Abstract

A simple, convenient, and eco-friendly procedure has been developed using meglumine (15 mol%) as a green catalyst for the synthesis of 1,2,4-triazolidine-3-thiones under one-pot condition. Variously substituted aldehydes or ketones reacted well with thiosemicarbazide to give desired compounds in extremely good quantity. The developed protocol offers several advantages such as shorter reaction times, mild reaction conditions, easy workup, simple purification procedures, water as a solvent, and wide substrate scope tolerance. Further, the catalyst was recycled (up to 4 cycles) without compromising the yield of the final products.

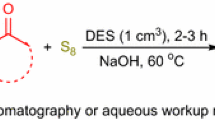

Graphical abstract

The current protocol demonstrates the synthesis of 1,2,4-triazolidine-3-thiones from variously substituted aldehydes or ketones with thiosemicarbazide under aqueous conditions. A simple stirring of the reaction at room temperature in the presence of the catalytic amount of meglumine quickly gave the desired product an excellent yield. The method is operationally simple and eco-friendly.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The development of the environment-friendly, non-toxic and energy-efficient methodology for the synthesis of organic molecules is a major attraction of current researchers. In this context, using novel, greener, and sustainable protocols, instead of older and traditional methods has been a major challenge from an ecological and economic point of view. One way to find the solution for this challenge is using a biodegradable catalyst and a greener solvent to carry out the chemical transformation without sacrificing the desirable outcome of the procedure.1,2,3,4,5

Recently, meglumine has been used as an extremely useful homogeneous catalyst in various organic reactions such as the synthesis of pyrazoles,6 2-amino-4H-pyrans,7 dihydropyrimidines,8 etc. Structurally, meglumine is a sugar alcohol derived from glucose molecules with a modified amino group on it. It possesses various advantages such as safe, stable, non-corrosive, easily available, economical, recyclable, non-inflammable, and having high heat capacity.9,10,11,12,13,14,15 Also, water as a reaction medium has gained much attention as it shows great diversity in the process of synthetic reactions.

The one-pot and single-step synthesis of Aza heterocyclicpyridines has captured a lot of attention of medicinal chemists in recent years due to their major impact on the drug discovery of complex, highly functionalized molecules.16,17,18 Among other triazole derivatives, 1,2,4-triazolidines-3 thiones derivatives have shown a vibrant pharmacological profile and have been surveyed deliberately for a variety of biological properties such as antiepileptic,19 anticancer,20 analgesic and anti-inflammatory,21 antiviral,22 anti-HIV,23 anti-tuberculosis,24 antidepressant,25 anticonvulsants,26 antimicrobial,26 antibacterial,27 and antiproliferative activities.28 Also substituted 1,2,4-triazolidines-3 thiones show therapeutic agents in the treatment of diabetes,29 influenza infection,30 and cancer metastatis20 (Figure 1).

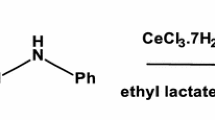

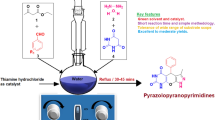

Further, its vital role in the growth and overall development of plants has brought an interesting application in the field of agrochemistry as well. Due to their multifarious applications and widespread interest, it has become the most important area of current synthetic chemistry.31Among all reported procedures for the synthesis of 1,2,4-triazolidines-3 thiones, the most convenient and straightforward method involves one-pot two-component cyclo-condensation of aromatic aldehydes or ketones with thiosemicarbazides utilizing various catalysts such as biomass husk derived activated carbon under metal-free conditions,32 Envirocat EPZ-10,33 L-proline,34 P-TSA,34 ceric ammonium nitrate,35 Sulfamic acid.34 Also, efficient ionic liquids like [(Py)2SO[HSO4]36 and [C16MPy]AlCl3Br37 in water as a solvent have been reported. Some of these procedures involve the use of solvents like Ethanol, Acetonitrile, PEG-400, DCM.38

Moreover, many of these protocols suffer drawbacks and limitations like poorer yield, use of harsh reaction conditions, expensive reagents, and longer duration. Therefore, inventing an efficient, environmentally benign, and cost-effective novel method is still in demand. In the course of our study and continuous interest in synthesizing heterocyclic molecules,39,40,41,42 we found a more convenient, efficient, milder reaction condition for the synthesis of 1,2,4, -triazolidines - 3 thiones, using meglumine as a reusable catalyst under aqueous conditions.

2 Experimental

2.1 Materials

All the chemicals were purchased from Sigma Aldrich, SD Fine chemicals, and Spectrochem companies. Thin-layer chromatography (TLC) was performed on 0.25 mm, silica gel 60F254 plates and viewed on UV light (254 nm). Nuclear magnetic resonance (1H NMR and 13C NMR) was recorded by using DMSO-d6 solvent on Agilent Technology (400 Mz), respectively, with Tetramethylsilane (TMS) as an internal standard. Mass spectra were recorded on the insertion probe on Agilent Technologies 5975 series. The melting point of all compounds was recorded on the AnalabThermoCal melting point apparatus in the one-end open capillary tube. All reagents used are analytically pure and directly without any further purification.

2.2 General procedure for the synthesis of 1,2,4-triazolidine-3-thiones

A mixture of aldehydes (1 mmol) or ketones (1 mmol) and thiosemicarbazide was stirred in water (8 mL) in the presence of meglumine as a catalyst (15 mol%) at room temperature for 5 min. The reaction was monitored by thin-layer chromatography. After completion of the reaction, the product was isolated by filtration, dried under vacuum, and recrystallized from ethanol to afford the pure product. The final confirmation of the product was done by spectroscopic methods 1H, 13C NMR, and MS. The filtrate-containing catalyst was isolated8 under the reduced pressure, and the recovered catalyst was then washed with diethyl ether and used at least four times without losing its catalytical activity as well as the yield of the product (Figure 2).

2.3 Characterization

2.3.1 5-Phenyl-[1,2,4]triazolidine-3-thione (3a)

White solid; M.p. 152-153 °C (Lit43152-154 °C); 1H-NMR (400 MHz, DMSO-d6): δ 11.37 (s, 1H), 8.16 (s, 1H), 8.01 (s, 1H), 7.95 (s, 1H), 7.75 (d, J=6.4 Hz, 2H), 7.37-7.36 (m, 3H); MS: 179 (M+) (m/z).

2.3.2 5-Thiophene-2-yl-[1,2,4]triazolidine-3-thione(3c)

Yellow solid; M.p. 219-221 °C (Lit44 220-222 °C); 1H-NMR (400 MHz, DMSO-d6): δ 11.41 (s, 1H), 8.18 (d, J=21.1 Hz, 2H), 7.61 (d, J=5.0 Hz, 1H), 7.50 (s, 1H), 7.40 (d, J=3.5 Hz, 1H), 7.10-7.05 (m, 1H). MS: 185 (M+) (m/z). Current approach for the synthesis of 1,2,4-triazolidine-3-thiones.

2.3.3 5-methyl-5-phenyl-1,2,4-triazolidine-3-thione (5a)

White solid; M.p. 216-218 °C (Lit36 215-218 °C); 1H NMR (400 MHz, DMSO-d6): δ 10.17 (s, 1H), 8.23 (s, 1H), 7.88 (s, 3H), 7.35 (s, 3H), 2.46 (s, 3H); MS: 193 (M+) (m/z).

2.3.4 5-methyl-5-(p-tolyl)-1,2,4-triazolidine-3-thione (5b)

White solid; M.p. 175-177 °C (Lit45 175 °C); 1H NMR (400 MHz, DMSO-d6): δ 10.11 (s, 1H), 8.19 (s, 1H), 7.89-7.74 (m, 3H), 7.15 (d, J=8.0 Hz, 2H), 2.29 (s, 3H), 2.23 (s, 3H); MS: 207 (M+) (m/z).

2.3.5 1,2,4-triazaspiro [4.5] decane-3-thione (5c)

White solid; M.p. 156-157 °C (Lit47 156-158 °C); 1H NMR (400 MHz, DMSO-d6): δ 10.09 (s, 1H), 7.89 (s, 1H), 7.46 (s, 1H), 2.35 (s, 2H), 2.23-2.12 (m, 2H), 1.54 (d, J=26.0 Hz, 6H); 13C NMR (100 MHz, DMSO-d6): δ 178.97, 157.47, 35.30, 27.60, 27.30, 26.11, 25.44; MS: 171 (M+) (m/z).

3 Results and Discussion

Initially, we commenced our experiment with a reaction of thiosemicarbazide (1) with benzaldehyde (2) as a model reaction stirred under the aqueous condition at room temperature in the presence of the meglumine as a catalyst. Surprisingly, within 5-6 mins, the pale white crude product was obtained, which was purified by recrystallization with ethanol and further characterized using different analytical techniques such as NMR, MS to confirm 1,2,4-triazolidine-3-thiones (3a).

Thus, to further determine the optimal reaction condition, we screened the different concentrations of meglumine in above model reaction. Initially, 5 mol% of meglumine at room temperature gives a trace amount of product even after 15 min of constant stirring. After carrying out the reaction with 8 mol%, 10 mol%, 15 mol%, 18 mol% of meglumine, it was observed that 15 mol% concentration of meglumine gives an excellent yield of 90% within 5 min of stirring at room temperature (Table 1).

Then, the reaction condition was optimized under different solvents and also solvent-free conditions. Reaction in a neat environment does not show any formation of the desired product, while the use of different solvents such as ethanol, THF, methanol, acetonitrile gave lesser yield as compared to an aqueous environment. Consequently, 15 mol% concentration of meglumine under aqueous conditions at room temperature was considered as optimized reaction conditions for this procedure.

The above-optimized reaction conditions were utilized to extend the scope of reaction to ketones as starting substrates instead of aldehydes and found to give satisfactory results. With the optimized reaction condition, different substituted aromatic aldehydes and ketones reacted smoothly with thiosemicarbazide and ended in excellent product yield (Table 3, 4). To show the versatility of the reported protocol, cyclic ketones like cyclohexanone (5c) and cycloheptanone (5g) and cyclic diketone such as isatine (5i), were allowed to react with thiosemicarbazide individually to give the respective desired products in an excellent yield. In the case of aromatic aldehydes, we have used five-membered heterocyclic rings, which do not show any changes in the final product under optimized conditions. Further, the reaction with a dialdehyde such as terephthaldehyde underwent satisfactorily to give the expected final compound when 2 equivalent of thiosemicarbazide is used (3k), while at 1 equivalent of thiosemicarbazide lower yield of the expected compound was observed. The other advantage of this protocol is the clean isolation of the product and catalyst, and the isolated catalyst further successfully recycled without affecting the yield of the product.

3.1 Plausible mechanism

As we used Meglumine as a catalyst for the synthesis of 1,2,4-triazolidine-3-thiones, the catalytic mechanism was shown in (Scheme 2). In our consideration, meglumine containing amine and hydroxyl groups play a significant role in promoting the reactions. In the initial step, meglumine increases the electrophilicity by protonating the carbonyl carbon of aldehyde (a) through hydrogen bonding (b), followed byanucleophilic attack of one of the amino groups of thiosemicarbazide to form an intermediate (c), which on the further loss of water molecules to gives imine product (d). Finally, another free amino group of thiosemicarbazide attacks on imine carbon. Their subsequent reaction, followed by intramolecular interaction, leads to cyclization to give the final desired product (e).

3.2 Comparative study

As per the previous literature, 1,2,4-triazolidine-3-thiones can be synthesized by various reaction models as shown in (Table 2), like glycin nitrate, DMAP, L-proline, ceric ammonium nitrate, etc., which was in the presence of aqueous as well as ethanol-treated with reactants. But here, we discover various drawbacks like using temperature or reaction time which was the main concern of our reaction model. From the study, it is evident that our current approach has numerous key features over others, including shorter reaction time, environmentally benign reaction, metal-free catalyst, simple purification methods, and high yield. Thus, all these factors contribute to the increase in its utility in the pharmaceutical industry.

4 Conclusions

In this report, we enclosed a highly efficient, one-pot. synthesis of 1,2,4-triazolidine-3-thiones by the cyclo condensation of an aldehyde or ketone with thiosemicarbazide at room temperature using meglumine as a catalyst in an excellent yield. The pure products were obtained by recrystallizing with ethanol. This reaction model offers numerous attractive features such as reduced reaction time, recovery, reusability of the catalyst, use of water as a solvent, and atom efficiency.

References

Mohamadpour F 2020 Green and convenient one-pot access to polyfunctionalized piperidine scaffolds via glutamic acid catalyzed knoevenagel- intramolecular [4+2] aza-diels-alder imin-based multi-component reaction under ambient temperature Poly. Arom. Comp. 40 681

Barkule A B, Gadkari Y U and Telvekar V N 2021 One-pot multicomponent synthesis of 3-methyl-4-(hetero)arylmethylene isoxazole-5(4H)-ones using guanidine hydrochloride as the catalyst under aqueous conditions Poly. Arom. Comp. 1

Indalkar K S, Khatri C K and Chaturbhuj G U 2017 Rapid, efficient and eco-friendly procedure for the synthesis of quinoxalines under solvent-free conditions using sulfated polyborate as a recyclable catalyst J. Chem. Sci. 129 141

Khatri C K, Potadar S M and Chaturbhuj G U 2017 A reactant promoted solvent free synthesis of 3,4-dihydropyrimidin-2(1 H )-thione analogues using ammonium thiocyanate Tetrahedron Lett. 58 1778

Gadkari Y U, Shanbhag R D and Telvekar V N 2022 An efficient one-pot, multicomponent synthesis of 1, 3-thiazolidin-4-ones using L-proline as catalyst in water Lett. Org. Chem. 19 9

Zhang M, Shang Z R, Li X T, Zhang J N, Wang Y, Li K, et al. 2017 Simple and efficient approach for synthesis of hydrazones from carbonyl compounds and hydrazides catalyzed by meglumine Synth. Commun. 47 178

Guo R Y, An Z M, Mo L P, Yang S T, Liu H X, Wang S X and Zhang Z H 2013 Meglumine promoted one-pot, four-component synthesis of pyranopyrazole derivatives Tetrahedron Lett. 69 9931

Guo R Y, An Z M, Mo L P, Wang R Z, Liu H X, Wang S X and Zhang Z H 2013 Meglumine: a novel and efficient catalyst for one-pot, three-component combinatorial synthesis of functionalized 2-amino-4 H -pyrans ACS Comb. Sci. 15 557

Govindaraju S, Tabassum S, Khan R-R and Pasha M A 2017 Meglumine catalyzed one-pot green synthesis of novel 4,7-dihydro-1 H -pyrazolo[3,4-b]pyridin-6-amines Chin. Chem. Lett. 28 437

Tabassum S, Govindaraju S and Pasha M A 2017 Sonochemistry – an innovative opportunity towards a one-pot three-component synthesis of novel pyridylpiperazine derivatives catalysed by meglumine in water New J. Chem. 41 3515

Rai P, Mishra A, Srivastava M, Yadav S, Tripathi B P and Singh J 2017 An amino sugar promoted green protocol: a one-pot, meglumine-catalyzed, multicomponent strategy for synthesis of multifaceted pyrroloacridin-1(2H)-one derivatives ChemistrySelect 2 2245

Nemallapudi B R, Zyryanov G V, Avula B, Guda M R, Cirandur S R, Venkataramaiah C, et al. 2019 Meglumine as a green, efficient and reusable catalyst for synthesis and molecular docking studies of bis(indolyl)methanes as antioxidant agents Bioorg. Chem. 87 465

Korade S N, Mhaldar P M, Kulkarni P P, Rashinkar G S and Pore D M 2021 Meglumine catalyzed one pot synthesis of new fluorescent 2-amino-4-pyrazolyl-6-aryldiazenyl-4 H -chromene-3-carbonitriles Synth. Commun. 51 2336

Pagadala R, Kasi V, Shabalala N G and Jonnalagadda S B 2022 Ultrasound-assisted multicomponent synthesis of heterocycles in water–A review Arab J. Chem. 15 103544

Bhadke P K, Pahelkar A R, Gadkari Y U, Naik J M, and Telvekar V N 2022 Eco-friendly and efficient greener process for the synthesis of chalcones and pyrazolones using the supramolecular catalyst β-cyclodextrin Org. Prep. Proced. Int. 7

Manning J R and Davies H M 2008 One-pot synthesis of highly functionalized pyridines via a rhodium carbenoid induced ring expansion of isoxazoles J. Am. Chem. Soc. 130 8602

Xiong X, Bagley M C and Chapaneri K 2004 A new mild method for the one-pot synthesis of pyridines Tetrahedron Lett. 45 6121

Davoodnia A, Bakavoli M, Soleimany M and Behmadi H 2008 A new one-pot neat synthesis of 1,2,4-triazol-3-ones through 4-(N, N-dimethylamino) pyridine (DMAP) catalyzed cyclocondensation of ethyl carbazate with aryl nitriles Chin. Chem. Lett. 19 685

Plech T, Kaproń B, Łuszczki J J, Paneth A, Siwek A, Kołaczkowski M, et al. 2014 Studies on the anticonvulsant activity of 4-alkyl-1,2,4-triazole-3-thiones and their effect on GABAergic system Eur. J. Med. Chem. 86 690

Kaur R, Ranjan Dwivedi A, Kumar B and Kumar V 2016 Recent developments on 1,2,4-triazole nucleus in anticancer compounds: a review Anti-Cancer Agents Med. Chem. 16 465

Dutta A, Saikia R A and Thakur A J 2022 A Mechanistic approach to liquid assisted mechanochemical synthesis of 5‐aryl/spiro‐[1, 2, 4]‐triazolidine‐3‐thiones: a revisit Eur. J. Org. Chem. e202101472

Ezabadi I R, Camoutsis C, Zoumpoulakis P, Geronikaki A, Soković M, Glamočilija J and Ćirić A 2008 Sulfonamide-1,2,4-triazole derivatives as antifungal and antibacterial agents: Synthesis, biological evaluation, lipophilicity, and conformational studies Bioorg. Med. Chem. 16 1150

Alvarez R, Velazquez S, San-Felix A, Aquaro S, Clercq E D, Perno C F, et al. 1994 1,2,3-Triazole-[2,5-bis-o-(tert-butyldimethylsilyl)-.beta.-d-ribofuranosyl]-3’-spiro-5’’-(4’’-amino-1’’,2’’-oxathiole 2’’,2’’-dioxide) (TSAO) analogs: synthesis and anti-HIV-1 activity J. Med. Chem. 37 4185

Kumar G S, Prasad Y R, Mallikarjuna B P and Chandrashekar S M 2010 Synthesis and pharmacological evaluation of clubbed isopropylthiazole derived triazolothiadiazoles, triazolothiadiazines and mannich bases as potential antimicrobial and antitubercular agents Eur. J. Med. Chem. 45 5120

Kane J M, Dudley M W, Sorensen S M and Miller F P 1988 2, 4-Dihydro-3H-1, 2, 4-triazole-3-thiones as potential antidepressant agents J. Med. Chem. 31 1253

Demirbas N, Karaoglu S A, Demirbas A and Sancak K 2004 Synthesis and antimicrobial activities of some new 1-(5-phenylamino-[1, 3, 4] thiadiazol-2-yl) methyl-5-oxo-[1, 2, 4] triazole and 1-(4-phenyl-5-thioxo-[1, 2, 4] triazol-3-yl) methyl-5-oxo-[1, 2, 4] triazole derivatives Eur. J. Med. Chem. 39 793

Trotsko N, Kosikowska U, Paneth A, Plech T, Malm A and Wujec M 2018 Synthesis and antibacterial activity of new thiazolidine-2, 4-dione-based chlorophenylthiosemicarbazone Hybrids Molecules 23 1023

Li Z, Gu Z, Yin K, Zhang R, Deng Q and Xiang J 2009 Synthesis of substituted-phenyl-1, 2, 4-triazol-3-thione analogues with modified d-glucopyranosyl residues and their antiproliferative activities Eur. J. Med. Chem. 44 4716

Palaska E, Şahin G, Kelicen P, Durlu N T and Altinok G 2002 Synthesis and anti-inflammatory activity of 1-acylthiosemicarbazides, 1,3,4-oxadiazoles, 1,3,4-thiadiazoles and 1,2,4-triazole-3-thiones Farmaco 57 101

Asatkar A, Saha A, Lambat T L, Singh M and Banerjee S 2020 Biomass rice husk derived activated carbon catalyzed synthesis of 5-aryl-1,2,4-triazolidine-3-thione derivatives under metal-free aqueous medium Mater. Today: Proceed. 29 698

El-Atawy M A, Omar A Z, Hagar M and Shashira E M 2019 Transalkylidation reaction: green, catalyst-free synthesis of thiosemicarbazones and solving the NMR conflict between their acyclic structure and intramolecular cycloaddition products Green Chem. Lett. Rev. 12 364

Korade S N, Patil J D and Pore D M 2016 Novel task-specific ionic liquid for room temperature synthesis of spiro-1, 2, 4-triazolidine-3-thiones Monatsh Chem. Month. 147 2143

Mhaldar P M and Pore D M 2020 An efficient catalyst for the synthesis of 1,2,4-triazolidine-3-thiones Lett. Org. Chem. 17 321

Mane M M and Pore D M 2014 A novel one pot multi-component strategy for facile synthesis of 5-aryl-[1,2,4]triazolidine-3-thiones Tetrahedron Lett. 55 6601

Mali D A and Telvekar V N 2017 Synthesis of triazolidines and triazole using DMAP Synth. Commun. 47 324

Patil P B, Patil J D, Korade S N, Kshirsagar S D, Govindwar S P and Pore D M 2016 An efficient synthesis of anti-microbial 1, 2, 4-triazole-3-thiones promoted by acidic ionic liquid Res. Chem. Intermed. 42 4171

Patil J D and Pore D M 2014 [C16MPy] AlCl3Br: an efficient novel ionic liquid for synthesis of novel 1, 2, 4-triazolidine-3-thiones in water RSC Adv. 4 14314

Ramesh R and Lalitha A 2015 PEG-assisted two-component approach for the facile synthesis of 5-aryl-1,2,4-triazolidine-3-thiones under catalyst-free conditions RSC Adv. 5 51188

Gadkari Y U, Hatvate N T and Telvekar V N 2021 Concentrated solar radiation-assisted one-pot/multicomponent synthesis of pyranopyrazole derivatives under neat condition Res. Chem. Intermed. 47 4245

Gadkari Y U, Hatvate N T and Telvekar V N 2021 Solar energy as a renewable energy source for preparative-scale as well as solvent and catalyst-free hantzsch reaction Sustain. Chem. Pharm. 21 100444

Gadkari Y U, Hatvate N T, Takale B S and Telvekar V N 2020 Concentrated solar radiation as a renewable heat source for a preparative-scale and solvent-free biginelli reaction New J. Chem. 44 8167

Gadkari Y U, Jadhav N L, Hatvate N T and Telvekar V N 2020 Concentrated solar radiation aided green approach for preparative scale and solvent-free synthesis of 3-methyl-4-(hetero) arylmethylene isoxazole-5 (4H)-ones ChemistrySelect 5 12320

Kamanna K and Khatavi S Y 2021 Waste to wealth: agro-waste catalyzed green method synthesis of 5-aryl-1,2,4-triazolidine-3-thiones and 1,2,4-triazospiro-3-thiones Org. Commun. 240

Pansambal S, Ghotekar S, Shewale S, Deshmukh K, Barde N and Bardapurkar P 2019 Efficient synthesis of magnetically separable CoFe2O4@SiO2 nanoparticles and its potent catalytic applications for the synthesis of 5-aryl-1,2,4-triazolidine-3-thione derivatives J. Water Environ. Nanotechnol. 4 174

Kumar H, Goyal R, Kaur S, Anand R D, Parmar A and Kumar B 2002 Synthesis of 1, 5-substituted-s-triazolinodino [1, 2-a]-s-triazolidine-3, 7-dithione and 1, 2,4-triazolidine-3-thione derivatives from azines Ind. J. Chem. 41 218

Ramesh R and Lalitha A 2016 Facile and green chemistry access to 5-aryl-1,2,4-triazolidine-3-thiones in aqueous medium ChemistrySelect 1 2085

Maddila S N, Maddila S, Gangu K K, van Zyl W E and Jonnalagadda S B 2017 Sm2O3/Fluoroapatite as a reusable catalyst for the facile, green, one-pot synthesis of triazolidine-3-thione derivatives under aqueous conditions J. Fluor. Chem. 195 79

Patil P J, Salunke G D, Deshmukh M B, Hangirgekar S P, Chandam D R and Sankpal S A 2019 Thiamine hydrochloride catalyzed synthesis of 1,2,4-triazolidine-3-thiones in aqueous medium ChemistrySelect 4 13071

Acknowledgment

The authors L.B.M, S.S.S, A.B.B, thank ADF and SARTHI Pune, respectively, for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Masram, L.B., Salim, S.S., Barkule, A.B. et al. An efficient and expeditious synthesis of 1,2,4-triazolidine-3-thiones using meglumine as a reusable catalyst in water. J Chem Sci 134, 94 (2022). https://doi.org/10.1007/s12039-022-02087-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-022-02087-5