Abstract

β-Glucosidases for industrial applications are mainly obtained from filamentous fungi. Kretzschmaria zonata is a phytopathogen fungus that produces an arsenal of enzymes with biotechnological potential and this work aimed to produce, purify, and characterize a β-glucosidase from the fungus K. zonata for its application in supplementation of a commercial cocktail for sugarcane bagasse saccharification. The elevated specific activity of β-glucosidase was induced by corn cob, reaching 1.085 U/mg of protein. At the end of all purification steps, a purification factor of 6.52 was reached, with an increase of specific activity from 1.22 U/mg, in the crude extract, to 7.97 U/mg. Concerning pH stability, at pH 4, the pH of maximal β-glucosidase activity, the enzyme was completely stable, with 100% activity after 1 h of incubation, while it kept over 50% activity in the pH range from 2.2 to 6. The optimum temperature was 60 °C and the half-life times were estimated as 307.8 and 10 min, for temperatures of 60 and 70 °C, respectively. The β-glucosidase showed a reduction in relative activity in the presence of 10 mM of manganese sulfate, zinc sulfate, manganese chloride, SDS, and glucose, maintaining 55, 56, 62, 70, and 73% of the relative activity, respectively. The commercial cocktail Multifect® CL supplemented with the K. zonata β-glucosidase enabled the release of 13.89 g/L of glucose and 5.34 g/L of xylose, an increase of 19.8 and 35.5% of glucose and xylose release, respectively, after sugarcane bagasse hydrolysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Increased depletion of oil reserves alongside an emphasis on environmental preservation policies motivates the exploration of renewable fuel sources [1]. Second-generation (2G) ethanol has emerged as a viable alternative due to its ability to enhance ethanol production without the need for expanding cultivation areas. This is achieved through the hydrolysis of lignocellulosic materials and subsequent fermentation of the liberated glucose into ethanol [2, 3]. Brazil is a major producer of plant biomass, such as sugarcane and corn. One ton of sugarcane harvest generates approximately 280–230 kg of bagasse [4], while the processing of 1 ton of corn produces about 1.96 tons of by-products such as stalk, leaf, cob, and straw [5]. All of them are potential alternative carbon sources for 2G ethanol production. However, the enzymatic hydrolysis of cellulose to glucose is a limiting step in biofuel production due to the low conversion efficiency and high costs of enzymes [6, 7].

The enzyme cocktails used in the hydrolysis of lignocellulosic biomass are formed mainly by cellulases, hemicellulases, and accessory enzymes. Cellulases are divided into three groups of enzymes, i.e., endoglucanases (EC 3.2.1.4), cellobiohydrolases (EC 3.2.1.91), and β-glucosidases (EC 3.2.1.21), which act synergistically to convert cellulose into the monomer glucose [8, 9]. Endoglucanases randomly catalyze the hydrolysis of glucosidic bonds, whereas cellobiohydrolases (exoglucanases) act on the cellulose chain to produce cellobiose, which is further hydrolyzed by β-glucosidases (β-d-glucoside-glucohydrolase, EC 3.2.1.21), releasing glucose [10]. Thus, the hydrolytic efficacy of enzymatic cocktails relies on the proportional representation and activity of each of these enzymes [9, 11].

β-Glucosidases are sourced from various organisms, including bacteria, fungi, yeast, animals, and plants [12]. The fungus Penicillium purpurogenum has been identified as a producer of intracellular β-glucosidase. Optimal activity of β-glucosidase was observed in the presence of sucrose. Several cultural parameters for the cultivation of P. purpurogenum to enhance β-glucosidase production were optimized. The maximum enzyme yield was achieved after 96 h of cultivation at 30 °C. Addition of the amino acids histidine and cysteine induced β-glucosidase synthesis to a certain extent. The optimal temperature and pH for β-glucosidase activity were determined to be 50 °C and 5.5, respectively. Notably, β-glucosidase from P. purpurogenum exhibits stability at pH 2, making it potentially suitable for debittering applications in the fruit juice and wine industries [13]. For industrial applications, β-glucosidases are mostly obtained from filamentous fungi, due to their facilitated cultivation and large production of extracellular enzymes with high industrial potential [14,15,16,17,18]. Most commercial cocktails contain a small amount of β-glucosidases, which reduces overall recyclability and causes low hydrolysis yields [19]. The presence of β-glucosidase results in higher saccharification yields, as it prevents the accumulation of cellobiose during the hydrolysis step and, therefore, there is no inhibition of the final product of endoglucanases and cellobiohydrolases [17, 20].

Kretzschmaria zonata is a phytopathogen fungus associated with root rot of forest species that has been little studied and described in the literature and it produces an arsenal of enzymes with biotechnological potential [21, 22]. When cultivated on corn cobs, this fungus was able to produce a wide variety of lignocellulolytic enzymes, highlighting the specific activities of xylanase (56.30 U/mg), endoglucanase (11.20 U/mg), pectinase (4.52 U/mg), and especially β-glucosidase (2.77 U/mg) [23]. These results highlight the significant potential of this fungus as a promising source to produce essential enzymes for the bioconversion of lignocellulosic biomass into value-added products [24]. Nevertheless, there remains a deficiency in research concerning these enzymes, including the supplementation of commercial cocktails with β-glucosidase, to fully harness their potential for the bioconversion of lignocellulosic biomass.

Therefore, this work aimed to produce, purify, and biochemically characterize a β-glucosidase from the fungus K. zonata after cultivation in different biomasses as carbon sources. Moreover, β-glucosidase was evaluated for its potential as a supplement to the commercial cocktail Multifect® CL, aiming to enhance the feasibility of second-generation (2G) ethanol production. The supplementation of commercial cocktails with supplementary enzymes represents one of the strategies employed to enhance saccharification processes [25, 26].

Material and Methods

Materials

The fungus K. zonata LPF 2118 was kindly sourced from the mycological collection of the Forest Pathology Laboratory, Federal University of Vicosa, Brazil. It was maintained on malt extract agar (MEA) plates at 28 °C. The commercial cellulase complex, Multifect® CL, was purchased from Genencor International Inc. (Rochester, NY, USA). The sugarcane bagasse, wheat bran, corn cob, corn straw, and soybean bran were obtained at the local market. All reagents used were of analytical grade purity and acquired from Sigma® Aldrich, except for the sugar standards used for calibration, which were of HPLC-grade purity. They were handled and stored according to the manufacturer’s instructions.

Growth Conditions and β-Glucosidase Production by Kretzschmaria zonata

K. zonata was activated in a sterile inoculum through submerged cultivation. This process involved transferring 10 agar plugs cut from a 7-day-old colony into Erlenmeyer flasks containing 100 mL of medium. The medium consisted of glucose (10.0 g/L), KH2PO4 (1.0 g/L), MgSO4 (0.5 g/L), NH4NO3 (1.0 g/L), and yeast extract (2.0 g/L). The flasks were then placed in a rotary shaker and incubated for 5 days at 28 °C and 150 rpm [27].

To obtain the enzymatic extract, K. zonata was grown on a semi-solid medium in 250-mL Erlenmeyer flasks containing 5 g of various carbon sources: wheat bran, corn cob, corn straw, and soybean bran. To achieve a final moisture content of 60%, 12 mL of medium containing CuSO4 (0.25 g/L), KH2PO4 (1.5 g/L), MgSO4 (0.5 g/L), NH4NO3 (1.0 g/L), and yeast extract (2.0 g/L) was added. Additionally, trace elements were included in the medium at the following concentrations (mg/L): FeCl3 (1.0), H3BO3 (0.75), MnCl2 (0.1), NaMoO4 (0.02), and ZnSO4 (3.5) [7]. The flasks were autoclaved at 120 °C for 20 min and then inoculated with 4.6 mL of the previously mentioned inoculum (containing 1.5 × 107 spores/mL).

The incubation time was 8 days at a temperature of 28 °C. The extraction of secreted enzymes was performed with sodium acetate buffer (50 mM, pH 5.0), at a ratio of 10:1 (buffer/dry substrate), with agitation of 150 rpm for 60 min at room temperature. The extracts were filtered on nylon filters and centrifuged at 10,000 × g for 15 min. The crude extract obtained was frozen and stored for further steps.

Enzymatic Assay

The β-glucosidase activity was determined using the synthetic substrate ρ-nitrophenyl-β-d-glucopyranoside (ρ-NPβGlc) as described by González-Pombo [13]. The reaction mixture was composed of 35 μL of sodium acetate buffer (100 mM, pH 5.0), 50 μL of 2 mM ρ-NPβGlc, and 15 μL of enzyme extract, incubated at 50 °C for 15 min. The reaction was stopped with 100 μL of 0.5 M sodium carbonate (Na2CO3). The absorbance was read at 410 nm in the spectrophotometer (Thermo Scientific™ Multiskan™ GO Microplate Spectrophotometer) and the values were converted in µmoles of ρ-NP, using a standard curve performed with 0–1.0 μmol of a ρ-nitrophenol solution. Enzyme assays were performed in triplicate and one unit of enzymatic activity (U) was defined as the amount of enzyme that released 1 μmol of p-nitrophenol per minute, in this assay condition.

Protein Determination

The protein concentrations of the different crude enzyme extracts were determined by the Bradford method [28], using a standard curve prepared with a 0.2 mg/mL bovine serum albumin solution (BSA).

Partial Purification of β-Glucosidase

The extract underwent precipitation with ammonium sulfate, resulting in fractions at 40, 60, and 80% salt saturation levels. Each fraction was derived from 2 mL of the initial crude extract volume, with respective amounts of 0.47 g, 0.75 g, and 1.07 g of (NH4)2SO4 used for the 40, 60, and 80% fractions, respectively. These quantities were calculated using the Ammonium Sulfate Calculator (https://www.encorbio.com/protocols/AM-SO4.htm). Each fraction was centrifuged at 12,000 × g for 15 min. β-Glucosidase was assessed for activity and protein quantification (sections “Growth Conditions and β-Glucosidase Production by Kretzschmaria zonata” and “Enzymatic Assay”) in both supernatants and precipitates, which was resuspended in sodium acetate buffer (50 mM, pH 5.0) at a 1:1 ratio (extract to buffer). The fraction with the highest specific enzymatic activity was submitted to dialysis for salt elimination, using 3.5 L of sodium acetate buffer (10 mM, pH 5.0), overnight, under agitation at 4 °C [3]. A dialysis membrane with a 3-kDa exclusion pore was used. Finally, the ultrafiltration step was applied for enzyme concentration. The dialyzed fraction was applied to an Amicon® Ultra, Millipore ultrafiltration membrane, with a 3-kDa exclusion pore. The process was conducted in a centrifuge at 4 °C, at 4900 × g, for 60 min. The ultrafiltered sample was subjected to ion exchange chromatography in fast protein liquid chromatography (FPLC), ÄKTA system. A Q-Sepharose column (5 × 5 mL) anion exchanger was used. The column was previously equilibrated with sodium acetate buffer (50 mM, pH 5.0). For the elution process of proteins adhered to the column, a linearly increasing salt gradient with 50 mM sodium acetate and 1 M NaCl buffer was used. Five milliliters of sample from the ultrafiltration was applied [3]. Chromatography was performed with a flow of 1 mL/min, a pressure of 0.3 MPa, and 1 mL fractions were collected in each tube. The collected fractions were submitted to β-glucosidase activity assay and protein quantification (sections “Growth Conditions and β-Glucosidase Production by Kretzschmaria zonata” and “Enzymatic Assay”).

For the construction of the purification table of β-glucosidase, the specific activity, which serves as an indicator of the sample’s purity relative to the total protein concentration, was calculated as Eq. 1.

The purification factor, which highlights how many times the protein of interest was concentrated when compared to the starting material, as calculated as Eq. 2.

Finally, the yield expresses, as a percentage, how much of the active enzyme was recovered from the starting material at the end of the purification step, and it was calculated as Eq. 3.

Purity Determination of β-Glucosidase

The samples from each purification step were concentrated, using precipitation with trichloroacetic acid (TCA 50%), and subjected to SDS-PAGE 12% (w/v) electrophoresis by a Mini-Protean II system (BioRad), as described by Laemmli [29]. The molecular mass standard Precision Plus Protein marker™ BIO-RAD (10–250 kD) was used. The proteins were visualized by Coomassie Blue and silver staining [30].

Zymogram

β-Glucosidase activity was performed in gel by zymography. The partially purified sample was submitted in duplicate to polyacrylamide gel electrophoresis (10%) under non-denaturing conditions. After electrophoresis, the substrate 4-methylumbelliferyl-β-d-glycopyranoside (MUG) was applied to the gel, and the fluorescent reaction product was visualized and photographed under ultraviolet light, as described by Ramani et al. [15].

Biochemical Characterization of Partially Purified β-Glucosidase

The ideal temperature range of β-glucosidase activity was determined by incubating the reaction at the following temperatures: 30, 40, 50, 60, 70, and 80 °C. Thermostability was performed at 60 and 70 °C, at time intervals of 0.25, 0.5, 0.75, 1, 2, 4, 6, 18, and 24 h. After each interval, an aliquot was removed and evaluated for residual activity. Time 0 was the maximum activity reference, and it was considered 100%. The optimum pH of the enzyme was analyzed using a citric acid-sodium phosphate buffer ranging from 2.2 to 8.0 pH [31]. McIlvaine’s buffer replaced the acetate buffer in the assays. The pH stability of the enzyme was analyzed in tubes containing 15 μL of enzyme and 45 μL of McIlvaine buffer at different pH values, from 2.2 to 8. The action of ions on the enzymatic activity was determined by the volume of 35 μL of sodium acetate buffer added by different ions and reducing agents (CaCl2, MnCl2, MnSO4, NaF, NaSO4, AgNO3, AlCl3, ZnSO4, sodium dodecyl sulfate (SDS), glucose, urea, and acid ethylenediamine tetraacetic acid (EDTA)) at a concentration of 10 mM. The reaction without the presence of these agents was used as a control, in which the activity was considered 100%. In all tests, the parameters described in the section “Growth Conditions and β-Glucosidase Production by Kretzschmaria zonata” were used.

Sugarcane Bagasse Saccharification

The sugarcane bagasse underwent alkaline pretreatment with sodium hydroxide before the saccharification process. First, the pretreatment was performed over 10% biomass with 1.5% NaOH solution for 1 h at 120 °C. Following this step, the pretreated biomass was washed with distilled water until clarification to remove soluble lignin. The biochemical composition of the pretreated sugarcane bagasse was determined and it was then stored at − 20 °C until further use in subsequent steps [27].

The enzymatic saccharification of alkaline pretreated sugarcane bagasse was performed in 25-mL Erlenmeyer flasks with 10 mL of working volume and 0.5 g of pretreated sugarcane bagasse in 50 mM sodium acetate buffer at pH 5.0. Tetracycline (40 mg/L) and sodium azide (10 mM) were added to the reaction mixture to inhibit microbial contamination. The commercial cocktail Multifect® CL, whose composition was determined by Maitan-Alfenas et al. [32], was applied in the saccharification experiment at the concentration of 2 units of β-glucosidase per gram of biomass. To evaluate the supplementation effect, the same experiment was performed with the addition of 2 units of the partially purified β-glucosidase per gram of biomass. A control experiment, without enzymes, was also conducted. The reaction was conducted in an orbital shaker at 250 rpm and 50 °C for 72 h. Samples of 1 mL were taken from the reaction mixture at 12-h intervals for process monitoring. Each sample was centrifuged for 10 min at 15,000 × g and the supernatant was stored at − 20 °C for further analysis.

The biomass conversion efficiency was calculated considering the biochemical composition of the pretreated sugarcane bagasse, by the cellulose and xylan hydrolysis rate, using Eqs. 4 and 5 [27].

Analysis of Hydrolysis Products

Products of the saccharification assays were analyzed by high-performance liquid chromatography (Shimadzu) to quantify the sugars released. For the analyses, the HPLC was equipped with an Aminex HPX-87P column (BioRad) at a flow rate of 0.6 mL/min and it operated at 80 °C. The analytical curve was constructed with glucose and xylose standards at different concentrations.

Statistical Analysis

ANOVA and Tukey’s test (p-value < 0.5) were utilized to assess significant differences among the outcomes of growth on various carbon sources and enzymatic hydrolysis of sugarcane bagasse, with and without cocktail supplementation. This analysis was performed using Minitab® 19 software.

Results and Discussion

β-Glucosidase Production by Kretzschmaria zonata After Growth in Different Carbon Sources

K. zonata exhibited the capability to generate the enzyme β-glucosidase after growth in various tested carbon sources (Table 1). The initial moisture content plays a significant role in enzyme production and secretion when fungal growth occurs in a semi-solid medium. Typically, an initial moisture content ranging from 60 to 78% is commonly employed for β-glucosidase production by filamentous fungi [33].

Filamentous fungi produce a wide variety of enzymes and, in general, they are important lignocellulosic biomass-degrading organisms since most of them have a complete set of enzymes for the hydrolysis of cellulosic and hemicellulosic materials [9]. The elevated specific activity of β-glucosidase induced from corn cob, 1.085 U/mg of protein, may be related to the greater availability of cellulose in this biomass [34]. Therefore, the corn cob was selected as the standard medium to produce β-glucosidase from K. zonata used for the further purification steps.

Sørensen et al. [35] revealed that Aspergillus saccharolyticus showed a maximum specific activity of 0.23 U/mg, which was induced by wheat bran, and 0.22 U/mg when xylan was used as a carbon source. On the other hand, studies demonstrated that the growth of Gongronella butleri in soybean bran gave a specific activity of 0.6 U/mg, whereas growth in corn husk resulted in a specific activity of 0.24 U/mg [36].

Several studies have been conducted involving the production of β-glucosidases by fungi of the genera Aspergillus, Penicillium, and Trichoderma [26]. The enzyme cocktails used for biomass hydrolysis, mostly composed of enzymes produced by these fungi, lack certain enzymes, such as β-glucosidases [19]. Therefore, the search for new microorganisms with potential for enzyme production aims to create a combination of cocktails made of enzymes from different microorganisms to maximize the conversion of lignocellulose into monosaccharides [18]. The high β-glucosidase activity obtained by the fungus K. zonata cultivated on corn cob compared to the literature justifies its use as a brand-new microorganism to produce β-glucosidase to complement enzymatic cocktails for industrial applications.

Partial Purification of β-Glucosidase

After precipitation with ammonium sulfate, the residual activities in the supernatant and the precipitate were evaluated (data not shown), and the supernatant of the sample saturated with 40% of ammonium sulfate was chosen to continue the experiments, with 0.835 U/mg of protein. The precipitate from the sample saturated with 80% of NH2(SO)4 had a higher specific activity, 1.281 U/mg of protein. However, the high concentration of ammonium sulfate derived from the precipitation step is one of the main interferents in the quantification of protein by the Bradford method [28]. Due to this limitation of the colorimetric assay, the precipitated extract with a lower ammonium sulfate concentration was chosen to proceed with the purification, even though its specific activity is lower than that of the extract precipitated with 80% salt.

The supernatant of the 40% fraction was submitted to dialysis to remove the remaining salt, which led to a 55.5% increase in the volume of the sample. Due to this expected dilution, the sample was subjected to an ultrafiltration process to concentrate the enzyme of interest, reducing the initial volume by 53%.

The concentrated sample was further subjected to a purification step by ion exchange chromatography, using a Q-Sepharose anion exchange column, at pH 5. By analyzing the chromatographic profile, it was possible to detect two peaks with β-glucosidase activity. The first one exhibited lower activity and it was eluted before the gradient. The second peak, with higher activity, was eluted during the salt gradient, at a concentration of 0.779 M of NaCl, and it was selected as the fraction of partially purified β-glucosidase (data not shown).

At the end of all purification steps, the SDS-PAGE showed that there was a reduction of the protein band numbers, as mentioned by Blum et al. [30] and zymogram analysis confirmed the β-glucosidase activity in native gel (data not shown). Table 2 shows that a purification factor of 6.52 was reached, with an increase of specific activity from 1.22 U/mg, in the crude extract, to 7.97 U/mg. This is related to the significant decrease in the amount of protein, which started at 0.187 mg/mL, in the crude extract, and dropped to 0.026 mg/mL after the ion exchange chromatography.

It was noticed that, after the ion exchange chromatography step, the enzymatic activity increased significantly compared to the previous steps, which could be explained by the influence of the sodium chloride salt on the gradient. The β-glucosidase activities of Penicillium roqueforti ATCC 10110 and Microbulbifer thermotolerans DAU221 exhibited similar increase in the presence of sodium chloride salt concentrations of up to 0.5 M [37, 38].

Enzymatic Characterization

pH Effect on β-Glucosidase Activity

The highest β-glucosidase activity was found at pH 4. At pH values of 3 and 5 more than 50 and 80% of the activity was maintained, respectively (Fig. 1). At a pH of 7, the enzyme lost its activity, showing a reduction of more than 98% in its value. The pH range of higher activities for β-glucosidases normally varies from pH 4 to 6 [39]. The β-glucosidase from the white rot fungus Flammulina velutipes CFK 3111 exhibited higher activity at pH 5, maintaining 95% of its activity at pH 6 and 44% at pH 7; however, at pH 4, its activity had a significant drop of 75% [40]. Bonfá et al. [41] induced the β-glucosidase from the thermophilic fungus Myceliophthora thermophila M.7.7 which showed the highest activity at pH 5, also maintaining activity greater than 50% up to pH 6.5. The β-glucosidase from the fungus Penicillium simplicissimum was reported with the highest activity in the pH range from 4.4 to 5.2 and maintained over 50% of its activity in the pH range from 3.6 to 6.8 [42].

The effect of pH was also evaluated by incubating the K. zonata β-glucosidase at different pH values for 1 h (Fig. 1). The stability at different pH values is an important characteristic for biotechnological application [43], as it indicates the renaturation capacity of enzymes. At pH 4, the pH of maximal β-glucosidase activity, it was completely stable, with 100% of activity after 1 h, while it kept over 50% of activity in the pH range from 2.2 to 6, showing good renaturation ability after exposure to more acidic environments. At more alkaline pH values, the enzyme was able to recover its native structure and, therefore, its activity. The β-glucosidase produced by the thermophilic fungus Myceliophthora thermophila M.7.7 was able to recover its native conformation after incubation at different pH values (3–9.5) maintaining 50% of its relative activity [41]. The β-glucosidase from the white rot fungus Flammulina velutipes CFK 3111 was not able to recover its native conformation at pH 2.6 and 3 after 1 h of incubation; however, in the pH range from 4 to 7, it maintained 50% of relative activity after 1 h of incubation [40].

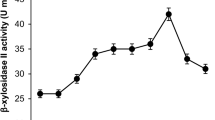

Temperature Effect on β-Glucosidase Activity and Thermal Stability

The partially purified β-glucosidase from the fungus K. zonata displayed the highest activity at 60 °C, maintaining 77 and 89% of activity at temperatures of 50 and 70 °C, respectively (Fig. 2A). The enzyme decreased significantly in its activity at temperatures above 70 °C. In some studies, the β-glucosidase produced by the thermophilic fungus Myceliophthora thermophila M.7.7 achieved higher activity at 60 °C, maintaining 85% of its activity at 70 °C [41]. The β-glucosidase generated by the AS 58 strain of Aspergillus exhibited elevated activity at 35 °C, with its activity notably diminished beyond 45 °C [44]. The β-glucosidase from white rot fungus Flammulina velutipes CFK 3111 exhibited its maximum activity at 50 °C and maintained 75% of its activity at 40 °C [40].

When incubated at 60 °C, the partially purified β-glucosidase from K. zonata retained 70% of its residual activity after 2 h and 36% after 18 h (Fig. 2B). Nonetheless, the β-glucosidase displayed a drastic reduction of activity after 15 min of incubation at 70 °C and it showed close to no residual activity after 30 min of incubation (Fig. 2C). The half-life times were estimated as 307.8 and 10 min, for temperatures of 60 and 70 °C, respectively. A plant-derived β-glucosidase from black plum seeds was reported to have practically no residual activity after 150 min at 60 °C [45], although the intracellular β-glucosidase from Termitomyces clypeatus maintained a residual activity of 64% after 1 h of incubation at 70 °C [46].

Effect of Ions, Sugars, and Reducing Agents on β-Glucosidase Activity

The partially purified β-glucosidase from K. zonata had a reduction in relative activity in the presence of 10 mM of manganese sulfate (MnSO4), zinc sulfate (ZnSO4), manganese chloride (MnCl2), SDS, and glucose, maintaining 55, 56, 62, 70, and 73% of the relative activity (data not shown). Inhibition of β-glucosidases by glucose is a common feature, as glucose is the final product of the reaction [47]. In the presence of 10 mM of silver nitrate ion (AgNO3), sodium chloride (NaCl), ammonium sulfate ((NH4)2SO4), and urea, the β-glucosidase activity remained mostly unchanged. The activity of β-glucosidase was increased by 17 and 24% in the presence of calcium chloride (CaCl2) and EDTA, respectively (data not shown).

The loss of activity when the β-glucosidase was incubated with SDS is probably due to the denaturing action of this anionic detergent, assuming that the three-dimensional structure of the enzyme was lost [38]. The increase of activity in the presence of EDTA suggests that it was able to chelate metal ions that negatively interfere with the β-glucosidase. The β-glucosidase of the white rot fungus Flammulina velutipes CFK 3111 showed similar results when incubated with 10 mM SDS and ZnSO4, presenting a decrease of 20 and 16% in relative activity, respectively, and keeping its activity practically unchanged with urea [40]. According to Villena et al. [48], the β-glucosidase from D. pseudopolymorphus revealed an inhibitory effect by 10 mM Zn2+ and Ca2+ but the enzyme increased its relative activity when incubated with 1 mM Co2+, Mg2+, K+, and Na+. The β-glucosidase from Periconia sp. showed an inhibition of 70, 50, 30, and 75% of relative activity by Cu2+, Zn2+, Mn2+, and Ca2+, respectively [49]. The β-glucosidase produced by the fungus Flammulina velutipes had a 61.5% decrease in its relative activity when incubated in 50 mM glucose [40].

Enzymatic Saccharification

To evaluate the supplementation effect, 2 units of the partially purified β-glucosidase was added per gram of biomass, which is equivalent to 0.46 mg of protein or 7.4 mL of enzyme, since the β-glucosidase activity was 0.28 U/mL before the supplementation. After supplementation, the total β-glucosidase activity that was expected to be 4 units was found to be 6.8 units, which corroborates synergism between the enzymes.

The Multifect® CL cocktail is a cellulase-rich mixture, containing 23.50 FPase/mL, 208.32 U/mL of endoglucanase, and 10.2 U/mL of β-glucosidase. Additionally, it exhibits other hemicellulolytic activities, such as 313.17 U/mL of xylanase, 2.12 U/mL of mannosidase, 2.33 U/mL of mannase, 10.40 U/mL of pectinase, and 0.38 U/mL of arabinofuranosidase [32].

Supplementation of the Multifect® CL cocktail with the β-glucosidase from K. zonata proved to be more efficient in the hydrolysis process of alkaline-pretreated sugarcane bagasse when compared to the hydrolysis performed only by the commercial cocktail Multifect® CL (Fig. 3). After 72 h of saccharification, the commercial cocktail individually applied produced 11.59 g/L of glucose and 3.94 g/L of xylose. The commercial cocktail supplemented with the K. zonata β-glucosidase produced 13.89 g/L of glucose and 5.34 g/L of xylose, an increase of 19.8 and 35.5% of glucose and xylose release, respectively. The residual cellobiose was 3.77 and 2.43 g/L for the commercial cocktail and the supplemented mixture, respectively, at the end of hydrolysis. After 72 h of saccharification, the commercial cocktail showed a productivity of 0.16 and 0.05 g/(L·h) for glucose and xylose, respectively, while the supplemented mixture had a productivity of 0.19 g/(L·h) for glucose and 0.07 g/(L·h) for xylose. Concerning biomass conversion efficiency and considering the content of 59.2% cellulose and 22.3% hemicellulose of the pretreated sugarcane bagasse, the Multifect® CL was able to convert 35.23% of cellulose and 31.02% of xylan. When supplemented with the K. zonata β-glucosidase, the conversion efficiency was 43.16 and 42.05%, for cellulose and hemicellulose, respectively.

Enzymatic saccharification of pretreated sugarcane bagasse with the commercial cocktail Multifect® C L (●) and with the same cocktail supplemented with β-glucosidase from the fungus Kretzschmaria zonata (○). A Glucose and B xylose concentrations. Different letters indicate significant differences among averages within the same time (ANOVA and Tukey test, p < 0.05)

The greater release of glucose was expected because the enzyme β-glucosidase is responsible for the release of glucose from cellobiose and other smaller oligosaccharides [50]. Furthermore, commercial cocktails are usually deficient in this enzyme [32]. The increase in xylose release indicates a possible synergistic activity between the β-glucosidase from K. zonata and the hemicellulolytic enzymes present in the commercial cocktail, in order to facilitate the hemicellulose access from sugarcane bagasse, which enables greater xylan degradation [3]. It is well known that the efficient hydrolysis of cellulosic biomass is more difficult than that of pure cellulose because the cellulosic fibers are usually entrapped in other structural biopolymers, mainly hemicelluloses and lignin. In this context, β-glucosidases that enable glucose and xylose release appear to be particularly well suited to maximize the overall efficiency of cellulosic biomass hydrolysis, acting in association with endo- and exocellulases and xylanases [8]. These findings support the notion that the supplementation of commercial cocktails with β-glucosidases can enhance the efficiency of biomass conversion processes, thus improving the overall yield of fermentable sugars for biofuel production. In accordance, Andrade et al. [3] reported that the hydrolysis of sugarcane bagasse by the Multifect® CL cocktail (15 U/g of biomass) supplemented with β-glucosidase from Crysoporthe cubensis (15 U/g of biomass) for 72 h led to an increase of 58% of glucose release and 15% of xylose release when compared to the commercial cocktail without supplementation.

Therefore, the β-glucosidase derived from K. zonata holds significant promise as a supplementary source for commercial enzyme cocktails aimed at enhancing the saccharification process for second-generation ethanol production.

Conclusions

The utilization of alternative carbon sources promotes sustainability in the production of valuable biotechnological products. K. zonata β-glucosidase induced by corn cob exhibits promising biochemical characteristics suitable for industrial applications. Moreover, the significant increase in sugars release observed with the addition of β-glucosidase underscores its potential to enhance fermentable sugar yields, which are essential for biofuel production. These findings emphasize the effectiveness of β-glucosidase supplementation in enzyme cocktails for improving the conversion of lignocellulosic materials. Further research can optimize supplementation conditions and evaluate their impact on an industrial scale, facilitating their implementation for a more sustainable and competitive bioeconomy.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Khan MAH, Bonifacio S, Clowes J et al (2021) Investigation of biofuel as a potential renewable energy source. Atmosphere 12:1289. https://doi.org/10.3390/ATMOS12101289

Pereira SC, Maehara L, Machado CMM, Farinas CS (2015) 2G ethanol from the whole sugarcane lignocellulosic biomass. Biotechnol Biofuels 8:1–16. https://doi.org/10.1186/S13068-015-0224-0/FIGURES/7

de Andrade LGA, Maitan-Alfenas GP, Morgan T et al (2017) Sugarcane bagasse saccharification by purified β-glucosidases from Chrysoporthe cubensis. Biocatal Agric Biotechnol 12:199–205. https://doi.org/10.1016/J.BCAB.2017.10.007

Ungureanu N, Vlăduț V, Biriș SȘ (2022) Sustainable valorization of waste and by-products from sugarcane processing. Sustainability 14:11089. https://doi.org/10.3390/SU141711089

Martins-Vieira JC, Lachos-Perez D, Draszewski CP et al (2023) Sugar, hydrochar and bio-oil production by sequential hydrothermal processing of corn cob. J Supercrit Fluids 194:105838. https://doi.org/10.1016/J.SUPFLU.2023.105838

Hess M (2008) Thermoacidophilic proteins for biofuel production. Trends Microbiol 16:414–419. https://doi.org/10.1016/J.TIM.2008.06.001

Visser EM, Falkoski DL, de Almeida MN et al (2013) Production and application of an enzyme blend from Chrysoporthe cubensis and Penicillium pinophilum with potential for hydrolysis of sugarcane bagasse. Bioresour Technol 144:587–594. https://doi.org/10.1016/J.BIORTECH.2013.07.015

Liu Y, Li R, Wang J et al (2017) Increased enzymatic hydrolysis of sugarcane bagasse by a novel glucose- and xylose-stimulated β-glucosidase from Anoxybacillus flavithermus subsp. yunnanensis E13T. BMC Biochem 18:1–8. https://doi.org/10.1186/S12858-017-0079-Z

Gupta VK, Kubicek CP, Berrin JG et al (2016) Fungal enzymes for bio-products from sustainable and waste biomass. Trends Biochem Sci 41:633–645. https://doi.org/10.1016/J.TIBS.2016.04.006

Bussamra BC, Freitas S, da Costa AC (2015) Improvement on sugar cane bagasse hydrolysis using enzymatic mixture designed cocktail. Bioresour Technol 187:173–181. https://doi.org/10.1016/J.BIORTECH.2015.03.117

Moya EB, Syhler B, Manso JO et al (2023) Enzymatic hydrolysis cocktail optimization for the intensification of sugar extraction from sugarcane bagasse. Int J Biol Macromol 242:125051. https://doi.org/10.1016/J.IJBIOMAC.2023.125051

Peralta RM, Kadowaki MK, Terenzi HF, Jorge JA (1997) A highly thermostable β-glucosidase activity from the thermophilic fungus Humicola grisea var. thermoidea: purification and biochemical characterization. FEMS Microbiol Lett 146:291–295. https://doi.org/10.1111/J.1574-6968.1997.TB10207.X

González-Pombo P, Pérez G, Carrau F et al (2008) One-step purification and characterization of an intracellular β-glucosidase from Metschnikowia pulcherrima. Biotechnol Lett 30:1469–1475. https://doi.org/10.1007/S10529-008-9708-3/TABLES/4

Jun H, Kieselbach T, Jönsson LJ (2011) Enzyme production by filamentous fungi: analysis of the secretome of Trichoderma reesei grown on unconventional carbon source. Microb Cell Fact 10:1–10. https://doi.org/10.1186/1475-2859-10-68/FIGURES/4

Ramani G, Meera B, Vanitha C et al (2012) Production, purification, and characterization of a β-glucosidase of Penicillium funiculosum NCL1. Appl Biochem Biotechnol 167:959–972. https://doi.org/10.1007/S12010-012-9645-4

Mule TA, Sawant SS, Odaneth AA (2024) Maize bran as a potential substrate for production of β-glucosidase. Biomass Convers Biorefin 14:4029–4039. https://doi.org/10.1007/S13399-022-02747-Z/TABLES/4

Tavares MP, Morgan T, Gomes RF et al (2024) Comparative analysis of Chrysoporthe cubensis exoproteomes and their specificity for saccharification of sugarcane bagasse. Enzyme Microb Technol 173. https://doi.org/10.1016/J.ENZMICTEC.2023.110365

Maitan-Alfenas GP, Visser EM, Guimarães VM (2015) Enzymatic hydrolysis of lignocellulosic biomass: converting food waste in valuable products. Curr Opin Food Sci 1:44–49. https://doi.org/10.1016/J.COFS.2014.10.001

Fernandes CG, Sawant SC, Mule TA et al (2023) Synergistic β-glucosidases for improving cellulases recyclability and biomass enzymatic saccharification in wheat straw. Biomass Bioenergy 175:106881. https://doi.org/10.1016/J.BIOMBIOE.2023.106881

Tramontina R, Robl D, Maitan-Alfenas GP, de Vries RP (2016) Cooperation of Aspergillus nidulans enzymes increases plant polysaccharide saccharification. Biotechnol J 11:988–992. https://doi.org/10.1002/BIOT.201500116

da Luz MM, de Souza Àzar RL, Guimarães VM et al (2022) Purification of xylanase from Kretzschmaria zonata with potential interest in the production of xylooligosaccharides. J Food Process Preserv 46:e16910. https://doi.org/10.1111/JFPP.16910

Alfenas RF, Arenhart ML, Alexandre FS, Maitan-Alfenas GP (2020) Root collar rot, a new lethal disease on Tectona grandis caused by Kretzschmaria zonata in Brazil. 101094/PDIS-03-20-0641-PDN 105:221. https://doi.org/10.1094/PDIS-03-20-0641-PDN

da Luz Morales M, Almeida LF, de Souza Ladeira Àzar RI et al (2021) First report on the enzymatic profile of Kretzschmaria zonata. 3 Biotech 11. https://doi.org/10.1007/S13205-021-02940-3

Monclaro AV, Gorgulho Silva C de O, Gomes HAR et al (2022) The enzyme interactome concept in filamentous fungi linked to biomass valorization. Bioresour Technol 344:126200. https://doi.org/10.1016/J.BIORTECH.2021.126200

Martins MP, Ventorim RZ, Coura RR et al (2018) The β-xylosidase from Ceratocystis fimbriata RM35 improves the saccharification of sugarcane bagasse. Biocatal Agric Biotechnol 13:291–298. https://doi.org/10.1016/J.BCAB.2018.01.009

de Sousa GK, Maitan-Alfenas GP, de Andrade LGA et al (2017) Purification and characterization of xylanases from the fungus Chrysoporthe cubensis for production of xylooligosaccharides and fermentable sugars. Appl Biochem Biotechnol 182:818–830. https://doi.org/10.1007/S12010-016-2364-5

Falkoski DL, Guimarães VM, de Almeida MN et al (2013) Chrysoporthe cubensis: a new source of cellulases and hemicellulases to application in biomass saccharification processes. Bioresour Technol 130:296–305. https://doi.org/10.1016/J.BIORTECH.2012.11.140

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1006/ABIO.1976.9999

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680A0

Blum H, Beier H, Gross HJ (1987) Improved silver staining of plant proteins, RNA and DNA in polyacrylamide gels. Electrophoresis 8:93–99. https://doi.org/10.1002/ELPS.1150080203

McIlvaine TC (1921) A buffer solution for colorimetric comparison. J Biol Chem 49:183–186. https://doi.org/10.1016/S0021-9258(18)86000-8

Maitan-Alfenas GP, Visser EM, Alfenas RF et al (2015) The influence of pretreatment methods on saccharification of sugarcane bagasse by an enzyme extract from Chrysoporthe cubensis and commercial cocktails: a comparative study. Bioresour Technol 192:670–676. https://doi.org/10.1016/J.BIORTECH.2015.05.109

El-Ghonemy DH (2021) Optimization of extracellular ethanol-tolerant β-glucosidase production from a newly isolated Aspergillus sp. DHE7 via solid state fermentation using jojoba meal as substrate: purification and biochemical characterization for biofuel preparation. J Genet Eng Biotechnol 19:1–18. https://doi.org/10.1186/S43141-021-00144-Z/FIGURES/7

Rastogi M, Shrivastava S (2023) Assessment of indigenous fungal biocatalysts towards valorization of delignified physico-chemically pretreated corn cobs and sugarcane bagasse. Biofuels Bioprod Biorefin 17:153–166. https://doi.org/10.1002/BBB.2435

Sørensen A, Andersen JJ, Ahring BK et al (2014) Screening of carbon sources for beta-glucosidase production by Aspergillus saccharolyticus. Int Biodeterior Biodegradation 93:78–83. https://doi.org/10.1016/J.IBIOD.2014.05.011

Santos FRS, Garcia NFL, da Paz MF et al (2016) Production and characterization of β-glucosidase from Gongronella butleri by solid-state fermentation. Afr J Biotechnol 15:633–641. https://doi.org/10.5897/AJB2015.15025

Pyeon HM, Lee YS, Choi YL (2019) Cloning, purification, and characterization of GH3 β-glucosidase, MtBgl85, from Microbulbifer thermotolerans DAU221. PeerJ 2019. https://doi.org/10.7717/PEERJ.7106/SUPP-5

das Neves CA, de Menezes LHS, Soares GA et al (2022) Production and biochemical characterization of halotolerant β-glucosidase by Penicillium roqueforti ATCC 10110 grown in forage palm under solid-state fermentation. Biomass Convers Biorefin 12:3133–3144. https://doi.org/10.1007/S13399-020-00930-8

Bhatia Y, Mishra S, Bisaria VS (2002) Microbial beta-glucosidases: cloning, properties, and applications. Crit Rev Biotechnol 22:375–407. https://doi.org/10.1080/07388550290789568

Mallerman J, Papinutti L, Levin L (2015) Characterization of β-glucosidase produced by the white rot fungus Flammulina velutipes. J Microbiol Biotechnol 25:57–65. https://doi.org/10.4014/JMB.1401.01045

Bonfá EC, de Souza Moretti MM, Gomes E, Bonilla-Rodriguez GO (2018) Biochemical characterization of an isolated 50 kDa beta-glucosidase from the thermophilic fungus Myceliophthora thermophila M.7.7. Biocatal Agric Biotechnol 13:311–318. https://doi.org/10.1016/J.BCAB.2018.01.008

Bai H, Wang H, Sun J et al (2013) Production, purification and characterization of novel beta glucosidase from newly isolated Penicillium simplicissimum H-11 in submerged fermentation. EXCLI J 12:528

Thapa S, Li H, OHair J et al (2019) Biochemical characteristics of microbial enzymes and their significance from industrial perspectives. Mol Biotechnol 61:579–601. https://doi.org/10.1007/S12033-019-00187-1

Elyas KK, Mathew A, Sukumaran RK et al (2010) Production optimization and properties of beta glucosidases from a marine fungus Aspergillus-SA 58. N Biotechnol 27:347–351. https://doi.org/10.1016/J.NBT.2010.02.007

Bi Y, Zhu C, Wang Z et al (2019) Purification and characterization of a glucose-tolerant β-glucosidase from black plum seed and its structural changes in ionic liquids. Food Chem 274:422–428. https://doi.org/10.1016/J.FOODCHEM.2018.09.007

Pal S, Banik SP, Ghorai S et al (2010) Purification and characterization of a thermostable intra-cellular beta-glucosidase with transglycosylation properties from filamentous fungus Termitomyces clypeatus. Bioresour Technol 101:2412–2420. https://doi.org/10.1016/J.BIORTECH.2009.11.064

López MC, Mateo JJ, Maicas S (2015) Screening of β-glucosidase and β-xylosidase activities in four non-saccharomyces yeast isolates. J Food Sci 80:C1696–C1704. https://doi.org/10.1111/1750-3841.12954

Arévalo Villena M, Úbeda Iranzo JF, Gundllapalli SB et al (2006) Characterization of an exocellular β-glucosidase from Debaryomyces pseudopolymorphus. Enzyme Microb Technol 2:229–234. https://doi.org/10.1016/J.ENZMICTEC.2005.10.018

Harnpicharnchai P, Champreda V, Sornlake W, Eurwilaichitr L (2009) A thermotolerant beta-glucosidase isolated from an endophytic fungi, Periconia sp., with a possible use for biomass conversion to sugars. Protein Expr Purif 67:61–69. https://doi.org/10.1016/J.PEP.2008.05.022

Tiwari R, Singh PK, Singh S et al (2017) Bioprospecting of novel thermostable β-glucosidase from Bacillus subtilis RA10 and its application in biomass hydrolysis. Biotechnol Biofuels 10:1–18. https://doi.org/10.1186/S13068-017-0932-8/TABLES/9

Funding

The authors thank the Research Support Foundation of the State of Minas Gerais (Fundação de Amparo à Pesquisa do Estado de Minas Gerais-FAPEMIG APQ-01251-22), the National Council for Scientific and Technological Development (Conselho Nacional de Desenvolvimento Científico e Tecnológico-CNPq), and the Higher Education Personnel Improvement Coordination (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-CAPES 001) for the financial support of the work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design, material preparation, and data collection. Analysis was performed by Danilo Canettieri, Lucas Almeida, Debora Pimentel, Yan Clevelares, and Gabriela Maitan-Alfenas. The first draft of the manuscript was written by Danilo Canettieri, Lucas Almeida, Riziane Gomes, Valéria Guimarães, and Gabriela Maitan-Alfenas. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Canettieri, D.L., Pimentel, D.C., Almeida, L.F. et al. Application of the β-Glucosidase from the Fungus Kretzschmaria zonata on Sugarcane Bagasse Hydrolysis. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10769-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10769-w