Abstract

Enzymatic catalysts, such as lipases, have been extensively studied due to their promise as an alternative to chemical catalysts. They offer advantages like biodegradability (green biotechnology) and the potential for enzyme recycling (turnover), leading to reduced operational costs. The primary objective of this study was to produce lipase from the fungus Penicillium polonicum through solid-state fermentation, utilizing agro-industrial waste as substrate. The aim was to apply the obtained lipase as a biological catalyst in the synthesis of ethyl oleate ester. In the lipase production process, the filamentous fungus P. polonicum, along with sunflower seed cake (SSC) and rice husk (RH), served as substrate and support, respectively, for solid-state fermentation (SSF). Experiments involved varying proportions of both substrate and support (0%, 25%, 50%, 75%, and 100% (RH) and 100% (SSC)). Subsequently, the impact of glycerol as an inducer (1%, 3%, and 5%, with a 25/75% SSC/RH ratio) at SSF was investigated. The obtained results revealed a catalytic activity of 29.3 U g−1 under optimal conditions: 55% moisture, 25/75% SSC/RH, and at 27 °C during 96 h of fermentation. The lipase produced was employed as an enzymatic catalyst in studies involving the synthesis of ethyl oleate ester in n-heptane, utilizing experimental design 23. Variables such as temperature, enzymatic activity, and molar ratio (alcohol/acid) were modified. The best experimental conditions for the enzymatic synthesis of ethyl oleate ester were determined to be an alcohol/acid molar ratio of 6:1, a temperature of 37 °C, and an enzymatic activity of 60 U. This resulted in 100% conversion into ester within 5 h of reaction time. The outcomes demonstrated that lipase effectively catalyzed the synthesis of ethyl oleate, a biodiesel ester, with a high yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Enzymes, also known as biocatalysts, speed up chemical reactions and metabolic processes with high specificity [1]. These biomolecules specialize in converting complex reactions into simpler steps, reducing activation energy barriers when the substrate binds to the enzyme’s active site, thus favoring the formation of ideal arrangements [2].

In the field of biotechnology, enzymes emerge as a promising alternative for efficiently producing compounds with high added value, promoting the sustainable use of renewable natural resources [3]. With appealing attributes such as enhanced biodegradability, adaptability to mild conditions, and the capacity for reuse, enzymes solidify their position as an environmentally conscious choice [4].

Among enzymes widely used in biotechnology, lipases stand out as the predominant class, known as triacylglycerol ester hydrolases, belonging to the group of serine hydrolases [5]. These enzymes enhance their catalytic activity at the water–oil interface in a process known as interfacial activation, utilizing the exposed hydrophobic area [6]. Lipases could hydrolyze triglycerides, converting them into glycerol and fatty acids [7].

The efficiency of lipase applicability depends on its origin, with microbial sources (bacteria, fungi, and yeast), most utilized [8]. Lipases, originating from microorganisms, are versatile enzymes capable of conducting a wide variety of bioconversion reactions, such as aminolysis, interesterification, alcoholysis, esterification, and hydrolysis [9].

Filamentous fungi, characterized by their ability to produce extracellular enzymes, emerge as attractive sources of production [9]. Notably, genera of filamentous fungi such as Penicillium, Rhizopus, Aspergillus, Fusarium, Mucor, and Geotrichum exemplify lipase producers with significant potential for applications across various industrial sectors [10, 11]. This versatility underscores the broad scope of lipase functionality in diverse biotechnological processes. The solid-state fermentation method is commonly employed to cultivate these filamentous fungi for enhanced enzyme production [12].

Solid-state fermentation (SSF) involves the utilization of a solid matrix in a process conducted with a low level of free water. To promote microbial development, the substrate or support must possess sufficient moisture and provide the necessary nutrients to sustain active metabolism and facilitate growth [13]. These processes are widely employed, utilizing microorganisms for the biological transformation of complex substrates into simpler molecules [14]. The advantages of utilizing SSF include low costs, reduced energy demand, simplified aeration, minimal risk of contamination, and the utilization of agro-industrial waste [13].

Common substrates in SSF include agricultural and forestry residues such as grains, legume seeds, bran like oats and soy, cakes (press cake or oil cake obtained after processing oilseeds), sugarcane bagasse, cassava, fruit and coffee pulps and peels, straw, sawdust, wood chips, and materials from both plant and animal origins. Most of them are cost-effective, are easily obtainable, and provide all the necessary nutrients for microbial growth in the SSF process [15].

Among these substrates, sunflower seeds are commonly utilized due to their high oleic acid content, which positively influences lipase production [16]. Consequently, sunflower seeds (Helianthus annuus) can be chosen as the substrate because they are readily available in our region, are cost-effective, and have a high lipid content [17]. The substantial oil content in sunflower seeds allows for their association with agro-industrial waste, such as rice husks, which are rich in carbohydrates [18]. This combination acts as a support, increasing the contact surface and providing essential nutrients, thereby favoring the development of microorganisms [19]. One of the primary advantages of using SSF for lipase production is that the fermented solid material can be directly employed as biocatalysts after drying, catering to various sectors in biotechnology [20].

Concerning the applications of lipase in biotechnology, its notable role as a catalyst in biodiesel production to replace alkaline catalysts, recover glycerol, and purify fatty methyl esters can be emphasized [21]. The demand for biofuels is on the rise in the chemical industry, leading to an increasing industrial need for lipase and other hydrolases. However, the use of lipases in biodiesel applications has not evolved as significantly as in other areas of biotechnology [22].

The justification for this research lies in its significant contribution to the advancement of sustainable and efficient processes in biotechnology. The utilization of lipases from Penicillium polonicum, combined with the optimization of both production and application conditions, not only enhances scientific understanding but also provides practical solutions for the synthesis of biodiesel esters. This, in turn, contributes to the broader objective of creating a more sustainable and environmentally friendly industrial landscape.

In this study, the aim is to enhance the application of fungal lipase as a biological catalyst in biodiesel production. To achieve this goal, lipase will be produced from the filamentous fungus Penicillium polonicum using solid-state fermentation with sunflower seeds as a substrate and agro-industrial waste (rice husk) as support. The objective is to make the process economically viable and sustainable, with the intention of utilizing the produced lipase as a catalyst in the synthesis of ethyl oleate, one of the biodiesel esters.

Materials and Methods

Materials

The endophytic filamentous fungus utilized in this study was isolated from castor bean leaves (Ricinus communis L.) by a biotechnologist at Tuiuti Paraná University in Curitiba, Paraná, Brazil. Molecular biology techniques were employed for the identification of fungi and were developed at the Federal University of Paraná in Palotina, Paraná, Brazil. These techniques involved amplifying specific DNA regions such as 28S, ITS1, and ITS2 using PCR. The amplified sequences are subsequently analyzed in BioEdit software and compared with databases using BLAST to determine similarity and thus identify the fungus. Subsequently, the fungal strain was generously provided and stored by Castellani methods (distilled water sterilized) at the State University of Western Paraná in Toledo, Paraná, Brazil.

Sunflower seeds were procured from a bulk food store in Toledo, Paraná, Brazil, while rice husks were kindly supplied by a local rice industry. The collaborative efforts between institutions and the inclusion of materials from regional sources contributed to the overall robustness and applicability of the research findings. All materials were sterilized in a vertical autoclave (autoclave–Prismatec 100 L) at 121 °C for 20 min. All the reagents used for this analysis were of analytical grade (AG), ensuring the highest quality and accuracy in the obtained results.

Microorganism

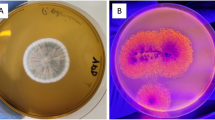

The endophytic filamentous fungus P. polonicum was activated on Petri plates using potato dextrose agar (PDA) medium (Kasv), supplemented with 0.05% chloramphenicol and 0.05% tetracycline hydrochloride to inhibit bacterial growth. The plates, already containing the inoculated material, were incubated in a bacteriological stove (42 L) at 27 °C for 96 h. For quality control, its morphology was examined both macroscopically (colony structures) and microscopically using an Olympus optic microscope [23].

Characterization of Different Parameters in Solid-State Fermentation Influencing Lipolytic Activity

Physical–Chemical Composition of the Substrate

Sunflower seeds (Helianthus annuus) were utilized as the substrate SSF owing to their high lipid content. Meanwhile, rice husks (Oryza sativa) served as the support (agro-industrial waste). The chemical composition of the substrates, including oil content, moisture, and total ash, was analyzed according to AOAC [24].

Inoculum and Fermentation Medium Preparation

After activation, the endophytic filamentous fungus was cultivated in Erlenmeyer flasks containing PDA medium supplemented with 0.05% tetracycline hydrochloride antibiotic. The cultivation was carried out in an oven at 27 °C for 168 h. A spore solution was prepared by adding distilled water and Tween 80 (a sterilized solution) to the flasks containing the filamentous fungus. Subsequently, the number of spores per milliliter was quantified using a Neubauer chamber (Fuchs Rosenthal).

For the fermentation tests, two substrates were investigated: only sunflower seed cake and mixtures of sunflower seed cake and rice husks in varying proportions. In the first assays, the fermentation medium contained 10 g of sunflower seed cake sieved through a round stainless sieve with particle sizes between 1.19 mm (16 mesh) and 2.0 mm (10 mesh), previously dried in an analog sterilization and drying oven (Solidsteel/SSA 40 L) at 50 °C for 24 h. The substrate was autoclaved in an Erlenmeyer flask at 121 °C for 15 min.

Kinetics of Lipase Production with Different Substrate Proportions

SSF assays were conducted according to Dickel et al. [23]. The inoculum was transferred to Erlenmeyer flasks containing the sterilized substrate (10 g). The moisture content was adjusted to 55% using phosphate buffer at pH 7.0 (50 mM), considering 108 spores per gram.

In pursuit of an economically viable and sustainable production of lipases, the effects of adding an agro-industrial residue rice husks (RH), to the substrate sunflower seed cake (SSC), were investigated. In these solid-state fermentation studies, kinetics were conducted over 168 h at 27 °C, considering five different proportions: 0%, 25%, 50%, 75%, and 100%. In this context, 0% corresponds to using only rice husk (RH), while 100% represents the exclusive use of SSC.

Kinetics of Lipase Production with the Addition of an Inducer

In these SSF studies, kinetics were conducted over 168 h at 27 °C, focusing on three different proportions of the inducer (glycerol): 1%, 3%, and 5%. The substrate proportion comprised a mixture of 25% SSC and 75% RH, aimed to complement the carbon source, given that SSC was in a smaller proportion.

Following this, the SSF was executed on a larger scale using 100 g of sterilized substrate in a glass tray (Marinex) measuring 30 × 20 × 8 cm at the optimal kinetic time. The same parameters described previously were applied (108 spores/g inoculum, 55% moisture, and incubation at 27 °C for 96 h).

Determination of Lipolytic Activity

Subsequently, the samples were incubated at 27 °C for 168 h, with triplicate samples being removed every 24 h. These samples were then frozen to halt microbial growth and subsequently dried. Lipase production was monitored by determining lipolytic activity through the titrimetric method applied to the fermented material [19, 23].

The determination of lipolytic activity was based on a titration method with NaOH of the fatty acids released by the enzyme from triacylglycerols [23]. The reaction medium for the substrate was prepared as an emulsion, consisting of 50 mM phosphate buffer pH 7.0, 10% arabic gum powder, and the substrate olive oil (acidity level 0.5%) (1.0 mM or 7.15% w/v).

The samples were incubated in a shaker, under stirring (150 rpm), for 20 min at 37 °C, containing 1.0 g of the fermented solid and 20 mL of the emulsion to release the fatty acids. To halt the reaction, 20 mL of an ethanol/acetone solution (1:1 v/v) was added. The released fatty acids were titrated with a NaOH solution (50 mM) containing phenolphthalein as an indicator, in a titrator (Digital Electronic Burette Kasv) until the pH endpoint of 10, and blank assays were conducted until pH 10. The assays were carried out in triplicate. One unit (U) of lipase activity was defined as the amount of enzyme that produces 1 µmol of fatty acids per minute under assay conditions. Lipolytic activity was expressed as units of enzyme activity per gram of fermented solid (U g−1).

Biocatalysis: Influence of Granulometry on Ethyl Oleate Synthesis

The synthesis study was conducted directly using the fermented solid under the optimal conditions determined in previous analyses. Experimental design studies were performed to assess the impact of temperature, enzymatic activity, and alcohol/acid molar ratio on the synthesis process. The response variable in these studies was the yield of the reaction in the production of ethyl oleate ester.

The fermented solid (SSC + RH) was employed in two different forms for biocatalysis: one in its whole form and the other crushed and sieved to a granulometry of 0.8 mm (20 mesh) to investigate the impact of granulometry on the synthesis process. The reaction mixture consisted of ethanol and oleic acid in a molar ratio of 6:1, with an enzymatic activity of 60 U, conducted in n-heptane at 37 °C. Reactions were conducted in a shaker incubator operating at 200 rpm for 9 h. The response variable evaluated in the experimental design was the conversion to ester (%), determined using the spectrophotometric Lowry-Tinsley method [25].

Experimental Assay and Statistical Analysis for Optimization Ethyl Oleate Ester Enzymatic Synthesis

After conducting a preliminary study on the influence of particle size on oleate synthesis, an experimental plan was implemented to assess the impact of temperature, enzymatic activity, and molar ratio on the synthesis process. The ester conversion percentage was evaluated using the Lowry-Tinsley spectrophotometric method [25]. A 23 factorial design was employed, with three replicas at the central point. Temperature levels of 30, 37, and 44 °C; enzymatic activity levels of 30, 60, and 90 U; and molar ratio levels of 3:1, 6:1, and 9:1 were examined and encoded for analysis as per Table 1. All 11 assays were conducted in an orbital shaker incubator (NL-343–02) at 200 rpm for 9 h, with samples collected (in triplicate) every 60 min.

The mean values underwent factorial analysis of variance (ANOVA), and a Pareto chart was generated to identify significant effects. A lack-of-fit test was conducted to assess the model’s adequacy. However, the lack-of-fit test results indicated that the data did not conform to the factorial model (see the “Results and Discussion” section). Consequently, second-order polynomial adjustments were carried out and interpreted individually for each factor (temperature, enzymatic activity, and molar ratio).

Biocatalysis: Kinetics of Ethyl Oleate Synthesis

After conducting the experimental design 23, reactions were conducted in a shaker incubator at 20 rpm for 9 h, utilizing the conditions that yielded the optimal results as identified in Table 1. This method enabled a more comprehensive examination of the selected factors’ influence on the reaction outcomes.

Ester Conversion Determination: Lowry-Tinsley Method

The spectrophotometric method, outlined by Lowry-Tinsley [25], was employed to quantify the residual content of fatty acids during the enzymatic synthesis of biodiesel ester from oleic acid. This method enabled the calculation of esterification yields and enzymatic hydrolysis activity. In the esterification process, the activity was determined by the absence of fatty acids in the reaction medium. One unit of esterification activity was expressed as the amount of enzyme that synthesizes 1 µmol of ester in a unit of time under the experimental conditions.

The method relies on the interaction between free fatty acids and copper II ions in an organic medium, allowing the assessment of the percentage of fatty acids converted to esters. Subsequently, 0.2 mL of the reaction medium was combined with 2.4 mL of toluene and 0.5 mL of the pyridine and copper II acetate solution (5%). The reactions were vortexed (VX-200 Vortex Mixer) for 30 s, and the organic phase was analyzed using a spectrophotometer (Labindia Analytical) set to a wavelength of 715 nm.

The conversion of esters was determined by assessing the reduction in the concentration of fatty acid in the reaction medium. The concentration of fatty acid in the medium corresponds to the absorbance determined by the calibration curve, which had been previously established with oleic acid (98% purity). The calibration curve was generated under the same test conditions, employing the spectrophotometric method of Lowry-Tinsley [25].

Results and Discussion

Characterization of Different Parameters in Solid-State Fermentation Influencing Lipolytic Activity

Physical–Chemical Composition of the Substrate

The activity of lipolytic production is linked to the concentration and composition of fatty acids present in the substrate. High oleic content exerts a positive effect, while high linoleic content has a negative impact during synthesis [18]. SSC was selected as a substrate due to its richness in oleic acid (55–70%) and low content of linoleic acid (20–25%), while rice husk was chosen as it represents an agro-industrial waste.

It was observed that SSC has a high lipid content (48.9%), making it the primary source of carbon available for the microorganism and inducing the production of lipase [26]. On the other hand, RH has an extremely low lipid content (0.47%) and was considered a support providing carbohydrates as a carbon source. Greater availability of carbohydrates promotes enhanced microorganism development [19]. Regarding moisture content, high values were not observed in both cases, serving as a basis for adjusting the fermentation moisture to 55%. Moisture control is crucial as the microorganism’s development depends on this factor as well [27]. The parameters mentioned above (ash, moisture, and oil content) may vary for several reasons, such as seasonality, different types of production, regions, climate, and handling methods.

The physical–chemical composition of the substrate SSC and RH such as ash, moisture, and oil content (lipids) is shown in Table 2.

Kinetics of Lipase

Production with Different Substrate Proportions

The kinetic study aimed to determine the optimal activity time of the microorganism building on previous investigations by Dickel et al. [23], Rodrigues et al. [28], and Haq et al. [29]. The results, as depicted in Fig. 1, demonstrated that upon the addition of the SSC substrate at their respective percentages, there was a notable increase in enzymatic activity. This phenomenon occurred due to the availability of carbon sources in the substrate, particularly lipids, which induced the production of lipases.

The most favorable outcome was observed after 96 h of fermentation, yielding enzymatic activities of 62.33 U g−1 with 100% SSC, 35.98 U g−1 with 75/25% SSC/RH, 37.03 U g−1 with 50/50% SSC/RH, and 27.32 U g−1 with 25/75% SSC/RH. In contrast, the condition with 0% SSC (only RH) exhibited a higher activity level of 4.12 U g−1 in 120 h. Following 96 h of fermentation, a decline in enzymatic activity was noted, likely attributed to the reduction in the nutrient source within the substrate [30].

The pivotal factor influencing enzyme production in SSF is the choice of substrate. In SSF, microorganisms thrive on a solid substrate, on moist substrate, or in the absence of water [31]. Consequently, the microorganism can proliferate between fragments of the substrate or on its surface, absorbing available nutrients and generating metabolites, including enzymes. Opting for a higher percentage of RH remains a viable option, even with a lower yield, due to the cost-effectiveness of an agro-industrial residue, facilitating the fermentation process. To enhance the lipid source, an inducer (glycerol) was introduced to augment enzymatic activity.

Kinetics of Lipase Production with the Addition of an Inducer

Kinetic experiment was conducted to assess the impact of adding the glycerol inducer on the growth and metabolism of the microorganism, aiming to enhance the production of lipases.

Glycerol was selected as the inducer due to its status as a carbon source that filamentous fungi can utilize for energy acquisition. Furthermore, glycerol serves as one of the co-products generated during the biodiesel synthesis process, constituting approximately 10% of the total biofuel production [32]. This aspect allowed for the utilization of the co-product itself in the enzymatic synthesis. The kinetic results are depicted in Fig. 2.

Analyzing Fig. 2, it was observed that despite glycerol being an additional carbon source for the microorganism, its addition inhibited the production of lipases. This is likely attributed to the potential toxicity of glycerol, depending on the concentration used, which could hinder the assimilation of substrates for enzyme production [33].

This suggests that while glycerol is assimilable by bacteria, microalgae, fungi, and yeasts as a primary carbon source, there might have been a decline in development during cell growth under unfavorable conditions, justifying the lower or null production of lipase with this inducer. Following the determination of the optimal parameters for lipolytic production by fermented solid (25/75% SSC/RH, 55% moisture, without the addition of an inducer), the enzyme was employed as a biocatalyst in the synthesis of ethyl oleate.

Biocatalysis: Influence of Granulometry on Ethyl Oleate Synthesis

Previous results demonstrated that when using 25% SSC and 75% RH, enzymatic activity reached 27.32 U g−1 (Fig. 1). These conditions were employed for lipase production, serving as catalysts in ethyl oleate synthesis. A selection of 25% was made, considering the higher added value of sunflower seeds, thus ensuring favorable results in ethyl oleate synthesis through the adjustment of enzyme quantity (total enzymatic activity). In these experiments, the fermented solid was utilized both in its entirety and ground to examine whether particle size would impact the synthesis of ethyl oleate (MR 6:1, enzymatic activity 60 U, temperature 37 °C). The results can be observed in Fig. 3.

Analyzing Fig. 3, it can be observed that 100% conversion was achieved after 5 h of reaction using the ground substrate (granulometry of 0.8 mm), whereas only 34% conversion was observed after 9 h using the whole substrate. These results are likely related to the exposure of the active sites present in the enzyme. When the enzyme was attached to the RH, a part of its area was covered, making it difficult or prevent the occurrence of the catalytic reaction. However, when the substrate was ground, the surface area of the enzyme was available, increasing the reaction rate as a greater amount of active sites were available for the reaction to occur.

Experimental Assay and Statistical Analysis for Optimization Ethyl Oleate Ester Enzymatic Synthesis

The enzymatic synthesis of ethyl oleate ester was investigated using a 23-factorial design, in which the effects of temperature, enzymatic activity, and molar ratio were evaluated, aiming to determine the optimal synthesis parameters. The values obtained in this experimental design are presented in Table 3 and were analyzed using the R software (R Core Team, 2022).

In the analysis of variance for factorial planning, a significant model was obtained (F = 5.714; p = 0.001; R2 = 0.68), with a positive influence for temperature identified in the Pareto diagram (Fig. 4).

However, the 23 factorial model exhibited a significant lack of fit to the data (F = 9133, p < 0.0001), as illustrated in Fig. 4 Consequently, individual polynomial adjustments were conducted for each predictor variable (Figs. 5a–d). The outcomes of these adjustments suggested that the maximum percentage conversion of ethyl oleate ester occurred near the central point of the design. This indicated 82.44% conversion at values of 37 °C, 60 U, and a 6:1 alcohol/acid ratio within a 4 h.

Therefore, both increasing the temperature to 44 °C and decreasing it to 30 °C caused a significant decrease in conversion. The thermal stability of the lipase used in this study plays a fundamental role in the obtained results. It can be observed that the ideal temperature for enzymatic activity is closely related to the increase in the number of effective collisions between molecules. Consequently, there would be an increase in the speed and denaturation of the enzyme due to temperature, leading to a lower reaction rate, and a decrease in productivity and efficiency of conversion into ester.

On the other hand, it can also be observed that reducing or increasing the number of enzyme units, as well as adjusting the molar ratio, had a direct influence on the synthesis of ethyl oleate. Therefore, the best results were obtained with 60 U of lipase as a biocatalyst and a molar ratio adjusted to 6:1 alcohol/acid. In addition to the interference of the microorganism and substrates used for lipolytic production, other factors such as temperature, number of enzyme units, and molar ratio influence the conversion yield into esterification esters, thus necessitating several adjustments for good results to occur.

Biocatalysis: Kinetics of Ethyl Oleate Synthesis

After obtaining the best parameters for the synthesis of ethyl oleate with the experimental design (Table 3), kinetics were performed to verify and confirm the results in relation to the reaction time (Fig. 6).

Under the specified test conditions, conversion was achieved in 5 h utilizing lipase from P. polonicum at 100%. These conditions included using n-heptane as the solvent, a molar ratio of 6:1 (alcohol/acid), and employing an enzyme activity of 60.0 U at 37 °C. By analyzing the efficiency of the process and comparing it to other studies in the literature utilizing lipase as a biocatalyst, the best result was achieved for the synthesis of ethyl oleate in 48 h with 77.69% conversion using lipase from Rhizopus homothallicus at a molar ratio of 3:1 and a temperature of 40 °C [34].

Oliveira et al. [35], utilizing lipase from P. polonicum, achieved the maximum conversion of methyl oleate (70%) in 12 h under the conditions of MR 9:1 at 30 °C with 60 U. In the same study, the authors obtained the best yields (90%) in 8 h using lipase from Aspergillus fumigatus, with a molar ratio of 12:1 and 60 U. In another work, Oliveira et al. [36] reached the maximum conversion of methyl ester (99.6%) in 20 h using lyophilized fermented substrate from Fusarium sp. under the conditions of MR 3:1, 40 °C, with 35 U. Carvalho et al. [37] reached the maximum conversion of ethyl oleate (100%) in 30 min under the conditions of MR 3:1, 6:1, and 9:1; 30 °C; and with 60 U.

Therefore, it was observable that, through the utilization of our parameters (time, molar ratio, and temperature), excellent results were attained with 100% conversion. The outcomes might be influenced by the thermal stability of the immobilized lipase within the fermented solid, which surpasses that of the free enzyme. Immobilized lipase prevented enzyme agglomeration when exposed to conditions with low water content in the medium. This not only ensured greater stability in the presence of organic solvents and high temperatures but also allowed for the possibility of enzyme reuse [29].

Conclusion

In conclusion, enzymatic catalysts, such as lipases, are a promising alternative to chemical catalysts due to their advantages of biodegradability, which contribute to the reduction of operational costs. The agro-industrial residues used in this work demonstrated efficiency in the production of fungal lipase from P. polonicum, obtaining good production of lipase (27.32 U g−1) even using a low proportion of sunflower seed (product with added value) and increasing the proportion of rice husk (agro-industrial waste). Moving beyond lipase production, the study successfully applied the obtained enzyme as a biological catalyst in the synthesis of ethyl oleate ester. Experimental design 23 was employed to modify variables such as temperature, enzymatic activity, and molar ratio (alcohol/acid). The results were impressive, with the enzymatic synthesis of ethyl oleate ester achieving 100% conversion into ester in just 5 h of reaction under specific conditions.

The work not only contributes to the understanding of enzymatic processes and their application but also holds practical significance in the production of biodiesel esters. The high yield obtained in the synthesis of ethyl oleate further emphasizes the potential of lipases as efficient and eco-friendly catalysts. Overall, this research represents a noteworthy contribution to the field of biotechnology, aligning with the principles of sustainability and offering a viable alternative to traditional chemical catalysts.

References

Höfer R (2015) Sugar-and starch-based biorefineries. In: Industrial biorefineries and white biotechnology, pp 157–235

Punekar NS (2018) Enzymes: catalysis, kinetics, and mechanisms. Springer. https://doi.org/10.1007/978-981-13-0785-0

Thangaraj B, Solomon PR, Muniyandi B, Ranganathan S, Lin L (2019) Catalysis in biodiesel production—a review. Clean Energy 3(1):2–23. https://doi.org/10.1093/ce/zky020

Thapa S, Li H, Ohair J, Bhatti S, Chen FC, Nasr KA, Johnson T, Zhou S (2019) Biochemical characteristics of microbial enzymes and their significance from industrial perspectives. Mol Biotechnol 61(8):579–601. https://doi.org/10.1007/s12033-019-00187-1

Fatima S, Faryad A, Ataa A, Joyia FA, Parvaiz A (2020) Microbial lipase production: a deep insight into the recent advances of lipase production and purification techniques. Biotechnol Appl Biochem 68(3):445–458. https://doi.org/10.1002/bab.2019

Priyanka P, Tan Y, Kinsella GK, Henehan GT, Ryan BJ (2019) Solvent stable microbial lipases: current understanding and biotechnological applications. Biotechnol Lett 41(2):203–220. https://doi.org/10.1007/s10529-018-02633-7

Lee LP, Karbul HM, Citartan M, Gopinath SC, Lakshmipriya T, Tang TH (2015) Lipase-secreting Bacillus species in an oil-contaminated habitat: promising strains to alleviate oil pollution. BioMed res inter. https://doi.org/10.1155/2015/820575

Vyas S, Chhabra M (2017) Isolation, identification and characterization of Cystobasidium oligophagum JRC1: a cellulase and lipase producing oleaginous yeast. Bioresour Technol 223:250–258. https://doi.org/10.1016/j.biortech.2016.10.039

Gutarra ML, Godoy MG, Maugeri F, Rodrigues MI, Freire DM, Castilho LR (2009) Production of an acidic and thermostable lipase of the mesophilic fungus Penicillium simplicissimum by solid-state fermentation. Bior tec 100:5249–5254. https://doi.org/10.1016/j.biortech.2008.08.050

Mahmoud GA, Koutb MM, Morsy FM, Bagy MM (2015) Characterization of lipase enzyme produced by hydrocarbons using fungus Aspergillus terreus. Eur J Biol Res 5:70–77

Çakmak M, Aydoğdu H (2021) Screening of microfungi for lipolytic activity and optimization of process parameters in lipase production by solid substrate fermentation using selected microfungi (Penicillium aurantiogriseum). Kuwait J Sci 48:98–105

Sukma A, Jos B, Sumardiono S (2018) Kinetic of biomass growth and protein formation on rice bran fermentation using Rhizopus oryzae. In: MATEC Web of Conferences. EDP Sci 156:01023. https://doi.org/10.1051/matecconf/201815601023

Vandenberghe LP, Pandey A, Carvalho JC, Letti LA, Woiciechowski AL, Karp SG, Thomaz-Soccol S, Martínez-Burgos WJ, Penha RO, Hermann LW, Soccol CR (2021) Solid-state fermentation technology and innovation for the production of agricultural and animal feed bioproducts. Syst Microbiol Biomanuf 1(2):142–165

Bharathi D, Rajalakshmi G (2019) Microbial lipases: an overview of screening, production and purification. Biocatal Agric Biotechnol 22:101368. https://doi.org/10.1016/j.bcab.2019.101368

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioprocess 5(1):1–15. https://doi.org/10.1186/s40643-017-0187-z

Kachrimanidou V, Kopsahelis N, Chatzifragkou A, Papanikolaou S, Yanniotis S, Kookos I, Koutinas AA (2013) Utilization of by-products from sunflower-based biodiesel production processes for the production of fermentation feedstock. Waste Biomass Valorization 4:529–537. https://doi.org/10.1007/s12649-012-9191-x

Adıgüzel AO (2020) Production and characterization of thermo-, halo-and solvent-stable esterase from Bacillus mojavensis TH309. Biocatal Biotransformation 38(3):210–226. https://doi.org/10.1080/10242422.2020.1715370

Putri DN, Khootama A, Perdani MS, Utami TS, Hermansyah H (2020) Optimization of Aspergillus niger lipase production by solid state fermentation of agro-industrial waste. Energy Rep 6:331–335. https://doi.org/10.1016/j.egyr.2019.08.064

Kumar A, Kanwar SS (2012) Lipase production in solid-state fermentation (SSF): recent developments and biotechnological applications. Dyn Biochem Process Biotechnol and Mol Bio 6(1):13–27

Paluzar H, Tuncay D, Aydogdu H (2021) Production and characterization of lipase from Penicillium aurantiogriseum under solid-state fermentation using sunflower pulp. Biocatal Biotransformation 39(4):333–342. https://doi.org/10.1080/10242422.2021.1901888

Maldonado RR, Lopes DB, Aguiar-Oliveira E, Kamimura ES, Macedo GA (2016) A review on Geotrichum lipases: production, purification, immobilization and applications. CABEQ 4:439–454

Quayson E, Amoah J, Hama S, Kondo A, Ogino C (2020) Immobilized lipases for biodiesel production: current and future greening opportunities. Renew Sustain Energy Rev 134:110355. https://doi.org/10.1016/j.rser.2020.110355

Dickel JDM, Carvalho JK, Silveira MAD, Menegotto dos Santos P, Rodrigues MLF, Fagundes-Klen MR, Rosa CA, Buzanello CV, Lucca RAS, Santos ARO, Da Rosa MF (2022) Aspergillus sclerotiorum lipolytic activity and its application in bioremediation of high-fat dairy wastewater environments. Environ Sci Pollut Res Int 1–11. https://doi.org/10.1007/s11356-022-24669-z.

AOAC - Association of Official Analytical Chemists (2005) Official methods of analysis of AOAC International, 18th edn. AOAC, Washington

Lowry RR, Tinsley JI (1976) Rapid colorimetric determination of free acids. J Am Oil Chem Soc 53:470–472. https://doi.org/10.1007/BF02636814

Shu ZY, Jiang H, Lin RF, Jiang YM, Lin L, Huang JZ (2010) Technical methods to improve yield, activity and stability in the development of microbial lipases. J Mol Catal B Enzym 62:1–8. https://doi.org/10.1016/j.molcatb.2009.09.003

Fernandes MLM, Saad EB, Meira JA, Ramos LP, Mitchell DA, Krieger N (2007) Esterification and transesterification reactions catalysed by addition of fermented solids to organic reaction media. J Mol Catal B Enzym 44:8–13. https://doi.org/10.1016/j.molcatb.2006.08.004

Rodrigues MLF, Da Silva EA, Borba CE, Oliveira ACD, Kruger C, Raimundo RW, Silva LP, Vanzin M, Stuani BT (2015) Produção de enzimas hidrolíticas pelo fungo endofítico Penicillium sp. Isolado das folhas de Ricinus communis L. Rev Bras Energias Renováveis 4:129–145

Haq IU, Mukhtar H, Umber H (2006) Production of protease by Penicillium chrysogenum through optimization of environmental conditions. J Agri Soc Sci 2(1):23–25 (1813–2235/2006/02–1–23–25)

Soccol CR, Costa ESF, Letti LAJ, Karp SG, Woiciechowski AL, Vandenberghe LPS (2017) Recent developments and innovations in solid state fermentation. Biotechnol Res Innov 1(1):52–71. https://doi.org/10.1016/j.biori.2017.01.002

Rattanapoltee P, Dujjanutat P, Muanruksa P, Kaewkannetra P (2021) Biocircular platform for third generation biodiesel production: batch/fed batch mixotrophic cultivations of microalgae using glycerol waste as a carbon source. Biochem Eng J 75:108128. https://doi.org/10.1016/j.bej.2021.108128

Dasari MA, Kiatsimkul PP, Sutterlin WR, Suppes GJ (2005) Low-pressure hydrogenolysis of glycerol to propylene glycol. Appl Catal A 228(1):225–231. https://doi.org/10.1016/j.apcata.2004.11.033

Alcala-Galiano DDM, López JAC, Borbón ER, González JAR, Cuadros RC, Ramos-Sánchez LB (2021) Condiciones para la transesterificación enzimática de aceite de Jatropha curcas con un sólido fermentado. Centro Azúcar 48(2):56–67

Oliveira BH, Coradia GV, Oliva-Neto P, Nascimento VMG (2020) Biocatalytic benefits of immobilized Fusarium sp. (GFC) lipase from solid state fermentation on free lipase from submerged fermentation. Ind Crops Prod 147:112235. https://doi.org/10.1016/j.indcrop.2020.112235

Oliveira ACD, Frenscha G, Marquesa FA, Vargasa JVC, Rodrigues MLF, Mariano AB (2020) Production of methyl oleate by direct addition of fermented solid Penicillium sumatrense and Aspergillus fumigatus. Renew Energy 162:1132–1139

Zhong L, Feng Y, Wang G, Wang Z, Bilal M, Lv H, Hexin LV, Jia CJ (2020) Production and use of immobilized lipases in/on nanomaterials: a review from the waste to biodiesel production. Int J Biol Macromol 152:207–222. https://doi.org/10.1016/j.ijbiomac.2020.02.258

Carvalho JK, Krüger C, Silveira MAD, Piana PA, Rodrigues MLF, Rosado AF, Lucca RAS, Fagundes-Klein MR, da Silva, EA, Buzanello CV, Teleken JG, Zanella RA (2024) Lipolytic production from solid-state fermentation of the filamentous fungus Penicillium polonicum and its applicability as biocatalyst in the synthesis of ethyl oleate. Envir Sci and Pol Res, 1–12. https://doi.org/10.1007/s11356-024-33007-4.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Jéssyca Ketterine Carvalho, Ricardo Antonio Zanella, Maria Luiza Fernandes Rodrigues, Adriana Fiorini Rosado, and Pitágoras Augusto Piana. The first draft of the manuscript was written by Jéssyca Ketterine Carvalho, Ricardo Antonio Zanella, Pitágoras Augusto Piana, Adriana Fiorini Rosado, Mairim Dahm da Silva, Rosemeire Aparecida da Silva de Lucca, Marcia Regina Fagundes-Klen, Edson Antônio da Silva, Karine Zanella, Cleide Viviane Buzanello, Álvaro Barcellos Onofrio, and Maria Luiza Fernandes Rodrigues, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Carvalho, J.K., Zanella, R.A., Piana, P.A. et al. Production of Fermented Solid Containing Lipases from Penicillium polonicum and Its Direct Use as Biocatalyst in the Synthesis of Ethyl Oleate. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10772-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10772-1