Abstract

The aroma compounds in the Chinese vinegar has been profiling by the technology of Headspace solid phase microextraction (HS-SPME) hybrid with gas chromatography mass spectrometry (GC-MS). Thirteen compounds were selected as the key aroma compounds to discriminate two protected geographical origin (PGI) Chinese vinegars named Shanxi extra-aged vinegar and Zhenjiang vinegar by using principal component analysis. The results demonstrate that volatile organic components as the markers combined with the appropriate chemometrics method can be used for PGI Chinese vinegar discrimination with good reliability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vinegar is an indispensable food condiment in human’s daily diet, especially for Chinese people, which is well-known for being food flavor enhancers and health beneficial. The quality and organoleptic properties of vinegar are highly related to the volatile compounds (Wang et al. 2012). The classification and discrimination both European and Asiatic vinegars with aroma substances or volatile compounds have been widely studied (Aceña et al. 2011; Durán et al. 2008; Pizarro et al. 2008). Vinegars in Europe are mainly made from fruit or any materials containing sugar, such as sherry wine vinegar, Modena balsamic vinegar, malt vinegar, and cider vinegar (Casale et al. 2006a). The aromatic substances in Sherry vinegar that might be generated during the alcoholic and acid fermentation processes or from wood flavor during aging process in wooden barrel were classified to 6 of aldehydes, 1 of acetal, 3 of ketones, 14 of ethyl esters, 11 of alcohols, 1 of terpene, 6 of acids, 4 of lactones, and 3 of phenols (Callejón et al. 2008b). Among them, diacetyl, ethyl acetate, and sotolon were proved to the important contributors to the typical aroma of this vinegar.

However, Chinese vinegars are mainly made from grain crops with longer manufacture period. There are four types of traditional vinegar in China, aromatic vinegar, mature vinegar, rice vinegar, and white vinegars. The volatile compounds in Chinese vinegar have also been studied detailedly. The research of Xiao et al. focused on the characteristic volatile profiles of China’s four traditional vinegar types mentioned above (Xiao et al. 2011). They found that the major compounds in Chinese vinegars are furfural, acetic acid, ethyl acetate, 3-hydroxy-2-butanone, 3-methyl-1-butanol, isopentyl acetate, benzaldehyde, and phenylethyl alcohol, which were also supported by the study of Lu et al. (Lu et al. 2011). These characteristics of aroma compounds in these traditional Chinese vinegars mainly contribute to the delightful flavors and health benefits. Therefore, local characteristics protection of the vinegar was involved in the schedule. A lot of local governments have carried out a series of regulations on food geographical protection. For instance, the protected geographical indications (PGIs) of European Parliament and Council Regulation (EC) No 510/2006 were set to protect the agricultural products and foodstuffs closely linked to the geographical area, which means at least one of the stages of production, processing, or preparation takes place in the area. In China, Zhenjiang vinegar, Shangxi extra-aged vinegar, Kazuo aged vinegar, Yongchun aged vinegar, and Duliu vinegar have been authorized with PGI certification by the government. The volatile compounds that exist in vinegars have been widely used as fingerprint for the discrimination of vinegars due to their abundant information (Xiao et al. 2011).

Based on the advantages of implementation of synchronized extraction and concentration steps, headspace-solid-phase microextraction (HS-SPME) is the most commonly used method for volatile compounds extraction (Aceña et al. 2011; Castro et al. 2002; Damascelli and Palmisano 2013; Natera et al. 2002; Pizarro et al. 2008; Ye et al. 2012). After determined by the dynamic head-space gas chromatography with FID detector (HS-GC-FID) (Del Signore 2001; Natera Marín et al. 2002; Pizarro et al. 2008), gas chromatography-mass spectrometer (GC-MS) (Callejón et al. 2008a, b), or direct gas chromatography-olfactometry (D-GCO) techniques (Aceña et al. 2011; Callejón et al. 2008a, b), the volatile compounds data were analyzed by multivariate statistical technique, such as principal component analysis (PCA) (Luo et al. 2013; Zheng et al. 2014), linear principal component analysis (LPCA) (Del Signore 2001), cluster analysis (CA) (Xiao et al. 2011), linear discriminant analysis (LDA) (Callejón et al. 2008a; Casale et al. 2006a), stepwise linear discriminant analysis (SLDA) (Pizarro et al. 2008), and parallel factor analysis (PARAFAC) (Cocchi et al. 2007). Moreover, besides identifying or quantifying each chemical substance, the techniques of head-space mass spectrometry (HS-MS) (Casale et al. 2006a; Cocchi et al. 2007) and electronic gas sensor (Zou et al. 2003) were also used to obtain the signal of the whole mixture of volatile compounds for the classification and discrimination of vinegar. However, only few works have been conducted for the discrimination on Chinese vinegars with the message from the volatile compounds, such as the method based on the method of HS-SPME-GC/MS (Xiao et al. 2011) and the gas sensors array reported by Yin et al. (2008) and Zou et al. (2003).

Until recently, few studies have been reported on the vinegar discrimination of Chinese PGI vinegar protection by using aroma composition. Hence, in this project, two kinds of geographical indication vinegar products, Shanxi extra-aged vinegar and Zhenjiang vinegar, were chosen to conduct the study of the geographical indication vinegar discrimination.

Aroma composition of vinegar, determined by Headspace solid phase microextraction (HS-SPME) coupled with gas chromatography mass spectrometry (GC-MS), coupled with the principal component analysis (PCA) was used for two PGI Chinese vinegar discrimination. Moreover, the Fisher discriminant analysis was primarily introduced to build a predictive model for the classification of unknown sample.

Experimental Section

Samples

Thirteen Shanxi extra-aged vinegar samples (SVs) and 22 Zhenjiang vinegar samples (ZVs), all labeled clearly with PGI mark, were purchased from supermarkets in Shanxi, Jiangsu, and Liaoning Province or directly obtained from PGI local factories. Meanwhile, 15 non-geographical indications (non-PGI) vinegar samples were obtained from different markets in Guangdong, Hunan, and Shanxi Provinces respectively. The samples were kept refrigerated at 4 °C. Shanxi extra-aged vinegar is a PGI vinegar in northern China, which is produced from sorghum, pea, and barley. Its manufacture processed as following: stewing the raw material, saccharification with the koji, alcoholization, high-temperature rapid acetification, roasting the solid fermentation substrate with medium-temperature fire, and aging for years with special cares such as solarization in summer and ice removing in winter (Chen et al. 2010). As a PGI vinegar in southern China, Zhenjiang vinegar is produced from sticky rice and rice bran, owning 3 months less aging process than Shanxi extra-aged vinegar without baking process following fermentation (Cocchi et al. 2007).

HS-SPME Procedure

The SPME holder for manual sampling with 75-μm CAR/PDMS fibers were purchased from Supelco (Bellefonte, PA, USA). The HS-SPME procedure was carried by TriPlus autosampler (Thermo-Finnigan, USA). With optimum conditions, 5.0-mL vinegar sample was placed into a 20-mL glass vial with the addition of 0.8 g NaCl. The SPME fiber was exposed in the headspace vial at 60 °C for 45 min. Afterward, the fiber was removed from the headspace vial and inserted into the injection port of the GC-MS for the desorption, which is conducted at 230 °C for 3 min in the splitless mode.

GC-MS Procedure

Analytes were analyzed by a Trace DSQ II GC-MS (Thermo-Finnigan, USA) using the capillary column of DB-624(60 m × 0.25 mm × 0.25 μm, with the stationary phase of 6 % cyanopropylphenyl and 94 % dimethyl polysiloxane, with helium as the carrier gas at a constant flow rate of 1.0 mL/min. After desorption, analytes were injected in splitless mode for 5 min and the split mode with the flow ratio of 1:20. Analyses were performed under the following conditions: The column was kept at 40 °C for 1 min and then heated to 250 °C with a 5 °C/min temperature raise rate and holding for 5 min, and the mass spectrometer in electron ionization mode was operated in full-scan mode (m/z 40–400). Additionally, the ion source temperature and transfer line temperature were both set at 260 °C.

Compounds Identification and Quantification

The volatile compounds detected by GC-MS were identified by comparing the retention time and MS fragmentation patterns with those of the reference compounds. Other compounds were tentatively identified with mass spectra with the aid of NIST library and Kovats RIs, since their corresponding standards were not available. The Kovats RI of unknown compounds were detected by sample injection with a homologous series of alkanes (C6-C40) purchased from Sigma-Aldrich. The quantification of aroma compounds was carried out by using the integrated areas based on the total ion chromatograms comparing to the area of known concentration of chemical standards. Each standard was dissolved in methanol to produce stock standard solution. Then, the stock standard solution was diluting by using the simulated vinegar solution made by acetic acid and water mixed with the ration of 1:25. Five levers concentration ranged from 10 μg/L to 10 μg/mL that were used to establish standard curves, whereas furfural was ranged from 5 to 500 μg/mL. Each standard solution was detected with the same condition as the vinegar samples. The volatile compounds were determined according to the standard curves. Each sample was detected by three parallel determinations. The chemical standards of the volatile compounds were also supplied by Sigma-Aldrich.

Multivariate Analysis

Principal component analysis (PCA), as an unsupervised pattern recognition technique, and the Fisher discriminant analysis (FDA), a supervised pattern recognition technique, were applied for the discrimination of two PGI protected Chinese vinegars. The pattern recognition analyses were analyzed by the MATLAB 6.5.

Results and Discussion

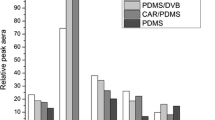

Influence of the Extraction Time and Extraction Temperature

To find the optimum extraction time, the CAR/PDMS fiber was evaluated at 20, 30, 45, and 60 min with the optimum condition respectively. The extraction temperature condition was also studied at 25, 40, 60, and 70 °C respectively. A mixture standard solution of benzyl alcohol, furfural, and 2,3,5,6-tetramethylpyrazine with 1.0 μg/mL was used to study the extraction time condition. The standard solution was dissolved in the simulated vinegar solution made by acetic acid and water mixed with the ration of 1:25. The three compounds represented as the low, median, and high concentration levers of the volatile compounds in vinegar samples, respectively. As seen in Fig. 1a, the peak area of benzyl alcohol and furfural reaches saturation at 30 min, while 2,3,5,6-tetramethylpyrazine needs 45 min. Therefore, 45 min was selected, as the most compounds were attained maximum uptake in SPME fiber. Moreover, the extraction temperature condition was studied at 25, 40, 60, and 70 °C with the optimum condition respectively. As seen in Fig. 1b, the peak area of three compounds reached the highest response at 60 °C. The results showed that the extraction time with 45 min and extraction temperature with 60 °C can be selected as the optimum conditions.

Identification of Aroma Compounds in Different Chinese Vinegars

Most of the traditional PGI Chinese vinegars were produced according to the following processes: saccharification, alcohol fermentation, acetic acid fermentation, and maturation. During these processes, a series of chemical and enzymatic reactions lead to pleasant organoleptic changes, among which Maillard reaction is the most important one. Maillard reaction could induce the condensation of the reducing carbohydrates (glucose, fructose) and free amino acid (praline, lysine), producing a series of reactions that culminate the polymerization and appearance of dark pigments or melanoidins (Casale et al. 2006b). During the intermediate steps, the aroma flavors, which is composed of pyrazine, aldehydes, furans, ketones, etc., were produced, giving potential fingerprint information for vinegar characterization (Xiao et al. 2011). Thereby, in order to apply the fingerprint information of vinegar aroma compounds into the classification of Chinese vinegars, volatile compounds from many different Chinese vinegars were identified detailedly. The samples, two kinds of PGI vinegars, and several non-PGI vinegars were collected. The volatile compounds in different Chinese vinegars were detected by using the HS-SPME-GC-MS. All of the volatile compounds detected in the vinegar samples used in this work are summarized in Table 1. The total ion chromatogram of the most volatile compounds detected in Shanxi extra-aged vinegar is shown in Fig. 2. Twenty-one of volatile compounds in Shanxi extra-aged vinegar were detected and identified corresponding to the compounds listed in Table 1.

The chromatogram for the retention time from 5 to 45 min in Shanxi extra-aged vinegar. The peak numbers correspond to the compounds in Table 1

The compound with an asterisk (*) in Table 1 was identified with by comaring Kovats retention indices (RI) as well as the MS spectra of the standard compounds. Other compounds were tentatively identified with mass spectra with the aid of NIST library and Kovats RIs. As listed in Table 1, 46 compounds were identified, which were classified in eight esters, seven acids, eight alcohols, three aldehydes, four phenols, five ketones, two furans, four pyrazines, and five other organic compounds. Most of them have been previously identified in the research studies of Shanxi aged vinegar (Wang et al. 2012), Zhenjiang vinegar (Lu et al. 2011), sherry vinegar (Callejón et al. 2008a, b), and balsamic vinegar (Durán et al. 2008). The compounds of acetic acid, ethyl acetate, benzyl alcohol, phenylethyl acetate, furfural, benzaldehyde, 2,3-butanedione, 3-hydroxy-2-butanone, γ-nonanolactone, and 2,3,5,6-tetramethylpyrazine have relatively high detection frequencies higher than 80 %. While for other compounds, such as butyl acetate, 2-methyl-butyric acid, furfuryl alcohol, 2,5-dimethyl-hexanol, 1-phenyl-2-propanone, 2-acetyl furan, and 2,2-dimethyl-1,3-dioxolane-4-carboxaldehyde appeared only once with the distribution of 2 %. Besides, furfuryl alcohol, 2-acetyl furan, and 2,2-dimethyl-1,3-dioxolane-4-carboxaldehyde are unstable at acidic condition for a long time. It can be explained that furan ring can open, and acetal could be hydrolyzed in the acidic condition. The instability of these compounds might be the reason for the low concentrations of these compounds in the vinegar samples. The ethylene glycol diacetate, 3-methylbutanoic acid, hexanoic acid, 2,3-butanediol, 4-ethylphenol, and 2-acetylfuran were detected with a relatively high frequency, around 50 %. Moreover, it is noteworthy that some compounds presented in the range of 16–24% showed a higher detection frequencies than other compounds in Shanxi extra-aged vinegars, which are identified as 2-propiony furan, 2,3-dimethylpyrazine, and 2,3,5-trimethylpyrazine. Thereamong, 2-propionyl furan was a new compound detected in Chinese vinegar, which may be generated from the Maillard reaction, and also was used as aging indicator for beer brewing (Herrmann et al. 2010). The high temperature throughout the thermal process of Shanxi vinegar can be beneficial for the formation of 2,3-dimethylpyrazine and 2,3,5-trimethylpyrazine, which contributes to the roasted odors along with 2,3,5,6-tetramethylpyrazine (Wang et al. 2012).

Discrimination of Two PGI Vinegar Samples

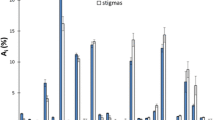

With the purpose of different PGI Chinese vinegar classification, PCA was used to emphasize the differences between vinegars. To select the idiographic aroma compounds that mainly induce the difference among Shanxi extra-aged vinegar, Zhenjiang vinegar, and other non-PGI vinegars, the compounds with high loading scores to the PCs (principal components) were chosen. As a result, the top 13 aroma compounds that effect most on the difference between PGI and non-PGI vinegars were selected as the feature variables shown in Fig. 3. Upon the optimum conditions, the linear range, quantifying ions, precision, and accuracy of the 13 volatile compounds used for discrimination of two PGI vinegar samples are studied and listed in Table 2. Thirteen different volatile compounds were quantified with corresponding standard substances listed in Table 3. These compounds showed clearly and reproducibly during the period of 20–40 min, which can be regard as the fingerprint region.

Thirteen selected idiographic aroma compounds correspond to Table 2 in Shanxi extra-aged vinegar (a), Zhenjiang vinegar (b), and non-PGI vinegar (c)

To identify the Shanxi extra-aged vinegars and Zhenjiang vinegars and other non-PGI Chinese vinegars, the first two PCs, with the 43.78 and 18.61 % variance explanation respectively, which could represent 62 % of the total variance, were used to provide a visualization of the data. Figure 4a showed the principle component projection plot of PC1 to PC2 from the 13 volatile compounds contents in vinegars. The splashes, representing different varieties of vinegars in the PC1-PC2 two dimension scatter plots, were completely separated, which indicates that the samples of different varieties can be discriminated properly. The loading values of each volatile compound in PCs illustrated the contributions of the individual volatile compounds to the overall variability. As shown in the loading plots of 13 variables between PC1 and PC2 in Fig. 4b, the major compounds (loading values > 0.3) that positively contribute to the PC1 were 2,3-dimethylpyrazine, 2,3,5-trimethylpyrazine, 2,3,5,6-tetramethylpyrazine, 2-acetyl pyrrole, 2-methoxyphenol, and 2-methoxy-4-methylphenol. On the contrary, the PC2 were highly contributed by the positive loading compounds (loading values > 0.4) of furfural, benzyl alcohol, and phenylethyl acetate.

Score plots-based PCA for Chinese vinegars classification (a) and the Loading plot of thirteen variables for Chinese vinegars (b). Thirteen variables correspond to aroma compounds in Table 2. Vinegar symbols: Zhenjiang vinegars (black asterisk), Shanxi vinegars (black circle), and non-PGI vinegars (asterisk)

The score plot of the PC1-PC2 comparison revealed three distinct groups of the vinegar samples. According to the volatile compound distribution in Fig. 4b, the group of triangle tag (▲), which was related to Zhenjiang vinegars and located on the positive side of PC2, was positively correlated to benzyl alcohol and phenylethyl acetate. These results indicate that the Zhenjiang vinegar had higher contents of benzyl alcohol and phenylethyl acetate, which was supported by the results in Table 2. Oppositely, the group of solid circular tag (●), related to Shanxi extra-aged vinegar positioned at positive of PC1 and negative side of PC2, was positively correlated to 2,4,5-trimethyloxazole, furfural, 2,3-dimethylpyrazine, benzaldehyde, 5-methylfurfural, 2,3,5-trimethylpyrazine, 2,3,5,6-tetramethylpyrazine, 2-acetyl pyrrole, 2-methoxyphenol, 2-methoxy-4-methylphenol, and 4-ethylphenol. Lastly, the non-PGI group marked as asterisk tag (*), gathered at the negative region of PC1 and PC2, nearly had no correlation compounds.

Discriminant Analysis

In order to further establish a classified model for Chinese PGI vinegars classification, the Fisher discriminated analysis was applied for these data. A set of discriminant functions were built based on 13 volatile compounds in identified membership which were also selected for PCA analysis method mentioned above. The three discriminant functions of Shanxi extra-aged vinegar (SV), Zhenjiang vinegar (ZV), and non-PGI Chinese vinegars (nPGI) were as follows:

These discriminant functions can be applied to identify the group of which the unknown sample belongs to. After quantification, put the values of the 13 compounds in unknown samples into these functions and calculate the results, the sample belongs to the group with the highest result. The discrimination performance was evaluated by the 28 vinegar samples with known original sources, and the results were given in Table 4. Each sample was calculated value of the three functions, and the discriminant group was depended on the highest value. The classification in Table 4 was satisfactory for every class, which indicates that this method is appropriate for practical application.

Conclusion

A total of 46 aroma compounds in Chinese vinegars were identified by SPME-GC-MS technique and then regarded as the geographical indication discriminators to distinguish two geographical indication protected Chinese vinegar, which are Shanxi extra-aged vinegars and Zhenjiang vinegars, from non-geographical indication protected vinegars all over China. After PCA analysis, 13 aroma compounds with high loading scores were selected as the feature variables. These compounds majorly contribute to the differences of vinegars between PGI and non-PGI vinegars. Moreover, a predictive model for unknown sample classification was established by Fisher discriminant analysis method, and reasonable results indicate that this method is appropriate for practical application.

References

Aceña L, Vera L, Guasch J, Busto O, Mestres M (2011) Chemical characterization of commercial sherry vinegar aroma by headspace solid-phase microextraction and gas chromatography−olfactometry. J Agric Food Chem 59(8):4062–4070

Callejón RM, Morales ML, Ferreira ACS, Troncoso AM (2008a) Defining the typical aroma of sherry vinegar: sensory and chemical approach. J Agric Food Chem 56(17):8086–8095

Callejón RM, Morales ML, Troncoso AM, Silva Ferreira AC (2008b) Targeting key aromatic substances on the typical aroma of sherry vinegar. J Agric Food Chem 56(15):6631–6639

Casale M, Armanino C, Casolino C, Oliveros CC, Forina M (2006a) A chemometrical approach for vinegar classification by headspace mass spectrometry of volatile compounds. Food Sci Technol Res 12(3):223–230

Casale M, Sáiz Abajo MJ, González Sáiz JM, Pizarro C, Forina M (2006b) Study of the aging and oxidation processes of vinegar samples from different origins during storage by near-infrared spectroscopy. Anal Chim Acta 557(1):360–366

Castro Mejías R, Natera Marín R, de Valme García Moreno M, García Barroso C (2002) Optimisation of headspace solid-phase microextraction for analysis of aromatic compounds in vinegar. J Chromatogr A 953(1):7–15

Chen JC, Chen QH, Guo Q, Ruan S, Ruan H, He GQ, Gu Q (2010) Simultaneous determination of acetoin and tetramethylpyrazine in traditional vinegars by HPLC method. Food Chem 122(4):1247–1252

Cocchi M, Durante C, Marchetti A, Armanino C, Casale M (2007) Characterization and discrimination of different aged ‘Aceto Balsamico Tradizionale di Modena’ products by head space mass spectrometry and chemometrics. Anal Chim Acta 589(1):96–104

Damascelli A, Palmisano F (2013) Sesquiterpene fingerprinting by headspace SPME-GC-MS: preliminary study for a simple and powerful analytical tool for traceability of olive oils. Food Anal Methods 6(3):900–905

Del Signore A (2001) Chemometric analysis and volatile compounds of traditional balsamic vinegars from Modena. J Food Eng 50(2):77–90

Durán GE, Chinnici F, Natali N, Marin RN, Riponi C (2008) Solid-phase extraction method for determination of volatile compounds in traditional balsamic vinegar. J Sep Sci 31:3030–3036

Herrmann M, Klotzbücher B, Wurzbacher M, Hanke S, Kattein U, Back W, Becker T, Krottenthaler M (2010) A new validation of relevant substances for the evaluation of beer aging depending on the employed boiling system. J Inst Brew 116(1):41–48

Lu ZM, Xu W, Yu NH, Zhou T, Li GQ, Shi JS, Xu ZH (2011) Recovery of aroma compounds from Zhenjiang aromatic vinegar by supercritical fluid extraction. Int J Food Sci Technol 46:1508

Luo MZ, Zheng YJ, Xiong C, Li BF, Chen SJ, Bai WL, Zeng YT, Li YL, Zhang XG (2013) A geographical discrimination of Shanxi extra aged vinegars using polyalcohols as the discriminators. J AOAC Int 96(5):1048–1053

Natera Marín R, Castro Mejías R, de Valme García Moreno M, García Rowe F, García Barroso C (2002) Headspace solid-phase microextraction analysis of aroma compounds in vinegar: validation study. J Chromatogr A 967(2):261–267

Pizarro C, Esteban-Díez I, Sáenz-González C, González-Sáiz JM (2008) Vinegar classification based on feature extraction and selection from headspace solid-phase microextraction/gas chromatography volatile analyses: a feasibility study. Anal Chim Acta 608(1):38–47

Wang AL, Song HL, Ren CZ, Li ZG (2012) Key aroma compounds in Shanxi aged tartary buckwheat vinegar and changes during its thermal processing. Flavour Fragance J 27:47–53

Xiao ZP, Dai SP, Niu YW, Yu HY, Zhu JC, Tian HX, Gu YB (2011) Discrimination of Chinese vinegars based on headspace solid-phase microextraction-gas chromatography mass spectrometry of volatile compounds and multivariate analysis. J Food Sci 76(8):C1125–C1135

Ye NS, Zhang LQ, Gu XX (2012) Discrimination of green teas from different geographical origins by using HS-SPME/GC-MS and pattern recognition methods. Food Anal Methods 5(4):856–860

Yin Y, Yu HC, Zhang HS (2008) A feature extraction method based on wavelet packet analysis for discrimination of Chinese vinegars using a gas sensors array. Sensors Actuators B Chem 134(2):1005–1009

Zheng YJ, Ruan GH, Li BF, Xiong C, Chen SJ, Luo MZ, Li YL, Du FY (2014) Multi- composition analysis and pattern recognition of Chinese geographical indication product: vinegar. Eur Food Res Technol 238(2):337–344

Zou XB, Zhao JW, Wu SY, Huang XY (2003) Vinegar classification based on feature extraction and selection from tin oxide gas sensor array data. Sensors 3(4):101–109

Acknowledgments

This work was founded by Special Fund for Quality Inspection Research in the Public Interest (No. 2012104019 and No. 10-85).

Conflict of Interest

Cen Xiong declares that she has no conflict of interest. Yanjie Zheng declares that she has no conflict of interest. Yuanna Xing declares that she has no conflict of interest. Sujuan Chen declares that she has no conflict of interest. Yongting Zeng declares that he has no conflict of interest. Guihua Ruan declares that he has no conflict of interest.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiong, C., Zheng, Y., Xing, Y. et al. Discrimination of Two Kinds of Geographical Origin Protected Chinese Vinegars Using the Characteristics of Aroma Compounds and Multivariate Statistical Analysis. Food Anal. Methods 9, 768–776 (2016). https://doi.org/10.1007/s12161-015-0243-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0243-2