Abstract

Solid supported copper (0) nanoparticles were prepared by physical adsorption of copper (0) nanoparticles (synthesized through bottom-up approach) on the solid supports such as silica, HAP, cellulose and basic alumina. Studies comparing these supported catalysts were done with the synthesis of arylmethylene-bis-(3-hydroxy-2-cyclohexene-1-one) via the cascade Knoevenagel/Michael reaction. The highly efficient catalyst was characterized by spectroscopic techniques like XPS, TGA, EDX, SEM, TEM and AAS. The biological importance of arylmethylene-bis-(3-hydroxy-2-cyclohexene-1-one) enforced us to synthesize these compounds catalytically using solid supported copper (0) nanopartcles.

SiO2-Cu(0) nanoparticles have been used as catalyst for the synthesis of 2,2′- arylmethylene-bis-(3-hydroxy-5,5-dimethyl-2-cyclohexene-1-one) via cascade Knoevenagel/ Michael reaction. The heterogeneity of the catalyst has been confirmed by post-characterization techniques like TEM micrographs and recyclability test.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Arylmethylene-bis-(3-hydroxy-2-cyclohexene-1-one) derivatives are important chemicals as they are the key intermediates to acridinones and xanthenes in laser dye technology.[1]Moreover, they have profound applications in biological and therapeutic activities like antioxidants, lipoxygenase inhibitors, antibacterial, antiviral activities,[2] agents as tyrosinase inhibitors in dermatological disorders including hyperpigmentation and skin melanoma.[3] A variety of synthetic methods for the synthesis of these compounds have been found in literature and the catalysts used for this reaction are diverse and include HClO4-SiO2,[4]Et4NBr/NH4Cl,[2]FeCl3⋅6H2O/ TMSCl/[bmim][BF4],[5]I2,[6] silica gel/sulfuric acid,[7]NaHSO4/SiO2,[8]PPA/SiO2,[4]SbCl3/SiO2,[9]FeCl3/ SiO2,[10]TiO2/SO4,[2,11]Dowex-50W,[12] polyaniline-p-toluenesulfonate,[13]p-dodecylbenzenesulfonic acid,[14] Amberlyst-15,[15]Fe 3+ montmorillonite,[16] diammonium hydrogen phosphate,[17] triethylbenzylammonium chloride,[18] tetrabutylammonium hydrogen sulfate,[19] TMSCl[20] and [Hmim] TFA.[21]But, many of the above methods suffer from limitations such as prolonged reaction time, tedious work-up processes, specialized apparatus, low yield, high temperature and hazardous reaction conditions.

In recent years, the use of metal nanoparticles in organic synthesis is gaining much attention but the stability factor of these particles restricts their use in many reactions. Further, if these metal nanoparticles especially when in zero oxidation state get stabilized onto a solid support, then such catalytic systems will be highly important. Copper is used in heterogeneous catalysis because of its low cost, non-toxic nature, selectivity, recyclability and high tolerance to various protocols and functional groups. Keeping in view the above said importance, we wish to explore the suitability of silica-supported copper (0) nanoparticles for the synthesis of arylmethylene-bis-(3-hydroxy-2-cyclohexene-1-one) derivatives through cascade Knoevenagel/ Michael reaction (scheme 1).

2 Experimental

2.1 Materials and instrumentation

Silica gel was purchased from ACROSS Organics and all the other chemicals were purchased from Sigma Aldrich and Merck and were used without further purification. TGA of the catalyst was obtained on a Linesis Thermal Analyser. XPS spectra of the catalyst were recorded on KRATOS ESCA model AXIS 165 (Resolution). SEM-EDX was recorded on JSM-7600F and TEM was recorded on Hitachi (H-7500) 120 kV with CCD camera. The atomic absorption spectrometric analysis (AAS) was done on Avanta-M atomic absorption spectrometer. 1H NMR and 13C NMR of the compounds were obtained on Bruker Avance III (400 MHz) spectrometer. Mass spectra of the products were obtained on a Bruker Daltonics Esquire 3000 spectrometer.

2.2 Preparation of solid supported copper (0) nanoparticles

The copper (0) nanoparticles have been prepared according to the bottom-up approach mentioned in the literature with some modifications.[22] The formed copper nanoparticles were then supported onto different solid supports which enhances its stability and its application as a heterogeneous catalyst.

A certain amount of poly(N-vinylpyrrolidone) (PVP), acting as a capping molecule, was dissolved in water in a flask. Later, at room temperature, copper (II) sulfate (1.5 mL of a 0.01 M solution in water) was added with strong magnetic stirring. This was followed by dropwise addition of 1 M NaOH aqueous solution to adjust the solution pH up to 11. After stirring for 10 min, 4 mL of 0.5 M NaBH4 in water was added into the flask. Firstly, the deep blue solution gradually became colourless, and then it turned burgundy, which shows the formation of copper colloid. Then, the solvent was evaporated using the rotary evaporator and the copper nanoparticles obtained was supported onto different supports such as SiO2, HAP, basic alumina and cellulose by stirring the solution of copper particles in ethanol in the presence of support for 18 h. Further, the solvent was removed under suction until a free flowing powder is obtained. The conditioning of the catalysts i.e. silica-copper(0) [A], HAP-copper(0) [B], basic alumina-copper(0) [C] and cellulose-copper(0) [D], was done in different solvents such as water, toluene and acetonitrile which remove all the physisorbed material adsorbed onto the surface of the catalyst. Due to van der Waals forces, copper (0) nanoparticles adhere to different solid supports thus giving stability to the catalysts.

2.3 Preparation of arylmethylene-bis-(3-hydroxy-2- cyclohexene-1-one) catalyzed by solid supported copper (0) nanoparticles

To the mixture of aldehyde (1 mmol), dimedone (2 mmol) and solid supported copper (0) nanoparticles (0.1 g) in a round bottom flask (100 mL), ethanol (5 mL) was added and the reaction mixture was stirred at room temperature in an oil-bath. After completion of the reaction, mixture was diluted with EtOAc (10 mL) and filtered to separate solid supported copper (0) nanoparticles from reaction mixture (monitored by TLC). The reaction mixture was poured into the separating funnel and water was added into it and finally the organic layer was collected and dried over anhydrous Na2SO4. Finally, the product was obtained after removal of solvent under reduced pressure followed by crystallization from EtOAc: petroleum ether (0.2 mL EtOAc in 10 mL petroleum ether). The catalyst was washed with EtOAc (2 × 5 mL) followed by double distilled water (2 × 10 mL). It was dried for 2 h and then reused for subsequent reactions.

3 Results and Discussion

3.1 Characterization of silica supported copper (0) nanoparticles

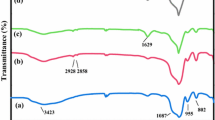

Among the four supported catalysts (A-D), SiO2-Cu(0) catalyst was found to be more active and was characterized through different spectroscopic techniques such as XPS, TGA, SEM-EDX, TEM and AAS. The oxidation state of copper in solid supported copper (0) which is our prime concern was determined thorough XPS graph (figure S1 in Supplementary Information). A peak due to 2p3/2 observed at 932 eV confirmed the presence of copper (0) state in silica supported copper (0) nanoparticles. In addition to this, a shakeup peak at 952 eV arises when the outgoing electron interacts with a valence electron and excites it (shakes it up) to a higher energy level. Another low intensity peak at 934 eV was recorded which may due to the oxidized surface of the catalyst (oxidized surface protects the metal (0) state in the core of the catalyst). But this peak is very insignificant. The stability of the catalyst is determined by thermogravimetric analysis (TGA). The curve (figure S2 in SI) showed an initial weight loss of 7.5% at 158°C which may be due to the residual water trapped onto the silica. Further, there is a slight weight loss of approx. 10% up to 321°C and followed by a major weight loss of about 18% at 465°C which shows that the catalyst is stable up to 200°C and therefore it is safe to carry out the reaction at 80°C which is our desired reaction temperature. The EDX spectrum shows the presence of Si, O and Cu in the silica supported Cu (0) nanoparticles which is in consistent with the expected elemental composition of the catalyst (figure S3 in SI). The morphology and distribution of the catalyst was studied using SEM and TEM images. The SEM image shows that the copper (0) nanoparticles are finely distributed onto the surface and there is no bulk aggregation of the copper (0) particles onto the surface (figure 1). The TEM micrographs gave detailed information about the internal structure of the catalyst like the morphology and particle size. It has been found that the size of copper (0) particles was 5 nm (figure 2). The amount of copper loaded onto the surface of silica was determined by AAS analysis. The catalyst was stirred in dil. HNO3 and then subjected to AAS analysis. It was found that SiO2-Cu(0) contained 0.0129 g of Cu per gram of catalyst.

3.2 Catalyst testing for the synthesis of arylmethylene-bis-(3-hydroxy-2-cyclohexene-1-one)

To select the appropriate reaction conditions, benzaldehyde (entry 1, table 1) was selected as test substrate and the reaction was carried out under different set of conditions with respect to different solvents, different catalysts and temperature. To select the most appropriate heterogenous solid supported copper (0) catalyst, the reaction was carried out using different supported copper (0) catalysts such as silica supported copper (0), HAP supported copper (0), cellulose supported copper (0) and basic alumina supported copper (0) oxide at 80°C using ethanol as solvent. The results are summarized in table 1. It can be seen from the Table that SiO2-Cu(0) gave best results and thus SiO2-Cu(0) was selected as the optimum reaction catalyst at which the reaction proceeded smoothly and furnished the products in good to excellent yields. The use of different solvents (water, ethanol, toluene, acetonitrile, DCM) has been investigated using the test substrates and silica supported copper (0) catalyst under refluxing conditions and it was found that ethanol gave the best results with respect to yield, selectivity and reaction time. To study the catalytic role of silica supported copper (0) catalyst, the reaction has also been carried out using test substrates catalyzed with activated silica, Cu(0) nanoparticles, silica supported copper (0) and in the absence of any catalyst (table 2), it has been inferred from the Table that silica supported copper (0) furnished the products in good yields in less time. To study the generality of the developed protocol for the synthesis of cyclohexen-1-one, various aldehydes having electron releasing and electron withdrawing groups were chosen and it was found that the reaction proceeds efficiently with all the aldehydes and there is a formation of arylmethylene bis(3-hydroxy-2-cyclohexene-1-one) exclusively without the formation of 9-aryl-1,8-dioxo-octahydroxanthene which is confirmed by 1H NMR, 13C NMR and mass spectrometry.

3.3 Post-characterization of SiO2-Cu(0) nanoparticles

Silica supported copper (0) nanoparticles which were obtained after the reaction work-up has been dried and subjected to post-characterization to examine any change in its morphology and its activity. For this, TEM micrographs were taken and it has been shown that there is no significant change in the surface morphology of the catalyst (figure 3). Further, to test the heterogeneity of the catalyst, recyclability tests of the catalyst were carried out. For this, a series of five consecutive runs was done with 4-chlorobenzaldehyde and dimedone using SiO2-Cu(0) nanoparticles as catalyst (entry 14, table 1). There is no significant loss in activity observed for SiO2-Cu(0) nanoparticles and the product is also obtained in good yields (figure 4).

4 Conclusions

In conclusion, we have developed a mild, simple and efficient methodology for the synthesis of 2,2\(^{\prime }\)-arylmethylene-bis-(3-hydroxy-5,5’-dimethyl-2-cyclohexen-1-one) using recyclable SiO2-Cu(0) nanoparticles. The developed protocol furnished the products in good to excellent yields and was fully characterized by 1H NMR, 13C NMR and mass spectrometry. The catalyst was post-characterized by transmission electron microscopy and recyclability technique and it has been observed that the catalyst is recyclable and reusable making the process completely heterogeneous.

References

Jung D H, Lee Y R, Kim S H and Lyoo W S 2009 Bull. Korean Chem. Soc. 30 1989

Maharvi G M, Ali S, Riaz N, Afza N, Malik A, Ashraf M, Iqbal L, Lateef M and Enzyme J 2008 Inhib. Med. Chem. 23 62

Khan K M, Maharvi G M, Khan M T H, Shaikh A J, Perveen S, Mild S B and Choudhary M I 2006 Bioorg. Med. Chem. 14 344

Kantevari S, Bantu R and Nagarapu L 2007 J. Mol. Catal. A: Chem. 269 53

Fan X S, Li Y Z, Zhang X Y, Hu X Y and Wang J 2005 J. Chin. Chem. Lett. 16 897

Kidwai M, Bansal V, Mothsra P, Saxena S, Somvanshi R K, Dey S and Singh T P 2007 J. Mol. Catal. A: Chem. 268 76

Seyyedhamzeh M, Mirzaei P and Bazgir A 2008 Dyes Pigm. 76 836

Das B, Thirupathi P, Reddy K R, Ravikanth B and Nagarapu L 2007 Catal. Commun. 8 535

Zhang Z H and Liu Y H 2008 Catal. Commun. 9 1715

Shaterian H R, Hosseinian A and Ghashang M 2008 Phosphorus, Sulfur Silicon Relat. Elem. 183 3136

Jin T S, Zhang J S, Wang A Q and Li T S 2005 Synth. Commun. 35 2339

Shakibaei G I, Mirzaei P and Bazgir A 2007 Appl. Catal. A: Gen. 325 188

John A, Yadav P J P and Palaniappan S 2006 J. Mol. Catal. A: Chem. 248 121

Jin T S, Zhang J S, Wang A Q and Li T S 2006 Ultrason. Sonochem. 13 220

Das B, Thirupathi P, Mahender I, Reddy V S and Rao T K 2006 J. Mol. Catal. A: Chem. 247 233

Song G, Wang B, Luo H and Yang L 2007 Catal. Commun. 8 673

Darviche F, Balalaie S, Chadegani F and Salehi P 2007 Synth. Commun. 37 1059

Shi D Q, Zhuang Q Y, Chen J, Wang X S, Tu S J and Hu H W 2003 Chin. J. Org. Chem. 23 694

Ma J J, Zhou X, Zhang X H, Wang C, Wang Z, Li J C and Li Q 2007 Aust. J. Chem. 60 146

Kantevari S, Bantu R and Nagarapu L 2006 ARKIVOC xvi 136

Dabiri M, Baghbanzadeh M and Arzroomchilar E 2008 Catal. Commun. 9 939

Zhang H X, Siegert U, Liu R and Cai W B 2009 Nanoscale Res. Lett. 4 705

Kumari S, Shekhar A and Pathak D 2014 Chem. Sci. Trans. 3 652

Khurana J M and Vij K 2012 J. Chem. Sci. 124 907

Sheldrick G M 2008 Acta Cryst. A64 112

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information (SI)

Supplementary Information related to characterization of SiO2-Cu(0), spectral details of some compounds and 1H NMR of selected compounds are available at www.ias.ac.in/chemsci.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

GUPTA, M., GUPTA, M. Copper (0) nanoparticles onto silica: A stable and facile catalyst for one-pot synthesis of 2,2′-arylmethylene bis (3-hydroxy-5,5-dimethyl-2-cyclohexene-1-one) via cascade Knoevenagel/Michael reaction. J Chem Sci 128, 849–854 (2016). https://doi.org/10.1007/s12039-016-1080-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-016-1080-6