Abstract

The technical and agricultural planning of sugarcane crops has been crucial to ensure that high-quality millable cane is supplied to the sugar and alcohol industry. This study aimed to evaluate sugarcane development, sucrose accumulation (pol cane), stalk productivity, invertase activity, and ratoon regrowth with the application of plant regulators of the growth inhibitors class [sulfometuron methyl, glyphosate, and compounds from organic carboxylic radicals (C.C.) + glyphosate] for two consecutive years in the middle of the cropping season in Brazil. The treatment with plant regulators made positive influence on the technological quality of millable cane, mainly with regard to increase in the pol content. In weather conditions unfavorable to ripening, the plant regulators sulfometuron methyl and glyphosate were more efficient in increasing the sucrose content than C.C. + glyphosate and control treatments. A positive correlation was also recorded between climate conditions and invertases activity levels, mainly for the neutral invertase (NI). The NI levels under favorable weather conditions to natural ripeness were reported higher than unfavorable conditions to natural ripeness. Sulfometuron methyl increased soluble acid invertase (SAI) and NI activity levels of the sugarcane juice under unfavorable weather condition for ripening while glyphosate applied alone or in association with compounds from organic carboxylic radicals do not change of activity of enzymes. The C.C. + glyphosate and control treatments provided increase in the stalk productivity, while glyphosate reduced the yield. The plant regulators did not affect sugarcane ratoon regrowth.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to expansion of crop areas and the milling period, technical and agricultural planning of sugarcane crops has been essential to ensure the supply of high-quality millable cane, which allows economic extraction during the entire cropping season and improves the profitability of sugar and alcohol production.

Despite the availability of genetic material, we still face problem with the precocity, since harvest of each crop year is anticipated, starting in April and May, or at the same time extends to November and December, and cannot comply with the industry demand for the same levels of pol required for crushing in June and July (Caputo et al. 2007).

Sugarcane crop is subjected to many adverse environmental conditions which affect the maturation of the sugarcane crop in fields (Scarpari and Beauclair 2004). According to Cardozo and Sentelhas (2013), climate has been the major factor affecting sugarcane production in recent seasons in Brazil and atypical weather conditions, such as extensive periods of rainfall, as observed in 2009/2010 season associated with an El Niño event, or extreme and prolonged droughts, such in 2010/2011 associated with a La Niña event, are responsible for unique and sometime undesirable consequences to sugarcane yield as well as quality, which is a clear example of how climate conditions may impact the Brazilian sugar–ethanol sector.

The cropping season of sugarcane in Brazil starts in April with climax in September. The temperature and water availability in the middle of the cropping season in southeastern Brazil, around June and July, make it difficult for the plant to reach maximum pol levels, since the prevailing weather conditions during that time of year favor sugarcane vegetative development with minimum of sucrose accumulation. When expansion of the milling period is planned, weather conditions that are detrimental to natural sugarcane ripening in the beginning of the cropping season are also compromised with the technological quality of millable cane supplied to mills in the middle and especially at the end of the cropping season.

During ripening, sucrose concentration increased in the stalk tissues while reducing sugars such as glucose and fructose decreased through acid or enzymatic hydrolysis. The invertase enzyme is responsible for catalyzing sucrose inversion (Melo et al. 1998). The active sucrose accumulation mechanism seems to be the same in sugarcane, regardless of tissue maturity; however, there are differences between tissues (ripen and immature cane stalks) with respect to sucrose accumulation due to invertase concentrations (Alexander 1973). Invertases, which may also be involved in long-distance sucrose transport by creating a sucrose concentration gradient between phloem loading and unloading sites, thus play an essential role in the partition of photosynthates between storage and growth (Chandra et al. 2012; Ansari et al. 2013). This is an evidence that sucrose metabolism in sugarcane undergoes changes during the development phase of the crop (Kirubakaran et al. 2013). Sugarcane productivity depends upon cane yield and its components traits, whereas sugar yield, as a final product, is greatly influenced by cane yield and quality traits at harvest (Abo El-Hamd et al. 2013).

Economically, ripening is considered as one of the most important processes of sugarcane crop production. The introduction of plant regulators into the crop production has provided greater management flexibility for harvest and is highly relevant for the productivity planning of the crop (Pontin 1995).

Growth inhibitors are natural or synthetic compounds that have the capacity to inhibit growth of the sub-apical meristem, modifying the morphology and physiology of the plants, and may cause qualitative and quantitative yield alterations (Silva and Caputo 2014). By slowing down plant growth, growth inhibitors allow increased sucrose contents, early ripening, increased productivity, and also influenced enzyme activities (invertases) that catalyze sucrose accumulation in the stalks (Lavanholi et al. 2002; Almeida et al. 2003). These compounds can be applied at different seasons (beginning, middle, or end of the cropping season), as they allow vegetative development to be delayed or inhibited, increasing sucrose content as well as stalk productivity. Even under unfavorable weather conditions, application of growth inhibitors provided high-quality millable cane (Almeida et al. 2003; Banasihan et al. 2007; Lavanholi et al. 2002).

Commercially available growth inhibitors act differently on crop—some may delay while others may inhibit sugarcane growth. Both of them, however, act on the balance of produced photoassimilates, favoring the accumulation of these reserves in the stem tissues, thus increasing sucrose content (Meschede et al. 2010). Despite the benefits provided by the growth inhibitors, there are reports that clearly revealed that glyphosate may cause phytotoxicity in the ratoon regrowth of the sugarcane (Leite and Crusciol 2008; Viator et al. 2011). Morgan et al. (2007) indicated that the extent of the carryover effects on the following ratoon crop depends on the variety, so the understanding of these factors would assist to know the knowledge gaps in research.

Therefore , the main objectives of this study were to evaluate sugarcane development and stalk productivity resulting from the application of plant regulators of the growth inhibitors class in the middle of the cropping season and observing its influence in the ratoon regrowth.

Materials and Methods

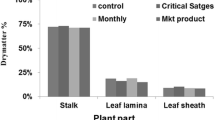

The experiment was performed in ratoon cane (1st cut performed on 10/21/2003) for two consecutive years (2004 and 2005) at Barra Sugar Mill, Igaraçu do Tietê, São Paulo State, southeastern Brazil (latitude 22°38′ 45″S, longitude 48°36′ 29″W, 620 m above sea level). The predominant climate in the region is Aw (Köppen), which is mainly a dry climate with mean annual temperature of 21.6 °C, mean relative humidity of 70 % (maximum 77 % in February and minimum 59 % in August), and annual average rainfall of 1344 mm. The monthly weather data for maximum, medium, and minimum temperatures, precipitation, and wind speed were collected at São Joaquim’s Farm Weather Station and recorded during the experimental period (Fig. 1).

The experiment was arranged in a randomized block design with four treatments and five replications. The treatments consisted of the application of three plant regulators of the growth inhibitors class (sulfometuron methyl, glyphosate, and compounds from organic carboxylic radicals (C.C.) + glyphosate), as well as a control treatment (natural ripening). The commercial products used were the following: Curavial, Roundup, and MTD + glyphosate, respectively, applied at the dose recommended by the manufacturers, i.e., 20 g ha−1, 0.4, and 1 + 0.15 L ha−1, respectively, without the addition of adjuvants. Each plot consisted of 8 rows (10 m long), spaced at 1.5 m. However, for evaluation purpose, only the central six middle rows were considered, disregarding 1 m at the extremities, for a total usable area of 72 m2. Variety SP80-3280 was used in the study, which is known for its high sucrose content and ratoon productivity.

The plant regulators were applied with a CO2 − pressurized backpack sprayer equipped with a 6-m-long, T-shaped boom, containing six AXI 11002 spray tips, at a working pressure of 50 PSI for a 100 L ha−1 flow in October 2004 and April 2005.

The two variables, plant height and stalk diameter, were determined at 0 and 90 days after application (DAA). Height was measured by means of a ruler marked in meters, from the soil surface up to the auricle region of the +1 leaf, according to the numbering system suggested by Kuijper (Dillewijn 1952), while diameter was determined on the 3rd internode above the ground using a digital caliper rule.

The soluble acid invertase (SAI) and neutral invertase (NI) (E.C. 3.2.1.26) activities were determined after milling the stalks to obtain the crude extract. Specific isozyme extract was prepared according to the methodologies described (Hatch et al. 1963; Ricardo and Rees 1970; Vieira et al. 1996a), and this extract was used for SAI and NI determinations. For the NI reaction, 1.25 mL of the extract, 6.25 mL of 50 mM sodium phosphate buffer, pH 7.5, and 2.5 mL 200 mM sucrose were used. The reaction system took place in a double boiler (at 37 °C) for 30 min. Upon cooling, 1 mL Somogyi’s reagent was added and the medium was again taken to a double boiler (37 °C) for another 10 min. Later, 1 mL Nelson’s reagent was added, and readings were taken in a UV/vis spectrophotometer at 530 nm. For the SAI reaction, 1.25 mL of the extract, 6.25 mL of 50 mM sodium acetate buffer, pH 4.5, and 2.5 mL 200 mM sucrose were used. As previously, the reaction system took place in a double boiler (at 37 °C) for 30 min. Upon cooling, 1 mL Somogyi’s reagent was added and the medium was incubated in a double boiler (37 °C) for another 10 min. Later, 1 mL Nelson’s reagent was added, and readings were taken in a UV/vis spectrophotometer at 530 nm.

The pol and total reducing sugars (TRS) were evaluated at the intervals of: 0, 15, 30, 45, 60, 75, 90, and 174 DAA in 2004, and at the intervals 0, 15, 30, 60, and 90 DAA in 2005. The stalks were collected in one meter established at random of two rows of plants of all plots in each sampling season, topped at apical bud height, defoliated, and then forwarded to the Beverage Laboratory at the Department of Agroindustrial Management and Technology, College of Agronomic Sciences, Botucatu campus, for being processed according to the methodology defined in the Sucrose Content-Based Sugarcane Payment System, in accordance with Consecana’s semiannual updates for the technological evaluations described by Fernandes (2003).

Stalk yield at harvest was determined in the four middle rows, mechanically harvesting the plots and weighing the cane using an electronic load cell. The number of stalks was also determined at harvest, by counting the stalks in 10 m line of each plot. Ratoon regrowth was determined at 45 days after harvesting (DAH) by counting the number of shoots in 10 m row within the usable area of each plot, and the corresponding values per meter were calculated later.

The results were subjected to analysis of variance, and treatment means were compared by the LSD test (p ≤ 0.05). The sampling season results were subjected to regression analysis (p ≤ 0.05) by t-test as criterion for choosing the model using the statistical program SISVAR (Ferreira 2008).

Results and Discussion

With decreased precipitation and decline in temperature from July and April, respectively, water and thermal availability in 2004 favored sugarcane vegetative development (Fig. 1a). On the other hand, with lower water availability and temperatures in 2005, the weather conditions favored the natural ripening process (Fig. 1b).

The plant regulators were not effective to inhibit the height growth process of sugarcane plants in 2004 since there was no difference between the treatments or between time samplings (Table 1). In 2005, only the C.C. + glyphosate treatment was not capable of delaying the height growth process significantly, differing from the ripener glyphosate at 90 DAA, which resulted in smaller plant height values (Table 1). Other studies showed reduction in stalk height of sugarcane as a consequence of glyphosate application (Abo El-Hamd et al. 2013; Banasihan et al. 2007; Kirubakaran et al. 2013; Viator et al. 2008); however Viator et al. (2011) concluded that glyphosate use had no influence in the stalk height.

Evaluating the effect of glyphosate in the post-harvest plant development, Meschede et al. (2010) observed interruption of growth in height in the initial plant development, at 30 DAH, but at the end of the cycle, there was no effect of treatments.

The weather conditions that prevailed in each experimental period (Fig. 1), the application season, and the specific mechanism of action of the plant regulators, along with the interactions between these factors, are responsible for the results obtained.

Glyphosate inhibits the activity of the enzyme 5-enolpyruvylshikimate 3-phosphate (EPSP) synthase, which results in preventing the shikimate conversion into chorismate, inhibiting the biosynthesis of the amino acids phenylalanine, tyrosine, and tryptophan, which are precursors of secondary compounds, including plant hormones (Rizzard et al. 2004). Consequently, indole acetic acid (IAA) biosynthesis is inhibited, since it is synthesized from tryptophan (Rodrigues and Leite 2004). Auxins have several effects on plant growth, stimulating elongation and encouraging cell division in stems, consequently affecting plant height growth (Rodrigues and Leite 2004).

The treatments did not induce stalk diameter alterations in 2004, since there was no difference between the treatments or between time samplings. The values found for stalk diameter in control treatment in 2005, within and between seasons, significantly outperformed over the other treatments, which mean that the plant regulators probably affected the integrity of terminal bud reducing the stalk diameter (Table 1). This result can probably be explained by the weather conditions (Fig. 1) and the hormonal balance between auxin and abscisic acid (ABA).

Auxin synthesis, which occurs when terminal bud integrity is maintained, can cause an increase in cell expansion and elongation, while ABA apparently acts upon the stomata and roots, causing stomatal closure and increases the influx of water and ions into the roots which is responsible for an irreversible process of cell growth that requires water absorption, permanent stretching, and synthesis of wall material (Rodrigues and Leite 2004).

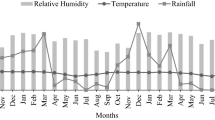

In 2004, SAI activity was higher than NI activity (Fig. 2a, b, respectively); however, in 2005, higher NI levels compared to the SAI levels were observed (Fig. 2c, d, respectively). The isozyme activity was influenced in different ways and intensities according to treatment applied. This observation leads to the deduction that both weather conditions (Fig. 1) and the active principle used as plant regulators influence enzymatic activity.

Acid (SAI) and neutral (NI) invertases (µg glucose 100 g−1 green matter) with the application of control (open square with line), sulfometuron methyl (filled square with dashed line), glyphosate (filled triangle with dashed line), and C.C. + Glyphosate (circle with dashed line) treatments in sugarcane variety SP80-3280, Igaraçu do Tietê, SP, in the 2004 (a, b) and 2005 (c, d) cropping seasons. * and ** are significant at 5 and 1 % probability by the LSD test, respectively

Under conditions of high air temperature and soil moisture, changes in invertase balance result in intense growth; additionally, sucrose accumulation decrease delays ripening (Cardozo and Sentelhas 2013). SAI activity can be high or low, respectively, under favorable vegetative development conditions or unfavorable conditions (water stress, short photoperiod, low temperatures, application of chemical ripeners) (Gayler and Glasziou 1972; Legendre 1975). High levels of the SAI in relation to the NI were reported by Vieira et al. (1996a) in stalks of cultivar CB41-76 sugarcane. They also explained that this fact could be associated with the role played by this enzyme in the growth regulation of immature tissues, corroborating Lingle (1999), who determined a positive correlation between SAI and elongation rate. Grof et al. (2007) found a direct correlation between high sucrose phosphate synthase activity and sucrose accumulation; however, they noted that soluble acid invertase was low in clones with both high and low commercial cane sugar (CCS) and it did not play direct role in the sucrose accumulation.

The research results have determined high NI levels compared to SAI. This relationship could be closely associated with sucrose-accumulating capacity (Sachdeva et al. 2011). Vieira et al. (1996a) also observed lower SAI activity levels than NI in stalks of many sugarcane varieties, in addition to a tendency of decline with plant physiological development, and Vieira et al. (1996b) for sugarcane variety NA56-79.

In general, the treatments exerted significant influence on enzymatic activity only in 2004 (Fig. 2a, b), probably due to the climatic conditions unfavorable to natural ripening. Sulfometuron methyl and glyphosate treatments promoted responses fitted in positive quadratic models for SAI activity. Minimum activity was determined at 18 and 34 DAA, with values of 103.65 and 63.53 μg glucose 100 g−1 green matter, respectively (Fig. 2a). The NI levels for the sulfometuron methyl and C.C + glyphosate treatments showed responses expressed by positive linear and quadratic models, respectively, with the lowest NI activity being determined at 43 DAA, with a value of 50.64 μg glucose 100 g−1 green matter (Fig. 2b).

In 2005, the treatments practically did not have significant influence on the pattern of enzymatic behavior of SAI and NI (Fig. 2c, d, respectively). The SAI activity (Fig. 2c) was not influenced by the treatments, and for NI activity (Fig. 2d), it was observed influence only by the glyphosate treatment as the sampling seasons progressed which promoted linear increase. However, these results are not conclusive about the relationship between the ripeners sulfometuron methyl and glyphosate and the invertases activity.

According to Gayler and Glasziou (1972) and Lingle (1999), SAI activity is responsible for the variations in sugar contents during growth, since it seems to be closely and inversely related to sucrose and total sugar content. There is a correlation between low acid isozyme levels under low temperature conditions (winter) and an increase in sucrose content during the sugarcane ripening process (Terauchi et al. 2000; Zhu et al. 1997); however, Rose and Botha (2000) demonstrated a significant correlation between sucrose content and NI level.

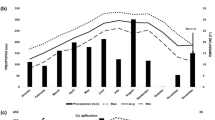

Sucrose accumulation in sugarcane stalks of variety SP80-3280 is shown in Fig. 3. In 2004, an increase in pol cane was observed with the progression of the sampling seasons, and a quadratic fitting was determined for the treatments (Fig. 3a). However, in 2005, the treatments glyphosate and C.C. + glyphosate did not have an effect on this parameter, while the control and sulfometuron methyl treatments fitted well in the quadratic equations (Fig. 3b). This increase in the pol cane is best represented by quadratic equations, since the plant tends to resume vegetative development when the environment provides favorable conditions.

Pol cane (%) with the application of control (open square with line), sulfometuron methyl (filled square with dashed line), glyphosate (filled triangle with dashed line), and C.C. + glyphosate (circle with dashed line) treatments in sugarcane variety SP80-3280, Igaraçu do Tietê, SP, in the 2004 (a) and 2005 (b) cropping seasons. * and ** are significant at 5 and 1 % probability by the LSD test, respectively

In 2004 cropping season, glyphosate and sulfometuron methyl treatments provided maximum pol cane at 168 DAA with values 17.70 and 17.50 %, respectively, while in the C.C. + glyphosate and control treatments such maximum increase occurred 26 days earlier, with values of 15.30 and 15.30 %, respectively (Fig. 3a). It is noted that the pol cane levels achieved through the C.C. + glyphosate and control treatments were, on average, 2.30 % lower than those obtained in the treatments involving glyphosate and sulfometuron methyl (Fig. 3a).

In 2005 cropping season, glyphosate treatment induced maximum pol cane at 66 DAA, with a calculated value of 15.00 %, while the sulfometuron methyl treatment caused a reduction in pol cane up to 17 DAA, with a minimum value of 13.80 % and a later increase in this parameter. At harvest, the pol cane value for the sulfometuron methyl treatment was 15.70 %, while values obtained in the glyphosate, C.C. + glyphosate, and control treatments came around 14.60 %, which represent 1.1 % lower than sulfometuron methyl treatment (Fig. 3b).

With regard to TRS content, it was observed increase with the sampling seasons progression which is probably due to the greater influence exerted by sucrose on total sugars. During the ripening process, there is a decrease in growth intensity, which leads to the decrease in glucose and fructose demand, resulting in sucrose accumulation in the plant (Fig. 4a, b).

Total reducing sugars (TRS, %) with the application of control (filled diamond with line), sulfometuron methyl (filled triangle with dashed line), glyphosate (diamond with dashed line), and C.C. + glyphosate (open triangle with dashed line) treatments in sugarcane variety RB855453, Igaraçu do Tietê, São Paulo, in the 2004 (a) and 2005 (b) cropping seasons. ns not significant. * and ** are significant at 5 and 1 % probability by the LSD test, respectively

The response to all treatments was characterized by a positive quadratic model in 2004 (Fig. 4a), where maximum TRS accumulation was determined at 138 DAA for the control (TRS = 16.40 %) and 165 DAA for glyphosate (TRS = 18.80 %) and sulfometuron methyl (TRS = 18.50 %) treatments. In 2005, the control and sulfometuron methyl treatments fitted a quadratic function (Fig. 4b); however, due to the natural ripening process, an increase and later decline in TRS content were observed, while the application of the plant regulators caused a reduction in TRS content until 25 DAA (TRS = 15.00 %), increasing later.

Although there are other reducing substances found in sugarcane juice, TRS only represent all forms of sugars in sugarcane in the form of reducing or inverted sugars. Since partitioning of sucrose into glucose and fructose is a two-way reaction in plants, i.e., both inversion and combination occur during the plants photosynthesis and respiration metabolism, the knowledge of the TRS content is important to evaluate the quality of millable cane, especially when it is intended for alcohol (ethanol) production (Fernandes 2003).

The plant regulators distinctly modified the ways, the pattern of accumulation and storage of sugars (TRS) in the sugarcane stalks according to their active ingredients (Fig. 4a, b), along with the influence of the weather conditions (Fig. 1a, b) and the seasons of application of the plant regulators and millable cane harvesting.

The TRS values resulting from the application of plant regulators in 2004 reached to higher levels than the control treatment (Fig. 4a), probably due to the interaction between weather (Fig. 1a) and application season, which favored the mode of action of the plant regulator and their implications on plant physiology. On the other hand, in general the plant regulators did not influence the TRS in 2005, probably due to the interaction between the weather, which favored the natural ripening process (Fig. 1b) and the application season.

With regard to the cane harvesting (cutting) season, a TRS content of 17.00 % was determined in 2005 for the sulfometuron methyl treatment at 90 DAA, surpassing the C.C. + glyphosate treatment by 4.20 % and glyphosate and control treatments by 6.70 % (Fig. 4b).

The number of stalks, performed at the harvest (Table 2), did not influence the treatments. The highest stalk productivity in the 2005 cropping season was quantified for the C.C. + glyphosate and control treatments, differing from glyphosate application which, in turn, presented the lowest mass of stalks per hectare. This result can be understood by the processes performed to measure the plant height and stalk diameter parameters (Table 1).

These results corroborate other findings from the literature, which reveal a significant reduction in sugarcane yield due to the glyphosate application (Abo El-Hamd et al. 2013; Viator et al. 2008). On the other hand, there are reports that the use of glyphosate and sulfometuron methyl did not cause negative or significant effects on sugarcane yield components and production (Banasihan et al. 2007; Meschede et al. 2010).

Viator et al. (2011) found that glyphosate application decreased stalk and sucrose yields when post-harvest residue was not removed on the second ratoon crop compared with the control, but when the residue was removed by burning, glyphosate application did not significantly affect cane or sucrose yields. Viator et al. (2008) suggested that the delaying harvest of first ratoon sugarcane until 60 days after the application of a ripener may result in decreased yields in the second ratoon crop.

Richard et al. (2006) reported an increase in total recoverable sugar in the sugarcane treated with glyphosate, but there was no increase in sugar yield due to reductions in cane yield. Millhollon and Legendre (2000) noted that plant stands of glyphosate-sensitive cultivars recovered substantially during the latter part of the growing season and produced relatively normal stalk populations, but the glyphosate treatment in the first-year crop and retreatment in the second-year crop generally reduced stalk weight and sugarcane yield.

Regarding sugarcane ratoon regrowth, the evaluation conducted at 45 DAH showed that the treatments did not significantly affect this parameter, regardless of cropping season (Table 2). For Morgan et al. (2007), treatments of ripeners, including glyphosate, also did not show any effect in the stalk numbers on the following ratoon crop; however, a carryover effect was found on the following variety dependent ratoon crop.

According to Meschede et al. (2010), glyphosate treatment increased the number of tillers in the sugarcane regrowth only at the beginning of the sugarcane growth, until 90 DAH, with subsequent reduction of about 50 %, followed by stabilization.

Conclusions

Our study demonstrated that regulators make positive influence on the technological quality of millable cane, mainly with regard to increase in the pol content; however, its effect in sucrose accumulation is higher when the climate conditions are unfavorable to natural ripening. In weather conditions unfavorable to ripening, the plant regulators sulfometuron methyl and glyphosate were more efficient in increasing the sucrose content than C.C. + glyphosate and control treatments. There is a correlation between climate conditions and invertases activity levels, particularly for the NI levels which is higher in weather conditions that favor natural ripeness. Sulfometuron methyl treatment increases SAI and NI activity levels in weather condition unfavorable to ripeness while glyphosate applied alone or in association with compounds from organic carboxylic radicals do not make any significant change in SAI and NI activity levels. The C.C. + glyphosate and control treatments have increased the stalk productivity, while glyphosate treatment reduced that parameter. The plant regulators did not influence the sugarcane ratoon regrowth.

References

Abo El-Hamd, A.S., M.A. Bekheet, and A.F.I. Gadalla. 2013. Effect of chemical ripeners on juice quality, yield and yield components of some sugarcane varieties under the conditions of sohag governorate. American-Eurasian Journal of Agriculture and Environmental Sciences 13(11): 1458–1464.

Alexander, A.G. 1973. Sugarcane Physiology. Amsterdam: Elsevier.

Almeida, J.C.V., R. Sanomya, C.F. Leite, and N.F. Cassinelli. 2003. Eficiência agronômica de sulfometuron methil como maturador na cultura da cana-de-açúcar. STAB 21(3): 36–37.

Ansari, M.I., A. Yadav, and R. Lal. 2013. An-overview on invertase in sugarcane. Bioinformation 9: 464–465.

Banasihan, V.T., V.V. Macalaguim, and T.C. Mendoza. 2007. Glyphosate as a ripener in sugarcane production in Batangas. Philippine Journal of Crop Science 32(3): 31–45.

Caputo, M.M., M.A. Silva, E.G.F. Beauclair, and G.J.C. Gava. 2007. Acúmulo de sacarose, produtividade e florescimento de cana-de-açúcar sob reguladores vegetais. Interciência 32(12): 834–840.

Cardozo, N.P., and P.C. Sentelhas. 2013. Climatic effects on sugarcane ripening under the influence of cultivars and crop age. Scientia Agricola 70(6): 449–456.

Chandra, A., R. Jain, and S. Solomon. 2012. Complexities of invertases controlling sucrose accumulation and retention in sugarcane. Current Science 102: 857–866.

Dillewijn, C.Van. 1952. Botany of sugar cane. Waltham: Chronica Botanica.

Fernandes, A.C. 2003. Cálculos na agroindústria da cana-de-açúcar. Piracicaba: STAB.

Ferreira, D.F.S.I.S.V.A.R. 2008. A program for statistical analysis and teaching. Revista Symposium 6: 36–41.

Gayler, K.R., and K.T. Glasziou. 1972. Physiological functions of acid and neutral invertases in growth and sugar storage in sugar cane. Plant Physiology 27: 25–31.

Grof, C.P.L., P.L. Albertson, J. Bursle, J.M. Perroux, G.D. Bonnett, and J.M. Manners. 2007. Sucrose-phosphate synthase, a biochemical marker of high sucrose accumulation in sugarcane. Crop Science 47: 1530–1539.

Hatch, M.D., J.A. Sacher, and K.T. Glasziou. 1963. Sugar accumulation cycle in sugarcane. I. Studies on enzymes of the cycle. Plant Physiology 38: 338–343.

Kirubakaran, R., S. Venkataramana, and M.S. Mohamed Jaabir. 2013. Effect of ethrel and glyphosate on the ripening of sugar cane. International Journal of ChemTech Research 5(4): 1927–1938.

Lavanholi, M.G.D.P., A.A. Casagrande, L.A.F. Oliveira, G.A. Fernandes, and R.F. Rosa. 2002. Aplicação de Ethephon e Imazapyr em cana-de-açúcar em diferentes épocas e sua influência no florescimento, acidez do caldo e teores de açúcares nos colmos – variedade SP70-1143. STAB 20(5): 42–45.

Legendre, B.L. 1975. Ripening of sugarcane: effects of sunlight, temperature, and rainfall. Crop Science 15: 349–352.

Leite, G.H.P., and C.A.C. Crusciol. 2008. Reguladores vegetais no desenvolvimento e produtividade da cana-de-açúcar. Pesquisa Agropecuária Brasileira 43(8): 995–1001.

Lingle, S.E. 1999. Sugar metabolism during growth and development in sugarcane internodes. Crop Science 39: 480–486.

Melo, W.J., L.M.A. Bertipaglia, G.M.P. Melo, and V.P. Melo. 1998. Carboidratos. Jaboticabal: Funep.

Meschede, D.K., E.D. Velini, and C.A. Carbonari. 2010. Efeitos do glyphosate e sulfometuron-methyl no crescimento e na qualidade tecnológica da cana-de-açúcar. Planta Daninha 28(1): 1135–1141.

Millhollon, R.W., and B.L. Legendre. 2000. Growth and yield response of Louisiana sugarcane cultivars to annual preharvest treatments with the ripener glyphosate. Sugar Cane International 18: 5–9.

Morgan, T., P. Jackson, L. McDonald, and J. Holtum. 2007. Chemical ripeners increase early season sugar content in a range of sugarcane varieties. Australian Journal of Agricultural Research 58: 233–241.

Pontin, J.C. 1995. Avaliação de maturadores vegetais na cana-de-açúcar. Álcool e Açúcar 77: 16–18.

Ricardo, C.P.P., and T. Rees. 1970. Invertase activity during the development of carrot roots. Phytochemistry 9: 239–247.

Richard Jr, E.P., C.D. Dalley, and R.P. Viator. 2006. Ripener influences on sugarcane yield in Louisiana. Proceedings of American Society of Sugar Cane Technologists 26: 54–55.

Rizzard, M.A., L. Vargas, E.S. Roman, and K. Kissmann. 2004. Aspectos gerais do manejo e controle de plantas daninhas. In Manual de manejo e controle de plantas daninhas, ed. Leandro Vargas and Erivelton Scherer Roman, 105–144. Bento Gonçalves: Embrapa.

Rodrigues, T.J.D., and I.C. Leite. 2004. Fisiologia vegetal – hormônios das plantas. Jaboticabal: Funep.

Rose, S., and F.C. Botha. 2000. Distribution patterns of neutral invertase and sugar content in sugarcane internodal tissues. Plant Physiology and Biochemistry 38: 819–824.

Sachdeva, M., S. Bhatia, and S.K. Batta. 2011. Sucrose accumulation in sugarcane: a potential target for crop improvement. Acta Physiologiae Plantarum 33: 1571–1583.

Scarpari, M.S., and E.G.F. Beauclair. 2004. Sugarcane maturity estimation through edaphic-climatic parameters. Scientia Agricola 61(5): 486–491.

Silva, M.A., and M.M. Caputo. 2014. Ripening and the use of ripeners for better sugarcane management. In Crop management: Cases and tools for higher yield and sustainability, ed. Fabio R. Marin, 2–24. Rijeka: InTech.

Terauchi, T., M. Matsuoka, M. Kobayashi, and H. Nakano. 2000. Activity of sucrose phosphate synthase in relation to sucrose concentration in sugarcane internodes. Japanese Journal of Tropical Agriculture 44: 141–151.

Viator, R.P., C.D. Dalley, and E.P. Richard Jr. 2011. Late-season glyphosate ripener application coupled with post-harvest residue retention impacts subsequent ratoon yields. International Sugar Journal 113(1349): 374–380.

Viator, R.P., R.M. Johnson, E.P. Richard Jr, H.L. Waguespack, and W. Jackson. 2008. Influence of nonoptimal ripener applications and postharvest residue retention on sugarcane second ratoon yields. Agronomy Journal 100(6): 1769–1773.

Vieira, I.M.S., E.T. Oliveira, L.A. Gallo, T.F.C. Batista, R.C. Rodrigues, and O.J. Crocomo. 1996a. Níveis de açúcares e atividade de invertases em cana-de-açúcar (Saccharumofficinalis spp.). I. Cultivares NA56-79 e CB41-76. Revista de Agricultura 71: 67–92.

Vieira, I.M.S., E.T. Oliveira, L.A. Gallo, T.F.C. Batista, R.C. Rodrigues, and O.J. Crocomo. 1996b. Níveis de açúcares e atividade de invertases em cana-de-açúcar (Saccharum spp.). II. Cultivares SP70-1143 e SP71-799. Revista de Agricultura 71: 197–224.

Zhu, Y.J., E. Komor, and P.H. Moore. 1997. Sucrose accumulation in the sugarcane stem is regulated by the difference between the activities of soluble acid invertase and sucrose phosphate synthase. Plant Physiology 115: 609–616.

Acknowledgments

To the Sao Paulo Research Foundation (FAPESP) for financial support (2003/11906-9), to the National Council for Scientific and Technological Development (CNPq) for an award for excellence in research to the first author and to Raízen Group for providing the area where the experiments were carried out.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Crusciol, C.A.C., Leite, G.H.P., de Siqueira, G.F. et al. Response of Application of Growth Inhibitors on Sugarcane Productivity and Sucrose Accumulation in the Middle of Cropping Season in Brazil. Sugar Tech 19, 155–164 (2017). https://doi.org/10.1007/s12355-016-0450-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-016-0450-1