Abstract

Microwave-assisted extraction was applied to Juglans regia L. fresh male flowers and unripe walnut seeds to evaluate the total phenolic contents of the extracts as well as the percentage of water-soluble polyphenols. The research was planned using the Design of Experiments technique to investigate the role on the extraction efficiency of different parameters, such as temperature, time and number of microwave heating cycles, together with their possible interactions. Optimization was achieved by applying a Response Surface Methodology comprising a three-factor, two-level, full-factorial Face-Centred Central Composite Design. The two input variables with a significant effect on the recovery of phenols from fresh male flowers were the extraction temperature and the number of microwave cycles. In the case of unripe walnut seeds, a linear two-factor interaction model was selected, with significant interactions occurring between temperature and time, and time and number of microwave cycles. The best experimental conditions were as follows: 100 °C, 6 min, three microwave heating cycles and 22.7 ± 0.2 mg gallic acid equivalent (GAE)/g (total phenolic content, PC); energy consumption calculations suggested slightly different conditions: 60 °C, 30 min, three microwave heating cycles and 20.7 ± 0.3 mg GAE/g (TPC).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The move towards using antioxidants from natural sources, such as fruits and vegetables, rather than synthetic compounds is gaining significant interest, due to the toxicity of some synthetic antioxidants and the costs of raw materials and manufacture (Contini et al. 2008; Oliveira et al. 2008). Indeed, these phytochemicals can be used as natural colourants and preservatives for foods (Loypimai et al. 2015; Li et al. 2012), as well as supplement ingredients in several foods and beverages (Namal Senanayake 2013; Shah et al. 2014).

Exploitation of by-products derived from processing of plant foods, thus avoiding disposal costs and reducing the impact of food waste on the environment, is also a driving force for use of naturally occurring bio-active compounds (Wijngaard et al. 2012). Moreover, from an environmental perspective, the complexity of synthetic products often means they persist longer, causing significant environmental pollution.

Among natural sources of antioxidants, Juglans regia L. has been a target of increased research interest (Oliveira et al. 2008; Slatnar et al. 2015), since epidemiological investigations reported that a regular consumption of walnut seeds (commonly named walnuts) greatly reduces the risk of coronary heart disease (Blomhoff et al. 2006; Bao et al. 2013; Ibarrola-Jurado et al. 2013), as well as several cancers (Cerdá et al. 2005; Le et al. 2014). Compounds associated with human health benefits are found in walnut kernels as well as in green husks (epicarps), shells, bark, flowers and leaves, all of which have been widely used for decades in cosmetic and pharmaceutical formulations (Martinez et al. 2015; Shah et al. 2014). These phytochemicals include tocopherols, tocotrienols, sterols, naphtoquinone, juglone, folate, gallic acid, ellagic acid, tannins and other polyphenols (Zhang et al. 2009). In addition to antioxidant properties related to total phenolic content (Yang et al. 2009), these bio-active components also possess antimicrobial (Oliveira et al. 2008; Pereira et al. 2007; Fernández-Agulló et al. 2013), as well as anti-inflammatory properties (González et al. 2011) which make these phytochemicals, among other things, particularly appealing as natural food preservatives and colourants.

Extraction of phenolic compounds from plants constitutes the first step for analysis and further utilization. Conventional extraction techniques include soaking, maceration, water percolation and Soxhlet extraction (Contini et al. 2008; Naczk and Shahidi 2004). However, the need for great amounts of solvents, energy consumption and long extraction times, together with the degradation of products, are significant drawbacks of these traditional extraction procedures and contrast with the concept of process intensification (PI), which is recognized by most chemical industries as a model to pursue for a sustainable development (Stankiewicz and Moulijn 2000). Thus, in recent decades, besides yet well-settled extractive methods such as supercritical fluid extractions (SFE) (Herrero et al. 2006) and ultrasound-assisted extraction (UAE) (Shirsath et al. 2012), several further ‘green’ extraction techniques have gained interest (Tobiszewski et al. 2010; Ignat et al. 2011; Chemat et al. 2012). Particularly, some of them have been implemented in continuous or semi-continuous processes, including pressurized fluid extraction (Mustafa and Turner 2011), cold screw-pressed extraction (Davies 2014), microwave-assisted extraction (MAE) (Chan et al. 2011) and microwave (MW) hydrodiffusion and gravity extraction (Vian et al. 2008).

Microwave irradiation probably represents the most intriguing procedure because of its unique heating mechanism, mainly relying in the interaction of the electromagnetic field with polar molecules and ionic species (Leonelli et al. 2013). This mechanism leads to some typical heating characteristics, such as the inversion of classical temperature profile (i.e. the inner portion of a sample irradiated by microwaves results typically hotter with respect to the outer regions, and this represents the opposite situation of what occurs with conventional heating techniques, in which the hotter zones are those in direct contact with the reactor walls), the volumetric and selective nature, together with the extremely high heating rates (since the heat is directly generated in the material and is not transferred from a radiating surface) (Leonelli et al. 2013). All of these characteristics led to the intensification of several processes, like organic (Leonelli and Mason 2010) and inorganic synthesis (Patzke et al. 2011), as well as advanced materials processing (Rosa et al. 2013).

In the extraction of phytochemicals, another advantage is that the heat gradient is directed from the inside to the outside; thus, in the same direction of the mass transport. Furthermore, the mass transfer becomes more effective, since microwaves can penetrate plant matrices, interacting with polar molecules such as water and phenolic compounds. The resulting increased pressure leads to plant cell wall rupture, facilitating the leaching of targeted phytochemicals into the solvent. Therefore, the synergy between heat and mass transfer phenomena is responsible for the process acceleration, the lower solvent consumption, less environmental pollution, higher extraction yields, and product quality (Veggi et al. 2013). These factors, together with opportunely designed dedicated microwave apparatus, leading to significant size reduction and efficiency enhancement, allowed widespread applications of MAE technologies to pine seeds, grapefruits, grape seeds and skins, tomatoes, potatoes, green coffee beans, green tea leaves and onions.

In spite of the increasing interest towards MAE of natural compounds with applications in food technology, especially as obtained from waste from agricultural production, studies on phytochemicals derived from J. regia flowers and seeds still remain surprisingly scarce (Sharma et al. 2009).

In the present study, the applicability of MAE to the extraction of phenolic compounds from fresh male flowers and unripe walnut seeds has been investigated in terms of dried extract yield, total phenolic content and water-soluble polyphenols content.

MAE optimization was achieved by means of Design of Experiment (DoE) techniques (Eriksson et al. 2008); response surface methodology (RSM) was applied, since it is a well-established collection of statistical and mathematical tools that has been widely exploited in order to improve and optimize extraction of phenolic compounds from plant matrices (Liyana-Pathirana and Shahidi 2005; Karacabey and Mazza 2010). The application of this optimization step to MAE of phenolic compounds from J. regia constitutes a further novelty of this study.

Materials and Methods

Plant Materials and Chemicals

Fresh male walnut flowers of Juglans regia L. cultivar were collected in early May 2015 in Castelfranco Emilia (Modena, north-eastern Italy, 44° 34′ 00″ North, 11° 02′ 00″ East), after completing their biological cycle. Green walnut fruits were collected in the same place at the beginning of June 2015, in order to avoid possible loss of precious antioxidant components as a consequence of the maturation and lignification processes. The flowers and unripe seeds were handpicked from the plant and taken to the laboratory, where they were put in plastic bags and frozen to −80 °C until they could be processed. The plant material was then thawed, manually cracked and crushed immediately before the extraction procedure.

All chemicals (solvents and reactants) were reagent grade and used without further purification; they were purchased from Sigma-Aldrich (Milan, Italy). Divergan® (F/RS) was purchased from BASF Corporation (Florham Park, USA).

Microwave-Assisted Extraction, MAE

Fresh male flowers and unripe walnut seeds were manually crushed and homogenized in order to increase their contact surface with the extraction medium. A preliminary treatment with n-hexane was performed on both the matrices in order to eliminate most of the essential oils and chlorophyll.

Microwave-assisted extraction was performed in closed 100 mL Teflon® vessel using a Milestone ETHOS TC (Milestone, Torre Boldone, Bergamo, Italy) multimode applicator, operating at the Industrial Scientific and Medical (ISM) frequency of 2.45 GHz, with the maximum output power fixed at 500 W and equipped with temperature and pressure monitoring devices.

In a typical experiment, 2 g of the plant matrix were weighted in a Teflon® vessel; then, 15 mL of the extraction solvent (ethanol/water, 50:50 vol.% mixture) were added before completely sealing the reactor and starting the microwave experiment according to the experimental design.

The time required to reach the extraction temperature was set to 3 min for all of the experiments. For those experiments requiring two or three microwave cycles, a cooling time of 15 min, before the next cycle was fixed in order to decrease the temperature of approximately 20 °C. The reported results are the average of three independent extraction experiments (±SD).

The built-in control system of the microwave multimode applicator used for the extraction experiments allows to continuously register the power emitted by the magnetron (together with the temperature and pressure values) as a function of time. These experimental curves have been used to calculate the specific energy consumptions relative to selected extracts, as it will be detailed in the ‘Energy Consumption Evaluation’ section.

Dried Extract

The extracts were centrifuged for 20 min at 4000 rpm. The supernatant was filtered through Whatman No. 1 filter paper, concentrated under vacuum at 40 °C on a rotary evaporator and then it was finally freeze-dried. The results are expressed as milligrams of dried extract per gram of fresh matrix.

Determination of Total Phenols Content

Oxidation of phenolic compounds with the Folin–Ciocalteau (F-C) reagent includes reactions with the mixture of H3PW12O40 and H3PMo12O40 acids in the alkaline medium. In this reaction, a mix of blue oxides is formed and the total phenols content is estimated by a colorimetric assay (Ignat et al. 2011). Briefly, 1 mL of the sample was mixed with 2.5 mL of Folin–Ciocalteu’s phenol reagent. After 3 min, 3 mL of Na2CO3 (20 % w/w) solution was added to the mixture. After 30 min in dark conditions and at room temperature, the solution volume was adjusted to 50 mL with distilled water. The reaction was kept in the dark for 90 min, after which the absorbance was read at 750 nm (UV-Vis Jasco 7800 spectrophotometer). Among the many standards for F-C assay, comprising catechin, pyrogallol, tannic acid and gallic acid, we selected the latter since experimental results frequently referred to it when a wide range of phenolic compounds is contained in the investigated matrices. The concentration of phenolic compounds was calculated using the following calibration curve that was obtained by least-squares regression analysis:

where A and X represent absorbance and concentration (ppm), respectively. The calibration curve was built using five standard solutions (1, 2, 5, 7 and 10 ppm), each standard was freshly prepared and read in triplicate.

Every extraction was performed in three independent experiments, and F-C assay was executed in triplicate on each independent extraction. The phenolic content was expressed as the mean [mg of gallic acid equivalents (GAEs) per 1 g of fresh matrix] ± SD. The percentage of phenolic content (PC) was referred to the dried extract, and this parameter was considered one of the responses to be maximized during optimization.

The sensitivity of the method was evaluated by determining the limits of detection (LoD) and quantification (LoQ); they were calculated by measuring the analytical background response reading 10 blank samples at 750 nm. LoD and LoQ were considered to be three and ten times the standard deviation, i.e. 0.05 and 0.09 ppm, respectively. Over the working range of concentration (1–10 ppm), the F-C method was linear; all the read samples gave values above 1 ppm (20 and 10 times the value of LoD and LoQ) and below 10 ppm; if necessary, the extracts were diluted in order to fit this range.

Determination of Water-Soluble Polyphenolic Content

The content of water-soluble phenols was determined by the use of Divergan® (F/RS) which is a cross-linked polyvinylpyrrolidone, known as polyvinylpolypyrrolidone (PVPP) that specifically adsorbs polyphenols. The freeze-dried extract (0.1 g) was suspended in 25 mL of distilled water, and kept at 50 °C while stirring, in order to increase solubility. The solution was then cooled to r.t. and micro-filtered (0.45 μm).

Ten millilitres of the solution were collected in a capsule and dried in an oven at 105 °C for 4 h, then in a desiccator until the weight was constant. The value obtained represents the water-soluble part of the extract (WE), and it is expressed as percentage of the freeze-dried extract. Another aliquot (10 mL) was pre-treated with Divergan® (F/RS), filtered and then dried as previously described. The amount obtained represents the water-soluble polyphenols-free part of the extract (PFWE), and is expressed as a percentage of the freeze-dried extract. The difference between the two values (WE-PFWE) represents the amount of water-soluble polyphenols (WPC) expressed as a percentage of the freeze-dried extract, which was the second response of interest in the analysis of the results.

Theory and Calculations

Experimental Design

Optimization of extraction parameters (namely, extraction temperature, extraction time and number of microwave cycles) for the microwave-assisted extraction of phenolic compounds from J. regia fresh male flowers and unripe seeds was carried out by RSM using a two-level, full-factorial Face-Centred Central Composite Design (FCCCD), whose graphical representation is reported in Fig. 1, in which the central point is indicated in red colour, while the experiments lying on the centre of each cube face represent the axial points (characterized by a distance from the central point, α = 1).

The independent variables (each at two levels, +1 and −1, respectively) in our experiments were temperature (X 1, for which 60 °C = level −1, and 100 °C = level +1), extraction time (X 2, for which 6 min = level −1, and 30 min = level +1) and number of microwave cycles (X 3, for which 1 cycle = level −1, and 3 cycles = level +1).

The experimental designs elaborated by the software Design Expert v.6 (Stat-ease Inc., Minneapolis, MN, USA), showing the ranges of the independent variables considered for the optimization of MAE from both the matrices are reported in Table 1, in the randomized order as indicated by the software itself. As shown, they both consist of the same 19 runs, even if performed in a different order, including five repetitions of the central point (which is characterized by the central values of the three independent variable ranges and denoted as level 0). Extracts obtained from flowers are denoted by ‘f‘, while those obtained from walnut seeds are denoted by ‘s’.

Table 2 shows the results obtained by the analysis of the extracts (detailed in the following section) in terms of the evaluated responses. Particularly, PC (percentage of phenols) and WPC (water-soluble polyphenolic content) were the two responses evaluated for the walnut fruit extracts while in the case of fresh male flowers, only the PC response was evaluated due to the lower amount of extracts obtained and the reduced amount of available plant material.

The analysis of variance (ANOVA) was performed with the aim to establish the optimal combination of experimental conditions for the microwave-assisted extraction procedure and determine the existing relationship between the two responses and the experimental variables investigated. Equation 1 shows the second-order polynomial model as an example of regression analysis which can be performed on the experimental data obtained; Y represents the response (PC and WPC in the present case), β 0 is a constant, β i is the linear coefficient (expressing the main effect), β ii is the quadratic coefficient, β ij is the two factors interaction coefficient, while X i and X j are independent variables.

Results and Discussion

Phenolic Content

Juglans regia L. is a natural source of phenolic compounds which have been reported to have excellent properties in food technology as natural colourants and preservatives. In addition they showed to be biologically active, i.e. having anti-inflammatory and antioxidant properties (Valls-Pedret et al. 2012). In previous studies, the phytoextracts obtained from leaves and ripe fruits of J. regia resulted to be characterized by a high content in polyphenols (Zhang et al. 2009). Phenolic compounds comprise several classes identified mainly as tannins, monomeric phenolic acids, flavonoids, stilbenes and lignans (Ignat et al. 2011).

In this paper, we aimed to investigate by Folin–Ciocalteu (F-C) assay the total phenolic content of the extracts obtained from unripe fruits and flowers from J. regia, without performing any separation nor quantification of the different phenolic classes, which is generally performed by chromatographic techniques, especially high-performance liquid chromatography (HPLC), as comprehensively reported in literature (Ignat et al. 2011).

In view of the potential application in the food industry, we selected solid-liquid extraction, and also in order to pursue green extraction principles, a mixture of water/ethanol 50 % v/v was employed as extraction solvent, because even though methanol is more efficient, ethanol displays a reduced toxicity, appearing as a recommended compound in several solvent selection guides (Prat et al. 2014).

The overall results comprising total phenols content (TPC, expressed as mg GAE/g fresh matrix), dried extract (DE, mg dried extract/g fresh matrix) and percentage of phenols in the dried extract (PC) are reported in Table 2 for flowers and fruits.

Despite the similar value of the dried extract for flowers and fruits (36 ± 7 vs. 35 ± 3), the total content of phenols is definitely higher for unripe fruits with respect to flowers, with an average value of 22 ± 2 against 7 ± 2 mg GAE/g, respectively. These data also suggest that, in the applied experimental conditions, the solid-liquid extraction implies the co-extraction of non-phenolic substances, such as sugars, organic acids and proteins, to a larger extent for flowers than unripe fruits. To the best of the authors’ knowledge, J. regia flowers are investigated for the first time as natural source of phenolic compounds, so a comparison with other experimental data is not possible.

The comparison between analytical data in food matrices represents a challenging point, because on the one hand, the experimental methodologies are different (i.e., extraction and quantification method), while on the other, it should be remembered that the composition and content of phytochemicals in plant-derived materials is strongly influenced by environmental factors, soil, and maturation level. However, the total phenol contents here reported for unripe fruits well agree with previously published results on similar matrices (Labuckas et al. 2008; Zhang et al. 2009; Slatnar et al. 2015), even if Salcedo et al. (2010) report a total polyphenol content of 26.7 (±0.5) mg GAE/g which is slightly higher, probably due to the use of methanol instead of ethanol in the extraction procedure, and to the higher liquid/solid ratio (2:50 vs. 2:15).

The results obtained in this work, being generally comparable in terms of extraction yields, were achieved with a significant reduction in the extraction time, with respect to conventional extraction procedures, thus contributing to highlight the green character of the here employed methodology, also in accordance with a recent review paper (Rombaut et al. 2014). Moreover, even if case-to-case calculations are necessary for precise evaluations, microwave-assisted extraction technique has already quantitatively proven to be more green with respect to conventional ones, by taking into account also its typical energy-saving character (Zerazion et al. 2016).

Another interesting finding of this work is the high percentage of water-soluble polyphenols (37 ± 6 %) found in fruits, a feature which should be of merit in nutraceutical preparations.

Optimum Extraction Conditions Based on PC for Fresh Walnut Male Flowers

The analysis of the PC response of the walnut flower extracts, according to the experimental design reported in Table 1, indicated a simple linear model as the most significant in describing the interaction between the input variables and the investigated response. Particularly, the extraction temperature (X 1) and the number of microwaves cycles (X 3) were the two input variables showing a significant and positive main effect (p < 0.05), while the extraction time (X 2) resulted as practically insignificant.

The linear relationship between the three input variables investigated and the percentage of phenolic compounds is expressed by Eq. 2:

With ANOVA, a correlation coefficient R 2 = 0.7814 was obtained suggesting that the proposed linear model can be considered a good approximation of the real relationship existing between the three extraction parameters and the PC response.

The surface response plot showing simultaneously the effect of extraction temperature and number of MW cycles versus the percentage of recovered phenolic compounds (at the fixed extraction time of 6 min, being not significant) is reported in Fig. 2. Higher temperatures result in significant enhancements in the obtained PC, which can be only slightly improved by the use of more than one MWs cycle.

Extraction Optimization for Walnut Seeds

The response analysis for the percentage of phenolic content (PC), obtained from walnut seeds, indicated that among the three independent variables considered, only the number of MW cycles had a significant main effect (p < 0.05) with a positive linear relationship, whereas both the extraction time and extraction temperature were found to have a not significant (p > 0.05) main effect. The main effects of the three independent variables investigated X 1, X 2, and X 3 on the PC response are reported in Fig. 3.

Main separate effects of the three independent variables (X 1 = temperature, °C; X 2 = time, min; X 3 = number of MW cycles) considered on the response PC, in the case of unripe walnut seed extracts. Each graph was obtained assuming the other two variables in the central value of their variability range. The dotted lines define the confidence bands

A strong and significant interaction effect was manifested between extraction temperature and extraction time as well as between extraction time and number of microwave cycles.

The empirical relationship between PC response and the extraction parameters (Eq. 3) was derived as follows:

The analysis of variance was performed in order to determine the significance of the model. The correlation coefficient (R 2) of the model was 0.7657, which confirms that the proposed model can represent in good approximation the existing relationship between the chosen variables. A non-significant lack of fit (p > 0.05) showed that the proposed linear two factors interaction model can be considered valid over the investigated range of variability of the independent variables considered.

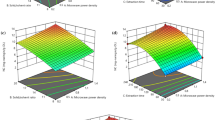

The effects of the independent variables mutual interactions (limitedly to those that are significant) on the PC value can be seen on the 3D response surface curves and contour plots reported in Fig. 4. The temperature-time interaction effect on the PC response is reported in the left graph of Fig. 4, and it can be easily seen how the temperature variation affects the percentage of recovered phenolic compounds slightly more significantly at shorter extraction times, compared to the situation occurring by prolonging MW treatment. However, coupling longer extraction times with lower temperature leads to higher PC of the extract compared to the extraction performed at 100 °C for 6 min (considering the number of MW cycles fixed at its central value, i.e. 2). The strong interaction effect between the number of MW cycles and the microwave extraction time is reported as well in Fig. 4 (right graph), from which it can be seen that the number of MW cycles strongly affects the percentage of recovered phenolic compounds mainly at shorter extraction times.

Response surface curves and contour plots showing the interactions between temperature (X 1, °C) and time (X 2, min) left graph, and between time (X 2, min) and number of MW cycles (X 3) right graph, in the extraction from unripe walnuts seeds. In each curve, the absent variable is fixed at its central value

Thus, from all of these considerations, the optimal conditions suggested in order to maximize PC value resulted the following: 100 °C, 6-min extraction time and three MW cycles. Particularly, as reported in Fig. 5a, these optimal conditions should allow reaching a PC value of 67.7 %. Being these latter values of the experimental parameters, characterizing an experimental point of our design, the predicted value of 67.7, obtained by the model Eq. 3, can be considered in close agreement with the actual PC value for the sample 17 s, i.e. 68 ± 1 (Table 2).

a Response surface plot showing the regions of the experimental space (delimited by the black circle) in which the PC response value can be optimized in the case of seed extracts, considering three MW cycles (X 1 = temperature, °C; X 2 = time, min). b Response surface plot for unripe walnut seeds extracts exploiting a single MW heating cycle. The suggested conditions (by forcedly minimizing the three independent variables) are delimited by the black circle

By forcing the extraction parameters to be as low as possible in order to better fit into a green process intensification perspective, the suggested conditions for obtaining the highest PC value are the following: X 1 = 60 °C, X 2 = 18 min, X 3 = 1 MW cycle, with a predicted value of 61.5 %, according to Eq. 3 (Fig. 5b). Although this value is significantly lower with respect to the one (67.7 %) obtained without forcing any of the input parameters to be as low as possible, it can be easily seen how it promptly increases to 66.3 % by prolonging the microwave extraction time up to 30 min, which is, however, a time significantly lower with respect to conventional extraction procedures.

The water-soluble polyphenols content (WPC) was evaluated as an additional response since it can be particularly useful for targeted nutraceuticals (Jimenez-Colmenero et al. 2010). Indeed, their hydrophilic nature allows achieving easier transport and absorption in human bodies leading to more efficient antioxidant and anti-ageing formulations.

The WPC response analysis suggested a two-factor interaction model as the most significant one, with temperature (X 1) and number of microwave cycles (X 3) as the two input parameters with a significant (p < 0.05) and positive (Fig. 6) main effect. The two-factor interaction model is described by the following Eq. 4:

Main separate effects of the three independent variables considered on the response WPC, in the case of unripe walnut seed extracts: a temperature, b time and c number of MW cycles. Each graph was obtained assuming the other two variables in the central value of their variability range. The dotted lines define the confidence bands

According to ANOVA, the correlation coefficient for this model is 0.6818, with an insignificant lack of fit. The optimal extraction conditions in order to maximize this latter response resulted to 60 °C, 30 min, and three microwave cycles.

For specific applications, both the responses (PC and WPC) need to be as high as possible, thus by concurrently analysing PC and WPC, and considering the desirability as the region/s of the experimental design/space characterized by the maximum values of both the responses, the contour plot reported in Fig. 7 can be considered. The highest desirability degree of the extract can be reached by working at the highest temperature investigated (100 °C) for the shortest extraction time (6 min) and using three MWs cycles. According to the models, the PC and WPC values predicted are 68 and 43.9 % respectively, which are in good agreement with those experimentally obtained by the sample 17 s (Table 2). A relative high desirability can, however, be obtained also by operating at the lower temperature of 60 °C but prolonging the extraction time to 30 min.

Energy Consumption Evaluation

The specific energy consumption typical of the two scenarios described in the previous section and characterized by the higher desirability has been calculated from the power and temperature versus time curves experimentally resulted from microwave heating of those mixture (registered by the software of the instrument), and the main results are summarized in Table 3. In detail, the total energy consumption (TE) has been calculated by summing all of the watts employed by the microwave generator over the time interval of the experiment. This value expressed in joule (W s) has been successively divided by the mass of the phenolic compounds and by the mass of the water-soluble polyphenols recovered, respectively, thus obtaining the corresponding specific energy consumptions (SE and SEW).

As reported in Table 3, the total energy consumption results slightly lower in the case of an extraction performed at the temperature of 60 °C, prolonged for a total extraction time of 30 min and employing three different microwave heating cycles. Being the recovered amounts of phenolic compounds and water-soluble polyphenols comparable for both samples 17 and 4 s, the calculated specific energy consumptions reflect the findings related to the total energy consumption.

It is, however, worth noting how the use of a conventional heating source (like a hot plate or heating mantle, employing typically 220–250 W) would require more energy due to the need of heating the plate/mantle itself, the reaction vessel and the load. Using microwaves, despite the low energy efficiency of the applicator used (theoretical energy requirement for heating the load alone is one order of magnitude lower than that measured), the specific energy consumption benefits from the higher yields.

Conclusions

Microwave-assisted extraction of phenolic compounds from unripe walnut seeds and fresh male flowers of J. regia was optimized in terms of extraction temperature, time and number of microwaves cycles, by exploiting DoE technique.

Some considerations can be derived as concluding remarks:

-

The number of microwaves cycles resulted as a factor with a significant main effect on the analysed responses;

-

The optimal extraction parameters for fresh J. regia male flowers resulted in 100 °C, 6 min of extraction time and three microwaves heating cycles;

-

In the case of unripe walnut seeds, the interaction between temperature and time and that between time and number of MWs cycles mainly affect the recovery of total phenolic compounds and water-soluble polyphenols;

-

The regions of the experimental space in which response values are as high as possible were predicted: 100 °C, 6 min of extraction time and three MW heating cycles; if energy consumption calculations is taken into account, they change to 60 °C, 30 min and three microwaves cycles;

-

The use of microwave energy allowed a significant reduction of the extraction times as compared to conventional extraction techniques (Zhang et al. 2009), leading to comparable and sometimes significantly higher extraction yields (Zhang et al. 2009; Fernández-Agulló et al. 2013);

-

In this latter perspective, a detailed and complete Life Cycle Assessment (LCA) of microwave-assisted extraction will be necessary in order to realize a cradle to grave environmental evaluation, thus considering not only the energy consumptions, but also all the factors which can significantly affect the environmental as well as the human health (e.g. equipments/plants, transport, waste materials and their final disposal treatments).

References

Bao Y, Han J, Hu FB, Giovannucci EL, Stampfer MJ, Willet WC, Fuchs CS (2013) Association of nut consumption with total and cause-specific mortality. New Eng J Med 369:2001–2011

Blomhoff R, Carlsen M, Andersen L, Jacobs D Jr (2006) Health benefits of nuts: potential role of antioxidants. Brit J Nutr 96:S52–S60

Cerdá B, Tomás-Barberán FA, Espín JC (2005) Metabolism of antioxidant and chemopreventive ellagitannins from strawberries, raspberries, walnuts, and oak-aged wine in humans: identification of biomarkers and individual variability. J Agric Food Chem 53:227–235

Chan CH, Yusoff R, Ngoh GC, Kung FWL (2011) Microwave-assisted extractions of active ingredients from plants. J Chromat A 1218:6213–6225

Chemat F, Vian MA, Cravotto G (2012) Green extraction of natural products: concept and principles. Int J Mol Sci 13:8615–8627

Contini M, Baccelloni S, Massantini R, Anelli G (2008) Extraction of natural antioxidants from hazelnut (Corylus avellana L.) shell and skin wastes by long maceration at room temperature. Food Chem 110:659–669

Davies RM (2014) Performance evaluation of continuous screw press for extraction soybean oil. Am J Sci Technol 1:238–242

Eriksson L, Johansson E, Kettaneh-Wold N, Wikstrom C, Wold S (2008) Design of experiments, principles and applications (3rd revised and enlarged edition). Umetrics Academy, Umea ISBN 91-973730-4-4

Fernández-Agulló A, Pereira E, Freire MS, Valentão P, Andrade PB, González-Álvarez J (2013) Influence of solvent on the antioxidant and antimicrobial properties of walnut (Juglans regia L.) green husk extracts. Ind Crop Prod 42:126–132

González R, Ballester I, López-Posadas R, Suárez MD, Zarzuelo A, Martínez-Augustin O, Sánchez De Medina F (2011) Effects of flavonoids and other polyphenols on inflammation. Critical Rev Food Sci Nutr 51:331–362

Herrero M, Cifuentes A, Ibañez E (2006) Sub- and supercritical fluid extraction of functional ingredients from different natural sources: plants, food-by-products, algae and microalgae a review. Food Chem 98:136–148

Ibarrola-Jurado N, Bullo M, Guasch-Ferré M, Ros E, Martinez-Gonzalez MA, Corella D, Fiol M, Warnberg J, Estruch R, Roman P, Aros F, Vinyoles E, Serra-Majem L, Pinto X, Covas MI, Basora J, Salas-Salvado J (2013) Cross-sectional assessment of nut consumption and obesity, metabolic syndrome and other cardiometabolic risk factors: the PREDIMED study. PLoS One 8:e57367

Ignat I, Volf I, Popa VI (2011) A critical review of methods for characterization of polyphenolic compounds in fruits and vegetables. Food Chem 126:1821–1835

Jimenez-Colmenero F, Sanchez-Muniz FJ, Olmedilla-Alonso B, Collaborators (2010) Design and development of meat-based functional foods with walnut: technological, nutritional and health impact. Food Chem 123:959–967

Karacabey E, Mazza G (2010) Optimisation of antioxidant activity of grape cane extracts using response surface methodology. Food Chem 119:343–348

Labuckas DO, Maestri DM, Perelló M, Martínez ML, Lamarque AL (2008) Phenolics from walnut (Juglans regia L.) kernels: antioxidant activity and interactions with proteins. Food Chem 107:607–612

Le V, Esposito D, Grace MH, Ha D, Pham A, Bortolazzo A, Bevens Z, Kim J, Okuda R, Kormarnytsky S, Lila MA, White JB (2014) Cytotoxic effects of ellagitannins isolated from walnuts in human cancer cells. Nutr Cancer 66:1304–1314

Leonelli C, Mason TJ (2010) Microwave and ultrasonic processing: now a realistic option for industry. Chem Eng Proces 49:885–900

Leonelli C, Veronesi P, Cravotto G (2013) In: Chemat F, G. C (eds) Microwave-assisted extraction: an introduction to dielectric heating, in microwave-assisted extraction for bioactive compounds, theory and practice. Springer, New York (Chapter. 1). ISBN 978-1-4614-4829-7

Li T, Li J, Hu W, Zhang X, Li X, Zhao J (2012) Shelf-life extension of crucian carp (Carassius auratus) using natural preservatives during chilled storage. Food Chem 135:140–145

Liyana-Pathirana C, Shahidi F (2005) Optimization of extraction of phenolic compounds from wheat using response surface methodology. Food Chem 93:47–56

Loypimai P, Moongngarm A, Chottanom P, Moontree T (2015) Ohmic heating-assisted extraction of anthocyanins from black rice bran to prepare a natural food colourant. Inn Food Sci Em Technol 27:102–110

Martinez ML, Curti MI, Roccia P, Llabot JM, Penci MC, Bodoira RM, Ribotta PD (2015) Oxidative stability of walnut (Juglans regia L.) and chia (Salvia hispanica L.) oils microencapsulated by spray drying. Powder Technol 270:271–277

Mustafa A, Turner C (2011) Pressurized liquid extraction as a green approach in food and herbal plants extraction: a review. Anal Chim Acta 703:8–18

Naczk M, Shahidi F (2004) Extraction and analysis of phenolics in food. J Chrom A 1054:95–111

Namal Senanayake SPJ (2013) Green tea extract: chemistry, antioxidant properties and food applications-a review. J Func Foods 5:1529–1541

Oliveira I, Sousa A, Ferreira ICFR, Bento A, Estevinho L, Pereira JA (2008) Total phenols, antioxidant potential and antimicrobial activity of walnut (Juglans regia L.) green husks. Food Chem Toxicol 46:2326–2331

Patzke GR, Zhou Y, Kontic R, Conrad F (2011) Oxide nanomaterials: synthetic developments, mechanistic studies, and technological innovations. Angew Chemie Int Ed 50:826–859

Pereira JA, Oliveira I, Sousa A, Valentão P, Andrade PB, Ferreira ICFR, Ferreres F, Bento A, Seabra R, Estevinho L (2007) Walnut (Juglans regia L.) leaves: phenolic compounds, antibacterial activity and antioxidant potential of different cultivars. Food Chem Toxicol 45:2287–2295

Prat D, Hayler J, Wells A (2014) A survey of solvent selection guides. Green Chem 16:4546–4551

Rombaut N, Tixier AS, Bily A, Chemat F (2014) Green extraction processes of natural products as tools for biorefinery. Biofuels, Bioprod Bioref 8:530–544

Rosa R, Veronesi P, Leonelli C (2013) A review on combustion synthesis intensification by means of microwave energy. Chem Engineer Proc 71:2–18

Salcedo CL, López de Mishima BA, Nazareno MA (2010) Walnuts and almonds as model systems of foods constituted by oxidisable, pro-oxidant and antioxidant factors. Food Res Int 43:1187–1197

Shah MA, Bosco SJD, Mir SA (2014b) Plant extracts as natural antioxidants in meat and meat products. Meat Sci 98:21–33

Shah TI, Sharma E, Ahmad G (2014a) Juglans regia Linn: a phytopharmacological review. World J Pharm Sci 2:364–373

Sharma N, Ghosh P, Sharma UK, Sood S, Sinha AK, Gulati A (2009) Microwave-assisted efficient extraction of juglone in different solvents from Juglans regia: quantification of six phenolic constituents by validated RP-HPLC and evaluation of antimicrobial activity. Anal Lett 42:2592–2609

Shirsath SR, Sonawane SH, Gogate PR (2012) Intensification of extraction of natural products using ultrasonic irradiations—a review of current status. Chem Engineer Proc 53:10–23

Slatnar A, Mikulic-Petkovsek M, Stampar F, Veberic R, Solar A (2015) Identification and quantification of phenolic compounds in kernels, oil and bagasse pellets of common walnut (Juglans regia L.). Food Res Int 67:255–263

Stankiewicz A, Moulijn JA (2000) Process intensification: transforming chemical engineering. Chem Engineer Prog 96:22–34

Tobiszewski M, Mechlinska A, Namiesnik J (2010) Green analytical chemistry—theory and practice. Chem Soc Rev 39:2869–2878

Valls-Pedret C, Lamuela-Raventos RM, Medina-Remon A, Quintana M, Corella D, Pinto X, Martinez-Gonzalez MA, Estruch R, Ros E (2012) Polyphenol-rich foods in the Mediterranean diet are associated with better cognitive function in elderly subjects at high cardiovascular risk. J Alzheimer Dis 29:773–782

Veggi PC, Martinez J, Meireles MAA (2013) In: Chemat F, Cravotto G (eds) Fundamentals of microwave extraction in microwave-assisted extraction for bioactive compounds, theory and practice. Springer, New York (Chapter 2), ISBN 978-1-4614-4829-7

Vian MA, Fernandez X, Visinoni F, Chemat F (2008) Microwave hydrodiffusion and gravity, a new technique for extraction of essential oils. J Chromat A 1190:14–17

Wijngaard H, Hossain MB, Rai DK, Brunton N (2012) Techniques to extract bioactive compounds from food by-products of plant origin. Food Res Int 26:505–513

Yang J, Liu RH, Halim L (2009) Antioxidant and antiproliferative activities of common edible nut seeds. LWT Food Sci Technol 42:1–8

Zerazion E, Rosa R, Ferrari E, Veronesi P, Leonelli C, Saladini M, Ferrari AM (2016) Phytochemical compounds or their synthetic counterparts? A detailed comparison of the quantitative environmental assessment for the synthesis and extraction of curcumin. Green Chem 18:1807–1818

Zhang Z, Liao L, Moore J, Wu T, Wang Z (2009) Antioxidant phenolic compounds from walnut kernels (Juglans regia L) Food Chem 113:160–165

Acknowledgments

The authors want to thank Dr. Sara Romeo for her support in experimental work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

Not applicable.

Conflict of Interest

Roberto Rosa declares that he has no conflict of interest. Lorenzo Tassi declares that he has no conflict of interest. Giulia Orteca declares that she has no conflict of interest. Monica Saladini declares that she has no conflict of interest. Carla Villa declares that she has no conflict of interest.

Paolo Veronesi declares that he has no conflict of interest. Cristina Leonelli declares that she has no conflict of interest. Erika Ferrari declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Rosa, R., Tassi, L., Orteca, G. et al. Process Intensification by Experimental Design Application to Microwave-Assisted Extraction of Phenolic Compounds from Juglans regia L.. Food Anal. Methods 10, 575–586 (2017). https://doi.org/10.1007/s12161-016-0624-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-016-0624-1