Abstract

Silicone applied to the exterior of jersey-lined neoprene may increase heat absorption and water repulsion without the loss of strength and durability observed in smoothskin neoprene. The purpose of this study was to compare skin temperature under silicone-coated jersey-lined neoprene and smoothskin neoprene during recreational surfing. A secondary purpose was to compare density, tensile strength, and tangent modulus of these materials. Thirty male surfers wore a 2-mm thick wetsuit designed with the chest and back panels on one side constructed of smoothskin neoprene and the other side silicone-coated neoprene (n = 30). Separate surf protocols were carried out in laboratory (n = 10) and field (n = 20) settings while skin temperature was collected bilaterally at the upper chest, upper back, abdomen, and lower back. In the field, skin temperatures under the smoothskin and silicone-coated neoprene were not significantly different at the upper chest, upper back, and lower back. In the laboratory, there were no significant differences in skin temperatures under the two materials at the upper chest and lower back. However, in both studies the skin temperatures were significantly higher under smoothskin neoprene at the abdomen (p < 0.01). In addition, the skin temperature at the upper back in the laboratory study was significantly higher underneath the silicone-coated neoprene (p < 0.01). Silicone-coated neoprene exhibited similar tensile strength but greater tangent modulus compared to smoothskin neoprene. These findings suggest that silicone-coated neoprene and smoothskin neoprene have similar thermal characteristics across most body sites but differ in tensile stiffness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Competitive and recreational surfing have increased in popularity in recent years [1]. Surfing occurs in diverse environments, including water that is far below body temperature [2,3,4,5]. Many surfers wear wetsuits to reduce convective heat loss to improve comfort and prolong the amount of time that they can be submerged in the water without developing hypothermia [3,4,5,6,7,8]. The market for surfing wetsuits is growing rapidly; in North America alone, the total wetsuit market is projected to reach $300 million in 2022 and surfing wetsuits are expected to account for the largest segment at 45% (Grand View Research, Wetsuit Market Size, Share, Industry Report, 2022).

Despite their popularity and widespread use, recent data suggest that there is potential for innovation and improvement in surfing wetsuits [9]. For example skin temperature, a physiological variable that is often used in apparel research to quantify heat transfer and insulation [10,11,12], has been reported to decrease significantly within minutes during a typical surf session while wearing a standard 2 mm thick wetsuit [3, 4, 7, 8]. Heat loss does not occur homogenously across the body because regions that interact more with cold water lose heat faster [3, 4, 7, 8]. Further, regions of the body that are more exposed to air were shown to be warmer under wetsuit materials with outer surfaces that more effectively repel water and absorb radiant heat from the sun [5].

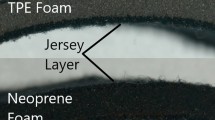

The most common wetsuit material comprised a layer of foamed chloroprene (neoprene) sandwiched between layers of nylon fabric or “jersey” [5,6,7]. In this design or “packaging,” the neoprene provides insulation and the nylon jersey improves the strength and durability of the material [5]. Smoothskin is another type of neoprene packaging that is made by adding heat and pressure to the outer layer of the chloroprene foam (known as embossing), leaving the exterior with a smooth and shiny surface [5]. Smoothskin neoprene is typically combined with a single layer of nylon jersey covering the interior surface of the wetsuit, but the exterior is comprised solely of embossed chloroprene foam. In a recent study, chest and upper back skin temperatures under smoothskin neoprene were 1.5 °C warmer than skin temperatures under jersey-lined neoprene of the same thickness [5]. These findings suggest that the water repellent and radiant heat absorption properties of the smoothskin material may lead to higher skin temperature [5]. However, smoothskin neoprene appears to be less durable than jersey-laminated neoprene and is prone to tearing [13]. Therefore, it would be advantageous to develop a material that combines the desirable thermal properties of smoothskin neoprene with the durability of nylon jersey laminated to neoprene.

Silicone-coated neoprene is a novel design that may exhibit both properties. Liquid silicone material can be applied to the nylon jersey neoprene packaging through a silk-screening process, and a silicone layer would create a smooth and shiny exterior surface that can reproduce the heat absorption and water repellent properties of smoothskin [14]. Also, since the nylon jersey is retained, the composite material retains the strength and durability provided by two layers of nylon jersey. Further, the intrinsic properties of silicone rubber material may enhance the insulation and durability of the wetsuit.

Currently there are no data comparing skin temperatures under silicone-coated neoprene and smoothskin neoprene. There are also no data comparing strength and stiffness of different wetsuit materials, which can impact the biomechanics of surfer’s movement while wearing a wetsuit [7, 15]. Therefore, the purpose of this study was twofold. The first purpose was to determine if skin temperatures were different under silicone-coated neoprene vs smoothskin neoprene, and a second purpose was to determine whether there are differences in material strength, stiffness, and density between standard jersey-lined neoprene, smoothskin neoprene, and silicone-coated jersey-lined neoprene. It was hypothesized that there would be no differences in skin temperature in the upper torso between silicone-coated neoprene and smoothskin neoprene while surfing in field and laboratory-based experiments. Further, it was hypothesized that silicone-coated neoprene would demonstrate the greatest material strength, stiffness, and density when compared to smoothskin and jersey-lined neoprene.

2 Methods

2.1 Participants

Thirty male recreational surfers from San Diego County between the ages of eighteen and forty-five years old were included in either a field or laboratory experiment (Table 1). This study was limited to male participants due to differences in skin temperature profiles between sexes [3, 4, 8]. All participants had at least one year of surfing experience and reported no known injuries. Volunteers who met the inclusion criteria provided their written informed consent before participation and then provided their physical and demographic characteristics as well as information relating to their surfing experience. These data were self-reported and were not verified by the investigators. All procedures were approved by the Institutional Review Board for Human Subjects’ Protection at California State University of San Marcos (IRB # 1302181).

2.2 Experimental protocol

Upon completion of the informed consent and questionnaire, participants (n = 20) were instrumented with ten iButton DS1921L skin temperature thermistors (Maxim Integrated/Dallas Semiconductor Corp., USA), with an accuracy of ± 0.5 °C per manufacturer specifications [16]. The thermistors were attached to the participant using a waterproof 3 M Tegaderm transparent dressing (Nex-care Tegaderm, USA). The ten thermistors were attached to the participants bilaterally at the upper chest (2 cm inferior to the clavicle), abdomen (5 cm below last palpable rib), upper back (2 cm superior to medial aspect of spine of scapula), lateral border of the scapula, and lower back (5 cm from posterior superior iliac spine) (Fig. 1). These sites were selected for consistency with prior research studies [2, 5]. Two additional thermal sensors were placed over the lateral border of the scapula under the standard jersey-lined neoprene packaging for reference to compare with silicone-coated neoprene and smoothskin neoprene (Fig. 2). Skin temperature data were acquired at one-minute intervals for the entire surfing session.

Following instrumentation, participants were fitted into a 2 mm prototype wetsuit with smoothskin neoprene on one half and silicone-coated neoprene on the other (Fig. 2). The experimental materials covered only the torso and shoulders (anterior and posterior), and the arms and legs of the wetsuit were comprised standard jersey-lined neoprene (2 mm thick). The physical appearance of the experimental materials was very similar, and the researcher and the participant were not informed which material was being tested on a specific side of the wetsuit. Wetsuit sizing was based on manufacturer guidelines for participants’ height and weight (Hurley Int., Costa Mesa, CA).

The prototype wetsuits were developed by Hurley International (Costa Mesa, CA) and comprised proprietary neoprene and silicon and were not based on any commercially available model. Six wetsuits (3 sizes: S,M,L and 2 versions: left silicone/right smoothskin and right silicone/left smoothskin) were constructed to allow for randomization of the assignment of materials to each side, thereby eliminating the potential impact that southern sun exposure may have on radiant heat absorption. The smoothskin neoprene occupied more surface area on the wetsuit due to a 2.5 cm margin of jersey lined neoprene between the seams and the silicone-coated neoprene (Fig. 2). After participants had donned their wetsuit, the iButton thermal sensors were palpated from the exterior of the wetsuit to ensure accurate placement under the materials being tested.

For the field study, participants (n = 20) engaged in surfing for at least an hour, which began once they entered the water and ended when the participant exited the water. The final length of their surf session was left to their discretion. Environmental conditions including ambient air temperature, water temperature, relative humidity, sun exposure and wind speed were recorded from the National Oceanic and Atmospheric Administration’s buoys located offshore during each surf session (surfline.com).

A separate laboratory experiment was performed to control more precisely for water temperature and differences in body heat that might occur due to differences in physical activity. After providing informed consent and completing the surfing and activity questionnaire, a separate group of participants (n = 10) were instrumented with ten iButton thermal sensors at the anatomical locations described above and fitted into the appropriately sized experimental wetsuit (same wetsuits used for the field study). Participants then completed a predetermined protocol in an outdoor Endless Pool Elite Model (Commercial Elite Endless Pools ®, Aston, PA) consisting of a custom-sized pool (2.75 m wide, 4.9 m long) and motorized turbine that can generate a constant flow of water against a paddling surfer. The flow of water can be started and stopped to allow for various activities within the simulated surf session. Water temperature was maintained at a constant 16 °C for all participants. This 60-min protocol consisted of resting, duck diving, and paddling against a 1.4 m/s current. Water velocity was measured and verified at one-minute intervals using a flow-watch flow meter (JDC Electronics, Yverdonles-Bains, Switzerland). This protocol was designed to simulate a typical surf session and has been used previously [5, 7, 8]. The predetermined water flow rate was based on the paddling speed of surfers observed in the field [17]. This protocol was repeated continuously for one hour, alternating the rest breaks between sitting and laying. All procedures took place outdoors during the day to simulate a surf session in the field. The laboratory experiment took place about a month after the field experiment, and the laboratory is located 10 miles (16.1 km) inland from the coast.

At the completion of the field or simulated surf session, participants were asked if one side of the wetsuit covering their torso was warmer and if one side was more comfortable. There were only three responses possible for each question: right side, left side, or no difference. No statistical tests were performed on perception data.

2.3 Material analysis

Following both field and laboratory experiments, eight material specimens were taken from three regions of one wetsuit that had been rinsed with freshwater and dried (24 specimens total). The three regions included the upper back on the left and right-hand sides (smoothskin and silicone-coated neoprene) as well as the upper scapular region of the right-hand side, where the wetsuit comprised standard jersey-lined neoprene. All specimens were taken from the same wetsuit to minimize variation in material properties due to differences in use and exposure to environmental conditions. A specialized die cutter and arbor press were used to ensure uniform size and shape of each specimen (ASTM D412-16 with Dog-Bone Type-C specimen) [18]. Care was taken to ensure that nylon fibers in the jersey material ran the same direction for all samples (parallel to the long axis of the sample) [19]. Dimensions of each specimen were verified using digital calipers (Mitutoyo model 500-196-30) and the mass of each specimen was determined by digital scale (model RD303–300 g/1mgRP, Ruishan).

All specimens were dry and at room temperature when tested. The tensile strength and stiffness of each specimen were evaluated using a material testing device (Instron 34SC-2, Norwood, MA) with a 2kN load cell and specialized pneumatic grippers (Instron 2712–042) with serrated surface to maintain an appropriate grip pressure throughout each test. Air pressure to the pneumatic grips was maintained at 6.2 BAR (90 psi), which results in a clamping force of 500N according to manufacturer specifications (Instron 2712 Series Operator’s Manual). Specimens were placed in the grips by hand, first by closing the specimen into the upper grip (via toggle switch) and allowing it to suspend freely. Alignment was confirmed by visual inspection. If the material was not aligned, it was released from the upper grip, repositioned, and then locked again. Once it was aligned properly, the lower grip was closed using the toggle switch. While this process ensured a relatively consistent level of tension in the sample before testing, each sample was visually inspected for slack and/or tension before testing began. All samples were tested in tension, beginning at resting length and stretched at a rate of 500 mm/min (strain rate 4.35 min−1) until the sample failed (complete rupture), per ASTM guidelines [18]. Displacement and force were recorded at 50 Hz. Tensile strength was calculated as the maximum tension recorded at any point during the test divided by the cross-sectional area of the mid-section of the dog-bone shaped specimen (engineering stress–strain curve). Because the stress-stain relationship was nonlinear, the tangent modulus was calculated at 10%, 30%, 50%, and 70% strain for each material (before the yield point).

2.4 Statistical analysis

Water temperature, surf duration, wind speed, and air temperatures between the field and lab-based experiments were compared using independent t-tests. Skin temperatures were analyzed using procedures described previously for experiments with a similar design [2, 5, 7, 20]. First, skin temperature time-series data were downloaded from the individual iButton thermistors onto the One Wire Viewer application and copied into an Excel sheet. Then, data from each thermistor were condensed into 12 intervals of time (epochs) by mean skin temperature in increments of five minutes from minute 1 to minute 60. Field sessions that were longer than 60 min were truncated at the 60-min mark. Data were then imported into RStudio (version 1.4.1106, Boston, MA) and a two-way repeated measures ANOVA (2 materials × 12 epochs of time) was used to evaluate skin temperature across time at each of the four thermistor locations. For locations with a significant main effect for material, separate paired t-tests were performed at each epoch, comparing skin temperatures under smoothskin and silicone-coated neoprene. The Benjamini–Hochberg analysis was utilized to account for false discovery rate [21]. A separate, two-way repeated measures ANOVA was also used to compare wetsuit materials with standard jersey material on the upper back region only. Statistical significance was defined a priori as p < 0.05. Effect sizes were estimated using partial eta squared for ANOVA and Cohen’s d for pairwise comparisons. Data are presented as mean ± standard error (SD) unless otherwise indicated.

3 Results

3.1 Environmental conditions

The mean duration of the surf session in the field experiment was 67.9 ± 12.1 min. There were no significant differences in water temperatures recorded in the field (15.3 ± 1.3 °C, range: 13.9–17.78 °C) and in the laboratory (16 ± 0.0 °C). There were also no significant differences in wind speed recorded in the field (5.4 ± 3.9 mph, range: 1.2 to 12.6 mph) and in the laboratory (6.2 ± 2.6 mph, range: 3.4 to 9.9 mph); however, mean air temperatures were significantly higher in the laboratory (23.7 ± 4.9 °C, range: 16.1 to 30.6 °C) than in the field study (15.7 ± 3.4 °C, range: 11.7 to 25.6 °C) (p < 0.001). Relative humidity was also significantly higher in the field (63.2 ± 22.4%, range: 26 to 97%) than in the laboratory (35.4 ± 23.2%, range: 9 to 79%) (p = 0.004). Lastly, environmental conditions were considered sunny in 90% of the trials performed in the laboratory compared to only 55% of trials during the field studies.

3.2 Thermoregulatory characteristics

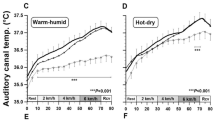

For the field study, a two-way repeated measures ANOVA revealed a significant main effect of time at the upper chest (p < 0.001, \({\eta }_{p}^{2}\) = 0.393), upper back (p = 0.012, \({\eta }_{p}^{2}\) = 0.172), abdomen (p < 0.001, \({\eta }_{p}^{2}\) = 0.712), and lower back region (p = 0.001, \({\eta }_{p}^{2}\) = 0.391) (Fig. 3). There was also a main effect of wetsuit material at the abdomen (p < 0.001, \({\eta }_{p}^{2}\) = 0.508). The interaction effect of wetsuit material by time was significant at the abdomen (p = 0.016, \({\eta }_{p}^{2}\) = 0.166), upper back (p = 0.009, \({\eta }_{p}^{2}\) = 0.147), and lower back (p = 0.045, \({\eta }_{p}^{2}\) = 0.115). Post hoc analysis for the abdomen revealed a significantly higher abdomen skin temperature under the smoothskin material compared to the silicone-coated material for all time epochs between minutes 5 and 60 (all p < 0.001, mean Cohen’s d = 0.57, Fig. 3). For the laboratory study, a two-way repeated measures ANOVA revealed a significant main effect of time at the upper chest (p < 0.001, \({\eta }_{p}^{2}\) = 0.756), upper back (p = 0.022, \({\eta }_{p}^{2}\) = 0.359), and abdomen (p < 0.001, \({\eta }_{p}^{2}\) = 0.909) (Fig. 4). There was also a significant main effect of wetsuit material at the abdomen (p = 0.008, \({\eta }_{p}^{2}\) = 0.558), lower back (p = 0.017, \({\eta }_{p}^{2}\) = 0.484), and upper back (p = 0.003, \({\eta }_{p}^{2}\) = 0.640). Finally, there was a significant interaction effect of wetsuit material by time at the upper (p = 0.017, \({\eta }_{p}^{2}\) = 0.388) and lower back regions (p = 0.004, \({\eta }_{p}^{2}\) = 0.424). Post hoc analysis revealed significantly higher skin temperature under the smoothskin material when compared to the silicone material at the abdomen for epochs between minute 30 and minute 60 (mean p = 0.01, Cohen’s d = 0.88). It also revealed significantly higher skin temperature under the silicone-coated material when compared to the smoothskin material at the upper back for all epochs between minutes 5 and 60 (mean p = 0.002, Cohen’s d = 0.61, Fig. 4).

Comparison of skin temperature differences between the silicone-coated neoprene and the smoothskin neoprene at the upper chest, upper back, abdomen and the lower back while surfing in the ocean. Bars represent standard error of the mean. The asterisk (*) represents a significant difference in skin temperature between the silicone and smoothskin neoprene (p value < 0.05)

Comparison of skin temperature differences between the silicone-coated neoprene and the smoothskin neoprene at the upper chest, upper back, abdomen and the lower back during the laboratory study. Bars represent standard error of the mean. The asterisk (*) represents a significant difference in skin temperature between the silicone and smoothskin neoprene (p value < 0.05)

3.3 Thermoregulatory characteristics: jersey vs. materials

Silicone-coated neoprene and smoothskin neoprene were both compared to the standard jersey material at the lateral upper back region (Fig. 5). In the field experiment, a two-way repeated measures.

Comparison of skin temperature differences between the silicone-coated neoprene, smoothskin neoprene and jersey-lined neoprene at the upper back region during the field and laboratory study. Bars represent standard error of the mean. The asterisk (*) represents a significant difference in skin temperature between the silicone or smoothskin and jersey-lined neoprene (p value < 0.05)

ANOVA revealed a significant main effect of time, a significant main effect of material, and a significant interaction effect of wetsuit material by time for comparisons of both silicone (all p < 0.001, \({\eta }_{p}^{2}\) = 0.372–0.887) and smoothskin neoprene (all p < 0.001, \({\eta }_{p}^{2}\) = 0.344–0.843) versus standard jersey neoprene. Post hoc analysis revealed significantly higher skin temperatures under both the silicone-coated material (all p < 0.001, mean Cohen’s d = 1.83) and smoothskin material (all p < 0.001, mean Cohen’s d = 1.83) when compared to the standard jersey material at all time points.

In the laboratory experiment, a two-way repeated measures ANOVA revealed a significant main effect of material and a significant interaction effect of wetsuit material by time for comparisons of both silicone-coated neoprene (p < 0.001, \({\eta }_{p}^{2}\) = 0.795–0.878) and smoothskin neoprene (p < 0.001, \({\eta }_{p}^{2}\) = 0.692–0.891) versus standard jersey neoprene. Post hoc analysis revealed significantly higher skin temperatures under both the silicone-coated material (mean p < 0.001, Cohen’s d = 1.72) and smoothskin material for minutes 5 through 60 (mean p < 0.001, Cohen’s d = 2.41) when compared to the standard jersey material.

3.4 Perception

When data from both experiments were pooled, a total of 20 out of 30 (66.7%) participants reported equal comfort between wetsuit sides (Table 2). A total of 21 out of 30 (70%) participants reported feeling equally warm between wetsuit sides (Table 3).

3.5 Materials testing

The smoothskin neoprene was 0.5 mm thicker than the silicone-coated neoprene and 0.4 mm thicker than the standard jersey-lined neoprene (Table 4) due to differences in the fabrication process. The smoothskin neoprene also exhibited the greatest density of the three types of wetsuit material. All three types of neoprene exhibited similar tensile strength but exhibited different behavior at failure. The smoothskin neoprene failed suddenly at 223.8 ± 8.6% strain, whereas the jersey-lined and silicone-coated neoprene failed in two stages: first the neoprene material ruptured at 115 ± 16.7% strain (both jersey and silicone coated), followed by failure of the nylon jersey material at 179.2 ± 33.3% (jersey lined) and 213.9 ± 22.0% (silicone coated) strain. Tangent modulus results indicated that smoothskin exhibited the lowest stiffness of the 3 materials up to 70% strain, suggesting that it may provide the least resistance to movement. The silicon-coated neoprene package exhibited the greatest stiffness at lower amounts of strain (10%, 30%) but jersey-lined neoprene exhibited greatest stiffness at 50% and 70% of strain (Table 4, Fig. 6).

Tensile stress vs strain curves for 3 different wetsuit materials. Jersey: standard neoprene lined with jersey on both sides. Silicone: standard neoprene lined with jersey on both sides and a silicone coating applied to the outer surface. Smoothskin: standard neoprene heated and embossed on the outer surface and nylon jersey on the interior surface. Each curve represents the average of eight uniform samples. All samples were tested until failure, but data are only presented here up to 0.75 (or 75%) strain, an approximation of the range of strain that a wetsuit might realistically experience in the field

4 Discussion

The purpose of this study was to determine if silicone-coated neoprene provides similar insulation to smoothskin neoprene, and to determine whether there are differences in density, tensile strength, and tangent modulus between wetsuit materials. There were several novel findings. First, skin temperatures under silicone-coated neoprene were significantly higher than those under standard jersey neoprene in the upper back. Second, skin temperatures under silicone-coated neoprene were similar to those under smoothskin neoprene in the upper chest and lower back. Third, skin temperatures under silicone-coated neoprene were significantly lower than those under smoothskin neoprene in the abdomen. Fourth, skin temperatures under silicone-coated neoprene were significantly higher than those under smoothskin neoprene in the upper back during laboratory studies. Fifth, the majority of participants did not perceive differences in comfort or warmth between the wetsuit materials. Finally, when the material properties of these different neoprene packages were compared, the silicone-coated neoprene exhibited greater stiffness when compared to smoothskin neoprene, but comparable stiffness when compared to standard jersey-lined neoprene. Taken together, these findings suggest that silicone-coated neoprene is a potential alternative to smoothskin neoprene for wetsuit design.

The smoothskin neoprene packaging utilized here was on average 0.5 mm thicker than the silicone-coated neoprene and jersey-lined neoprene packaging (Table 4), and this may have impacted the insulating behavior of each material [6, 20]. However, skin temperatures under silicone-coated neoprene were either not different or warmer than skin temperatures under smoothskin neoprene for three of the four locations compared here. This suggests that a thinner packaging of silicone-coated neoprene can achieve a similar thermoregulatory effect to that of smoothskin in multiple anatomical locations. A thinner, more efficient wetsuit package is desirable because it may also have a beneficial effect on movement biomechanics through reduced mass and material stiffness [15].

Recently published data established that upper back skin temperature under smoothskin neoprene was on average ~ 1.5 °C higher compared to skin temperature under standard jersey neoprene due to its radiant heat absorption and water repellent properties [5]. The current results are consistent with these previous findings, since significantly higher skin temperatures were found under the smoothskin neoprene compared to jersey material at the upper back (Fig. 5). Similarly, upper back skin temperatures under silicone-coated neoprene were also significantly higher than skin temperatures under standard jersey neoprene (Fig. 5).

4.1 Smoothskin vs silicone-coated neoprene—thermal results

At the upper back, skin temperatures under silicone-coated neoprene were significantly higher than those under smoothskin neoprene in the laboratory study but not in the field. It is well known that between 2 and 16% of the total time surfing consists of miscellaneous activities where the upper back of the surfer is directly interacting with the water (i.e., swimming, diving under waves, and falling after riding waves) [22]. The difference in skin temperature found in the laboratory may be a result of the upper back interacting with the water less than during experiments in the ocean since in the laboratory setting the upper back of the participants only interacted with the water briefly when duck diving between rest and paddling phases. Skin temperature differences in the upper back between laboratory and field setting may also be attributed to differences in environmental conditions. Specifically, ambient air temperature, humidity, and sun exposure differed between research settings. These factors suggest that silicone-coated neoprene may absorb radiant heat from the sun more effectively than smoothskin neoprene at the upper back in conditions with warmer air temperature, higher exposure to the sun and minimal relative humidity. However, without direct measure of radiation-mediated heat absorption, these conclusions are speculative. Additional study is needed to determine the exact mechanisms behind differences in skin temperature under different neoprene packages.

In both the laboratory and field experiments, no significant differences were found between the skin temperatures under the smoothskin neoprene and silicone-coated neoprene at the lower back and chest. During paddling and resting phases, the lower back and chest experience greater exposure to the water and less exposure to radiant heat from the sun than the upper back. These findings support the previous assertion that relative exposure to water, sun and air likely contribute to the insulation capacity of smoothskin and silicone-coated neoprene [5]. Therefore, in conditions where there is intermittent interaction with water and sun exposure, smoothskin neoprene and silicone-coated neoprene may provide very similar insulation.

Skin temperatures under the smoothskin neoprene were significantly warmer than the skin temperatures under silicone-coated neoprene at the abdomen (Fig. 3). Similar findings at the abdomen were also observed in the laboratory (Fig. 4). It is interesting that the abdomen is the only location where skin temperatures under the smoothskin were greater than those under silicone-coated neoprene. These differences in skin temperatures may be influenced by lack of sun exposure and more consistent interaction with cold water during prone paddling and resting while surfing. Skin temperatures at the abdomen may also be influenced by differences in neoprene package thickness, since the silicone-coated neoprene was 0.5 mm thinner than the smoothskin neoprene.

The combined results of this study suggest that silicone-coated neoprene would have the greatest impact on thermoregulation when applied to the regions of the body that are most exposed to radiant heat from the sun. These regions include the upper chest, shoulders, and the upper and lower back. Conversely, this material may have little impact on thermoregulation when used in the abdomen of wetsuits due to greater exposure to cold water. In addition, recent research that reported no differences in skin temperature at the abdomen when smoothskin was compared to standard jersey neoprene [5]. Therefore, since jersey material provides greater durability than smoothskin material, the combined results suggest that jersey-lined neoprene should be utilized at the abdominal region. By the same logic, silicone-coated neoprene should also not be placed in the lower extremities due to the higher interactions with cold water and lack of sun exposure.

4.2 Mechanical results

These results suggest that adding silicone increases material density to a level that is greater than standard jersey-lined neoprene, but less than or comparable to that of smoothskin (Table 4). Unexpectedly, the silicone-coated neoprene did not exhibit greater tensile strength than the smoothskin neoprene (Table 4). The stiffness of the material is an important factor in predicting its impact on an athlete’s movement. It is interesting that smoothskin neoprene exhibited less than 33% of the stiffness (i.e., tangent modulus) of silicone-coated neoprene up to 70% strain (Table 4, Fig. 6). However, the silicone-coated neoprene exhibited similar stiffness to that of the standard jersey-lined neoprene, suggesting that adding a silicone coating will have minimal impact on movement biomechanics when these two packages are compared. The impact of a silicone-coated neoprene on human movement should be evaluated in a future study.

The combination of multiple materials into a composite package has a complex effect on material strength and stiffness. The current data suggest that silicone coating contributes more to overall package stiffness at smaller amounts of stretch. This effect can be seen in Fig. 6 where both the jersey-lined and smoothskin neoprene curves exhibit reduced slopes at lower strain (e.g., 10–30%) than the silicone-coated neoprene. It is also interesting that the jersey-lined neoprene exhibits a clear increase in stiffness at around 50% strain, which may indicate that the nylon jersey fibers become more engaged at this level of stretch. It should also be noted that there were differences in behavior of the different materials at failure. Smoothskin neoprene tended to fail/rupture more abruptly, while the jersey-lined neoprene failed in two stages. The inconsistent behavior at failure among materials was a limitation to the current study. Future research should incorporate methods that limit this effect, potentially using other sample shapes such as those recommended for fabric. In addition, a closer examination of tearing would improve understanding of the durability of each material. While this analysis provides some initial insight into the mechanical properties of these materials, additional research is needed to provide a more detailed analysis of the behavior of different neoprene packages. Finally, additional research is needed to evaluate the environmental impact of silicone in the manufacture and disposal of wetsuits, including additional energy costs associated with production. Neoprene wetsuits are difficult to recycle and/or dispose of properly and a silicone coating may add to this challenge.

4.3 Conclusion

The findings from this study demonstrate for the first time that silicone-coated neoprene results in comparable skin temperatures when compared to smoothskin neoprene in regions that have intermittent interactions with water and exposure to radiant heat from the sun. In addition, silicone-coated neoprene exhibited comparable tensile strength and greater stiffness when compared to smoothskin neoprene. Additional study is needed to determine the impact of silicone-coated neoprene on human movement, particularly the paddling motion. The impact on thermoregulation observed here suggests that manufacturers should consider the application of a silicone coating for specific regions of their wetsuits to increase insulation capacity and durability.

Data availability

Data and material are available upon request.

Code availability

Code available upon request.

References

Moran L, Webber J (2013) Surfing injuries requiring first aid in New Zealand, 2007–2012. Int J Aquatic Res Ed 7:192–203

Denny A, Moore B, Newcomer SC, Nessler JA (2022) Graphene-infused nylone fleece versus standard polyester fleece as a wetsuit liner: comparison of skin temperatures during a recreational surf session. Res J Text Appar Press. https://doi.org/10.1108/RJTA-07-2022-0079

Corona LJ, Simmons GH, Nessler JA, Newcomer SC (2018) Characterization of regional skin temperatures in recreational surfers wearing a 2mm wetsuit. Ergonomics 61(5):729–735. https://doi.org/10.1080/00140139.2017.1387291

Warner ME, Nessler JA, Newcomer SC (2019) Skin temperatures in females wearing a 2mm wetsuit during surfing. Sports 7(6):145. https://doi.org/10.3390/sports7060145

Smith C, Saulino M, Luong K, Simmons M, Nessler JA, Newcomer SC (2020) Effect of wetsuit outer surface material on thermoregulation during surfing. Sports Eng 23(1):1–8. https://doi.org/10.1007/s12283-020-00329-8

Naebe M, Robins N, Wany X, Collins p (2013) Assessment of performance properties of wetsuits. J Sports Eng Technol 227:25–264

Wiles T, Simmons M, Gomez D, Schubert MM, Newcomer SC, Nessler JA (2022) Foamed neoprene versus thermoplastic elastomer as a wetsuit material: a comparison of skin temperature, biomechanical, and physiological variables. Sports Eng. https://doi.org/10.1007/s12283-022-00370-9

Skillern NP, Nessler JA, Schubert MM, Moore B, Newcomer SC (2021) Thermoregulatory sex differences among surfers during a simulated surf session. Sports Eng. https://doi.org/10.1007/s12283-021-00353-2

Romanin A, English S, Furness J, Kemp-Smith K, Newcomer SC, Nessler JA (2021) Surfing equipment and design: a scoping review. Sports Eng. https://doi.org/10.1007/s12283-021-00358-x

Jiao J, Li Y, Yao L, Chen Y, Guo Y, Wong SHS, Frency SFN, Hu J (2015) Effects of body-mapping-designed clothing on heat stress and running performance in a hot environment. Egonomics 60(10):1435–1444

Schindelka B, Litzenberger S, Sabo A (2013) Body climate differences for men and women wearing functional underwear during sport at temperatures below zero degrees Celsius. Proc Eng 60:46–50

Domenico ID, Hoffmann SM, Collins PK (2022) The role of sports clothing in thermoregulation, comfort, and performance during exercise in the heat: a narrative review. Sports Med. https://doi.org/10.1186/s40798-022-00449-4

Co., CS. The Wetsuit Guide. [cited 2023 1/30/2023]; Available from: www.cleanlinesurf.com/wetsuit-guide/

Balan G, Panikker UG (2006) Chemical, water, and thermal durability of silicone rubber/ethylene vinyl acetate blends. Mat Res Innov 10(3):305–320

Nessler JA, Silvas M, Carpenter S, Newcomer SC (2015) Wearing a wetsuit alters upper extremity motion during simulated surfboard paddling. PLoS ONE. https://doi.org/10.1371/journal.pone.0142325

Maxim Integrated Products, I (2015) DS1922L Technical Specifications, M.I.P. Inc., Editor.

Farley O, Harris NK, Kilding AE (2012) Anaerobic and aerobic fitness profiling of competitive surfers. J Strength Cond Res 26(8):2243–2248

ASTM International. D412-16 (2021) Standardized test methods for vulcanized rubber and thermoplastic elastomers - tension. https://doi.org/10.1520/D0412-16R21

Vlad, D and M Oleksik (2019) Research regarding uniaxial tensile strength of nylon woven fabrics, coated and uncoated with silicone, in 9th International Conference on Manufacturing Science and Education: Sibiu, Romania

Kellogg D, Wiles TNJA, Newcomer SC (2020) Impact of velcro cuff closure on forearm skin temperature in surfers wearing a 2mm and 3mm wetsuit. Int J Exerc Sci 13(6):1574–1582

Benjamini Y, Hochberg Y (1995) Controlling the false discovery rate: a practical and powerful approach to multiple testing. J Royal Statist Soc 57(1):289–300

LaLanne CL, Cannady MS, Moon JF, Taylor DL, Nessler JA, Crocker GH, Newcomer SC (2017) Characterization of activity and cardiovascular responses during surfing in recreational male surfers between the ages of 18–75 years old. J Aging Phys Act 25(2):182–188. https://doi.org/10.1123/japa.2016-0041

Funding

No funding was obtained for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors state no conflicts of interest.

Ethical approval

Experimental procedures were approved by the California State University-San Marcos Institutional Review Board (IRB#1302181).

Consent to participate

All participants provided their informed consent prior to participation.

Consent for publication

All authors approve submission of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is a part of Topical Collection in Sports Engineering on Surf Engineering, Edited by Prof. Marc in het Panhuis, Prof. Luca Oggiano, Dr. David Shormann and Mr. Jimmy Freese.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Paterson, M., Moore, B., Newcomer, S.C. et al. Insulation and material characteristics of smoothskin neoprene vs silicone-coated neoprene in surf wetsuits. Sports Eng 26, 23 (2023). https://doi.org/10.1007/s12283-023-00417-5

Accepted:

Published:

DOI: https://doi.org/10.1007/s12283-023-00417-5