Abstract

This study investigates an underlying mechanism by which manufacturing firms’ supplier relationship management facilitates the project success of their new product development (NPD). This study uses 292 responses collected from manufacturing firms to test the hypotheses driven by social exchange and organizational information processing theories. The findings suggest that a manufacturing firm’s trust relationship and IT use with its key suppliers promote NPD project success through their adaptability to changing needs and active involvement in NPD processes. Besides, the results reveal that the trust relationship with suppliers is more critical in facilitating supplier adaptability during the NPD processes than IT use with suppliers. This study contributes to the supplier relationship management study by clarifying underlying mechanisms through which trust relationships and IT use with suppliers influence NDP project success.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Achieving new product development (NPD) success is essential for manufacturing firms to maintain competitiveness and sustainable development in this innovative and competitive environment. To acquire expected NPD performance, the firms need to not only enhance internal technical capabilities but also leverage external resources and capabilities. Among external partners, suppliers have been increasingly viewed as an essential resource for reaching manufacturing firms’ operational-level outcomes (i.e., high quality, cost leadership, fast and reliable delivery) as well as strategic-level outcomes (i.e., sufficient flexibility, competitive capability, and technological knowledge) (Feng et al. 2010; Jean et al. 2014). In highly networked and collaborative business environments, collaborating with key suppliers in product development processes is very important for successful NPD projects (Luo et al. 2010; Melander and Lakemond 2015; Veloso and Fixson 2001; Johnson and Filippini 2010; Li and Chen 2019). However, although collaborating with suppliers provides some benefits, but also leads to crucial risk factors such as poor quality, increased transaction costs, opportunistic behaviors, increased dependency, and loss of innovative capabilities (Kang et al. 2012). Thus, a lack of proper supplier management approaches can result in unexpected supplier collaboration outcomes during product development. Supplier management typically includes firms’ formal control system for supplier selection, evaluation, and development (Lee et al. 2018).

Besides, supplier relationship management as a relational governance measure rather than contractual governance or a formal control system plays a more important role in dealing with a high degree of technology uncertainty and complexity of innovation practices by communication and interaction (Lee et al. 2017; Kang et al. 2021). Due to the resource limitations of most manufacturing firms, they cannot cover all the new product development projects relying exclusively on their internal activities and need to access and utilize the capabilities and knowledge of external partners. Researchers have also suggested that a firm’s long-term relationships with external partners such as key suppliers are necessary to conduct product development more efficiently and effectively by collaborating closely with them (Johnson and Filippini 2010; Wen et al. 2021; Petersen et al. 2005). However, despite its important role in innovation practices, previous studies on supplier relationship management have mainly focused on firm-level performance (e.g., competitive organizational performance and market performance) (Tseng 2014; Zhang et al. 2018; Huo et al. 2014; Yu 2015) and supply chain performance (e.g., procurement performance, sustainable supply chain performance, operational performance) (Wong et al. 2011; Sanders 2008; Tidy et al. 2016; Lee and Dawes 2005; Sertan and Sungmin 2007; Wei et al. 2012; Zhang and Huo 2013; Yu et al. 2021; Narasimhan et al. 2008). Little research has investigated supplier relationship management’s strategic role in promoting successful new product development. Specifically, there are research gaps in the literature concerning the underlying mechanisms by which supplier relationship management influences NPD project success.

In response to this research gap, this study classifies supplier relationship management into two primary categories (i.e., trust relationship and IT use with suppliers) to examine the underlying mechanisms that link relational supplier management to NPD project success. Specifically, among the external parties, committed suppliers are one of the important sources of necessary resources and knowledge when a manufacturing firm develops new products (Haakonsson and Kirkegaard 2016). In this study, supplier adaptability and involvement are assumed to mediate the relationship between supplier relationship management and the NPD project’s success. Thus, this study aims to answer the following two research questions: RQ1) Does supplier adaptability mediate the association between supplier relationship management (i.e., trust relationship and IT use with suppliers) and NPD project success? RQ2) Does supplier involvement mediate the association between supplier relationship management (i.e., trust relationship and IT use with suppliers) and NPD project success?

By answering these research questions, this study attempts to supplement the existing research on supplier relationship management and provide valuable insights into how manufacturing firms manage supplier relationships and utilize their key suppliers’ capabilities to promote NPD project success.

2 Theory and hypothesis development

2.1 Trust relationship with suppliers

The increasing number of various forms of inter-organizational relationships in the current dynamic environment has sparked an interest among academics and practitioners in identifying certain critical success factors in governing such relationships effectively and efficiently (Miao et al. 2018; Zaheer et al. 1998; Das and Teng 1998; Wagner et al. 2011). One of the most critical factors is trust in addressing the operation and coordination of activities between exchanging parties (Min et al. 2007; Zaheer et al. 1998; Ganesan 1994). Trust is viewed as one party’s confidence in the counter partner’s integrity, credibility, and benevolence in an exchange relationship, wherein a certain level of risk is involved (Das and Teng 1998; Ganesan 1994). The establishment of trust encourages exchanging partners to (1) discharge genuine information (Um and Kim 2019; Um and Oh 2020), (2) derive benefits from a relationship in an equitable manner (Palmatier et al. 2007, Cropanzano and Mitchell 2005), (3) show favorable motives and intentions to an ongoing relationship (Siguaw et al. 1998), and (4) exhibit a long term orientation (Chen et al. 2011). This study applies the aforementioned advantages to our current research setting, where trust plays a key role in persuading suppliers, influencing their attitudes, and eventually establishing a long-term relationship.

Inter-organizational trust shapes and carries expectations of greater flexibility, the willingness to collaborate, and resource and information sharing (Narasimhan et al. 2008). From the manufacturing firm’s point of view, on the one hand, its trust determines its supplier’s perceptions about the manufacturer’s capabilities and intentions (Ganesan 1994) and encourages the suppliers to engage in more open and honest information sharing based on the belief that the shared information will not act against them (Zaheer et al. 1998; Wagner et al. 2011). From the supplier’s point of view, on the other hand, the manufacturing firm’s trust cultivates the long-term orientation of the supplier in that the suppliers’ concern about the manufacturing firm’s opportunistic behaviors is mitigated and that the suppliers’ belief is formed that short-term inequities will be alleviated over a long period. Therefore, based on previous arguments, the extent to which a manufacturing firm develops trust with its key suppliers is likely to affect its suppliers’ perception of the exchange relationship. In other words, suppliers would likely consider showing genuine commitment and efforts and making long-term idiosyncratic investments if the manufacturing firm is deemed trustworthy. In line with previous findings (Min et al. 2007; Siguaw et al. 1998), this study conceptualizes the trust relationship with suppliers as the extent to which a manufacturing firm is deemed reputable, reliable, trustworthy, and open to its suppliers.

2.2 IT use in the supply chain

According to the information processing theory, organizations build information processing capabilities to cope with uncertainty and increased information needs (Premkumar et al. 2005). A firm can improve information flow and reduce uncertainty within an organization by implementing an integrated information system and creating better information flow with supply chain partners. Thus, information technology can make a substantial impact when it is used in the supply chain. Sharing accurate and timely information with supply chain partners using IT can significantly improve a focal firm’s performance. Better information sharing between a firm and suppliers enables it to identify risks in its supply chain (Narkhede et al. 2013). Prior literature on supply chain information integration has acknowledged that the adoption of and connection of information technology to supply chain members result in several benefits (Cai et al. 2010; Devaraj et al. 2007; Narasimhan and Kim 2001). First, IT usage in the supply chain facilitates the flows of production and inventory that need to be shared among supply chain partners to maintain the production schedule (Devaraj et al. 2007; Lee et al. 2007). Second, IT enables supply chain members to effectively manage supply chain activities that are highly interrelated by providing real-time information (Chen and Paulraj 2004; Klein 2007). Third, IT usage promotes responsiveness, visibility, real-time information sharing, communication, and coordination among supply chain partners beyond the temporal and geographical constraints, generating better partnership structures (Holweg and Pil 2008).

Given the growing complexity of the business environment, a firm can transfer and share its information through IT use and achieve virtual integration with its supply chain partners (Cao et al. 2017). Supply chain integration using IT positively impacts supply chain service capabilities, enhancing operational and market performance through efficient and effective collaboration between supply chain partners (Yang 2016). In this way, IT use with suppliers also increases manufacturer-supplier information sharing and improves supply chain collaboration and integration (Mathu 2019). Eventually, it enables a manufacturer to access suppliers’ resources and capabilities, resulting in positive outcomes such as inter-firm collaboration, operational efficiency, and innovation performance.

2.3 Supplier adaptability and involvement in NPD projects

Adaptability in strategic management refers to a quick response to changing market needs and technological environments (Weigelt and Sarkar 2012). Given the strategic importance of adaptability, supply chain researchers viewed adaptability as an essential factor of dynamic supply chain capabilities (Aslam et al. 2018) and also introduced the concept of the triple-a supply chain that encompasses supply chain agility, adaptability, and alignment (Sheel and Nath 2019; Ketchen and Hult 2007) addressed supply chain adaptability as “a willingness to reshape supply chains when necessary” and similarly, Ketchen and Hult (2007) defined it as the “ability to respond to long-term and structural changes to supply, demand, and business environment.” As an extension of the previous studies, supplier adaptability in this study refers to suppliers’ ability to quickly respond to buyers’ short notice and willingness to adjust their processes and products to meet buyers’ changing needs.

Supplier involvement in a focal firm’s NPD projects may range from giving simple suggestions on design ideas to being fully responsible for the complete development of components or sub-assembly (Wynstra and Pierick 2000; Petersen et al. 2005). Previous studies suggested the positive role of supplier involvement in NPD projects (Ragatz et al. 1997; Bidault et al. 1998a; Afuah 2000) and also emphasized that supplier involvement is more influential at the early design stage in the NPD process (Song and Di Benedetto 2008; Bidault et al. 1998b; Petersen et al. 2005). Given the critical role of supplier involvement in the early stage of NPD, its concept in this study refers to the extent to which key suppliers are involved in a manufacturer’s early design stage of new products by providing necessary resources and knowledge.

2.4 The effects of trust relationship on supplier adaptability and involvement

Trust facilitates cooperative behavior and beneficial relational exchange (Morgan and Hunt 1994; Moorman et al. 1992; Saeki and Horak 2014) and promotes inter-organizational cooperation (Anderson and Narus 1984). When conceptualized as a determinant of joint performance, trust aids in enhancing collaboration, reducing transaction costs, improving capability, and increasing strategic flexibility (Fawcett et al. 2012; McAllister 1995).

Leveraging theory from the social exchange literature, this study examines how a manufacturing firm’s trust influences supplier adaptability and involvement, respectively. The social exchange theory focuses on the relational aspects of organizational context in addressing the dynamic nature of relationships between organizations (Cropanzano and Mitchell 2005). The trust embedded between the exchange partners will positively impact the partners’ desire and ability to cope with a changing environment (Young-Ybarra and Wiersema 1999). Accordingly, trust plays a crucial role in developing and maintaining relationships because it encourages a sense of cooperation and beneficial reciprocity in an exchange (Young-Ybarra and Wiersema 1999; Moorman et al. 1992). When the concept of trust is applied to inter-organizational contexts such as partnerships, buyer-supplier relationships, and strategic alliances, trust proves to play a critical role in facilitating cooperation, minimizing transaction costs, improving capability, and increasing strategic flexibility (Morgan and Hunt 1994; McAllister 1995; Moorman et al. 1992).

Based on the previous findings, we propose two hypotheses. First, we anticipate that the trust relationship with suppliers determines the extent to which supplier adaptability is enhanced. Prior literature on inter-organizational relationships has revealed that trust-based relationships between exchange parties positively impact the partners’ ability to cope with the turbulent and dynamic business environment, respond to changing environmental demands, and adjust to unanticipated events (Lorenz 1999; Mody 1993). The trust that a manufacturing firm establishes for its suppliers motivates them to actively meet the firm’s requirements (Liao et al. 2010). The rationale behind this mechanism can be explained by social exchange theory. Social exchange theory emphasizes that social exchange is featured by mutual obligations that are often not stipulated (Bandura 1986). Successful and stable relationships can be achieved if both exchange parties perceive them as positive through a cost-benefit analysis (Cropanzano and Mitchell 2005). If an exchange is perceived to be beneficial, both parties are likely to stay longer in the exchange and commit themselves to the relationship. In this case, trust is crucial for stable and long-term relations. Applying the theoretical lens to our research settings, we argue that the evidence that a manufacturing firm is perceived to be trustworthy motivates the suppliers to commit themselves to the ongoing exchange with the manufacturing firm. As a result, the manufacturing firm can increase the ability and willingness of the suppliers to meet the manufacturer’s requests, whether specified or unspecified, as long as the suppliers consider the exchange to be economically and socially beneficial (Cropanzano and Mitchell 2005). In this sense, trust acts as effective social persuasion, which shapes the supplier’s efficacy belief (Tierney and Farmer 2002). The suppliers are more likely to make an idiosyncratic investment (i.e., supplier adaptability) in the exchange with the manufacturing firm when the firm is perceived as professional in the field, reliable, and trustworthy (Zaheer et al. 1998; Das and Teng 1998). Leveraging from social exchange theory, we argue that a manufacturing firm can effectively put forward higher requirements on the adaptability of the suppliers by using trust. As an effective means of social persuasion, trust can instill a “can do” attitude in the supplier (Liao et al. 2010). Thus, we propose the following hypothesis that.

Hypothesis 1

Trust relationship with suppliers will be positively associated with supplier adaptability.

Second, this study proposes that the trust relationship with suppliers determines supplier involvement. Again, social exchange theory postulates that one party’s attitude and behavior in an exchange with the other can be shaped by calculating the rewards and costs through the interactions (Bandura 1986; Liao et al. 2010). The relationship ends if the costs outweigh the rewards. To maintain exchanges, exchange parties must show unspecified obligation and reciprocity: otherwise, the exchanges tend to be terminated. If exchange parties fail to obey the rules of reciprocity, they will be isolated from social relationships (Blau, 1964; Cropanzano and Mitchell 2005). Applying the social exchange perspective to our research setting, we argue that if manufacturing firms put more effort into building a trust-based relationship with suppliers, they are more likely to consider the involvement of their suppliers in the early design stage of new products. From the manufacturing firm’s point of view, the efforts that the manufacturing firm exerts to develop trust with the suppliers form an “expectation of reciprocity”. Due to the expectation of reciprocity, the manufacturing firm expects that the suppliers produce value for the firm in return when they are involved in the manufacturing processes (Walter 2003). In addition, social exchange theory also views that the pie of rewards is distributed fairly and equitably (Chen et al. 2011). When the account is applied to our hypothesis, this evidence persuades the manufacturing firm to involve their suppliers in the manufacturing processes in the hope that the opportunistic behaviors of the suppliers are minimized, and the genuine cooperative behaviors of the suppliers are promoted in return: otherwise, the relationship between the manufacturing firm and suppliers would be no longer beneficial. Therefore, it is hypothesized that:

Hypothesis 2

Trust relationship with suppliers will be positively associated with supplier involvement.

2.5 The effects of IT use with suppliers on supplier adaptability and involvement

IT use with suppliers refers to the extent to which manufacturing firms use IT to communicate with their primary suppliers for daily operation and understanding market trends. Prior research on supplier management has highlighted the importance of adopting information technology in supply chain collaboration (Devaraj et al. 2007; Cai et al. 2010; Kembro et al. 2014). From the view of information processing theory, information processing capabilities obtained from IT use with suppliers can reduce uncertainties by promoting information sharing, further influencing manufacturer-supplier relationship quality and collaboration (Premkumar et al. 2005). Thus, this study proposes that a manufacturing firm’s IT use with its key suppliers positively impacts supplier adaptability and involvement.

In today’s dynamic business environments, the suppliers should be adaptable to meet customers’ changing needs (Stevenson and Spring 2007). IT use with suppliers provides real-time information on the production and inventory status as well as effective communication and coordination (Chen and Paulraj 2004; Holweg and Pil 2008; Prajogo and Olhager 2012), which enables suppliers to respond to a manufacturer’s short notice and changing needs more quickly. It also provides suppliers with market information, allowing them to make effective decisions and adjust their processes and products to address changing environments (Gurzawska 2020; Yang et al. 2022). In addition, previous studies point out that information asymmetry hinders suppliers’ adaptation (Barbaroux 2014; Stiglitz 2000). Information asymmetry is regarded as one of the major sources of supply chain disruptions because it impacts the quality of innovative goods and services and distracts the process of assigning resources efficiently (Barbaroux 2014). Information asymmetry may make it difficult for suppliers to quickly adjust their processes and products to meet manufacturers’ demands. IT use with suppliers can help them cope with the problem of information asymmetry by increasing the speed of information flow and extending the scope of information flow among supply chain partners, which allows suppliers to be adaptable to a manufacturer’s changing needs. With the information sharing through IT use, suppliers’ willingness to adapt to the changing market may also increase, as manufacturers demonstrate commitment by opening access to their own data and information. Thus, this study hypothesizes that IT use with suppliers is a positive relationship with supplier adaptation.

Hypothesis 3

IT use with suppliers will be positively associated with supplier adaptability.

On the other hand, as IT use with suppliers improves the flow of information and the quality of information between companies, suppliers can more efficiently involve themselves in a manufacturer’s new product development process (Handfield et al. 1999). Besides, a manufacturer involves key suppliers in its NPD projects to access their knowledge and specific technological know-how (Johnsen 2009). However, the increasing complexity of NPD projects requires various information flow as well as formal and informal interactions. (Lee et al. 2017). Information processing theory also emphasizes that the greater the complexity, the greater the amount of information that should be processed between partners during projects to achieve desired performance (Premkumar et al. 2005). Thus, partnering with suppliers to design new products leads to greater difficulty and even higher coordination costs. IT use with suppliers promotes information exchange about product features, design specifications, and functions, thereby helping overcome the difficulty of involving suppliers in product development processes. Information sharing through IT may also motivate suppliers to work with manufacturers more closely and seek better understanding of the changing market and customers’ needs when designing new products, thus forming better synergies between the two players. Thus, IT use with suppliers may be an important antecedent for implementing supplier involvement.

Hypothesis 4

IT use with suppliers will be positively associated with supplier involvement.

2.6 The effects of supplier adaptability and involvement on NPD project success

In such a volatile and competitive environment, suppliers are an increasingly important resource for manufacturers. Successful manufacturer-supplier collaboration during the NPD process results in competitive advantage (Handfield et al. 1999; Yan and Dooley 2014). Previous studies revealed potential benefits from supplier integration in NPD led to reduced cycle time, reduced errors, increased cash-flow rate, significant reductions in cost, quality improvements, technological improvements, financial support, and innovative new designs (Handfield et al. 1999; Clark 1989).

As part of the Triple-A supply chain, performance outcomes of adaptability have also been highlighted (Dubey et al. 2018; Lee 2004; Eckstein et al. 2015) suggest that supply chain adaptability is the capability that influences the long-term sustainability of a firm’s competitive advantage. Supplier adaptability is associated with suppliers’ ability and willingness to analyze the manufacturer’s needs and adjust their processes and products to meet its changing needs (Ketchen and Hult 2007). Supplier adaptability focuses on identifying new markets and changes in customer needs and maintaining alertness to technological and product life cycles (Lee 2004). Adaptability enables a supplier to adapt to the increased rate of structural changes in the current business landscape. Such structural changes may stem from fundamental shifts in supply, demand, and the business environment (Gligor et al. 2020). Supplier adaptability may also help manufacturers quickly change new product designs per market requirements (Sheel and Nath 2019) and modify strategies to launch new products or break into new markets (Lee 2004). Over the long term, supplier adaptability plays a significant role in developing manufacturer-supplier relations (Ford 1984). All these arguments lead to our fifth hypothesis:

Hypothesis 5

Supplier adaptability will be positively associated with NPD project success.

As an inter-organizational knowledge-sharing process, involvement in the NPD projects benefits the manufacturing firm and its suppliers. Supplier involvement in NPD projects can be characterized by the responsibility suppliers assume, the activities they perform, and the resources they supply, all of which are influenced by the task they are asked to carry out (Laursen and Andersen 2016). Suppliers’ design involvement can help select and supply the best components and technologies in the early design stages, identify potential problems and solutions earlier, and make the appropriate investments in equipment, tools, and training where necessary (Maloni and Benton 1997). Suppliers’ technical capabilities and responsiveness for the product design can reduce development costs and time, minimize the possibility of design errors, and improve product quality (Song and Di Benedetto 2008; Ragatz et al. 1997). The specific benefits from outside suppliers may provide include: (1) lower-priced materials and services; (2) higher delivery performance; (3) innovative products or technologies; (4) better information; (5) technological risk sharing; (6) shared capital investment; (7) joint problem-solving efficiency; (8) cross-learning and successful technology commercialization (Handfield et al. 1999; Zahra and Nielsen 2002; Claro et al. 2003; Tracey and Leng Tan 2001). Therefore, involving suppliers in product development facilitates the achievement of broader benefits, such as enhanced technological capabilities (Cousins and Lawson 2007) and extended social networks considering suppliers sit at the intersection of many firms and ties to different parts of the social system (Feng et al. 2010). Thus, we advance the following hypothesis:

Hypothesis 6

Supplier involvement will be positively associated with NPD project success.

2.7 The mediating role of supplier adaptability and involvement

This study anticipates that manufacturing firms can take advantage of the establishment of trust with their key suppliers because inter-organizational trust plays an important role in improving performance (i.e., NPD project success). In addition to the direct effect of trust on NPD project success, this study also predicts that trust may trigger supplier adaptability and involvement from the social exchange perspective. Thus, combining H1, H2, H5, and H6 with previous findings and theoretical evidence, we seek to examine whether the expected positive effect of a trust relationship with suppliers on NPD project success can be achieved through supplier adaptability and involvement. Thus, we suggest the following hypotheses:

Hypothesis

a,b: Supplier adaptability (a) and involvement (b) will mediate the relationship between trust relationship with suppliers and NPD project success.

In addition, according to the arguments of Hypothesis3, 4, 5, and 6, IT use with suppliers helps reduce the uncertainty and complexity of NPD projects by promoting information sharing, thereby facilitating supplier adaptability and involvement that further positively influences NPD project success. Thus, we suggest the following hypotheses:

Hypothesis

a,b: Supplier adaptability (a) and involvement (b) will mediate the relationship between IT use with suppliers and NPD project success.

3 Methods and results

3.1 Data collection and measurement

We used the data collected from the fourth round of the High-Performance Manufacturing (HPM) international project to test our hypotheses. This project was conducted by a worldwide research network and focused on collecting survey data from manufacturing firms. The initial survey questionnaires were developed in English and were translated into a country-specific language. Then, they were back-translated into English to verify the accuracy of the translation. In the 15 countries and regions, the research team collected data from manufacturing plants in three industries (i.e., (machinery, electronics, and transportation). Among these industries, the plants with more than 100 employees were contacted using a random sampling approach. The plant coordinators who agreed to participate in the HPM survey project received our questionnaires and collected data sets. In order to enhance measurement reliability, each questionnaire was administered to different respondents who were the most knowledgeable informants in the appropriate department. For instance, supplier-related survey items were answered by upstream supply chain management managers, and a firm’s strategic performance, such as NPD success, was answered by the top management team, such as plant managers. In addition, all the survey items were answered by two informants at the designated department. After collecting the data, the regional project coordinator averaged the responses from the two informants to generate a single score per survey item. Then, 330 responses in those 15 countries and regions were collected. After dropping 38 samples with over 20% missing data and replacing the rest of the missing values with the average value of the attribute, 292 responses were used in our analysis. Table 1 shows the sample number information for each industry. Table 2 presents the sample characteristics with the information of firm size (i.e., employee number), firm age (i.e., the years since incorporation), and Six Sigma (i.e., the years since the implementation of Six Sigma).

To measure trust relationship with suppliers, three items were adapted from Min et al. (2007) by focusing on reliability, reputation, and openness. IT use with suppliers was measured by using four items according to Subramani (2004). The informants were asked to indicate the extent to which they use IT to communicate with their primary suppliers. Based on the work of Hallén et al. (1991), the three items for supplier adaptability were used to measure key suppliers’ ability to quick response and willingness to adapt their processes and products to meet the focal firm’s changing needs. The measurements of the above variables (i.e., trust relationship with suppliers, IT use with suppliers and supplier adaptability) were conducted by surveying manufacturing firms’ upstream supply chain management managers. For supplier involvement, four items were adopted from Luo et al. (2010) by focusing on the level of suppliers’ partnership and collaboration in the new product development. The major informants for supplier involvement were product development manager, product engineer, product designer, or product development team leader. According to Suurmond et al. (2020), five items were utilized to measure the NPD project success. The plant managers or chief operation officers familiar with firm-level performance were asked to evaluate how successfully they achieved NPD goals, including NPD project effectiveness (i.e., market and commercial success) and efficiency (i.e., time to market and technical performance). All items for major constructs were measured on a 5-point Likert scale and presented in Appendix 1. The data for independent and dependent variables were collected from multiple sources. This procedural remedy minimized the potential of common method variance (CMV) (Podsakoff et al. 2003).

In addition, several control variables (e.g., firm size, firm age, R&D investment, Six Sigma, industry) were included in our analysis. The firm size was measured by the natural logarithm of the number of employees, while firm age was measured by the number of years since incorporation. The R&D investment was measured by the percentage of sales spent on R&D relative to leading competitors. Because Six Sigma usage can influence overall firms’ operations, we included it as a control variable by measuring the years since a firm started implementing Six Sigma. We also controlled industry effects to reduce sample heterogeneity by using two industry dummies (i.e., machinery and electronics, with transportation as the baseline group).

3.2 Construct validity

According to the process suggested by Brahma (2009), we tested construct validity by testing unidimensionality, reliability, convergent, and discriminant validity. Firstly, we assessed unidimensionality and reliability. The results of exploratory factor analysis (EFA) showed that all the items have high loading (greater than 0.5) on their intended constructs, indicating unidimensionality of each construct. Besides, the coefficients alpha of all the constructs ranged from 0.725 to 0.856 (see Table 3), indicating good reliability of the measurement items. Then, a confirmatory factor analysis (CFA) and average variance extracted (AVE) were conducted to test convergent and discriminant validity. The results of CFA showed that the fit of the measurement model was acceptable (DMIN/DF = 1.470, GFI = 0.928, IFI = 0.967, TLI = 0.960, CFI = 0.967, RMSEA = 0.040). Table 3 showed that the values of factor loadings ranged from 0.549 to 0.857, which indicates acceptable convergent validity. Discriminant validity is supported if the AVE for each construct is greater than the squared correlations between constructs. Tables 3 and 4 show the value of AVE and inter-construct correlations. The AVE values are higher than the corresponding squared correlation coefficient, providing evidence of discriminant validity.

3.3 Results

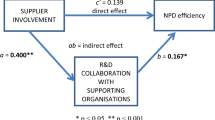

This study used the structural equation modeling (SEM) method to test the proposed hypotheses. The model fit indices for the structural model provided evidence of an acceptable fit (DMIN/DF = 1.637. GFI = 0.891, IFI = 0.926, TLI = 0.916, CFI = 0.925, RMSEA = 0.047). Figure 1; Table 5 present the results of SEM. The results show that the trust relationship with suppliers is positively associated with supplier adaptability (path coefficient = 0.535, p < 0.001) and supplier involvement (path coefficient = 0.271, p < 0.001), supporting Hypotheses 1 and 2. Also, the effects of IT use with suppliers on supplier adaptability (path coefficient = 0.251, p < 0.001) and supplier involvement (path coefficient = 0.142, p < 0.05) are positively significant, which supports Hypotheses 3, and 4. Furthermore, the results showed that both supplier adaptability (path coefficient = 0.228, p < 0.01) and supplier involvement (path coefficient = 0.319, p < 0.001) are positively associated with NPD project success, supporting Hypotheses 5 and 6.

We further conducted the posthoc analyses. Using the critical ratios for differences technique, we attempted to test whether the effects of a trust relationship with suppliers and IT use with suppliers are significantly different. The results indicated that a trust relationship with suppliers has a stronger effect on supplier adaptability than IT use with suppliers does so (with statistically significant differences at the 0.05 level, z-score=-2.433). However, the results showed non-statistically significant differences at the 0.05 level (z-score = 1.147) when comparing the effects of a trust relationship with suppliers and IT use with suppliers on supplier involvement.

Lastly, we tested the indirect mediation effect of supplier adaptability and involvement in the relationship between supplier relationship management (i.e., trust relationship and IT use with suppliers) and NPD project success. A path analysis using a multi-mediation model was conducted by AMOS 26 software. The bootstrap results in Table 6 show that all the confidence intervals do not exclude zero, indicating that the four paths of indirect effects are statistically significant and supporting Hypotheses 7a,b, and 8a,b. In other words, trust relationships and IT use with suppliers can indirectly influence NPD project success via supplier adaptability and involvement.

4 Discussions

4.1 Theoretical implications

In the manufacturer-supplier relationship, this study demonstrates the underlying mechanism that explains the effect of supplier relationship management (i.e., trust relationship and IT use with suppliers) on NPD project success. Previous studies have investigated the benefits of supplier relationship management for enhancing supply chain performance, firm competitive performance, and market performance (Tseng 2014; Zhang et al. 2018; Yu 2015; Wong et al. 2011; Sanders 2008; Tidy et al. 2016; Lee and Dawes 2005; Sertan and Sungmin 2007; Yu et al. 2021). The supply chain integration literature also emphasized that supplier integration plays an important role in promoting a manufacturer’s operational performance (Danese and Romano 2011; Zhang et al. 2018; Kim 2013) and also in enhancing its innovation performance (Hertenstein and Williamson 2018; Thomas 2013; Petersen et al. 2005). However, little research has been done into the indirect mediating mechanisms that link supplier relationship management and NPD project success. Focusing on the mediating role of supplier adaptability and involvement in the relationship between supplier relationship management and NPD, this study sheds light on how manufacturers apply supplier relationship management for successful NPD projects.

First, the findings of this study reveal that a manufacturer’s trust relationships with key suppliers indirectly improve NPD project success by promoting supplier adaptability and involvement. Previous literature on inter-organizational relationships emphasized that trust is essential to partners’ committed partnership and collaboration outcomes (Morgan and Hunt 1994; Narasimhan et al. 2008). According to the social exchange theory, trust in the inter-firm relationship influences partners’ attitudes and behavior and motivates them to commit to the exchange relationship because they can perceive the relationship as a mutually beneficial one (Bandura 1986; Liao et al. 2010). In a similar way, our findings show that a manufacturer’s effort to build a trust relationship with its key suppliers helps them commit to the collaboration with the manufacturer, involve themselves in the NPD process, and adapt their products or processes to meet its changing needs. In other words, the trust relationship with suppliers is a necessary antecedent for promoting supplier adaptability and involvement that further positively influences NPD project success.

Second, our findings reveal that a manufacturer’s IT use with suppliers indirectly improves the NPD project success by promoting supplier adaptability and involvement. Given the increasing market and technology uncertainty and product complexity, NPD projects increasingly require a great amount of information to be processed with external partners. Information processing theory suggests that firms must build information processing capabilities to overcome such uncertainty, complexity, and increased information needs (Premkumar et al. 2005). Our findings also show that IT use with suppliers is useful for promoting supplier adaptability and involvement in NPD projects by enhancing information processing capabilities. A manufacturer’s IT use with suppliers reduces NPD projects’ uncertainty by facilitating the flow of quality information about its daily operation processes, changing needs, design specifications, and market trends (Peng et al. 2014). Thus, IT use with suppliers enable them to adjust their processes and to involve in the manufacturer’s NPD project more efficiently, subsequently enhancing its NPD project success. Our findings demonstrate that IT use with suppliers is an important antecedent for promoting supplier adaptability and involvement in the processes of successful NPD projects.

Lastly, one interesting finding reveals that according to the path coefficient values in our analysis, a trust relationship with suppliers has a more statistically significant positive impact on supplier adaptability than IT use with suppliers. However, a statistically significant difference is not found when comparing the effects of the trust relationship and IT use with suppliers on supplier involvement. From the supplier’s perspective, adapting their processes and products according to a manufacturer’s changing requires time, personnel resources, and even financial investment (Schoenherr and Swink 2015). Supplier adaptation is not cost-free and requires substantial effort. Thus, without trust in a manufacturer, suppliers might be unwilling to adapt them to its needs. In general, trust is required when incomplete contracting exists because neither party can rely on contractual mechanisms completely to manage the relationship (Nyaga et al. 2010). The trust relationship with suppliers eliminates objective risks and improves both partners’ self-enforcement, leading to integration and reducing transaction costs and opportunism in collaboration. Therefore, trust relationship with suppliers may be a more critical enabler of supplier adaptability than IT use with suppliers. In other words, suppliers can actively commit themselves to adapting to the manufacturer’s changing needs during the NPD projects, especially under the confidence of mutual trust and long-term business relationships.

In sum, our findings suggest that supplier involvement and adaptability help explain the underlying mechanisms linking supplier relationship management (i.e., trust relationship and IT use with suppliers) to NPD project success. In addition, cultivating a trusting relationship with suppliers can be a more meaningful foundation for supplier adaptability than IT use with suppliers, further enhancing NPD project success.

4.2 Managerial implications

The findings of this study also provide some managerial implications for supplier relationship management in NPD projects. Our findings show that trust relationship and IT use with suppliers are critical in advancing manufacturers’ NPD performance. Often, manufacturers focus on formal supplier selection and evaluation approaches to maximize supplier performance in terms of cost, quality, and delivery. Although such approaches can provide operational and economic benefits, they are not enough for NPD project success. A manufacturing firm should pay close attention to building a trusting relationship with key suppliers in the context of NPD to maintain long-term collaborative relationships and motivate their active contribution to its NPD projects. In addition, manufacturers’ relationship with suppliers has been increasingly based on information exchange by IT usage. In the NPD context, a manufacturer needs to actively apply IT with its key suppliers to facilitate information flow and overcome NPD project uncertainty and complexity.

Further, manufacturers need to understand the intervention role of supplier adaptability and involvement in the relationship between supplier relationship management and NPD project success. By carefully understanding and promoting suppler adaptability and involvement, a manufacturer can leverage supplier relationship management more efficiently for successful NPD projects. Especially given the increasing complexity of products and demanding customer requirements, greater supplier adaptability is required during NPD projects. When a manufacturer needs to advance NPD performance specifically through supplier adaptability, it is more effective and useful to focus on cultivating trusting relationships with its key suppliers.

5 Conclusion

The role of suppliers during the new product development processes is increasingly important in this highly networked and interdependent business context. This study provides valuable insights into leveraging supplier relationship management for successful NPD projects. The findings of this study emphasize that to improve the success of NPD, manufacturers should adopt appropriate supplier relationship management (i.e., trust relationship and IT use with suppliers) to motivate suppliers to involve in NPD projects and actively adapt practices to manufacturers changing needs. Although the results of this study provide some useful insights into the role of supplier relationship management in NPD projects, it also has some limitations and opportunities for further research.

First, the results of this study rely on the cross-sectional analysis method that requires model parameters to be constant across firms and over time. However, since NPD processes are not static but dynamic and uncertain, the appropriate supplier relationship management approaches and supplier adaptability and involvement level may vary at the different stages of NPD processes. Thus, future research would benefit from conducting longitudinal qualitative studies by observing real contexts of supplier relationships during the NPD project processes.

Second, another limitation is related to the measurement of NPD project success. Our research mainly measured NPD success by focusing on NPD effectiveness (e.g., customer satisfaction and market share), NPD efficiency (e.g., time to market), and technical performance. However, the concept of NPD performance is highly complicated and multi-dimensional and may not be accurately represented by a single dimension. Thus, it would be interesting to adopt multi-dimensional performance measurement for NPD success (e.g., NPD effectiveness and efficiency, financial performance, product performance, and innovativeness) to evaluate NPD success more broadly and accurately.

Lastly, this study examines the indirect effects of supplier adaptability and involvement on the relationship between supplier relationship management and NPD success. However, these indirect effects may be dependent on various environmental contexts. The effectiveness of supplier relationship management may be moderated by contingency factors such as product complexity, technological uncertainty, market uncertainty, and different stage of the NPD process. Further consideration of such contingency factors may provide a more meaningful way of examining the relationship between supplier relationship management and NPD success.

References

Afuah A (2000) “How much do your co-opetitors’ capabilities matter in the face of technological change?“. Strateg Manag J 21(3):397–404

Anderson JC, Narus JA (1984) “A model of the distributor’s perspective of distributor-manufacturer working relationships”. J Mark 48(4):62–74

Aslam H, Blome C, Roscoe S, Azhar TM (2018) “Dynamic supply chain capabilities”. Int J Oper Prod Manage 38(12):2266–2285

Bandura A (1986) “The explanatory and predictive scope of self-efficacy theory”. J Soc Clin Psychol 4(3):359–373

Barbaroux P (2014) “From market failures to market opportunities: managing innovation under asymmetric information”. J Innov Entrepreneurship 3(1):1–15

Bidault F, Despres C, Butler C (1998a) “The drivers of cooperation between buyers and suppliers for product innovation”. Res Policy 26:7–8

Bidault F, Despres C, Butler C (1998b) “New product development and early supplier involvement (ESI): the drivers of ESI adoption”. Int J Technol Manage 15(1–2):49–69

Brahma SS (2009) “Assessment of construct validity in management research”. J Manage Res 9(2):59–71

Cai S, Jun M, Yang Z (2010) “Implementing supply chain information integration in China: The role of institutional forces and trust”. J Oper Manag 28(3):257–268

Cao Q, Schniederjans DG, Schniederjans M (2017) “Establishing the use of cloud computing in supply chain management”. Oper Manage Res 10(1):47–63

Chen IJ, Paulraj A (2004) “Towards a theory of supply chain management: the constructs and measurements”. J Oper Manag 22(2):119–150

Chen Z, Huang Y, Sternquist B (2011) “Guanxi practice and Chinese buyer–supplier relationships: The buyer’s perspective”. Ind Mark Manage 40(4):569–580

Clark KB (1989) “Project Scope and Project Performance: The Effect of Parts Strategy and Supplier Involvement on Product Development”. Manage Sci 35(10):1247–1263

Claro DP, Hagelaar G, Omta O (2003) “The determinants of relational governance and performance: How to manage business relationships?“. Ind Mark Manage 32(8):703–716

Cousins PD, Lawson B (2007) “The Effect of Socialization Mechanisms and Performance Measurement on Supplier Integration in New Product Development”. Br J Manag 18(3):311–326

Cropanzano R, Mitchell MS (2005) “Social exchange theory: An interdisciplinary review”. J Manag 31(6):874–900

Danese P, Romano P (2011) “Supply chain integration and efficiency performance: a study on the interactions between customer and supplier integration”. Supply Chain Management: An International Journal 16(4):220–230

Das T, Teng B (1998) “Between trust and control: developing confidence in partner cooperation in alliances”. Acad Manage Rev 23(3):491–512

Devaraj S, Krajewski L, Wei JC (2007) “Impact of eBusiness technologies on operational performance: the role of production information integration in the supply chain”. J Oper Manag 25(6):1199–1216

Dubey R, Altay N, Gunasekaran A, Blome C, Papadopoulos T, Childe SJ (2018) “Supply chain agility, adaptability and alignment”. Int J Oper Prod Manage 38(1):129–148

Eckstein D, Goellner M, Blome C, Henke M (2015) “The performance impact of supply chain agility and supply chain adaptability: the moderating effect of product complexity”. Int J Prod Res 53:9–10

Fawcett SE, Jones SL, Fawcett AM (2012) “Supply chain trust: The catalyst for collaborative innovation”. Bus Horiz 55(2):163–178

Feng T, Sun L, Ying Z (2010) “The effects of customer and supplier involvement on competitive advantage: An empirical study in China”. Ind Mark Manage 39(8):1384–1394

Ford D (1984) “Buyer/seller relationships in international industrial markets”. Ind Mark Manage 13(1):101–112

Ganesan S (1994) “Determinants of long-term orientation in buyer-seller relationships”. J Mark 58(2):1–19

Gligor D, Feizabadi J, Goldsby TJ, Maloni MJ, Russo I (2020) The triple-a supply chain and strategic resources: developing competitive advantage”. Int J Phys Distribution Logistics Manage 50(2):159–190

Gurzawska A (2020) “Towards responsible and sustainable supply chains–innovation, multi-stakeholder approach and governance”. Philos Manage 19(3):267–295

Haakonsson SJ, Kirkegaard JK (2016) “Configuration of technology networks in the wind turbine industry. A comparative study of technology management models in European and Chinese lead firms”. Int J Technol Manage 70(4):281–299

Hallén L, Johanson J, Seyed-Mohamed N (1991) “Interfirm Adaptation in Business Relationships”. J Mark 55(2):29–37

Handfield RB, Ragatz GL, Petersen KJ (1999) “Involving Suppliers in New Product Development”. Calif Manag Rev 42(1):59–82

Hertenstein P, Williamson PJ (2018) “The role of suppliers in enabling differing innovation strategies of competing multinationals from emerging and advanced economies: German and Chinese automotive firms compared”, Technovation, Vol.70–71No., pp. 46–58

Holweg M, Pil FK (2008) “Theoretical perspectives on the coordination of supply chains”. J Oper Manag 26(3):389–406

Huo B, Qi Y, Wang Z, Zhao X (2014) “The impact of supply chain integration on firm performance: The moderating role of competitive strategy”. Supply Chain Management: An International Journal 19(4):369–384

Jean R-JB, Sinkovics RR, Hiebaum TP (2014) “The effects of supplier involvement and knowledge protection on product innovation in customer-supplier relationships: a study of global automotive suppliers in China”. J Prod Innov Manage 31(1):98–113

Johnsen TE (2009) “Supplier involvement in new product development and innovation: Taking stock and looking to the future”. J Purchasing Supply Manage 15(3):187–197

Johnson WHA, Filippini R (2010) “Collaboration practices, strategic capabilities and performance in Japanese and American product development: Do they differ?“. Oper Manage Res 3(1):22–32

Kang M, Lee G, Hwang DW, Wei J, Huo B (2021) “Effects of cross-functional integration on NPD success: mediating roles of customer and supplier involvement”. Total Qual Manage Bus Excellence 32:13–14

Kang M, Wu X, Hong P, Park Y (2012) “Aligning organizational control practices with competitive outsourcing performance”. J Bus Res 65(8):1195–1201

Kembro J, Selviaridis K, Näslund D (2014) “Theoretical perspectives on information sharing in supply chains: a systematic literature review and conceptual framework”. Supply Chain Management: An International Journal 19(5/6):609–625

Ketchen DJ, Hult GTM (2007) “Bridging organization theory and supply chain management: The case of best value supply chains”. J Oper Manag 25(2):573–580

Kim D-Y (2013) “Relationship between supply chain integration and performance”. Oper Manage Res 6(1):74–90

Klein R (2007) “Customization and real time information access in integrated eBusiness supply chain relationships”. J Oper Manag 25(6):1366–1381

Laursen LN, Andersen PH (2016) “Supplier involvement in NPD: A quasi-experiment at Unilever”. Ind Mark Manage 58:162–171

Lee CW, Kwon IWG, Severance D (2007) “Relationship between supply chain performance and degree of linkage among supplier, internal integration, and customer”. Supply chain management: an International journal 12(6):444–452

Lee DY, Dawes PL (2005) “Guanxi, Trust, and Long-Term Orientation in Chinese Business Markets”. J Int Mark 13(2):28–56

Lee G, Shin G-c, Haney MH, Kang M, Li S, Ko C (2017) “The impact of formal control and guanxi on task conflict in outsourcing relationships in China”. Ind Mark Manage 62:128–136

Lee G, Shin G-c, Hwang DW, Kuper P, Kang M (2018) “How manufacturers’ long-term orientation toward suppliers influences outsourcing performance”. Ind Mark Manage 74:288–297

Lee HL (2004) “The triple-A supply chain”. Harvard Business Rev 82(10):102–113

Li S, Chen X (2019) “The role of supplier collaboration and risk management capabilities in managing product complexity”. Oper Manage Res 12(3):146–158

Liao H, Liu D, Loi R (2010) “Looking at both sides of the social exchange coin: A social cognitive perspective on the joint effects of relationship quality and differentiation on creativity”. Acad Manag J 53(5):1090–1109

Lorenz E (1999) “Trust, contract and economic cooperation”. Camb J Econ 23(3):301–315

Luo C, Mallick DN, Schroeder RG (2010) “Collaborative product development: Exploring the role of internal coordination capability in supplier involvement”. Eur J Innov Manage 13(2):244–266

Maloni MJ, Benton W (1997) “Supply chain partnerships: opportunities for operations research”. Eur J Oper Res 101(3):419–429

Mathu KM (2019) “The information technology role in supplier-customer information-sharing in the supply chain management of South African small and medium-sized enterprises”. South Afr J Economic Manage Sci 22(1):1–8

McAllister DJ (1995) “Affect- and Cognition-Based Trust as Foundations for Interpersonal Cooperation in Organizations”. Acad Manag J 38(1):24–59

Melander L, Lakemond N (2015) “Governance of supplier collaboration in technologically uncertain NPD projects”. Ind Mark Manage 49:116–127

Miao F, Wang G, Jiraporn P (2018) “Key supplier involvement in IT-enabled operations: When does it lead to improved performance?“. Ind Mark Manage 75:134–145

Min S, Mentzer JT, Ladd RT (2007) “A market orientation in supply chain management”. J Acad Mark Sci 35(4):507

Mody A (1993) “Learning through alliances”. J Econ Behav Organ 20(2):151–170

Moorman C, Zaltman G, Deshpande R (1992) “Relationships between providers and users of market research: The dynamics of trust within and between organizations”. J Mark Res 29(3):314–328

Morgan RM, Hunt SD (1994) The commitment-trust theory of relationship marketing”. J Mark 58(3):20–38

Narasimhan R, Kim SW (2001) “Information system utilization strategy for supply chain integration”. J Bus logistics 22(2):51–75

Narasimhan R, Mahapatra S, Arlbjørn JS (2008) “Impact of relational norms, supplier development and trust on supplier performance”. Oper Manage Res 1(1):24–30

Narkhede BE, Raut RD, Patil BT, Mahajan SK (2013) “Performance Improvement in Small and Medium-Sized Enterprises Due to Information Systems Implementation”. Perform Improv 52(9):24–32

Nyaga GN, Whipple JM, Lynch DF (2010) “Examining supply chain relationships: Do buyer and supplier perspectives on collaborative relationships differ?“. J Oper Manag 28(2):101–114

Palmatier RW, Dant RP, Grewal DJJ. o. m. (2007), “A comparative longitudinal analysis of theoretical perspectives of interorganizational relationship performance”, Vol. 71 No. 4, pp.172–194.

Peng DX, Heim GR, Mallick DN (2014) “Collaborative product development: The effect of project complexity on the use of information technology tools and new product development practices”. Prod Oper Manage 23(8):1421–1438

Petersen KJ, Handfield RB, Ragatz GL (2005) “Supplier integration into new product development: coordinating product, process and supply chain design”. J Oper Manag 23:3–4

Podsakoff PM, MacKenzie SB, Lee JY, Podsakoff NP (2003) “Common method biases in behavioral research: A critical review of the literature and recommended remedies”. J Appl Psychol 88(5):879–903

Prajogo D, Olhager J (2012) “Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration”. Int J Prod Econ 135(1):514–522

Premkumar G, Ramamurthy K, Saunders CS (2005) “Information Processing View of Organizations: An Exploratory Examination of Fit in the Context of Interorganizational Relationships”. J Manage Inform Syst 22(1):257–294

Ragatz GL, Handfield RB, Scannell TV (1997) “Success Factors for Integrating Suppliers into New Product Development”. J Prod Innov Manage 14(3):190–202

Saeki Y, Horak S (2014) “Trust and the cultivation of relation-specific skills. Evidence from a multinational automotive supplier in Japan and Germany”. Manag Decis 52(8):1433–1450

Sanders NR (2008) “Pattern of information technology use: The impact on buyer–suppler coordination and performance”. J Oper Manag 26(3):349–367

Schoenherr T, Swink M (2015) “The Roles of Supply Chain Intelligence and Adaptability in New Product Launch Success”. Decis Sci 46(5):901–936

Sertan K, Sungmin R (2007) “The protection of the trustor through the use of control mechanisms and its performance implications”. J Bus Industrial Mark 22(4):260

Sheel A, Nath V (2019) “Effect of blockchain technology adoption on supply chain adaptability, agility, alignment and performance”. Manage Res Rev 42(12):1353–1374

Siguaw JA, Simpson PM, Baker TL (1998) “Effects of Supplier Market Orientation on Distributor Market Orientation and the Channel Relationship: The Distributor Perspective”. J Mark 62(3):99–111

Song M, Di Benedetto CA (2008) “Supplier’s involvement and success of radical new product development in new ventures”. J Oper Manag 26(1):1–22

Stevenson M, Spring M (2007) “Flexibility from a supply chain perspective: definition and review”. Int J Oper Prod Manage 27(7):685–713

Stiglitz JE (2000) “The Contributions of the Economics of Information to Twentieth Century Economics*”. Q J Econ 115(4):1441–1478

Subramani M (2004) “How Do Suppliers Benefit from Information Technology Use in Supply Chain Relationships?“. MIS Q 28(1):45–73

Suurmond R, Wynstra F, Dul J (2020) “Unraveling the Dimensions of Supplier Involvement and their Effects on NPD Performance: A Meta-Analysis”. J Supply Chain Manage 56(3):26–46

Thomas E (2013) “Supplier integration in new product development: Computer mediated communication, knowledge exchange and buyer performance”. Ind Mark Manage 42(6):890–899

Tidy M, Wang X, Hall M (2016) “The role of Supplier Relationship Management in reducing Greenhouse Gas emissions from food supply chains: supplier engagement in the UK supermarket sector”. J Clean Prod 112:3294–3305

Tierney P, Farmer SM (2002) “Creative self-efficacy: Its potential antecedents and relationship to creative performance”. Acad Manag J 45(6):1137–1148

Tracey M, Leng Tan C (2001) “Empirical analysis of supplier selection and involvement, customer satisfaction, and firm performance”. Supply Chain Management An International Journal 6(4):174–188

Tseng S-M (2014) “The impact of knowledge management capabilities and supplier relationship management on corporate performance”. Int J Prod Econ 154:39–47

Um K-H, Kim S-M (2019) “The effects of supply chain collaboration on performance and transaction cost advantage: The moderation and nonlinear effects of governance mechanisms”. Int J Prod Econ 217:97–111

Um K-H, Oh J-Y (2020) “The interplay of governance mechanisms in supply chain collaboration and performance in buyer–supplier dyads: substitutes or complements”. Int J Oper Prod Manage 40(4):415–438

Veloso F, Fixson S (2001) “Make–Buy Decisions in the Auto Industry: New Perspectives on the Role of the Supplier as an Innovator”. Technol Forecast Soc Chang 67(2):239–257

Wagner SM, Coley LS, Lindemann E (2011) “Effects of suppliers’ reputation on the future of buyeresupplier relationships: the mediating roles of outcome fairness and trust”. J Supply Chain Manage 47(2):29–48

Walter A (2003) “Relationship-specific factors influencing supplier involvement in customer new product development”. J Bus Res 56(9):721–733

Wei H-L, Wong CWY, Lai K-h (2012) Linking inter-organizational trust with logistics information integration and partner cooperation under environmental uncertainty”. Int J Prod Econ 139(2):642–653

Weigelt C, Sarkar M (2012) “Performance implications of outsourcing for technological innovations: managing the efficiency and adaptability trade-off”. Strateg Manag J 33(2):189–216

Wen J, Qualls WJ, Zeng D (2021) “To explore or exploit: The influence of inter-firm R&D network diversity and structural holes on innovation outcomes”. Technovation 100:102178

Wong CY, Boon-itt S, Wong CWY (2011) “The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance”. J Oper Manag 29(6):604–615

Wynstra F, Pierick Et (2000) “Managing supplier involvement in new product development: a portfolio approach”. Eur J Purchasing Supply Manage 6(1):49–57

Yan T, Dooley K (2014) “Buyer-Supplier Collaboration Quality in New Product Development Projects”. J Supply Chain Manage 50(2):59–83

Yang C-S (2016) “The antecedents and consequences of supply chain service capabilities in the context of container shipping”. Int J Logistics Manage 27(2):236–262

Yang L, Huo B, Gu M (2022) “The impact of information sharing on supply chain adaptability and operational performance”. Int J Logistics Manage 33(2):590–619

Young-Ybarra C, Wiersema M (1999) “Strategic Flexibility in Information Technology Alliances: The Influence of Transaction Cost Economics and Social Exchange Theory”. Organ Sci 10(4):439–459

Yu W (2015) “The effect of IT-enabled supply chain integration on performance”. Prod Plann Control 26(12):945–957

Yu Y, Huo B, Zhang Z (2021) “Impact of information technology on supply chain integration and company performance: evidence from cross-border e-commerce companies in China”. J Enterp Inform Manage 34(1):460–489

Zaheer A, McEvily B, Perrone V (1998) “Does trust matter? Exploring the effects of interorganizational and interpersonal trust on performance”. Organ Sci 9(2):141–159

Zahra SA, Nielsen AP (2002) “Sources of capabilities, integration and technology commercialization”. Strateg Manag J 23(5):377–398

Zhang M, Huo B (2013) “The impact of dependence and trust on supply chain integration”. Int J Phys Distribution Logistics Manage 43(7):544–563

Zhang M, Lettice F, Chan HK, Nguyen HT (2018) “Supplier integration and firm performance: the moderating effects of internal integration and trust”. Prod Plann Control 29(10):802–813

Funding

This research was supported by Science Foundation for Young Scholars of Zhejiang University of Science and Technology (#2021QN071) and Scientific Research Foundation of Zhejiang University of Science and Technology (#F701118K01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

APPENDIX 1

Definitions and survey items of major constructs.

Trust relationships with suppliers.

Definition

the extent to which a manufacturing firm is deemed reputable, reliable, trustworthy, and open to its suppliers.

TRS1) The promises that our plant makes to its suppliers are reliable.

TRS2) Our organization has a good reputation when we are doing business with our suppliers.

TRS3) Our plant is open in dealing with our suppliers.

IT use with suppliers.

Definition

the extent to which a manufacturing firm uses IT to communicate with their primary suppliers for daily operation and understanding market trends.

ITUS1) Order Processing, invoicing and settling accounts.

ITUS2) Exchange of shipment and delivery information.

ITUS3) Managing warehouse stock and inventories.

ITUS4) Understanding trends in sales and customer preferences.

Supplier adaptability:

Definition

the key suppliers’ ability to quickly respond to a manufacturer’s short notice and willingness to adjust their processes and products to meet its changing needs.

SA1) Quick response on short notice.

SA2) willingness to adapt processes to meet your changing needs.

SA3) willingness to adapt products to meet your changing needs.

Supplier involvement.

Definition

the extent to which key suppliers are involved in a manufacturer’s early design stage of new products.

SI1) Suppliers are involved early in product design efforts.

SI2) We partner with suppliers for the design of new products.

SI3) Suppliers are frequently consulted during the design of new products.

SI4) Suppliers are an integral part of new product design efforts.

NPD project success.

Definition

the extent to achieve the NPD project’s intended goals from the perspective of project outcomes such as project efficiency and effectiveness.

NPD1) Customer satisfaction.

NPD2) Market share.

NPD3) Technical performance relative to specifications.

NPD4) Time to market.

NPD5) Overall commercial success.

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Um, KH., Wang, S. et al. The mediating role of key supplier adaptability and involvement in the relationship between supplier relationship management and NPD project success. Oper Manag Res 16, 794–807 (2023). https://doi.org/10.1007/s12063-022-00325-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12063-022-00325-0