Abstract

Indoor swimming pools are buildings with relatively complex energy systems and relatively high energy and water consumption. This paper presents a methodological approach to energy auditing of indoor swimming pool buildings based on ISO 50002. It also includes the application of a multi-criteria decision making (MCDM) method for ranking the proposed energy conservation measures. Since an MCDM method used in energy auditing should not be complex, the authors suggested using the weighted sum method (WSM). A simple ranking method was used for the selection of weights of performance. For the justification of this approach, the authors compared the results of the ranking method with the widely used AHP and fuzzy AHP that are more complex and time-consuming. The methodology was applied to a case study indoor swimming pool in Kragujevac (Serbia). Applying energy conservation measures that enable relatively fast payback period (less than 5 years), energy consumption in the swimming pool can be reduced by 29%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

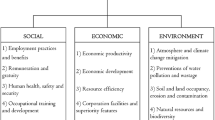

Indoor swimming pools are important sports centers for recreation and social roles. They are considered as high energy-consuming public buildings, with needs for heating, dehumidification, and ventilation (Lebon et al., 2017). As these buildings need forced ventilation, it is assumed that indoor swimming pools are three times greater energy consumers than offices with the same area (Seneviratne, 2006). Besides, Delgado Marín and Garcia-Cascales (2020) show that increasing pool water temperature by 1 °C increase energy demand by 9.5%. In swimming pools, energy is predominantly used for HVAC system (27–50%) and pool heating (28–50%). Pump systems use 2.2–30%, lighting 3–13%, and domestic hot water (DWH) 3–40% of total delivered energy (LEITAT&SEA, 2014; Saari & Sekki, 2008; Trianti-Stourna et al., 1998). Different percentages are the consequence of different sizes of facilities, the number of swimming pools in a facility, operating schedule, building characteristics, and the efficiency of energy-consuming equipment. The influence of pool size area and year of built on energy consumption were analyzed in (Kampel et al., 2013). The most efficient swimming pools were built from 1990 to 2000, while the swimming pools built after 2000 are the biggest energy consumers due to increased pool size, new services, and new equipment that need more energy. A case study of the energy audit of a fitness center in Ireland based on ISO 50002 (international standard on energy audit) was performed in (McLean, 2017). Authors proposed and evaluated energy efficiency measures that were categorized according to the implementation costs. The measures were ranked according to a single criterion—payback time, as it is usually done in energy auditing of industrial facilities. However, since swimming pools are public buildings, prioritizing measures for this type of building should not be that straightforward. Additional criteria (economic, environmental, and social) for ranking energy conservation measures in public buildings should be included (Huang et al., 2013; Knijnenburg et al., 2014). Criteria depend on the facility’s needs. For example, in developed countries, environmental performance is more conspicuous than in developing countries where priorities are predominantly economical, such as implementation costs and the payback time (Akhanova et al., 2020). Therefore, it is important to emphasize that prioritization of the measures is different for every indoor swimming pool and it depends on experts’ judgment.

Multi-criteria decision making (MCDM) has been used in different energy planning processes that involve multiple objectives. For this purpose, different MCDM methods could be used (Kaya et al., 2018) but never as a compulsory factor in the energy auditing process.

Based on all of the abovementioned, the authors of the paper propose a methodology of energy auditing of indoor swimming pool facilities which includes the usage of MCDM in the process of prioritizing defined energy efficiency measures. The application of this methodology could be useful since Pereira and da Silva (2017) emphasize that engaging different stakeholders are the most important for achieving EE targets. Since an MCDM method should be simple and understandable both for energy auditors and for decision-makers, the authors suggest using the weighted sum method (WSM). The method is widely used and broadly popular as it does not require special mathematical knowledge and the application of specialized decision-making software. For the selection of weights of performance for each criterion, the authors used simple ranking method. To justify the proposed approach, the authors compared the suggested method for the selection of weights of performance with pairwise comparison methods (AHP, fuzzy AHP) that are far more complex and time-consuming.

As every swimming pool facility represents a unique energy system, the results of every energy audit of unexplored cases are very significant. Therefore, the paper also contributes to the enlargement of “catalog of knowledge” referring to the energy efficiency of this type of public buildings.

Methodology of energy auditing in a swimming pool facility

The auditing structure (Fig. 1) was based on the general approach of energy auditing presented in the ISO 50002 (ISO, 2014) and recommendations presented by Fresner et al. (2017) and Kluczek and Olszewski (2017).

Goals and scope of the audit and all requirements to accomplish the set goals should be defined during the energy audit planning phase. Basic information and characteristics of the analyzed building should be collected from technical operators using a pre-audit questionnaire. The questionnaire should consist of data on building characteristics, energy and water systems, a variety of services provided, and users’ behavior. The questionnaire should also include information about sub-metering systems, sensors, and measuring equipment in the building. Energy and water bills and other available consumption data (including weather data) for at least three consecutive years should be collected. Analysis of the energy bills provides information about patterns of energy and water consumption. Besides, data collection involves the creation of a list of all energy consumption systems and equipment with their detailed characteristics. A measurement plan that will be used during the site visit for on-site data measurement and collection should be created according to the obtained data. Water supply (including leakage), water heating, water treatment systems, HVAC, lighting system, pumps, fans, and other electrical equipment are usually included in the measurement plan. Where it is possible, the process parameters that influence the energy consumption in all systems should be collected through sub-metering data from the energy monitoring system. If there are no measurement sensors, data should be provided using portable equipment. A well-designed measurement plan ensures a productive visit where an auditor should compare pre-audit questionnaire data with a real situation. Also, preliminary ideas for energy conservation measures (ECMs) should be generated. If there is a need for an additional site visit, an auditor should make a system register for new measurements which are necessary for later analysis.

The analysis step includes the analysis of current energy performance and identification, evaluation, and ranking of ECMs. The current energy performance should include data on a breakdown of the energy consumption by use and source; the historical pattern of energy performance; and evaluation and benchmarking of energy performance indicators. The most commonly used energy performance indicators for benchmarking analysis of swimming pool facilities are annual delivered energy consumption per usable area (kWh/m2 UA), per water surface (kWh/m2 WS) (Banjac et al., 2016; Kampel et al., 2013; LEITAT&SEA, 2014; McLean, 2017; Passipedia, 2017; Saari & Sekki, 2008), and per user of indoor swimming pool (kWh/user) (Kampel et al., 2016). Duverge et al. (2017) recommend a clear definition of what area has been included in the analysis since using the indicators with different building area can confuse. Kampel et al. (2016) recommend using water surface as it is an explicit measurement that is easy to obtain with high accuracy and precision. The range of values for annual delivered energy consumption per water surface ranges from 1302.7 (Kampel et al., 2016) to 4475 kWh/m2 WS (Saari & Sekki, 2008). Using multiple linear regression, the authors (Kampel et al., 2016) concluded that for benchmarking purposes, the energy usage of swimming facilities should be preferably normalized to the number of visitors. They also concluded that it was difficult to obtain consistent data on visitors for a large number of swimming pools. Therefore, if no reliable visitor count is available, the water surface should be used. Water consumption is usually normalized with the number of visitors. Swimming facilities with water consumption less than 107 l/person are the most efficient (Kampel et al., 2014). In best practice guide (Sydney Water Corporation (SWC), 2011), the values of water consumption less than 70 l/person are considered for water-efficient swimming pools. The consumption can be reduced up to 40 l/person. In the paper where energy conservation strategies for swimming pools were analyzed, the average shower water consumption was 0.04 m3/person (Trianti-Stourna et al., 1998).

The possibilities for improving energy and water efficiency in swimming pool facilities are presented in Table 1 (Artuso & Santiangeli, 2008; Kampel, 2015; Kampel et al., 2014; LEITAT&SEA, 2014; Good Practice Guide 219 (GPG219), 1997; Seneviratne, 2006; Sydney Water Corporation (SWC), 2011; Trianti-Stourna et al., 1998). The primary analysis includes the estimation of energy savings and relevant costs based on energy bills-invoices and a short on-site visit. Otherwise, a detailed analysis requires a more detailed analysis of energy/water consumption and other site data.

ECMs should be ranked according to certain criteria. In the process of prioritizing measures, the usage of an MCDM method helps in identifying the best solutions according to the interdependence between criteria. It gives a more realistic ranking of the possibilities. The authors propose weighted sum method (WSM) as an MCDM method because of its straightforwardness. In WSM, for each of the proposed ECMs, the weighted sum method score Ai [−] is calculated according to:

where n [−] is the number of criteria, m [−] is the number of proposed ECMs, wj [%] is the weight of performance of jth criterion, and \( \overline{a_{ij}} \) [−] is the normalized value of ith ECM in terms of jth criterion. The ECM with the higher score has a higher rank.

In the case of ranking ECMs of indoor swimming pool facilities, the authors suggest five criteria (n = 5):

-

Payback period;

-

Implementation cost;

-

CO2 emission reduction;

-

Reduction of primary energy use;

-

Investment in renewable energy sources (RES).

The weight of performance is determined by expert opinions according to the importance of the suggested criteria. For determining the weight of performance, the authors propose a ranking method. According to this method, an expert should rank every criterion from 1 to 100% according to the personal attitude. The total sum of weight performance values has to be equal to 100%.

The authors compared the results of the ranking method with pairwise comparison methods (AHP, fuzzy AHP) to check the proposed approach. The analytic hierarchy process (AHP), one type of the weighted sum method (Si et al., 2016), is one of the most used methods to obtain quantitative weights of performance from a qualitative evaluation of the importance of suggested criteria (Zardari et al., 2015). Determining the weight of performance using a pairwise comparison method includes a comparison of the importance between every two criteria with a 9-scale for relative importance. Usage of the AHP method for the assessment in the renewable energy industry was explained by San Cristóbal Mateo (2012). The fuzzy AHP method is used when it is difficult for experts to provide a precise value for criteria but it makes the evaluation process more complex. The detailed calculation procedure for the fuzzy AHP was given by Chiu et al. (2014).

To ensure the comparability of criteria, their values should be adjusted to a common scale in the interval [0, 1]. For non-beneficial (cost) criteria, where the lowest value is the best value, the linear normalization is performed using:

While for beneficial criteria, where the highest value is the best value, the normalization is performed using:

where \( {a}_j^{\mathrm{min}} \) [−] is the minimum value of all ECMs in terms of jth criterion, \( {a}_j^{\mathrm{max}} \) [−] is the maximum value of all ECMs in terms of jth criterion, and aij [−] is the value of ith ECM in terms of jth criterion.

The results of energy auditing should be systematized in the form of a clear and concise report. A good report should convince decision-makers to invest in proposed ECMs to increase the energy efficiency of the swimming pool facility.

A case study—indoor swimming pool in Kragujevac (Serbia)

Indoor swimming pool in Kragujevac is a part of municipality-owned sports and recreation Center “Park.” Characteristics of analyzed swimming facility are shown in Table 2.

The building is connected to the city water supply, sewage, and electricity network. There is a central heating system with two natural gas boilers (700 kW each) that work intermittently (switch after 100 h of operation). Simplified scheme of the system is shown in Fig. 2.

According to energy and water bills for the period from 2014 to 2016, the system annually consumes on average 691,533 kWh of electricity, 261,057 m3 of natural gas (equivalent to 2,000,900 kWh of heat), and 37,269 m3 of water (Table 3).

The values of energy and water performance indicators are shown in Table 4.

Average annual consumption of delivered energy per water surface is 2153 kWh/m2WS, while the average annual consumption of delivered energy per usable area is 475 kWh/m2UA.

Annual water consumption is 340 l/person. It can be concluded that water consumption in the analyzed swimming pool facility is greater than the values shown as a good practice (Kampel et al., 2016). This is the consequence of the fact that the number of visitors is significantly lower than the capacity of the swimming pool building (less than 25%). Distribution of average annual energy and water consumption data is presented in Table 5. Average distribution of electrical energy was calculated using operating hours and the power rating of the equipment. Distribution of heat consumption was determined using the data from the measurement. The analysis shows that 74% of total annual energy consumption is used on heating and 26% on electricity. Forty-nine percent of total energy costs went on heat generation, 39% on electricity, and 12% on water.

Based on the performed energy audit, ECMs were considered. For each of the proposed ECMs, annual primary energy savings, implementation costs, payback period, and the reduction of CO2 emission were calculated (Table 6).

Because of the high thermal energy demand for indoor swimming pool buildings, the use of solar collectors for water heating represents the most efficient way of using solar energy (Ilić & Lepotić, 2013). In the analyzed building, the conventional way of pool heating could be completely replaced with solar collectors during the summer. For the rest of the year, solar collectors could be used as an addition to the existing heating system.

Using solar collectors for DHW supply was also considered. This measure implies the installation of high-volume hot water storages that increase the implementation costs, so the payback period is nearly 10 years.

Daily heat loss of the water surface is estimated at 2.5 kWh/m2 (Banjac et al., 2016). Based on the estimation, daily heat loss in the swimming pool is 3125 kWh. According to (Reduce Swimming Pool Energy Costs, n.d.), 27% of heat loss is the consequence of ventilation, while 70% of heat loss is related to pool water evaporation. The evaporation can be reduced by using pool covers when the swimming pool is not in use. As pool covers in the indoor swimming pool in Kragujevac could be used 6 h per day, it can be assumed that 25% of evaporative losses can be reduced by implementing this measure.

Implementation of LED replacement was considered according to the methodology shown by Josijevic et al. (2017). A comparative review of existing lighting and adequate LED replacement is presented in Table 7. Besides the bulb connector type, the main criterion for the replacement is the appropriate light flux level. LED bulb replacements were proposed based on the same or similar value of light flux. Since there is no adequate LED replacement on the market for existing 58-W fluorescent tube (in terms of flux level), this type of fluorescent bulb was not recommended for replacing. Annual consumption of the existing lighting system was 100,550 kWh of electrical energy, while the potential savings obtained with LED replacement would have been 60,770 kWh (60.4% of current electricity consumption for lighting).

Due to the absence of reactive power compensation, electricity bills show excessive reactive energy during certain months. For power factor correction to cosφ = 0.98, the 75 kVAr capacitors are needed (a combination of 2 × 5 kVAr, 2 × 12.5 kVAr, and 2 × 20 kVAr capacitors).

Baseload heat consumption was the criterion for CHP selection. According to heat and electricity consumption profiles of the swimming pool facility (Fig. 3), internal combustion (IC) CHP with a 70 kW electrical power and 109 kW thermal output was selected using RETScreen software package. This IC CHP can cover 46.2% of the total heating load. This amount of heat can be used for water heating while existing boilers can be used for HVAC systems as an addition. This provides the continual operation of the system with maximum efficiency and electricity production equivalent to 90.4% of the current average annual electricity consumption. The estimated price of documentation, installation, and maintenance of CHP plant is 79,100 €. Taking into account that natural gas price is 0.35 €/m3 and the electricity price (average) is 8.91 €c/kWh in Kragujevac, the estimated payback period would be approximately 3.4 years.

To rank the suggested measures, swimming pool manager and municipal energy manager were interviewed, as the city of Kragujevac is the owner of the indoor swimming pool. The values of the weights of importance were determined according to their priorities. Besides the payback period, the implementation costs have a significant weight of importance for the municipality. Although environmental and social criteria were not significant to the swimming pool manager, they were significant to energy manager of the city of Kragujevac since the local government promotes the implementation of RES and have targets to reduce both primary energy use and CO2 emissions.

For comparing the results obtained by the ranking method with the AHP and fuzzy AHP, decision-makers were interviewed again to complete the pairwise comparison matrix. Pairwise comparison was assigned between all criteria to define their relative importance as can be seen in Table 8. The correctness of the decisions has been established since the consistency ratio (CR) was 0.04, which was less than 0.1 as proposed in (Si et al., 2016).

The calculated values for the weight of performance obtained from the ranking method and the pairwise comparison matrix are slightly different (Table 9.).

Using Eqs. (2) and (3), data from Table 6 were normalized. Using Eq. (1), the weighted sum method score Ai for each of the proposed ECMs was calculated so the ranking of the proposed measures was performed (Table 10).

The ranking of the proposed energy efficiency measures significantly differs from the case when prioritization is performed according to a single criterion—implementation costs or payback period. For the analyzed swimming pool facility, using the AHP and fuzzy AHP provides the same results. On the other hand, there is a small difference in results when using the ranking method which can justify its usage for ranking the ECMs.

Considering its simplicity, the authors propose using the ranking method. If energy auditors doubt about weights of performance defined by experts, they should consider the prioritization using the AHP method.

Conclusion

The energy auditing is a substantial and comprehensive approach for improving the energy efficiency of buildings. It is necessary to define distinct energy and water consumption performance indicators in energy auditing of indoor swimming pools. Besides, the energy conservation measures that may be proposed during the auditing are specific because of the necessity for providing special ambient conditions for users. The measures could not be ranked using a single economic criterion (payback time) like it is usually the case in industrial auditing. Ranking of the measures is a relatively complex procedure since many different criteria must be taken into account. Therefore, using the multi-criteria decision making method based on simple and well-established weighted sum method is proposed in the energy auditing of indoor swimming pool facilities. This approach enables a sustainable ranking of energy conservation measures.

The proposed energy auditing approach has been implemented in the case study swimming pool building in Serbia. Although this is a relatively new building and the results of energy consumption benchmarking analysis do not indicate high energy consumption, there is a significant potential for energy efficiency improvement. The results of auditing showed that energy conservation measures that enable relatively fast payback period (less than 5 years) and energy consumption reduction by 29% could be proposed. The suggested approach could be also applied to other types of buildings with minor modifications and adjustments.

References

Akhanova, G., Nadeem, A., Kim, J. R., & Azhar, S. (2020). A multi-criteria decision-making framework for building sustainability assessment in Kazakhstan. Sustainable Cities and Society, 52, 101842. https://doi.org/10.1016/j.scs.2019.101842.

Artuso, P., & Santiangeli, A. (2008). Energy solutions for sports facilities. International Journal of Hydrogen Energy, 33(12), 3182–3187. https://doi.org/10.1016/j.ijhydene.2007.12.064.

Banjac, M., Đukanović, D., Matejić, M., Galić, R., Bradarević, L., Lazarević, B., & Tica, S. (2016). Manuals for energy managers in municipalities. UNDP Serbia.

Chiu, R.-H., Lin, L.-H., & Ting, S.-C. (2014). Evaluation of green port factors and performance: A fuzzy AHP analysis. Mathematical Problems in Engineering, 2014, 1–12. https://doi.org/10.1155/2014/802976.

Delgado Marín, J. P., & Garcia-Cascales, J. R. (2020). Dynamic simulation model and empirical validation for estimating thermal energy demand in indoor swimming pools. Energy Efficiency, 13(5), 955–970. https://doi.org/10.1007/s12053-020-09863-7.

Duverge, J. J., Rajagopalan, P., & Fuller, R. (2017). Defining aquatic centres for energy and water benchmarking purposes. Sustainable Cities and Society, 31, 51–61. https://doi.org/10.1016/j.scs.2017.02.008.

Fresner, J., Morea, F., Krenn, C., Aranda Uson, J., & Tomasi, F. (2017). Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe. Journal of Cleaner Production, 142, 1650–1660. https://doi.org/10.1016/j.jclepro.2016.11.126.

Good Practice Guide 219 (GPG219). (1997). Energy Efficiency in Swimming Pools-for Centre Managers and Operators. https://www.cibse.org/getmedia/f36a292c-8eea-4610-b764-e23774a52cb9/GPG219-Energy-Efficiency-in-Swimming-Pools.pdf.aspx

Huang, Z., Jiang, D., & Huang, Y. (2013). Attributes affecting the application of energy saving measures. In 2013 IEEE 12th International Conference on Cognitive Informatics and Cognitive Computing (pp. 446–453). Presented at the 2013 12th IEEE International Conference on Cognitive Informatics & Cognitive Computing (ICCI*CC), New York, NY, USA: IEEE. https://doi.org/10.1109/ICCI-CC.2013.6622281.

Ilić, S., & Lepotić, B. (2013). Construction of thermo solar plants, guide for investors (First ed.). UNDP Serbia http://www.mre.gov.rs/doc/efikasnost-izvori/Thermo%20Solar%20Plants%20-%20Detailed%20Guide.pdf.

ISO. (2014). Energy audits-requirements with guidance for use, ISO 5002:2014. International Organization for Standardization.

Josijevic, M., Gordic, D., Milovanovic, D., Jurisevic, N., & Rakic, N. (2017). A method to estimate savings of led lighting instalation in public buildings: The case study of secondary schools in Serbia. Thermal Science, 21(6 part B), 2931–2943. https://doi.org/10.2298/TSCI161209118J.

Kampel, W. (2015). Energy Efficiency in Swimming Facilities, PhD Thesis, Norwegian University of Science and Technology, Trondheim.

Kampel, W., Aas, B., & Bruland, A. (2013). Energy-use in Norwegian swimming halls. Energy and Buildings, 59, 181–186. https://doi.org/10.1016/j.enbuild.2012.11.011.

Kampel, W., Aas, B., & Bruland, A. (2014). Characteristics of energy-efficient swimming facilities – A case study. Energy, 75, 508–512. https://doi.org/10.1016/j.energy.2014.08.007.

Kampel, W., Carlucci, S., Aas, B., & Bruland, A. (2016). A proposal of energy performance indicators for a reliable benchmark of swimming facilities. Energy and Buildings, 129, 186–198. https://doi.org/10.1016/j.enbuild.2016.07.033.

Kaya, İ., Çolak, M., & Terzi, F. (2018). Use of MCDM techniques for energy policy and decision-making problems: A review. International Journal of Energy Research, 42(7), 2344–2372. https://doi.org/10.1002/er.4016.

Kluczek, A., & Olszewski, P. (2017). Energy audits in industrial processes. Journal of Cleaner Production, 142, 3437–3453. https://doi.org/10.1016/j.jclepro.2016.10.123.

Knijnenburg, B. P., Willemsen, M., & Broeders, R. (2014). Smart sustainability through system satisfaction: Tailored preference elicitation for energy-saving recommenders. In Human Computer Interaction (p. 15). Presented at the Twentieth Americas Conference on Information Systems (AMCIS), Georgia.

Lebon, M., Fellouah, H., Galanis, N., Limane, A., & Guerfala, N. (2017). Numerical analysis and field measurements of the airflow patterns and thermal comfort in an indoor swimming pool: A case study. Energy Efficiency, 10(3), 527–548. https://doi.org/10.1007/s12053-016-9469-0.

LEITAT&SEA. (2014). D2.2. Integrated report, Energy audits and Energy Performance Certification (p. 49). http://step2sport.eu/sport/wp-content/uploads/2015/09/WP2_20150612_2_STEP-2-SPORT_D2-2_Integrated_report.pdf

McLean, E. D. (2017). Energy Audit of a Fitness/Leisure Centre. Dublin Institute of Technology. https://doi.org/10.21427/d7fq74.

Passipedia (2017), The passive House Resource. https://passipedia.org/examples/non-residential_buildings/passive_house_swimming_pools

Pereira, G. I., & da Silva, P. P. (2017). Energy efficiency governance in the EU-28: Analysis of institutional, human, financial, and political dimensions. Energy Efficiency, 10(5), 1279–1297. https://doi.org/10.1007/s12053-017-9520-9.

Reduce Swimming Pool Energy Costs (RSPEC). (n.d.) http://www.rlmartin.com/rspec/factsheets/covers.htm.

Saari, A., & Sekki, T. (2008). Energy consumption of a public swimming bath. The Open Construction and Building Technology Journal, 2(1), 202–206. https://doi.org/10.2174/1874836800802010202.

San Cristóbal Mateo, J. R. (2012). Multi-criteria analysis in the renewable energy industry. Springer.

Seneviratne, M. (2006). A practical approach to water conservation for commercial and industrial facilities. Elsevier. https://doi.org/10.1016/B978-1-85617-489-3.X5001-2.

Si, J., Marjanovic-Halburd, L., Nasiri, F., & Bell, S. (2016). Assessment of building-integrated green technologies: A review and case study on applications of multi-criteria decision making (MCDM) method. Sustainable Cities and Society, 27, 106–115. https://doi.org/10.1016/j.scs.2016.06.013.

Sydney Water Corporation (SWC). (2011). Best practice guidelines for water management in aquatic leisure centers.https://www.sydneywater.com.au/web/groups/publicwebcontent/documents/document/zgrf/mdq1/~edisp/dd_045262.pdf

Trianti-Stourna, E., Spyropoulou, K., Theofylaktos, C., Droutsa, K., Balaras, C. A., Santamouris, M., Asimakopoulos, D. N., Lazaropoulou, G., & Papanikolaou, N. (1998). Energy conservation strategies for sports centers: Part B. Swimming pools. Energy and Buildings, 27, 123–135.

Zardari, N. H., Ahmed, K., Shirazi, S. M., & Yusop, Z. B. (2015). Weighting methods and their effects on multi-criteria decision making model outcomes in water resources management. Cham: Springer International Publishing. https://doi.org/10.1007/978-3-319-12586-2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nikolic, J., Gordic, D., Jurisevic, N. et al. Energy auditing of indoor swimming facility with multi-criteria decision analysis for ranking the proposed energy savings measures. Energy Efficiency 14, 36 (2021). https://doi.org/10.1007/s12053-021-09949-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12053-021-09949-w