Abstract

The characteristics of the starch granule such as swelling, breakdown and retrogradation in large determines the texture and stability of starchy foods. However, other characteristics of the grain and/or the presence or addition of chemical compounds to the grain/food matrix can modify or alter these properties. The aim of this study was to evaluate the effect of the addition of an emulsifier (Tween 20 and 80) on the pasting properties of barley grain and malt using the rapid visco analyser (RVA). A decrease in peak viscosity (PV, cP), breakdown (B, cP) and final viscosity (FV, cP), while an increase in time to peak (TTP, min) and pasting temperature (PT, °C) as consequence of the addition of Tween 20 was observed. However, this trend was not the same for all the varieties analysed. Overall, these results showed that complex between sugars and lipids are present in barley flour and malt. The practical implications of this study are related with the fact that starch alone (amylose and amylopectin) might not be necessarily the only main driver of malt quality in barley.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The characteristics of the starch granule such as swelling, breakdown and retrogradation in large determines the texture and stability of starchy foods (BeMiller 2011; Blazek and Copeland 2009). However, other characteristics of the grain and/or the presence or addition of chemical compounds to the grain/food matrix can modify or alter these properties (BeMiller 2011). It has been reported that amylose forms complexes with several polar and nonpolar compounds such as lipids (Blazek and Copeland 2009). Therefore, the formation of complexes resulting from the interaction between starch and fatty acids are of particular importance since they can modify the texture and structural stability of starch-based raw materials and foods (Blazek and Copeland 2009).

In the presence of ligands such as lipids, the amylose in solution undergoes conformational changes in ordering from coil to helix (Blazek and Copeland 2009). These amylose–lipid complexes tend to precipitate as partially crystalline structures (Jovanovich and Añon 1999; Cozzolino et al. 2014, 2015; Gelders et al. 2004). Fu and Chen (2015) suggested that the study of starch and lipid complexes and the understanding of the effect on retrogradtaion will be of benefit in order to contribute to the development of novel application in food processing.

Emulsifiers, which are widely used in bread, pasta and noodle products, are surface-active compounds that possess both lipophilic and hydrophilic properties (Choy et al. 2010). The addition of emulsifiers or surfactants to starch has been evaluated by other authors in order to determine and study the interactions between starch with other components such as sugars or lipids (Copeland et al. 2009; Blazek and Copeland 2009). However, most of these studies were carried our using pure starch extracted from the flour and non-reports were found on the study of such approach on barley malt. It is in this context that the addition of an emuslsifier will inhibit the effect of amylose and lipid complexes affecting the pasting properties of both the grain and the malt.

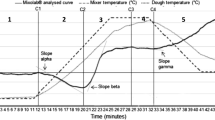

The rapid visco analyser (RVA) is worldwide used to measure the pasting properties of starch in grains and starchy foods (Bason et al. 1993; Booth and Bason 2007; Cozzolino et al. 2012; Fox et al. 2014; Juhasz and Salgo 2008; Meadows 2002; Ross et al. 1987). The RVA have been used to simulate the commercial processing conditions with regards to brewhouse, pH, malt to water ratio and time to temperature profiles (Cozzolino et al. 2012; Fox et al. 2014). For example, simulating the brewery mashing process during RVA analysis allows the enzyme degradation processes on starch to be followed (Cozzolino et al. 2012; Fox et al. 2014). Studies have been also conducted to simulate a commercial mashing process, in which the time and temperature profile resembled that of an upward infusion mashing programme (Cozzolino et al. 2012; Fox et al. 2014). The RVA has been used to detect major viscosity changes, owing to starch gelatinization and liquefaction processes, and minor viscosity changes, such as proteolytic and saccharification activity (Cozzolino et al. 2012; Fox et al. 2014).

This study aims to evaluate the effect of the addition of an emulsifier (Tween 20 and 80) at different concentrations on the pasting properties of different barley grain varieties and malt samples.

Materials and Methods

Grain (n = 30) and malt (n = 20) barley samples (Hordeum vulgare L.) were sourced from the University of Adelaide, Barley Breeding Program (Adelaide, Australia). Samples used in this study were commercial barley varieties (e.g. Flagship, Commander, Navigator, Admiral, Schooner, Gairdner), grown at two locations in South Australia (Roseworthy and Charlick), and harvested in 2011, 2012 and 2013 seasons. Before RVA analysis, samples were milled using an UDY Cyclone Mill (Fort Collins, CO, USA) through a 0.8-mm screen.

Ground samples (3.0 g of flour corrected using the moisture content of the sample, ±0.01 g) were slurried with distilled water (25.0 g as a function of the amount of adjusted sample, ±0.1 g) in an aluminium canister. Tween 20 was added directly into the canister in a concentration of 1 % (w/w) and 10 % (w/w) while Tween 80 only at 1 %. Tween 20 is a nonionic emulsifier (reagent grade, nonionic emulsifier, polysorbate surfactant, polyoxyethylene sorbitan monolaurate, Sigma-Aldrich, USA), with a hydrophilic–lipophilic balance (HLB) = 16.7), while Tween 80 is a nonionic emulsifier (polyoxyethylene sorbitan trioleate, Sigma-Aldrich, USA, HLB = 11.0). The mixtures were agitated by raising and lowering the plastic paddle through the aluminium canister before inserting the can into the RVA instrument. The test profile had a starting temperature of 50 °C, which was held for 1 min, raised to 90 °C in 4 min, held for 10 min, cooled to 50 °C in 1 min, and held for 1 min, with a stirring speed of 160 rpm for the remainder of the test period. The RVA instrument was controlled by the software Thermocline (TCW3) for Windows (v. 3.11, NewPort Scientific, NSW, Australia) (Batey 2007; Cozzolino et al. 2012). The RVA profile parameters calculated by the TCW3 software were peak (PV) and final viscosity (FV), breakdown (B), setback (STB), time to peak (TTP) and pasting temperature (PT) (Batey 2007; Cozzolino et al. 2012).

The RVA profiles were exported from the TCW3 software in csv format into the Unscrambler X software (v 10.1, CAMO ASA, Oslo, Norway) for principal component analysis (PCA). Full cross-validation (leave-one-out) was used to validate the PCA models and to avoid overfitting (Naes et al. 2002). The RVA parameters were statistically analysed using GenStat (14th Ed., VSN International, UK, 2011) (p < 0.05).

Results and Discussion

Table 1 shows the mean and standard error of the mean (SEM) for the RVA parameters measured in the flour barley samples analysed without and with the addition of Tween 20 (1 % w/w) and 80 (1 % w/w). A decrease in PV, B and FV, while an increase in HPV, TTP and PT as a consequence of the addition of either Tween 20 or 80 to the flours amples, was observed. However, it has been noticed that this trend was not the same for all the varieties analysed. In particular, the Flagship variety showed an increase in PV as consequence of the addition of Tween 20 (data not shown). The effect of the addition of different concentrations of Tween 20 to barley flour was also evaluated. Figure 1 shows the effect of the concentration of Tween 20 (1 vs 10 %) on PV in two barley flour varieties. It has been observed that an increase on the concentration of Tween 20 dramatically reduces the PV in barley flour samples. Table 2 shows the mean and SEM for the RVA parameters measured in the malt samples analysed using water and by the addition of Tween 20 (note that Tween 80 was not added to the malt samples). An increase in PV, B and TTP, while a decrease in FV, was also observed in the malt samples analysed.

Figures 2 and 3 show the RVA profiles for the barley flour and malt samples analysed with the addition of Tween 20, 80 and using water as solvent. When the RVA trace was analysed, two clear changes were observed which is not observed from the analysis of the RVA parameters alone. One was related with the shift in PV, mainly associate with the main changes or effect of the emulsifier on the swelling of the granule during the initial steps of the RVA analysis. Changes in PV are related to the combination of the amount of swelling that the granule undergoes as well as the rate of disruption of the granules (e.g. granules that have high swelling power tend to have high viscosity) (Batey 2007; Cozzolino et al. 2012). In addition, a second and large peak appeared at the end of the RVA trace located or related with FV. The same trend was observed for the analysis of malt samples using RVA (Fig. 3). An increase in PV, shift in PV and second peak related with FV were observed.

The PCA score plot (first and second principal component) derived from the barley samples analysed using the RVA are shown in Fig. 4. A separation between samples associated with the addition of Tween 20 (1 % w/w) was observed. The first principal component (PC) explains 78 % of the variation of the RVA profile, and it is associated with the main differences between water and the addition of Tween 20 to the profile of the flour samples. The eigenvectors derived from the first PC1 resembled the raw RVA profile of the barley flour samples analysed, showing the main influences of both PV and FV at the beginning and the end of the analysis (Fig. 5). The scores and eigenvectors derived from the second PC that explains 19 % of the variation, are related with the effect of the addition of Tween 20 in each variety, explaining the observed increases in FV. A shift in the localization of the peak associated with PV was also observed, similarly to the one observed in the raw RVA trace.

Tween (20, 60 and 80) has been used by other authors as emulsifier due to its chemical characteristics (Deffenbaugh and Walker 1990; Azizi and Rao 2005; Mira et al. 2005; Yuan et al. 2008). It has been suggested by other authors that the presence of esters of different fatty acids in Tween might determine the leaching of amylose from the granule, which either tend to increase viscosity or retain the structure of the granule extending the swelling power of the sample (Deffenbaugh and Walker 1990; Copeland et al. 2009). The effect of emulsifiers on starch pasting properties has been reported in other starchy raw materials such as wheat, corn and potato (Ghiasi et al. 1982; Azizi and Rao 2005). The results obtained in this study are in agreement with those reported by other authors (Ghiasi et al. 1982; Azizi and Rao 2005). Previous authors showed a decrease in PV as well as an increase in pasting temperature as consequence of the addition of emulsifiers on wheat, corn and potato (Ghiasi et al. 1982; Azizi and Rao 2005). This data showed that addition of Tween 20 as emulsifier would increase the gelatinization temperature of barley flour, concomitantly the PV decreases with the addition of Tween 20. Similar results were reported by (Azizi and Rao 2005). Yuan et al. (2008) showed that Tween 20 (which has the highest HLB value among the Tween series emulsifiers) was able to produce nano-emulsion with very small droplets and a fine distribution. Recently, other authors reported that the effect of emulsifiers on the PT of wheat starch was determined to a great extent by the chain length of the surfactant used (Mira et al. 2005). The increase in PT as consequence of the addition of the emulsifiers was explained by the delay in starch swelling (Mira et al. 2005). However, contradictory reports on the effect of the addition of emulsifiers on PV have been also found (Krog 1973). This author reported that for wheat starch an increase in PV when distilled monoacylglycerols were added was observed.

Gelatinization is a process involving the irreversible swelling of the starch granules with a destruction of structural order and followed by leaching of amylose (Morris 1990). It has been reported that PT tends to increase with the increase of HLB of the sugar ester used and this can be attributed to the formation of a complex between the emulsifier and the molecule of amylose (Gunaratne et al. 2007). These complexes are insoluble and tend to cover the surface of starch granules hindering the leaching of amylose from the granule (Gunaratne et al. 2007). This effect has been explained by the presence of the multiple hydrophilic hydroxyl groups in sugar esters molecules determining the formation of extensive hydrogen bonding network with water molecules around the starch granules (Sharma and Gujral 2014). Therefore, the less amount of water available to the starch granules may restrict and delay the swelling and disintegration process of starch which consequently leads to the increase of PT values (Copeland et al. 2009; Sharma and Gujral 2014). The breakdown value is a result of the disintegration of the swollen granules and the leaching out of amylose molecules during continuous stirring and heating (Copeland et al. 2009). In particular, a lower breakdown viscosity value has been associated with a greater resistance to disintegration in response to heat and shear (Copeland et al. 2009). It is known that the capability of sucrose stearate to form inclusion complexes with the helical amylose molecule is determined by its chemical and geometrical factors (Addo et al. 1995). Since sucrose monostearate (with high HLB value) has better linear structure and smaller steric hindrance, a more robust gel network can be formed (Meng et al. 2014).

Most polysaccharides are not surface active in an emulsion due to the absence of lipophilic groups. Amphiphilic polysaccharides have hydrophilic and hydrophobic subregions; therefore, they can act like low-molecular-weight surfactants (Sadtler et al. 2002). The hydrophobic side chains anchor the modified polysaccharide to the oil–water interface, and they may have the ability to protect against flocculation, due to steric stabilization with respect to their macromolecular structure (Dickinson 2009; Kaewprapan et al. 2012). Their functional properties can be fine-tuned by adjusting the ratio between the hydrophilic part (the oligosaccharide or polysaccharide) and the hydrophobic (lipophilic) part, as well as the amount and the chain length of the alkyl (fatty acid) residue (van den Broek and Boeriu 2013). Tang and Copeland (2007) reported that the increase in FV of starch pastes is correlated with decreased iodine-binding capacity and provides a measure of the extent of complexation between starch and lipids/fatty acids. Addition of complexing agents impedes the formation of double helical structures mainly because single helical complex is a favoured conformation (Tang and Copeland 2007). An increased amount of amylose in a single helical conformation in the presence of complexing lipid reduces the ability of amylose to form networked double helical structures, resulting in an increased spacing between junction zones and a looser gel with higher FV (Tang and Copeland 2007). Sugar esters complexes altered in a similar manner the pasting behaviour of both starches in the similar way as the amylose-lipid complexes.

Conclusion

Overall, these results showed that complex between sugars and lipids are present in barley flour and malt. The practical implications of this study are related with the fact that starch alone (amylose and amylopectin) alone might not be necessarily the only main driver of malt quality in barley. These results suggested that it is not simply a specific constituent (e.g. amylose content), but the combination and interactions of other compositional characteristics of the starchy endosperm which provides the necessary information related with the starch pasting properties of barley (e.g. proteins, lipids, granule size or interactions between chemical properties).

References

Addo K, Slepak M, Akoh CC (1995) Effects of sucrose fatty acid ester andblends on alveograph characteristics of wheat flour doughs. J Cereal Sci 22:123–127

Azizi MH, Rao GV (2005) Effect of surfactants in pasting characteristics of various starches. Food Hydrocoll 19:739–743

Bason ML, Ronalds JA, Wrigley CW, Hubbard LJ (1993) Testing for sprout damage in malting barley using the Rapid Visco Analyser. Cereal Chem 70:269–272

Batey IL (2007) Interpretation of RVA curves. In: Ross AS (ed) Crosbie, G.B. The RVA Handbook, AACC International, pp 19–31

BeMiller JN (2011) Pasting, paste, and gel properties of starch-hydrocolids combinations. Carbohydr Polym 86:386–423

Blazek J, Copeland L (2009) Effect of monopalmitin on pasting properties of wheat starches with varying amylose content. Carbohydr Polym 78:131–136

Booth R, Bason ML (2007) Principles of operation and experimental techniques. In: Crosbie GB, Ross AS (eds) The RVA Handbook. AACC international, pp.1-19

Choy AL, Hughes JG, Small DM (2010) The effects of microbial transglutaminase, sodium stearoyl lactylate and water on the quality of instant fried noodles. Food Chem 122:957–964

Copeland L, Blazek J, Salman H, Tang MC (2009) Form and functionality of starch. Food Hydrocoll 23:1527–1534

Cozzolino D, Allder K, Roumeliotis S, Eglinton J (2012) Feasibility study on the use of multivariate data methods and derivatives to enhance information from the Rapid Visco Analyser. J Cereal Sci 56:610–614

Cozzolino D, Roumeliotis S, Eglinton J (2014) Combining partial least squares (PLS) discriminant analysis and Rapid Visco Analyser (RVA) to classify barley samples according to year of harvest and locality. Food Anal Methods 7:887–892

Cozzolino D, Roumeliotis S, Eglinton J (2015) Relationships between fatty acids content and malt quality in barley grain, malt and wort. Cereal Chem 92:93–97

Deffenbaugh LB, Walker CE (1990) Use of the rapid visco analyzer to measure starch pasting properties. II: Effects of emulsifiers and sugar-emulsifier interactions. Starch 42:89–95

Dickinson E (2009) Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocoll 23:1473–1482

Fox G, Visser J, Skov T, Meijering I, Manley M (2014) Effect of different analysis conditions on Rapid Visco Analyser malt viscograms in relation to malt of varying fermentability. J Inst Brew 120:183–192

Fu Z, Chen J (2015) Shun-Jing Luo, Liu, Ch-M., Liu, W. Effect of food additives on starch retrogradation: A review. Starch-Starke 67:69–78

Gelders GG, Vanderstukken TC, Goesaert H, Delcour JA (2004) Amylose-lipid complexation: a new fractionation method. Carbohydr Polym 56(4):447–458

Ghiasi K, Hoseney RC, Varriano-Marston E (1982) Gelatinization of Wheat Starch 1, Excess Water Systems.”. Cereal Chem 59:81–85

Gunaratne A, Ranaweera S, Corke H (2007) Thermal, pasting, and gelling properties of wheat and potato starches in the presence of sucrose, glucose, glycerol, and hydroxypropyl b-cyclodextrin. Carbohydr Polym 70:112–122

Jovanovich C, Añon MC (1999) Amylose–lipid complex dissociation. A study of the kinetic parameters biopolymers. 49:81–89

Juhasz R, Salgo A (2008) Pasting behaviour of amylose, amylopectin and their mixtures determined by RVA curves and first derivatives. Starch 60:70–78

Kaewprapan K, Baros F, Marie E, Inprakhon P, Durand A (2012) Macromolecular surfactants synthesized by lipase-catalyzed transesterification of dextran with vinyl decanoate. Carbohydr Polym 88:313–320

Krog N (1973) Influence of food emulsifiers on pasting temperature and viscosity of various starches. Starch 25:22–27

Meadows F (2002) Pasting process in rice flour using rapid visco analyser curves and first derivatives. Cereal Chem 79:559–562

Meng YC, Sun MH, Fang S, Chen J, Li YH (2014) Effect of sucrose fatty acid esters on pasting, rheological properties and freeze-thaw stability of rice flour. Food Hydrocoll 40:64–70

Mira I, Eliasson A-C, Persson K (2005) Effect of surfactant structure on the pasting properties of wheat flour and starch suspensions. Cereal Chem 82(1):44–52

Morris VJ (1990) Starch gelation and retrogradation. Trends Food Sci Technol 1:2–6

Naes T, Isaksson T, Fearn T, Davies T (2002) A User-friendly guide to multivariate calibration and classification. NIR Publications, Chichester

Ross AS, Walker CE, Booth RI, Orth RA, Wrigley CW (1987) The Rapid Visco Analyser: a new technique for the evaluation of sprout damage. Cereal Foods World 32:827–829

Sadtler VM, Imbert P, Dellacherie E (2002) Ostwald ripening of oil-in-water emulsions stabilized by phenoxy-substituted dextrans. J Colloid Interface Sci 254:355–361

Sharma P, Gujral HS (2014) Anti-staling effects of b-glucan and barley flour in wheat flour chapatti. Food Chem 145:102–108

Tang MC, Copeland L (2007) Analysis of complexes between lipids and wheat starch. Carbohydr Polym 67:80–85

van den Broek LAM, Boeriu CG (2013) Enzymatic synthesis of oligo- and polysaccharide fatty acid esters. Carbohydr Polym 93:65–72

Yuan Y, Gao YX, Mao LK, Zhao J (2008) Food Res Int 41:61–68

Acknowledgments

The authors thank technical staff of the Barley Quality Laboratory and Barley Breeding Program, University of Adelaide. This project (UA00126) is supported by Australia’s grain growers through their investment body the Grain Research and Development Corporation (GRDC), with matching funds from the Australian government.

Compliance with Ethical Standards

ᅟ

Funding

This study was funded by project UA00126, supported by Australia’s grain growers through their investment body the Grain Research and Development Corporation (GRDC), with matching funds from the Australian government.

Conflict of Interest

Daniel Cozzolino declares that he has no conflict of interest. Sophia Degner declares that she has no conflict of interest. Jason Eglinton declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants performed by any of the authors.

Informed Consent

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cozzolino, D., Degner, S. & Eglinton, J. The Effect of the Addition of Emulsifiers on the Pasting Properties of Barley Grain and Malt. Food Anal. Methods 9, 664–669 (2016). https://doi.org/10.1007/s12161-015-0235-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0235-2