Abstract

As direct food contact material, wood is subject to European regulation no. 1935/2004 of 27 October 2004, which specifies that materials intended for safe food contact must not interfere with foodstuff characteristics. In order to comply with this regulation, it is important to provide an efficient recovery method so that the microbial load on wooden surfaces in direct contact with products can be determined. This study compares three methods of recovering microorganisms from wooden packaging surfaces: grinding, brushing, and planing techniques. We chose three microorganism models, at various concentrations, which are well-known risks in the food industry: Escherichia coli (vegetable sector), Listeria monocytogenes (dairy sector), and Penicillium expansum (fruit sector). Tests were carried out on three types of wooden surface, either dry or wet, and made of poplar, Scots pine, and spruce, which are commonly used in France for wooden packaging in the food industry. We identified which factors influenced microorganism recovery rates: wood moisture content, contact time, and wooden species. The grinding technique was the one which delivered the best recovery yield with an average of 30.1 % for L. monocytogenes on spruce and E. coli on poplar and 30.4 % for P. expansum on poplar at 37 % of wood moisture content. Planing method was also chosen to be applied to thicker wooden samples. These most reliable recovery methods will be used as a basis for the development of a specific standard to assess the food safety of wooden packaging.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since ancestral times, wood has been used for its properties as a “technological tool” in contributing to the organoleptic qualities of some products, for instance, in wine barrels (Gougeon et al. 2009), in vinegar barrels in which vinegars were found to be related to the wooden species of the barrels (Callejón et al. 2010), and in cheese ripening shelves (Richard 1997). Because of their lightness, their mechanical resistance to shocks, and their high tolerance to moisture, manufacturers now use wooden materials to make crates or boxes for packaging foodstuffs as varied as fruits, vegetables, fish, shellfish, and cheese. Another situation where direct contact with food arises is the use of wooden cutting boards in kitchens and some slaughterhouses. In Europe, as direct food contact material, wood is subject to European regulation no. 1935/2004 (Anonymous 2004b), which specifies that materials intended for safe food contact must not interfere with foodstuff characteristics. In order to prevent food safety issues, the food industry widely uses the HACCP-based processes to maintain a high level of hygienic production of foodstuffs. Microbiological analyses of working material surfaces are a common, even essential, procedure to reach this objective. These analyses are generally used to prevent contamination of foods (Kusumaningrum et al. 2003), to detect a specific microorganism on the surface (Beresford et al. 2001), or to check hygiene procedures like cleaning and/or disinfection (Joseph et al. 2001).

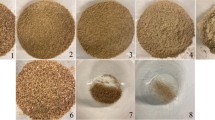

For this purpose, and in the French Arrêté November 1945 (Anonymous 1945) and the information note of DGCCRF (Anonymous 2012), three common species of non-treated wood were tested: poplar, pine, and spruce. Poplar and pine are widely used for manufacturing wooden packaging, such as crates for fruits, vegetables, and oysters, while spruce is only used as wooden shelves for ripening cheese.

Many methods to analyze the microbial contamination of working or packaging surfaces have been published. Some of them are quantitative, such as the agar contact plate and the swabbing methods (Miller 1996; Lortal et al. 2009), and have been used on wooden surfaces in accordance with the international standard ISO 18593:2004 (Anonymous 2004a), although these methods gave poor recovery rates on this type of porous material (Carpentier 1997). Stomacher and ultrasonic sound methods have also been used, such as in the studies of (Ak et al. 1994a, b ; McEvoy et al. 2005; Mariani et al. 2007). Other techniques include the brushing method used in the study of Mariani et al. (2007), but no standard method has been described for wooden surfaces because of the difficulty of recovering microorganisms from this natural material.

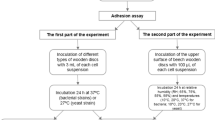

The aim of this study is to compare three existing methods for recovering microorganisms from wooden packaging surfaces, which could be used in the field and are easily performed in laboratories. These are the following: (i) the destructive method of grinding, (ii) the semi-destructive method of planing, and (iii) the non-destructive method of brushing (scrubbing). The method that shows the best results in terms of reproducibility, repeatability, and average rate will be used for microbial assessment on wood. For instance, wooden packaging surfaces that are in direct contact with cheese, fruit, vegetable, and meat packaging or processing would be analyzed following this method.

Materials and Methods

Microorganism Strains

Three microorganism models were chosen according to a risk analysis of agri-food companies that use wooden packaging. The bacterial pathogen Listeria monocytogenes was chosen as a known risk for dairies (Midelet and Carpentier 2002; Carrascosa et al. 2012; Awang Salleh et al. 2003), which may also be responsible for cross-contamination of products because of its great survival on working surfaces (Kang et al. 2007; Cox et al. 1989; Ringus and Moraru 2013). A reference strain of Escherichia coli was chosen to investigate the behavior of a gram-negative bacterium on wooden surfaces (Dore and Lees 1995; Pangloli et al. 2009; Taylor et al. 2013). It is also a relevant risk issue since outbreaks of E. coli O157:H7 have been linked to the consumption of contaminated meat (Banatvala et al. 1996) and fresh produce like lettuce or apple cider (Beuchat 2002). Arthur et al. (2008) described the persistence of this bacterium on working surfaces in cattle and swine slaughterhouses. The third model is Penicillium expansum described as a common contaminant of fruits and vegetables (Snowdon 2010; Yao et al. 1996) and as a mold producing mycotoxins (Ikeura et al. 2011).

In order to establish the detection threshold of each method, three concentrations of the inoculum were chosen: 10, 103, and 104 CFU/cm2. Lyophilized strains of E. coli ATCC700926 and P. expansum ATCC7861 were rehydrated according to the ATCC instructions. The L. monocytogenes SIR436 strain came from the Actalia collection. The bacterial strains were grown on nutrient agar at 37 °C for 24 h and subcultured. After confirmation of its identity, the strain was centrifuged at 5,000g for 20 min, suspended in glycerine milk, and stored in cryo-tubes with porous beads at −20 °C for the stock collection and in simple cryo-tubes at −80 °C for the working collection. To prepare E. coli or L. monocytogenes inoculum solutions, two beads were suspended in 10 mL Tryptone Soy Casein Broth (TSCB, Biokar) for 24 h at 37 °C incubation and subcultured once. The concentration of these subcultures was measured by spectrophotometry at an OD of 620 nm in order to standardize each bacterial inoculum solution at targeted concentrations by successive dilutions in sterile water containing 0.9 % NaCl.

The rehydrated mold strain ATCC7861 was inoculated on malt agar inclined tubes and incubated for 2 weeks at 22 °C/65 % relative humidity. Spores were then transferred into sterile water with 0.9 % NaCl supplemented by 0.5 % (v/v) Tween 80, filtered on sterile gauzes, and centrifuged at 7,500g for 15 min. This solution of spores was counted on a Malassez cell to determine its concentration and then diluted in sterile water containing 0.9 % NaCl to obtain the required concentration of P. expansum inoculum.

Viability Control of the Inoculum Cultures

A viability control of the microorganisms was carried out to check the concentration of viable cells present in the microbial solution. The viability of E. coli ATCC700926 and L. monocytogenes SIR436 was checked by placing 1 mL of culture on a Petri dish before adding TBX (Biokar) and ALOA (Biokar) agar and counting colonies after incubation at 37 °C for 24 h. A complementary test was performed with the P. expansum recovery solution obtained by the grinding method on 12 T24 pine samples with 37 % moisture content. The spores recovered in the 25-mL solution were counted on Malassez cells and compared to the enumerating malt agar plate method.

Preparation and Inoculation of Wooden Samples

Origin of Wooden Samples

Wooden samples measuring 6 by 4 cm (24 cm2) were selected as reference surfaces. Pinus pinaster, known as Maritime pine, and Populus euramericana poplar sapwood samples, freshly rotary cut, were 0.4 cm thick (Bois Diffusion, Valanjou, France) while the spruce sapwood specimens, which were sawn from new ripening shelves from Actalia’s supplier, had a thickness of 1.5 cm. Every wooden sample was cut in the direction of the wood grain and untreated. Prior to testing, they were sterilized by ionization (gamma radiation) at a dose rate of 25 kGy.

Wetting of the Wooden Samples

Two moisture contents were tested: 18 % (dry packaging storage conditions) and 37 % (wet packaging storage conditions). To obtain the targeted moisture conditions, the wooden samples, which initially had a moisture content of around 11 %, were soaked in sterilized distilled water, and then, some were dried beneath a laminar flow hood as described in Table 1. The wooden sample was weighed after wetting and then put in an oven at 103 °C for 48 h to determine its dry weight. The moisture content of the wooden samples was determined by calculation on the basis of the weight of moisture contained in the piece of wood (Schirp and Wolcott 2005).

Inoculation of Wooden Surfaces

Then, 0.3 mL of an inoculation solution was spread homogeneously in drops of 10 μL (using a multichannel pipette) on the 24-cm2 sterile wooden surface. The inoculated samples were immediately submitted to one of the three recovery methods (T0). The T24-inoculated wooden samples were stored for 24 h in a climatic enclosure at 20 °C/95 % relative humidity in order to maintain their moisture level, before recovery methods were applied.

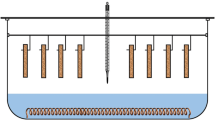

Grinding Recovery Method

Each inoculated wooden sample was first dry-ground in a sterile blender for 10 s at 18,000 rpm to crush it into pieces. Then, 25 mL of 0.9 % NaCl sterile water was added to the sample pieces, and the mixture was ground again for 5 s at 18,000 rpm to remove the inoculated microorganisms from the wood to the recovery solution. Next, the recovery liquid was transferred into stomacher filter bags and homogenized for 2 min by a stomacher (Le Bayon et al. 2010).

Planing Recovery Method

The planing recovery method was first described by Zangerl et al. (2010). The inoculated wooden samples were fixed with a vice to a workbench and were planed with a sterilized Fisher Darex D102T planer, which contains a 34-mm steel cutting blade. The planing was done homogeneously on the wooden specimen at a thickness of 2 mm on average from the surface. The shavings of each wooden block were weighed into a stomacher filter bag to obtain 25 g of shavings. These were then immersed in 25 mL of sterile water with 0.9 % NaCl and homogenized for 2 min.

Brushing Recovery Method

This method consisted of vigorous scrubbing using a sterilized hard toothbrush on the wooden surface moistened with 1 mL of a sterile water solution containing 0.9 % NaCl and 5 % agar. Then, the surface was rubbed with squares of wipes (3 × 3 cm Bleu Twill) held with sterilized tweezers. Next, the toothbrush and the wipes were put into a stomacher bag and immersed in 25 mL of sterile water with 0.9 % NaCl and homogenized for 2 min (Mariani et al. 2007).

Microbial Enumeration

In all cases, the recovery solutions obtained were enumerated on plate count agar directly after stomaching. Following a step of successive 1/10 mL dilutions in sterile water containing 0.9 % NaCl, 1 mL of the bacterial solutions was plated in duplicate onto Petri dishes before the medium was added. All agar media were purchased from Biokar except for the mold. L. monocytogenes was enumerated on ALOA (Biokar) agar plates and incubated for 48 h at 37 °C. E. coli was enumerated on TBX (Biokar) agar plates and incubated for 48 h at 37 °C. For P. expansum, 0.1 mL of the solution was plated in duplicate onto the surface of a malt extract agar (Difal). The inoculated agar plates were spread before incubation at 22 °C/95 % humidity for 3 to 5 days.

Statistical Analysis

Each condition was tested with six wooden samples and replicated once at a different time. All the results were expressed in colony-forming unit (CFU)/cm2 and analyzed with Excel. The four parameters, namely, the microbial recovery method, the wooden species, the inoculated microorganism, and the moisture content of the wooden samples, were tested, and the microbial recovery method rates were compared by ANOVA variance analysis and Bonferroni test with Minitab® statistical software v17 (Minitab® Inc.).

Results

Influence of Different Factors on the Microbiological Recovery Method Rates

The three methods tested provided results for each wood timber and microorganism selected for this study but with varied recovery rates under different parameters.

Influence of the Microorganism Contact Time with the Wooden Samples and of the Wooden Species

The microorganism contact time with the wooden samples demonstrated a large decrease in recovery yield between T0 and T24 hours as shown in Fig. 1.

Difference in recovery rates for three microorganisms from spruce and poplar samples (N = 6 wooden samples × 2 replicates = 12) of 37 % moisture content. The inoculum solutions were at 104 CFU/cm2 on average ±0.1 log10 (CFU/cm2) for L. monocytogenes, 104 CFU/cm2 on average ±0.2 log10 (CFU/cm2) for E. coli, and 104 CFU/cm2 on average ±0.5 log10 (sp/cm2) for the P. expansum

The wooden species showed a slight influence on the rates of microbial recovery. Poplar samples seemed to give better overall results for every method and microorganism tested in this study. However, this small influence disappeared when the results were studied microorganism by microorganism as shown, for example, by the E. coli recovery rates from poplar and pine samples in Fig. 2.

Recovery rate percentages (N = 6 × 2 replicates = 12) for E. coli and P. expansum on pine and poplar samples and L. monocytogenes on spruce samples The results were obtained by three different methods at an inoculation concentration of 104 CFU/cm2 and for wooden samples of 37 % moisture content on average. The numbers in bold represent yield values. The letters correspond to statistical homogenous family of recovery rates. Numbers that are followed by the same letter are not significantly different after the Bonferroni test at a confidence level of 95 % (Minitab software)

Repeatability

The ANOVA results showed that there was no significant difference between the recovery rates obtained by 12 replicates in two sets of repetitions (p > 0.05), meaning that the three tested methods had good reproducibility. For the same inoculation concentration level, the same method, and the same moisture level of wooden samples, the microorganism tested had no statistically significant effects on recovery rate either, as shown in Fig. 2.

Influence of Wood Moisture Levels

Wetting and drying wooden samples before inoculation provided the selected moisture contents. Table 2 shows the wood moisture content obtained for eight wooden standard controls during the different experiments when the selected moisture content was 37 %. The standard deviation means for these spruce samples were 35.7 ± 1.8 % moisture content at T0 and 35.1 ± 1.7 % at T24. For poplar and pine samples, the standard deviations means were, respectively, 35.6 ± 7.1 and 35.5±4.1 % moisture content at T0 and 33.1 ± 7.7 and 32.8 ± 4.4 % at T24. The loss of moisture between samples at T0 and at T24 was not relevant for all the species studied.

However, the degree of wood moisture demonstrated the highest significant influence on microbial recovery rate (Fig. 3). Poplar and pine samples at 18 and 37 % moisture content were used to determine the influence of wood moisture on microbial recovery rates. Figure 3 shows the results obtained for the grinding method applied to poplar and pine samples at these two humidity levels after an inoculation of E. coli or P. expansum solutions at 104 CFU/cm2 (sp/cm2). For the bacterial model, E. coli, on poplar or on pine, the recovery rates at 18 % of wooden moisture content are significantly lower than the value of the recovery rates from wooden samples with 37 % moisture content. In the case of P. expansum, the difference in recovery rates from poplar samples between 18 and 37 % moisture content was the highest with a loss of 26.7 %.

Recovery rate percentages (N = 6 × 2 replicates = 12) for E. coli and P. expansum on pine and poplar samples at 18 and 37 % moisture content The results were obtained by grinding method at an inoculation concentration of 104 CFU/cm2. The numbers in bold represent yield values. The letters correspond to statistical homogenous family of recovery rates. Numbers that are followed by the same letter are not significantly different after the Bonferroni test at a confidence level of 95 % (Minitab software)

Recovery Effectiveness of the Three Tested Recovery Methods

Effectiveness on Microbial Recovery Rates

The second factor showing a high influence on recovery rates was the method itself. As expected, the destructive and semi-destructive recovery methods, i.e., grinding and planing, tended to be more effective than the non-destructive brushing method.

For the bacterial models, the grinding method gave the highest recovery rate for E. coli on poplar and pine samples (Fig. 2) and L. monocytogenes on spruce samples, at a concentration level of 104 CFU/cm2 on average and 37 % moisture content of wood. Brushing and planing methods gave lower recovery rates for the bacterial strains used in this study. Moreover, according to the Bonferroni test, there was no difference between both methods for the recovery of these bacteria at a 95 % confidence level.

The minimum recovery rate, observed in Fig. 2, was obtained by grinding on pine to recover P. expansum. However, like the bacterial models, the mold was highly recovered by the grinding method on poplar samples with a similar recovery yield to that for E. coli as shown in Fig. 2. The highest Penicillium strain recovery yield was obtained by the grinding method on poplar samples and by the planing and brushing methods on pine samples. Moreover, P. expansum gave similar recovery rates to bacterial models for the planing method. However, it should be underlined that the brushing method was more efficient for the mold model recovery. On pine samples, although the brushing and planing methods showed similar results to P. expansum, grinding provided its lowest recovery rate. This particular result was repeatable and obtained only under these coupling conditions.

Sensitivity

The sensitivity of the three methods was tested by the inoculum concentration: 10 and 102 CFU/cm2 or sp/cm2 for the three microorganisms on the three species at T0 and at 37 % moisture content of wood. The results obtained on poplar and pine samples were similar. As described in Fig. 4, every method enabled the detection of 10 CFU/cm2 on the wooden surface when the wood moisture content was 37 %. The grinding method had the best detection threshold for L. monocytogenes on spruce and for E. coli and P. expansum on poplar and pine samples, with a detection sensitivity of 2 CFU/cm2 and a quantification sensitivity of less than 60 CFU/cm2 for each model. However, the brushing method gave similar detection thresholds to the grinding method for the mold while the planing method gave similar results to the grinding method for E. coli on poplar. This confirms the better efficiency of the brushing method for the mold than for the bacterial model.

Discussion

Decrease in Recovery Rate After 24 h of Inoculum Contact

The decrease in the recovery rate values obtained from samples that were in contact with the microorganisms for 24 h was observed for the three applied methods and for all tested microorganisms and wood species. This significant reduction could be explained by different parameters. First, it could be the cultivation-based methods used in this study; only cultivable cells were detected, and the recovery rate had to be subjected to this consideration. Moreover, the fact that recovery rates became much lower within a short contact time of the microorganism with wood, rather than throughout 24 h, could be explained by the hypothesis of microbial mortality on inoculated wooden samples. This tendency for microorganisms not to survive on wood was previously shown by (Milling et al. 2005). In their study, E. coli and Enterococcus faecium showed a dramatic reduction in recovery by the swabbing method after 24 h on pine chips. Beyond this period, E. coli was not detectable by either cultivation-based or cultivation-independent methods on pine and spruce woods. Enterococcus faecium remained detectable on spruce chips but with a significant loss compared to the initial cell density of the bacterial solution. In the same work, wooden samples were maintained at a moisture content of 37 % for 24 h. Therefore, the mortality of the tested microorganisms could not be linked to desiccation due to wood drying, unless the surface moisture content of the wooden samples decreased, while the overall moisture content of the wooden pieces remained at a high level.

In a complementary experiment using six replicates, the Malassez cell counting of grinding recovery solutions gave a total count of Penicillium spores, and the difference between this number and the enumeration on plates showed a loss of 2.2 log10 (sp/cm2), which means that 2.2 log10 sp/cm2 became non-viable and non-cultivable after 24 h on pine surface samples (data not shown).

We suggest that the antimicrobial effect could increase when microorganisms are in contact with a wooden surface for a long time as proposed by Schönwälder et al. (2002). In this study, Schönwälder et al. demonstrated that the antimicrobial properties of pine were responsible for the low survival rate of P. expansum on pine wooden surfaces. However, antimicrobial properties were not shown for poplar or spruce surfaces.

Influence of Wood Moisture Content

The difference in recovery rates between wooden samples at 18 and 37 % moisture content, regardless of the method, the microorganism, or the species tested, was highly significant. A higher wood moisture content implies better conditions for survival, and even growth, of bacteria or mold. The low recovery rates found for samples at 18 % moisture content could be related to mortality and dryness. Another hypothesis for the better recovery rate with wooden samples at 37 % moisture content could be linked to the inoculation method. If inoculation had been conducted by immersion in the microbial solution, the low moisture content would have been hard to reach. Therefore, the inoculation method by spots on the surface of the samples was chosen. There is a possibility that drops of inoculums on dry wooden surfaces (18 % moisture content) could penetrate more through the first millimeters of the surface than through one saturated with water (37 % moisture content). This approach could be explored by further goniometer-based experiments. This technique measures the penetration speed of the drops of inoculum into the wooden sample by calculating the angle contact of the drop with the surface (Bico 2000). Based on these results, it is clearly important to remember that during the analysis of ground wooden packaging in the food industry, the sampling step must be chosen carefully because wood products have varied moisture contents at the beginning of their manufacture and at the end of their storage.

Grinding as an Optimal Recovery Method

The grinding method showed the best recovery rate for the bacterial models E. coli and L. monocytogenes on every tested wooden species and for P. expansum on poplar samples. Even at the lowest concentration, 10 CFU/cm2, the method remained significantly quantitative. As this method destroys the wooden sample, these results could be explained by a more in-depth extraction. The semi-destructive planing method repeatedly scored lower recovery rates but showed better results for the bacterial strains than for P. expansum mold. On the contrary, the brushing method, which led to similar recovery rates, was better for P. expansum than for bacteria.

P. expansum on pine samples was the only case of a low recovery rate with the grinding method. We suggest that grinding could release more antimicrobial compounds (Schönwälder et al. 2002) from pine wood than the planing or brushing methods, but this hypothesis does not explain why this action is not the same for bacteria. Another hypothesis could be that grinding releases sap or resin compounds from this resinous species, which could entangle P. expansum spores that already have a tendency to aggregate. Bacteria have smaller cell sizes so would be less affected. A complementary test to explore this hypothesis was carried out as follows: Dilutions were performed in a grinder according to the classic protocol and a modified protocol in which Tween 80 was added to the 25 ml of sterile water with 0.9 % NaCl in order to limit spore aggregation (Carson et al. 1995). No significant difference was found as shown on Table 3.

Today, the grinding method is already recommended by the French norm NFQ 03-070-1 (Anonymous 1988) for analyzing microbiological contamination of paper and cardboard used as food packaging. This method was used, following a protocol developed by Le Bayon et al. (2010), to compare grinding with agar contact plates, stomacher, ultrasonic sound, and vacuum pressure methods on poplar samples. Agar contact, which is recommended by the international standard ISO 18593:2004 (Anonymous 2004a), and stomacher methods showed low rates of microbial removal from wood because of its porosity, which makes the release of microbial contaminants difficult (Moore and Griffith 2007). Although the coupling of ultrasonic sound and vacuum pressure methods showed good results previously showed by Le Bayon et al. (2010), grinding gave a rather good recovery rate (between 35 and 38 %) with a maximum bacterial loss of 0.5 log10. Planing and brushing techniques were used with the protocol described by Zangerl et al. (2010) and Mariani et al. (2007), respectively. Microorganisms that contaminate wooden specimens can be present on surfaces but can also penetrate the first 2 to 3-mm thickness of the wooden surface, as demonstrated in previous studies carried out by two laboratories (FCBA, Actalia) on spruce ripening shelves and confirmed by scan-ning electron microscopy observations (Abrishami et al. 1994). As destructive methods that enter the first millimeters of the wooden surface lead to a greater exchange between the wooden matrix and the microbial recovery solution, these methods seem to be more relevant than those that only sample the superficial wooden surface.

From a practical aspect, the grinding method was easy to handle, like the two other methods tested. It is very suitable for thin wooden surfaces, but for thicker ones, it should be preceded by a sampling step such as planing. Tests were performed to determine if a modified protocol of sampling by planing followed with the grinding recovery method would lead to an optimized recovery rate. Results showed no significant difference between the classic and modified protocols. The granulometry of ground wooden chips could also be investigated to improve the recovery rates of the grinding method using more efficient grinders (Milling et al. 2005).

Conclusion

For the first time, three methods for recovering microorganisms from wooden surfaces were compared, and four other factors related to recovery rates were studied. The type of microorganism, the type of wooden species, the inoculated wood moisture content, and the inoculation contact time have not previously been studied and analyzed together.

We have demonstrated that the grinding recovery method is fast and easy to handle under sterile conditions, as well as giving a rather better recovery rate than the others. It could be used to analyze microbiological contamination of wooden packaging, provided that the thickness is less than 5 mm. The grinder blades are not suitable for wooden boards that have a greater thickness. Thus, the planing method could be more appropriate for thicker wooden working surfaces such as spruce ripening shelves and wooden chopping boards.

An optimization of this microbial recovery method could be studied by coupling planing as a wood sampling method with grinding as the effective recovery method, instead of a stomacher step using a higher granulometric blender.

The influence of moisture is significant and could be determinant for the level of hygiene in connection with food and food contact surfaces as shown by Beyer and Gudbjörnsdottir (2002). Following those conclusions, grinding and planing methods will be used in further studies to analyze wooden packaging and microflora from thick working surfaces. This could be an important tool for microbial assessment on wooden working surfaces used in the agri-food industry.

References

Abrishami SH, Tall BD, Bruursema TJ, Epstein PS, Shah DB (1994) Bacterial adherence and viability on cutting board surfaces. J Food Saf 14(2):153–172

Ak NO, Cliver DO, Kaspar CW (1994a) Cutting boards of plastic and wood contaminated experimentally with bacteria. J Food Prot 57:16–22

Ak NO, Cliver DO, Kaspari CW (1994b) Decontamination of plastic and wooden cutting boards for kitchen use. J Food Prot 57(1):23–30

Anonymous (1945) Arrêté du 15 Novembre 1945 fixant la liste des matériaux susceptibles d'être utilisés sans inconvénient pour la santé publique dans la fabrication des instruments de mesures. Journal officiel, France

Anonymous (1988) NF Q 03-070-1 Août 1988—papiers et cartons—détermination des propriétés microbiologiques—Partie 1: dénombrement bactériologique total. NFQ 03-070-1 AFNOR, France

Anonymous (2004a) ISO 18593:2004—Microbiology of food and animal feeding stuffs—horizontal methods for sampling techniques from surfaces using contact plates and swabs. Geneva, Switzerland

Anonymous (2004b) RÈGLEMENT (CE) No 1935/2004 DU PARLEMENT EUROPÉEN ET DU CONSEIL du 27 octobre 2004 concernant les matériaux et objets destinés à entrer en contact avec des denrées alimentaires et abrogeant les directives 80/590/CEE et 89/109/CEE. vol ECR 1935/2004.

Anonymous (2012) Matériaux au contact des denrées alimentaires—cas du bois. Note d’information 2012–93-DGCCRF. vol 2012–93. DGCCRF, France

Arthur TM, Bosilevac JM, Brichta-Harhay DM, Kalchayanand N, King DA, Shackelford SD, Wheeler TL, Koohmaraie M (2008) Source tracking of Escherichia coli O157:H7 and Salmonella contamination in the lairage environment at commercial U.S. beef processing plants and identification of an effective intervention. J Food Prot 71(9):1752–1760

Awang Salleh N, Rusul G, Hassan Z, Reezal A, Hajar Isa S, Nishibuchi M, Radu S (2003) Incidence of Salmonella spp. in raw vegetables in Selangor, Malaysia. Food Control 14(7):475–479

Banatvala N, Magnano AR, Cartter ML, Barrett TJ, Bibb WF, Vasile LL, Mshar P, Lambert-Fair MA, Green JH, Bean NH, Tauxe RV (1996) Meat grinders and molecular epidemiology: two supermarket outbreaks of Escherichia coli 0157:H7 infection. J Infect Dis 173:480–483

Beresford TP, Fitzsimons NA, Brennan NL, Cogan TM (2001) Recent advances in cheese microbiology. Int Dairy J 11(4–7):259–274. doi:10.1016/S0958-6946(01)00056-5

Beuchat LR (2002) Ecological factors influencing survival and growth of human pathogens on raw fruits and vegetables. Microbes Infect 4(4):413–423. doi:10.1016/S1286-4579(02)01555-1

Beyer G, Gudbjörnsdottir B (2002) Wood in the food industry. Nordic Wood 2

Bico J (2000) Mouvement spontané de liquides dans des capillaires. Superhydrophobie, mouillage et imprégnation de surfaces texturées. Collège de France, France

Callejón R, Torija M, Mas A, Morales M, Troncoso A (2010) Changes of volatile compounds in wine vinegars during their elaboration in barrels made from different woods. Food Chem 120(2):561–571

Carpentier B (1997) Sanitary quality of meat chopping board surfaces: a bibliographical study. Food Microbiol 14(1):31–37. doi:10.1006/fmic.1996.0061

Carrascosa C, Saavedra P, Millán R, Jaber JR, Pérez E, Grau R, Raposo A, Mauricio C, Sanjuán E (2012) Monitoring of cleanliness and disinfection in dairies: comparison of traditional microbiological and ATP bioluminescence methods. Food Control 28(2):368–373

Carson C, Hammer K, Riley T (1995) Broth micro-dilution method for determining the susceptibility of Escherichia coli and Staphylococcus aureus to the essential oil of Melaleuca alternifolia (tea tree oil). Microbios 82(332):181–185

Cox LJ, Kleiss T, Cordier JL, Cordellana C, Konkel P, Pedrazzini C, Beumer R, Siebenga A (1989) Listeria spp. in food processing, non-food and domestic environments. Food Microbiol 6(1):49–61. doi:10.1016/S0740-0020(89)80037-1

Dore WJ, Lees DN (1995) Behavior of Escherichia coli and male-specific bacteriophage in environmentally contaminated bivalve molluscs before and after depuration. Appl Environ Microbiol 61(8):2830–2834

Gougeon RD, Lucio M, Frommberger M, Peyron D, Chassagne D, Alexandre H, Feuillat F, Voilley A, Cayot P, Gebefügi I (2009) The chemodiversity of wines can reveal a metabologeography expression of cooperage oak wood. Proc Natl Acad Sci 106(23):9174–9179

Ikeura H, Somsak N, Kobayashi F, Kanlayanarat S, Hayata Y (2011) Application of selected plant extracts to inhibit growth of Penicillium expansum on apple fruits. Plant Pathol J 10(2)

Joseph B, Otta S, Karunasagar I, Karunasagar I (2001) Biofilm formation by Salmonella spp. on food contact surfaces and their sensitivity to sanitizers. Int J Food Microbiol 64(3):367–372

Kang D, Eifert J, Williams R, Pao S (2007) Evaluation of quantitative recovery methods for Listeria monocytogenes applied to stainless steel. J AOAC Int 90(3):810–817

Kusumaningrum HD, Riboldi G, Hazeleger WC, Beumer RR (2003) Survival of foodborne pathogens on stainless steel surfaces and cross-contamination to foods. Int J Food Microbiol 85(3):227–236, 10.1016/S0168-1605(02)00540-8

Le Bayon I, Callot H, Kutnik M, Denis C, Revol-Junelles A-M, Millière J-B, Giraud M, Gabillé M, Passédat N (2010) Development of microbiological test methods for the wooden packaging of foodstuffs. Paper presented at The International Research Group on Wood Protection, Biarritz

Lortal S, Di Blasi A, Madec M-N, Pediliggieri C, Tuminello L, Tanguy G, Fauquant J, Lecuona Y, Campo P, Carpino S, Licitra G (2009) Tina wooden vat biofilm: a safe and highly efficient lactic acid bacteria delivering system in PDO Ragusano cheese making. Int J Food Microbiol 132(1):1–8. doi:10.1016/j.ijfoodmicro.2009.02.026

Mariani C, Briandet R, Chamba JF, Notz E, Carnet-Pantiez A, Eyoug RN, Oulahal N (2007) Biofilm ecology of wooden shelves used in ripening the French raw milk smear cheese Reblochon de Savoie. J Dairy Sci 90(4):1653–1661. doi:10.3168/jds.2006-190

McEvoy JM, Nde CW, Sherwood JS, Logue CM (2005) An evaluation of sampling methods for the detection of Escherichia coli and Salmonella on turkey carcasses. J Food Prot 68(1):34–39

Midelet G, Carpentier B (2002) Transfer of microorganisms, including Listeria monocytogenes, from various materials to beef. Appl Environ Microbiol 68(8):4015–4024. doi:10.1128/aem.68.8.4015-4024.2002

Miller A (1996) Wooden and polyethylene cutting boards: potential for the attachment and removal of bacteria from ground beef. J Food Prot 59(8):854–859

Milling A, Kehr R, Wulf A, Smalla K (2005) Survival of bacteria on wood and plastic particles: dependence on wood species and environmental conditions. Holzforschung 59(1):72–81

Moore G, Griffith C (2007) Problems associated with traditional hygiene swabbing: the need for in-house standardization. J Appl Microbiol 103(4):1090–1103

Pangloli P, Hung Y-C, Beuchat LR, King CH, Zhao Z-H (2009) Reduction of Escherichia coli O157:H7 on produce by use of electrolyzed water under simulated food service operation conditions. J Food Prot 72(9):1854–1861

Richard J (1997) Utilisation du bois comme matériau au contact des produits laitiers. Comptes rendus de l'Académie d'agriculture de France 83(5):27–34

Ringus DL, Moraru CI (2013) Pulsed Ligh inactivation of Listeria innocua on food packaging materials of different surface roughness and reflectivity. J Food Eng 114(3):331–337

Schirp A, Wolcott MP (2005) Influence of fungal decay and moisture absorption on mechanical properties of extruded wood-plastic composites. Wood Fiber Sci 37(4):643–652

Schönwälder A, Kehr R, Wulf A, Smalla K (2002) Wooden boards affecting the survival of bacteria? Holz als Roh-und Werkstoff 60(4):249–257

Snowdon AL (2010) Post-harvest diseases and disorders of fruits and vegetables: volume 2: vegetables, vol 2. Manson Publishing, England

Taylor J, Davies M, Canales M (2013) The persistence of flood-borne pathogens on building surfaces under drying conditions. Int J Hyg Environ Health 216(1):91–99

Yao C, Conway WS, Sams CE (1996) Purification and characterization of a polygalacturonase produced by Penicillium expansum in apple fruit. Phytopathology 86(11):1160–1166

Zangerl P, Matlschweiger C, Dillinger K, Eliskases-Lechner F (2010) Survival of Listeria monocytogenes after cleaning and sanitation of wooden shelves used for cheese ripening. Eur J Wood and Wood Products 68:415–419

Acknowledgments

We sincerely thank Martine Gabille (FCBA) and Sylvie Engelmann (Actalia) for their valuable technical support. This work was financially supported by the French Scientific Consortium EMABOIS, the French Packaging Pole, and the French institution, France Bois Forêt.

Compliance with Ethics Requirements

Rached Ismail has received research grants from the French Scientific Consortium EMABOIS.

Isabelle Le Bayon has received research grants from the French Scientific Consortium EMABOIS.

Valérie Michel has received research grants from the French Scientific Consortium EMABOIS.

Florence Aviat has received research grants from the French Scientific Consortium EMABOIS.

Conflict of Interest

Marc Jequel declares that he has no conflict of interest. Magdalena Kutnik declares that she has no conflict of interest. Michel Fédérighi declares that he has no conflict of interest. This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ismaïl, R., Le Bayon, I., Michel, V. et al. Comparative Study of Three Methods for Recovering Microorganisms from Wooden Surfaces in the Food Industry. Food Anal. Methods 8, 1238–1247 (2015). https://doi.org/10.1007/s12161-014-0008-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-014-0008-3