Abstract

A method for the determination of the sulfur amino acids methionine and cysteine in milk- and plant-derived protein powders and in protein-based nutritional products is described. Samples and calibration standards are prepared by acid hydrolysis (6-M HCl, 110 °C, 24 h) with 3,3’dithiopropionic acid, evaporation, and resuspension. The released methionine and cysteine mixed disulfide are quantified by direct LC/UV, without pre- or post-column chromophore/fluorophore derivatization. Since tyrosine is also released by the acid hydrolysis and elutes in the same chromatogram, it was included in all determinations. Method performance has been defined by assessments of linearity (R2 averaged > 0.999, n = 10, for 5-point plots of each analyte), intermediate precision (within-day RSD < 2%, n = 3, and day-to-day RSD < 3%, n = 3 days, for each analyte), accuracy (cystine spike recovery = 101%; measured methionine, cystine, and tyrosine concentrations were 95–111% of published concentrations), selectivity (reagent blanks and peak purity found analyte bias ≤ 2%), and quantitation limit (25 mg of methionine and tyrosine, and 50 mg of cystine, per 100 g of protein powder). The method provides a relatively simple means for the accurate and precise determination of both sulfur amino acids in protein powders and in nutritional products, and may be performed by conventional LC/UV, without specialized amino acid analysis instrumentation.

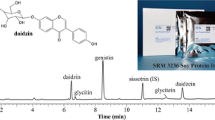

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The 2007 WHO/FAO/UNU minimum requirement for sulfur amino acid (methionine + cysteine) ranges from 22 mg (for adults) to 28 mg (for infants) per g of food protein (WHO/FAO/UNU 2007). Food proteins that show promise as sustainable alternatives to milk-derived proteins, but that are also limiting or relatively low in sulfur amino acids (with or without digestibility correction), include fava bean, green and yellow pea, almond, soybean, and chickpea (Kalman 2014; Nosworthy et al. 2017; House et al. 2019; Ma et al. 2019; Rafii et al. 2020). Interest in the sulfur amino acids is not limited to compliance with indispensable amino acid concentration requirements; e.g., nutritional significance has also been associated with the ratio of methionine/cysteine (Sarwar et al. 1991; Shoveller et al. 2003; Kurpad et al. 2004; Pacheco et al. 2018), cysteine may be used as a marker of casein adulteration (Ballin 2006), and methionine may be used as a marker of peroxide treatment (Baxter et al. 2007). Although the determination of methionine in proteins and nutritional products may be performed by the conventional acid hydrolysis/LC methods (including post-column ninhydrin derivatization/ion exchange chromatography and pre-column fluorophore [AQC, FMOC, OPA, PITC] derivatization/reversed phase LC), cysteine is unstable to acid hydrolysis so that an alternative procedure is required to enable its accurate quantification (Creighton 1993). Perhaps the most common alternate procedure entails performic acid oxidation (by which cysteine is oxidized to cysteic acid), acid hydrolysis (which releases protein bound cysteic acid), and LC determination in conjunction with pre-column or post-column cysteic acid derivatization (Moore et al. 1958; Szkudzinska et al. 2017). The considerable time and labor required by the performic acid oxidation procedure prompted the development of alternative approaches to cysteine determination, including derivatization with the disulfides 3,3’-dithiopropionic acid (DTDPA) and 2,2’-dithiodiacetic acid (DTDAA, aka dithioglycolic acid) (Barkholt and Jensen 1989; Hoogerheide and Campbell 1992). In contrast to many of the reagents suitable for the quantitative derivatization of free cysteine, both DTDPA and DTDAA enabled the formation of a stable in situ acid hydrolysis derivative (Samara et al. 2016). A 53-lab cysteine determination collaborative study by the Association of Biomolecular Resource Facilities concluded that “disulfide exchange [DTDPA, DTDAA] yielded excellent results,” “the present study indicates that accurate results can be achieved by the easy to use disulfide exchange reagents,” and that study results “suggested that bench skills in amino acid analysis, rather than specific methodology, is the determining factor in high quality cysteine analysis” (Strydoma et al. 1993). On the basis of this validation of the cysteine determination disulfide exchange methodology, along with the fact that both methionine and cystine exhibit sufficient UV absorptivity (1020 and 1180 AU/M at 214 nm) to allow direct UV detection without chromophore/fluorophore derivatization, the objective of the present research was to develop a relatively simple method for the simultaneous determination of both sulfur amino acids (in proteins and in protein based food products) that could be performed by conventional LC/UV, without pre- or post-column derivatization and without a dedicated amino acid analyzer (Johns et al. 2004). Accordingly, described here is a method for the simultaneous quantification of both methionine (Met) and cystine (Cys), accomplished by acid hydrolysis with DTDPA, followed by LC/UV analysis of the acid digest, which contains (free) Met and the cysteine/DTDPA mixed disulfide (Cys-X, Fig. 1). Since tyrosine (Tyr) elutes in the same chromatogram, Tyr has been included with the sulfur amino acids in all applications of the method. The accuracy, precision, linearity, selectivity, and limits of quantitation associated with the determinations of Met, Cys-X, and Tyr have been assessed experimentally, as documented below. The method provides for an accurate and precise determination of Met, Cys, and Tyr in protein powders and in nutritional products, and may be performed by conventional LC/UV without pre- or post-column derivatization.

Experimental

Reagents and Materials

Analytical standard grade L-methionine (Met), L-cystine (Cys), and L-tyrosine (Tyr) reference materials were obtained from Sigma-Aldrich (St. Louis, MO, USA). 3,3’-dithiodipropionic acid (DTDPA, [1119-62-6]), potassium phosphate monobasic, and sodium hydroxide were also obtained from Sigma-Aldrich (St. Louis, MO, USA). 6-M hydrochloric acid (HCl), double distilled, catalog #504, was obtained from GFS Chemicals (Columbus, OH, USA). HPLC grade acetonitrile (ACN) was obtained from Honeywell Burdick & Jackson (Muskegon, MI, USA). Intact and hydrolyzed protein powders (milk, whey, casein, soy, pea, fava bean, brown rice, and almond) were obtained from commercial protein suppliers. Nutritional products were obtained from Abbott Nutrition, a division of Abbott Laboratories (Chicago, IL, USA). The nutritional products (liquids and powders reconstituted at standard dilution) generally comprised protein-based, shelf-stable, oil-in-water emulsions, containing macronutrient levels as high as 25% (w/w) carbohydrate, 4% (w/w) fat, and 9% (w/w) protein, and containing a variety of vitamins (both water and oil soluble; A, B, C, D, E, and K), minerals, other micronutrients, buffers, and flavoring agents. The nutritional product carbohydrates included maltodextrin, sucrose, and oligosaccharides; the fats included vegetable oils, fish oils, and medium chain triglycerides; and the proteins included milk, casein, whey, and soy.

HPLC Instrumentation and Column

Direct HPLC determinations of Met, Cys-X, and Tyr were performed on an Agilent Model 1260 HPLC system (Agilent Technologies, Wilmington, DE, USA) with an Agilent model G4212B diode array detector. The system was equipped with a YMC-Pack ODS-AQ analytical column (5 μm, 4.6 × 250 mm, 120 Å, Waters Corporation, Milford, MA, USA), maintained at 11 °C with a model G1316A thermostatted column compartment (Agilent Technologies). Step gradient elution of all analytes was achieved with mobile phases composed of a 1000/25 (v/v) mixture of 0.05-M KH2PO4, pH 2.9, and ACN (Mobile Phase A) and an 800/200 (v/v) mixture of ACN and Milli-Q Plus water (Mobile Phase B), with 0% B from 0 to 20 min, 100% B from 20 to 25 min, and 0% B from 25 to 45 min. The flow rate was 0.4 mL/min, the injection volume was 10 μL, the primary UV detection wavelength was 214 nm, and the run time was 45 min. Each determination was calibrated with five reference standard solutions, prepared as described below.

Preparation of Reference Standard Solutions

A reference standard stock solution (RSSS) was prepared by (a) accurately weighing 13–15 mg of Met, 10–12 mg of Cys, and 17–19 mg of Tyr into a tared 25-mL volumetric flask, (b) adding 15–20 mL of 6-M HCl to the flask, (c) gently swirling the flask until the amino acids are completely dissolved, (d) bringing the flask to volume with 6-M HCl, (e) placing a stopper in the flask, and (f) inverting the flask repeatedly to thoroughly mix. A reference standard intermediate solution (RSIS) was prepared by diluting 10.0 mL of RSSS to 50 mL with 6-M HCl. Reference standard solutions A–E were prepared by pipetting the specified volumes of the specified solutions/reagents into individual 20-mL glass ampules (Kimble P/N 12010 L 20):

Reference standard solution | RSIS | 6-M HCl | DTDPA, 2.00% (w/v) in 0.2-M NaOH |

|---|---|---|---|

A | 2.00 mL | 18.0 mL | 1.00 mL |

B | 4.00 mL | 16.0 mL | 1.00 mL |

C | 6.00 mL | 14.0 mL | 1.00 mL |

D | 8.00 mL | 12.0 mL | 1.00 mL |

E | 10.0 mL | 10.0 mL | 1.00 mL |

Each ampule is then nitrogen-blanketed and flame-sealed, and then placed in a 110 °C oven for 15 h. The ampules are removed from the oven and allowed to cool to room temperature (21 °C). From each ampule, a 2.00-mL aliquot is pipetted into a 1-dram glass vial. Using a water bath (with temperature ~ 60 °C) and a stream of compressed nitrogen gas, the liquid in each vial is carefully evaporated just to dryness. The vial residue is then resuspended by adding 2.00 mL of 0.1-M HCl, capping the vial securely, and alternately shaking and sonicating it for 60 s. The resuspended residue is then syringe filtered through a 0.2-μm PTFE membrane into an HPLC autosampler vial. The five vials obtained by this procedure (reference standard solutions A–E) are used to calibrate each HPLC determination of Met, Cys, and Tyr. The Met, Cys-X, and Tyr concentrations in the standard solutions range from ~ 70–400 μM, ~ 30–200 μM, and ~ 70–400 μM, respectively. The vials may be stored frozen at − 20 °C between analyses, taking care to completely redissolve any precipitate (by shaking and sonication) prior to HPLC analysis.

Preparation of Proteins and Nutritional Products for Determination of Met, Cys, and Tyr

Prepare an aqueous suspension of the protein powder by diluting 1.00–3.00 g to 100.0 g with Milli-Q Plus water, and stirring vigorously until a solution or homogeneous suspension is attained. The solution/suspension should contain a protein concentration in the range of 1.0 to 3.0%, w/w, and should contain an expected cystine concentration < 0.095%, w/w (< 0.95 g of total Cys per kg of solution/suspension). Pipet 1.00 mL of protein solution/suspension (while stirring if necessary) into a tared 20-mL glass ampule. Alternatively, pipet 1.00 mL of a liquid nutritional product or a reconstituted nutritional product powder, provided that it complies with the protein concentration and the Cys concentration requirements (if not, dilute accordingly with Milli-Q Plus water prior to pipetting) into a tared 20-mL glass ampule. Pipet 20.0 mL of 6-M HCl (redistilled, veritas) into the ampule. Pipet 1.00 mL of DTDPA solution, prepared at 2.00% (w/v) in 0.2-M NaOH, into the ampule. Nitrogen-blanket and flame-seal the ampule, and place the sealed ampule in a 110 °C oven for 24 h (note: for the determination of free Cys, no more than 3 h at 110 °C is needed). Remove the ampule from the oven, allow it to cool to room temperature, and filter the contents through Whatman No. 41 paper. Pipet 2.00 mL of filtrate into a 1-dram vial. Using a water bath (~ 60 °C) and a stream of compressed nitrogen gas, carefully evaporate the liquid in the vial just to dryness. Resuspend the vial residue in 2.00 mL of HPLC Mobile Phase A, cap vial securely and use shaking and sonication to completely dissolve the analytes. Syringe filter the vial suspension through a 0.2-μm PTFE membrane into an HPLC autosampler vial. Test the prepared sample for Met, Cys-X, and Tyr (Fig. 2) by the HPLC system described above, after calibration with reference standard solutions A–E. It should be noted that the content of total protein in the protein powders and in the nutritional products was not determined experimentally, but was obtained from the manufacturer (i.e., from the protein powder certificate of analysis or from the nutritional product label). The protein content obtained in this manner was used to express the measured Met, Cys, and Tyr concentrations on a protein basis (e.g., x g of Met, y g of Cys, and z g of Tyr per 100 g of protein).

Method Validation Experimentation

Experiments were performed to establish suitable method parameters and to assess analyte linearity, precision, accuracy, and selectivity. The required ratio of DTDPA to Cys was established by measuring Cys spike recoveries for a series of milk protein isolate preparations to which increasing quantities of Cys (0, 4.89, 9.88, and 14.7 g of Cys per 100 g of protein) had been added. The acid hydrolysis time required for quantitative Cys-X formation was established by time study; i.e., by measuring the Cys concentration in a milk protein concentrate at six time points from 4 to 21 h (at 110 °C). The uniformity of the Cys-X response over the calibration range was verified by reference standard solution response factor (peak area/concentration) comparison. The absence of a DTDPA effect on Met and Tyr was verified by comparing their concentrations in the absence and the presence of DTDPA. Linear response was assessed as standard curve coefficient of determination for ten independent calibrations, intermediate precision was assessed as day-to-day RSD, accuracy was assessed by comparing experimental analyte concentrations to published concentrations, and analyte selectivity was assessed (as HPLC peak purity) by comparing sample peak area ratios (254 nm/214 nm for Cys-X; 280 nm/214 nm for Tyr) to reference standard peak area ratios.

Results and Discussion

Method Validation

Based on the Cys spike recoveries plotted in Fig. 3, the DTDPA to Cys ratio (molar) was specified at ≥ 24:1 (or ≥ 21:1 on a w/w basis). Accordingly, since the amount of DTDPA in the acid hydrolysis preparation is ~ 95 μmoles (or ~ 20 mg), the amount of (total) Cys in the acid hydrolysis preparation should not exceed 4 μmoles (or 0.95 mg). Based on the Cys concentrations plotted (vs. time at 110 °C) in Fig. 4, the acid hydrolysis time was set at 24 h (the Cys concentration determined at the 21-h time point matched the expected milk protein concentrate Cys concentration). The validity of the reference standard Cys concentration range was verified by calculating the average Cys-X response factor (the ratio of peak area as mAU-min to Cys concentration as mg/L) for the five reference standard solutions: the average was 3.832 ± 0.072 mAU-min-L/mg (RSD = 1.9%; n = 5) and the range was 3.760–3.929 mAU-min-L/mg. The corresponding values for Met and Tyr were 11.84 ± 0.08 mAU-min-L/mg (RSD = 0.6%; n = 5) and 11.77–11.93 mAU-min-L/mg, and 10.25 ± 0.05 mAU-min-L/mg (RSD = 0.5%; n = 5) and 10.17–10.30 mAU-min-L/mg, respectively. The absence of a significant DTDPA effect on Met and on Tyr was verified by comparing their liquid nutritional product concentrations determined in the absence of DTDPA (0.173 ± 0.001 g/100 g; n = 3, and 0.278 ± 0.009 g/100 g; n = 3, respectively) to their concentrations determined in the presence of DTDPA (0.172 ± 0.001 g/100 g; n = 3, and 0.272 ± 0.001 g/100 g; n = 3, respectively).

Standard curve linearity was evaluated as the coefficient of determination (R2) and slope uniformity for ten standard curves from analyses performed over a 20-week period; i.e., for 10 × 5-point plots of peak area vs. concentration. For Met, R2 averaged 0.9992 ± 0.0020 (n = 10), with all values ≥ 0.994, and slope averaged 11.87 ± 0.14 mAU-min-L/mg (n = 10), with RSD = 1.2%. For Cys-X, R2 averaged 0.9994 ± 0.0004 (n = 10), with all values ≥ 0.999, and slope averaged 3.814 ± 0.092 mAU-min-L/mg (n = 10), with RSD = 2.4%. For Tyr, R2 averaged 0.9999 ± 0.0003 (n = 10), with all values ≥ 0.999, and slope averaged 10.35 ± 0.16 (n = 10), with RSD = 1.6%. These values illustrate the strong positive correlation between HPLC peak area and analyte concentration, and the calibration consistency from analysis to analysis.

Method precision was characterized by an assessment of within-day RSD and by an assessment of day-to-day RSD. Within-day RSD was assessed by triplicate determination of Met, Cys, and Tyr in a liquid nutritional product. The within-day RSD values were 0.6% for Met (1.74 ± 0.01 g/kg; n = 3), 0.8% for Cys (0.952 ± 0.008 g/kg; n = 3), and 1.9% for Tyr (2.68 ± 0.05 g/kg; n = 3). Day-to-day RSD was assessed by testing, in triplicate, three milk protein concentrate (MPC) powders on each of three days. The Met concentrations determined in the three powders, expressed as g per 100 g of powder, averaged 2.40 ± 0.06, 2.37 ± 0.03, and 2.50 ± 0.04, so that the day-to-day RSD values (n = 3 days) were 2.5%, 1.3%, and 1.6%, respectively. The Cys concentrations (also as g/100 g powder) averaged 0.644 ± 0.016, 0.613 ± 0.016, and 0.658 ± 0.015, so that the day-to-day RSD values were 2.5%, 2.6%, and 2.3%, respectively. The Tyr concentrations (also as g/100 g powder) averaged 4.55 ± 0.11, 4.44 ± 0.09, and 4.66 ± 0.06, so that the day-to-day RSD values were 2.4%, 2.0%, and 1.3%, respectively. On the basis of these assessments, a day-to-day variation of < 3% in the Met, Cys, and Tyr concentrations would be expected.

Three assessments of method accuracy were performed. In the first assessment, a 101% recovery of the free Cys added (at 4.89 g per 100 g of protein, or 700% of the unspiked Cys concentration) to an MPC, for a DTDPA: Cys (molar) ratio of 22.9, was determined, thereby verifying the capacity of the method to quantify free Cys (i.e., including Cys released from protein by acid hydrolysis). In the second assessment, the Met, Cys, and Tyr concentrations determined experimentally in three MPC powders were compared with milk protein concentrations (both measured and calculated) published in the Handbook of Milk Composition (Williams et al. 1976; Swaisgood 1995). The MPC Met concentrations determined by the present method (2.89 ± 0.04 g/100 g protein; n = 3) were 111 ± 1% (n = 3) of the published measured milk protein Met concentration, and were 102 ± 1% (n = 3) of the published calculated milk protein concentration. The MPC Cys concentrations determined by the present method (0.760 ± 0.006 g/100 g protein; n = 3) were 95.0 ± 0.7% (n = 3) of the published measured milk protein Cys concentration, and were 109 ± 1% (n = 3) of the published calculated milk protein concentration. The MPC Tyr concentrations determined by the present method (5.42 ± 0.06 g/100 g protein; n = 3) were 106 ± 1% (n = 3) of the published measured milk protein Tyr concentration, and were 96.8 ± 1.1% (n = 3) of the published calculated milk protein concentration. Accordingly, by this assessment, the present method is capable of measuring Met, Cys, and Tyr concentrations that are 102–111%, 95–109%, and 97–106%, respectively, of the expected concentrations. In the third assessment, the concentrations of Met (2.22 g/100 g protein), Cys (2.45 g/100 g protein), and Tyr (3.06 g/100 g protein) determined in a commercial whey protein hydrolysate (WPH) by the present method were compared with the concentrations provided by the WPH manufacturer. The method generated concentrations were 96.0%, 95.7%, and 95.5%, respectively, of the concentrations reported by the manufacturer. On the basis of these three assessments, it seems reasonable to conclude that the present method enables estimates of Met, Cys, and Tyr concentrations that are at least within 11% (the largest difference between experimental and published concentrations), and more likely within 5% (the largest difference between independently performed experimental concentrations), of the true concentrations.

Three experimental assessments of method selectivity were performed. The absence of reference standard solution chromatographic interference (i.e., coelution with Met, Cys-X, and Tyr) was verified by testing a reference standard solution reagent blank prepared without an aliquot of the RSIS. In the second assessment, aliquots of a liquid nutritional product prepared for analysis with DTDPA and without DTDPA were tested for Cys-X. The Cys results were 0.0945 ± 0.0006 g/100 g, n = 3 (with DTDPA) and 0.002 ± 0.001 g/100 g, n = 3 (without DTDPA), showing a minimal but measurable positive bias (0.002/0.0945 = 2%) from a chromatographic interference (present in the preparation without DTDPA). Finally, assessments of Cys-X and Tyr peak purity were performed by comparing MPC peak area ratios—254 nm/214 nm for Cys-X and 280 nm/214 nm for Tyr—with the corresponding reference standard peak area ratios (i.e., the ratio averages for the five reference standard solutions). The MPC Cys-X ratios were 99.0 ± 2.6% (n = 3) of the reference standard Cys-X ratio, and the MPC Tyr ratios were 99.4 ± 0.4% (n = 3) of the reference standard Tyr ratio. Met peak purity could not be assessed in this manner because a suitable second wavelength was not available. These assessments, taken together with the accuracy assessments, indicated that the method offered a high level of analyte selectivity.

The limits of Met, Cys, and Tyr quantitation for a protein powder suspended at 2.00% (w/w) in water were experimentally determined (S/N = 10) to be 25, 50, and 25 mg per 100 g, respectively. These limits are significantly lower than the Met, Cys, and Tyr concentrations in nearly all protein powders, so that the method would appear to have broad applicability to both milk-derived and plant-derived protein powders.

Method Application to Protein Powders and Nutritional Products

The method was applied to a total of twenty-six milk-derived (from milk, whey, and casein) and plant-derived (from almond, brown rice, fava bean, pea, and soy) protein powders. The measured Met, Cys, and Tyr concentrations, along with the sulfur amino acid totals (Met + Cys) and the Met/Cys ratios (w/w), are shown in Table 1. The range of total sulfur amino acid concentrations (1.58 to 5.45 g/100 g protein) is illustrated in Fig. 5, and the range of Met/Cys ratios (0.62 to 8.88) is illustrated in Fig. 6. Not surprisingly, the lower concentrations of total sulfur amino acids (< 3 g/100 g protein) were found in the plant-derived protein powders (the brown rice protein hydrolysate, with total sulfur amino acids = 4.55 g/100 g protein, was the lone exception in this regard, among the plant-derived proteins). The method was also applied to six nutritional products, and the results of this testing is shown in Table 2. Among the nutritional products, the total sulfur amino acid concentrations ranged from 3.95 to 4.89 g/100 g protein, and the Met/Cys ratios ranged from 0.81 to 1.82.

A chart showing the range of sulfur amino acid concentrations (1.58 to 5.45 g/100 g protein) in twenty-six milk-derived and plant-derived protein powders. WPC = whey protein concentrate, WPH = whey protein hydrolysate, RPH = brown rice protein hydrolysate, MPC = milk protein concentrate, CPH = casein protein hydrolysate, SPI = soy protein isolate, PPC = pea protein concentrate, APC = almond protein concentrate, and FBPC = fava bean protein concentrate

A chart showing the range of Met/Cys (w/w) ratios (0.62 to 8.88) in twenty-six milk-derived and plant-derived protein powders. WPC = whey protein concentrate, WPH = whey protein hydrolysate, RPH = brown rice protein hydrolysate, MPC = milk protein concentrate, CPH = casein protein hydrolysate, SPI = soy protein isolate, PPC = pea protein concentrate, APC = almond protein concentrate, and FBPC = fava bean protein concentrate

Conclusion

Described here is an LC/UV method for the determination of the sulfur amino acids (Met and Cys) in protein powders and in nutritional products. Since Tyr elutes in the same chromatogram, it was included as a method analyte. Experimental assessments of method linearity (the average R2 was > 0.999, and slope day-to-day RSD was < 3% [n = 10 days], for all three analytes), precision (day-to-day RSD was < 2%, n = 3, and day-to-day RSD was <3%, n = 3 days, for all three analytes), and accuracy (Cys spike recovery = 101%; method measured MPC Met, Cys, and Tyr concentrations were 95 to 111% of published [both experimental and calculated] milk protein concentrations; and measured Met, Cys, and Tyr concentrations were 95–96% of manufacturer-supplied concentrations) were performed. Analyte selectivity was evaluated by reagent blank analyses and by peak purity (UV detection peak area ratio vs. reference standard solution, for Cys-X and for Tyr); no more than minimal positive bias (≤ 2%) was found. The limits of Met, Cys, and Tyr quantitation were 25, 50, and 25 mg per 100 g of protein powder, respectively. Although the method is limited to the quantification of only three amino acids (Met, Cys, and Tyr), its simultaneous determination of both sulfur amino acids (Met and Cys) comprises a capability that is especially valuable for compositional assessments of plant proteins (wherein sulfur amino acids are often the limiting indispensable amino acids). The method provides for a reliable quantification of both sulfur amino acids in protein powders and in nutritional products, without requiring derivatization of the acid hydrolysis-released amino acids and without requiring a specialized/dedicated amino acid analyzer; i.e., the determinations are performed on a conventional LC equipped with a UV detector.

Data Availability

Not applicable.

References

Ballin NZ (2006) Estimation of whey protein in casein coprecipitate and milk powder by high-performance liquid chromatography quantification of cysteine. J Agric Food Chem 54:4131–4135

Barkholt V, Jensen AL (1989) Amino acid analysis: determination of cysteine plus half-cystine in proteins after hydrochloric acid hydrolysis with a disulfide compound as additive. Anal Biochem 177:318–322

Baxter JH, Lai CS, Phillips RR, Dowlati L, Chio JJ, Luebbers ST, Dimler SR, Johns PW (2007) Direct determination of methionine sulfoxide in milk proteins by enzyme hydrolysis/high-performance liquid chromatography. J Chromatogr A 1157:10–16

Creighton TE (1993) Proteins. Structures and molecular properties, 2nd edn. W.H. Freeman and Company, New York, p 29

Hoogerheide JG, Campbell CM (1992) Determination of cysteine plus half-cystine in protein and peptide hydrolysates: use of dithioglycolic acid and phenylisothiocyanate derivatization. Anal Biochem 201:146–151

House JD, Hill K, Neufield J, Franczyk A, Nosworthy MG (2019) Determination of the protein quality of almonds (Prunus dulcis L.) as assessed by in vitro and in vivo methodologies. Food Sci Nutr 7:2932–2938

Johns P, Phillips R, Dowlati L (2004) Direct determination of free methionine in soy-based infant formula. J AOAC Int 87:123–128

Kalman DS (2014) Amino acid composition of an organic brown rice protein concentrate and isolate compared to soy and whey concentrates and isolates. Foods 3:394–402

Kurpad AV, Regan MM, Varalakshmi S, Gnanou J, Lingappa A, Young VR (2004) Effect of cystine on the methionine requirement of healthy Indian men determined by using the 24-h indicator amino acid balance approach. Am J Clin Nutr 80:1526–1535

Ma Y, Ma W, Hu D, Zhang X, Yuan W, He X, Kan G, Yu D (2019) QTL mapping for protein and sulfur-containing amino acid contents using a high-density bin-map in soybean (Glycine max L. Merr). J Agric Food Chem 67:12313–12321

Moore S, Spackman DH, Stein WH (1958) Chromatography of amino acids on polystyrene resins. An improved system. Anal Chem 30:1185–1190

Nosworthy MG, Franczyk AJ, Medina G, Neufield J, Appah P, Utioh A, Frohlich P, House JD (2017) Effect of processing on the in vitro and in vivo protein quality of yellow and green split peas (Pisum sativum). J Agric Food Chem 65:7790–7796

Pacheco LG, Sakomura NK, Suzuki RM, Dorigam JCP, Viana GS, Van Milgen J, Denadai JC (2018) Methionine to cystine ratio in the total sulfur amino acid requirements and sulfur amino acid metabolism using labelled amino acid approach for broilers. BMC Vet Res 14:364

Rafii M, Pencharz RB, Ball RO, Tomlinson C, Elango R, Courtney-Martin G (2020) Bioavailable methionine assessed using the indicator amino acid method is greater when cooked chickpeas and steamed rice are combined in healthy young men. J Nutr 00:1-11

Samara A, Zotou A, Tzanavaras P (2016) Use of a core-shell column for the development of a green LC method for thiol determination in fresh fruits following derivatization with methyl propiolate. Food Anal Methods 9:680–690

Sarwar G, Peace RW, Botting HG (1991) Dietary cysteine/methionine ratios and taurine supplementation: effects on rat growth, amino acids and bile acids. Nutr Res 11:355–363

Shoveller AK, Brunton JA, House JD, Pencharz PB, Ball RO (2003) Dietary cysteine reduces the methionine requirement by an equal proportion in both parenterally and enterally fed piglets. J Nutr 133:4215–4224

Strydoma DJ, Andersenb TT, Apostolc I, Foxd JW, Paxtone RJ, Crabbf JW (1993) Cysteine and tryptophan analysis of ABRF92-AAA. In: Techniques in Protein Chemistry IV. Academic Press, Inc., pp 279–288

Swaisgood HE (1995) In: Jensen RG (ed) Handbook of Milk Composition. Academic Press, Boca Raton, p 467

Szkudzinska K, Smutniak I, Rubaj J, Korol W, Bielecka G (2017) Method validation for the determination of amino acids in feed by UPLC. Accred Qual Assur 22:247–252

WHO/FAO/UNU (2007) Protein and amino acid requirements in human nutrition. Report of a joint WHO/FAO/UNU expert consultation. World Health Organization Technical Report Series. Geneva (Switzerland)

Williams AP, Bishop DR, Cockburn JE, Scott KJ (1976) Composition of ewe’s milk. J Dairy Res 43:325–329

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of Interest

Paul W. Johns declares that he has no conflict of interest.

Informed Consent

Not applicable.

Code Availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Johns, P.W. Determination of Sulfur Amino Acids in Milk and Plant Proteins. Food Anal. Methods 14, 108–116 (2021). https://doi.org/10.1007/s12161-020-01854-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-020-01854-9