Abstract

There is an upsurge in industrial production to meet the rising demands of the rapidly growing population globally. The enormous energy demand of the growing economies still depends upon petroleum. It has also resulted in environmental pollution due to the release of petroleum origin pollutants. Soil and aquifers, especially in the direct impact zones of petroleum refineries, are the worst hit. The integrated concept of bioremediation and resource recovery offers a sustainable solution to mitigate environmental pollution. It involves biodegradation, a benign utilization of toxic wastes, and the recycling of natural resources. Bioremediation is considered an integral contributor to the emerging concepts of bio-economy and sustainable development goals. This review article aims to provide an updated overview of bioremediation involving petroleum-based contaminants. Microbial degradation is discussed as a promising strategy for petroleum refinery effluent and sludge treatment. The review also provides an insight into resource reuse and recovery as a holistic approach towards sustainable refinery waste treatment. Furthermore, the integrated technologies that deserve in-depth exploration for future study in the refinery sector are highlighted in the present study.

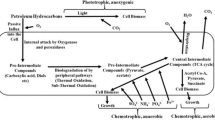

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Petroleum-derived products such as fuels and petrochemicals are essential for economic development and constitute a vital role in our everyday lives. Steadily increasing demand since the late nineteenth century has elevated crude oil consumption globally. Petroleum is the fossilized fuel source that is an indispensable source of energy but adversely impacts our environment and living beings' health. Given this, bio-derived fuels' significance is highlighted, which also ensures to minimize our dependence on fossil fuels [1,2,3,4]. The main routes for petroleum-derived pollutants entering the environment include refinery emissions, automobile exhaust, industrial combustion facilities, accidental spills and leaks during exploration, transportation, refining, and storage [5]. The enormous anthropogenic activity in the oil and gas sector is a prominent contributor to air, soil, and terrestrial water pollution, including greenhouse gas emissions like methane and carbon dioxide. Methane is known to cause 20-fold higher global warming effects than carbon dioxide and is generated at around 331 teragrams per year globally, which is very alarming [6, 7]. The primary route of soil and water contamination is refinery discharge, which mainly comprises petroleum products like total petroleum hydrocarbons (TPH), polycyclic aromatic hydrocarbons (PAHs), and other organic compounds like benzene, ethylbenzene, toluene, xylene (BTEX). Among these, PAHs have been enlisted as priority pollutants by the United States Environmental Protection Agency based on their extreme toxicity, carcinogenicity, and mutagenicity. Industrial wastewater, mainly from petrochemical industries, contains high concentrations of toxic chemicals is considered a significant source of water pollution. Therefore the treatment of refinery wastewater must be strictly enforced before its legal discharge. It is imperative to sustainably utilize these pollutants from the refinery wastewater and contaminated soil. Compared to traditional chemical effluent treatment, biological methods are considered more versatile and eco-friendly. These generally involve microbes, plants, or biocatalysts derived from them (from enzyme pathways) to degrade complex chemical pollutants to simpler forms. Additionally, they have the advantages of high conversion rates, selectivity, and economy over chemical methods [8]. An overview of bioremediation is presented (Fig. 1).

The removal of petroleum toxicants can be accomplished either by reviving the growth of native microbes in an impacted ecosystem or through the external addition of hydrocarbon-degrading microbes and plants. It is applicable for various environmental matrices, including oil reservoirs, oil spill sites, and other contaminated water bodies. However, the application of single microbial species has limitations in its effectiveness for specific hydrocarbons only. This problem can be overcome using a mixed population which acts due to synchronized influence and diverse enzymatic action in the mineralization of a broad range of petroleum hydrocarbons. Their better adaptability, performance over broad physiological conditions, tolerance towards various waste matrices, and enhancement of biocatalytic potential make them superior [9, 10]. Another sustainable approach for refinery waste remediation is based on the adsorptive potential of bio-sorbents derived from bio-derived wastes like microbial and lignocellulosic biomass. This philosophy towards valorization of refinery wastes opens a gateway to achieve a cradle-to-cradle approach. This article provides an overview of removing petroleum contaminants through the bioremediation approach integrated with resource recovery and reuse by combining ecological and economic drivers. It also narrates the applications of biological products like natural fibers, bio-composites, and biocatalysts for remediation of refinery wastes.

Petroleum Refinery Effluents

Hydrocarbons, PAHs, phenols, inorganic complexes, sulfur, and nitrogen-containing organic chemicals are the major environmental pollutants in the petroleum refinery effluents and sludge. According to a Transportation Research Board and National Research Council report, global annual hydrocarbon and PAHs releases are 4,988,699 and 6,319 tonnes per year, respectively, through land-based sources [11]. Nearly 85% of hydrocarbon release in the environment is attributed to petroleum processing industries [12]. PAHs, possessing high-toxicity and carcinogenicity, are reported to alter aquifers' community structure and soil microflora [12]. Petroleum refineries cause soil contamination due to oil spills either during transportation or exploration, tank leakage, or improper dumping of petroleum waste. Refinery contaminants that cause soil pollution was sub-categorized (Fig. 2).

Petroleum refineries are also significant sources of water pollution. A large quantity of water is required in petroleum refining, typically in the range of 30–50% v/v of the input crude processed [13]. While the composition of petroleum refinery waste depends upon the complexity of the refining process, refinery wastewater broadly contains a range of organic, inorganic compounds, especially aromatic hydrocarbons and heavy metals, found in various effluent streams from the refining process, which include dissolved oil, minerals, gases, and solid compounds (Fig. 3). More efficient management and reuse of this wastewater are required in petroleum industries to minimize the freshwater intake and meet strict regulatory requirements.

Methods for Remediation of Petroleum Refinery Waste

Bioaugmentation

The toxicity, carcinogenicity, teratogenicity of petroleum refinery wastes poses a threat to both humans and the environment. Removal of these hazardous contaminants can be effectively achieved by augmentation with native or exogenous microbes. The aforesaid approach can be implanted either alone or in microbial consortia to treat refinery waste [14] and hence considered more economical and feasible due to the application of microbes capable of mineralizing diverse pollutants [15]. Musa et al. reported the degradation of refinery wastewater effluents using bioaugmentation with native microbes, and the result showed 66% hydrocarbon removal [16]. Isaac et al. reported 100% removal of naphthalene and phenanthrene and almost six times higher pyrene removal in case of a mixed microbial consortium due to secretion of bioemulsifier when compared to native microbes [17]. The advantage of the mixed microbial consortium over indigenous microbes is the diversity in substrate-directed activity and inhibitor tolerance across consortium members. It is an essential prerequisite for detoxification as bioremediation efficiency directly correlates with individual microbes' metabolic potential [1, 2]. This bioaugmentation approach can also be made to remove various organic contaminants from wastewater through an activated sludge process before its discharge. This treatment process offers a sustainable solution to overcome the scarcity of water through reuse and recycle. As the activated sludge process could become limited to a few contaminants due to the complexity of refinery waste, bioaugmentation of activated sludge can counterbalance such limitations. It involves the addition of potent hydrocarbon-degrading microorganisms for enhanced treatment.

In a recent study, Jamal et al. reported the PAH contaminated refinery wastewater in higher saline conditions using a continuous stirred tank reactor. The study resulted in the complete removal of phenanthrene and fluorene and 90% degradation of pyrene using halophilic microbial consortia [18]. Similarly, in another study, the addition of hydrocarbon-degrading microbes was investigated for PAH degradation in aged contaminated soil, which resulted in a 99% reduction in PAH concentration, signifying the process's effectiveness at PAH contaminated site [19]. Despite various reported examples of this approach for removing priority pollutants like PAH from soil and water, a few limitations associated with the bioaugmentation process include low inoculums size or competition with the existing indigenous microbes under natural conditions [20]. Furthermore, the introduction of a new strain under natural conditions may fail to deliver desired growth rates due to bacteriophages' presence or lack of acclimatization to the hostile environmental conditions [21]. Additionally, studies also reported retardation of bioaugmentation under extreme environmental conditions such as starvation periods, pH, and low temperatures [22].

Biostimulation

Unlike bio-augmentation, which requires the addition of external microbes to accelerate contaminant degradation by complementing indigenous microbiota, biostimulation focuses on inhabitant microbes in the affected environment and seeks to strengthen their metabolic potential. However, adding bacteria with the desirable catabolic capabilities into a particular environment does not always guarantee enhanced degradation of petroleum toxicants. Therefore the average contribution of inoculated microbial diversity to the total richness of species to tolerate the targeted environment is essential for survival. Even after employing native microbial populations, the success of on-site bioremediation is primarily constrained by imbalanced nutrients and/or unfavorable factors, which include: adequate nutrients, pH, ambient temperature, moisture, oxygen, and contaminant concentration [23]. Among these factors, nutrient deficiency severely retards inhabitant microbes' catalytic activity and limits the rate of intrinsic bioremediation [24]. In a study, Sun et al. reported the retardation during crude oil degradation due to ammonium and phosphorous deficiency [25]. In general, the addition of nutrients also plays a pivotal role, and therefore the adequate concentration of nutrients is essential for efficient degradation; the deficiency thereof may be counterproductive. The aforesaid process also includes the addition of other stimulants like surfactants for the availability of hydrocarbons since increased mobility of any hydrocarbon molecule, enabled by surfactant-induced emulsification dispersion, makes it more susceptible to microbial action. Borah et al. reported a biosurfactant-producing strain Bacillus cereus for the remediation of a hydrocarbon-contaminated subsurface, signifying applicability in enhanced oil recovery [26], as did Marchut-Mikolajczyk et al. [27]. Gharibzadeh et al. reported removal of phenanthrene via sequential washing of phenanthrene contaminated soil with biosurfactant. The process showed 97% removal efficiency of a real PAH contaminated site over seven cycles, suggesting the effectiveness of reuse and potential economic viability [28]. Roy et al. demonstrated enhanced hydrocarbon reduction from 57 to 75% by simultaneous application of nutrient and biosurfactant producing microbes [23]. Therefore the application of biosurfactant-mediated removal of petroleum contaminants is considered promising due to its low toxicity, biodegradability, broader applicability over diverse substrate range.

Another recently reported interesting approach for biostimulation involves accelerated PAH degradation through the addition of sawdust and wheat straw biochar; simultaneous adsorption of PAH on the biochar surface while the biochar provides a better habitat for consortium survival enhanced microbial degradation significantly [18]. Additionally, other biostimulation agents like electron acceptors can play a significant role during anaerobic treatment since, in the absence of oxygen, anaerobic microbes may grow on an alternative substrate such as nitrate, sulfate, iron, and CO2, which link to the anaerobic processes of denitrification, desulphurization, iron reduction and methanogenesis [29]. The combination of bioaugmentation, biostimulation, and biosurfactant addition, depending upon the defiled site's attributes, might be a promising strategy to accelerate bioremediation [30].

Composting

In composting, often a cost-effective strategy, contaminated soil is mixed with a bulking agent (primarily agricultural residue) to create pores and make the process aerobic. The bulking agent is utilized as a carbon source by microbes and makes degradation co-metabolic. Advantage of using composting as a bioremediation technique is the generation of mature compost that can be used in land restoration [31]. Composting increases the metabolic diversity of microbes and has been referred to as "super bioaugmentation" [32]. Apart from the degradation of organic components, heavy metal contamination can also be addressed effectively by composting. Cadmium, which is considered the most mobile metal in an oil-contaminated surface, is removed through the combined composting action of cellulolytic bacteria and organic-degrading species [33]. Removal of PAH was also reported through the co-composting action of cattle manure and wheat straw [34]. Abtahi et al. investigated the composting process's efficiency with indigenous compost microbes and petroleum degrading microbes in a composting bioreactor, which suggested a decline in the effectiveness of petroleum degrading microbes due to competition among them [35]. During composting, the optimizations of rate-limiting factors like pollutant concentration, soil: compost ratio, and compost stability significantly affects composting efficiency. Therefore, the ratio of oily sludge and amendments must be balanced. Given this, Koolivand et al. performed two-stage composting (windrow composting and in-vessel composting) of storage tank bottom sludge in which the effect of the various mixing ratio of C/N/P and nutrients addition was investigated for the removal of TPH, which resulted in the removal of 93.72% of TPH [36].

Enzymatic Bioremediation

The degradation of petroleum hydrocarbons can be accomplished by microbes or their extracted cellular components, i.e., enzymes. Compared to microbes, enzymatic bioremediation is a rapid method for the removal of petroleum toxicants. The enzymes have broad substrate specificity and helpful in the bioremediation of various petroleum-based toxic compounds like phenols, PAHs, etc. [37, 38]. The mechanism of degradation in both cases is similar since, in whole cell-mediated degradation, the organism secretes enzymes that either cleave the aromatic structure of hydrocarbons or substitute it with different functional groups that make the degradation products less harmful. Although whole cells are also used for remediation purposes, the process is slow, and competition with native microflora is generally a concern. Sometimes, the degradation efficiency or the viability of the chosen microbe is impaired due to the unavailability of appropriate conditions at the contaminated site as compared to in-vivo. The enzymatic approach provides alternative ways to improve xenobiotic bioremediation approaches. Since enzymes are biocatalysts, they increase the reaction rate by lowering the activation energy, and therefore, degradation can be achieved quickly [39]. Several enzymes, like oxidoreductases, laccase, peroxidase, have been used in the bioremediation of petroleum toxicants [40,41,42].

A special significance of enzymatic bioremediation is that it can be applied in a nutrient-deprived contaminated site. The biocatalyst size is another critical parameter that should be considered, as the small size of the biocatalyst increases the diffusion rate of enzymes and thus accelerates the degradation process. Unlike whole cell-mediated degradation, no toxic by-products are generated, and the cost of operation is also less [43]. Enzymes can be used directly in crude or semi-purified forms in many cases, depending upon the prevailing requirements. Different microorganisms produce biocatalysts with different catalytic efficiencies for various contaminants. Biocatalysts used for the degradation of petroleum hydrocarbons are listed (Table 1).

Bio-Materials and Bio-Composites for Refinery Waste Treatment

Microbial biomass can be utilized for the treatment of petroleum effluents either directly or in immobilized form. Various microbial biomass immobilization approaches on biomaterials and biocomposites, including adsorption, encapsulation, and covalent methods, have been demonstrated to improve bioprocess stability and waste effluents treatment [48,49,50,51]. Banerjee et al. deployed immobilized microbial biomass to treat petroleum spills, delivering the removal of more than 95% of phenolic content from refinery water [52]. Cost et al. reported plant-derived biomass—peat and angico hardwood sawdust—as adsorbent material for removing prominent refinery contaminant family BTEX from waste discharge [53]. Recently, Imam et al. utilized rice straw biochar as an adsorbent for anthracene removal [54].

The utilization of natural fibers and bio-composites is another potentially cost-effective approach for treating liquid refinery waste streams. Limited research has yet been done in this direction. Akhbarizadeh et al. engineered a low-cost bio-composite derived from shrimp shell and acid-activated montmorillonite for simultaneous removal of 93 and 87% for metals crude oil, respectively [55].

Bio-sorbents can thus be considered desirable choices for the treatment of refinery waste due to their low cost, density, strength, and eco-friendly nature. Moreover, they help in the mitigation of greenhouse gases (GHGs).

Integrated Refinery Waste Treatment and Resource recovery

Energy Recovery

The integrated refinery waste treatment and simultaneous energy recovery (usable heat, electricity, or bioenergy production) using microbial action could be the significant breakthrough in waste to energy research in the coming days. This integrated process using the microbial route can simultaneously have the potential for environmental, economic benefit, and value addition. A recent study reported simultaneous hydrogen and electricity generation from biodiesel effluents [56]. Like refinery waste, other bio-derived waste can also be minimized via microbial action through the integrative approach with simultaneous value addition [57, 58]. Electricity generation using microbial fuel cells (MFC), innovative and sustainable technology for treating organic pollutants from wastewater, is considered promising since no external source of energy is required for its operation; this ensures dual benefits of waste treatment and simultaneous energy recovery through biochemical reaction. MFCs can remediate a wide range of contaminants, such as biological wastes, heavy metals, petroleum products, dyes, phenolic compounds, quinolone, pyridine derivatives from wastewater. However, not much has been reported on MFCs in the general treatment of refinery effluents like refinery wastewater, petroleum sludge, and oily waste.

Guo et al. set-up both single and doubled-chambered MFC configurations for recycling refinery wastewater as fuel. A dual-chambered MFC showed the highest power density output of 310.08 mW/m3 and the pollutant removal efficiency of 83.6%, comparatively higher than a corresponding single-chambered MFC [59]. Mohanakrishna et al. also demonstrated the treatment of refinery wastewater and simultaneous electricity generation using single chamber air–cathode MFC technology, eliminating aeration during operation and improving sustainability. A maximum power density of 132 mW/m2 and substrate removal efficiency of 48% was reported in the study [60].

The MFC approach is considered regenerative as the organism is generally self-replicating and cost-effective compared to energy-intensive conventional treatment. Moreover, MFCs enable the recovery of sustainable energy from the wastewater with the simultaneous assimilation of effluents while limiting both the energy input and the excess sludge production. Apart from these additional advantages, MFCs are mostly insensitive to the operational environment. The key challenges remain scale-up to refinery volume requirements, which need to be addressed through engineering design.

Similar to electricity generation via MFC, anaerobic digestion through microbial action is another integrated approach for refinery waste treatment and simultaneous resource recovery in the form of renewable energy, namely biogas [61]. Compared to conventional wastewater pre-treatment approaches, anaerobic digestion has significant advantages like low nutrient requirement, little or no external input of energy, low sludge production, and installation ease. Despite several advantages, there remains a significant limitation of hydraulic retention time and influent feedstock concentration during the operation of anaerobic treatment, and therefore a proper optimization is required for the operation of the process. However, Up-flow anaerobic sludge blanket digestion (UASB) could be a practical solution for the treatment of refinery wastewater because of its improved effectiveness relative to other digester configurations in terms of flexibility for a vast concentration of feedstock due to a wide range of hydraulic retention times [62]. Unlike aerobic bioremediation processes, anaerobic digestion requires no external energy supply is required and also helps in recovering bio-energy as biogas (a mixture of methane and CO2), which reduces net dependence on fossil fuel within a petroleum refinery. Additionally, obtained methane can also be utilized as a substrate for electricity generation through MFC or an alternate feed for value-added products to minimize their emissions via methanotrophic microbial action [63, 64].

Water Recovery

Water recovery through Constructed Wetland (CW) is another exciting development for resource recovery from refinery waste. CW removes contaminants while generating fresh water for irrigation, water reuse in the refinery, fodder for livestock, and some energy. CW uses shallow beds or channels, marsh plants, soil, sand and gravels, and various microorganisms for the treatment of typical refinery wastewater streams [65]. Compared to traditional wastewater treatment methods, CW is considered to have a low maintenance cost in operations and appears visually attractive, mimicking the aesthetics and functionality of a natural wetland for the improvement of water quality to enable its productive reuse. Additionally, CW also reduces GHG emissions via carbon capture and can serve as a renewable energy source via the produced biomass.

Several recent studies have sought to treat refinery effluents using the CW approach. Information about the wastewater characteristics, the efficiency of treatment, and installation location has been presented (Table 2). Plant species like Typha latifolia, Pragmites Australis, Eichhornia crassipes have treated refinery effluent in low maintenance operations. These plants also serve as habitats for diverse microbial communities, which also enhance degradation. Several limiting factors include retention time, effluent concentration, type of wastewater, water depth, type of plant species, microbes, and climatic conditions that can constrain pollutant removal using CW [66]. However, this approach is beneficial due to the low set-up cost for effluent remediation at a large field-scale study.

Hybrid MFC-CW systems are now being explored, which combine the benefit and leverage synergies of both methods for simultaneous waste treatment and energy generation. The combined bio-cum-electrochemical approach using MFC-CW may be even more promising for removing refinery contaminants than the standalone bioremediation or phytoremediation process CW.

The MFC-CW approach works on a principle similar to that of a standalone MFC. However, in MFC-CW, the potential difference is generated across the rhizosphere's oxic zone and the anoxic zone of CW, thereby making the process sustainable. These unique characteristics make the integrated MFC-CW an ideal approach for waste treatment and recovery of resources in electrical energy while also mitigating methane emissions [70].

Wei et al. implemented integrated microbial electrochemical technology-CW in-situ to remove major refinery contaminants benzene, methyl-tert-butyl ether, and ammonium from groundwater. This study reported the complete removal of contaminants with a significantly low power density of 1.74 mW m−2 due to limited substrate concentration [71]. Yang et al. did the comparative analysis between MFC and MFC-CW and investigated the improved power generation in MFC-CW due to the enhanced redox activity in the rhizosphere due to photosynthesis or due to increased accumulation of active microbes [70]. CW and MFC are compatible and complementary technologies since both are dependent on microbes or plants' actions to remove contaminants from wastewater and recover energy. Though combined MFC-CW retains the best features of both the subcomponent technologies, bioelectricity generation at the present power level is not yet significant for real-world applications. Therefore, the optimized use of such hybrid systems for the treatment of petroleum effluents appears to be a gap that can be addressed in further research.

Co-product Recovery

Another approach of resource recovery from refinery waste involves product recovery either from sludge or refinery waste. Oil sludge comprises a viscous mixture of sediment, water, oil, a combination of complex hydrocarbons like aliphatic and aromatic hydrocarbons. Besides, oil and hydrocarbons sludge also comprise heavy metals, asphaltenes, etc., that are a potential threat to the environment and health and are generated in substantial amounts during refining operations, cleaning of oil storage tanks, and even as a residue from conventional refinery wastewater treatment plants themselves [72].

The first step of oily sludge treatment involves oil recovery since it constitutes 80% of oil and 20% solids. Incorporating a microbial-derived biosurfactant is an alternative to increase the available reactive surface area of hydrophobic compounds. Surfactants accumulate at the hydrocarbon and water interphase and stabilize smaller droplets of the dispersed oil phase by reducing the interfacial tension. It increases the bioavailability of the oily contaminants for remediation [73]. Biosurfactant-mediated degradation of aged contaminated petroleum hydrocarbons is gaining rapid currency due to the resilient and versatile nature, low toxicity, eco-friendliness, biodegradability, and applicability of these biosurfactants even under extreme conditions of temperature, pH, and salinity. In a recent study, biosurfactant (rhamnolipid) application was demonstrated for oil recovery from oil tank bottom sludge [74]. The use of biosurfactants enables compliance with legislative requirements and environmental considerations. A deeper investigation and technology scale-up of ex-situ oil recovery after biosurfactant treatment appears to be warranted. Apart from oil recovery, biosurfactants have also been used to obtain petrochemical products such as emulsifying agents, biocides for sulfate-reducing bacteria against biocorrosion, and bitumen from coal tar.

Recovery of metal from spent catalysts is another opportunity for resource recovery in the petroleum processing sector. These catalysts, used in several process units involved in converting crude oil to fuels and petrochemicals, essentially contain valuable metals like Ni, V, Mo, Co, Cu, Pb, Zn, and Cr, which require regeneration once they lose their activity with time. However, due to such spent catalysts' toxic and hazardous nature, there exist stringent environmental regulations for their disposal. Recovery of these valuable metals is hence considered a beneficial solution from both economic and ecological standpoints. Biological processes (bioleaching) for metal extraction of refining spent catalysts are reported in several studies. Vemic et al. reported a comparative evaluation of chemical and biological leaching to recover molybdenum from spent catalyst, wherein 90% leaching efficiency in the chemical process and 70% in the biological process was observed; however, bioleaching is a simple and cost-effective technology for the extraction of metal from low-grade ores and minerals concentrates [75]. Srichandan et al. showed 79 and 90% recovery of nickel and vanadium in 240 h through sequential biological leaching from decoked spent refinery catalyst [76]. In another study, Srichandan et al. reported the highest leaching of 97 and 92% for nickel and vanadium using a thermophilic consortium [77]. Microbe-mediated metal recovery results in enhanced metal recovery; such secondary raw material generation reduces the primary raw material dependence from environmentally unsustainable mining activities. Bioleaching of spent catalyst from bench to pilot scale-up to commercial deployment is yet to be industrially realized and offers an opportunity for exploration.

Challenges, Knowledge Gaps, and Perspectives

Waste generated from petroleum refineries comprises a complex mixture of hydrocarbons, a few of which are classified as priority pollutants, along with toxic metals. Although various approaches have been reported for the degradation of petroleum contaminants from soil and aquifers, no single technique to date is effective for the complete removal of these contaminants. The search continues, therefore, for scalable, affordable, and sustainable technologies. A core failure mode arises in transferring microbes from labs where they are cultured to the actual site of contamination. Incomplete understanding of microbial physiology under field conditions and bioavailability of hydrocarbons to the microbes contribute to the deployment challenge.

Scientists worldwide are also looking for cost-effective bio-stimulating agents for enhancing the growth of microbes under natural conditions. Methanotrophs are potential microbes for this purpose due to substantial susceptibility to unfavorable conditions and broad substrate specificity. In keeping with the increasing global focus on circular economy practices, novel materials derived from various wastes are sought to be reutilized in the form of bio-composites to remove petroleum hydrocarbons and metals from refinery wastewater. A deep understanding of the critical factors limiting the biodegradation of priority pollutants like PAH, biphenyls, etc. can help develop superior microbial consortia and treatment processes.

Apart from developing feasible techniques for bioremediation, estimation of degradation using analytical techniques is also an important step. It helps determine the efficacy of microbes and offers insights into degradation kinetics under various conditions, and helps to understand the degradation products of such bioremediation at contaminated sites and their environmental implications.

This paradigm shift in refinery waste management by incorporating a waste-to-resource approach is an innovative step towards addressing sustainability goals. The integrated concept of bioremediation and resource recovery in the form of energy, water, and other valuable products can, in principle, enable companies that operate such refineries to make investments in environmentally sound emerging technologies in anticipation of multi-pronged benefits to the triple bottom line. However, significant scale-up challenges (such as for MFCs and microbial metals recovery), field application-oriented architecture design for large capacities of wastewater treatment, and appropriate sustainability assessments need to be addressed at all development and deployment stages. Similarly, in the constructed wetland approach, climatic conditions, wide-area occupancy, plant species choice, and non-standard design are some illustrative challenges to be overcome. As product recovery is key to this integrated approach's economic viability, greater effort is predicated in this direction.

Conclusions/Opinion

Petroleum refinery waste comprises various hydrocarbons that are detrimental to health, biodiversity, and the overall environment. While bioremediation overcomes the well-recognized limitations of physico-chemical treatment methods, the integration of multiple processes generally appears to deliver superior outcomes compared to individual component approaches. This review on the treatment of refinery waste through microbial or plant-based interventions suggests an emerging and exciting gateway for waste valorization and resource recovery while addressing the environmental impact and pushes the existing boundaries of bioremediation. Process intensification and bioengineering aspects of integrated refinery waste treatment and resource recovery shall also be explored for future research.

Change history

16 March 2023

A Correction to this paper has been published: https://doi.org/10.1007/s12088-023-01072-x

References

Patel SKS, Lee J-K, Kalia VC (2016) Integrative approach for producing hydrogen and polyhydroxyalkanoate from mixed wastes of biological origin. Indian J Microbiol 56:293–300. https://doi.org/10.1007/s12088-016-0595-3

Patel SKS, Lee J-K, Kalia VC (2017) Dark-fermentative biological hydrogen production from mixed biowastes using defined mixed cultures. Indian J Microbiol 57:171–176. https://doi.org/10.1007/s12088-017-0643-7

Patel SKS, Ray S, Prakash J, Wee JH, Kim S-Y, Lee J-K, Kalia VC (2019) Co-digestion of biowastes to enhance biological hydrogen process by defined mixed bacterial cultures. Indian J Microbiol 59:154–160. https://doi.org/10.1007/s12088-018-00777-8

Patel SKS, Kondaveeti S, Otari SV, Pagolu RT, Jeong SH, Kim SC, Cho BK, Kang YC, Lee J-K (2018) Repeated batch methanol production from a simulated biogas mixture using immobilized Methylocystis bryophila. Energy 145:477–485. https://doi.org/10.1016/j.energy.2017.12.142

Imam A, Suman SK, Ghosh D, Kanaujia PK (2019) Analytical approaches used in monitoring the bioremediation of hydrocarbons in petroleum-contaminated soil and sludge. TrAC—Trends Anal Chem 118:50–64. https://doi.org/10.1016/j.trac.2019.05.023

Patel SKS, Jeon MS, Gupta RK, Jeon Y, Kalia VC, Kim SC, Cho BK, Kim DR, Lee J-K (2019) Hierarchical macroporous particles for efficient whole-cell immobilization: application in bioconversion of greenhouse gases to methanol. ACS Appl Mater Interfaces 11:18968–18977. https://doi.org/10.1021/acsami.9b03420

Patel SKS, Shanmugam R, Kalia VC, Lee J-K (2020) Methanol production by polymer-encapsulated methanotrophs from simulated biogas in the presence of methane vector. Bioresour Technol 304:123022. https://doi.org/10.1016/j.biortech.2020.123022

Patel SKS, Selvaraj C, Mardina P, Jeong J-H, Kalia VC, Kang YC, Lee J-K (2016) Enhancement of methanol production from synthetic gas mixture by Methylosinus sporium through covalent immobilization. Appl Energy 171:383–391. https://doi.org/10.1016/j.apenergy.2016.03.022

Patel SKS, Kumar V, Mardina P, Li J, Lestari R, Kalia VC, Lee JK (2018) Methanol production from simulated biogas mixtures by co-immobilized Methylomonas methanica and Methylocella tundrae. Bioresour Technol 263:25–32. https://doi.org/10.1016/j.biortech.2018.04.096

Patel SKS, Gupta RK, Das D, Lee J-K, Kalia VC (2020) Continuous biohydrogen production from poplar biomass hydrolysate by a defined bacterial mixture immobilized on lignocellulosic materials under non-sterile conditions. J Clean Prod 287:125037. https://doi.org/10.1016/j.jclepro.2020.125037

Board M, Board OS, Council NR (2003) Oil in the sea III: inputs, fates, and effects. national academies Press. https://doi.org/10.17226/10388

Saito L, Rosen MR, Roesner L, Howard N (2010) Improving estimates of oil pollution to the sea from land-based sources. Mar Pollut Bull 60:990–997. https://doi.org/10.1016/j.marpolbul.2010.02.003

Sun P, Elgowainy A, Wang M, Han J, Henderson RJ (2018) Estimation of US refinery water consumption and allocation to refinery products. Fuel 221:542–557. https://doi.org/10.1016/j.fuel.2017.07.089

Lee J-K, Kalia VC (2020) Mapping microbial capacities for bioremediation: genes to genomics. Indian J Microbiol 60:45–53. https://doi.org/10.1007/s12088-019-00842-w

Bhardwaj P, Singh KR, Jadeja NB, Phale PS, Kapley A (2020) Atrazine Bioremediation and its influence on soil microbial diversity by metagenomics analysis. Indian J Microbiol 60:388–391. https://doi.org/10.1007/s12088-020-00877-4

Musa NM, Suleiman ADI (2015) Bioremediation of petroleum refinery wastewater effluent via augmented native microbes. J Emerg Trends Eng Appl Sci 6:1–6

Isaac P, Martínez FL, Bourguignon N, Sanchez LA, Ferrero MA (2015) Improved PAHs removal performance by a defined bacterial consortium of indigenous Pseudomonas and actinobacteria from Patagonia, Argentina. Int Biodeterior Biodegrad 101:23–31. https://doi.org/10.1016/j.ibiod.2015.03.014

Jamal MT, Pugazhendi A (2018) Degradation of petroleum hydrocarbons and treatment of refinery wastewater under saline condition by a halophilic bacterial consortium enriched from marine environment (Red Sea), Jeddah, Saudi Arabia. Biotech 8:276. https://doi.org/10.1007/s13205-018-1296-x

Haleyur N, Shahsavari E, Jain SS, Koshlaf E, Ravindran VB, Morrison PD, Osborn AM, Ball AS (2019) Influence of bioaugmentation and biostimulation on PAH degradation in aged contaminated soils: response and dynamics of the bacterial community. J Environ Manage 238:49–58. https://doi.org/10.1016/j.jenvman.2019.02.115

Raper E, Stephenson T, Anderson DR, Fisher R, Soares A (2018) Industrial wastewater treatment through bioaugmentation. Process Saf Environ Prot 118:178–187. https://doi.org/10.1016/j.psep.2018.06.035

Herrero M, Stuckey DC (2015) Bioaugmentation and its application in wastewater treatment: a review. Chemosphere 140:119–128. https://doi.org/10.1016/j.chemosphere.2014.10.033

Low A, Zhao S, Rogers MJ, Zemb O, Lee M, He J, Manefield M (2019) Isolation, characterization and bioaugmentation of an acidotolerant 1,2-dichloroethane respiring Desulfitobacterium species from a low pH aquifer. FEMS Microbiol Ecol 95:fiz055. https://doi.org/10.1093/femsec/fiz055

Roy A, Dutta A, Pal S, Gupta A, Sarkar J, Chatterjee A, Saha A, Sarkar P, Sar P, Kazy SK (2018) Biostimulation and bioaugmentation of native microbial community accelerated bioremediation of oil refinery sludge. Bioresour Technol 253:22–32. https://doi.org/10.1016/j.biortech.2018.01.004

Sarkar J, Kazy SK, Gupta A, Dutta A, Mohapatra B, Roy A, Bera P, Mitra A, Sar P (2016) Biostimulation of indigenous microbial community for bioremediation of petroleum refinery sludge. Front Microbiol 7:1407. https://doi.org/10.3389/fmicb.2016.01407

Sun Y, Chen W, Wang Y, Guo J, Zhang H, Hu X (2021) Nutrient depletion is the main limiting factor in the crude oil bioaugmentation process. J Environ Sci 100:317–327. https://doi.org/10.1016/j.jes.2020.07.025

Borah D, Yadav RNS (2017) Bioremediation of petroleum based contaminants with biosurfactant produced by a newly isolated petroleum oil degrading bacterial strain. Egypt J Pet 26:181–188. https://doi.org/10.1016/j.ejpe.2016.02.005

Marchut-Mikolajczyk O, Drożdżyński P, Pietrzyk D, Antczak T (2018) Biosurfactant production and hydrocarbon degradation activity of endophytic bacteria isolated from Chelidonium majus L. Microb Cell Fact 17:1–9. https://doi.org/10.1186/s12934-018-1017-5

Gharibzadeh F, Kalantary RR, Nasseri S, Esrafill A, Azari A (2016) Reuse of polycyclic aromatic hydrocarbons (PAHs) contaminated soil washing effluent by bioaugmentation/biostimulation process. Sep Purif Technol 168:248–256. https://doi.org/10.1016/j.seppur.2016.05.022

Zhang Z, Lo IMC (2015) Biostimulation of petroleum-hydrocarbon-contaminated marine sediment with co-substrate: involved metabolic process and microbial community. Appl Microbiol Biotechnol 99:5683–5696. https://doi.org/10.1007/s00253-015-6420-9

Varjani S, Upasani VN (2019) Comparing bioremediation approaches for agricultural soil affected with petroleum crude: a case study. Indian J Microbiol 59:356–364. https://doi.org/10.1007/s12088-019-00814-0

Chen M, Xu P, Zeng G, Yang C, Huang D, Zhang J (2015) Bioremediation of soils contaminated with polycyclic aromatic hydrocarbons, petroleum, pesticides, chlorophenols and heavy metals by composting: applications, microbes and future research needs. Biotechnol Adv 33:745–755. https://doi.org/10.1016/j.biotechadv.2015.05.003

Kästner M, Miltner A (2016) Application of compost for effective bioremediation of organic contaminants and pollutants in soil. Appl Microbiol Biotechnol 100:3433–3449. https://doi.org/10.1007/s00253-016-7378-y

Xu P, Lai C, Zeng G, Huang D, Chen M, Song B, Peng X, Wan J, Hu L, Duan A, Tang W (2018) Enhanced bioremediation of 4-nonylphenol and cadmium co-contaminated sediment by composting with Phanerochaete chrysosporium inocula. Bioresour Technol 250:625–634. https://doi.org/10.1016/j.biortech.2017.11.069

Leech C, Tighe MK, Pereg L, Winter G, McMillan M, Esmaeili A, Wilson SC (2020) Bioaccessibility constrains the co-composting bioremediation of field aged PAH contaminated soils. Int Biodeterior Biodegrad 149:104922. https://doi.org/10.1016/j.ibiod.2020.104922

Abtahi H, Parhamfar M, Saeedi R, Villasenor J, Sartaj M, Kumar V, Coulon F, Parhamfar M, Didehdar M, Seifi H, Koolivand A (2020) Effect of competition between petroleum-degrading bacteria and indigenous compost microorganisms on the efficiency of petroleum sludge bioremediation: field application of mineral-based culture in the composting process. J Environ Manage 258:110013. https://doi.org/10.1016/j.jenvman.2019.110013

Koolivand A, Rajaei MS, Ghanadzadeh MJ, Saeedi R, Abtahi H, Godini K (2017) Bioremediation of storage tank bottom sludge by using a two-stage composting system: effect of mixing ratio and nutrients addition. Bioresour Technol 235:240–249. https://doi.org/10.1016/j.biortech.2017.03.100

Patel SKS, Choi SH, Kang YC, Lee J-K (2016) Large-scale aerosol-assisted synthesis of biofriendly Fe2O3 yolk–shell particles: a promising support for enzyme immobilization. Nanoscale 8:6728–6738. https://doi.org/10.1039/C6NR00346J

Patel SKS, Choi H, Lee J-K (2019) Multi-metal based inorganic-protein hybrid system for enzyme immobilization. ACS Sustain Chem Eng 7:13633–13638. https://doi.org/10.1021/acssuschemeng.9b02583

Patel SKS, Gupta RK, Kim S-Y, Kim I-W, Kalia VC, Lee J-K (2020) Rhus vernicifera laccase immobilization on magnetic nanoparticles to improve stability and its potential application in Bisphenol A Degradation. Indian J Microbiol 1–10. https://doi.org/10.1007/s12088-020-00912-4

Okino-Delgado CH, Zanutto-Elgui MR, do Prado DZ, Pereira MS, Fleuria LF (2019) Enzymatic bioremediation: current status, challenges of obtaining process, and applications. In: Microbial metabolism of xenobiotic compounds. Springer, pp 79–101. https://doi.org/10.1007/978-981-13-7462-3_4

Patel SKS, Choi SH, Kang YC, Lee J-K (2017) Eco-friendly composite of Fe3O4-reduced graphene oxide particles for efficient enzyme immobilization. ACS Appl Mater Interfaces 9:2213–2222. https://doi.org/10.1021/acsami.6b05165

Patel SKS, Otari SV, Li J, Kim DP, Kim SC, Cho B-K, Kalia VC, Kang YC, Lee J-K (2018) Synthesis of cross-linked protein-metal hybrid nanoflowers and its application in repeated batch decolorization of synthetic dyes. J Hazard Mater 347:442–450. https://doi.org/10.1016/j.jhazmat.2018.01.003

Kumar V, Shahi SK, Singh S (2018) Bioremediation: an eco-sustainable approach for restoration of contaminated sites. In: Microbial bioprospecting for sustainable development. Springer, pp 115–136. https://doi.org/10.1007/978-981-13-0053-0_6

Zhang S, Ning Y, Zhang X, Zhao Y, Yang X, Wu K, Yang S, La G, Sun X, Li X (2015) Contrasting characteristics of anthracene and pyrene degradation by wood rot fungus Pycnoporus sanguineus H1. Int Biodeterior Biodegradation 105:228–232. https://doi.org/10.1016/j.ibiod.2015.09.012

Suganthi SH, Murshid S, Sriram S, Ramani K (2018) Enhanced biodegradation of hydrocarbons in petroleum tank bottom oil sludge and characterization of biocatalysts and biosurfactants. J Environ Manage 220:87–95. https://doi.org/10.1016/j.jenvman.2018.04.120

Agrawal N, Verma P, Shahi SK (2018) Degradation of polycyclic aromatic hydrocarbons ( phenanthrene and pyrene ) by the ligninolytic fungi Ganoderma lucidum isolated from the hardwood stump. Bioresour Bioprocess. https://doi.org/10.1186/s40643-018-0197-5

Apriceno A, Bucci R, Girelli AM (2017) Immobilization of laccase from Trametes versicolor on chitosan macrobeads for anthracene degradation. Anal Lett 50:2308–2322. https://doi.org/10.1080/00032719.2017.1282504

Patel SKS, Singh RK, Kumar A, Jeong JH, Jeong SH, Kalia VC, Kim I-W, Lee J-K (2017) Biological methanol production by immobilized Methylocella tundrae using simulated biohythane as a feed. Bioresour Technol 241:922–927. https://doi.org/10.1016/j.biortech.2017.05.160

Prakash J, Sharma R, Patel SKS, Kim IW, Kalia VC (2018) Bio-hydrogen production by co-digestion of domestic wastewater and biodiesel industry effluent. PLoS ONE 13:e0199059. https://doi.org/10.1371/journal.pone.0199059

Patel SKS, Gupta RK, Kondaveeti S, Otari SV, Kumar A, Kalia VC, Lee J-K (2020) Conversion of biogas to methanol by methanotrophs immobilized on chemically modified chitosan. Bioresour Technol 315:123791. https://doi.org/10.1016/j.biortech.2020.123791

Patel SKS, Kalia VC, Joo JB, Kang YC, Lee J-K (2020) Biotransformation of methane into methanol by methanotrophs immobilized on coconut coir. Bioresour Technol 297:122433. https://doi.org/10.1016/j.biortech.2019.122433

Banerjee A, Ghoshal AK (2016) Biodegradation of real petroleum wastewater by immobilized hyper phenol-tolerant strains of Bacillus cereus in a fluidized bed bioreactor. Biotech 6:137. https://doi.org/10.1007/s13205-016-0447-1

Costa AS, Romão LPC, Araújo BR, Lucas SCO, Maciel STA, Wisniewski A, Alexandre MR (2012) Bioresource Technology Environmental strategies to remove volatile aromatic fractions ( BTEX ) from petroleum industry wastewater using biomass. Bioresour Technol 105:31–39. https://doi.org/10.1016/j.biortech.2011.11.096

Imam A, Suman SK, Singh R, Vempatapu BP, Ray A, Kanaujia PK (2020) Application of laccase immobilized rice straw biochar for anthracene degradation. Environ Pollut 11582 https://doi.org/10.1016/j.envpol.2020.115827

Akhbarizadeh R, Moore F, Mowla D, Keshavarzi B (2018) Improved waste-sourced biocomposite for simultaneous removal of crude oil and heavy metals from synthetic and real oilfield-produced water. Environ Sci Pollut Res 25:31407–31420. https://doi.org/10.1007/s11356-018-3136-2

Kondaveeti S, Kim I-W, Otari S, Patel SKS, Pagolu R, Losetty V, Kalia VC, Lee J-K (2019) Co-generation of hydrogen and electricity from biodiesel process effluents. Int J Hydrogen Energy 44:27285–27296. https://doi.org/10.1016/j.ijhydene.2019.08.258

Patel SKS, Kumar P, Singh M, Lee J-K, Kalia, (2015) Integrative approach to produce hydrogen and polyhydroxybutyrate from biowaste using defined bacterial cultures. Bioresour Technol 176:136–141. https://doi.org/10.1016/j.biortech.2015.01.138

Patel SKS, Gupta RK, Kalia VC, Lee J-K (2021) Integrating anaerobic digestion of potato peels to methanol production by methanotrophs immobilized on banana leaves. Bioresour Technol 323:124550. https://doi.org/10.1016/j.biortech.2020.124550

Guo X, Zhan Y, Chen C, Sun S, Zhao L, Guo S (2015) Simultaneous bioelectricity generation and biodegradability improvement of refinery wastewater using microbial fuel cell technology. Desalin Water Treat 53:2740–2745. https://doi.org/10.1080/19443994.2014.931535

Mohanakrishna G, Abu-Reesh IM, Kondaveeti S, AI-Raoush RI, He Z, (2018) Enhanced treatment of petroleum refinery wastewater by short-term applied voltage in single chamber microbial fuel cell. Bioresour Technol 253:16–21. https://doi.org/10.1016/j.biortech.2018.01.005

Nasirpour N, Mousavi SM, Shojaosadati SA (2015) Biodegradation potential of hydrocarbons in petroleum refinery effluents using a continuous anaerobic-aerobic hybrid system. Korean J Chem Eng 32:874–881. https://doi.org/10.1007/s11814-014-0307-9

Hallenbeck PC, Ghosh D, Skonieczny MT, Yargeau V (2009) Microbiological and engineering aspects of biohydrogen production. Indian J Microbiol 49:48–59. https://doi.org/10.1007/s12088-009-0010-4

Purohit HJ (2019) Aligning microbial biodiversity for valorization of biowastes: conception to perception. Indian J Microbiol 59:391–400. https://doi.org/10.1007/s12088-019-00826-w

Kondaveeti S, Patel SKS, Pagolu R, Li J, Kalia VC, Choi M-S, Lee J-K (2019) Conversion of simulated biogas to electricity: sequential operation of methanotrophic reactor effluents in microbial fuel cell. Energy 189:116309. https://doi.org/10.1016/j.energy.2019.116309

Rehman K, Imran A, Amin I, Afzal M (2019) Enhancement of oil field-produced wastewater remediation by bacterially-augmented floating treatment wetlands. Chemosphere 217:576–583. https://doi.org/10.1016/j.chemosphere.2018.11.041

Sudarsan JS, Annadurai R, Subramani S, George RB (2016) Petrochemical wastewater treatment using constructed wetland technique. Pollut Res 35:727–732

Agarry SE, Oghenejoboh KM, Latinwo GK, Owabor CN (2020) Biotreatment of petroleum refinery wastewater in vertical surface-flow constructed wetland vegetated with Eichhornia crassipes: lab-scale experimental and kinetic modelling. Environ Technol 41:1793–1813. https://doi.org/10.1080/09593330.2018.1549106

Mustapha HI, Van Bruggen JJA, Lens PNL (2018) Fate of heavy metals in vertical subsurface flow constructed wetlands treating secondary treated petroleum refinery wastewater in Kaduna, Nigeria. Int J Phytoremediation 20:44–53. https://doi.org/10.1080/15226514.2017.1337062

Sudarsan JS, Subramani S, Rajan RJ, Shah I, Nithiyananantham S (2018) Simulation of constructed wetland in treating wastewater using fuzzy logic technique. JPhCS 1000:12137. https://doi.org/10.1088/1742-6596/1000/1/012137

Yang Q, Wu Z, Liu L, Zhang F, Liang S (2016) Treatment of oil wastewater and electricity generation by integrating constructed wetland with microbial fuel cell. Materials (Basel) 9:885. https://doi.org/10.3390/ma9110885

Wei M, Rakoczy J, Vogt C, Harnisch F, Schumann R, Richnow HH (2015) Enhancement and monitoring of pollutant removal in a constructed wetland by microbial electrochemical technology. Bioresour Technol 196:490–499. https://doi.org/10.1016/j.biortech.2015.07.111

Sarkar J, Roy A, Sar P, Kazy SK (2020) Accelerated bioremediation of petroleum refinery sludge through biostimulation and bioaugmentation of native microbiome. In: Emerging technologies in environmental bioremediation. Elsevier, pp 23–65. https://doi.org/10.1016/B978-0-12-819860-5.00002-X

Rajmohan KS, Chandrasekaran R, Varjani S (2020) A Review on occurrence of pesticides in environment and current technologies for their remediation and management. Indian J Microbiol 60:125–138. https://doi.org/10.1007/s12088-019-00841-x

Liu C, Zhang Y, Sun S, Huang L, Yu L, Liu X, Lai R, Luo Y, Zhang Z, Zhang Z (2018) Oil recovery from tank bottom sludge using rhamnolipids. J Pet Sci Eng 170:14–20. https://doi.org/10.1016/j.petrol.2018.06.031

Vemic M, Bordas F, Guibaud G, Lens PNL, Van-Hullebusch EDV (2017) Leaching and recovery of molybdenum from spent catalysts. In: Sustainable heavy metal remediation. Springer, New York, pp 207–239. https://doi.org/10.1007/978-3-319-61146-4_7

Srichandan H, Singh S, Blight K, Pathak A, Kim DJ, Lee S, Lee SW (2015) An integrated sequential biological leaching process for enhanced recovery of metals from decoked spent petroleum refinery catalyst: a comparative study. Int J Miner Process 134:66–73. https://doi.org/10.1016/j.minpro.2014.11.002

Srichandan H, Singh S, Pathak A, Kim DJ, Lee S-W, Heyes G (2014) Bioleaching of metals from spent refinery petroleum catalyst using moderately thermophilic bacteria: effect of particle size. J Environ Sci Heal Part A 49:807–818. https://doi.org/10.1080/10934529.2014.882211

Acknowledgments

The authors are grateful for the financial support by the Council of Scientific and Industrial Research (CSIR), New Delhi, India, under the project OLP-1094. INSPIRE fellowship of the first author from Department of Science and Technology, India is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations of competing interest

The authors declare no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised as affiliation 3 had incorrect information.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Imam, A., Kanaujia, P.K., Ray, A. et al. Removal of Petroleum Contaminants Through Bioremediation with Integrated Concepts of Resource Recovery: A Review. Indian J Microbiol 61, 250–261 (2021). https://doi.org/10.1007/s12088-021-00928-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-021-00928-4