Abstract

In this paper, we develop a Kinetic Monte Carlo (KMC) based model to simulate the atomistic growth behavior of metallic nanoparticle in the solution of its ions and understand the growth pattern. KMC is used as it can model the growth of nanoparticle to the timescale comparable with that actual experiments. Energy minimas where metal atom can adsorb or surface diffuse have been found using Shrake–Rupley algorithm and conjugate gradient energy minimization algorithm. The rate of adsorption, desorption, and surface diffusion was artificially accelerated, and decelerated to observe different shapes. We demonstrate the model by a case study on growth of gold nanoparticles and find that shapes like the truncated octahedron, cuboctahedron, truncated cube, cube, rhombic dodecahedron, and sphere are seen to form by the model during the growth of NP. This KMC model provides a simplistic understanding of the mechanism and progression of shapes that may be seen during the growth of nanoparticle; these in turn may provide clues to synthesize NP of specific shapes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanoparticles (NPs) is usually defined as the particles whose diameter lies between 1 and 100 nm.1 Nanoparticles occur widely in nature and are objects of study in various branches of science such as physics, chemistry, biology, geology, etc.1 Nanoparticles are an important component of atmospheric pollution and are also found in many products such as paints, ceramics, plastic, metals, etc.2 Various kinds of nanoparticles are being used in different industry such as agriculture, automotive, cosmetics, environment, etc.2 NPs can be classified into different types depending on shape, size and properties. Depending on the overall shape, these materials can be 0D, 1D, 2D or 3D.3 The importance of these nanomaterials was realised when it was found their size, shape, and surface area can influence the properties of a substance, e.g. optical properties.2

Gold nanoparticles (AuNPs) have diverse applications in the field of nanotechnology, nanoscience, and medicine. It is also being used to produce optical and data storage systems.4 An important development is the use of nanoparticles in the field of biomedicine to diagnose and treat several diseases such as cancer, rheumatoid arthritis, etc.5,6 In recent years, a lot of effort has been made by scientists around the world to develop nanotechnology for lower molecular weight drugs, as well as for cellular delivery of proteins, peptides and genes.7 AuNPs are considered important for drug delivery because of the relative stability of the gold complexes outside cells with its decreased stability within the cells.7

C. J. Murphy et al.14 and K. T. Nam et al.15 have claimed that it is the concentration of surfactant Cetyl Trimethyl Ammonium Bromide (CTAB) which plays a major role in determining the shape of AuNPs.14,15 Different shapes like cube, hexagon, triangle etc of AuNPs have been synthesized experimentally14 by varying the concentration of CTAB, gold salt, gold seed and ascorbic acid which acts as a reducing agent. It has been found that CTAB molecules appear to bind more strongly to the {100} facets than the {111} facets of AuNP.14,15 Due to different affinity of CTAB towards different facets, each facet has a different rate of growth leading to different shape during the growth of AuNPs. The relative ratio of CTAB and ascorbic acid 15 in seed-mediated growth also affects the shape of AuNPs. Morphology map has been drawn for different shapes like cubes, cuboctahedron, and rhombic dodecahedron as a function of concentration of CTAB and ascorbic acid.15 Despite all the above studies, there is still no clear understanding of the factors that control the shape of nanoparticles.

To understand shape change, experiments with different molecules like \(\hbox {AgNO}_3\) have been reported.16,17 The shape transformation from the octahedron to a cube has been found with intermediate species such as truncated octahedron, cuboctahedron, truncated cube during the entire course of experiments. The shape transformation happens by incrementally varying the \(\hbox {AgNO}_3\) concentration. The silver species produced has different packing density on different gold facets {100}, {110} leading to these different shapes.16,17

In the past, different methods such as phase-field method,9 level-set method,10 adaptive mesh techniques,11 random walks with adaptive step sizes,12 and so forth were used to model the growth of nanoparticles. In this study, we have used KMC8 because it allows considering only the processes deemed to be most pertinent for growth process while ignoring others, and find that the model is able to simulate the growth at timescales approaching the actual experiments. KMC8 algorithm has been used to model atomistic growth behavior of AuNP in solution13 and values of following simulation parameters such as temperature, gold ions (\(Au^+\)) concentration in the solution, rate constant of adsorption, rate constant of reduction and volume of the solution were adjusted by bench-marking with the experimental data for AuNP.

Molecular Dynamics (MD) simulations were utilised to investigate the anisotropic growth of gold nanorods. It has been found that CTAB forms a distorted cylindrical micelles on the gold surface leading to ion channel through which gold atom from the solution diffuses and attaches to the surface. CTAB molecules have different packing density on different facets, with maximum packing density on {100} facets18,19,20 which is in agreement with the experimental studies. Due to different packing density of CTAB on different surfaces, number of gold atoms adsorbed to the surface are different leading to anisotropic growth. Wulff construction is a well-established technique whereby equilibrium (i.e. final and stable) shapes of nanoparticles can be predicted;30 modern modifications like Kinetic Wulff construction can be used to predict growth shapes.31 Underlying such schemes is the idea that if energetics (or kinetics of growth) of every facets of nanoparticles are known, then optimization of the surface free energy (or change in area of facets) of the nanoparticle can determine the equilibrium shape (or growth) of nanoparticle. Unlike these facet based models, the simplistic KMC model studied here grows the nanoparticle by single site dynamics; the additional simplifying assumption is that all sites have identical rates for individual processes: adsorption at, desorption from and surface hopping to/from the site. Study by Turner et al.13 also models site based dynamics, but has site-specific parameters determining rate of each of the above mentioned processes. In a few studies, it has been reported that the particle shape is dependent upon in situ seed-growth time of one-pot synthesis of AuNPs and rate of adsorption of the gold atom from solution. It was found that the yield of cube increased with time while a short time (15 min) resulted in the formation of octahedron AuNP.21,22 Few computational modeling studies have reported synthesis of different shape AuNP. Nanorod synthesis mechanism has been proposed using the population balance based model and the physical phenomenon of twinning.23 Another study reported a mathematical model developed to capture the growth of gold nanorod in presence of surfactant and it was found that the length of nanorod is an exponential function of time.24 Investigations have been done on varying the temperature during the process of melting and freezing and the effect on shape of small gold and silver nanoclusters (55 and 147 atoms) using Monte Carlo simulation.25 It was identified that during freezing final shape has a large fraction of surface atoms compared to the initial shape.25

The properties of AuNPs significantly depend on shape and size; slight change in the shape and size can severely affect the application for which AuNPs are being used. In this study, we aim to model the factors that control the growth of nanoparticle while allowing for accessing the shape changes during growth and approach the timescales seen in actual experiments: Kinetic Monte Carlo (KMC) scheme8 are well known for their utility for these purposes. KMC model developed in this study models the growth of the nanoparticle by modelling the site dynamics, and to simplify the model, we adopt the assumption of identical dynamics for all surface sites/atoms; in reality, we expect that sites/atoms on various facets will have different energetics and hence site/atom dependent dynamics. Previous studies13 implement site/surface atom dynamics, unlike them we report on the shapes seen during the growth of nanoparticle: we are able to synthesize different shapes such as truncated octahedron, cuboctahedron, truncated cube, cube, rhombic dodecahedron, and sphere. The factors that lead to these different shapes during the growth were the rate of adsorption, rate of desorption, rate of surface diffusion and reaction time; the effect of these factors on the equilibrium shapes will be left for a future study.

2 Computational methodology

2.1 Kinetic Monte Carlo model

KMC8 defines all the possible events in the system, and probabilistically picks one of these events for the time evolution. Compared to other existing methods, KMC can model the growth at timescale approaching actual experiments.8 Our system consists of nanoparticle seed and metal ions; with three processes modelled, namely: (a) adsorption of a atom from solution to surface of nanoparticle, (b) desorption of a surface atom to solution and c) surface diffusion of a surface atom to its neighbouring vacant surface sites. All the rates are defined for each of the processes. In adsorption, an atom formed in solution by reduction of its ion can adsorb possibly to any one of the vacant sites available on the nanoparticle lattice. Similarly in desorption, all the surface atoms have a possibility to desorb back to salt solution; and in surface diffusion any of the surface atom could diffuse to a empty neighbouring site. All the sites are considered identical irrespective of their location. The event happening out of all the possible events (adsorption, desorption and surface diffusion) was then determined by KMC algorithm. Detailed implementation of KMC algorithm is presented in Supplementary Information (SI).

2.2 Algorithm to find surface sites

The Shrake–Rupley algorithm26 is a numerical method that draws a mesh of points equidistant from each atom of the NP and the count of number of these points that are solvent accessible determines the surface area. The points are drawn on a sphere centered at a atom with estimated diameter beyond the van der Waals radius of the atom, which is similar to ‘rolling a ball’ along the surface; all points are checked against the surface of neighbouring atoms to determine whether they are accessible or buried. The number of accessible points is multiplied by the portion of the surface area, estimates the accessible surface area (ASA).

To determine the surface sites, we extend Shrake–Rupley algorithm. We generate N points at a distance of \(d_o\) from each atom in NP. Among those generated points, we determine the surface points which lie outside the NP by simply iterating over all the points and then calculating the distance from each atom. If for all atoms considered, distance is greater than equal to \(d_o\), then that particular point is a surface point and can be used as an initial search point for conjugate gradient algorithm to find minima of total energy of NP; surface points are shown clearly in Figure 1.

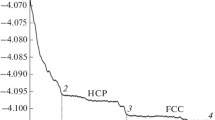

The energy minima on the surface of NP are the locations where atoms from solution can adsorb onto NP; additionally these sites can become occupied by a nearby atom that is already part of NP by way of surface hopping. We use the conjugate gradient method27 to find the energy minima. It is similar to steepest descent as the search takes in the direction of the largest gradient. To converge faster towards the energy minima, this method uses the previous direction in the next search. Points generated by Shrake–Rupley algorithm served as initial points of search to find minima. While the methodology can be applied to nanoparticle of any metal atom, in this study we have used parameters relevant for gold atom and gold nanoparticle. The primary reason to choose AuNP was because of number of experimental studies and general interest of scientific community. Atoms are assumed to interact with each other by Lennard-Jones potential energy function (\(V=4\epsilon \left( \left( \frac{\sigma }{r}\right) ^{12} - \left( \frac{\sigma }{r}\right) ^{6}\right) \) and parameters28\(\epsilon = 5.29\) kcal/mol, \(\sigma = 2.63\) Å) and the total potential energy of the AuNP was minimized to find the sites where atoms can adsorb or diffuse on to the surface. Energy minimas are shown clearly in Figure 2. Please note that Lennard-Jones potential energy is reasonable but approximate energy function, and a more accurate energy function (e.g. on the fly QM calculation) can be used depending on the available computing resources.

2.3 Algorithm to find surface atoms

We generate \(N=150\) random points at a distance of \(d_o\) = 2.88 Å (which is diameter of gold atom) from all the atoms. For a particular atom, if the generated points are at a distance greater \(d_o\)=2.88 Å from all the atoms in the NP, then such an atom is considered a surface atom. Therefore, the atoms corresponding to accessible points or surface points will be surface atoms. These surface atoms are considered for desorption and surface diffusion events.

2.4 Model constraint

The following constraint was put in the model to observe the shape changes of AuNP: only after all the old sites have adsorbed a gold atom, the new sites which might have been created due to adsorption/surface diffusion will be considered for adsorption and surface diffusion. Figure 4 shows the implementation of site list update logic. The constraint can be justified by analysis of energy28 of newly created sites and old sites along the course of simulation; the minimum energy site mostly belonged to old sites as clearly seen in Figure 3.

Hence, newly created sites on the fly were less stable and therefore they were not considered for adsorption and surface diffusion until all old sites are exhausted. This constraint was put to model it more closer to real experiment where adsorption is highly likely to occur on minimum energy sites, in comparison to other sites. Refer Figures S7, S8, S9 in Supplementary Information, where minimum energy of both newly created sites on the fly and the old sites have been plotted. There is slight overlap of minimum energy of newly created sites on the fly which are not considered by model and sites considered by model which can be clearly seen in Figures S8 and S9 (Supplementary Information). This overlap happens when the list of old sites are about to be empty because at that point most of the sites have been adsorbed by gold atom and new sites become equally stable. Similar constraint was used by V. Gorshkov et al 29 by introducing registration rule in their model; whereby the original substrate atoms are kept fixed to prevent the formation of defects.29

2.5 Experimental

Multiple simulations were conducted at different experimental conditions by artificially accelerating, decelerating rate of adsorption, desorption and surface diffusion. Table 1 lists the rates used in these simulations. For all the reported simulations, same initial seed octahedron is used to enable comparison of sysnthesis of these different shapes. All the (local) energy minima around the rigid gold atoms are assumed to have the same energy and adsorptions, surface diffusion rates are assumed to be the same for all the sites.

In simulation S1 when all the three rates were equal, we were not able to observe any specific shape (Figure 5b). In simulation (S2-S3) when the rate of adsorption was higher than the rates of desorption and surface diffusion, different shapes of AuNP such as truncated octahedron, cuboctahedron, truncated cube, cube, rhombic dodecahedron and sphere (Figure 5c–h) were synthesized. In simulation S4, when the desorption rate was more than the other 2 rates; desorption dominated and the entire cluster was dissolved in the solution of ions. In simulation S5, when rate of surface diffusion was more than rate of adsorption, desorption; most of the events were of movements of atoms and hence we were not able to observe any specific shape. In simulation S6, when rate of desorption, surface diffusion was 100 times more than rate of adsorption; desorption again dominated and the entire cluster was dissolved in the solution of ions. In simulation S7, when rate of adsorption, desorption was 100 times more than rate of surface diffusion; their was almost equal addition and removal of atoms so no shape change was observed. More details of analysis are presented in Supplementary Information.

3 Results and Discussion

Shape transformation from octahedron to cube was observed in the simulations when rate of adsorption was higher than rate of desorption and surface diffusion. Shape transformation was faster when rate of adsorption was larger in comparison to other rates (Table 2) due to increased rate of growth of nanoparticle seed. In simulation-S2 when rate of adsorption is 10 times (Table 2) we were only able to see till cube shape due to computational limitations.

The above results are in agreement with the work of Mijin Kim21 who found that, the shape change completely depends on in-situ growth time, and the cube yield increased with the increase of the seed-growth time while a short seed-growth time resulted in the formation of high-yield octahedron particles. Initially they observe octahedron shape but when the reaction is done for a longer time the octahedron shape converts to cubical shape leading to shape transformation.21,22

We synthesized cubical AuNP starting with octahedron seed and found that three additional shapes truncated octahedron, cuboctahedron, truncated cube are seen. Octahedron to cubical AuNP conversion is a 4 step process and this information can be used to generate these shapes by varying the reaction time. The final shape changed in sequence from cuboctahedron to cubes, and finally to rhombic dodecahedron and the results are in agreement with the work of.15,16,17,22 The simulation was continued for some more time, finally converting it to a spherical shaped nanoparticle. Here relative ratio of rate of adsorption, desorption, surface diffusion, and reaction time turns out to be a significant factor in synthesizing these shapes.

In this study, we develop a KMC based model which models the growth of the nanoparticle; the model identifies the sites and atoms on the surface of the nanoparticle where the processes (adsorption, desorption, and surface hopping) can take place. Clearly, like all KMC models, the model studied here allows for artifically manipulating the rates of these process; additionally the simplifying assumption that all other processes have negligible rates, allows simulation of the model to reach experimental timescales. Starting from a specific nucleus (octahedron, here) when adsorption rate is larger than the desorption and surface hopping rates (Simulations S2 and S3, in Table 2), we see that site dynamics can result in growth of facets, and a definite progression of shapes during the growth. We note that in all simulations (S1-S7, in Table 2), we see considerable fraction of surface hopping events throughout the growth of the nanoparticle. We see the following general trend in simulations S2 and S3 (Table 2): under growth conditions, for the surface hopping process a small asymmetry is introduced at the face edges, primarily due to the difference in (a) number of nearby atoms available for surface hopping and (b) number of vacant sites for an atom to hop to. We find that all faces of octahedron grow nearly symmetrically; thus, this small asymmetry at face edges has a very minor contribution and the shape change from ocathedron to other shapes with additional crystal faces is primarily driven by large rate of adsoprtion.

4 Conclusions

We developed a KMC based model to simulate the atomistic growth behavior of AuNP and also synthesized different shapes like truncated octahedron, cuboctahedron, truncated cube, cube, rhombic dodecahedron and sphere by varying the relative ratio of rate of adsorption, desorption and surface diffusion. The experimental conditions which synthesize these different shapes gives significant insights about the mechanism underlying and focuses on the importance of rate of adsorption, desorption and surface diffusion and reaction time in determining shape. These observations may provide specific clues to scientists, nanotechnologists, and experimentalists to synthesize different shapes.

Shape of AuNP is known to depend on certain other factors such as surfactant (CTAB) or other ligands; in future studies, we intend to extend the model by introducing an appropriate modelling of CTAB in the solution. Such modelling will require to incorporate CTAB interactions with different surfaces of AuNP and affects rate of adsorption, desorption and surface diffusion, thus enabling synthesis and understanding of mechanism of formation of other shapes of AuNP which are feasible experimentally and also making this model more closer to experimental scenarios. Similarly, other factors like the difference in energies of sites where gold atom can adsorb, surface diffuse can strongly influence the growth and hence the shape. In this study, we use Shrake–Rupley algorithm for site determination; simple enhancements to Shrake–Rupley algorithm can provide additional parameters may be more realistically relevant. For example, one such parameter is the extent of overlap of the hypothetical atom at the site with all neighbouring atoms which can represent the energy of the site than the bond counting model,13 and hence model the site-specific dynamics better. Future studies extending the model presented in this study will incorporate all such factors and their variation to find their relative contribution in determining the growth and shape of nanoparticles.

References

Vert M, Doi Y, Hellwich K H, Hess M, Hodge P, Kubisa P, Rinaudo M and Schué F O 2012 Terminology for biorelated polymers and applications (IUPAC Recommendations 2012) Pure Appl. Chem. 377

Khan I, Saeed K and Khan I 2019 Nanoparticles: Properties, applications and toxicities Arab. J. Chem. 12 908

Tiwari J N, Tiwari R N and Kim K S 2012 Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices Prog. Mater. Sci. 57 724

Kelly K L, Coronado E, Zhao L L and Schatz G C 2003 The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment J. Phys. Chem. 107 668

Dreaden E C, Alkilany A M, Huang X, Murphy C J and El-Sayed Mostafa A 2012 The golden age: Gold nanoparticles for biomedicine Chem. Soc. Rev. 41 2740

Fricker and Simon 1996 Medical uses of gold compounds: Past, present and future Gold Bulletin 29 53

Arvizo R, Bhattacharya R and Mukherjee P 2010 Gold nanoparticles: Opportunities and challenges in nanomedicine Expert Opin. Drug Deliv. 7 753

Arthur V 2007 Introduction to the kinetic Monte Carlo method (Radiation Effects in Solids) p. 1

Boettinger W J, Warren J A, Beckermann C and Karma A 2002 Phase-field simulation of solidification Ann. Rev. Mater. Res. 32 163

Gibou F, Fedkiw R, Caflisch R and Osher S 2002 A level set approach for the numerical simulation of dendritic growth J. Sci. Comput. 19 183

Provatas N, Greenwood M, Athreya B, Goldenfeld N D and Dantzig J 2005 Multiscale modeling of solidification: Phase-field methods to adaptive mesh refinement Int. J. Mod. Phys. B 19 4525

Mathis P and Alain K 2000 Multiscale random-walk algorithm for simulating interfacial pattern formation Am. Phys. Soc. 84 1740

Heath T C, Yu L and Yuping B 2016 Modeling the atomistic growth behavior of gold nanoparticles in solution Nanoscale 8 9354

Sau T K and Murphy C 2004 Room temperature, high-yield synthesis of multiple shapes of gold nanoparticles in aqueous solution J. Am. Chem. Soc. 126 8648

Ahn H-Y, Lee H-E, Jin K and Nam K T 2013 Extended gold nano-morphology diagram: Synthesis of rhombic dodecahedra using CTAB and ascorbic acid J. Mater. Chem. C 1 6861

Daeha S, Choong Il Y, Chan P J, Min P S, Seol R and Hyunjoon S 2008 Directed surface overgrowth and morphology control of polyhedral gold nanocrystals Angew. Chem. Int. Edit. 47 763

Seo D, Park J C and Song H 2006 Polyhedral gold nanocrystals with O h symmetry: From octahedra to cubes J. Am. Chem. Soc. 128 14863

Kumar M S and Marialore S 2013 Understanding the microscopic origin of gold nanoparticle anisotropic growth from molecular dynamics simulations Langmuir 29 14954

da Silva J A and Meneghetti M R 2018 New aspects of the gold nanorod formation mechanism via seed-mediated methods revealed by molecular dynamics simulations Langmuir 34 366

da Silva J A, Dias R P, da Hora G C A, Soares T A and Meneghetti M R 2018 Molecular dynamics simulations of cetyltrimethylammonium bromide (CTAB) micelles and their interactions with a gold surface in aqueous solution J. Brazil. Chem. Soc. 29 191

Mijin K, Hyung P, Sang H, Jimin P and Wan Y 2013 Shape Transformation of gold nanoparticles from octahedron to cube depending on in situ seed-growth time Bull. Kor. Chem. Soc. 34

Li C-Y, Fan F-R, Yin B-S, Chen L, Ganguly T and Tian Z W 2012 Au+-cetyltrimethylammonium bromide solution: A novel precursor for seed-mediated growth of gold nanoparticles in aqueous solution Nano Res. 6 29

Chhatre A, Thaokar R and Mehra A 2018 Formation of gold nanorods by seeded growth: Mechanisms and modeling Cryst. Growth Des. 18 3269

Thomas N and Mani E 2016 An analytical solution to the kinetics of growth of gold nanorods RSC Adv. 6 30028

Reinaudi L and Gimenez M 2013 Monte Carlo simulation of gold and silver nanoparticles in interaction with strongly surfactant media J. Comput. Theor. Nano. 10 2507

Shrake A and Rupley J A 1973 Environment and exposure to solvent of protein atoms. Lysozyme and insulin J. Mol. Biol. 79 351

Hestenes M R and Stiefel E 1952 Methods of conjugate gradients for solving linear systems J. Res. Nat. Bureau Stand. 49 409

James C P, Rosemary B, Wei W, James G, Tajkhorshid E, Villa E, Chipot C, Skeel R D, Kale L and Schulten K 2005 Scalable molecular dynamics with NAMD J. Res. Nat. Bureau Stand. 26 1781

Gorshkov V, Zavalov O, Atanassov P B and Privman V 2011 Morphology of nanoclusters and nanopillars formed in nonequilibrium surface growth for catalysis applications Langmuir 27 8554

Barmparis G D, Lodziana Z, Lopez N and Remediakis I N 2015 Nanoparticle shapes by using Wulff constructions and first-principles calculations Beilst. J. Nanotechnol. 6 361

Ringe E, Van Duyne Richard P and Marks Laurence D 2013 Kinetic and thermodynamic modified Wulff constructions for twinned nanoparticles J. Phys. Chem. C 117 15859

Acknowledgements

We acknowledge Dr. Semparithi Aravindan and High Performance Computing Centre for technical support of the computing resources used in this study. We also acknowledge intramural financial support from DST India.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Punjani, K., Bhimalapuram, P. Study of shape changes during nanoparticle growth using Kinetic Monte Carlo simulation: a case study on gold nanoparticles. J Chem Sci 133, 101 (2021). https://doi.org/10.1007/s12039-021-01949-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-021-01949-8