Abstract

Growing potato conventionally for dehydration is not economically feasible. The key cost would be seed under organic farming. The objective is to identify seed-piece sizes and spacings producing a profitable return for potato dehydration in western Nebraska. Atlantic potatoes were grown under dryland conditions using organic practices. Rain was 205, 270, and 360 mm in 2013, 2014, and 2015. Seed-pieces were hand-cut into five weights from 42.5 to 85.0 g and planted in five spacings from 15.2 to 45.7 cm. Seeding rates were 1.02 to 6.1 Mg/ha. Yield was highest at the spacing of 15.2 cm (16.1 Mg/ha) and decreased to 12.4 Mg/ha when seed-pieces were planted at 38.1 and 45.7 cm apart. Seed-piece size had little effect except that yield was lowest with 42.5 g pieces at 13.2 Mg/ha and increased to 14.2 Mg/ha with 63.8 g and larger. Specific gravity decreased slightly when pieces were spaced 30.5 cm (1.092) compared to 15.2 cm (1.094). Seed size had no effect. The size and spacing combinations with the highest yield were not found to be economical due to higher seed cost. Planting seed-pieces weighing 56.7 g, and planted 38.1 and 45.7 cm apart in 91 cm rows were economically feasible for dry matter production. The net returns, taking into account seed cost, transportation, and operations, for this combination was $326/ha, greater than for dryland winter wheat and millet. This study showed that western Nebraska would be a good location to grow dryland potatoes for organic dry matter production.

Resumen

Cultivar la papa convencionalmente para deshidratación no es económicamente factible. El costo clave sería la semilla bajo siembra orgánica. El objetivo es identificar los tamaños de fragmentos de semilla y espaciamientos que produzcan un ingreso con ganancia para deshidratación de la papa en el oeste de Nebraska. Se cultivaron papas Atlantic bajo condiciones de suelo seco usando prácticas orgánicas. La lluvia fue de 205, 270 y 360 mm en 2013, 2014 y 2015. Se cortaron a mano los fragmentos de semilla en cinco pesos, de 42.5 a 85.0 g, y se plantaron en cinco espaciamientos de 15.2 a 45.7 cm. Los niveles de semilla fueron de 1.02 a 6.1 Mg/ha. El más alto rendimiento se obtuvo con el espaciamiento de 15.2 cm (16.1 Mg/ha) y disminuyó a 12.4 Mg/ha cuando los fragmentos de semilla se plantaron a 38.1 y 45.7 cm de distancia. El tamaño del fragmento de semilla tuvo poco efecto, excepto que el rendimiento fue el más bajo con piezas de 42.5 g a 13.2 Mg/ha y aumentó a 14.2 Mg/ha con 63.8 g y más grandes. Las gravedad específica disminuyó ligeramente cuando los fragmentos se espaciaron a 30.5 cm (1.092) en comparación con 15.2 cm (1.094). El tamaño de la semilla no tuvo efecto. Las combinaciones de tamaño y espaciamiento con el rendimiento más alto no se vio que fueran económicas, debido al costo más alto de semilla. Al sembrar piezas de semilla con peso de 56.7 g, a separaciones de 38.1 y 45.7 cm entre ellas, en surcos a 91 cm, fue económicamente posible para la producción de materia seca. La recuperación neta, tomando en consideración el costo de semilla, transporte y operaciones, para esta combinación, fue de $ 326/ha, mayor que para trigo de invierno y mijo en suelo seco. Este estudio mostró que el oeste de Nebraska pudiera ser un buen lugar para cultivar papa en suelo seco para producción de materia seca orgánica.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the early twentieth century, many dryland acres in Nebraska were dedicated to growing potatoes as a major subsistence crop (Pavlista 2015). This changed when consumers demanded a high quality potato for chips and fries. Pesticide use increased and potatoes were grown under center-pivot irrigation for greater yield and improved quality. Potatoes grown for starch and dry matter production (i.e. dehydrated), do not need to be and usually are not market quality. Cull potatoes (unmarketable due to shape, blemishes, etc.) are stripped off from marketable potato production (tablestock, chip, fry, seed) and sold for dehydration. Under irrigation and normal-input practices, it is not economically feasible for potatoes to be grown for the dehydration industry. But, for dry matter production, tuber quality, specifically external defects, are not marketing factors. The key factor is dry matter yield. Most of the cost of production would be the price of seed potato tubers themselves. Using organic production practices, potato dry matter and starch could be used in organic-based dehydration products. There has not been any completed study of growing potatoes specifically for dry matter production using sustainable agricultural practices under semi-arid conditions. Western Nebraska is an ideal location for such a study due to its rich soil, dry climate, and low disease and insect pressures.

In a study on Irish Cobbler, Houghland and Parker (1948), comparing row spacing, in-row seed spacing and fertilizer rate, stated “... seed spacing was found to have the greatest influence on yield ...” They observed that in two of three years under non-irrigated conditions, increasing seed spacing in the row from 25 to 38 to 46 cm decreased yield. Since then, there have been several studies on several cultivars that reported the same conclusion (Love and Thompson-Johns 1999; Rex et al. 1987; Rex 1991). Arsenault et al. (2001) compared several cultivars at seed spacings of 25, 30, and 36 cm under rain-fed conditions over five years. Two years had above normal rain (>48 cm), two below normal rain (<39 cm), and one near normal rain (43 cm). They reported that, in general, yield decreased as seed spacing increased. On the other hand, Entz and LaCroix (1984) reported no yield effect on Russet Burbank when seed spacing was increased from 30 to 46 to 61 cm. Among the many cultivars studied, increasing seed spacing decreased yield of Atlantic when grown under irrigation for maximum yield and chip quality (Creamer et al. 1999; DeBuchananne and Lawson 1991; Rykbost and Maxwell 1993). The range of seed spacing in these studies was from 15 to 46 cm. Zebarth et al. (2006) tested Atlantic under rain-fed conditions with the same observation where one year had low rainfall and high temperature resulting in lower yield while the other year had high rainfall and low temperature resulting in higher yield.

Seed-piece size has been studied much less than seed-piece spacing. Kleinhenz and Bennett (1992) observed no effect of size on yield of Atlantic when seed weights between 35 and 58 g were planted under non-irrigated but wet conditions. Studying three russet cultivars in Oregon, Rykbost and Locke (1999) observed that increasing seed weight upto 50 g corresponded with increasing yield with no significant yield difference using seed larger than 50 g.

Combinations of seed-piece spacing with seed-piece size have been studied under irrigated conditions for maximum yield and quality. Bishop and Wright (1959) observed that White Rose yield was increased by planting 57 g seed-pieces versus smaller seed and planting at 19 cm versus 38 cm in 81 cm rows. They concluded that “Planting more than approximately 16 sacks of seed potato per acre (1.8 Mg/ha) did not increase the yield sufficiently to justify the greater expenses.” Studies on Russet Burbank gave similar results (Iritani et al. 1972; Schotzko et al. 1984) concluding that optimal yields occurred when seed-piece weight was 57 g and seed spacing was 23 cm. Bohl et al. (2011) observed that, across three russet cultivars, yield increased to seed-piece size of 64 g and spacing of 30 cm. They also reported that there was no difference in yield for the same amount of seed planted regardless of seed-piece size or spacing. Under adequate rainfall conditions, Smith et al. (1943) reported that for Sebago, yield increased with 57 g seed-piece versus 43 g and with 28 cm spacing versus 36 cm. Pioneer Rural in that study showed no consistent effect. In the United Kingdom, similar studies agreed with those showing a positive effect on yield by larger seed and closer spacing (Bremner and Taha 1966; Wurr 1974). Both studies also showed a varietal difference as Smith et al. (1943) and that differences due to spacing was greater in a drier year.

The objective of this study is to produce a high-yielding potato crop with high dry matter under dryland conditions utilizing the principles of sustainable agriculture to keep costs to a minimum. Therefore, to lower potato seed tuber cost, determining the most economical seed-piece size and spacing of a high-starch cultivar is essential. The specific objective is to lower production costs by compare five plant spacings and five seed-piece weights for one high-yielding and high-dry matter containing potato cultivar, Atlantic, the principle potato chip cultivar grown in Nebraska. The aim is to develop a sustainable seed-piece planting strategy for economic feasibility based on seed tuber costs, farming operations inputs, and price for starch potatoes by dehydrators.

Materials and Methods

Field Conditions

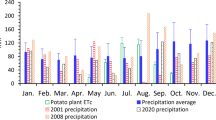

In 2013, 2014 and 2015, dryland trials on potato (Solanum tuberosum L.) cultivar Atlantic were conducted at the University of Nebraska’s Panhandle Research and Extension Center, Scottsbluff, NE (lat. 41.9 N, long. 103.7 W, elevation 1126 m). A Tripp fine sandy loam soil at pH 8.0 with an organic matter content of 1 % was the soil characteristic. Pre-plant soil N levels in the top 20 cm were 24, 26, and 21 kg ⋅ ha−1 for each year respectively. No fertilizer was added. Previous crops were dry bean (Phaseolus vulgaris L.) in 2013 and 2014, and potato in 2015. Soil water content in the top 20 cm at planting was 16 to 17 % or 75 % of saturation. No irrigation was added. Rainfall and temperature were monitored by the High Plains Regional Climate Center (Changnon et al. 1990) and presented for each year by month with comparison to the 30-year mean in Table 1. In keeping with the objectives of minimizing cost and growing the crop under organic conditions, no pesticides were applied. Weed control was accomplished by cultivation. Plots were cultivated between planting and emergence with a sub-soiler to rip the centers and break compaction. At the start of emergence, rows built up using a ridger with discs. Later in June, a Lilliston cultivator was used for the last cultivation to control weeds. There was a total of three cultivation passes each year.

Experimental Conditions

Untreated tubers were cut and stored at 16 °C to heal for two to three weeks, and planted on 10 May 2013, 15 May 2014 and 13 May 2015. Seed tubers were cut to five weight classes, 42.5, 56.7, 63.8, 70.9, and 85.0 g (1.5, 2.0, 2.25, 2.5, and 3 oz) using a customized, variable hand-operated cutting block. Seed-pieces were individually weighed, and counted per plot row and placed in buckets for planting. Planting was with a custom-built, horizontal-cup planter to allow for precision planting. Seed-pieces were planted in five plant spacings, 15.2, 22.9, 30.5, 38.1, and 45.7 cm (6, 9, 12, 15, and 18 in. apart. The seeding rate for each size and spacing combination is presented in Table 2. The seeding range was from 1.02 to 6.10 Mg/ha. Plots consisted of four rows spaced 91 cm apart and 13.7 m long. Emergence (50 %) occurred 18 to 20 days after planting. Vines were senesced (90–100 %) by the end of September. Vines were not flailed in 2013 and 2014, but were in 2015 a week before harvest. Harvests were on 22 Oct 2013, 16 Oct 2014, and 13 Oct 2015 using a custom-built, one-row harvester. Only the center two rows were harvested.

Data Collection

Stand count of emerged plants were taken by counting plants in the two center rows in mid June, two to three weeks after emergence and dividing that by the number of seed-pieces planted to calculate percentages. Plot weediness was visually estimated based on percent ground covered by weeds on a scale of 0 to 100 % before harvest in early Oct. Plant senescence was visually determined in mid Sep. in 2013, and before harvest on 2 Oct in 2014 and 2015. The center two rows of each plot were individually estimated for senescence by the comparison of brownness versus greenness of plants in the row. Tuber yield and specific gravity were measured one to two weeks after harvest. Tubers were graded using a chain conveyor, eliminating those with a diameter less than 47 mm. Specific gravity was measured on 3.6 kg samples of tubers with a diameter greater than 57 mm using a Snack Food Association hydrometer (Gould and Plimpton 1985; Pavlista 1997). Plots were placed in a Latin Square design with five replications. Data were analyzed as a factorial comparison of seed-piece weight versus seed-piece spacing using Proc ANOA in SAS with means separated using least significant differences and inferences based on a 5 % significance level (SAS Institute 2003) when p < 0.05. Possible interactions between weight and spacing were determined as well.

Economic Costs

All monetary values are given in U.S.A. currency. In calculating costs, it was assumed that land for dryland wheat would be used and that the land would be owned with no liens. The University of Nebraska-Lincoln Crop Budgets reported that the tax on non-irrigated wheat land in western Nebraska is $37 /ha ($15 /a). Fixed operating costs including fuel, labor and equipment depreciation consisted of planting at $49.40 /ha ($20 /a), harvesting at $74.10 /ha ($30 /a), and three cultivation passes totaling $49.40 /ha ($20 /a) (grower communications). Total fixed cost, operating plus tax, was estimated at $210 /ha ($85 /a) for calculating profit. Transportation cost for a non-refrigerated semi-truck, hauling 25 Mg (550 cwt), was $1.05 /km ($1.70 /mi). The distance from Imperial NE to Wray CO, where a dehydration plant was operating until recently, was 120 km (75 mi). Therefore, the transportation cost was $127 per load or $5.08 /Mg ($0.23/cwt) (grower communications). The cost of shipping from Imperial to Wray equaled the yield (Mg/ha) multiplied $5.08 /Mg [yield (cwt/a) multiplied by $0.23/cwt]. The actual amount varied based on yield. Seed purchase of cv. Atlantic from the Panhandle of Nebraska was $22 /100 kg ($10 /cwt) plus $2.20 /100 kg ($1 /cwt) for cutting and less than $2.20 /100 kg ($1 /cwt) for shipping [Alliance NE to Imperial NE calculated as 320 km (200 mi) at $1.2 /km with a 18.1 Mg (400 cwt) load] or $264 /Mg ($12 /cwt) (grower communications). Seed cost varied depending on seed-piece weight and spacing. It was assumed that the harvest would go to dehydration from the field and therefore storage costs were not considered. Note that there was no cost for irrigation, fertilization, pesticides, or application of any of these as this study was conducted under dryland organic conditions.

Results

Field Observations

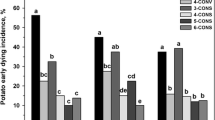

Plant stand averaged between 64 and 80 % (Table 3). The stand of seed-piece spacings of 15.2 and 22.9 cm were lower than that of spacings 30.5 to 45.7 cm. The seed-piece weight of 42.5 g gave a lower stand than the other four weights. Note that 42.5 g seed-pieces are not recommended for planting. There was no interaction between seed-piece spacing and weight on stand. Years were significantly different (Table 3). Weediness of the plots were estimated before harvest. When seed-piece spacing was between 30.5 and 45.7 cm, plots were weedier than when spacing was 15.2 or 22.9 cm (Table 3). Seed-piece weight had no effect on plot weediness. Years were significantly different (Table 3), and this correlated with receiving greater rainfall showing greater weediness (Table 1). Vine senescence, measured at the end of the season, was not affected by seed-piece spacing, but increased with heavier seed-pieces (Table 3). The difference in senescence for the three years was related to when the visual estimate of vine senescence was observed.

Tuber Observations

Across years, tuber yield decreased with increasing seed-piece spacing (Table 4). The highest yields in all years was from the closest spacing, 15.2 cm. Spacing of 22.9 cm yielded was not significantly different from the closer spacing in two of the years. The lowest yields were obtained from the two farthest seed-piece spacing, 38.1 and 45.7 cm (Table 4). In contrast, seed-piece weight had no effect when weight was 56.7 g or greater. Across years, the lightest seed-piece, 42.5 g, showed a significant yield reduction (Table 4). Note, however, that a seed-piece weight of 42.5 g is below the recommendation for planting. There was no interaction on yield between spacing and weight in any year. Years were significantly different (Table 4) and this may be related to rainfall and temperature (Table 1). Seed-piece size and spacing combinations that resulted in equal seeding rates were compared for their resulting yield (Table 5). Of the four seeding rates, only planting 2.03 Mg/ha showed a difference in yield. Lighter seed-pieces (52.5 and 56.7 g) planted closer (22.9 and 30.5 cm) resulted in a higher yield than planting heavier seed-pieces (70.9 and 85.0 g) further apart (38.1 and 45.7 cm). Specific gravity was slightly decreased when seed-pieces were planted further apart with the row (Table 3). Seed-piece weight had no effect. Specific gravity was lower in 2013 then in the other two years and may be explained by temperature (Table 1). Across years, the lowest specific gravity averaged 1.091 for the two furthest spacings (Table 3). Using the standard formula for calculating dry matter and starch from potato tuber specific gravity (von Scheele et al. 1936), a specific gravity of 1.091 represents 22.5 % dry matter and 16.0 % starch.

Economic Observations

Although the highest yield was obtained from the closest spacing, 15.2 cm, of seed-pieces and planting heavier seed, 63.8 to 85.0 g, high yield may not necessarily be economical, giving growers a profit over the cost of seed purchase for planting. Profit was calculated by subtracting the production cost from the sale value. The production cost was calculated as the sum of the fixed operating cost or $210 /ha ($85 /a), the shipping cost of harvested tubers which varied depending on yield (Table 4), and the cost of seed which varied based on seed spacing and weight (Table 2). Shipping cost from Imperial NE to Wray CO or 120 km ranged from $62.99 to $81.79 /ha ($25.53 to $33.12 /a). The cost of seed tubers planted ranged from $268 to $1610 /ha ($109 to $654 /a). The sum of these costs constituted the fixed cost of production for the combinations of seed-piece spacing and weight. Sales value fluctuates with supply and demand each year. A price range of $0.70 /Mg ($3.00 /cwt) to $1.25 /Mg ($5.50 /cwt) was obtained from two dehydrated product companies. For calculating profit, the sales price of $77 /Mg ($3.50 /cwt) was used. The profit, both in $ /ha and $ /a, from each combination of seed-piece spacing and weight are given in Table 6. A profit of $ 300 /ha ($ 120 /a) were obtained in five combinations, 42.5 g (1.5 oz) seed spaced 45.7 cm (18 in), 56.7 g (2.0 oz) seed spaced 30.5 to 45.7 cm (9 to 18 in), and 63.8 g (2.25 oz) seed spaced 45.7 cm (18 in. (Table 6).

Discussion

Yield

In preliminary trials conducted in the Nebraska Panhandle, several potato cultivars were evaluated for yield and specific gravity under drought conditions using organic farming practices (Pavlista 2013). Seed spacing was 38.1 cm and seed-piece weight was 85.0 g. There were no inputs, i.e. fertilizer, pesticides, irrigation. The conclusions were that Atlantic performed the best with the highest yield and starch produced and therefore, this cultivar was used in the study reported here.

In the three years of the study, spacing Atlantic seed-pieces 38.1 and 45.7 cm decreased yield compared to spacing 15.2 and 22.9 cm (Table 4). This agreed with previous research on Atlantic grown under irrigated or wet conditions (Creamer et al. 1999; DeBuchananne and Lawson 1991; Rykbost and Maxwell 1993; Zebarth et al. 2006). Under warm, dry conditions, with no added fertilization, spacing Atlantic and Shepody seed-pieces at 40 cm yielded less than spacing at 30 cm (Zebarth et al. 2006). Shepody and Conestoga grown without irrigation under wet conditions in Manitoba decreased yield when seed-piece spacing was increased from 30 to 46 cm (Rex 1991; Rex et al. 1987). Love and Thompson-Johns (1999) showed that for three russet cultivars, yield decreased when increasing spacing from 23 to 31 to 46 cm. However, the effect on yield by spacing further apart may not be the same for all varieties as some were less affected (White and Sanderson 1983; Wurr 1974).

Seed-piece size had less of an effect on yield than spacing. Averaged over three years, 42.5 g seed-pieces yielded less than seed-pieces weighing 63.8 g or greater (Table 4). Studying Atlantic and Monona under non-irrigated conditions in Ohio, seed-piece size between 35 and 58 g did not affect yield (Kleinhenz and Bennett 1992). Rykbost and Locke (1999) reported that three russet cultivars grown under irrigation yield highest when seed-piece weight was at least 50 g (Russet Norkotah) or 64 g (Russet Burbank and Century Russet); Bohl et al. (2011) reported 64 g for Alturas, Ranger Russet and Russet Norkotah. These studies agreed with the findings here on Atlantic. The study reported here on Atlantic showed a lower plant stand with 42.5 g seed-pieces than larger ones, but this did not negatively affect yield. Kleinhenz and Bennett (1992), however, reported no effect by size from 35 to 58 g. Note, in their study, fertilizer and pesticides were applied unlike organic conditions.

In a study on seed-piece size and spacing with Alturas, Russet Norkotah and Ranger Russet, Bohl et al. (2011) compared different combinations of seed-piece size and spacing with a seeding rate of 2.28 Mg/ha. They found that all three combinations compared produced the similar yield, and neither seed-piece size or spacing had an effect. This did not agree with Iritani et al. (1972) where such a comparison showed that planting 57 g seed-pieces at 30 cm spacing or 43 g seed-pieces at 23 cm had a greater yield than planting 28 g seed-pieces planted at 15 cm. In our study, four seeding rates could be compared at different seed-piece size and spacing combinations. Only at the 2.03 Mg/ha seeding rate did yield differ between combinations and spacing had a greater effect of decreasing yield than size had on increasing it (Table 5). Such a trend may exist at the other seeding rates as well.

Specific Gravity

For the dehydration industry, an important factor is dry matter yield. Specific gravity of tubers is an accepted method to determine dry matter content. Specific gravity of Atlantic was slightly lowered when seed-pieces were spaced at 30.5 cm compared to 15.2 cm (Table 3). Zebarth et al. (2006) reported a similar, slight decrease in specific gravity (dry matter accumulation) in Atlantic without applied fertilizer when increasing spacing from 20 to 30 cm. DeBuchananne and Lawson (1991) reported the same conclusion on irrigated Atlantic that specific gravity decreased slightly as spacing was increased from 15 to 31 cm. Seed-piece size had no effect agreeing with Rykbost and Locke (1999) on irrigated Russet Burbank, Russet Norkotah and Century Russet. There is no previous data on the effect of size in Atlantic.

Weather

Year had a major effect with the highest yield and specific gravity occurring in 2014 (Tables 3 and 4). The year, 2014, was characterized as a near-normal year for western Nebraska with seasonal rainfall at 91 % of the 30-year mean and temperature at 0.2 o C below (Table 1). In 2013, the season was considered a drought year with 69 % of the mean rainfall and hot with a temperature 1 o C above the mean (Table 1). Rain fell that year primarily in September (40 % of the season’s rain) otherwise the drought would have been much worse. Atlantic seemed to have the ability to wait for rain as tubers did most of their growth in September. As a result of the unusual dry, hot weather, yields and specific gravity were the lowest in 2013 compared to the other two years (Tables 3 and 4). In 2015, although significantly less than 2014, yield was similar, 95 % that of 2014, and specific gravity was still above 1.09 (Tables 3 and 4). Rainfall in 2015 was above the mean for the season with 48 % of it occurring in May during planting (Table 1). The early season wetness may have caused some plant loss and increased weed severity (Table 3). The year was characterized as somewhat wet with normal seasonal temperature. Therefore, these three years gave a broad range of rain and temperature conditions to estimate the yield and specific gravity range for growing Atlantic potato in western Nebraska (Table 1). Zebarth et al. (2006) reported a similar effect by rainfall and temperature on Atlantic yield in Prince Edward Island. In their study, yield was highest in 2000 when rainfall was near normal, 107 % of the 30-year mean, and temperature cool, 0.7 o C below the mean. The yield, compared to 2000, was lower in 2001 and 2002. In 2001, the weather was very dry, 68 % of the mean rainfall, and hot, 0.6 o C above the mean seasonal temperature. In 2002, the weather was dry, 82 % of the mean rainfall, and cool, 0.6 o C below the mean. These studies suggested that rainfall may have a greater influence on yield and specific gravity than temperature.

Economics

Two studies reported economic analyses on potato grown for maximum fresh market yield where value depends on the grade of harvested tubers (Bohl et al. 2011; Love and Thompson-Johns 1999). Both studies used a “partial budgeting” approach where the only cost variable is seed purchase. Using this approach, ignoring transportation and operating costs, Love and Thompson-Johns (1999) found that the highest net return was when seed-piece spacing was 31 and 46 cm for Russet Burbank, Ranger Russet and Frontier Russet. Using the same method, Bohl et al. (2011) analyzed Russet Norkotah for the fresh-pack industry and concluded that planting 85 g seed-pieces 40 cm apart resulted in a higher “gross return” based on harvest size distribution and contract prices in place at the time. Using Shepody under dryland conditions, Rex et al. (1987) concluded that “Optimum net crop values were achieved at an in-row spacing of 38 cm (15 in.) between seedpieces ... regardless of seed cost.” As Table 6 demonstrates, there were five combinations of seed-piece spacing and weight that resulted in profits of $ 300 /ha ($ 120 /a) or greater. Of these, seed-pieces of 42.5 g (1.5 oz), in general, would not be recommended due to their susceptibility to seed decay and low plant vigor. Planting 63.8 g (2.25 oz) pieces spaced 45.7 cm (18 in. would allow little flexibility. Taking these considerations, it seems that the best recommendation for consistent and acceptable profit is planting 56.7 g (2 oz) seed-pieces 38.1 to 45.7 cm (15 to 18 in. apart for dryland, organic production of potato dry matter in western Nebraska using the cultivar Atlantic with a high dry matter content.

Conclusion

The principle reasons motivating this study are:

-

1.

to establish a consistent source of potato dry matter so that dependency on culls is avoided,

-

2.

to produce raw potato using of organic farming, and

-

3.

to be able to provide potato dry matter and starch organic products to consumers.

Although the highest yield was obtained by spacing larger seed-pieces closer together in a row, the result was an economic loss. Profitability was attained when seed-pieces were spaced further apart. The recommendation from this study was to plant seed-pieces, weighing 56.7 (2.0 oz.), 38.1 to 45.7 cm (15 to 18 in.) apart. Since it is expected that growers would be planting on ground used for winter wheat or millet production, these two crops were compared to potato. In this comparison, costs considered were operating, seed, shipping, pesticides and fertilizer; equipment, labor and land were not included. Potato yields were from 56.7 g seed-pieces planted 45.7 cm apart. The information for wheat and millet was obtained from The University of Nebraska-Lincoln Crop Budgets for western Nebraska and discussion with growers. Shipping of wheat and millet was not included in their calculations with the assumption that grain elevators would be nearby and the cost would be relatively negligible. The net gain from wheat was $ 188 /ha ($ 77 /a) and $ 178 /ha ($ 72 /a) for millet; for potato, the net gain was $ 326 /ha ($ 133 /a) (Table 7). These calculations showed that not only can growing potatoes under these circumstances are profitable, but that the net gain can be greater than that from conventionally grown wheat or millet.

References

Arsenault, W.J., D.A. LeBlanc, G.C.C. Tai, and P. Boswall. 2001. Effects of nitrogen application and seedpiece spacing on yield and tuber size distribution in eight potato cultivars. American Journal of Potato Research 78: 301–309.

Bishop, J.C., and D.N. Wright. 1959. The effect of size and spacing of seed pieces on the yield and grade of white rose potatoes in Kern County, California. American Potato Journal 36: 235–240.

Bohl, W.H., J.C. Stark, and C.S. McIntosh. 2011. Potato seed piece size, spacing, and seeding rate effects on yield, quality and economic return. American Journal of Potato Research 88: 470–478.

Bremner, P.M., and M.A. Taha. 1966. Studies in potato agronomy 1. The effects of variety, seed size and spacing on growth, development and yield. Journal of Agricultural Science 66: 241–252.

Changnon, S.A., P. Lamb, and K.G. Hubbard. 1990. Regional climate centers: new institutions for climate servicesand climate-impact research. Bulletin of the American Meteorological Society 71: 527–537.

Creamer, N.G., C.R. Crozier, and M.A. Cubeta. 1999. Influence of seedpiece spacing and population on yield, internal quality, and economic performance of Atlantic, superior, and Snowden potato varieties in eastern North Carolina. American Journal of Potato Research 76: 257–261.

DeBuchananne, D.A., and V.F. Lawson. 1991. Effect of plant population and harvest timing on yield and chipping quality of Atlantic and Norchip potatoes at two Iowa locations. American Potato Journal 68: 287–297.

Entz, M.H., and L.J. LaCroix. 1984. The effect of in-row spacing and seedtype on the yield and quality of a potato cultivar. American Potato Journal 61: 93–105.

Gould, W.A. and S. Plimpton. 1985. Quality evaluation of potato cultivars for processing. North Central Regional publication # 305.

Houghland, G.V.C., and M.M. Parker. 1948. A study of three factors in potato production: row spacing, seed spacing, and fertilizer rate. American Potato Journal 25: 393–406.

Iritani, W.M., R. Thornton, L. Weller, and G. O’Leary. 1972. Relationships of seed size, spacing, stem numbers to yield of russet Burbank potatoes. American Potato Journal 49: 463–469.

Kleinhenz, M.D., and M.A. Bennett. 1992. Growth and yield of potato (Solanum tuberosum L.) cultivars Atlantic and Monona as influenced by seed type and size. American Potato Journal 69: 117–129.

Love, S.L., and A. Thompson-Johns. 1999. Seed piece spacing influences yield, tuber size distribution, stem and tuber density, and net returns of three processing potato cultivars. Hortscience 34: 629–633.

Pavlista, A.D. 1997. Potato types & characteristics: laboratory exercises. The American Biology Teacher 59: 30–34.

Pavlista, A.D. 2013. Organic, dryland potatoes for starch in western Nebraska. American Journal of Potato Research. 90: 144.

Pavlista, A.D. 2015. Growth of the Nebraska Potato Industry. University of Nebraska - Lincoln NebGuide G2272.

Rex, B.L. 1991. The effect of in-row seed piece spacing and harvest date of the tuber yield and processing quality of Conestoga potatoes in southern Manitoba. Canadian Journal of Plant Science 71: 289–296.

Rex, B.L., W.A. Russell, and H.R. Wolfe. 1987. The effect of spacing of seedpieces on yield, quality and economic value for processing of Shepody potatoes in Manitoba. American Potato Journal 64: 177–189.

Rykbost, K.A., and K.A. Locke. 1999. Effect of seed piece size on performance of three potato varieties in the Klamath Basin of Oregon. American Journal of Potato Research 75: 75–82.

Rykbost, K.A., and J. Maxwell. 1993. Effects of plant population on the performance of seven varieties in the Klamath Basin of Oregon. American Potato Journal 70: 463–474.

SAS Institute. 2003. SAS System for Windows. Release 9.1. ed. SAS Institute Inc., Cary, NC.

Schotzko, R.T., W.M. Iritani, and R.E. Thornton. 1984. The economics of russet Burbank seed size and spacing. American Potato Journal 61: 57–66.

Smith, O., R.F. Hommel, and W.C. Kelly. 1943. Relation of rate and placement of fertilizer, variety, seed spacing, and size of seed-piece to yields of potatoes. American Potato Journal 20: 267–277.

von Scheele, C., G. Svensson, and J. Rasmusson. 1936. Die Bestimmung des Starkegehalts und der Trochensubstanz der Kartoffel mit Hilfe des spezifischen Gewichts (determination of the dry substance and starch content of potatoes with the aid of specific gravity). Landw. Vers. Sta. 127: 67–96.

White, R.P., and J.B. Sanderson. 1983. Effect of planting date, nitrogen rate, and plant spacing on potatoes grown for processing in Prince Edward Island. American Potato Journal 60: 115–126.

Wurr, D.C.E. 1974. Some effects of seed size and spacing on the yield and grading of two maincrop potato varieties 1. Final yield and its relationship to plant population. Journal of agricultural Science, Cambridge 82: 37–45.

Zebarth, B.J., W.J. Arsenault, and J.B. Sanderson. 2006. Effect of seedpiece spacing and nitrogen fertilization on tuber yield, yield components, and nitrogen use efficiency parameters of two potato cultivars. American Journal of Potato Research 83: 289–296.

Acknowledgments

The author is grateful for the technical support of Les Kampbell, and the assistance of summer interns. I give appreciation for the financial support of the USDA Specialty Crops Block Grant Program administered by the Nebraska Department of Agriculture.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pavlista, A.D., Groskopf, J. Growing Potato Profitably for Organic Dry Matter Production in Western Nebraska. Am. J. Potato Res. 93, 509–517 (2016). https://doi.org/10.1007/s12230-016-9527-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-016-9527-3