Abstract

Cities in Sub-Saharan Africa suffer from widespread disparities in water supply due to depletion in groundwater and global-warming-induced changes in weather patterns. The offset of water head from the design considerations of water pumping systems has increased energy requirements leading to worsening of the situation with respect to availability of energy and water. Consequently, highly capitalized water supply schemes, which have been designed to meet the demand, are underutilized leading to operational inefficiencies. Robust empirical equations can help detect inefficiencies in water pumping systems, and this paper discusses the equations which were developed by analysing data obtained from various water supply utilities facing water scarcity. These equations provide cost-benefit analysis for decision making in water utilities and can bring about energy efficiency in municipal pumping operations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One third of the global population especially those in the developing countries will face serious water shortages by 2025 (Seckler et al. 1998).Between 2010 and 2020, it is predicted that 95 % of the global population growth (766 million) will be in urban areas (690 million), and the bulk of these (632 million) will be added to urban regions in developing countries (UN 2010). This clearly highlights the huge requirement of water infrastructure and additional energy in coming years.

Except Africa, the rest of the world has met 88 % of the target for sustainable access to water (World Health Organization and UNICEF 2012). But, Africa accounts for more than 40 % people who do not have access to safe drinking water (UNECA 2013).The issues overwhelming the water sector include disparity in water supply across regions, depletion of groundwater and undercapitalized municipalities, increasingly irregular rains, ever-growing population, and rising energy tariffs (Biswas and Ching 2011; Rogers et al. 2002). This has left the municipalities in Africa with an ever greater challenge of meeting urban water demand in a cost-effective manner. The high amount of energy consumption, coupled with high maintenance expenditure, is a common factor plaguing the water supply utilities (Halpeth 2002). There are several models and simulation exercises for water utilities to gain the benefits of energy efficiency using control systems. An updated review of all these have been done by Diniz et al. (2014).

Most countries in Africa use fossil fuels as a source to generate electricity (Jacob 2012). Use of fossil fuels leads to air pollution and climate change. Improving energy efficiency and de-linking economic development from energy consumption (particularly fossil fuels) are essential for sustainable development of a region (IPCC 2007). By 2030, over 80 % increase in global annual energy demand above 2006 levels will come from urban areas in developing countries (International Energy Agency 2008).

The main objective of this paper is to validate the drop in operating efficiency of water pumps operating under a water scarcity scenario in African cities. The issue has been addressed with reference to water pumping stations in developing countries, where instrumentation is lacking. Field measurements also show that the instantaneous delivery flow rate of the pumping station and operating head of the system are available, but there are no individual pump input power measurement (kW) devices. The paper discusses a case study and argues for use of equations to make a decision on whether to go in for a detailed investigation of measurements for performance evaluation of urban water utilities or not. The return on investment as well as emission reduction quantification for 5 % improvement in operating efficiency, for rating of pumps up to 500 kW, is also highlighted.

Water supplies in African cities

In Sub-Saharan Africa, despite the progress of providing water supply to 49 % of the population in 1990 to 56 % in 2004, a great effort is needed to achieve the target of 75 % by 2015 (World Health Organization and UNICEF 2006). Meeting this target will be a challenge because of rapid urbanisation and climate change issues, which can delay the progress. Therefore, a continuous review of the urban infrastructure is needed from time to time. The major causes for water scarcity have been discussed below.

Climate change

Climate change impacts in Africa have been strongly felt. Droughts have ravaged the Horn of Africa and left nearly a million people facing starvation, with no access to food, clean water, energy, and public health services. The impact of climate change in Africa was aggravated by the low resilience of the continent, lack of adaptation, and dependence of livelihoods predominantly on rainfall. In the water sector, although the impact has been uneven in Africa, it has been indicated that 350 to 600 million people will face water stress by 2050 (Lamptey 2011).

In Africa the power generation sector is one of the major contributors of CO2 emissions, even though the share of electricity for use by water utilities is low compared to the overall energy consumption. Efficient use of energy and its conservation is the least-cost option to mitigate the gap between the demand and supply (International Rivers 2009).

Urbanization and water supply management

More than 90 % of the world’s urban population growth is taking place in developing countries (UN 2010). Rural-urban migration and natural population growth rates in African cities are the major causes of the increasing rate of urban growth and slum proliferation. In the developing world, Africa has experienced the highest urban growth during the last two decades at 3.5 % per year, and the growth rate is expected to continue up to 2050. In 2010, the share of the African urban population was about 36 %, and this is projected to increase to 50 and 60 % by 2030 and 2050, respectively (UN-Habitat 2011).

In Sub-Saharan Africa, which faces acute water scarcity, the water supply utilities employ various demand management schemes in order to regulate the demand for water (Ruth and Gasper 2008). The demand management programmes taken up by the utilities include intermittent water supply, water loss reduction, comprehensive metering, changes in water pricing concepts, installation of water-saving devices, wastewater reuse, institutional development, public awareness on use of water and educational campaigns. Out of the various schemes, the intermittent supply of water is the most common practice for regulating water supply in developing countries. Various parameters such as duration of water supply, timing of supply and pressure at the outlet are not accounted during the design stage along with water scarcity scenario which results in an over-sized water pumping system (Variravamoorthy et al. 2008).

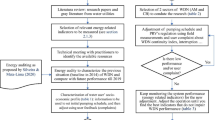

Methodology

Energy conservation studies were carried out across water utilities in least developed and developing countries in Africa. The flow rate and quantity of water pumped, number of pumps in use, duration of operation, monthly energy consumption bills and motor rewinding history were recorded for each pumping station. The actual flow rate of water, inlet and outlet pressures at the pump and power consumed at each installation were measured using the following instruments:

-

Portable load manager to monitor and log the transformer parameters (voltage, current, power factor, kW, kVA, kVAR, Hz and kWh);

-

Clamp on electrical power analysers to measure and log the individual motor parameters connected to pumps (voltage, current, power factor, kW, kVA, kVAR, Hz and kWh);

-

Ultrasonic water flow meter to measure the velocity and flow rate of water at the pump and in the piping system; and

-

Digital pressure sensor to measure the delivery head of the pumps.

The applied research is carried out to obtain pumping station operating data using portable instruments. The portable load manager and clamp on power analyser instruments were applied online, i.e. on running motors without any need to stop the motor connected to the pump. Instant measurements can be taken with hand-held meters; load manger also facilitates cumulative readings with print outs at specified intervals. The same load manger has also been used to monitor power supply to a water supply station at incoming transformer level. Ultrasonic flow meter is non-contact flow measuring device using Ultra sonic principle. There is a transmitter and receiver which are positioned on opposite sides of the pipe connected to a pump. The meter directly gives the delivery water flow. Digital pressure sensors are connected to existing provisions of suction and delivery pipes as well as to main headers to monitor the pump delivery pressure.

The measurements related to the operation of individual pumps and its connected piping system were compared with the design parameters. Motor characteristic curves for various ratings were collected from the manufacturers and used for the analysis. All measurements were made in SI units. These analyses were carried out to realistically assess losses and understand the potential for energy savings which could be implemented. Pumps which are operating at lower head and higher flow rate to design were divided into four categories on the basis of flow and head. Regression analysis was carried out with deviation in percentage flow and head using DataFit software, to evaluate drop in operating efficiency of the pumps.

Urban water utilities of 7 African cities and 10 small towns in Uganda share pumps operating in water scarcity and deviating from design pump efficiency levels. The measured pump performance data from these cities have been used for the validation analysis of equations which were developed (TERI 2013). The return on investment is due to improvement of pump efficiency by 5 % with prevailing electricity unit cost in African countries for pump rating up to 500 kW calculated. Also taking into account emission factors for studied African countries for 5 % efficiency improvement of pumps, CO2 emission reduction per annum is presented.

Energy conservation opportunities

The measurements and analysis were carried out for 208 pumps of different ratings (connected motor to pumps from 11 to 1190 kW) installed across 7 African cities and 10 smaller towns in Uganda. The number of pumping stations, water resource and its energy consumption data location-wise are provided in Table 1. The specific energy consumption per cubic metre of water pumped in the cities and towns is given in Fig. 1. The operating specific energy consumption of the pumping stations depends upon the length of the system and the elevation changes involved (Plappally and Lienhard 2012). Based on the analysis, the identified energy-saving measures were categorised into two sections—electrical systems and pumping systems.

Electrical system

The water utility draws power from the local electricity distribution companies for operations. Electricity is drawn from the grid via a substation, and it is stepped down to the required voltage for operating motors and lighting. It was observed that each electrical distribution company has its own demand charges and unit electricity cost charges (except Jos City, Nigeria, has only energy charges). Power factor penalty surcharge was applicable to the water utilities that were studied. Based on the operations of the pumps to meet the water demand and analysis of past monthly energy bills, potential areas like improving power factor to reduce demand, surrendering of contract demand and realizable cost savings were computed. The evaluated annual cost savings potential by improving the power factor is 1.0 and 2.2 % for Accra and Bamako cities, respectively. However, for other cities, the annual cost saving potential is to the tune of 0.1 to 0.3 % of the energy bill.

Pumping system

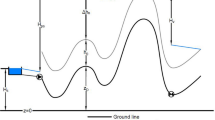

In a water pumping system, the objective is to transfer the water from a source to a required destination, i.e. filling a high-level reservoir or a tank. It consists of motors to drive pumps and pipelines connected to the pumps to transfer water to storage facilities (reservoirs, overhead tanks, etc.) or to the end users (customers). The pressure (head) and flow rate (capacity) are the main factors which affect the horsepower size of the motor to be used. The higher the quantity of water to be pumped, the higher is the energy required. The pump is among the most inefficient of the components that comprise a pumping system, including the motor, transmission drive, piping and valves. When a pump is installed in a system, the operating point will always be an intersect point of the pump and system curves. The intersect point should be a high-efficiency point in a pump curve. Whenever the pump’s operational point shifts to either side of the best efficient line, there is scope for pump’s efficiency improvement (TERI 2009).

In most developing countries, urban water supply systems operate on a continuous mode due to increased demand for water. In a well-designed system, pumps operate close to their designed pump efficiency. The operational pattern of the pumps in a given system deviates based on the physical quantity of water availability (as water demand or water scarcity scenario). For easy understanding, the inefficiencies that can be seen in urban water supply pumping systems are given in Fig. 2.

During the water demand scenario in a given piping system, the installed pumps operate as (i) additional water pumps operate for incremental flow rate, (ii) for a given rated flow of pumps, existing pipe size will be smaller to get combined delivery flow and (iii) the installed capacity of the pumps will be higher where the piping system will resist the flow rate.

Similarly, during the water scarcity scenario, the installed pumps operate as (i) less number of pumps operates to maintain the minimum reservoir levels, (ii) pumps operate based on the water availability, by less number or as per design and (iii) piping systems are designed for future demand, and less number of pumps operates based on the water availability.

In the above two scenarios, offset of water head from the design consideration of water pumping systems usually increases the energy requirements leading to worsening of the situation in the availability of both energy and water. A deviation in the system curve (to design) is also likely to make the centrifugal pumps operate in a lower efficiency zone.

Based on the analysis of the pumps in the African cities (shown in Fig. 3), the pumps were categorized as best efficiency, drop in efficiency due to water demand or scarcity and drop in efficiency due to operational and maintenance (O&M) problems. Best-efficiency mean pumps operate close to its design pump efficiency (drop by 3 %). The pump efficiency drops over 3 % due to defined operating conditions of water demand and scarcity. During the studies, it was observed that some of the pump’s internals were damaged, erosion of the impellers had taken place, due to frequent power failures, motors had gotten burnt out, and those connected to pumps were categorised as O&M. The figure clearly shows that more number of pumps was operating at a lower efficiency under the water scarcity scenario.

Analysis of data: case study

About 70 % of water demand of OuAgadougou City in Burkina Faso is met by the Ziga water supply scheme which started in 2004. In 2012, the water treatment capacity of Ziga Scheme was enhanced from 72 to 100 million litres per day (over 33 %) to meet the additional water demand of the city. The Ziga Reservoir (200 million m3 storage) is about 50 km away from the main city. A long-distance water source along with a wide distribution network has led to a substantial expenditure on pumping. Water is supplied through a network of reservoirs, overhead tanks and pipes for distribution. The reservoirs/overhead tanks are located according to their altitudes and booster pumps are used to lift the water. The final city distribution is done by gravity from these reservoirs. The share of energy consumption by Ziga Scheme (SP1 and SP2) is 47.8 % of the total water utility’s electricity consumption.

The intake well gets water from the barrage (dam) built across Nakambe River. The raw water pumping station (SP1) acts like a first-level booster station, where the water pressure is raised to reach the treatment plant storage tank at an elevation, and then, the water is allowed to pass through the water treatment plant. The distance between the raw water intakes to the treatment plant is about 2 km. The capacity of the Ziga water pumping station has been augmented, and during augmentation works, the Ziga scheme raw water pump impellers were substituted with higher capacity ones (from initial pump flow of 790 to 900 m3/h). Five raw water pumps are continuously operated to meet the water demand, and the measured delivery flow rate was 4615 m3/h.

The raw water is collected in the surface storage tank at SP2 Ziga Scheme, where the treatment process is carried out. The treated water is pumped in a single-stage parallel pumping scheme to an elevated storage tank before supplying to the user end (with intermediate storage SP3) tanks by pumping/gravity. The elevated reservoir of 5400 m3 is located at Boudtenga, which is 17.3 km from the SP2 pump house.

During the augmentation programme, the low pressure (81 m) pump impellers were replaced with high pressure (104 m) ones at the clear water pumping station (SP2). During normal operations, five clear water pumps are operated in parallel to meet the water demand. The delivery flow and head developed by individual operating pumps as well as combined flow of five pumps are measured. The measured delivery combined flow rate (4280 m3/h) from the pumps is slightly higher compared to the design capacity (750 m3/h for each pump), but the pumps operate at a lower pressure (85 m) than the design value (104 m).

New empirical equations

In many municipal water utilities in developing countries, there is a lack of information about the operational efficiency of the pumps. Moreover, getting the manufacturer’s pump design efficiency figures is difficult for municipal engineers at site. The authors have developed the empirical equations based on field measurements done during the last 7 years across several water utilities in various developing countries. A regression analysis using DataFit software (version 9.0.59) was used.

The ratio of design to operational flow and head was used as inputs to assess the drop in operational pump efficiency. The empirical equations developed are grouped into four categories based on the pump design flow rate.

-

Category A1: flow rate up to 500 m3/h and lower head (below 100 m)

-

Category A2: flow rate up to 500 m3/h and higher head (above 100 m)

-

Category B: flow rate between 501 and 1000 m3/h

-

Category C: flow rate between 1001 and 2000 m3/h

The empirical equations for the different categories are given in Table 2.

The values of the coefficients for the four categories are given in Table 3.

If the operating head and flow rate are known, the above equations can be used to evaluate the drop in operating efficiencies of the pumps in the relevant category (A1, A2, B and C). Once the drop in efficiencies is known, an economic analysis can be carried out for decision-making with the cost and benefit of replacing the existing pumps. The developed equations are verified with a set of pump data for four categories to identify deviation between actual calculation and predicted values from the empirical equations. Figure 4 shows the referred values.

Thus, there is significant scope for energy as well as cost savings by improving the operating efficiencies of the pumps in the municipal water utilities. The empirical equations also help in decision-making regarding the replacement of pumps in the water pumping stations under water scarcity. The <R 2> values for the generated equations fall within the range of 0.924 to 0.995, proving that there will be very close variations in the predicted values of the efficiencies.

Validation of empirical equations

The empirical equations developed have been tested using field measurement data gathered during the study of operational pumps (SP1 and SP2). The average measured values for five running pumps are used for comparative analysis. The predicted values from the equations are given in Table 4.

The combined efficiency (pump and motor) is evaluated based on the actual measured flow (m3/h), head (m) and power (kW). Taking into account the motor efficiency values from the manufacturer’s curves, actual efficiency values of individual pumps have been derived and compared with predicted efficiency values. The efficiency predicted by using the empirical equations proposed in the paper is very close to the actual operational efficiency of the pumps (given in Table 3).

The operating efficiency of SP1 pumps (~82 %) is close to the design pump efficiency level (85 %). The SP2 pumps are operating in the range of 63 %, which is lower compared to the design efficiency levels of 80 %. Due to a lower operating pressure, the operating efficiency of the water pumps (SP2) is less by over 15 %. Replacement of impellers for SP2 pumps, to match the required head and flow, can result in electrical load reduction of 196 kW, which is equivalent to 2.8 % of the electrical load of Ouagadougou City towards water supply. The evaluated return on investment for replacement of the impellers for the seven pumps is 1.8 years.

Considering the efficiency of the motor, ŋm 94 % (based on the manufacturer’s data)

Results and discussions

Identification of drop in operating efficiency of pumps is very important for urban water supply systems working under the water scarcity scenario. Based on the drop in operating efficiency, a decision can be made for replacement of pumps or refurbishment of internals (impellers) to match the pumping system curves. The drop in operating efficiency of pumps is as high as 17.7 % in the design efficiency levels in the case study discussed in this paper. The pumps operating under the water scarcity scenario have been verified using empirical equations as well as actual measurements, and the category-wise verified pump details are given in Fig. 5.

A drop in operating efficiency of the pumps below 5 % can be allowed. However, more than 5 % drop in efficiency calls for a detailed examination. The rating of a large number of water supply pumps is below 500 kW. Based on the pump rating, the realisable energy savings potential with a 5 % drop in efficiency level along with the unit energy cost and return on investment cost is provided in Fig. 6 (a, b, c, d).

Operating pumps in a water scarcity scenario also result in higher emissions due to higher energy consumption. An analysis for the drop in efficiency to 5 % level is calculated over the pump rating up to 500 kW taking into account the country-wise emission factors. According to a report, the carbon dioxide emissions for generating 1 kWh of electricity in Sub-Saharan nations (International Energy Agency 2012) are as follows:

-

Nigeria, 402 g of CO2/kWh of electricity generated

-

Ethiopia, 82 g of CO2/kWh of electricity generated

-

Ghana, 221 g of CO2/kWh of electricity generated

-

Zimbabwe, 660 g of CO2/kWh of electricity generated and

-

Uganda, Mali and Burkina Faso (as other African countries), 479 g of CO2/kWh of electricity generated.

Using the above values, the reduction in carbon dioxide emissions for 5 % improvement in pump efficiency (for available pump ratings) is given in Fig. 7. Studied African nations’ emissions are falling between the developed and developing countries (Europe—243, USA—528, China—790, India—936 g of CO2 /kWh of electricity generated).

Over and above the 5 % improvement in pumping systems, it is important to evaluate the energy efficiency of the municipal water pumps with respect to cost savings as well as emission reductions. Energy efficiency, in turn, reduces the carbon footprint for urban water utilities by the same percentages, adding up to thousands of tonnes of CO2 per year. So, water supply systems are a good candidate for an emission reduction programme under local climate change mitigation actions.

Conclusions

End use (like urban water utilities) energy efficiency is the largest contributor to CO2 emission abatement in 2030, accounting for more than half of the total savings needed to maintain greenhouse gas emissions in the atmosphere to 450 parts per million CO2 equivalent (International Energy Agency 2008). This is based on options and technologies available today. Various energy efficiency instruments are in use to achieve energy savings. The derived empirical equations are an easy and cost-effective means to assess the drop in operating efficiency of urban water supply pumps during the water scarcity scenario. This can be used to take a policy decision for the replacement of pumps or internals (Impellers) as an investment leading to energy and cost savings and also help mitigate the impacts of climate change.

References

Biswas, A., & Ching, L. (2011). Why water weeks count. Singapore: The Strait Times. Water World 2011.

Diniz, A. M. F., Fontes, C. H., Da Costa, C. A., & Costa, G. M. N. (2014). Dynamic modeling and simulation of a water supply systems with applications for improving energy efficiency. Energy Efficiency Journal. doi:10.1007/s12053-014-9292-4.

Halpeth, M. K. (2002). Emerging trends in energy management of pumping system. .Sponsor- Indian pump manufacturers association. Journal of the Institution of Engineers, 36-43.

International Energy Agency. (2008). World energy outlook 2008. International energy agency. Paris http://www.worldenergyoutlook.org/media/weowebsite/2008-1994/weo2008.pdf Accessed on 26 Sept 2013.

International Energy Agency. (2012). CO2 emissions from fuel combustion highlights. 2012 Edition. 111-113. www.iea.org http://www.iea.org/co2highlights/co2highlights.pdf Accessed on 6 Oct 2013.

International Rivers. (2009). Energy efficiency: the greenest electricity source. Publication of the International Rivers. www.internationalrivers.org.

IPCC. (2007). Climate change 2007: the physical science basis. Contribution of working group I to the fourth assessment report of the intergovernmental panel on climate change. Cambridge: Cambridge University Press.

Jacob, K. (2012). Africa yearns for electricity. Wartsila report. Finland. 7-10 www.smartpowergeneration.com. Accessed on 13 Oct 2013.

Lamptey, B. (2011). Vulnerability and climate change hotspots in Africa mapping based on existing knowledge. First conference on climate change and development in Africa (CCDA-I). Development First: Addressing Climate Change in Africa, Addis Ababa, Ethiopia.

Plappally, A. K., & Lienhard, V. J. H. (2012). Energy requirements for water production, treatment, end use, reclamation and disposal. Renewable and Sustainable Energy Reviews, 16, 4818–4848.

Rogers, P., de Silva, R., & Bhatia, R. (2002). Water is an economic good: how to use prices to promote equity, efficiency and sustainability. Water Policy, 4(2002), 1–17.

Ruth, M., & Gasper, R. (2008). Water in the urban environment: meeting the challenge of a changing climate. OECD International Conference: Competitive Cities in Climate Change. Milan. Italy.

Seckler, D., Molden, D., & Barker, R. (1998). Water scarcity in the twenty first century. IWMI Water Brief 1. Colombo: International Water Management Institute (IWMI).

TERI. (2009). Best practices guide: energy efficiency in municipal water pumping, Bangalore. India. 59-71.

TERI. (2013). Municipal energy efficiency outreach programme reports (2002–2013). Bangalore. India.

UN. (2010). World urbanization prospects: The 2009 revision. United Nations. Department of Economic and Social Affairs. Population Division. New York. NY http://esa.un.org/unpd/wup/Documents/WUP2009_Highlights_Final.pdf Accessed on 24 Sept 2013.

UNECA. (2013). Assessing progress in Africa towards the millennium development goals: Food security in Africa - Issues, challenges and lessons. MDG report 2013.

UN-Habitat. (2011). Cities and climate change global report on human settlements 2011. http://www.zaragoza.es/contenidos/medioambiente/onu/538-eng-ed2011.pdf Accessed on 3 Oct 2013.

Variravamoorthy, K., Gorantiwar, D. S., & Pathirana, A. (2008). Managing urban water supplies in developing countries – climate change and water scarcity scenarios. Physics and Chemistry of the Earth, 33(2008), 330–339.

World Health Organization and UNICEF 2006 Report. (2006). Meeting the MDG drinking water and sanitation target: the urban and rural challenge of the decade. http://www.wssinfo.org/fileadmin/user_upload/resources/1198239354-JMP_06.pdf Accessed on 29 Sept 2013.

World Health Organization and UNICEF 2012 Report. (2012). Progress on drinking water and sanitation 2012 update http://www.unicef.org/media/files/JMPreport2012.pdf Accessed on 24 Sept 2013.

Acknowledgments

The authors thank UNHABITAT for providing opportunities to work with Urban Water Supply Companies on energy efficiency projects. We would also like to thank the following water and electrical utility for sharing the data and information of Addis Ababa Water and Sewerage Authority (AAWSA), Ghana Water Company Limited (GWCL), National Water and Sewerage Corporation (NWSC), Office National Del’Eau etdel’ Assainissement (ONEA), Plateau State Water Board (PSWD), Societe Malienne De Gestian De Leau Potble—S.A (SOMAGEP—S.A) and Zimbabwe Electricity Transmission and Distribution Company (ZETDC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rao, G.R.N., Ahmed, S., Sailaja, R.R.N. et al. A decision-making approach for energy efficiency improvement in municipal water pumps during water scarcity scenario. Energy Efficiency 9, 141–151 (2016). https://doi.org/10.1007/s12053-015-9354-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-015-9354-2