind speed of the area are 77.4%, 8:46 h, 4.12 m/s, respectively (Degefa et al. 2016). In 2016, Metahara farm had 10,230 hectares of land planted with sugarcane and reported an average annual sugar production of 825,000 tons, but the average production capacity is 136,692 tons of sugar per year the bioethanol production capacity is 12,500 m3/year (Fito et al. 2017a, b).

Wastewater Sampling and Characterization

Wastewater samples were collected from the Metahara sugar factory and the ethanol distillery. Wastewater sampling was carried out monthly throughout the study period of 2 months excluding the preliminary tests for both physicochemical parameters and metal constituents of the sugar industry and ethanol distillery wastewater using a time-composite sampling technique. In all cases, the wastewater samples were collected at the effluent exit point of each factory while the wastewater was discharging into the environment (Fig. 2). A time-composite sampling technique was applied for physicochemical parameters, including TS, COD, BOD5 phosphates, nitrates, sulfate, and chloride which were measured in the laboratory. A grab-sampling technique was used to measure physicochemical parameters (temperature and pH) on sites. Time-composite sampling usually refers to the collection of numerous individual discrete wastewater samples taken at regular intervals over a period of hours. In all cases, the wastewater samples were collected in pre-cleaned, acid-washed plastic bottles and stored in a refrigerator at 4 °C until used for analyses. Finally, the laboratory analyses of the wastewater samples were performed according to the standard methods (Zhang 2007).

Among the physicochemical parameters of the sugar industry and ethanol distillery wastewater, pH was measured immediately on site while the other physicochemical parameters such as total solids (TS) (APHA 2540 B, total solid dried at 103–105 °C), nitrate (APHA 4500-NO3− B, ultraviolet spectrophotometric screening methods), phosphate (APHA 4500-PC, vanadomolybdophosphoric acid), COD (APHA 5220 B, open reflex method), BOD5 (APHA 5210 B, 5-days BOD test), chloride (APHA 4500-Cl-B, argentometric), and sulfate (APHA 3030E, turbidmetric method) were measured using standard methods (APHA 1998). For metal analyses, the wastewater samples were digested to extract the metals of interest and make them free in the form of ions that could be easily measured to avoid organic matter interference with the metal concentration measurements. Concentrated nitric acid was used for digestion of the wastewater using a microwave digester of the closed-vessel system with a maximum temperature of 250 °C for 15 min. Then, the digested samples were diluted, centrifuged, and filtered through a 0.45-μm-pore diameter membrane filter. Finally, the prepared samples were aspirated through a nebulizer into an inductively coupled plasma optical emission spectrometer (ICP-OES, Agilent 700 series ICP OES, USA), which has low detection limits for metal determination. The analyzed metals were Na, K, Mg, Ca, Cr, Cu, Ni, Zn, Mn, and Fe. The advantage of using a multi-element analyzer (ICP-OES) is the reduction of time for sample analysis and chemical consumption. All measurements of the metals were taken in the laboratory by considering the instrumental detection limit of each metal. Generally, the analyses of these metals were performed as per the standard methods set by international organizations (ISO 11885, 2007). In all cases, the measurements were taken in a duplicate manner.

Statistical Analysis

Descriptive statistical analysis and one-way analysis of variance (ANOVA) tests were used for data analyses at 95% confidence level. The ANOVA test was done for comparing metal concentration mean values of the summer and winter seasons for both sugar industry and ethanol distillery wastewater. The relationship between the metal constituents of the sugar industry and ethanol distillery wastewater was determined using two-tailed correlation analyses.

Results and Discussion

Physicochemical Properties of Wastewater

In this study, physicochemical properties of sugar industry and ethanol distillery wastewater were analyzed and the results were compared with the Ethiopian industrial effluent discharging limits shown in Table 1. Total solids 3050 ± 628.0 mg/L and 150,300 ± 9200 mg/L, and pH 7.6 ± 0.5 and 3.9 ± 0.1 of sugar industry and ethanol distillery wastewater, which are beyond the Ethiopian industrial effluent discharging limits 50 mg/L and 6–9, respectively, were recorded. The high concentrations of total solids were attributed to carbonates, chlorides, sulfates, nitrates, metal constituents, organic matter, silts, and other particle matters in the effluent, whereas alkalinity of the sugar industry wastewater was associated with the utilization of the of Ca(OH)2 for bleaching and pH adjustment in sugar production processes. Cleaning of heat exchangers and evaporators with NaOH to removes the scales on the tube surface also contributes to alkalinity levels. However, the strong acidic property of the distillery spent wash is directly associated with the use of sulfuric acid in the fermentation process and sometimes the use of phosphoric acid. These high amounts of particulate matter can cause rapid depletion of available oxygen, endangering fish and other aquatic life in the water bodies that receive the effluent, whereas the acidity of the spent wash causes the dissolution of metals in the water bodies, which creates unfavorable environmental conditions for aquatic life (Dahiya et al. 2001). Furthermore, the lower pH (acidic) value of the effluent can affect the rate of biochemical reaction and survival of various microorganisms in the ecosystem.

The comparison of organic matters in sugar industry wastewater with ethanol distillery spent wash in terms of BOD5 1052 ± 560, 40,271 ± 3014 mg/L and COD 1752 ± 433, 132,445 ± 6655 mg/L were found, respectively. These results indicate that organic matters are the major pollutants in both types of industrial wastewaters, which are beyond the Ethiopian effluent discharging limits of COD and BOD5 60 and 250 mg/L, respectively. Poddar and Sahlu (2017) reported BOD5 970 mg/L and COD 3, 682 mg/L in sugar industry wastewater and Mohana et al. (2009) and Kazemi et al. (2015) reported COD 110,000–190,000 mg/L, BOD 50,000–60,000 mg/L in ethanol distillery spent wash. Analysis of the organic matter with the intention of BOD5 and COD conjugation is also helpful in indicating toxic conditions and the presence of biological resistance (Poddar and Sahu 2017). The discharge of untreated wastewater into the water bodies can reduce photosynthetic activities and oxygen concentration that inhibit the survival of aquatic life in addition to the soil alkalinity reduction (Dahiya et al. 2001). The BOD/COD ratio, the biodegradability index (BI), has been used as criteria for biodegradability measurement. Furthermore, the BI is used to provide basic information for the selection of appropriate biological treatment technology. Usually, for fairly degradable and effective biological treatment, BOD/COD > 0.6 is expected, and BI values between 0.3 and 0.6, seeding of acclimatized microorganisms is required. For BOD/COD < 0.3, biologically treatment becomes difficult since biodegradation will not proceed (Zaher and Hammam 2014). The BI of the sugar industry wastewater in this study was 0.6 and the ethanol distillery spent wash was 0.30, indicating that for spent wash biological treatment is difficult to carry out. Blending of the two wastewaters may be considered as an possible solution to this problem.

In nutrient analyses of the Metahara sugar industry and ethanol distillery wastewater (mg/L), nitrates (0.4 ± 0.3, 3.2 ± 1.0), phosphates (3.5 ± 1.5, 21.2 ± 2.7), and sulfates (30 ± 9, 4502 ± 69) were obtained, respectively. In all cases, the nutrient concentrations of the ethanol distillery spent wash were higher than those of the sugar industry parameters. The disposal of these inadequately treated effluents into the water bodies may result in severe eutrophication since nutrients (phosphate and nitrate) are the potential contributors to this phenomenon (Khairnar et al. 2013). These high nutrient concentrations are attributed to the amount of urea [CO(NH2)2], diammonium phosphate [(NH4)2HPO4] and sulfuric acid (H2SO4) used in the distillery fermentation process for the propagation of yeast (Saccharomyces cerevisiae) and pH adjustment of the broth, respectively. In line with this, the application rates fertilizers, urea 1.81 kg and DAP 0.63 kg for every 1kL of ethanol production in Metahara ethanol distillery were reported (Fito et al. 2017a, b). However, for biological wastewater treatment, the nitrate and phosphate contents are really low compared to the COD concentration in both industrial wastewater which might require to supplement additional nutrients.

Light Metals Constituent of Sugar and Ethanol Industry Wastewater

Light metals analyses of the sugar industry and ethanol distillery wastewater were performed, and the results of the study are presented in Table 2. Two different samples were collected in summer and winter, and the results of the metal compositions were described in the form of their ranges. Normally, the wastewater of the sugar industry is generated in different units, including the mill house, process house, and boiler house with variable qualities and quantities. However, we applied the time-composite wastewater sampling technique to analyze metals composition. Similarly, the wastewater of the ethanol distillery is generated at different units of operation, resulting in three types of the wastewater, namely spent wash, fermenter sludge and spent lees. Spent wash is the dominant wastewater in terms of the quantities produced and its qualities in terms of its complexity, recalcitrant nature, eco-toxicity, and highly acidic levels. The sugar industry’s wastewater metals concentrations of Na (61.1–113.4 mg/L, K 87–161 mg/L), Mg (274.2–341 mg/L), and Ca (376.9–468 mg/L) were lower than the light metal concentrations of the distillery spent wash, such as Na (207.6–263 mg/L), K (1143.9–2987 mg/L), Mg (816.3–927.6 mg/L), and Ca (1787.4–3389.8 mg/L), respectively. These large amounts of Ca, Mg, Na, and K in sugar mill and ethanol distillery effluents might be attributed to the production processes of the factories and the uptake of metals from the soil by sugarcane plants. Other studies of the metal constituents of sugar industry wastewater reported comparable results. For example, Poddar and Sahu (2017) reported concentrations of K 113 mg/L, Mg 268 mg/L and Ca 361 mg/L in sugar industry wastewater and Rajeshwari et al. (2000) found Na concentrations of 150–200 mg/L and K concentrations of 5000–12,000 mg/L distillery wastewater.

Statistically significant variation of metals concentrations between the two seasons was recorded at p < 0.05. Hence, the discussion of this study is considering the seasonal variation of metal concentrations in the wastewater of the sugar industry and ethanol distillery is important. The concentrations of metals during the two seasons were averaged for each industry and presented in Fig. 3. In all cases, the concentration of metals in ethanol distillery spent wash was higher than in sugar industry’s wastewater except the concentrations of Na, which were nearly the same. Probably, this attributed to the same source, but the production process of the sugar industry and ethanol distillery is quite different. Hence, the concentration level of the sodium ion might be associated with the soil sources which could be taken up by the sugarcane. Furthermore, high concentration differences of light metals within and across the two industries were observed. For instance, the maximum concentration of Ca was 2584 mg/L in spent wash, whereas the minimum value of the light was recorded for Na (61.10 mg/L) in sugar industry’s wastewater. Furthermore, analysis of variance of the mean concentration of light metals in both the sugar industry and distillery wastewater showed significant differences (p < 0.05). This high concentration of metals in ethanol distillery spent wash may be attributed metal compositions of molasses which have already been confirmed by the high metal contents. Although the spent wash is the residue of molasses fermentation, the wastewater generated by the sugar industry at the different houses is mainly from washing the floor and apparatus, which does not directly contact with the sugar production process in the factory. Generally, the error bars of the metal concentrations of the wastewater from both industries during the winter and summer did not overlap, which indicates significant differences between the metal concentrations of the sugar industry to ethanol distillery. This variation of the metal concentrations between the two the industries can be considered as an opportunity for anaerobic biological treatment by blending the two wastewaters to homogenize them in a concentration zone suitable for microbial populations.

Heavy Metals Constituent of Sugar and Ethanol Industry Wastewater

Samples were collected during summer and winter at the factory closing and opening, respectively. The characterization of the sugar industry and ethanol distillery wastewater was performed in terms of metal composition (Table 3). These results are expressed as mean values, standard deviations and the concentration ranges for both sets of seasonal samples.

The concentrations of Cr and Cu in sugar industry wastewater and ethanol distillery spent wash were 0.01–0.06; 0.8–2.3 mg/L and 0.2–0.7; 1.1–1.5 mg/L, respectively. These results show higher concentrations of Cr and Cu in ethanol distillery spent wash than in sugar industry wastewater. The Zn concentrations of ethanol distillery were also higher (1.4–2.8 vs. 1.3–3.5 mg/L), as where the Fe concentrations of ethanol distillery spent wash (13.8–19.6 vs. 3.2–4.3 mg/L) and Mn (1.5–6.6 vs. 1–1.5 mg/L). The concentration of Ni in sugar industry wastewater could not be detected but was in the range of 0.13–2.7 mg/L in distillery spent wash. Likewise, both Cd and Pb were not detected in both industrial wastewater and therefore, they were not discussed.

The high concentration of heavy metals in sugar mill and ethanol distillery effluents may be due to the production processes of sugarcane in the sugar factory and molasses in the ethanol distillery. Srivastava and Jain (2010) reported concentrations of the heavy metals Cd (0.025), Zn (4.01), Cr (0.172), Ni (0.863), Cu (2.66), Fe (68.5), and Mn (3 mg/L). Amare et al. (2017b), in his dry weight analysis of sugarcane molasses for heavy metal concentrations, confirmed the presence of high concentrations of Fe (302.7), Mn (23.9), and Zn (6.4 mg kg−1). In another study of sugar industry wastewater, high amount of calcium (393 mg/L), magnesium (299 mg/L), sodium (106 mg/L), potassium (125 mg/L), and the heavy metals Fe2+ 17.00 mg/L, Zn2+ 0.79 mg/L, Pb2+ 0.52 mg/L, Cu2+ 0.346 mg/L, and Mn2+ 0.095 mg/L were recorded (Saranraj and Stella 2012).

Similar to the concentration of light metals, the average value of each heavy metal of the sugar industry and ethanol distillery wastewater was calculated and the results are presented in Fig. 4. The average concentrations of Cu and Zn in both the sugar industry and ethanol distillery wastewater are almost the same (Fig. 4). However, the average values of all other heavy metals concentrations in ethanol distillery spent wash were higher than those in the sugar industry’s wastewater. The average concentration of Ni in all sugar industry wastewater samples could not be detected. Large concentration discrepancies among the heavy metals were observed in the wastewater of both industries, confirming that the maximum average concentration of Mn was nearly 16 mg/L, whereas the minimum for Ni could not be detected. Analysis of variance of the mean concentration of heavy metals showed significant differences between sugar industry and distillery wastewater (p < 0.05). Generally, the error bars of the heavy metal concentrations of the winter and summer of both industries did not overlap, indicating significant differences between the metal concentrations of the sugar industry and the ethanol distillery. The analyses of sugar and ethanol industry wastewater indicate that spent wash might be the main contributor to the adverse environmental effect of heavy metals due to the waste generated from the sector and a challenge for biological wastewater treatment technology. Therefore, in sugar–ethanol industry wastewater management, the main attention should be given to ethanol distillery spent wash because of the high concentration of the pollutants (mainly organic matters, nutrients, and metals), recalcitrant nature and huge volume of spent wash generated.

Correlation of Metal Concentration in Sugar Industry Wastewater

Sugar industry wastewater was characterized in terms of the metal constituents and correlation among the metal concentrations. The results of the bivariate two-tailed correlation analysis are presented in Table 4. The correlation coefficients are used as the measure of the association between metal concentration of the wastewaters. Correlation coefficients of r < 0.50 were considered to be weak and above r > 0.50 as strong. The strongest relationships were between Na and Zn (r = 1.0), Fe and Cr, Fe and Mg, (both with r = 0.99), Fe and Na, Mn and Cu, and Ca and Na (all with r = 0.99). In general, all the relationships among metal concentrations in this analysis were strong and positive, with r > 0.80, except for the relationship between Zn and Ca (r = 0.70). Although strong correlations between metals were observed any change in the concentration of one metal may not affect the metal concentrations of the others. Furthermore, although the correlations of metal concentrations give good information on the magnitude and direction of the associations, it does not show cause and effect relations. Although a strong correlation between the parameters does not necessarily imply that a change in the concentration of one parameter resulted in changes in the concentrations of the others, it indicates the magnitude and direction of the associations (Fito et al. 2018).

Correlation of Metal Concentrations in Ethanol Distillery Wastewater

The relations between metal concentrations were analyzed for ethanol distillery spent wash. Correlation analyses were performed and the correlation coefficient (r) was used to judge the relations between individual metals as either negative, neutral or positive. Bivariate two-tailed correlation tests showed the strongest correlations between Ni and K (r = 1.0) and between Ni and Ca, Ni and Na, Ca and K, Mn and K, and Mn with Ca (all with r = 0.99), and the weakest relationship between Cr and Cu (r = 0.49) (Table 5. The associations among metal concentrations were strong overall, at r ≥ 0.54, except for Cr and Cu (r = 0.49). However, many metal concentrations in ethanol distillery spent wash were strongly negatively associated. The strongly positive or negative parameters are beneficial, inactive indicators.

The Suitability of the Metals Constituent for Anaerobic Treatment

Anaerobic wastewater treatment involves a large number of chemical, biochemical and microbiological reaction processes. The microbial reactions and degradation of organic matter and nutrients for physiology, nutritional needs, and growth kinetics are vital for the building of new microbial cells. The concentration of metals in industrial wastewaters can have synergistic or antagonistic effects on anaerobic digestion. However, the presence of metals such as Na, K, Mg, and Ca enhances the treatment process under normal concentrations because these metals are essential for optimal growth, development of microorganisms, and proper function of the treatment system. The stimulating concentration ranges of the light metals K 200–400 mg/L, Mg 75–150 mg/L, Ca 100–200 mg/L were reported. In this study, all the metal concentrations of the sugar industry wastewater are within these stimulating ranges, whereas the metal concentrations of the distillery spent wash are beyond the ranges. Despite the advantages of normal concentrations ranges, some limitations, such as inhibiting microbial degradation processes, are expected at higher concentration ranges. Moderately inhibitory concentrations of Na 3500–5500 mg/L, K 2500–4500 mg/L, Mg 2500–4000 mg/L, and Ca 1000–1500 mg/L were reported by Appels et al. (2008). Higher concentrations can disrupt the treatment system and can also cause bacterial cell dehydration because of the osmotic pressure difference. Normally, the toxicity of the metals in anaerobic treatment is related to their bioavailability, which can be determined by many factors, including the presence of other toxicants that may cause synergism or antagonism. Factors such as pH and temperature can affect chemical or biological reactions (Wu et al. 2016).

Minimal amounts of the trace metals (heavy metals) are essential for many microbial enzymes and co-enzymes activation processes and activities (Appels et al. 2008). Particularly heavy metals such as Cr, Cu, Zn, Fe, Mn, and Ni are essential for normal function of enzymatic catalysts, nutrient transportation, protein structure, charge neutralization, and control of osmotic pressure (Rajendran et al. 2003), at high concentrations; however, they are toxic and inhibit anaerobic wastewater treatment. Some investigations reported that the presence of heavy metals in the anaerobic digester which packed by the municipal sludge decreased the efficiency of the digestion process (Abdel-Shafy and Mansour 2014). The toxic effect of heavy metals can also disrupt enzyme function and structure by binding the metals with thiol and other groups on protein molecules or by replacing naturally occurring metals with enzyme prosthetic groups (Gómez 2011). The severity of metal inhibition depends upon factors like metal concentration in a soluble, ionic form in the solution, type of metal species, and the amount and distribution of biomass in the digester. However, inhibitory and toxicity level of Cu 1–10 mg/L, Zn 5–40 mg/L, Fe2+ 4.0–8.5 mmol/L, and Cd2+ at 0.53–3.0 mmol/L were reported by Demirel and Yenigün (2002) and Kumar and Mudhoo (2013). Certain other heavy metal ions, such as Cu and Cr, can inhibit the growth of bacteria and inactivate the enzymatic functions and thus affect the anaerobic digester treatment system, which may lead to system failure. In this study, the concentration of heavy metals in sugar industry wastewater appears to be suitable for microbial remediation, whereas the concentrations of the metals in the distillery spent wash are above the maximum permissible limits. Severe inhibition and toxicity of microbial actions will result in the reduction of treatment efficiency and may lead to treatment system failure.

Anaerobic digestion is a state of an art in terms of efficiency with the environmentally friendly approach and suitable for high strength sugar industry wastewater treatment, but the spent wash is a challenge for this treatment technology. However, high rate anaerobic reactors can minimize overcome many constraints. Among the mechanisms of bioremediation of heavy metals, biosorption is a metabolism-independent binding of heavy metals to living cells, non-living biomass or microbial extracellular polymers (Chipasa 2003). To overcome metal concentration discrepancies between sugar industry and ethanol distillery wastewaters, it is advisable to blend the two wastewaters to reduce the concentration of metals to normal ranges to create fertile conditions for microbial communities. This has two additional advantages. First, it can minimize or avoid the injection of purchased metal ions into the treatment system for the health of microbial growth and proper function of wastewater treatment system and second, it can reduce the inhibiting effect and toxicity of high metal concentrations.

Legal Framework for Industrial Wastewater Management

The Ethiopian government is currently emphasizing economic development and job creation as primary policy objectives but is also attempting to achieve sustainable development goals, which are to be finalized by 2030 (Pahlow et al. 2015). During the UN Conference on Environment and Development in Rio 1992, the compatibility concept of the environment and development was developed and has been accepted by nearly all nations. Ethiopia has made a promising start in environmental protection, including industrial wastewater management, since the environmental protection legal framework was formulated and incorporated into the country’s constitution, proclamations, policies and regulations. The issue of environmental protection in Ethiopia is elaborated in detail in Proclamation No. 1/1995 of the constitution (Constitution 1995). According to Proclamation No. 299/2002 (Proclamation 2002b), the environmental impacts of any development related project must be assessed and monitored through environmental impact assessment procedures. These safeguards are strengthened by Environmental Pollution Control Proclamation No. 300/2002 (Proclamation 2002), which was formulated with the intention of safeguarding public health and protecting the environment from ecological upsets caused by anthropogenic activities. Article 20 of the Environmental Pollution Control Proclamation No. 300/2002 was formulated to guide the regulation of industrial pollution prevention. The Prevention of Industrial Pollution Council of Ministers Regulation No. 159/2008 states that any factory subjected to this regulation, including the sugarcane mills and ethanol distilleries, must minimize the generation of pollutants to levels that do not exceed the standard limits set by for former national Environmental Protection Agency (EPA 2003). However, these regulations have not been enforced. The majority of the industries in the country, including the sugar industry, are discharging their wastewater into nearby water bodies and open land without any form of the treatment.

On the other hand, the government has given special attention to the development of sugarcane farms and sugar-bioethanol distilleries with the vision to make Ethiopia a leader of sugar and bioethanol producer in Africa. As part of this effort, sugarcane farms and bioethanol distilleries are being expanded and the blending of bioethanol and benzene has been started to provide the alternative, affordable and sustainable bioenergy for the transportation sector. While these activities augment and are in harmony with economic development overall, waste management of the sugar industry and bioethanol distillery have not been adequately addressed. Existing industrial effluent discharging limits by the EPA for the sugar industry and ethanol distillery cover only organic compounds, not metals (Table 6), which were found in high concentrations on Metahara sugarcane farm. Other studies in Ethiopia confirmed the presence of high concentrations of metals in wastewater emitted by this industry, particularly ethanol distillery wastewater. The existing wastewater treatment facilities were not designed to remove heavy metals (Amare et al. 2017a). Our study points to the need for these metal parameters to be incorporated into the effluent discharging limits for sugar producers and ethanol distilleries.

Conclusion

Most physicochemical properties of ethanol distillery effluents, such as nutrients (nitrate and phosphate), organic matters (COD, BOD5), acidity (pH), and total solids, were higher than those of the corresponding sugar industry’s parameters. The concentrations of these parameters were higher than the discharging limits set by the Ethiopian Environmental Protection Agency. Similarly, high concentrations of metals were found in sugar and ethanol production wastewater in Metahara sugar cane farm. The maximum concentration was recorded for Ca (3389.8 mg/L), followed by K (2987 mg/L) in ethanol distillery spent wash. In both the sugar industry and ethanol distillery wastewater, the order of metal concentrations was Ca > K > Mg > Na > Fe > Mn > Zn > Cr > Cu > Ni. Some concentrations of metals in ethanol distillery spent wash were above the suitability level in biological treatment systems, which may affect both the microbial actions and treatment performance. These properties indicate that if the effluents are not properly treated before being discharged into the environment, they may have adverse effects on aquatic and terrestrial ecosystems. Therefore, we recommended biological wastewater treatment method, particularly anaerobic high rate reactor followed by aerobic processes, since the analysis of the biodegradability index indicated that this treatment technology is a promising option in developing countries. We also recommend that discharging limits be set by the Ethiopian environmental pollution prevention legal framework for individual metals emitted by sugar and ethanol producers and that metals be monitored by these industries.

References

Abdel-shafy, H.I., and M.S.M. Mansour. 2014. Biogas production as affected by heavy metals in the anaerobic digestion of sludge. Egyptian Journal of Petroleum 23 (4): 409–417.

Akpomie, K.G., F.A. Dawodu, and K.O. Adebowale. 2015. Mechanism on the sorption of heavy metals from binary-solution by a low cost montmorillonite and its desorption potential. Alexandria Engineering Journal 54 (3): 757–767.

Akpor, O.B., G.O. Ohiobor, and T.D. Olaolu. 2014. Heavy metal pollutants in wastewater effluents: Sources, effects and remediation. Advances in Bioscience and Bioengineering 2 (4): 37–43.

Amare, E., F. Kebede, H. Kloos, and W. Mulat. 2017a. Wastewater confronting realities for sustainable Livelihood in developing countries: Case study Mekelle University, Ethiopia. Water Conservation Science and Engineering. https://doi.org/10.1007/s41101-017-0021-7.

Amare, E., F. Kebede, and W. Mulat. 2017b. Analysis of heavy metals, physicochemical parameters and effect of blending on treatability of wastewaters in Northern Ethiopia. International Journal of Environmental Science and Technology 14 (8): 1679–1688.

APHA. 1998. Standard methods for the examination of water and wastewater. Washington, DC: American Public Health Association; American Water Works Association; Water Environment Federation.

Appels, L., J. Baeyens, J. Degrève, and R. Dewil. 2008. Principles and potential of the anaerobic digestion of waste-activated sludge. Progress in Energy and Combustion Science 34 (6): 755–781.

Arimi MM, Y. Zhang, G. Götz and S. Geißen. 2015. Treatment of melanoidin wastewater by anaerobic digestion and coagulation. Environmental Technology 36: 2410–2418

Barakat, M.A. 2011. New trends in removing heavy metals from industrial wastewater. Arabian Journal of Chemistry 4 (4): 361–377.

Basu, S., S. Mukherjee, A. Kaushik, and V.S. Batra. 2015. Integrated treatment of molasses distillery wastewater using micro filtration (MF). Journal of Environmental Management 158: 55–60.

Carolin, C.F., P.S. Kumar, A. Saravanan, G.J. Joshiba, and M. Naushad. 2017. Efficient techniques for the removal of toxic heavy metals from aquatic environment: A review. Journal of Environmental Chemical Engineering 5 (3): 2782–2799.

Chipasa, K.B. 2003. Accumulation and fate of selected heavy metals in a biological wastewater treatment system. Waste Management 23 (2): 135–143.

Christofoletti, C.A., J.P. Escher, J.E. Correia, J.F.U. Marinho, and C.S. Fontanetti. 2013. Sugarcane vinasse: Environmental implications of its use. Waste Management 33 (12): 2752–2761.

Dahiya, J., D. Singh, and P. Nigam. 2001. Decolourisation of synthetic and spentwash melanoidins using the white-rot fungus Phanerochaete chrysosporium JAG-40. Bioresource Technology 78 (1): 95–98.

Damodharan, U., and M.V. Reddy. 2012. Impact of sugar industrial treated effluent on the growth factor in sugarcane—Cuddalore, India. Journal of Sustainable Bioenergy Systems 2 (3): 43–48.

David, C., M. Arivazhagan, and F. Tuvakara. 2015. Decolorization of distillery spent wash effluent by electro oxidation (EC and EF) and Fenton processes: A comparative study. Ecotoxicology and Environmental Safety 121: 142–148.

Degefa, A., M. Bosie, Y. Mequanint, E. Yesuf, and Z. Teshome. 2016. Determination of crop water requirements of sugarcane and soybean intercropping at Metahara Sugar Estate. Advances in Crop Science and Technology 4 (5): 10–13.

Demirel, B., and O. Yenigün. 2002. Two-phase anaerobic digestion processes: A review. Journal of Chemical Technology and Biotechnology 77: 743–755.

Fito, J., N. Tefera, S. Demeku, and H. Kloos. 2017a. Water footprint as an emerging environmental tool for assessing sustainable water use of the bioethanol distillery at Metahara sugarcane farm, Oromiya Region, Ethiopia. Water Conservation Science and Engineering 2: 165–176.

Fito, J., N. Tefera, and S.W.H. Van Hulle. 2017b. Adsorption of distillery spent wash on activated bagasse fly ash: Kinetics and thermodynamics. Journal of Environmental Chemical Engineering 5 (6): 5381–5388.

Fito, J., N. Tefera, H. Kloos, and S.W.H. Van Hulle. 2018. Anaerobic treatment of blended sugar industry and ethanol distillery wastewater through biphasic high rate reactor. Journal of Environmental Science and Health, Part A 53 (5): 676–685.

Gómez EMG. 2011. Biological treatment of industrial wastewater for biogas production. University of Stavanger (unpublished)

Gopi Kiran, M., K. Pakshirajan, and G. Das. 2017. A new application of anaerobic rotating biological contactor reactor for heavy metal removal under sulfate reducing condition. Chemical Engineering Journal 321: 67–75.

Hampannavar, U., and C. Shivayogimath. 2010. Anaerobic treatment of sugar industry wastewater by upflow anaerobic. International Journal of Environmental Sciences 1 (4): 631–639.

Kadam, A., and K. Upadhyay. 2012. Wastewater treatment of alcohol distillery plant by catalytic thermolysis. Journal of Industrial Pollution Control 28 (1): 1–4.

Kazemi, N., O. Tavakoli, S. Seif, and M. Nahangi. 2015. High-strength distillery wastewater treatment using catalytic sub- and supercritical water. Journal of Supercritical Fluids 97: 74–80.

Khairnar, P., F. Chavan, and V.R. Diware. 2013. Generation of energy from distillery wastewater. International Journal of Science, Spirituality, Business and Technology 2 (1): 29–35.

Kulbat E, K. Olańczuk-Neyman, B. Quant, M.Geneja and E. Haustein. 2003. Heavy metals removal in the mechanical-biological wastewater treatment plant “Wschód” in Gdańsk. Polish Journal of Environmental Studies 12: 635–641

Kumar A. and S. Mudhoo. 2013. Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. International Journal Environment Science Technology 2013 (6): 1383–1398

Kumar, V., and A. Chopra. 2012. Fertigation effect of distillery effluent on agronomical practices of Trigonella foenum-graecum L. (Fenugreek). Environmental Monitoring and Assessment 184: 1207–1219.

Latif, M.A., R. Ghufran, Z.A. Wahid, and A. Ahmad. 2011. Integrated application of upflow anaerobic sludge blanket reactor for the treatment of wastewaters. Water Research 45 (16): 4683–4699.

Martinelli, L., S. Filoso, C.D.B. Aranha, S.F.B. Ferraz, T.M.B. Andrade, E.D.C. Ravagnani, and C.L. Della. 2013. Water use in sugar and ethanol industry in the State of São Paulo (Southeast Brazil). Journal of Sustainable Bioenergy Systems 3: 135–142.

Mirbagheri, S.A., N. Biglarijoo, and M. Keyhannejad. 2014. Pilot plant studies for the removal of heavy metals from industrial wastewater using adsorbents. Turkish Journal of Engineering and Environmental Sciences 38: 159–166.

Mohana, S., B.K. Acharya, and D. Madamwar. 2009. Distillery spent wash: Treatment technologies and potential applications. Journal of Hazardous Materials 163: 12–25.

Nath, K., D. Singh, and Y.K. Sharma. 2007. Combinatorial effects of distillery and sugar factory effluents in crop plants. Journal of Environmental Biology 28 (3): 577–582.

Nure, J.F., N.T. Shibeshi, S.L. Asfaw, W. Audenaer, and S.W.H. Van Hulle. 2017. COD and colour removal from molasses spent wash using activated carbon produced from bagasse fly ash of Matahara sugar factory, Oromiya region, Ethiopia. Water SA 43 (3): 470–479.

Pahlow, M., J. Snowball, and G. Fraser. 2015. Water footprint assessment to inform water management and policy making in South Africa. Water SA 41 (3): 300–313.

Pant, D., and A. Adholeya. 2007. Biological approaches for treatment of distillery wastewater: A review. Bioresource Technology 98: 2321–2334.

Perovano Filho, N., K.F.S. Da Silva, E.C.L. Dos Santos, D.D. Queissada, and A.M.Q. López. 2016. Physicochemical monitoring of wastewater from a sugar and ethanol industry after bioaugmentation, with a proposal for reuse. Acta Scientiarum 38 (4): 383–389.

Poddar, P.K., and O. Sahu. 2017. Quality and management of wastewater in sugar industry. Applied Water Science 7 (1): 461–468.

Rajasulochana, P., and V. Preethy. 2016. Comparison on efficiency of various techniques in treatment of waste and sewage water—A comprehensive review. Resource-Efficient Technologies 2 (4): 175–184.

Rajendran, P., J. Muthukrishnan, and P. Gunasekaran. 2003. Microbes in heavy metal remediation. Indian Journal of Experimental Biology 41 (9): 935–944.

Rajeshwari, B.M., A. Kansal, K. Lata, and V.V.N. Kishore. 2000. State-of-the-art of anaerobic digestion technology for industrial wastewater treatment. Renewable and Sustainable Energy Reviews 4: 135–156.

Renu, M.A., K. Singh, S. Upadhyaya, and R.K. Dohare. 2017. Removal of heavy metals from wastewater using electrocoagulation. Materials Today: Proceedings 4 (9): 10534–10538.

Ruffeis, D., W. Loiskandl, S.B. Awulachew, and E. Boelee. 2010. Evaluation of the environmental policy and impact assessment process in Ethiopia. Impact Assessment and Project Appraisal 28 (1): 29–40.

Sahu, O. 2017. Treatment of sugar processing industry effluent up to remittance limits: Suitability of hybrid electrode for electrochemical reactor. MethodsX 4: 172–185.

Salehzadeh, J. 2013. Removal of heavy metals Pb2+ , Cu2+ , Zn2+ , Cd2+ , Ni2+ , Co2+ and Fe3+ from aqueous solutions by using xanthium pensylvanicum. Leonardo Journal of Sciences 12 (23): 97–104.

Saranraj, P., and D. Stella. 2012. Effect of bacterial isolates on reduction of physico-chemical characteristics in sugar Mill effluent. International Journal of Pharmaceutical and Biological Archives 3 (5): 1121–1128.

Siddiqui, W.A., and M. Waseem. 2012. A comparative study of sugar mill treated and untreated effluent—A case study. Oriental Journal of Chemistry 28 (4): 1899–1904.

Srivastava, S., and R. Jain. 2010. Effect of distillery spent wash on cytomorphological behaviour of sugarcane settlings. Journal of Environmental Biology 31: 809–812.

UN-Water. 2017. Wastewater: The untapped resource. UN World Water Development Report 180.

Wei, Y., and X.Y. Jin. 2004. Eco-friendly management of sugar industry effluent in Guangxi, China. Sugar Tech 6 (4): 285–290.

Wu, X., S.J. Cobbina, G. Mao, H. Xu, Z. Zhang, and L. Yang. 2016. A review of toxicity and mechanisms of individual and mixtures of heavy metals in the environment. Environmental Science and Pollution Research 23 (9): 8244–8259.

Zaher, K., and G. Hammam. 2014. Correlation between biochemical oxygen demand and chemical oxygen demand for various wastewater treatment plants in Egypt to obtain the biodegradability indices. International Journal of Sciences: Basic and Applied Research 3 (1): 42–48.

Zhang, C. 2007. Fundamentals of environmetal sampling aand analysis. London: Wiley.

Acknowledgements

We want to thank the Ethiopian Institute of Water Resources, Addis Ababa University, for supervising financial support given by the United States Agency for International Development (USAID) under the USAID/HED funded Grant in Africa–US Higher Education Initiative—HED 052-9740-ETH-11-01. We also like to thank Mr. Ayele and Endris Yesuf for their cooperation and professional assistance at Metahara Sugar Industry and Wonji Research and Development Center, respectively. We also want to thank Metahara sugarcane factory for providing us wastewater samples and Wonji Research and Development Center for transportation support and technical assistance. Finally, we want to acknowledge the support of the Leather Industry and Development Institute for providing us the laboratory analysis facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Fito, J., Tefera, N., Kloos, H. et al. Physicochemical Properties of the Sugar Industry and Ethanol Distillery Wastewater and Their Impact on the Environment. Sugar Tech 21, 265–277 (2019). https://doi.org/10.1007/s12355-018-0633-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-018-0633-z