Abstract

The status of energy balance and energy economics of irrigated and rain-fed rice production systems is studied and compared for highlighting the effect of farm size. Primary data were collected from 51 irrigated and 54 rain-fed rice farms in Northern Ayeyarwaddy Region, Myanmar. Farm classes were identified as small (<2.5 ha) and large (2.5–25 ha). Energy estimates were calculated from actual amount of inputs and outputs and corresponding conversion factors. Results showed that the total energy inputs were 19,170.5 and 11,031.1 MJ/ha, respectively, in irrigated and rain-fed rice systems, while the total energy outputs were 104,162.7 and 65,033.5 MJ/ha in the two systems, respectively. Energy efficiency ratios, defined as output-to-input energy values, were 5.6 and 5.9 in irrigated and rain-fed rice production systems. Interestingly, the two systems were not statistically different for their energy efficiencies. Similarly, the energy efficiency ratios for different farm classes under both rice production systems were also not statistically different. Energy productivity and specific energy were 0.27 and 3.8 kg/MJ; 0.29 and 3.9 MJ/kg in irrigated and rain-fed systems, respectively. The energy benefit–cost ratio was higher in rain-fed rice (1.1) than in irrigated rice (0.9) system. Rain-fed system seems to have potential of further increasing yield through the increased yet appropriate use of energy inputs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A major contribution to the economy of Myanmar comes from agriculture with a 36 % share to GDP (ADB 2013). Rice is designated as national crop, and then, it is one of the major income and important employment sources of Myanmar. In addition, Myanmar is the seventh largest rice-producing country in the world (FAO 2009). Its total rice sown area in 2011–2012 was 8.1 million ha (MOAI 2012), and out of which, 23 % is under the rain-fed and 43 % is under the irrigated condition. Proportionately, 25 and 45 % of the country’s rice production come from rain-fed and irrigated fields, respectively (MOAI 2012).

As one of the economic objectives of Myanmar, “Building the modern industrialized nation through the agricultural development, and all-round development of other sectors of the economy,” the nation is trying to increase the crop production through area expansion and intensification of agriculture (MOAI 2012). Agricultural intensification highly depends on a number of agricultural inputs used. Energy inputs are critical to agricultural production, whereas the increased use of fossil fuel-based energy sources has become an increasingly important concern to both the developed and the developing countries (AghaAlikhani et al. 2013). Agriculture itself is both an energy consumer as well as energy supplier in the form of bio-energy. All agricultural operations require energy in one form or the other: human labor, animal power, fertilizer, fuels, and electricity. The relation between agriculture and its corresponding energy use has been of great attention since the total energy use (efforts, inputs, and intensity) has been rising in response to increasing production, amidst limited availability of arable land and the ongoing drive of mechanization. In most of the intensive crop production systems, these factors have either encouraged an increase in energy inputs to maximize yields, minimize labor-intensive practices, or both (Esengun et al. 2007). Recent researches have mentioned that efficient use of energy in agriculture is one of the requisites for sustainable agricultural production, since it offers financial savings, fossil resource preservation, and above all, reduction in its global warming potential (AghaAlikhani et al. 2013). Besides land, farm power is the second most important input to agriculture production (Chamsing et al. 2006).

Ayeyarwaddy Region, also known as “rice bowl of Myanmar,” is the major rice-growing area, housing 26 % of the country’s sown area and producing 28 % of the country’s rice production. Average rice yields of Ayeyarwaddy region are 587.20 and 777.23 kg/ha in rain-fed and irrigated fields, respectively (MOAI 2012). Rice yield in the study area relatively higher than that of other rice-growing regions because of the increasing utilization of modern rice varieties together with intensive use of fertilizers. The rate of chemical fertilizer use in the study area records to be the highest among the agricultural regions of Myanmar (Zaw et al. 2011). Farmers of this region practice double or triple cropping systems through intense input application. Utilization of agricultural inputs in the study area has noticeably been increasing for the past 4 to 5 years, despite the prevailing fact that Myanmar farmers are poorer compared to those of the other countries.

Irrigation is one of the major fossil fuel consuming operations in irrigated rice production system of the study area (Dapice 2011). Summer rice (irrigated rice), grown by pumping ground water for irrigation, involves consumption of almost half of the total energy inputs. However, the current status of agricultural input utilization in Myanmar is still lower when compared to its neighboring countries (Kyung-Ryang and Abafita 2014).

While going through a transition period and opening up for foreign investment (ADB 2013), Myanmar is now standing on the verge to determine appropriate prospective ways. It is also planning to invest in agriculture sector, and at the same time, more advanced agricultural technologies and inputs are expected to get introduced. The input intensification should be cautiously and judicially implemented as it may raise environmental concerns in the country’s agriculture sector in the near future. Therefore, it is urgently needed to identify effective ways that can lead to the efficient use of efforts (energy), pose the least stress on the environment, and ensures higher economic efficiency for agriculture systems of the future. Moreover, it is also needed to adapt to the prevailing/expected climate change as well as to secure food by promoting sustainable crop production. Given the serious lack of research reported in Myanmar in this context, it is therefore important to examine the two most prevailing rice production systems by performing energy balance and energy economic analyses to determine and compare their energy efficiency.

Methodology

Study area

Ayeyarwaddy region is situated in the southern part of Myanmar and on the delta of the Ayeyarwaddy River. It is bordered by Bago region in the north, Bago and Yangon region in the east, and Andaman Sea and the Bay of Bengal in western sides (Sandrine et al. 2008). The region lies between about 15° 40′ to 18° 30′ north latitude and between 94° 15′ to 96° 15′ east longitudes. Its total area is approximately 35,138 km2 (Sandrine et al. 2008).

This region is characterized in the country as having the highest population density, the highest land productivity (mostly alluvial soil), a moderately high rainfall, a generally flat topography, and an excellent environment for growing rice (Sandrine et al. 2008). This delta region is playing an important role in the cultivation of rice on alluvial soil. Its topography is only about 3 m above the sea level in most parts of the region (Myo 2012). About 40 % of total population is housed in this area, out of which, about 85 % are living in the rural parts of Region, mainly engaged in agriculture (Zaw et al. 2011). The average temperature range is from minimum 22 °C to maximum 32 °C, and annual rainfall varies widely within the region: northern part of Ayeyarwaddy receives between 2000 to 3000 mm and coastal area receives between 3500 to 4000 mm (MOAI 2012).

Management practices of rice production systems

Rain-fed rice refers to the rice grown in favorable conditions and it fully depends on the rainfall. Irrigated rice-growing areas are actually marshy during the whole rainy season. When the water drains out at the end of rainy season, rice can be grown there as a single crop with irrigation water sources. In irrigated rice, more than half of the farmers are practicing direct broadcasting method, while in rain-fed rice, about 80 % of farmers grow paddy by transplanting. Although farmers are moving to mechanization, they are still using draft cattle for land preparation and transportation activities; about 50 % of these activities are done by using draft cattle. About 85 % of rain-fed farmers grow high yielding varieties (HYVs) whereas all of irrigated farmers use HYVs. Water source is underground water through pumping. Irrigation is done at a frequency of about 4–14 times with 10–15-day interval depending on the type of soil and duration of rice varieties in irrigated rice. Harvesting is done manually. Machinery and draft cattle are generally used in transportation, threshing, and winnowing—subject to the terrain condition of rice field and availability of machinery.

Method and data collection

Primary data were collected using in-depth interviews from 51 irrigated and 54 rain-fed rice farmers using random sampling method in Zalun Township, Northern Ayeyarwaddy Region during the period of October–December, 2012. Farm classes were identified as small (<2.5 ha) and large (2.5–25 ha) based on the frequency analysis of the respondents’ farm acreage. Fossil fuel, fertilizers, chemicals, human labor and draft cattle used, farm yard manure (FYM), seed, and machineries used were recorded as inputs, and rice (paddy) production (main product) and straw produced were noted as outputs for each farm. Information related to inputs’ cost and product’s returns were also collected to perform the energy benefit–cost analysis.

The physical, chemical, and biological units of agricultural inputs were transformed to energy units by using respective energy conversion factors. The energy equivalents of agricultural inputs in rice production systems are summarized as in Table 1.

Energy balance

Energy inputs include both direct and indirect interventions. Direct energy (DE) and indirect energy (IDE) are widely used classifications in agricultural production—based on source. The DE sources are those that bring out the intended energy directly, like efforts from human and animal, fossil fuel (diesel), and electricity, while the indirect energy (IDE) sources comprise seeds, chemicals, pesticide, fertilizer, manure, and machinery which do not release the energy directly but by conversion process (Kuswardhani et al. 2013). Indirect energy can be further divided into three subgroups: physical energy, chemical energy, and biological energy. The physical energy is a kind of energy that is dissipated when operating machineries and equipment during farm activities. The mechanical power is the main source of physical energy among all the energy used in farm operations (Soni et al. 2013; Taewichit 2012). Chemical energy is the energy that corresponds to chemical fertilizers, pesticides, herbicides, and fungicides. Biological energy includes the inherent energy of seed and hormones (Chamsing et al. 2006).

Energy balances for both the rice production systems are performed by using the Eqs. 1, 2, and 3 (Khan et al. 2009b; Ozkan et al. 2011a, b).

The conversion process of input factors into output (a specific desired commodity) can be summarized by the production function, which also reflects the efficiency of resource allocation (Kuswardhani et al. 2013). It is important to observe that the production function describes technology, not economic behavior. For this purpose, Cobb-Douglass (CD) production function was chosen as this has been reported as an appropriate function in terms of statistical significance and expected sign of parameters (Heidari and Omid 2011; Ozkan et al. 2011a; Ozkan et al. 2011b; Singh et al. 2004). This function has been used by several researchers to examine the relationship between energy inputs and yield, which is expressed as

The linear form of Eq. 5 can be written as

where Y i represents the yield of ith grower, X ij is vector of inputs used in the production process, α 0 is a constant term, α j denotes coefficient of inputs that are estimated from the model, and e i is the error term. As a function of energy input, yield can be expressed as

where Y i represents the ith grower’s yield and X j (j = 1, 2, ….8) designates input energies including human labor (X 1), cattle (X 2), diesel fuel (X 3), fertilizer (X 4), FYM (X 5), seed (X 6), chemicals (X 7), and machinery (X 8). The constant term α 0 in Eq. 7 was considered zero as there is no meaningful production without any energy input.

In terms of the effect of direct and indirect energy sources, the rice production is expressed as

where Y i represents the ith grower’s yield in each production system, β i is the coefficient of exogenous variables, and DE and IDE are direct and indirect energy.

Energy benefit–cost analysis

Agricultural production consumes significant amounts of energy, either directly through combustion of fossil fuels, or indirectly through use of energy-intensive inputs, like fertilizer. Consequently, energy prices affect the costs of production of crops in the agricultural sector (USDA 2012). Energy-related production expenses vary significantly for different crops and cropping systems. Costs and returns of different sources of energy input use in rice cultivation were analyzed to understand the nature of inputs in relation to their energy content (Prasannakumar and Hugar 2011) and were used to demonstrate the energy inputs use along with the efficiency of rice production system by using Eqs. 9 and 10.

Production costs are important to determine farmers’ net returns (profitability), defined as receipts for selling their output less costs of its production. Net returns influence farmers’ decisions (USDA 2012).

Results and discussion

Energy inputs and outputs in irrigated and rain-fed rice production systems

Energy inputs and total energy outputs of irrigated and rain-fed rice production systems are presented in Table 2. The total energy input in irrigated rice is notably higher than that of rain-fed rice. However, the extra investment in energy inputs has also rewarded in proportionately greater energy returns. The total energy input and output respectively are 19,170.5 and 104,162.7 MJ/ha for irrigated and 11,031.1 and 65,033.5 MJ/ha for rain-fed rice production systems.

As shown in Table 2, diesel fuel, fertilizers, and machinery utilization are distinctly higher in irrigated rice than in rain-fed rice. Rain-fed rice in study area is seen as a traditional system while irrigated rice is considered as a relatively more mechanized system. Machinery and diesel fuel use and fertilizer use in irrigated rice system are almost triple and double, respectively, than those of rain-fed rice system. As well as in energy outputs, irrigated rice system produced about 1.5 times that of rain-fed rice system.

The rain-fed rice grown during rainy season may be subjected to surface runoff, especially under heavy rainfall; as such farmers tend to apply lesser quantity of fertilizers in order to avoid fertilizer losses through surface runoff. Under the rain-fed conditions, farmers do not need to pump irrigation water and ultimately they consume less amount of energy compared to irrigated rice system. Due to lesser use of fertilizers and energy consumption, the total energy input in rain-fed condition is less, whereas under irrigated condition, farms are using higher doses of fertilizers as well as utilizing extra fuel for irrigation. However, production remains proportionate with respect to the amount of energy used in both rice production systems.

Results from the study of Iranian traditional rice production systems showed that energy input and output (including straw) were 71,092.26 and 122,962.76 MJ/ha, respectively, while energy input and energy output of mechanized rice system were 79,460.33 and 129,965.88 MJ/ha, respectively (AghaAlikhani et al. 2013).

Energy balance of irrigated and rain-fed rice production systems

Energy balance is important to evaluate the efficiency of agricultural systems in context of energy expenditure and gain. The results (Table 3) revealed that interestingly, the energy efficiency ratios (EER) of irrigated (5.55) and rain-fed rice (5.92) production systems are not statistically significantly different. The specific energy and energy productivity are 3.8 and 0.27 kg/MJ in irrigated and 3.94 and 0.29 kg/MJ in rain-fed rice production systems, respectively. The net energy gain of irrigated and rain-fed rice production systems are 84,992.2 and 54,002.4 MJ/ha, respectively.

It has also been revealed through the results of EER, specific energy, and energy productivity that both rice production systems still have the potential to produce a higher amount of energy output with a higher amount of energy input applied. But in irrigated rice production system, the difference between the energy input and output (net energy gain) is greater than that of rain-fed rice production system. The significance of the differences of these variables between the production systems and the farm sizes was tested using the Mann–Whitney U test (two-sided).

The EER of traditional and mechanized rice systems in Iran were 1.72 and 1.63, respectively (AghaAlikhani et al. 2013). The researchers have also mentioned that the energy productivity of traditional and mechanized rice system were 0.086 and 0.081 kg/MJ, respectively. Then, Ullah (2009) presented the variations of energy productivity in terms of farm size in irrigated rice farming systems of central Thailand. The small (<3.2 ha), medium (3.2–9.5 ha), and large (>9.5 ha) farms had energy productivity of 0.32, 0.28, and 0.24 kg/MJ, respectively. This showed the smaller farms in Thailand were more energy productive than larger farms.

AghaAlikhani et al. (2013) showed the specific energy of traditional and mechanized rice systems were 11.56 and 12.30 MJ/ha, respectively, in Iran. The net energy gains were 51,870.5 and 50,506. 6 MJ/ha in two rice systems, respectively.

Effect of farm size on energy indicators

Energy efficiency ratios are nearly equal in different farm sizes of irrigated rice production system, while for large farms, it is slightly higher than small farms in rain-fed rice production system as shown in Fig. 1. There is no statistically significant difference in energy efficiency ratio between different farm sizes as well as between different rice production systems as shown in Table 4.

Statistically similar energy efficiency ratios in both rice production systems infer that the higher energy input in irrigated rice system resulted proportionately higher production, and at the same time, the lower energy use in rain-fed rice resulted in the lower production. Therefore, efficiency ratios are almost similar although the energy input utilizations are much different in the two systems.

Ullah (2009) reported dissimilar values of energy efficiency for different farm sizes of rice cultivation system in Ayutthaya, Central Thailand. For small (<3.2 ha), medium (3.2–9.5 ha), and large (>9.5 ha) farms, the values were 8.20, 7.00, and 6.02, respectively. These results showed that the smaller farm size in Thailand had the higher energy efficiency. Chamsing et al. (2006) studied the energy consumption for rice production in Thailand and showed that the total energy input for rice production varied between 1790 and 18,490 MJ/ha; energy output–input ratio was 4.0 for irrigated and 2.8 for rain-fed rice.

Khan et al. (2009a) studied energy use pattern of two regimes of rice cultivation (bullock-operated farms (BOF) and tractor-operated farms (TOF)) in a district of Pakistan. Animate energy use in BOF was more than that in TOF due to heavy use of animate energy in land preparation operation. The output–input energy ratio in BOF (6.32) was higher than that in TOF (4.16). Bautista and Miniwa (2010) studied the energy balance for different rice production systems in the Philippines and reported that the energy output–input ratio were 9.0 and 7.5 in rice production systems with canal and pump facility, respectively. In all farms, fertilizer (nitrogen), fuel, and seed inputs still have the highest energy use.

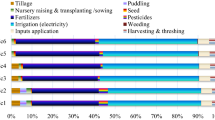

Source-wise and operation-wise energy consumption in rice production systems

Figure 2 depicts the source-wise consumption of energy inputs in rice production systems. Fuel energy consumption is the highest that occupied 33 % of total energy consumption in irrigated rice production system, while in rain-fed rice production system, fertilizer share in total energy consumption is the highest (24 %) among all the sources of energy inputs.

Irrigation accounts the highest input in irrigated rice farming systems due to frequent use of irrigation water. In rain-fed rice system, fertilizer accounts the highest energy input though rain-fed farmers’ fertilizer consumption is lower compared to that in irrigated rice production system.

There are six major operations identified in rice production systems of the study area. Operation-wise energy consumptions were calculated using direct energy such as human labor, draft cattle, and fossil fuel. Irrigation is the highest energy-consuming operation that accounted for 48 % of the total direct energy consumption of farm activities, whereas the land preparation is the highest energy-consuming operation in rain-fed rice production system. Levels of energy consumption in the other operations are shown as in Fig. 3.

In irrigated system, paddy field requires irrigation at 10–12-day intervals throughout the crop growth period and, therefore, consumes additional amount of labor, mechanical, and fuel energy for irrigation. But under rain-fed rice production system, land preparation consumes the highest amount of labor, mechanical, and fuel energy; however, other activities require less amount of energy.

Bockari-Gevao et al. (2005) analyzed energy consumption in lowland rice-based cropping system of Malaysia and reported that the highest average operational energy consumption was for tillage (48.6 %) followed by harvesting (32.6 %) and planting (15.7 %). Operation-wise energy consumptions of irrigated rice system are higher except planting/broadcasting and transportation activities whereas rain-fed rice shows slightly higher energy consumption as depicted in Fig. 3. In irrigated rice system, farmers try to reduce crop duration and, therefore, most of them adopt broadcasting approach. In rain-fed condition, transplanting of seedling is widely practiced. Moreover, in rain-fed condition, farmers have to take away their harvest from paddy field in order to avoid late monsoon rain as well as to make the field available for forthcoming crop. The transplanting of seedling as well as the removal of paddy harvest from the field requires additional labor, animal, machinery, and fuel energy. In irrigated condition, the threshing is performed in paddy field and, therefore, transportation energy is saved.

Costs of energy inputs and energy benefit-cost ratio in rice production systems

The average costs of energy inputs in irrigated and rain-fed rice production systems are shown in Table 5. The total energy cost of irrigated rice production (844.5 USD/ha) is significantly higher than that of rain-fed rice (504.8 USD/ha). Human labor energy source cost component is the highest and the second highest in irrigated and rain-fed rice production systems, respectively. Level of agricultural mechanization is recorded to be very poor. In study area, most of the farm activities in rice production are still heavily depending on human labor. Every farm operation including the machinery operations require the manpower. Thus, irrigation is the highest labor-consuming operation in irrigated rice system. Draft cattle are the biggest source of energy in rain-fed rice system, because rain-fed rice system in Myanmar is a traditional system and use of a large number of cattle in farm activities is highly common. Moreover, use of machinery involves a higher cost per unit of energy dissipation in both the rice production systems.

Total cost of energy inputs, gross returns, net returns, and energy benefit–cost ratio for different farm sizes are shown in Table 6. Total costs of energy inputs are not significantly different between different farm sizes of irrigated rice systems, while those of rain-fed rice system are significantly different. Gross returns, net returns, and energy benefit–cost ratio are significantly different in the two systems but not different in different farm sizes within a given rice production system. The energy benefit–cost ratios of irrigated and rain-fed rice production systems, as shown in Table 6, are 0.9 and 1.1, respectively. Net return in irrigated rice is negative (−56.9 USD/ha), whereas that of rain-fed system, it scores positive value (18 USD/ha). Irrigated rice appear to be heavy energy input consumer, and thus, cost of energy inputs per hectare is relatively higher, which although resulted in higher rice yield, the price of products (rice) is much lower as compared to the cost of inputs. Cost of higher energy input used in the irrigated rice production cannot be covered by the price of produce in the irrigated rice production.

Prasannakumar and Hugar (2011) reported that the cost of input energy for irrigated rice in India was 803 USD/ha, while Cicek et al. (2011) showed that the total cost for rain-fed wheat production was 1205 USD/ha in Turkey. The energy benefit–cost ratio of irrigated rice in India was 2.68 and the energy benefit–cost of rain-fed wheat in Turkey was 0.53.

Interaction of farm size, total input–output energy, and EER

Total input energy use is found to be increasing with the farm size in the study area. Figure 4 shows a non-linear increase in input energy with the farm size in both the rice production systems. Higher coefficient of quadratic input term in the irrigated system confirms that increasingly more amount of input would be needed for larger irrigated farms than in rain-fed production system.

Figure 5 depicts the responsiveness of total input energy used on a farm for generating corresponding output energy in the two rice production systems. In study area, both the rice production systems are very responsive to the energy inputs used (R 2 values in irrigated and rain-fed rice production systems are 0.89 and 0.85, respectively) and show strong linear relationship. However, the slopes (i.e., energy output–input ratio, or EER) are not significantly different. For not following the law of diminishing rate of return of production economics, it can be notably argued that the rice production systems in the study area have yet not reached to their farming inputs’ potential use and hence still represent rather a linear input–output relationship. Every increase in the energy input use could produce proportionally higher energy output. Therefore, these results indicate the potential of rice production systems of study area, which can move along promoting mechanization and modernization to accelerate the increasing rice production.

Relative proportion of direct and indirect energy inputs in both the systems is shown in Fig. 6. Further analysis confirms that in both the systems, this relative proportion did not influence the total output energy (MJ), output energy per unit farm area (MJ/ha), paddy yield (kg/ha), as well as the EER. However, the proportion of human energy to the total input energy was found significantly associated with the farm size (Fig. 7). As can be seen from the power curves, increasing the farm size potentially reduced the human labor involvement in the total input energy from as high as 25 % (in very small farms) to as low as around 1 % (in larger farms). This trend also confirms that larger size farms favor mechanization.

Results of regression of energy input sources and rice yield in both the systems are shown in Table 7. The rice yield was assumed to be a function of inputs including human labor (X 1), cattle (X 2), diesel fuel (X 3), fertilizer (X 4), FYM (X 5), seeds (X 6), chemicals (X 7), and machinery (X 8) (Eq. 7). The production (energy) variables found significantly (p < 0.01) affecting yield in irrigated rice system were human, diesel fuel, fertilizer, and seeds, whereas in rain-fed rice system, the variables were human, fertilizer, seeds, and chemicals (p < 0.05). It has been observed that in irrigated rice system, with partial increase of any energy input by 1 %, while keeping other inputs constant, the potential yield response of labor is 0.34 %, fuel 0.38 %, fertilizer 0.13 %, and seed 0.31 %. In case of rain-fed system, with 1 % increase of any energy inputs, potential yield response of labor is 0.56 %, fertilizer 0.25 %, and seed 0.35 %. In irrigated rice production system, negative coefficient of machinery, though it is not significant, indicates that it has an inverse impact on rice yield which proves that mechanical energy is being overutilized and not being efficiently used practically for irrigation purpose. However, in rain-fed system, fuel consumption as well as chemicals has negative but not statistically significant impact on the yield.

The coefficient of the factors of production shows that that irrigated systems exhibit constant returns to scale, while in rain-fed system, exhibit increasing return to scale, and farmers may increase their output if proper and proportionate input mixes are used.

The relationships among the direct (DE) and indirect (IDE) energy inputs and rice yield (Eq. 8) in both the systems are summarized in Table 8. In the irrigated system, both DE and IDE are related to rice yield significantly (p < 0.01), but in rain-fed system, only IDE was significant (p < 0.01). In the irrigated system, human labor and fuel (DE) and fertilizers and seed (IDE) are the most influencing energy inputs; however, in case of rain-fed systems, labor (DE) and fertilizers and seed (IDE) are the most influencing energy inputs.

Plot of variation in rice yield with the energy efficiency of corresponding farm (EER) (Fig. 8) reveals that the yield is non-linearly related to EER on rain-fed rice farms, where higher rice yields are corresponding to the higher energy efficient farms (farms with higher EER). Whereas irrigated rice yield is not associated with its EER, hence, improving the EER on irrigated rice farms not necessarily improves yield. As its yield has been saturated, it exhibits constant returns to scale.

Furthermore, the effect of intensity of energy input per unit farm area was investigated on EER (Fig. 9). Interestingly, energy input (MJ/ha) intensity on rain-fed rice farms was not associated with its EER. However, on irrigated farms, EER observed a logarithmic decrease with increasing energy input intensity indicating that the inputs on those energy-intensive farms were not being efficiently managed.

Conclusions and recommendations

Based on the aforementioned results, the following conclusions and recommendation may be considered:

-

a)

The total energy input was notably higher in irrigated rice than in rain-fed rice production system—mainly due to higher fuel use and fertilizer application in the irrigated system.

-

b)

Fuel (33 %) and fertilizer (24 %) were the highest contributors among the energy input sources in irrigated and rain-fed rice, respectively. Then, irrigation operation (48 %) and land preparation practice (38 %) were the highest energy-intensive operations in irrigated rice and rain-fed rice systems, respectively.

-

c)

The total energy cost was significantly higher in irrigated rice (844.5 USD/ha) than in rain-fed rice (504.8 USD/ha). Results showed that rain-fed rice did fetch more economic return than the irrigated rice even though the former received the lower energy output.

-

d)

Higher rice yields within the rain-fed farms are corresponding to the farms with higher EER, whereas irrigated rice yield is not associated with its EER.

Based on the mentioned results in irrigated rice, it seems that efficient water use technology and an effective nutrient management could potentially reduce the energy consumption from these operations. It is obviously due to the fact that if inputs (water and fertilizers) in right amount are applied at the right time, it can not only reduce the fuel consumption but also save the costs of fuel, labor, and machinery.

In rain-fed rice, the system seems to have the potential of increasing yield through the increased use of energy inputs, but caution should be taken for judicial utilization of inputs.

References

AghaAlikhani, M., Kazemi-Poshtmasari, H., & Habibzadeh, F. (2013). Energy use pattern in rice production: a case study from Mazandaran province, Iran. Energy Conversion and Management, 69, 157–162.

Asian Development Bank. (2013). Asian development outlook 2013: Asia’s energy challenge. Philippines: Asian Development Bank.

Bautista, E. G., & Miniwa, T. (2010). Analysis of the energy for different rice production systems in the Philippines. The Philippine Agricultural Scientist, 93(3), 346–357.

Bockari-Gevao, S. M., Wan Ishak, W. I., Azmi, Y., & Cahn, C. W. (2005). Analysis of energy consumption in lowland rice-based cropping system of Malaysia. Songklanakarin Journal of Science and Technology, 27(4), 819–826.

Cervinka, V. (1980). Fuel and energy efficiency. In D. Pimentel (Ed.), Handbook of energy utilization in agriculture (pp. 15–21). Boca Raton: CRC Press.

Chamsing, A., Salokhe, V. M., & Singh, G. (2006). Energy consumption analysis for selected crops in different regions of Thailand. Agricultural Engineering International: The CIGR E Journal, 2006, 8.

Cicek, A., Altintas, G., & Erdal, G. (2011). Energy consumption patterns and economic analysis of irrigated wheat and rain-fed wheat production: case study for Tokat Region, Turkey. Bulgarian Journal of Agricultural Science, 17(3), 378–388.

Dapice, D.O. (2011). Myanmar Agriculture in 2011: old problems and new challenges, Ash Center for Democratic Governance and Innovation, Harard Kennedy School.

Esengun, K., Gunduz, O., & Erdal, G. (2007). Input-output energy analysis in dry apricot production of Turkey. Energy Coversion and Management, 48, 592–598.

FAO. (2009). Food security and agricultural mitigation in developing countries: options for capturing synergies. Rome: Food and Agriculture Organization.

Heidari, M. D., & Omid, M. (2011). Energy use patterns and econometric models of major greenhouse vegetable production in Iran. Energy, 36(1), 220–225.

Khan, M. A., Khan, S., & Mushtaq, S. (2009a). Energy and economic efficiency analysis of rice and cotton production in China. Sarhad Journal of Agriculture, 25(2), 291–300.

Khan, M. A., Awan, I. U., & Zafar, J. (2009b). Energy requirement and economic analysis of rice production in western part of Pakistan. Soil and Environmental, 28(1), 60–67.

Kuswardhani, N., Soni, P., & Shivakoti, G. P. (2013). Comparative energy input-output and financial analyses of greenhouse and open field vegetables production in West Java, Indonesia. Energy, 53, 83–92.

Kyung-Ryang, K., & Abafita, J. (2014). Agricultural development in Myanmar: lessons from Korean experience. Korean Journal of International Agriculture, 24(2), 136–151.

MOAI. (2012). Annual report of ministry of agriculture and irrigation. Nay Pyi Taw: Department of Agriculture.

Myo, K.M. (2012). An assessment of soil salinity problems, its impact on rice cultivation and coping strategies of local farmers: a case study in Pyopon Township, Ayeyarwaddy Delta Region, Myanmar after Cyclone Nargis. Master Thesis, Asian Institute of Technology.

Nassiri, S. M., & Singh, S. (2009). Study on energy use efficiency for paddy crop using data envelope analysis (DEA) technique. Applied Energy, 86, 1320–1325.

Ozkan, B., Akcaoz, H., & Fert, C. (2004). Energy input output analysis in Turkish agriculture. Renewable Energy, 29(1), 39–51.

Ozkan, B., Ceylan, R. F., & Kizilay, H. (2011a). Energy input and crop yield relationships in greenhouse winter crop tomato production. Renewable Energy, 36(11), 3217–3221.

Ozkan, B., Ceylan, R. F., & Kizilay, H. (2011b). Comparison of energy inputs in glasshouse double crop (fall and summer crops) tomato production. Renewable Energy, 36(5), 1639–1644.

Prasannakumar, P. S., & Hugar, L. B. (2011). Economic analysis of energy use in paddy cultivation under irrigated situation. Karnataka Journal of Agricultural Science, 24(4), 467–470.

Sandrine, R. (2008). Water, sanitation & hygiene disaster risk reduction assessment, Ayeyarwaddy Division. Action Contre La Faim- Mission Myanmar Report.

Singh, S., & Mittal, J. P. (1992). Energy in production agriculture. New Delhi: Mittal Publications.

Singh, H., Mishra, D., & Nahar, N. M. (2002). Energy use pattern in production agriculture of a typical village in arid zone India: part I. Energy Conversion and Management, 43(16), 2275–2286.

Singh, G., Singh, S., & Singh, J. (2004). Optimization of energy inputs for wheat crop in Punjab. Energy Conversion and Management, 45(3), 453–465.

Soni, P., Taewichit, C., & Salokhe, V. M. (2013). Energy consumption and CO2 emissions in rain-fed agricultural production systems of Northeast Thailand. Agricultural Systems, 116(1), 25–36.

Taewichit, C. (2012). Multiple criteria decision making in integrated agricultural production systems under Thai rain-fed condition. PhD Dissertation, Asian Institute of Technology, Thailand.

Ullah, A. (2009). A comparative analysis of energy use patterns in small and large scale irrigated rice farming systems: a case study in Ayutthaya Province in the central region of Thailand. Master Thesis, Asian Institute of Technology, Thailand.

USDA. (2012). Impacts of higher energy prices on agriculture and rural economies, United States Department of Agriculture.

Zaw, K., Lwin, N., Nyein, K., & Thandar, M. (2011). Agricultural transformation, institutional changes, rural development in Ayeyarwaddy delta, Myanmar. Economic Research Institute for ASEAN and East Asia(ERIA).

Acknowledgments

The authors gratefully acknowledge the support received from the Norwegian Ministry of Foreign Affairs, the Asian Institute of Technology, and the farmers of Myanmar.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soni, P., Soe, M.N. Energy balance and energy economic analyses of rice production systems in Ayeyarwaddy Region of Myanmar. Energy Efficiency 9, 223–237 (2016). https://doi.org/10.1007/s12053-015-9359-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-015-9359-x