Abstract

A QuEChERS (quick, easy, cheap, effective, rugged and safe) method combined with a clean-up step followed by gas chromatography-tandem mass spectrometry was validated for the determination of more than 150 pesticides in ginkgo biloba nutraceutical products. Due to the complexity of the matrix after QuEChERS extraction, the mixture of four sorbents (primary secondary amine, C18, Zr-Sep+ and graphitized black carbon) was used for the clean-up step. Matrix-matched standard solutions were utilized for calibration purposes. The method was validated and recoveries were evaluated at 10, 50 and 100 μg/kg, ranging between 73 and 107 %. The relative standard deviation for intra-day precision was always lower than 20 % and for inter-day precision lower than 25 %. Limits of detection ranged from 0.1 to 10.0 μg/kg; whereas, limits of quantification from 0.5 to 20.0 μg/kg. The validated method was successfully applied to the analysis of ginkgo nutraceutical samples. Nine samples were analysed and four samples contained pesticide residues (deltamethrin, kresoxym-methyl, myclobutanyl and procymidone). The highest concentration was found for deltamethrin, 10.1 μg/kg. Putative transformation products of pesticides, 3-phenoxybenzoic acid and BF 490-2 or BF 490-9, were also detected in the analysed samples using liquid chromatography-high resolution mass spectrometry analyaser (Exactive-Orbitrap).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ginkgo biloba is considered the oldest surviving tree species, with geological records indicating this plant has been growing on earth for 150–200 million years. Ginkgo has a long medical history with its use being recorded as early as 2800 BC in the Chinese medical literature (Jager et al. 2006). Ginkgo has been used in China as a traditional medicine for a range of conditions, including asthma, bronchitis and heart dysfunction (Birks and Evans 2009). Ginkgo biloba leaf extract is well recognized as ingredient in various pharmaceutical and nutraceutical products all over the world owing to the many types of bioactive constituents that contains. Flavonol glycosides, terpenetrilactones, gingkolides and proanthocyanidins are included in the extract and they contribute to improve cognition and memory (Lee et al. 2013).

Dietary supplements with botanical ingredients are often perceived as being safe because of their “natural” origin, traditional use, historical evidence of safety, and over-the-counter availability. However, on numerous occasions, they have become a matter of concern owing to adulteration, contamination, misidentification, their intrinsic or metabolism-mediated toxicities, and unfavorable botanical-drug interactions (Pawar et al. 2013). Despite the impression that these botanicals or herbals are cultivated in the wild, many of these products are farmed using conventional agricultural practices, including pesticide application to control insects, molds and other pests. The increasing risks to human health generated by the widespread use of pesticides in the environment and food supply are well established (Chen et al. 2012b). Furthermore, pesticides in the environment can be transformed into a large number of degradation products, which may undergo various reactions such as hydrolysis, photolysis or biodegradation. As a result of these reactions, pesticide transformation products are formed, which can sometimes be as toxic and as persistent as the original pesticide (Tang et al. 2014). Consequently, analyses of residual quantities of pesticides not only in raw agricultural crops, but also in nutraceutical products are one of the principal preventive measures employed to ensure public health and safety. Therefore, it is necessary to develop a method for the rapid and sensitive determination of multiple pesticide residues and the screening of transformation products in nutraceuticals.

The use of high resolution mass spectrometry (HRMS) can overcome these challenges by studying parent compounds and transformation products with and without reference standards based on accurate mass acquisition and fragmentation patterns (Hernández et al. 2012; Picó et al. 2007, 2010). In addition to the classical quantitative target analysis approach (using reference standards), a qualitative suspect screening approach (exact mass as a priori information) or non-target screening (no previous information of the chemical available) can be pursued with high resolution mass spectrometers (Moschet et al. 2013; Masiá et al. 2014). Modern HRMS based on time-of-flight (ToF) or Orbitrap technology provides accurate mass data at satisfactory sensitivity, which opens up for comprehensive non-target screening of a theoretically unlimited number of polar organic compounds (Li et al. 2014; Farré et al. 2014). Additionally, full-scan acquisition allows retrospective analysis for emerging contaminants years after the data has been acquired (Hernández et al. 2012).

Recently a number of works related to the determination of pesticide residues in herbals and herbal medicines have been published (Chen et al. 2012a, b; Du et al. 2012, 2011; Dai et al. 2011; Wan et al. 2010; Xu et al. 2011; Harris et al. 2011; Łozowicka et al. 2014; Mastovska and Wylie 2012; Ho et al. 2013; Hayward et al. 2013; Liu et al. 2012; Nguyen et al. 2010; Sadowska-Rociek et al. 2013). However, the determination of pesticide residues in nutraceutical products represents an analytical challenge, due to the broad physicochemical properties of these pesticides and the complexity of the matrixes (Mao et al. 2012).

Only a few analytical methods have recently been described for the determination of pesticide residues in ginkgo products (Sun et al. 2007; Zhang et al. 2009). In these studies, pesticide residues have been analysed in the raw material but not in the nutraceutical products, which are more complex matrices, because contain high concentrations of flavonoids, polysaccharide, saponin, alkaloids, essential oils, etc.

To the best of our knowledge, no analytical method has been developed to the simultaneous determination of multiclass pesticide residues in ginkgo nutraceuticals by GC-MS/MS, and there is only one, which uses LC (Martínez-Domínguez et al. 2015). In this study, a modified QuEChERS (quick, easy, cheap, effective, rugged and safe) extraction technique combined with gas chromatography-tandem mass spectrometry has been used for multi-residual determination of 177 pesticides from different chemical groups in complex ginkgo nutraceuticals. The transformation products of pesticides in real samples were identified by LC-Orbitrap-MS.

Materials and Methods

Chemicals and Reagents

Anhydrous magnesium sulphate was obtained from Panreac (Barcelona, Spain). Sodium acetate (NaOAc) was purchased from J.T. Baker (Deventer, The Netherlands). Octadecyl silica (C18) was obtained from Agilent Technologies (Avondale, PA, USA). Zirconia-coated silica (Zr-Sep+) was obtained from Supelco (Bellefonte, PA, USA). Primary secondary amine (PSA) and graphitized black carbon (GBC) were obtained from Scharlab (Barcelona, Spain). Acetonitrile and methanol were also obtained from Scharlab. Ethyl acetate was received from Sigma-Aldrich (Madrid, Spain). Acetone was obtained from Carlo Erba (Milan, Italy). Every solvent used was pesticide residue grade.

Pesticide standards were obtained from Dr. Ehrenstorfer (Augsburg, Germany) and Riedel-de-Haën (Seelze-Hannover, Germany) with purity >99 %. Stock standard solutions of the pesticides (with concentration ranging from 200 to 300 mg/L) were prepared by weighing the pesticides and dissolving with 50 mL of methanol, acetone or acetonitrile. A working standard solution (2 mg/L) was prepared in acetone by dilution and stored at 4 °C. Internal standard (I.S.) isotopically labeled parathion ethyl-d10 (20 mg/L) solution was also prepared.

Instrument and Apparatus

High-volume centrifuge equipped with a bucket rotor (4 × 250 mL) from Orto Alresa, Mod. Consul (Madrid, Spain) was used for the centrifugation.

Scion GC system (Bruker Corporation, Freemont, CA, USA) equipped with an autosampler from the same company was used for chromatographic analyses. Capillary column GC 30 m × 0.25 mm i.d. × 0.25 μm film thickness VF-5MS (Varian) was utilized for GC separation. Helium was used as carrier gas with a constant flow rate of 1 mL/min. The glass liner was fitted with a carbofrit plug, from Restek (Bellefonte, PA, USA). A fused silica untreated capillary column (2 m × 0.25 mm) from Supelco (Bellefonte, Pennsylvania, USA) was used as a pre-column. Mass spectrometric detection was carried out by the triple quadrupole Scion QqQ-MS/MS (Bruker) operating in electron ionization mode (EI, 70 eV).

Positive samples were analysed by Transcend 600 LC (Thermo Scientific TranscendTM, Thermo Fisher Scientific, San Jose, CA, USA) coupled to a single stage Orbitrap mass spectrometer (ExactiveTM, Thermo Fisher Scientific, Bremen, Germany) operating with a heated electrospray interface (HESI-II, Thermo Fisher Scientific, San Jose, CA, USA), in positive (ESI+) and negative ionization mode (ESI−). A mixture of an aqueous solution of ammonium formate 4 mM and formic acid 0.01 % (v/v; eluent A) and methanol solution with ammonium formate 4 mM and formic acid 0.01 % (v/v; eluent B) were used as the mobile phase at a constant flow rate of 0.3 mL/min. The column used for the compounds separation was a Hypersil GOLD aQ column (100 × 2.1 mm, 1.9 μm particle size) from Thermo Scientific (San Jose, CA, USA). Column temperature was set at 30 °C and the injection volume was 10 μL.

Data obtained from LC-Orbitrap-MS were processed with the XcaliburTM program version 2.2.1 from Thermo Fisher Scientific (Les Ulis, France) with Qual and Quanbrowser. Genesis peak detection was applied. The ToxIDTM program 2.1.1, also from Thermo Scientific, was used for screening and the LCQuanTM2.6 software from the same company was used for quantification of the target compounds.

Samples

Pesticide free ginkgo nutraceutical products were used as blank matrix to prepare matrix-matched standard solutions for the calibration and fortified samples for recovery studies. The products were purchased from a local store (Almería, Spain), from Poland (Krakow) and from different internet retailers (www.ebay.com). Several capsules were chopped with a blender and they were stored at 5 °C until the analysis. Samples were analysed by GC-MS/MS and by LC-Orbitrap-MS.

Sample Preparation

Certain changes in the original QuEChERS procedure (Anastassiades et al. 2003) were made according to our needs and possibilities. Two grams of homogenized sample was weighed into a 50 mL centrifuge tube. Eight mL of water was added to the sample and shaken 30 s by vortex, and the sample was left to hydrate for 15 min. Then, 10 mL of ethyl acetate was added to the mixture and shaken by vortex 1 min. After that, 4 g of MgSO4 and 1 g of anhydrous NaOAc were added, and the mixture was shaken vigorously by hand for 1 min. Subsequently, the mixture was centrifuged at 3700 rpm for 10 min.

Clean Up with a Mixture of Sorbents (PSA+GCB+C18+Zr-Sep+)

1.5 mL of the organic phase was transferred to an Eppendorf vial, which contains 50 mg of each sorbent (PSA, GCB, Zr-Sep+ and C18). The vial was shaken 1 min by vortex and subsequently centrifuged at 3700 rpm for 10 min. Then, 975 μL of the organic phase was transferred to a vial and 25 μL of the solution of the IS was added for GC-QqQ-MS/MS analysis. The final extract obtained after the cleaning step was diluted with ethyl acetate (1:1, v/v) prior GC analysis.

For the LC-Orbitrap-MS analyses of samples, 1 mL of extract was transferred to a glass tube and heated to dryness under a nitrogen stream. One milliliter of acetonitrile with 1 % of formic acid was added and transferred to a vial.

GC-QqQ-MS/MS Analysis

Three μL of the final extract was injected into the chromatographic system at a syringe injection flow rate of 5 μL/s. The injector temperature program started at 70 °C (hold for 5 min), and then it was increased with a rate of 200 °C/min until 300 °C (hold for 20 min). The injector split ratio was initially set at 20:1. Splitless mode was switched on at 0.5 min until 3.5 min. At the beginning of the injection, the column temperature was set at 70 °C (hold for 3.5 min), and the temperature was increased until 180 °C at a 25 °C/min rate, and then until 325 °C (hold 5 min) at a rate of 15 °C/min. A cryogenic cooling with air was used when the injector temperature was at 250 °C in order to reach the initial injector temperature as fast as possible for the next injection. The total run time was 23 min.

The QqQ mass spectrometer was operated in the selected-reaction monitoring (SRM) mode. The temperatures of the transfer line, manifold, and ionization source were set at 280, 40 and 280 °C, respectively. The analysis was performed with a filament-multiplier delay of 4.5 min in order to prevent instrument damage. The electron multiplier voltage was set at 1600 V (+200 V offset above the value obtained in the auto-tuning process). Mass peak widths set in the first and third quadrupole were of 1.5 and 2.0 m/z, respectively.

LC-Orbitrap-MS

For the identification of transformation products in contaminated samples by LC-MS, a gradient profile was applied as follows: the analysis started with 95 % of eluent A; after 1 min, this percentage was linearly decreased to 0 % in 7 min; this composition was held during 4 min and increased again up to 95 % in 0.5 min, followed by a re-equilibration time of 1.5 min. The total running time was 14 min.

The Orbitrap mass spectrometer parameters were: spray voltage, 4 kV; sheath gas (N2, 99.999 %), 35 (adimensional); auxiliary gas (N2, 99.999 %), 10 (adimensional); skimmer voltage, 18 V (−18 V in ESI-); capillary voltage, 35 V (−35 V in ESI−); tube lens voltage, 95 V (−95 V in ESI−); heater temperature, 305 °C and capillary temperature, 300 °C. Mass range in the full scan experiments was set at m/z 100–1,000. All the analyses were performed without lock mass. Mass accuracy was carefully monitored as follows: checked every day with multi-compound standard solution; evaluated (once a week) and calibrated when necessary (every two weeks at least) with mass accuracy standards. The automatic gain control (AGC) was set at a target value of 1 × 106. The mass spectra were acquired using four alternating acquisition functions: (1) full MS, ESI+, without fragmentation (the higher collisional dissociation (HCD) collision cell was switched off), mass resolving power = 25,000 FWHM; scan time = 0.25 s; (2) full MS, ESI− using the aforementioned settings; (3) all ion fragmentation (AIF), ESI+, (HCD on, and collision energy = 30 eV, mass resolving power = 10,000 FWHM; scan time = 0.10 s; and (4) AIF, ESI− using the settings explained for (3).

Validation Process

The method was validated according to the international SANCO Guidelines 2013/12571 (SANCO 2013). The stock solution containing 177 pesticides standards and the internal standard were diluted to appropriate concentrations using extract from blank ginkgo nutraceuticals for the construction of calibration curves. Linearity was studied at eight concentration levels (1, 2, 5, 10, 25, 50, 100 and 150 μg/L). Linear last square regression analysis was applied using relative peak area as analytical signal.

The matrix effect is usually caused by interfering matrix components in the extract, eluting at the same retention time of the analyte and thereby competing in the ionization process in the ion source. The number of ions formed then can be decreased, also called ion suppression, or increased, resulting in a corresponding negative or positive matrix effect, respectively. The matrix factors (MF) were calculated for each studied pesticide by comparing analyte response in matrix-matched solution vs. the pesticide response obtained in pure solvent, according to the following equation:

Exceeding the MF higher than 20 % or smaller than −20 % indicates the peak signal suppressing or enhancing due to the matrix effects in the calibration procedure.

The recovery was used to evaluate the trueness of the method and it was studied at three concentration levels, 10, 50 and 100 μg/kg. Blank gingko nutraceuticals were fortified with pesticides before the extraction. Spiked samples were left to stand for 30 min prior to their extraction. Relative peak areas of pesticides after the application of the modified QuEChERS method to the spiked blank samples were compared with relative peak areas of matrix-matched standards (Rspiked/Rmatrix-matched).

The precision of the developed method was studied by intra- and inter-day precision. For intra-day precision, spiked samples at 10, 50 and 100 μg/kg were analysed (five replicates). Inter-day precision was studied at the same concentration levels by processing spiked samples in five different days. Variations were indicated by relative standard deviation (RSD) values.

Finally, limits of detection (LODs) and quantification (LOQs) were calculated by injecting six fortified samples at lower concentration levels, being 0.1, 0.5, 1, 2, 5 and 10 μg/kg. The lower limits were determined for the quantification transition by the signal-to-noise ratio (S/N) criteria. Lower limits were defined as the lowest concentration of the analyte yielding a S/N of 3 (LODs) or 10 (LOQs).

Results and Discussion

One hundred seventy-seven pesticides were investigated using the modified QuEChERS procedure in this study. These analytes represent various substance groups with different physical and chemical properties. Therefore, the development of a simple multi-residual analytical method for the determination of pesticide residues in such complex matrix as ginkgo nutraceuticals was a challenge. Table S1 (see Electronic Supplementary Material) summarizes the studied pesticides, including retention time, precursor ion, product ions and the ion ratio (Martínez-Domínguez et al. 2014).

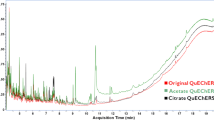

The QuEChERS-based extraction technique was developed for soy-based nutraceuticals in previous article (Páleníková et al. 2015), observing that ethyl acetate provides better results than acetonitrile. This extraction technique was tested for this matrix and provided suitable results, despite the differences observed between both matrices. Using this modified QuEChERS procedure with the mixture of sorbents (PSA, C18, Zr-Sep+ and GCB), 86 % of 177 pesticides were extracted with suitable recoveries (from 70 to 120 %).

Method Validation

The validation of the proposed method in this new matrix was established in terms of precision, linearity, trueness, LOD and LOQ. Precision was evaluated as inter- and intra-day precision. On the basis of preliminary studies, we discarded some of the pesticides before the validation process was applied. Some of them were not considered due to low sensitivity or low recoveries. Finally, the method was validated for 158 pesticides.

From the calculated matrix effect results, it can be concluded, that only 24 % of the pesticide residues did not present matrix effect (MF values were between −20 up to 20 %), whereas matrix effect was significant for the other compounds, and most of the pesticides showed matrix suppression.

Matrix-matched standard solutions were used to eliminate the matrix effect. Linearity was studied at 8 concentration levels, 1, 2, 5, 10, 25, 50,100 and 150 μg/L. The obtained determination coefficient (R2) was higher than 0.98 for most of the pesticides at a concentration range from 1 to 100 μg/L. It was observed that the calibration curves were not linear in the whole concentration range, and at 150 μg/L the calibration curves started to be not linear. For two pesticides, acephate and azinphos methyl, the calibration curve was linear in the range 10–100 μg/L, and for folpet, the calibration curve was linear from 5 to 100 μg/L.

Trueness was evaluated in terms of recoveries and the average recoveries are given in Table S2 (see Supplementary Information), showing a summary of the results in Table 1. Recoveries were between 73 and 107 % at 10 μg/kg. Some of the pesticides had recoveries higher than 67 %, but lower than 70 % (azinphos ethyl, diazinon and tetradifon) and one of the pesticides, metamidophos, presented a recovery value higher than 120 % (125 %) at this concentration level. For 50 μg/kg, the recoveries ranged from 75 to 102 %, and for 100 μg/kg, between 87 and 103 %.

Precision was studied in terms of repeatability (intra-day precision) and intermediate precision (inter-day precision). The obtained values were expressed by RSD % (see Table S2). Repeatability values ranged between 1 and 20 %. In the case of inter-day precision, the RSD values were lower than 25 % for all pesticides as it can be observed in Table 1. Only few compounds showed inter-day precision higher than 20 %, but this could be explained considering the complexity of the assayed matrix.

The obtained LODs were in the range 0.1–10 μg/kg and LOQ 0.5–20 μg/kg, as it can be seen in Table S2 (see Supplementary Information), and most of the compounds have LOQs lower or equal than 5 μg/kg (see Table 1). The obtained LODs are lower than maximal residual limits (MRLs) in raw herbals. Therefore, the method is useful for pesticide residue analysis in nutraceutical products.

Pesticide Residue Determination and HRMS Screening of Transformation Products

The validated analytical method was applied to monitor more than 150 pesticide residues in nine samples. Four pesticides were detected in four samples. In these samples, deltamethrin with a concentration of 10.1 μg/kg, kresoxim-methyl at 9.4 μg/kg, myclobutanil at 2.1 μg/kg and procymidone at 1.2 μg/kg were detected. Three of them are fungicides (procymidone, kresoxim methyl and myclobutanil), which could be used against Phytophthora root rot, and one is insecticide (deltamethrin). The MRLs for nutraceutical products are not defined by the European Union (EU), although they are set in the raw material, ginkgo leaves. The detected concentrations in ginkgo nutraceuticals do not exceed these limits. MRL of deltamethrin and myclobutanyl in ginkgo leaves is 0.05 mg/kg and the MRL of kresoxim-methyl and procymidone is 0.1 mg/kg (EU pesticide databases, Eurpean Commission).

It is well known that pesticides could be degraded in the environment. These degradation products can be even more hazardous and persistent than the original compound. The major degradation product of deltamethrin is 3-phenoxybenzoic acid (Ding et al. 2004), the residues of kresoxim-methyl are BF-490-2 and BF-490-9 (Rahman et al. 2013), myclobutanyl is able to transform to hydroxyl- and keto-myclobutanyl (Athanasopoulos et al. 2003) and the main transformation product of procymidone is 3,5-dichloroanilin (Vanni et al. 2000). These degradation products were screened by LC-Orbitrap-MS in order to check if the parent compounds were also degraded into their corresponding transformation products, applying a generic chromatographic method developed previously (Martínez-Domínguez et al. 2015). Although these compounds were not included in the original method, they were monitored as post-target compounds, knowing their molecular formula and molecular weight (see Table 2). According to the different levels of identification established by Sumner et al. (2007), the identification of transformation products has been reported as “putative identification” in this study, bearing in mind that this can be considered a preliminary and tentative study. Two transformation products were “putative identified”, with mass error lower than 5 ppm in all the cases. 3-phenoxybenzoic acid was detected, as a transformation product of deltamethrin (see Fig. 1). In relation to kresoxim-methyl, both transformation products, BF 490-2 and BF 490-9 are isobaric compounds (see Table 2) with the same MS spectra, and it is not possible to distinguish between each other. Although the characteristic ions were adequate monitored, the sensitivity of the potential fragments was not enough when AIF was carried out, and therefore, MS/MS data cannot be compared with literature MS/MS spectra, to distinguish between both compounds.

The putative identified compounds endorse the idea that a deeper and continuous investigation of pesticide residues in nutraceutical products is necessary in order to guaranty consumers safety. The validated methodology provides a sufficient sensitivity to test ginkgo nutraceutical samples in compliance with MRL established for raw materials by EU, and is adequate for routine determination since a large number of samples can be analysed within a working day.

Conclusions

Simple, rapid and inexpensive modified QuEChERS extraction was applied for the determination of more than 150 pesticides by GC-MS/MS in complex ginkgo nutraceuticals products. The developed method was completely validated. The quantification limits achieved were below the MRL established in EU regulation for the raw materials of ginkgo. The developed methodology was applied to the analysis of samples for testing the applicability of the method. Positive samples were also analysed by LC-Orbitrap-MS in order to investigate the presence of transformation products of the detected pesticides in the analysed samples. The proposed method is fast and simple and the presence of transformation products in these products indicated the need of further investigations in this topic (identification of potential transformation products of pesticides not identified in the samples) in order to assure the harmlessness of nutraceuticals.

References

Anastassiades M, Lehotay S, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412–431

Athanasopoulos PE, Pappas CJ, Kyriakidis NV (2003) Decomposition of myclobutanil and triadimefon in grapes on the vines and during refrigerated storage. Food Chem 82:367–371

Birks J, Evans GJ (2009) Ginkgo biloba for cognitive impairment and dementia. Cochrane Database Syst Rev 1, CD003120

Chen L, Song F, Liu Z, Zheng Z, Xing J, Liu S (2012a) Multi-residue method for fast determination of pesticide residues in plants used in traditional Chinese medicine by ultra-high-performance liquid chromatography coupled to tandem mass spectrometry. J Chromatogr A 1225:132–140

Chen Y, Al-Taher F, Juskelis R, Wong JW, Zhang K, Hayward DG, Zweigenbaum J, Stevens J, Cappozzo J (2012b) Multiresidue pesticide analysis of dried botanical dietary supplements using an automated dispersive SPE clean up for QuEChERS and high-performance liquid chromatography-tandem mass spectrometry. J Agric Food Chem 60:9991–9999

Dai R, Ren X, He X, Huo Y (2011) Convenient analytical method for quantitative determination of 23 pesticide residues in herbs by gas chromatography–mass spectrometry. Bull Environ Contam Toxicol 86:559–564

Ding Y, White CA, Muralidhara S, Bruckner JV, Bartlett MG (2004) Determination of deltamethrin and its metabolite 3-phenoxybenzoic acid in male rat plasma by high-performance liquid chromatography. J Chromatogr B 810:221–227

Du G, Song Y, Wang Y (2011) Rapid simultaneous determination of multiple pesticide residues in traditional Chinese medicines using programmed temperature vaporizer injection-fast gas chromatography coupled with mass spectrometry. J Sep Sci 34:3372–3382

Du G, Xiao Y, Yang HR, Wang L, Song Y, Wang IT (2012) Rapid determination of pesticide residues in herbs using selective pressurized liquid extraction and fast gas chromatography coupled with mass spectrometry. J Sep Sci 35:1922–1932

EU pesticide databases (European Commission) http://ec.europa.eu/sanco_pesticides/public/?event=commodity.resultat

Farré M, Picó Y, Barceló D (2014) Application of ultra-high pressure liquid chromatography linearion-trap orbitrap to qualitative and quantitative assessment ofpesticide residues. J Chromatogr A 1328:66–79

Harris ESJ, Cao S, Littlefield AB, Craycroft AJ, Scholten R, Kaptchuk T, Fu Y, Wang W, Liu Y, Chen H, Zhao Z, Clardy J, Woolf AD, Eisenberg DM (2011) Heavy metal and pesticide content in commonly prescribed individual raw Chinese Herbal Medicines. Sci Total Environ 409:4297–4305

Hayward DG, Wong JW, Shi F, Zhang K, Lee NS, DiBenedetto AL, Hengel MJ (2013) Muliresidue pesticide analysis of botanical dietary supplements using salt-out acetonitrile extraction, solid-phase extraction cleanup column, and gas chromatography-triple quadrupole mass spectrometry. Anal Chem 85:4686–4693

Hernández F, Sancho JV, Ibáñez M, Abad E, Portolés T, Mattioli L (2012) Current use of high-resolution mass spectrometry in the environmental sciences. Anal Bioanal Chem 403:1251–1264

Ho YM, Tsoi YK, Leung YK (2013) High sensitive and selective organophosphate screening in twelve commodities of fruits, vegetables and herbal medicines by dispersive liquid-liquid microextraction. Anal Chim Acta 755:58–66

Jager LS, Perfetti GA, Diachenko GW (2006) Analysis of ginkgolides and bilobalide in food products using LC–APCI–MS. J Pharm Biomed Anal 41:1552–1559

Lee H, Lim H, Yang J, Hong J (2013) Rapid determination of ginkgolic acids in ginkgo biloba leaf using online column switching high-performance liquid chromatography-diode array detection and confirmation by liquid chromatography-tandem mass spectrometry. Bull Korean Chem Soc 34:3629–3634

Li Z, Maier MP, Radke M (2014) Screening for pharmaceutical transformation products formed in riversediment by combining ultrahigh performance liquidchromatography/high resolution mass spectrometry with a rapiddata-processing method. Anal Chim Acta 810:61–70

Liu Q, Kong W, Qiu F, Wei J, Yang S, Zheng Y, Yang M (2012) One-step extraction for gas chromatography with flame photometric detection of 18 organophosphorus pesticides in Chinese medicine health wines. J Chromatogr B 885–886:90–96

Łozowicka B, Jankowska M, Rutkowska E, Hrynko I, Kaczyńsky P, Maciński J (2014) The evaluation of a fast and simple pesticide multiresidue method in various herbs by gas chromatography. J Nat Med 68:95–111

Mao X, Wana Y, Yan A, Shen M, Wei Y (2012) Simultaneous determination of organophosphorus, organochlorine, pyrethriod and carbamate pesticide in Radix astragali by microwave-assisted extraction/dispersive-solid phase extraction coupled with GC-MS. Talanta 97:131–141

Martínez-Domínguez G, Plaza-Bolaños P, Romero-González R, Garrido Frenich A (2014) Multiresidue method for the fast determination of pesticides in nutraceutical products (Camellia sinensis) by GC coupled to triple quadrupole MS. J Sep Sci 37:665–674

Martínez-Domínguez G, Romero-González R, Garrido-Frenich A (2015) Determination of toxic substances, pesticides and mycotoxins, in ginkgo biloba nutraceutical products by liquid chromatography Orbitrap-mass spectrometry. Microchem J 118:124–130

Masiá A, Campo J, Blasco C, Picó Y (2014) Ultra-high performance liquid chromatography–quadrupole time-of-flight mass spectrometry to identify contaminants in water: an insight on environmental forensics. J Chromatogr A 1345:86–97

Mastovska K, Wylie PL (2012) Evaluation of a new column back flushing set-up in the gas chromatographic-tandem mass spectrometric analysis of pesticide residues in dietary supplements. J Chromatogr A 1265:155–164

Moschet C, Piazzoli A, Singer H, Hollender J (2013) Alleviating the reference standard dilemma using a systematic exact mass suspect screening approach with liquid chromatography-high resolution mass spectrometry. Anal Chem 85:10312–10320

Nguyen TD, Lee KJ, Lee MH, Lee GH (2010) Rapid determination of 95 pesticides in soybean oil using liquid-liquid extraction followed by centrifugation, freezing and dispersive solid phase extraction as cleanup steps and gas chromatography with mass spectrometric detection. Microchem J 95:43–49

Páleníková A, Martínez-Domínguez G, Arrebola FJ, Romero-González R, Hrouzková S, Garrido FA (2015) Multifamily determination of pesticide residues in soya-based nutraceutical products by GC/MS-MS. Food Chem 173:796–807

Pawar RS, Tamta H, Ma J, Krynitsky AJ, Grundel E, Wamer WG, Rader JI (2013) Updates on chemical and biological research on botanical ingredients in dietary supplements. Anal Bioanal Chem 405:4373–4384

Picó Y, Farré M, Soler C, Barceló D (2007) Confirmation of fenthion metabolites in oranges by IT-MS and QqTOF-MS. Anal Chem 79:9350–9363

Picó Y, Farré M, Segarra R, Barceló D (2010) Profiling of compounds and degradation products from the postharvest treatment of pears and apples and ultra-high pressure liquid chromatography quadrupole-time-of-flight mass spectrometry. Talanta 81:281–293

Rahman MM, Park JH, El-Aty AMA, Choi JH, Cho SK, Yang A, Park KH, Shim JH (2013) Analysis of kresoxim-methyl and its thermolabile metabolites in Korean plum: an application of pepper leaf matrix as a protectant for GC amenable metabolites. J Sep Sci 36:203–211

Sadowska-Rociek A, Surma M, Cieślik E (2013) Application of QuEChERS method for simultaneous determination of pesticide residues and PAHs in fresh herbs. Bull Environ Contam Toxicol 90:508–513

SANCO/12571/2013 Guidance document on analytical quality control and validation procedures for pesticide residues in food and feed. European Commision Health & Consumer Protection Directorate-General

Sumner LW et al (2007) Proposed minimum reporting standards for chemical analysis. Metabolomic 3:211–221

Sun N, Hao L, Xue J, Jin H, Tian J, Lin R (2007) Proposed minimum reporting standards for chemical analysis. J Health Sci 53:464–469

Tang Q, Wang X, Yu F, Qiao X, Xu Z (2014) Simultaneous determination of ten organophosphate pesticide residues in fruits by gas chromatography coupled with magnetic separation. J Sep Sci 37:820–827

Vanni A, Gamberini R, Calabria A, Nappi P (2000) Determination and identification of metabolites of the fungicides Iprodione and Procymidone in compost. Chemosphere 41:1431–1439

Wan YQ, Mao XJ, Yan AP, Shen MY, Wu YM (2010) Simultaneous determination of organophosphorus pesticides in Chinese herbal medicines by microwave-assisted extraction coupled with dispersive-solid phase extraction and gas chromatography. Biomed Chromatogr 24:961–968

Xu R, Wua J, Liu Y, Zhao R, Chen B, Yang M, Chen J (2011) Analysis of pesticide residues using the Quick Easy Cheap Effective Rugged and Safe (QuEChERS) pesticide multiresidue method in traditional Chinese medicine by gas chromatography with electron capture detection. Chemosphere 84:908–912

Zhang JJ, Zhang LG, Zhang J, Cui GW, Tang B, Li XY, Li Z (2009) Determination of cypermethrin residues in gingko biloba leaves by high performance liquid chromatography. Soc Ethiop 23:97–100

Acknowledgments

The authors gratefully acknowledge the Spanish Ministry of Economy and Competitiveness (MINECO) and FEDER (Project ref. CTQ2012-34304). This work was also supported by the Scientific Grant Agency of the Slovak Republic VEGA Project No. 1/0503/14 and by the Slovak Research and Development Agency under Contract No. APVV-0797-11. AP is grateful for National Scholarship Program of the Slovak Republic. RRG is also grateful for personal funding through the “University Research Plan” (Almería University) and Cajamar.

Conflict of Interest

Agneša Páleníková declares that she has no conflict of interest. Gerardo Martínez-Domínguez declares that he has no conflict of interest. Francisco Javier Arrebola declares that he has no conflict of interest. Roberto Romero-González declares that he has no conflict of interest. Svetlana Hrouzková declares that she has no conflict of interest. Antonia Garrido Frenich declares that she has no conflict of interest. The authors declare that they have no conflict of interest and they certify that this article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Electronic supplementary material associated with this article can be found in the online version.

ESM 1

(DOC 402 kb)

Rights and permissions

About this article

Cite this article

Páleníková, A., Martínez-Domínguez, G., Arrebola, F.J. et al. Determination of Pesticides and Transformation Products in Ginkgo biloba Nutraceutical Products by Chromatographic Techniques Coupled to Mass Spectrometry. Food Anal. Methods 8, 2194–2201 (2015). https://doi.org/10.1007/s12161-015-0103-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0103-0