Abstract

Extra virgin olive oil (EVOO) contains a higher ratio of antioxidants and monounsaturated fatty acids, and the price of EVOO is higher than that of other vegetable oils due to the complicated production process and storage condition. Adulteration of extra virgin olive oils with inferior vegetable oils has attracted increasing attentions. In this paper, we detect and quantify adulteration of extra virgin olive oil by 473 nm laser-induced fluorescence (LIF) with the help of multivariate analysis. Two hundred eighty sets of data are successfully classified to four groups (including olive, rapeseed, peanut, and blend oils). Moreover, a partial least squares model is built to predict the adulteration concentration with the errors lower than 2 %. The detection system will be assembled into a module (110 × 100× 25 mm). Due to non-destructive and requiring no sample pre-treatment characteristic, this method can be effectively employed for food safety detection.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most vegetable oils contain high levels of polyunsaturated fatty acids. However, extra virgin olive oil (EVOO) contains a higher ratio of antioxidants and monounsaturated fatty acids, mainly oleic acid (64 %), and lower level of saturated fatty acids (16 %) (Poulli and Mousdis 2006; Guimet et al. 2005; Mignani et al. 2011). Certainly, the price of EVOO is higher than that of other vegetable oils due to the complicated production process and storage condition, which promotes sellers to adulterate EVOO with other low-grade vegetable oils. Rapeseed and peanut oils are usually used to adulterate EVOO owing to the low price. Not only economic fraud but also the consumer health should attract increasing attentions about the edible oil adulteration. In food trade and consumption, adulteration of EVOO has become a focus and a severe problem.

In recent years, many advanced methods are emerging in the adulteration detection. High-performance liquid chromatography (HPLC) has been employed to carry out a rapid detection of adulteration of vegetable oils by Salghi R. et al. Five percent adulteration of extra argan oil with vegetable oils such as soybean, peanut, and olive oil can be sensitively detected by HPLC (Salghi and Armbruster 2014). Gas chromatography-mass spectrometer (GC-MS) has also been widely applied in the oils classification and adulteration analysis (Woodbury et al. 1995; Fang et al. 2013; Troya et al. 2015).

As a new technique, electronic nose has also been developed to analzying edible oils by Martin YG (Martin et al. 1999). Electronic nose has been widely used in edible oils analysis including oils classification and adulteration identification (Oliveros et al. 2002; James et al. 2004; Cosio et al. 2006; Mildner-Szkudlarz 2010). In addition, synchronous scanning fluorescence spectroscopy has been a main tool in food quality analysis due to its advantages (rapid, sensitive, non-intrusive) (Poulli and Mousdis 2005; Kadiroglu et al. 2011; Ntakatsane et al. 2013). Fourier transform infrared spectrometry (FTIR) and FT-Raman spectroscopy have also been applied successfully in oil classification (Lerma-Garcia et al. 2010; Samyn et al. 2012; Man et al. 2011; Mansor et al. 2011). However, FT-IR and FT-Raman need sample preparation which slows the detection speed. Also, the FTIR and FT-Raman spectrometer are a bit big for portable detection.

All the previous methods need either trial sample preparation or large complicated equipment which imposes restriction on portable measurement. Then, it is necessary to develop a rapid and portable method to detect adulteration of edible oils. Laser-induced fluorescence (LIF) has been used in many fields (Mu et al. 2013, 2014, 2015). In this work, olive, peanut, rapeseed, and blend oils have been successfully classified combined with the multivariate analysis methods. Four hundred seventy-three-nanometer LIF is proposed as a potable method to identify adulteration of EVOO with peanut and rapeseed oils. The detection system will be assembled into a module (110 × 100 × 25 mm). The adulteration concentration identification with prediction errors lower than 2 % is achieved. This method can be applied in other fields (Zhang et al. 2014).

Materials and Methods

Samples

EVOO, peanut oils, and rapeseed oils are bought from local market. The adulteration concentration of peanut and rapeseed oils ranges from 2.5 to 50 % with an increment 2.5 %. Eighty sets of blend oils are the adulteration of olive oils with peanut oil, and the other 80 sets of blend oils are adulteration of EVOO with rapeseed oil from 2.5 to 50 % at an increment 2.5 %. Then, 4 sets samples are prepared for blend oils of each concentration. Forty sets for peanut and 40 sets for rapeseed oils are also prepared. Total 280 set samples (40 sets for each individual oils and 160 sets for blend oils) are measured in the experiments.

Instrumentation

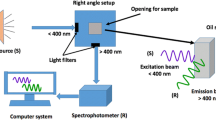

A typical LIF system is shown in Fig. 1. A 473 nm laser module (40 × 25 × 20 mm) is used as excited light source. The power of laser module is 50 mw and the beam diameter is 10 mm. The oil samples contained in the cuvette are illuminated by 473-nm laser and emit fluorescence. The 45° rotation of cuvette and front face illumination are used to decrease the inner filter effect. An optical fiber (numerical apertures (NA) = 0.22) is linked to spectrograph (95 × 68 × 20 mm, Ocean optics) to collect the emission fluorescence. The 473-nm long-pass edge filter (Semrock) is employed to avoid the strong elastic scattering light. The spectral region ranges from 480 to 780 nm. Finally, the collected fluorescence of different oils is analyzed by a computer. The integration time of spectrograph is 1 s. For portability, all the parts will be assembled into a module (110 × 100 × 25 mm).

Statistical Analysis

Chlorophyll plays a major role in the adulteration identification and concentration recognition. Data are analyzed by Matlab 2010a (The Mathworks). Signal smoothing and de-noising are carried out in the spectral preprocessing. Then, principal component analysis (PCA) is employed to reduce the dimensionality of the data and to remove white noise, as well as examine the intrinsic variation of the LIF spectral data (Fang et al. 2013). Due to the stable chemical property of chlorophyll, the chlorophyll composition of blend oils equals to the sum of chlorophyll composition of individual oils. Partial least squares regression (PLSR) is applied in the identification adulteration of EVOO with peanut oil and rapeseed oil. In the classification experiments, artificial neural network and support vector machine are employed to classify 280 sets of data to four groups (including olive, rapeseed, peanut, and blend oils).

PCA is used to make data set have some independence characteristics and remove noise from data (Cabanac et al. 2002). SVM is an important learning method of statistical learning theory and is also a powerful tool for pattern recognition. SVM constructs an optimal hyper-plane utilizing a small set of vectors near boundary and extracts the features. According to extracted features, one SVM is constructed for one pattern for identification (Mu et al. 2013). ANN is also a classification method which is usually used in material identification (Szymczyk and Szymczyk 2015). PLSR is a novel multivariate analysis method. It is shown that PLSR method was applicable to the regression modeling analysis, especially when there are highly correlate relations between the variables. In addition, PLAR can be effectively applied in the situation when samples are less than variables (Gao and Li 2015).

Results and Discussion

Identification of Adulteration of EVOO

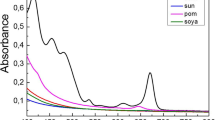

In this study, firstly, three types of individual edible oils are analyzed by LIF. The distinct spectra can be utilized to distinguish them from each other. The spectra of three individual oils (olive, peanut, and rapeseed oils) are shown in Fig. 2. The peaks at ~675 nm are due to chlorophyll groups which indicate that olive oils contain more chlorophyll groups than other vegetables oils. The difference in chlorophyll content is used to identify the adulteration of EVOO in this research.

Then PCA is used to reduce the dimensionality of the data before classification by finding attributes. It is demonstrated that PCA has been successfully applied to classify these samples (Fig. 3). It is shown that the first three factors of Z scores explained 93.14 % of the total variance (87.14, 4.92, and 1.08 %). Then, artificial neural network (ANN) and support vector machine (SVM) are used to classify individual and blend oils. Training set consists of 210 sets of data (30 sets for each individual oils and 120 sets for blend oils), and test set consists of 70 sets of data (10 sets for each individual oils and 40 sets for blend oils). The classification accuracy 100 % is obtained for the testing sample which demonstrates the sensitivity and effectivivity of LIF in oil classification.

Quantitative Analysis of Adulteration Concentration

Adulteration concentration analysis of blend oils is another important task in this study. The EVOO is adulterated with peanut oil or rapeseed oil range from 2.5 to 50 %.

The various LIF spectra appear when the blend samples excited by 473-nm laser. It is shown that the relative fluorescence intensity around ~675 nm, mainly emitted by chlorophyll, increases with the decreasing of adulteration concentration (Figs. 4a and 5a). For the purpose of display clearly, only blend concentration from 0 to 45 % at an increment 5 % is shown in Figs. 4a and 5a. EVOO contain more chlorophyll than other vegetable oils, and then, adulteration decreases the content of chlorophyll which generates the various fluorescence spectra (Mu et al. 2013, 2014; Christodouleas et al. 2012; Sikorska and Romaniuk 2004).

The blend concentration from 2.5 to 47.5 % at an increment 5 % is served as test set (Figs. 4b and 5b). Applying chemometrics to the LIF spectral data, very good calibration and prediction statistics are obtained for blend oils. It notes that linearity R 2 values greater than 0.997 are obtained when EVOO is blended with peanut and rapeseed oil with a mean square error less than 2 % (Figs. 4b and 5b). The calculated results are excellent agreement with the actual value, which verifies the feasibility of this method in quantification of adulteration.

Conclusions

In conclusion, with the help of ANN and SVM, the classification accuracy 100 % is obtained by 473-nm LIF. In addition, the prediction of the adulteration concentration range from 2.5 to 50 % with prediction errors lower than 2 % is achieved. It is demonstrated that adulteration of EVOO with peanut and rapeseed oils can be successfully detected by 473-nm LIF combined with multivariate analysis. Due to non-destructive and requiring no sample pre-treatment characteristic, this method can be effectively employed for portable detection and quantification of oils adulteration.

References

Cabanac RA, de Lapparent V, Hickson P (2002) Classification and redshift estimation by principal component analysis. Astron Astrophys 389:1090–1116

Christodouleas D, Fotakis C, Papadopoulos K, Dimotikali D, Calokerinos AC (2012) Luminescent methods in the analysis of untreated edible oils. A review. Anal Lett 45:625–641

Cosio MS, Ballabio D, Benedetti S, Gigliotti C (2006) Geographical origin and authentication of extra virgin olive oils by an electronic nose in combination with artificial neural networks. Anal Chim Acta 567:202–210

Fang GH, Goh JY, Tay M, Lau HF, Li SFY (2013) Characterization of oils and fats by H-1 NMR and GC/MS fingerprinting: classification, prediction and detection of adulteration. Food Chem 138:1461–1469

Gao L, Li XB (2015) Utilizing partial least square and support vector machine for TBM penetration rate prediction in hard rock conditions. J Cent South Univ 22:290–295

Guimet F, Ferre J, Boque R (2005) Rapid detection of olive-pomace oil adulteration in extra virgin olive oils from the protected denomination of origin “Siurana” using excitation-emission fluorescence spectroscopy and three-way methods of analysis. Anal Chim Acta 544:143–152

James D, Scott SM, O’Hare WT, Ali Z, Rowell FJ (2004) Classification of fresh edible oils using a coated piezoelectric sensor array-based electronic nose with soft computing approach for pattern recognition. T I Meas Control 26:3–18

Kadiroglu P, Korel F, Tokatli F (2011) Classification of turkish extra virgin olive oils by a SAW detector electronic nose. J Am Oil Chem Soc 88:639–645

Lerma-Garcia MJ, Ramis-Ramos G, Herrero-Martinez JM, Simo-Alfonso EF (2010) Authentication of extra virgin olive oils by Fourier-transform infrared spectroscopy. Food Chem 118:78–83

Man YBC, Abidin SZ, Rohman A (2011) Discriminant analysis of selected edible fats and oils and those in biscuit formulation using FTIR spectroscopy. Food Anal Method 4:404–409

Mansor TST, Man YBC, Rohman A (2011) Application of fast gas chromatography and Fourier transform infrared spectroscopy for analysis of lard adulteration in virgin coconut oil. Food Anal Method 4:365–372

Martin YG, Pavon JLP, Cordero BM, Pinto CG (1999) Classification of vegetable oils by linear discriminant analysis of electronic nose data. Anal Chim Acta 384:83–94

Mignani AG et al (2011) Visible and near-infrared absorption spectroscopy by an integrating sphere and optical fibers for quantifying and discriminating the adulteration of extra virgin olive oil from Tuscany. Anal Bioanal Chem 399:1315–1324

Mildner-Szkudlarz S, Jelen HH (2010) Detection of olive oil adulteration with rapeseed and sunflower oils using mos electronic nose and Smpe-Ms. J Food Quality 33:21–41

Mu TT, Chen SY, Zhang YC, Guo P, Chen H, Liu XH, Ge XY (2013) Classification of edible oils using 532 nm laser-induced fluorescence combined with support vector machine. Anal Methods-Uk 5:6960–6963

Mu TT, Chen SY, Zhang YC, Chen H, Guo P (2014) Analyzing fluorophore electronic structure and depolarization by fluorescence polarizing angle spectrum. Appl Phys Lett 105

Mu T, Chen S, Zhang Y, Guo P, Chen H (2015) Determining the orientation of transition moments and depolarization by fluorescence polarizing angle spectrum. Opt Express 23:11748–11754

Ntakatsane MP, Liu XM, Zhou P (2013) Short communication: rapid detection of milk fat adulteration with vegetable oil by fluorescence spectroscopy. J Dairy Sci 96:2130–2136

Oliveros MCC, Pavon JLP, Pinto CG, Laespada MEF, Cordero BM, Forina M (2002) Electronic nose based on metal oxide semiconductor sensors as a fast alternative for the detection of adulteration of virgin olive oils. Anal Chim Acta 459:219–228

Poulli KI, Mousdis GA, Georgiou CA (2005) Classification of edible and lampante virgin olive oil based on synchronous fluorescence and total luminescence spectroscopy. Anal Chim Acta 542:151–156

Poulli KI, Mousdis GA, Georgiou CA (2006) Synchronous fluorescence spectroscopy for quantitative determination of virgin olive oil adulteration with sunflower oil. Anal Bioanal Chem 386:1571–1575

Salghi R, Armbruster W, Schwack W (2014) Detection of argan oil adulteration with vegetable oils by high-performance liquid chromatography-evaporative light scattering detection. Food Chem 153:387–392

Samyn P, Van Nieuwkerke D, Schoukens G, Vonck L, Stanssens D, Van den Abbeele H (2012) Quality and statistical classification of brazilian vegetable oils using mid-infrared and raman spectroscopy. Appl Spectrosc 66:552–565

Sikorska E, Romaniuk A, Khmelinskii IV, Herance R, Bourdelande JL, Sikorski M, Koziol J (2004) Characterization of edible oils using total luminescence spectroscopy. J Fluoresc 14:25–35

Szymczyk P, Szymczyk M (2015) Supervised learning Laplace transform artificial neural networks and using it for automatic classification of geological structure. Neurocomputing 154:70–76

Troya F, Lerma-Garcia MJ, Herrero-Martinez JM, Simo-Alfonso EF (2015) Classification of vegetable oils according to their botanical origin using n-alkane profiles established by GC-MS. Food Chem 167:36–39

Woodbury SE, Evershed RP, Rossell JB, Griffith RE, Farnell P (1995) Detection of vegetable oil adulteration using gas-chromatography combustion isotope ratio mass-spectrometry. Anal Chem 67:2685–2690

Zhang ZE, Yan YF, Zhang L, Ju SX (2014) Hollow fiber membrane contactor absorption of Co2 from the flue gas: review and perspective. Global Nest J 16:354–373

Compliance with Ethical Standards

Funding

This study was funded by the National Natural Science Foundation of China (no. 61178072).

Conflict of Interest

Taotao Mu declares that he has no conflict of interest. Siying Chen declares that she has no conflict of interest. Yinchao Zhang declares that he has no conflict of interest. He Chen declares that he has no conflict of interest. Pan Guo declares that he has no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, T., Chen, S., Zhang, Y. et al. Portable Detection and Quantification of Olive Oil Adulteration by 473-nm Laser-Induced Fluorescence. Food Anal. Methods 9, 275–279 (2016). https://doi.org/10.1007/s12161-015-0199-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0199-2