Abstract

A selective synthesis of gem-diacetates from the reaction of aldehydes and acetic anhydride in the presence of recyclable nanoporous solid sulfonic acid (CMK-5-SO3H) under solvent-free reaction conditions is reported. The catalyst was also found to be highly active for deprotection of resulting acylals in water.

Recyclable nanoporous solid sulfonic acid (CMK-5-SO3H)-catalyzed synthesis of gem-diacetates from the reaction of aldehydes and acetic anhydride under solvent-free reaction conditions are reported. The catalyst was also found to be highly active for deprotection of resulting acylals in water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

From the green chemistry point of view, safety considerations and the simplicity of the process, implementation of methods that avoid the use of harmful organic solvents are fundamental strategies. In this context, with an objective to develop environmentally benign reaction media and conditions for organic reactions with excellent efficiency, solvent-free conditions or using water as the green solvent have aroused considerable attention.[1–5] Consequently, it is important to investigate new catalysts for organic reactions using less hazardous solvents.

Acylals have often been used as protecting groups for carbonyl compounds because of their stability in neutral and basic conditions and ease of chemoselective preparation in the presence of ketone.[6,7] Hence, they play an important role for the protection of aldehydes in multi-step organic synthesis. Accordingly, methods for their synthesis have received considerable attention.

Generally, acylals can be prepared from aldehydes by treatment with acetic anhydride and Brønsted acids,[7–9] Lewis acids,[10–14] or inorganic heterogeneous catalysts.[15,16,16–21] However, while acknowledging the pioneering advances in this area, some of these methods suffer from disadvantages such as the use of hazardous organic solvents, harsh reaction conditions, low yields, tedious work-up and effluent pollution. Moreover, some of these procedures are not chemoselective in terms of aldehydes and keto carbonyl functional groups. Additionally, a few of the above mentioned catalysts are claimed to give protection as well as deprotection. Therefore, the development of efficient, recyclable and environmentally benign catalytic methods for these transformations by using nonpolluting reagents and solvents is desirable. Along this line, very recently, we used sulfonic acid nanoreactor SBA-15-Ph-PrSO3H in the synthesis of gem-diacetates under solvent-free reaction conditions. In continuation of our studies toward the development of new and cleaner methods for organic transformations,[22–25] we report herein the results of chemoselective preparation of acylals under solvent-free reaction conditions and deperotection of the corresponding acylals in water as green solvent at room temperature using catalytic amounts of heterogeneous recyclable sulfonic acid CMK-5-SO3H (scheme 1).

2 Experimental

2.1 General procedure for the preparation of 1,1-diacetates

To a mixture of aldehyde (1 mmol) and freshly distilled acetic anhydride (1.2 mmol) was added (0.023g, 1 mol%) CMK-5-SO3H, and the whole mixture was stirred in a round bottomed flask at room temperature for the appropriate time (table 1). The reaction progress was followed by GC and TLC (eluent, n-hexane:ethyl acetate, 4:1). After completion of the reaction, EtOAc was added to the reaction mixture, and the resulting mixture was filtered and then the extracts concentrated under vacuum. The pure product was isolated following silica gel column chromatography to afford pure acylals. Spectroscopic data for selected examples listed below.

(Entry 1): 1H NMR (400 MHz; CDCl3): d H= 2.15 (s, 6H), 7.41–7.55 (m, 5H), 7.70 (s, 1H); 13C NMR (100 MHz, CDCl3): d C= 20.9, 89.7, 126.7, 128.6, 129.8, 135.5, 168.8.

(Entry 3): 1H NMR (400 MHz; CDCl3): d H= 2.14 (s, 6H), 7.33–7.52 (m, 4H), 7.64 (s, 1H); 13C NMR (100 MHz, CDCl3): d C= 20.8, 88.8, 125.0, 126.8, 129.91, 129.97, 134.5, 137.2, 168.7.

(Entry 14): 1H NMR (400 MHz; CDCl3): d H= 2.17 (s, 6H), 7.70 (s, 1H), 7.73 (d, 2H), 8.28 (d, 2H); 13C NMR (100 MHz, CDCl3): d C= 20.8, 88.3, 123.9, 127.9, 141.8, 148.6, 168.6.

(Entry 20): 1H NMR (400 MHz; CDCl3): d H= 2.12 (s, 6H), d H= 2.36 (s, 3H), 7.13–7.15 (d, J = 8.4 Hz, 1H), 7.31–7.34 (t, J = 7.6 Hz, 1H), 7.43–7.47 (t, J = 7.6 Hz, 1H), 7.65-7.67 (d, J = 7.8 Hz, 1H), 7.92 (s, 1H).

2.2 General procedure for deprotection of 1,1-diacetates

To a stirred mixture of aldehyde (1 mmol) and acetic anhydride (1.2 mmol), CMK-5-SO3H (0.023g, 1 mol%) was added, and the mixture was stirred at room temperature for the appropriate time (table 1). The reaction progress was followed by GC. After completion of the protection reaction, water (3 mL) was added to the reaction mixture to perform the deprotection reaction. After completion of the cleavage reaction, Et2O (20 mL) was added and the reaction mixture was filtered to separate the catalyst. The solvent was evaporated under reduced pressure to afford the corresponding aldehydes.

2.3 Preparation of CMK-5

Templated synthesis of CMK-5 has been achieved using known procedure described by Ryoo and co-workers.[26,27] Initially, Al was incorporated into SBA-15[28] (molar ratio Si/Al = 20) by well dispersion of calcined SBA-15 into an aqueous solution of AlCl3, followed by removal of H2O by rotary evaporator and calcination in air. Impregnation of Furfuryl alcohol (FA) into Al-SBA-15 was achieved by incipient wetness infiltration at room temperature. The mixture was then heated up at 80 °C oven for 16 h for Al-catalyzed polymerization of FA. The obtained composite was recovered by filtration to remove excess and unpolymerized FA, and washed by EtOH and acetone. The composite was heated to 850 °C under vacuum at a ramp of 10 °C/min, and the carbonization was carried out at the same temperature for 3 h under vacuum. Ordered mesoporous carbon (CMK-5) was obtained by removal of silica template by HF (10% in 1: 1 EtOH – H2O), washed with copious water and EtOH, and finally dried at 100 °C.

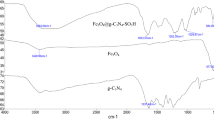

2.4 Preparation of sulfonated ordered mesoporous carbon (CMK-5-SO3 H)

In a typical modification, 1.2 g of CMK-5 was added in a three-necked round bottom flask containing 12.0 g of 4-benzene-diazoniumsulfonate[29] in 200 mL of distilled water and 200 mL of ethanol. Subsequently, the mixture was cooled down to 5 °C and 200 mL of 50 wt% H3 PO 2 aqueous solution was added. After stirring for 30 min, another 200 mL of H3 PO 2 aqueous solution was added. The mixture was stirred at 5 °C for another 30 min. The sulfonic acid functionalized carbon material (denoted as CMK-5-SO3H) was recovered by filtration, washed thoroughly with distilled water and finally acetone, and dried in an oven at 80 °C.

3 Results and Discussion

For our initial protection studies, we carried out the reaction between 1 mmol benzaldehyde, 1 mmol Ac2O and 1 mol% catalyst at room temperature under solvent free reaction conditions to afford the desired acylal. It was observed that the starting material was consumed after long reaction time (90 min) as indicated by GC analysis. To optimize the reaction conditions, the reaction was performed using 1.2 mmol acetic anhydride in the presence of 2 mol% catalyst (scheme 1), and considerable improvement was observed in the yield of product after 10 minute (table 1, entry 1). It is also important to mention that when the same reaction was performed without catalyst and no product was obtained.

To generalize the scope and versatility of this protocol, different substituted aldehydes were used for the synthesis of substituted acylals. Aldehydes bearing both electron-donating and electron-withdrawing substituents resulted in the corresponding acylals in good to excellent yields (table 1, entries 1–15). The catalyst was also found to be active for the preparation of acylal from sterically hindered aldehyde, 1-naphtaldehyde (table 1, entry 16). Notably, furan-2-carbaldehyde and thiophene-2-carbaldehyde as acid sensitive substrates gave the related 1,1-diacetates in excellent yields (table 1, entries 17–18). Also the present protocol works well for aliphatic aldehydes to give the corresponding geminal diacetates in excellent yields (table 1, entries 19–20). When the reaction was extended towards hydroxybenzaldehydes, the hydroxyl group was also protected as acetate (table 1, entry 21).

Under the selected conditions, acylation of ketones was not successful and the starting material was recovered unchanged even when the reaction mixture was stirred for 24 h (table 1, entry 22). Encouraged by this result, in a competitive experiment, equimolecular mixture of benzaldehyde and acetophenone was allowed to react with 1.2 mmol of acetic anhydride under the same reaction condition, gave only 1,1-diacetates of benzaldehyde while the ketone functionality remained unaffected (scheme 2). Hence, chemoselective acylal formation from aldehydes in the presence of ketones could be achieved with this catalytic system.

The feasibility of recyclable properties of the catalyst was examined through a series of sequential synthesis of acylal from benzaldehyde and Ac2O as model substrates. The catalyst was easily separated by filtration after completion of each run, with addition of ethyl acetate. Interestingly, the recycled catalyst was used for eight consecutive runs without any appreciable change in catalytic activity.

In order to show the efficiency of the present method, we have compared our results obtained from the acetylation of 4-nitrobenzaldehyde with acetic anhydride catalyzed by CMK-5-SO3H with other results reported in the literature. As can be seen in table 2, this method avoids some disadvantages of other procedure such as long reaction times[12,31,32] toxic solvents,[32] excess reagents,[31,32] and non-recoverable catalyst.[11,12,29–33]

In addition to these results, to evaluate the cleavage of resulting acylals, we also investigated the deprotection procedure by addition of water as a green solvent to the reaction mixture. Indeed, when the formation of 1,1-diacetates were completed, water was added. All reactions were performed at room temperature in good to high yields (scheme 1, table 1).

4 Conclusion

To summarize, we have reported an efficient, green, and chemoselective method for the preparation of gem-diacetates from aldehydes under solvent-free reaction conditions at room temperature using heterogeneous CMK-5-SO3H. Deprotection of the resulting 1,1-diacetates can also be achieved by addition of water, a green solvent. The elimination of toxic solvents, simple workup procedure, excellent catalytic capacity and outstanding recyclability of catalyst make a valid contribution to the existing methodologies.

References

Martins M A P, Frizzo C P, Moreira D N, Buriol L and Machado P 2009 Chem. Rev. 109 4140

Walsh P J, Li H and De Parrodi C A 2007 Chem. Rev. 107 2503

Toda F and Tanaka K 2000 Chem. Rev. 100 1025

Li C J and Chan T H 1999 Tetrahedron 55 11149

Li C J 2005 Chem. Rev. 105 3095

Greene T W and Wuts P G M 1999 In Protective Groups in Organic Synthesis 3rd ed. (New York: John Wiley and Sons) p. 306

Gregory M J 1970 J. Chem. Soc. B. 1201

Jin T S, Sun G, Li Y W and Li T S 2002 Green Chem. 4 255

Heravi M M, Bakhtiari K and Bamoharram F F 2006 Catal. Commun. 7 499

Aggen D H, Arnold J N, Hayes P D, Smoter N J and Mohan R S 2004 Tetrahedron 60 3675

Ghosh R, Maiti S, Chakraborty A and Halder R 2004 J. Mol. Catal. A: Chem. 215 49

Roy S C and Banerjee B 2002 Synlett. 1677

Zhang X, Li L and Zhang G 2003 Green Chem. 5 464

Smitha G and Reddy Ch S 2003 Tetrahedron 59 9571

Olah G A and Mehrotra A K 1982 Synthesis 962

Curini M, Epifano F, Marcotullio M K, Rosati O and Nocchetti M 2002 Tetrahedron Lett. 43 2709

Kamble V T, Jamode V S, Joshi N S, Biradara A V and Deshmukh R Y 2006 Tetrahedron Lett. 47 5573

Wu H, Shen Y, Fan L Y, Wan Y and Shi D Q 2006 Tetrahedron 62 7995

Jermy B R and Pandurangan A 2008 Catal. Commun. 9 577

Javad Kalbasi R, Massah A R and Shafiei A 2011 J. Mol. Catal. A: Chem. 335 51

Shirini F, Mamaghani M and Seddighi M 2013 Catal. Commun. 36 31

Karimi B and Zareyee D 2008 Org. Lett. 10 3989

Karimi B and Zareyee D 2009 J. Mater. Chem. 19 8665

Zareyee D, Asghari R and Khalilzadeh M A 2011 Chin. J. Catal. 32 1864

Zareyee D, Moosavi S M and Alaminezhad A 2013 J. Mol. Catal. A: Chem. 378 227

Joo S H, Choi J, Oh I, Kwak J, Liu Z, Terasaki O and Ryoo R 2001 Nature 412 169

Kurk M, Jaroniec M, Kim T W and Ryoo R 2003 Chem. Mater. 15 2815

Yu C, Fan J, Tian B, Zhao D and Stucky G D 2002 Adv. Mater. 14 1742

Bouchet M J, Rendon A, Wermuth C G, Goeldner M and Hirth C 1987 J. Med. Chem. 30 2222

Heravi M M, Bakhtiari K, Taheri S and Oskooie H A 2005 Green Chem. 7 867

Karimi B and Maleki J 2003 J. Org. Chem. 68 4951

Chandra K L, Saravanan P and Singh V K 2000 Synlett 359

Firouzabadi H, Iranpoor N, Nowrouzi F and Amani K 2003 Tetrahedron Lett. 44 3951

Acknowledgements

The authors acknowledge the Islamic Azad University of Qaemshahr Research Councils for support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information

Schematic preparation of CMK-5-SO3H (figure S1), TGA (figure S2), BJH (figure S3), N2 ads-des (figure S4), and XRD diagrams for CMK-5 (figure S5) and CMK-5-SO3H (figure S6), TEM image for recovered catalyst (figure S7) and copy of 1H and 13C spectra for some products are available at www.ias.ac.in/chemsci.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

ZAREYEE, D., MIRZAJANZADEH, E. & KHALILZADEH, M.A. Green procedures for the chemoselective synthesis of acylals and their cleavage promoted by recoverable sulfonic acid based nanoporous carbon (CMK-5-SO3H). J Chem Sci 127, 1229–1234 (2015). https://doi.org/10.1007/s12039-015-0884-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-015-0884-0