Abstract

Unconventional shale petroleum systems, owing to their petroleum generation and storage properties have gained tremendous exploitation and research interest in recent years. Moreover, their emergence as potential atmospheric carbon dioxide sinks has further warranted a detailed examination of their multiple properties. Laboratory geochemical screening and geomechanical investigations provide valuable information for classifying these reservoirs. Although some guidelines exist for conducting such analyses, the analytical methods and sampling techniques applied do influence the quality of the derived measurements. For laboratory geochemical screening using the Rock-Eval technique, various factors including sample grain size, type of kerogen, sample quantity, and nature of S2 and S4 curves, all substantially influence the quality of the data generated. In this work, we summarize the different factors that influence the data generated from Rock-Eval analysis and recommend a method that involves optimization of sample weight and sizes for the generation of reliable geochemical data. A new emerging technology in the field of organic petrography for the simultaneous characterization of organic and inorganic phases in shales has also been discussed. Once source-rock potential of the shale formation is ascertained, the next step is a selection of suitable target shale reservoir zones, and designing successful hydraulic fracturing programs for the exploitation of the reservoir. For this purpose, detailed knowledge of geomechanical properties is essential. However, the quantity of intact shale-core samples recovered from coring operations is typically insufficient for reliably analyzing geomechanical properties by applying the established standards. A comparison is made between the uniaxial compressive strength and Young's modulus measurements on shale specimens of different length-to-diameter ratios. It reveals that specimens smaller than the recommended standard exhibit unacceptable variations in the values of strength and elastic parameters they generate. To overcome this, it is justified to use alternative techniques suited to the small sample sizes typically recovered in borehole shale cores. For instance, a punching tool and nanoindentation, which require small sample sizes, can both be used to reliably analyze geomechanical properties in circumstances where larger shale samples are not available from borehole zones of interest.

Research highlights

-

Sample handling and preparation is critical for producing reliable data from geochemical and geomechanical screening measurements of shales.

-

Sample weight and sizes have significant influence on the quality of the geochemical data generated using Rock-Eval technique.

-

Optical-electron correlative microscopy- a new tool for shale heterogeneity study

-

Critical evaluation of the generated pyrograms is necessary before accepting the Rock-Eval measurements.

-

The limited shale core sample availability issues can be mitigated using techniques like punching-tool and nano-indentation which are specifically tailored for small samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, unconventional shale petroleum systems have received continued interest from researchers due to their development as commercial hydrocarbon plays (Curtis 2002; Jarvie et al. 2007; Loucks et al. 2009; Ross and Bustin 2009; Mastalerz et al. 2012; Varma et al. 2015; Singh et al. 2021a). Additionally, with global concern associated with increasing carbon dioxide (CO2) in the atmosphere and the ambition set by several countries to off-set CO2 emissions, shales have emerged as potentially viable reservoirs for geological sequestration of CO2 (Godec et al. 2013; Heller and Zoback 2014; Hazra et al. 2018a; Vishal et al. 2019). For understanding gas-in-place estimates and sequestration potential in shale reservoirs, organic and inorganic matter-hosted porosity has been identified as a critical factor that controls the success of these reservoirs. Using multiple analytical techniques, viz., imaging and microscopy, low-pressure gas adsorption, and small angle scattering techniques, notable developments have occurred in recent years toward understanding the factors that control the evolution of porosity in shale reservoirs (Kuila and Prasad 2013; Tian et al. 2013; Wang et al. 2016; Liu et al. 2017; Hazra et al. 2018b, 2020a, 2022; Chandra et al. 2020, 2022, 2023; Chandra and Vishal 2020, 2021).

Laboratory screening of shale cuttings or core samples, in terms of their oil and/or gas generation potential, is a critical first step for the evaluation of any potential shale reservoir (Jarvie et al. 2012a, b; Varma et al. 2014; Carvajal-Ortiz and Gentzis 2015; Hazra et al. 2017, 2018c; Singh et al. 2021a, b). Different important parameters, viz., amount of free hydrocarbons present, organic matter thermal maturity levels, organic richness, reactivity, and type of kerogen present, are routinely analyzed as part of the basic first step of laboratory geochemistry screening of shales (Jarvie et al. 2012a, b; Carvajal-Ortiz and Gentzis 2015; İnan et al. 2017; Hazra et al. 2019a, b).

Open-system pyrolysis-oxidation analysis using Rock-Eval has found extensive use for critical evaluation of conventional hydrocarbon source rocks, unconventional shales petroleum systems, coalbed methane systems, utilization suitability of coal types, and organic matter characterization in soils and shallow sediments (Lafargue et al. 1998; Behar et al. 2001; Sykes et al. 2002; Disnar et al. 2003; Vinci Technologies 2003; Sanei et al. 2005; Peterson 2006; Poot et al. 2009; Sebag et al. 2016; Hazra et al. 2020a, b; Raghuvanshi et al. 2020). In general, the technique provides reliable estimates for several rock characteristics that help in the screening of prospective horizons. These factors combined with a simple Rock-Eval operation mechanism, minimal sample handling steps, and output of easy-to-interpret data, have led to the extended application of the Rock-Eval system for geochemical screening studies. However, different factors influence the quality of data produced by Rock-Eval. Although a set of guidelines has been prescribed in the Rock-Eval user's guide, often researchers have highlighted additional factors that should be considered comprehensively before analysts can rely confidently on the data generated (Snowdon 1995; Inan et al. 1998; Dembicki 2009; Carvajal-Ortiz and Gentzis 2015; Hazra et al. 2017). Moreover, different sampling methodologies and temperature ranges have been applied for characterizing shales and coals (see section 2.1). For comparison and critical evaluation of data, it is pertinent that a uniform approach is taken for laboratory geochemical screening of shales. In this paper, we discuss the different factors that affect Rock-Eval-derived data and touch on what steps should be taken for generating reliable and reproducible data.

Once a shale formation is successfully identified for its potential hydrocarbon generation capacity, the next step is its economic development for production through hydraulic fracture (HF) stimulation. Unlike conventional gas and oil reservoirs, shale plays have very low permeability (<nano-darcies) (Holden et al. 2012). Therefore, HF is employed to induce artificial permeability by creating dense and extensive fracture network systems for the tight gas or oil to flow to the wellbore (Ozkan et al. 2009). The development of a successful HF program also requires a sound understanding of the geomechanical properties of the targeted formation (Josh et al. 2012; Eshkalak et al. 2014). Geomechanical parameters such as uniaxial compressive strength (UCS), tensile strength, Young's modulus, Poisson's ratio, fracture orientations, and geometry are essential in developing models for predicting the geomechanical environment in the sub-surface formations based on the quantitative and/or qualitative measurements of the geomechanical properties (Iferobia and Ahmad 2020). These properties are either directly measured through laboratory techniques (so-called static properties) or are estimated from down-hole wireline-log recordings (so-called dynamic properties). Static properties are generally considered to be more representative of actual geomechanical formation properties (Jin et al. 2018). Consequently, dynamic properties are typically calibrated against core-derived static data in geomechanical analysis using wireline datasets for shale and coalbed methane reservoirs (Wood and Cai 2022). A fundamental challenge in determining the static properties of shales is to meet the suggested sample preparation standards. Commonly, there is an insufficient recovery of intact shale-core samples from wellbores (Nguyen et al. 2007; Lee et al. 2014; Han et al. 2017). This study addresses the problems associated with shale coring and handling, and laboratory estimation of geomechanical properties, and recommends alternate techniques as solutions to those problems.

2 Requirements for a shale assessment protocol

2.1 Organic geochemistry

2.1.1 Basic protocol for laboratory geochemical screening using Rock-Eval

Open-system, temperature-programmed, combined pyrolysis-oxidation, analytical techniques such as Rock-Eval have convincingly been used throughout the recent decade for source-rock screening of conventional hydrocarbon systems, unconventional shale petroleum systems, coal and coalbed methane, whole-rock, and kerogen kinetics (Espitalié et al. 1977; Behar et al. 2001; Jarvie et al. 2007; Jarvie 2012a, b; Chen et al. 2017a, b; Hazra et al. 2021a, b; Singh et al. 2021a, b). The Rock-Eval equipment operational guidelines recommend using ground rock samples with particle sizes within the range of 100 μm to 2 mm, and sample weight between 50–70 mgs for shales and 10–20 mgs for coals (Vinci Technologies 2003). In general, the first stage of the analysis is the pyrolysis cycle and that is followed by the oxidation cycle. Ideally, when the Rock-Eval Basic/Bulk-Rock method is used for analysis, the following analytical sequence takes place:

-

Initial isothermal phase at the start of the pyrolysis cycle (inert atmosphere) at 300°C for 3 minutes. The free hydrocarbons within the samples are released during this phase and detected by the Flame Ionization Detector (FID). The data generated during this phase is denoted as the S1 curve.

-

Non-isothermal heating phase from 300–650°C at 25°C/min heating rate. The heavier hydrocarbons within the kerogen crack during this non-isothermal phase. The gases they release are detected by the FID and the recorded data is denoted as the S2 curve. The temperature peak (Tmax) of the S2 curve is used as a thermal maturity proxy.

-

The oxygenated compounds within the kerogen also crack during the S2 phase up to a temperature of about 400°C, generating CO2 and carbon monoxide (CO). These are detected by the Infrared detector (IR) and recorded as the S3 curve. Hydrocarbons released under S1, S2, and S3 curves are used to calculate the pyrolyzable carbon (PC) content of the samples.

-

Once the final pyrolysis temperature is reached, the pyrolysis oven is cooled to 300°C. This is followed by transferring the sample-loaded crucibles to the oxidation chamber where a subsequent heating ramp is applied from 300°C, in presence of oxygen, to a final temperature of 850°C or 750°C (depending on whether carbonate minerals need to be quantified; Hazra et al. 2017, 2019a, b). The heating rate applied during the oxidation phase is 20°C/min. The pyrolyzed-kerogen within the sample is burnt during this oxidation stage generating CO and CO2, which is detected by a separate IR detector. The CO and CO2 generated from the decomposition of organic matter are represented as S4CO and S4CO2, and ideally, the decomposition takes place below 650°C (Behar et al. 2001). The data of the S4 curve indicates the presence of residual carbon (RC) in the sample and contributes towards the total organic carbon (TOC; TOC = PC + RC) content of the rock sample.

Although the Rock-Eval methodology described is straightforward, and the data generated is relatively simple to interpret for screening purposes, published research using Rock-Eval data is associated with alternative methodologies and fluctuating results, leading to ambiguities. For example, Khangar et al. (2021) while assessing Permian shales from India specified the use of 1–2 grams weight of samples for the Rock-Eval analysis they conducted. Considering the shape and dimension of the stainless-steel crucibles used for Rock-Eval analysis, it is almost impossible for that equipment to accommodate such large samples. Moreover, earlier research has documented using minimal sample quantities for type I-II kerogen-bearing shales (~5 mgs; Carjaval-Ortiz and Gentzis 2015) and type III-IV kerogen-bearing shales (5–10 mgs; Hazra et al. 2019a, b). The reason for this requirement is that larger samples are likely to saturate the FID equipment and consequently generate inaccurate TOC calculations (see section 2.1.2). These considerations indicate that Khangar et al. (2021) might not have followed the appropriate steps for generating reliable data using Rock-Eval equipment. In the same study, they also mentioned that for S2 determination the samples were pyrolyzed from 300–550°C. While, heating programs and cycles of Rock-Eval can be altered depending upon the end requirement of users, applying a maximum temperature of 550°C for the S2 curve raises doubt about the quality of data being generated. This is of concern as the samples analyzed in that study were predominantly type III kerogen-bearing, mature shales from the Jharia basin, India. Pyrolysis upto 550°C would result in the incomplete release of hydrocarbons during the S2 phase, and, consequently, the S2 curves would be abruptly truncated. Unfortunately, the S2 pyrograms were not displayed in that study. Similar, unusual heating rates have also been reported by other researchers. For example, Li et al. (2021) and Małachowska et al. (2022) mentioned that for the Rock-Eval oxidation stage, a heating rate of 25°C/min was used. However, as per the protocol suggested in the Rock-Eval user's guide, during the oxidation stage, a heating rate of 20°C/min should be used for analysis. At different heating rates, the decomposition range of the pyrolyzed organic matter during the oxidation stage is likely to also change, and, consequently, the TOC estimated could be inaccurate.

The above discrepancies in the Rock-Eval methodologies adopted by different researchers/laboratories create doubt and uncertainty about the reliability of some of the data generated using the Rock-Eval method, as reported in the literature. In this regard, a common approach must be taken by researchers for generating consistent and reliable data. However, the approach taken and protocol adopted, would, to some extent, be dependent on the nature of the samples. Consequently, visual examination of the Rock-Eval pyrograms and oxidation graphics generated is essential to provide confidence in the data generated (Carjaval-Ortiz and Gentzis 2015; Hazra et al. 2019a, b).

2.1.2 The need for a unified Rock-Eval analytical protocol

In recent years, for the purpose of effective source rock screening, different researchers have adopted different approaches which have helped in identifying the factors that can affect the precision of the data generated. The different factors identified are summarized below:

(a) Impact of particle crush-size on Rock-Eval recorded values: When a range of grain sizes are used for experiments, different results can be generated. This occurs due to the differences in the amount of surface area provided by the number of grains in the sample being subjected to pyrolysis and oxidation. The surface area provided by the crushed grains will control the ease with which reactions and heat transfer within the sample can take place. Consequently, some of the data generated can be strongly influenced when samples with different particle sizes are subjected to Rock-Eval. Inan et al. (1998) examined the influence of particle crush-size on the quality of data generated using the Rock-Eval technique. Their results indicate that for humic coals and organic-rich shales, the nature of hydrocarbon generation across different particle sizes is primarily dependent on the nature of the kerogen. For hydrogen-rich-kerogen-bearing samples, there was the least resistance to hydrocarbon generation in coarser-sized samples. On the other hand, hydrogen-poor-kerogen-bearing samples coarse samples displayed greater resistance to hydrocarbon generation.

A strong influence of particle crush-size on hydrocarbon generation from shale samples was reported by Hazra et al. (2019a, b) for type III-IV kerogen-bearing Permian shales (India). For shales of different organic richness (TOC: ~8 wt% and ~30 wt%), they observed S1, S2, TOC, PC, and RC to be substantially reduced when the particle crush-sizes were between 1 mm and 500 µm. Conversely, the recorded values of those parameters were higher when the sample particle crush-sizes were between 212 and 75 µm. Similar influences of particle crush-sizes on recorded parameter values were also identified by Hazra et al. (2019a, b) and Singh et al. (2021a, b). Table 1 shows the results of a Permian shale, RB5, from Rajmahal basin, India, crushed at two particle sizes of (a) –1 mm and (b) –212 µm. Figure 1 shows the S2 pyrograms generated for those two samples. An increase in FID signal and thereby S2 curve magnitude can be observed with decreasing particle size for those samples. Consequently, an increase in hydrogen index (HI) and TOC can be observed for the sample with finer-grained particle sizes. Both PC and RC were observed to increase as sample crush size becomes finer, indicating enhanced reactivity caused during both pyrolysis and oxidation Rock-Eval cycles.

(b) Impact of sample weight on Rock-Eval recorded values: Similar to particle crush-size, sample weight used for analysis can substantially affect the precision of the data generated. In a study addressing precise geochemical screening of type I-II kerogen-bearing Green River shale, Carvajal-Ortiz and Gentzis (2015) demonstrated that at higher sample weights, the Rock-Eval-model-6 equipment's FID becomes saturated and consequently the S2 and TOC values it generates are substantially reduced, resulting in imprecise interpretations. When high-pyrolyzate-yielding samples are analyzed, the Rock-Eval user's guide recommends using higher sample weights. However, with larger samples, greater amounts of hydrocarbons are generated beyond the upper reliable detection limit of the FID. As a consequence, the shape of the S2 curves generated becomes broader and does not follow an ideal, narrow Gaussian shape. Based on their observations, Carvajal-Ortiz and Gentzis (2015) recommended using low sample weights of ~5 mgs for high oil-yielding samples. In another work, Hazra et al. (2019a) noted an increase in S2 and more importantly HI with increasing sample weight used for type III kerogen-bearing Permian shales (India) and a Norwegian geochemical standard, JR-1. They postulated an explanation for those results in terms of nonlinear effective thermal conductivities and different thermal conduction paths. That concept suggests that a larger weight sample may present more heat conduction paths and heat-trapping at the same time than smaller weight samples.

The strong impact of sample weight on the Rock-Eval oxidation-stage derived data is well documented (Hazra et al. 2017, 2019a, b, 2020a, b) for carbonaceous shales and coals. Ideally, organic matter in shales and coals during the second stage of Rock-Eval analysis, i.e., during the oxidation stage should be combusted below 650°C, because at higher oxidation temperatures beyond 650°C, calcite decomposes. The CO2 generated from the decomposition of organic matter is denoted as S4CO2, while the CO2 generated from calcite (consisting of inorganic carbon) is denoted as S5 (Lafargue et al. 1998). For shale samples containing carbonates minerals, a CO2 minima tends to occur between the temperature of 550 and 720°C. The Rock-Eval-model-6 software places a boundary in the CO2 signal recorded at those minima (Behar et al. 2001). This boundary is generally observed close to 650°C (Hazra et al. 2017). To the left of the boundary (lower temperature), the CO2 is considered to be organic and is used for the calculation of RC and TOC. To the right of the boundary, the CO2 generated is considered to be generated from the decomposition of calcite and is used to calculate the quantity of carbonate minerals within the sample.

With an increasing quantity of samples loaded into the Rock-Eval crucibles, for coals and carbonaceous shales, Hazra et al. (2017, 2019a, b, 2020a, b) observed the S4CO2 curve tends to be shifted to the right. As a consequence of that shift, some of the organic CO2 generated from the decomposition of organic matter was assigned by the in-built software to be of ‘inorganic’ origin or S5. This resulted in a sharp drop in TOC recorded for such samples. This led Hazra et al. (2019a, b) to recommend using 5–10 mg sample sizes for type III-IV kerogen-bearing, organic-rich shales and coals for more reliable and precise TOC estimation. More importantly, their research stressed the visual examination of S4-S5 graphics prior to reporting data. However, the nature of the shale and its thermal maturity level, in addition to the organic richness, is also likely to impact the disposition of the S4CO2 curve.

Table 2 shows Rock-Eval data of three contrasting shales from Rajmahal basin (RB5), Raniganj basin (RN), and Jharia basin (JB) analyzed at increasing sample weights and crushed to 212-µm sample sizes. The Rajmahal basin shale (RB5) is marked by lower Tmax (422°C), i.e., immature (estimated vitrinite reflectance: 0.44%, i.e., equivalent sub-bituminous coal rank). In contrast, the Jharia basin shale (JB) is marked by a higher Tmax (475–477°C), i.e., thermally mature in the gas generation phase (estimated vitrinite reflectance: 1.39–1.43%, i.e., equivalent medium volatile bituminous coal rank), whereas the Raniganj basin shale (RN) is marked by a Tmax of 446°C, i.e., early peak oil window mature (estimated vitrinite reflectance: 0.87%, i.e., high volatile bituminous coal rank). Figure 2 shows the S4CO2 curves of the three samples at two sample sizes (weights). The RB5 shale is marked by a much lower S4Tpeak value compared to the RN and JB shales. Hazra et al. (2021a, b) proposed the S4Tpeak as a thermal maturity proxy for shales marked by thermally metamorphosed organic matter or low TOC. In general, the hinge of the S4CO2 curves for sample RB5 consists of two sub-peaks, with one sub-peak, on the upper left flank of the S4 curve, showing a spiky form (figure 2A and B). At lower sample weights, the lower temperature spiky sub-peak generates a higher signal, compared to the higher temperature sub-peak. Consequently, the S4Tpeak occurs at 395°C for the lower weight sample (figure 2A) and 425°C for the higher weight sample (figure 2B). However, for the RN (554°C) and JB (568°C) shales, at both the sample weights, the S4Tpeak is higher than that recorded for sample RB5, indicating the higher thermal maturities of samples RN and JB.

A closer examination of the S4CO2 curves indicates interesting features which can be explained in terms of the level of thermal maturity of the shales. For the Rajmahal basin RB5 shale, at both the sample weights, the S4CO2 curves are positioned to the left of the S4-S5 boundary (marked as a yellow line in figure 2A–F). Consequently, no decrease in the TOC of RB5 shale was observed at the higher sample weight (figure 2B). In contrast, for the more thermally mature RN and JH shales, even when a lower sample weight of ~5 mgs were used, small portions of the S4CO2 curves (shaded in grey in figure 2C–F) are positioned beyond the S4-S5 boundary. The RN and JH shales, due to their higher thermal maturity, are likely to contain more aromatized organic matter. This means that their organic content does not undergo complete combustion below 650°C. Consequently, a part of the S4CO2 curve for these samples extends beyond 650°C, and it is this part of the S4 curve that is undercounted for the RC contribution to the TOC calculation. As these shales do not contain any carbonates, the CO2 released during oxidation results from the decomposition of their organic matter. For these reasons, it is recommended that the entire S4CO2 curve should be used to generate the RC value to avoid underestimating a sample's TOC (Hazra et al. 2017, 2019a).

The results described for shale samples RB5, RN, and JB demonstrate that the sample weight used in the Rock-Eval analysis and the thermal maturity level of the organic matter within the samples influences the precision of the data generated. Consequently, for immature shales, higher sample weights may be permissible. However, for hydrogen-rich kerogen, higher amounts of hydrocarbons generated during pyrolysis can saturate the FID and decrease the data reliability (Carvajal-Ortiz and Gentzis 2015). Similarly, for type III-IV kerogen-bearing mature shales, sample weights should be kept low for higher precision of the data generated.

2.2 Application of organic petrography for shale petroleum systems

The petrographic method for shale petroleum system evaluation has often been favoured as a superior technique, compared to other geochemical screening techniques (Hackley and Cardott 2016). Dembicki (2009) pointed out that source rocks rarely consist of only one type of kerogen, and the mixtures of different kerogen types can produce deceptive results, complicate interpretation, and therefore necessitates complementary organic petrographic data for shale appraisal. For instance, what the TOC and kerogen type implied by programmed pyrolysis consist of, can be described by the organic petrography, including the proportional amounts of oil-prone, gas-prone, or inert kerogen and/or solid bitumen. Also, sometimes the Rock-Eval analysis of certain shale samples can lead to erroneous reporting of Tmax due to its suppression from oil-rich kerogen, low FID signals during pyrolysis, and problematic S2 curve-shapes (Snowdon 1995; Carvajal-Ortiz and Gentzis 2015; Hazra et al. 2019a). Organic petrography underpins the assessment of thermal maturity, which is important for identifying the best locations for source-rock reservoir exploration (Hackley and Cardott 2016) and calibrating burial history models (Suárez-Ruiz et al. 2012). Acquiring knowledge about the organic facies is equally crucial for the evaluation of the shale petroleum system (Tyson 1995; Ercegovac and Kostić 2006). In organic petrography, the measurement of vitrinite reflectance (Ro) is one of the most reliable approaches for the determination of the thermal maturity of rock strata in a sedimentary basin. Vitrinite is a type of maceral (derived from the woody tissue of plants) found in sedimentary rocks which under reflected light shows a systematic increase of reflectance with increasing thermal maturity (Dow 1977). Vitrinite reflectance measurements of shales differ slightly from coals: Ro measured for a coal sample show normalized distribution over a narrow range compared to shales, which show a much broader distribution (Hackley and Cardott 2016). Analogous to Tmax suppression in the Rock-Eval analysis, Ro suppression is a problem typically observed in black shales wherein the measured Ro is observed to be lower than the predicted value from the Ro-depth profile (Liu et al. 2020a, b). The main influencing factors of this phenomenon are solid bitumen mistakenly identified as vitrinite (Hackley and Lewan 2018), and the enrichment of hydrogen in vitrinite during diagenesis (Price and Baker 1985). Nevertheless, there are other optical thermal maturity parameters other than vitrinite reflectance: (i) fluorescence – as the thermal maturity increases, the fluorescence colours of liptinite macerals under reflected blue light vary from green to greenish yellow to yellow to orange (Teichmüller and Durand 1983); (ii) thermal alteration index (TAI) – a transmitted light optical maturity parameter that shows a gradual change of colour from yellow to black occurring in pollen grains and spores as thermal maturity advances (Staplin 1982). The palynomorphs (pollen and spores) are compared to a colour chart after being extracted from the whole rock using acidification; (iii) conodont alteration index (CAI) – involves identification of the remnants of Cambrian-Triassic vertebrate (conodonts) composed of carbonate fluoroapatite. During the diagenesis process, the organic material present in fluoroapatite changes colour according to a five-colour scale (CAI: 1–5) which is used for delineating the CAI (Epstein et al. 1977). Although this approach is mainly applied to limestone (Hackley and Cardott 2016), some studies have also been conducted on shales (e.g., Sandberg et al. 1980; Repetski et al. 2006).

2.2.1 Use of electron microscope for shale studies

SEM has wide-ranging applications in shale studies, such as the evaluation of organic matter-hosted porosity (e.g., Loucks et al. 2009; Milner et al. 2010; Milliken et al. 2013; Inan et al. 2018; Delle Piane et al. 2022), distinguishing mineral phases (e.g., Camp 2013), shale micromechanics (e.g., Veytskin et al. 2017; Yang et al. 2018; Cheng et al. 2022), etc. Loucks et al. (2009) used SEM to image micropores present in Barnett shale. They observed that nanopores were the predominant pore type found in the organic matter of the Barnett shale. The thermal maturity of the organic matter directly governs the genesis and development of organic porosity (Loucks et al. 2012). As organic matter within the rock reach higher maturity levels, the expulsion of hydrocarbon ensues, resulting in the formation of porous structures in organic matter (Wang et al. 2009). Organic-matter-hosted porosity is widely acknowledged as the more important part of the shale pore system and observed as the key element behind successful shale gas reservoirs (Loucks et al. 2009, 2012; Milliken et al. 2013). However, the inability of SEM to scan pores smaller than 5 nm in diameter is a significant drawback (Singh et al. 2022). Another major drawback of SEM petrography of organic matter is its inability to differentiate between different kerogen types (Hackley and Cardott 2016). In recent years, several studies have employed correlative microscopy techniques for better characterization of organic matter in shales (e.g., Hackley et al. 2017; Valentine and Hackley 2019; Sethi et al. 2022). The technique involves the identification and marking of dispersed organic matter (DOM) under an optical microscope followed by their relocation under SEM (discussed broadly in the following section). Another widely used method for organic petrography is vibrational spectroscopy (Hackley et al. 2021), which makes use of the scattering of radiation or the molecular absorption at a certain resonance frequency that depends on the type of absorbing bond and its chemical surroundings. The commonly used techniques in organic petrography based on vibrational spectroscopy are Raman spectroscopy, Fourier transform infrared spectroscopy (FTIR), and atomic force microscopy (AFM) (reviewed in detail by Hackley et al. 2021).

2.2.2 Optical-electron correlative microscopy: A new emerging technique

Magnifications used in traditional organic petrography can go as high as 2500×, although they are normally 500×, which is sufficient for characterizing and identifying dispersed organic matter, which is typically 10–30 µm in size (Hackley et al. 2021). However, DOM in shale can vary from <1 µm to several 100's of µm in size, necessitating the use of other imaging techniques, such as scanning electron microscopy (SEM), to characterize it adequately at higher magnifications (Hackley et al. 2021). As discussed earlier, one major limitation of SEM compared to an optical microscope is that it cannot help in identifying different kerogen types present in the sedimentary rock. In particular, SEM can neither distinguish between the primary kerogen and its secondary products after catagenesis (i.e., solid bitumen), nor it can differentiate between kerogen types using the Secondary Electron (SE) and backscattered electron detection system of the SEM alone (Valentine and Hackley 2019). Optical-electron correlative microscopy is a technique that can evaluate the same field of view to identify and characterize DOM in shales using both light and electron microscopy (Valentine and Hackley 2019; Liu et al. 2022).

Hackley et al. (2017) applied the optical-electron correlative method for imaging the organic matter in sedimentary rocks. They used an integrated correlative light and electron microscope (iCLEM) to identify and characterize organic matter present in the argon ion-milled thin sections of shales collected from Green River Mahogany Zone (immature oil shale) and Upper Cretaceous Tuscaloosa Group (paralic shale). The study involved the identification of the organic matter with the help of fluorescence microscopy at low resolutions followed by the evaluation of its microstructures (e.g., OM-hosted porosity) at higher resolutions under SEM. Valentine and Hackley (2017) conducted a similar study on shale samples of different thermal maturity levels using correlative light and electron microscopy (CLEM) technique. Stressing the importance of this technique, Liu et al. (2022) in their review on SEM petrography of DOM in black shales suggested that SEM alone cannot differentiate the organic matter types, so the observed organic matter hosted pores cannot be related to the specific macerals. It is a big drawback since this inability to relate limits our understanding of the organic porosity evolution during thermal maturation. Similarly, simultaneous characterization of organic matter and inorganic matter in shale can be difficult when optical and electron microscopes are used separately, resulting in improper reservoir characterization. Sethi et al. (2022) conducted optical-electron correlative microscopy on shale samples from Rajmahal basin, India for simultaneous characterization of the organic and inorganic constituents of the sample.

To illustrate the advantages of this technique over standalone optical and electron microscopes, two shales, collected from the Rajmahal (RM shale) and Jharia (JH shale) basins of India, were examined using the optical-electron correlative microscopic facility at CSIR-CIMFR, Dhanbad, India. This facility consists of a Zeiss AX10 optical microscope and Zeiss Merlin VP Compact electron microscope (FE-SEM) equipped with a Zeiss Shuttle & Find (S&F) correlative microscope interface, which allows seamless transfer of the samples between the microscopes for quick and automatic relocation of marked DOM or mineral matter. The shale samples were initially assessed for their source rock attributes (table 3). The analysis reveals that RM shale is marked by a lower Tmax of 420°C, i.e., immature (estimated vitrinite reflectance: 0.44%, i.e., equivalent sub-bituminous coal rank), whereas the JH shale is marked by a higher Tmax of 453°C, i.e., thermally mature in the gas generation phase (estimated vitrinite reflectance: 1.39–1.43%, i.e., equivalent to medium volatile bituminous coal rank). Figure 3 displays the S2 pyrograms of RM shale and JH shale. Shale pellets prepared from the crushed samples (<1 mm in size) of RM and JH shales were used for the correlative microscopy. In addition to the correlative study, elemental analysis of the organic and mineral matter surfaces was performed using an energy dispersive spectroscopy (EDS) facility equipped with the FE-SEM.

The DOM present in RM and JH shales (figures 4 and 5, respectively) were distinguishable under AsB (Angle Selective Back-scatter) and SE2 (Secondary Electron) scanning modes. The DOM in both samples appears dark compared to the surrounding mineral matrix. In SE2 mode, the organic matter in RM shale appears to have negative relief compared to the surrounding mineral matrix (figure 4D), whereas in the JH shale sample, it appears to have positive relief (figure 5D). In figure 4(A), the inertinite maceral with partially preserved cell structure is semi-fusinite. Cellular structures in some inertinites formed from vascular plant cell lumens can be a great distinctive feature during SEM (Liu et al. 2022). However, if no such features are observed, it can be difficult to ascertain the maceral type under SEM alone. For example, in figure 5 without prior marking of the inertinite and vitrinite macerals during optical microscopy, it would have been difficult to distinguish between the maceral types as no distinctive features can be observed under SEM. Sporinites can be identified under SEM due to their distinctive morphology (figure 5C and E: marked as ‘L’ i.e., liptinite). Furthermore, the minerals surrounding or in association with the organic matter can be studied for their elemental composition using EDS, and identification of mineral matter during reflected light microscopy presents certain challenges. For example, the result of EDS analysis (table 4) revealed the occurrence of mineral matter within the cellular structure of the inertinite maceral (figure 4E: EDS Spot 1). Similarly, the result of EDS analysis (table 5) during the SEM study of RM shale revealed the presence of quartz near the liptinite maceral (figure 4B and C: EDS Spot 1) which was otherwise not identifiable under the optical microscope. Due to its distinctive morphology, pyrite in JH shale was easily identified under both optical and electron microscopes (figure 5). Additionally, EDS analysis (table 6) of the mineral matrix revealed the presence of silicate minerals (figure 5C: EDS Spot 1). The above observations suggest that the correlative microscopy technique is more helpful in the conclusive identification of the organic matter type and mineral matter compared to the standalone use of either microscope.

RM shale sample correlative image set: (A) DOM under white light illumination; (B) Liptinites showing fluorescence under blue light illumination; (C) SEM photomicrograph in AsB mode; (D) SEM photomicrograph in SE2 mode; (E) Inertinite imaged at 10.62 KX magnification under SE2 mode; (F) Vitrinite imaged at 2.49 KX magnification under SE2 mode. Abbreviations: V - Vitrinite; I - Inertinite; L - Liptinite.

JH shale sample correlative image set: (A) DOM under white light illumination; (B) Liptinites showing fluorescence under blue light illumination; (C) SEM photomicrograph in AsB mode; (D) SEM photomicrograph in SE2 mode; (E) Inertinite and liptinite imaged at 5.55 KX magnification under SE2 mode; (F) Vitrinite imaged at 5.55 KX magnification under SE2 mode. Abbreviations: V - Vitrinite; I - Inertinite; L - Liptinite; Py – Pyrite.

2.3 Geomechanical properties

Fracture stimulation of shale reservoirs increases the production rate and can be credited with adding petroleum reserves to a basin’s resources which otherwise would have been uneconomical to develop. Since 2005, oil and gas production in the United States has remarkably increased, and in 2021 it increased to approximately 34.5 TCF, most of which has been achieved through HF and horizontal drilling of shales, and other tight formations (U.S. EIA 2021). Economic shale plays are characterized based on TOC content, thermal maturity, kerogen type (Zargari et al. 2016; Gottardi et al. 2019), and stiffness/brittleness, i.e., the ability to fracture easily and keep the fracture network open long enough using suitable proppants so that profitable quantities of hydrocarbons can flow more readily into the wellbores (Zhang et al. 2016). A shale's propensity to fracture requires an understanding of its mineralogical composition, brittleness index, extent and orientation of natural fracturing, which is related to in-situ stress directions (Mba and Prasad 2010; Holden et al. 2012; Labani and Rezaee 2015). To obtain this information it is essential to assess the petrophysical data available and the geomechanical properties of shales and other tight reservoir rocks (Sone and Zoback 2013). By determining the geomechanical properties of shales it is possible to predict with more confidence their mechanical behaviour in response to fracture stimulation (Iferobia and Ahmad 2020). These geomechanical properties can be divided into two broad categories: (i) strength properties and (ii) elastic properties.

(i) Strength properties. The ability of a rock to resist failure under stress is known as its strength. In nature, rocks are subjected to mainly tensional, compressive, and shear stress conditions. Consequently, tensile, compressive, and shear strengths of rock formations are desirable parameters to measure and understand (Addis 2017). The stability of wellbores depends substantially on the strength properties (tensile, compressive, and shear strength) of the rock formations it penetrates (Iferobia and Ahmad 2020). Tensile failure occurs when the rock mass splits along fracture planes; shear failure happens when shear stress exceeds a rock's shear strength; and compressive failure occurs when a rock's compressive strength is overwhelmed by compressive stresses. The most commonly used techniques to determine these properties are uniaxial and triaxial compression testing.

(ii) Elastic properties. Young's modulus and Poisson's ratio are two rock properties of high significance used for determining the elastic deformation of rock formations. Young's modulus refers to the ratio between longitudinal stress and longitudinal strain, whereas, Poisson's ratio is the ratio between longitudinal strain and lateral strain. Values of these parameters help to define the in-situ stresses acting on a rock formation at a certain depth (Iferobia and Ahmad 2020), and how those rocks are likely to behave if the prevailing stress field changes.

Shale gas wells often have different production efficiencies even within reservoirs that have similar fracture permeability and gas content (Luffel et al. 1993; Hill and Nelson 2000; King 2010). This variation is caused by the rock matrix heterogeneity, the fracture network (both natural and induced) of gas shales, and the geomechanical characteristics of the shales (Bustin and Bustin 2012). The microporous rock matrix and the permeability through fractures are controlled by the rock fabric. Permeability (both fractures and the matrix) is controlled by geomechanical properties when reservoir stress increases (Bustin and Bustin 2012; Ali et al. 2015). Bustin and Bustin (2012) conducted a numerical-based production simulation to evaluate how the geomechanical properties of gas shales affect the flowability of hydrocarbons through the fractures and matrix under stress. They observed that when the fabric parameters (large matrix permeability, small fracture spacing, small fracture permeability) produce a matrix-independent production, the production is entirely governed by stress-dependent fracture permeability. On the other hand, higher initial fracture permeability, higher Young's modulus, and higher Poisson's ratio lead to more production. Like permeability, evaluation of strength and elastic properties of tight reservoir formations helps in deriving other basic reservoir properties such as brittleness index, porosity, permeability, fluid-flow rates and declines, fluid saturations. These variables are useful for developing and interpreting shale plays and basin-wide models and finding the ‘sweet-spots’ to drill and fracture stimulate (Wood and Hazra 2017). However, there are some inherent problems in measuring these parameters from shale rock samples that are discussed in the following sections. These issues undermine the confidence to some extent in the laboratory measurements of certain static mechanical properties.

2.3.1 Problems associated with determining static geomechanical properties

2.3.1.1 Issues with shale coring and sample handling

A major issue regarding the evaluation of the geomechanical properties of shales is the preservation of the borehole core from the moment of retrieval to the final laboratory testing (Josh et al. 2012; Basu et al. 2020). Exposure of shale rocks to air alters their water content significantly, resulting in the formation of desiccation or shrinkage cracks (Basu et al. 2020) which reduces the chance of obtaining reliable measurements of static geomechanical properties. Furthermore, clay minerals such as smectite in shales undergo volume expansion due to osmotic swelling of interlamellar spaces during the drilling process (Wilson et al. 2014). Also, stress unloading and core relaxation during the coring and core retrieval processes induce substantial splitting along the laminated layers of the cored shale (Handwerger et al. 2012). Since the core is retrieved from in-situ stress conditions, it experiences volume expansion of about 6–8% due to de-compaction or stress relief (Basu et al. 2020). This process causes a substantial increase in porosity and permeability leading to erroneous results during their measurements. Basu et al. (2020) proposed suitable practices to handle shale cores before commencing laboratory tests on them, which are as follows:

-

(a)

Shale cores need to be retrieved from the core barrel in a horizontal orientation so that the mechanical impact is minimized.

-

(b)

After retrieval it is important to store shale cores using suitable inserts or, by using epoxy, wax, or resin for casting to render them mechanically stabilized.

-

(c)

Capped and sealed aluminum or fiberglass, or corrugated plastic trays having a good size match with the core should be used for core storage.

-

(d)

Polyethylene plastic, Teflon, or closed airtight containers are also appropriate for core storage.

2.3.1.2 Shale anisotropy and brittleness index

Shale rocks vary spatially in terms of mineralogical composition and show fissility (King et al. 2010; Sone and Zoback 2013; Liu et al. 2016; Liu et al. 2020a, b). In addition to this, bedding anisotropy influences fracture propagation during the fracture stimulation process. Such heterogeneities, which often are multi-scale in nature ranging from microscopic to macroscopic throughout the entire formation, can significantly impact the mechanical behaviour of a formation during laboratory testing (Jin et al. 2018). Similarly, in-situ stress conditions experienced by tight reservoirs may vary from one formation to another. This can substantially influence the optimum way in which hydraulic fracturing should be designed and conducted for maximum hydrocarbon recovery from a tight reservoir. Zheng et al. (2020) compared and analyzed the impact of in-situ stresses on the hydraulic fracture stimulation designs employed in China's Fuling shale gas play with the USA's Marcellus shale gas play. They observed that hydraulic fracture stimulation in the Fuling shale gas play involves a higher formation breakdown pressure, as it displays much higher minimum horizontal stress compared to the Marcellus shale gas play. Thus, for a tight reservoir subjected to hydraulic fracture stimulation, inaccurate measurements and estimations of geomechanical parameters can lead to stimulation design and implementation problems. Such problems include poor fracture propagation, failure during well perforation, casing collapse, and sub-optimal production levels being achieved post-stimulation (Josh et al. 2012).

On the other hand, proper geomechanical characterization can aid precise estimation of a shale's brittleness index (BI) which is an important parameter that indicates a formation's ability to fracture, often referred to as ‘frackability’ (Labani and Rezaee 2015; Meng et al. 2021). Generally, BI cut-offs are pre-defined, i.e., a shale formation with less than a certain BI value is not considered suitable for hydraulic fracture stimulation. If a rock is brittle then it tends to be easier to initiate and propagate fractures within it, as well as keep those induced fractures open. On the other hand, ductile shale, especially those with high clay mineral contents, tends to cause an induced fracture to close rapidly and self-seal (Josh et al. 2012). Methods for the measurement of rock brittleness have not yet been standardized (Yagiz and Rostami 2012). Nevertheless, BI of rocks has been widely studied (Guo et al. 2012; Yagiz and Rostami 2012; Schön 2015; Hu 2018; Hou et al. 2018) and there are various methods of calculation based on mineralogical composition, wireline logging data, and geomechanical properties (Wood 2021). Mineral-based evaluation of BI is performed through the derivation of mineral weight-fraction correlations, log-based evaluation through total porosity and sonic logs, and elastic-based evaluation through the determination of Young’s modulus and Poisson’s ratio (Mews et al. 2019).

The brittle nature of the shales with high BI values, those that are likely to be the most frackable, translates into their easy breakdown into smaller pieces. Such shales tend to shatter when subjected to tensile stresses when they are drilled and cored. This characteristic renders ‘intact’ core recovery in large quantities from such shales extremely difficult (Josh et al. 2012).

A sequence of shale core samples taken at a depth of about 696 m in a borehole drilled in the Mand Raigarh basin (part of the Son–Mahanadi Gondwana Master Basin, India) illustrate this point in relation to the evaluation of static geomechanical properties (figure 6). The length of the cored sequence studied is 39 cm. It is apparent from figure 6 that the core is not intact and is fragmented into three pieces. Attempts were made to evaluate the strength and elastic properties of samples from this shale core in accordance with the ISRM (International Society for Rock Mechanics and Rock Engineering) suggested Methods (ISRM 2007) and ASTM (American Society for Testing and Materials) standard (ASTM 1994, 2000). However, only one specimen with length-to-diameter (L/D; ‘L’ is length and ‘D’ is diameter) ratio of 2 (figure 7) for the analysis of UCS and Young's modulus, and three specimens with L/D ratio of 0.5 (figure 8) for the analysis of Brazilian Tensile Strength (BTS), could be recovered from that core. The remaining portion was used for the preparation of a specimen with an L/D ratio of 1 to understand the variations in compressive strength measurements that occur when using samples of different (smaller) sizes to the standard requirements.

A state-of-the-art MTS 815 rock mechanic test system at CSIR-CIMFR Dhanbad, India was used for the analysis of UCS, Young's modulus, and BTS parameters of the shale samples. The samples were loaded uniaxially at a rate of 0.5 kN/sec until failure. Table 7 displays the measurements taken for the strength and elastic properties of the shale samples. The UCS of the specimen having an L/D ratio of 1 (P-2) is 17% higher than the one having an L/D ratio of 2 (P-1). The strength of rock samples generally increases with decreasing length-to-diameter ratio (Tuncay and Hasancebi 2009). However, Young's modulus of the smaller specimen (P-2) was found to be lower than the one having twice the length (P-1). Therefore, there is an apparent inconsistency in the obtained strength and elastic properties of the shale samples when the L/D ratios of the samples are not those of the established standards (e.g., ASTM 1994, 2000; ISRM 2007). In a similar study, Mokhtari et al. (2013) conducted a strength analysis of Eagle Ford shale samples subjected to axial stresses under a confining pressure of 2,260 psi. They observed that shale samples that were shorter in length showed higher compressive strength (about 19% higher) compared to the samples with classical dimensions. At similar stress conditions, a 42% difference in Young’s modulus was observed between the short samples and samples with standard dimensions.

Table 8 shows the results of the specimens prepared for BTS analysis. The BTS values of the shale samples are quite consistent, averaging at 6.8 MPa with a variation of ±0.4 MPa. Since the standard L/D ratio requirement for BTS analysis is 0.5, it is somewhat easier to retrieve samples complying with standard size requirements for the evaluation of tensile strength compared to the samples required for other strength parameters.

Researchers have made various attempts to indirectly estimate the UCS of rocks from BTS measurements (Hobbs et al. 1964; Nazir et al. 2013; Tavallai et al. 2019; Iyare et al. 2021). However, these predictive models are not universal, meaning that such models are not applicable for all rock types. Indeed, they are problematic when applied to shales due to their anisotropic nature. Besides, shale-cores are sometimes retrieved in such poor condition that even preparation of samples for BTS analysis becomes impossible (e.g., figure 9).

A potential solution to this problem is to measure the geomechanical properties of shales using alternative techniques that require very small sample sizes. Performing geomechanics tests on small samples generally makes it possible to sample more material. A larger sample base should facilitate verification of the measured geomechanical parameters through testing multiple aliquots. In the following sections, different techniques for the evaluation of the geomechanical properties of shales and other rock formations using small sample sizes are discussed.

2.3.2 Geomechanical measurement techniques using small size samples

2.3.2.1 Puncture method

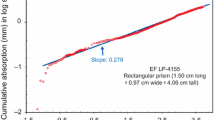

In this method, a specialized puncture tool (figure 10) is used for the determination of the mechanical properties of small shale samples of a diameter of 15 mm and a length of 3 mm. Samples of such dimensions are prepared using core plugs which are cut into disc-shaped samples followed by manual grinding with abrasive paper (P 320) to ensure both ends of the sample are flat and parallel. An inert fluid (e.g., Marcol™ 82 oil) having high viscosity should be used during the grinding process to avoid samples becoming desiccated. The tool consists of two punching pistons, two clamping pistons, and two locknuts (Edvardsen et al. 2021). The punching pistons are made of hardened tool steel so that the wear on the piston surfaces can be minimized, the clamping pistons are made of stainless steel, and to avoid the seizure of the pistons the locknuts are made from brass. Shear force is exerted on the rock samples when the pistons (camping and punching) are forced in opposite directions by an external force until failure. The peak strength required to punch a hole in the sample is divided by the area of the cylindrical cut to calculate the shear strength of the rock.

Adapted from Edvardsen et al. (2021).

Schematic of a punching tool (left), and illustration of its component parts (right).

The samples required by this method are small and easy to prepare and the results are provided quickly. This makes them well-suited for studies that benefit from the analysis of multiple closely spaced samples. The technique is employed for tests on drill cuttings at the rig-site, and investigation on the anisotropy or fluid sensitivity of rocks (Stenebraten et al. 2008). Edvardsen et al. (2021) used this method to assess the shear strength of shale samples exposed to six different conditions (Brine; CO2 gas dissolved in brine; supercritical CO2 dissolved in brine; dry CO2; dry supercritical CO2; air) for the varying amount of time to evaluate variations in a shale's strength. The shale sample was the caprock to a subsurface reservoir. They observed that shale samples exposed to brine solution experienced significant loss in shear strength, whereas CO2 did not seem to change the shale sample's strength. Small mm-sized disk shale samples allowed them to conduct tests on multiple aliquots taken at a close spacing from a borehole core. Analysis of the shear strength of the caprock through conventional means (laboratory direct shear strength) following the established standards (e.g., ISRM 2007; ASTM 2008) would have required large sample sizes. For instance, according to ASTM, the test plane of the sample should have a minimum area of 1900 mm2 (3 inch2). The availability of shale samples of these sizes is quite difficult to retrieve. In such scenarios, using special tools for the determination of shale strength properties becomes an attractive alternative. Guan (2016) used a shale puncture tool for determining the creep behaviour of small shale samples using two different loading paths: firstly, standard creep tests through a stepwise loading path, and secondly, strain-rate tests with a continuous loading path.

The conventional approach to conduct the above experiments would have required intact shale samples of standard L/D ratios which in itself is a difficult task considering the earlier discussed problems associated with the retrieval of unbroken shale-cores through the drilling process. Furthermore, the use of the puncture tool method in combination with the continuous wave technique (CWT) can be a useful approach for measuring the mechanical properties of rocks. CWT consists of acoustic transducers that are mounted on the opposite ends of the samples with one working as the acoustic wave generator and the other as the signal detector (Stenebråten et al. 2008). This method is suitable for acoustic velocity measurements of small mm-thick disk-shaped shale samples (Nes et al. 1998; Stenebråten et al. 2008). Conducting acoustic analysis on small samples would generally give access to more material for a variety of other experiments as well, such as the estimation of drilling-fluid effects, seismic parameters, and pore pressure (Guan 2016). Since CWT is a non-destructive technique, the same samples can be used later for testing by applying the puncture method.

2.3.2.2 Nano-indentation method

This method involves the determination of nano-scale mechanical properties of rocks using a hard tip/diamond indenter that is pushed into the sample surface and then retracted perpendicularly (De Block et al. 2014; Xie 2016; Zhang et al. 2016; Esatyana et al. 2020). The depth of the indent (penetration depth) created is measured using capacitive displacement sensors. After indentation, the obtained load vs. displacement curve typically consists of three stages: loading, holding, and unloading (figure 11; Liu et al. 2016). Measurement of the elastic properties is performed during the unloading stage. Preparation of shale samples for conducting nano-indentation tests can even be conducted using drill cuttings recovered during the borehole drilling process. Prior to nano-indentation tests, samples are coated with resins and then polished using grit paper to remove surface roughness. It has been confirmed through several studies (Bobji and Biswas 1999; Kim et al. 2006; Miller et al. 2008) that if the surface roughness of the sample being prepared for nano-indentation analysis is very high then it results in increased scatter, and an overall reduction in the measured micromechanical properties. An optimum sample preparation technique for nano-indentation analysis of shale should aim at reducing the surface roughness to the minimum. ASTM standard E2546 for nano-indentation testing also emphasizes the importance of the surface finish of the sample which has a direct impact on the quality of the test result (ASTM 2007). It is crucial because the contact area is determined by the contact depth and area function assuming that the surface is absolutely smooth prior to the indentation (Kumar et al. 2012a, b). As shales are mineralogically heterogeneous, it causes great difficulty during polishing: harder mineral phases (e.g., quartz) are easily polished, whereas the softer phases (e.g., clay and kerogen) show scratches or are even pulled out during fine polishing (Kumar et al. 2012a, b). Some studies on nano-indentation of shales (Kumar et al. 2012a, b; Shukla et al. 2013, 2015) have used a sequence of an emery paper with grit sizes varying from 60 to 3000, followed by broad beam argon ion milling of the sample for further reduction of the roughness. The nano-indenter can be combined with an optical or scanning electron microscope to locate the point of interest while keeping in mind that the size of the indenter is small enough to target specific mineral phases in a sample.

Schematic of an indentation load vs. displacement curve. Modified after Liu et al. (2016).

Mechanical parameters that can be obtained through the nano-indentation method are elasticity, hardness, fracture toughness, Young's modulus, residual stress, etc. This technique has been widely used in the last decade to evaluate the micro-mechanical properties of different rock types (Ortega et al. 2010; Liu et al. 2016; Zhang et al. 2016; Shi et al. 2020). Shales have been well studied using this technique for two important reasons: firstly, its compositionally heterogeneous nature, juxtaposing different minerals at the micro- and nano-scales with significantly different properties that can affect the shales' mechanical properties at the macro-scale (Du et al. 2020); and, secondly, the unavailability of standard size and continuous cores from boreholes which makes it difficult to evaluate the geomechanical parameters from core fragments through conventional methods (Kumar et al. 2012a, b).

For example, to address the mineralogical heterogeneity, Du et al. (2020) compared the geomechanical properties of the Pottsville and Marcellus shales (USA) at the mineral scale using nano-indentation technology. Their study involved indentation tests on small and polished shale samples at both micrometer and nanometer scales to determine the geomechanical parameters of bulk (average mechanical properties of different grains spread over a large area) and separate (localized geomechanical parameters of individual grain) phases. They observed that the mechanical property values of the Pottsville shale are higher than those of the Marcellus shale due to the former having higher contents of evenly distributed ‘rigid’ grains of uniform size with uneven boundaries, acting as a barrier to restrict the development of fractures.

Gupta et al. (2020) addressed the problem of intact shale core unavailability by using the nano-indentation technique to compare the fracture toughness of different types of shales based on their bedding anisotropy. They found that the fracture toughness of horizontal samples (indentation direction parallel to the bedding) was on average 33% higher than the vertical samples (indentation direction perpendicular to the bedding). On the other hand, for Young's modulus measurements of shales, mechanical anisotropy is not as high as it is for fracture toughness (Xiang et al. 2017). Also, no anisotropic characteristics were found in a study evaluating anisotropy in the hardness property of shales (Cala et al. 2017).

Fluid–rock interactions during hydraulic fracturing have a great influence on the hydraulic-fracture conductivity and thereby, reservoir productivity (Gupta et al. 2019). Therefore, for optimum reservoir production, studies of the influences of the wettability of shale on its geomechanical properties are of great importance. Gupta et al. (2019) compared the weakening effect of 2.5 and 7.5% KCL brine solutions, and dodecane on Young's modulus and hardness of samples from the Eagle Ford, Woodford, Wolfcamp, and Marcellus shale formations (USA) by applying the nano-indentation method. The results show that brine solution led to 45, 25, 12, and 21 percent reduction in Young's modulus of Marcellus, Woodford, Eagle Ford, and Wolfcamp shales, respectively, whereas dodecane caused 25, 17, 4, and 3 percent reduction in Young's modulus values of Marcellus, Woodford, Eagle Ford, and Wolfcamp shales, respectively. The wettability of the samples played a major role in the water-weakening effect. Strongly water-wet shale samples (Marcellus shale) experienced large reductions in Young's modulus and hardness values compared to the shale samples that were oil-wet (Eagle Ford shale).

Memon et al. (2020) applied the nano-indentation technique to investigate the influence of cryogenic liquid nitrogen (LN2) on Young's modulus of Mancos shale (USA). They observed a decrease in the nano-indentation moduli with increasing treatment time. A similar effect of LN2 has been observed in the nano-indentation moduli of different rock formations, such as sandstone (Maheshar et al. 2020), limestone (Ali et al. 2022), and coal (Akhondzadeh et al. 2020). Tian et al. (2020) employed the nano-indentation technique to investigate the effect of carbonic acid (formed due to interaction between CO2 and formation water) on the micro-mechanical properties of the shale samples. They observed that Young's modulus and hardness of the shale reduced significantly and became more ductile after the acid treatment, which agreed with the observations made by Zhang et al. (2019).

Nano-indentation testing in conjunction with SEM and energy EDS helps to map and characterize the micro-mechanical strength differences between separate material and mineral phases (Kumar et al. 2012a, b; Bennett et al. 2015; Boulenouar et al. 2017; Xian et al. 2019; Yoon and Ringer 2019; Memon et al. 2021). Kumar et al. (2012a, b) employed SEM and EDS to identify the kerogens present in the Woodford shale (USA). High organic content resulted in the reduction of both Young's modulus and hardness of the Woodford shale samples. That application demonstrates that the nano-indentation technique can potentially be applied to understand the effects of the mechanical properties of individual organic minerals (kerogens) on the bulk mechanical properties of the host shales. Boulenourar et al. (2017), applying similar techniques on shale samples observed high hardness to be associated with dolomite, pyrite, calcite, or quartz inclusions, whereas low hardness was associated with the organic materials. Yoon and Ringer (2019) performed multi-scale nano-indentation testing to evaluate the influence of compositional heterogeneity on the geomechanical properties of shale. They observed considerable differences in the geomechanical properties of shales, which were linked directly with the multiscale mineralogical and structural heterogeneity of the samples tested.

Apart from the above-mentioned ‘influencing factors’ the influences of temperature, loading rate, penetration depth, and grain size have also been studied with nano-indentation testing in terms of the geomechanical properties of shales (Ma et al. 2020). This suggests that nano-indentation is an excellent tool to investigate the micromechanics of shales, making it possible to bridge the nano- and macro-scale analytical results (Akono and Kabir 2016). The nano-indentation testing technique is particularly valuable for borehole shale samples due to the inability to consistently retrieve intact shale core samples.

If the rock properties are measured at different scales, i.e., at the reservoir scale (seismic/logging method), outcrop/drilled cores at the macro-scale (measurement of macro-mechanical properties), and drill cuttings or rock fragments at the micro-scale (measurement of micro-mechanical properties), together can lead to better characterization of its geomechanical behaviour. However, as discussed earlier, retrieving intact shale core samples for macro-scale geomechanical analysis can be difficult. In such scenarios, analysis at the micro-scale can be helpful as the rock properties at the micro/nanoscale can influence the strength properties of rock materials at the macro-scale (Du and Radonjic 2019). Susceptibility of the rock to fracturing at a larger scale can be predicted by analyzing its behaviour at the micro-scale since fractures tend to be associated with atomic scale imperfections (Du et al. 2020).

3 Recommended protocols

3.1 Rock-Eval shale sample geochemical analysis

Shale sample preparation influences the quality of the measurements derived from Rock-Eval geochemical screening equipment. Rigorous procedures need to be followed to obtain reliable and reproducible results. Specifically:

-

As recommended in the IFP guidelines, sample sizes should be between 50 and 70 mgs for low-TOC shales for the generation of reliable data.

-

Sample sizes used for the pyrolysis cycle analysis (S1, S2 and S3 curves) with respect to shale samples with type I-II kerogen (or oil-rich shales) should be about 5 mg to avoid saturating the FID recordings and distorting key measurements.

-

Sample crush sizes for the pyrolysis cycle analysis (S1, S2 and S3) should be consistent to enable the results of different samples to be reliably compared. A sample crush size of 200 to 275 µm maximizes pyrolysate generation at the standard pyrolysis cycle heating ramp of 25°C/min.

-

The S2 heating ramp should not be terminated at temperatures below 650°C to avoid truncating the S2 curve at its high end.

-

Sample sizes used for the S4 oxidation cycle analysis with respect to shale samples with type III-IV kerogen should be in the 5–10 mg range to avoid shifting the S4 curve too much to the right.

-

The entire S4CO2 curve should be used for RC and TOC determinations, avoiding arbitrary cutoffs of the S4 data on the high-side of the S4 curve, especially in absence of carbonate minerals.

-

The oxidation cycle heating ramp should be set consistently at 20°C/min to achieve constant decomposition of the pyrolyzed organic matter during the oxidation stage and ensure reliable TOC measurements.

-

Prior to accepting any Rock-Eval measurements the S2 and S4 pyrograms should be carefully inspected for each sample tested to rule out anomalous peak shifts or FID saturations.

-

It is prudent to accompany batches of sample analysis with regular analysis of appropriate calibrated standards at the same Rock-Eval instrument settings.

3.2 Geomechanical analysis of shale wellbore cores

Utilization of shale-core samples for laboratory investigation of geomechanical properties requires careful handling from the time of its retrieval to the final testing. Specifically:

-

The extraction of core samples from the core-barrel should be done in such a way that mechanical impact is minimized.

-

The core should be removed from the core-barrel in a horizontal position.

-

Core fragments can be further stabilized mechanically with the use of suitable enclosures or by using epoxy, wax, or resin for casting.

-

Polyethylene-type plastics, Teflon, or closed airtight containers, well-matched in size to the recovered cores should be employed to store shale cores.

-

Sampling for laboratory tests of strength (UCS and tensile strength) and elastic parameters (Young's modulus and Poisson's ratio) of shale-core samples should be conducted according to the availability of ‘intact’ samples.

-

In few cases where the sizes of the intact shale core fragments are sufficient, samples should be prepared according to the recommended ISRM/ASTM standards (ASTM 1994, 2000; ISRM 2007).

-

In many cases where core fragments are too small to extract to meet the ISRM/ASTM standard (ASTM 1994, 2000; ISRM 2007) sample dimensions, those samples should not be analyzed using conventional methods as they are likely to generate unreliable strength and elastic parameter measurements.

-

Smaller than ISRM/ASTM standard (ASTM 1994, 2000, 2008; ISRM 2007) samples should be analyzed with alternative techniques, specifically proven techniques using a calibrated punching tool and nano-indentation. Such techniques can provide reliable measurements on multiple, closely spaced samples rapidly and cheaply.

-

Nano-indentation analysis should be combined with SEM and EDS techniques to provide nano- and mineral-scale geomechanical analysis providing insight to anisotropy within the samples tested.

-

Punch-tool analysis should be combined with the non-destructive continuous wave (acoustic) technique to assist in calibrating static geomechanical measurements with the dynamic geomechanical measurements estimated from borehole wireline acoustic log data.

4 Conclusions

Geochemical and geomechanical screening measurements to assess the prospectivity of shales as gas and oil reservoirs can be problematic unless due consideration is given to sample handling and preparation. Moreover, the analytical equipment settings and measurement techniques used can be unsuitable for specific shale types and/or sample preparations. For these reasons, separate analytical screening protocols for geochemical and geomechanical measurements are proposed and justified based on analytical case studies that identify and describe the specific problematic issues. These protocols prescribe clear guidelines for sample preparation, equipment settings, and analytical techniques that need to be taken into account in order to generate reliable and reproducible measurements.

In the case of the Rock-Eval technique, there are key issues surrounding sample weights and sample-crush sizes that are suitable for specific types of shale. Moreover, the heating ramps and temperature cutoffs used to delineate the S2 and S4 peaks, in particular, need to be carefully selected. It is prudent to pay careful attention to the generated pyrograms relative to calibrated standards of appropriate materials before accepting Rock-Eval measurements. Unfortunately, there are examples of recently published studies where such steps have not been followed resulting in measurements of dubious quality being sanctioned. Nonetheless, the geochemical screening technique as a whole has some major drawbacks, such as its inability to differentiate between kerogen types and Tmax suppression. In such cases, organic petrography adds to the information needed for shale appraisal. New techniques in the form of optical-electron correlative microscopy have been developed for better characterization of the organic and inorganic phases of shales. In the case of geomechanical analysis of shale cores recovered from boreholes, a real problem exists in terms of the quality and size of the shale core material recovered. This is particularly the case for the most brittle and prospective shales, for which the recovered cores tend to be highly fragmented. This poses a problem in preparing samples from recovered cores to meet the ISRM/ASTM sample preparation standards for geomechanical analysis. For the majority of shale sections cored this cannot be achieved comprehensively and reliably. Using samples that are too small to meet those standards, leads to inaccurate results, for certain geomechanical parameters, using conventional measurement techniques.

The limited shale core sample availability issues justify the use of alternative measurement techniques, specifically tailored for small samples. Punching-tool and nano-indentation geomechanical sampling and testing techniques have proven their reliability with respect to shale samples. Indeed, they deliver certain advantages over conventional techniques in which they can analyze multiple, closely-spaced samples quickly and more readily take into account the anisotropy characteristics that are associated with many shales. Coupling the nano-indentation technique with SEM and EDS analysis can provide nano- and mineral-scale geomechanical analysis revealing important details of the anisotropy within the samples tested. Also, coupling punch-tool analysis with the continuous wave (acoustic) technique can help to calibrate dynamic and static geomechanical measurements.

References

Addis M A 2017 The geology of geomechanics: Petroleum geomechanical engineering in field development planning; Geol. Soc., London, Spec. Publ. 458(1) 7–29.

Akhondzadeh H, Keshavarz A, Al-Yaseri A Z, Ali M, Awan F U R, Wang X, Yang Y, Iglauer S and Lebedev M 2020 Pore-scale analysis of coal cleat network evolution through liquid nitrogen treatment: A Micro-Computed Tomography investigation; Int. J. Coal Geol. 219 103370.

Akono A T and Kabir P 2016 Nano-scale characterization of organic-rich shale via indentation methods; In: New frontiers in oil and gas exploration, Springer, Cham., pp. 209–233.

Ali T A and Sheng J J 2015 Evaluation of the effect of stress-dependent permeability on production performance in shale gas reservoirs; In: SPE Eastern Regional Meeting, OnePetro.

Ali M, Shar A M, Mahesar A A, Al-Yaseri A, Yekeen N, Memon K R, Keshavarz A and Hoteit H 2022 Experimental evaluation of liquid nitrogen fracturing on the development of tight gas carbonate rocks in the Lower Indus Basin, Pakistan; Fuel 309 122192.

ASTM 1994 American Society for Testing and Materials. Annual book of ASTM standards, Vol. 04.08, Philadeplhia, PA, USA.

ASTM 2000 American Society for Testing and Materials. Annual book of ASTM standards, Vol. 04.08, Philadeplhia, PA, USA.

ASTM 2007 American Society for Testing and Materials. Standard Practice for Instrumented Indentation Testing, E2546-07, Vol. 03.01, Philadelphia, USA.

ASTM 2008 Standard test method for performing laboratory direct shear strength tests of rock specimens under constant normal force. ASTM International, West Conshohocken, 12.

Basu S, Jones A and Mahzari P 2020 Best practices for shale core handling: Transportation, sampling and storage for conduction of analyses; J. Mar. Sci. Eng. 8(2).

Behar F, Beaumont V and Penteado H D B 2001 Rock-Eval 6 technology: Performances and developments; Oil Gas Sci. Technol. 56(2) 111–134.

Bennett K C, Berla L A, Nix W D and Borja R I 2015 Instrumented nanoindentation and 3D mechanistic modeling of a shale at multiple scales; Acta Geotech. 10(1) 1–14.

Bobji M S and Biswas S K 1999 Deconvolution of hardness from data obtained from nanoindentation of rough surfaces; J. Mater. Res. 14(6) 2259–2268.

Boulenouar A, Mighani S, Pourpak H, Bernabé Y and Evans B 2017 Mechanical properties of Vaca Muerta shales from nano-indentation tests; In: 51st US Rock Mechanics/Geomechanics Symposium, OnePetro.

Bustin A M and Bustin R M 2012 Importance of rock properties on the producibility of gas shales; Int. J. Coal Geol. 103 132–147.

Cala M, Cyran K, Kawa M, Kolano M, Lydzba D, Pachnicz M, Rajczakowska M, Rózanski A, Sobótka M, Stefaniuk D and Stopkowicz A 2017 Identification of microstructural properties of shale by combined use of X-ray micro-CT and nanoindentation tests; In: ISRM European Rock Mechanics Symposium-EUROCK, OnePetro.

Camp W K 2013 Enhancing sem grayscale images through pseudocolor conversion: Examples from Eagle Ford, Haynesville, and Marcellus shales; In: SPE/AAPG/SEG URTeC, OnePetro.