Abstract

The primary objective of the investigation was to synthesize biocomposite nanofibres by electrospinning technique with different weight percentages of polycaprolactone (PCL) with chitosan (CS)–pectin (PEC) blend along with the characterization and antimicrobial activity of the novel electrospun nanofibres. This article for the first time describes the architecture of PCL–CS–PEC electrospun nanofibres along with its antimicrobial activity to the foremost of our information. The present work used CS–PEC, a biocompatible and non-toxic polysaccharide. Electrospinning was used to successfully produce CS–PEC nanofibres coupled with PCL polymer. The structural morphology of the PCL–CS–PEC nanofibres clearly displays the presence of nanofibres. The distinct peaks for the corresponding primary functional groups were clearly identified in the Fourier transform infrared characterization of PCL–CS–PEC nanofibres, as well. TGA confirmed that PCL–CS–PEC nanofibres have greater thermal stability. The antibacterial activity (agar disc diffusion method) of PCL–CS–PEC nanofibres was tested, and it was found to be effective against a wide range of microbial organisms, which aids in wound healing. Nanofibres of 19% PCL–CS–PEC demonstrated better antimicrobial activity against control than 15% and 17%, which might be attributable to concentration. Future studies will be conducted for the validation of the analysed nanofibres using in vivo investigations for the purpose of the wound dressing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nanofibre membranes have gained popularity in recent decades owing to their exclusive features, like huge precise surface areas, great permeability, connected pores and extraordinary functionality. Electrospun composite nanofibres finds its application in tissue engineering [1,2,3], wound therapeutic [4,5,6] and delivery of medicine [7,8,9], apart from other uses magnetism [10], photonics [11], filtration [12], composites [13], shape memory [14], and lithium batteries [15]. It is well known that electrospun nanofibre’s diameter has an impact on the biological individualities of non-woven textiles [16,17]. Fibre diameter is critical and important for cell characteristics (adhesion, proliferation and migration) on the scaffold, according to various research [18].

Polycaprolactone (PCL) nanofibres, commonly applied as aliphatic polyester electrospun nanofibres find their application in wider areas (tissue engineering, delivery of drugs and biosensor) due to their remarkable characteristics (mechanical and biodegradability) [19,20,21]. Biomedical applications of PCL have gained significance due to their relaxed disintegration proportion, harmless biodegradation elements and remarkable physicochemical capabilities for chemical modifications [22]. Electrospun PCL nanofibres are preferred for biomedical applications because of their intrinsic hydrophobicity (surface coating, plasma treatment, poly (dopamine) treatment, copolymer blending, alkali treatment and polymer grafting), resulting in the amplified product in biocompatibility and hydrophilicity [23]. Studies on PCL nanofibres have demonstrated changes in physical properties such as surface roughness to increase protein adsorption, cell adhesion and cell spreading, apart from the detection of single-stranded DNA (polypyrrole-coated) but at the same time, it has limited biological activity [24,25,26].

A rapidly expanding global population and parallel resource depletion have motivated further research into the usage of sustainable materials such as pectin (PEC) [27,28,29], lignin [30,31,32], cellulose [33] and chitosan (CS) in the postindustrial period [34]. CS is a naturally occurring cationic polysaccharide that is composed of glucosamine and n-acetylglucosamine residues [35,36]. It is an extensively known material for wound healing initiation process as they have precise biological activity (hemostatic, granulation, epithelization and biodegradability) [37,38], which can be processed into desired materials such as membranes, sponges, meshes and scaffolds. Studies have proved already that CS is biodegradable into non-toxic oligomers by a series of enzymes such as lysozymes, chitinase, and chitosanase and that are capable to trigger the process of wound healing [39,40]. Another benefit of CS is that it resembles numerous glycosaminoglycans, which are distributed throughout the human body and are crucial for maintaining the morphology and differentiation of cells [41,42]. Other studies have also suggested that CS offers an ideal microenvironment for cell differentiation and wound healing through its extracellular matrix properties [31,32,43,44,45]. CS also exhibited antimicrobial properties against a different diversity of bacteria, fungi and algae, inhibiting infection of wounds [46,47].

The most prevalent renewable polymer, PEC, is made by the units of galacturonic acid linked together by α-(1→4) linkages [48]. Industrial PEC is manufactured from the food industries surplus product, including as apple pomace, citrus peel, etc., which are acid extracted. In food industries, it is commonly used as an emulsifier, glazing agent, etc. Research has attributed that PEC has been employed as a biomaterial in healthcare and biomedical applications due to its non-toxic, biodegradable and biocompatible qualities [48]. PEC’s typical insolubility in organic solvents prevents it from being used in the synthesis of polymers but chemical modification like methylation, acetylation, amidation, quaternization, etc. is required to offset this disadvantage [49,50]. These modified PECs have better-quality features (solubility, gelling, etc.) like anticoagulation and bioadhesion. Numerous studies have also identified that the derived PECs showed properties of emulsion stabilizing, antimicrobial and antioxidant [51].

PCL nanofibres possess major limitations in a biological activity that is mainly concentrated on hydrophobicity, and microbial degradation properties, and therefore cannot provide a suitable cell adhesion environment [24,25,26]. PCL is recognized for its mechanical properties, but it lacks ionizable side groups (–COOH and –NH2) that are found in the CS and a variety of polysaccharides and proteins (anionic). The chitin-derived CS (amino polysaccharide) is identical to PEC and is also identified to possess similar biological properties like biodegradability, hydrophilicity, non-toxicity, biocompatibility along with the antimicrobial and antithrombotic activity. Natural polysaccharide PEC with an anionic nature was employed to cross-link the cationic polymers. Furthermore, investigations have demonstrated that CS cross-linked with PEC has enhanced hydrophilicity, biocompatibility and mechanical strength at pH levels ranging from 3 to 6 [52,53,54,55], making it suitable for the delivery of drugs and engineering of tissue.

Croisier et al [56] and Safari et al [57] successfully demonstrated positive antibacterial activity with core–shell nanofibres made of a PCL core coated with CS and CS/polyvinyl alcohol-PEC/polyvinyl alcohol nanofibrous film, respectively. Hence the primary objective of the investigation was to synthesize biocomposite nanofibres by electrospinning technique with different weight percentages of PCL with CS–PEC blend. Further, the study assessed the morphology, mechanical and biocompatibility properties of the novel electrospun nanofibres using scanning electron microscope (SEM), Fourier transform infrared spectroscopy analysis (FT-IR), thermogravimetric analysis (TGA), and tensile strength testing, and antimicrobial activity. This is the first article that described the architecture of PCL-CS-PEC nanofibres along with their antimicrobial activity to our understanding.

2 Experimental

Pellet form of PCL (molecular weight: 80,000 g mol–1), chitosan (molecular weight: 50,000–1,90,000 dalton (Da)—deacetylated chitin) and pectin (citrus peel) were procured from Sigma Aldrich, USA. Formic acid with a density of 1.22 g ml–1 and acetic acid with a density of 1.050 g ml–1 were purchased from Fisher Scientific, Mumbai. The microorganisms such as Bacillus subtilis (MTCC No. 2390), Escherichia coli (MTCC No.294), Staphylococcus aureus (MTCC No. 9760) and Pseudomonas aeruginosa (MTCC No. 4682) were obtained from MTCC, Chandigarh, for antimicrobial assay. Mueller Hinton Agar (MHA) was purchased from Hi-Media Laboratories, Chennai, and the remaining chemicals were of analytical grade.

2.1 Sample preparation

2.1a PCL:

To make 15% of PCL, 1.943 g PCL was mixed with 3 ml of formic acid and 7 ml of acetic acid. Similarly, 17 and 19% PCL were engendered by mixing the solvents in quantities of 3 and 7 ml in 2.255 and 2.583 g of PCL, respectively. A magnetic stirrer was used to agitate the solutions for 3 h at room temperature until a homogenous solution was achieved.

2.1b CS–PEC:

CS (0.2 g) and 0.2 g of PEC were mixed with formic acid and acetic acid (ratio of 3:7) and suspended followed by continuous swirling for 1 h at room temperature in a magnetic stirrer to fetch the uniform mixture.

2.1c PCL–CS–PEC blends:

Sample 15% PCS–CS–PEC was prepared by adding drop by drop of 7 ml of 15% PCL to 3 ml of CS–PEC solution and constantly swirled for 1 h at room temperature in a magnetic stirrer to make a homogenized solution of honey-like consistency. For all other varied weight percentages, the samples were prepared using the above-stated procedure.

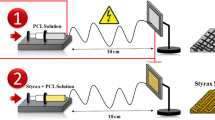

2.2 Electrospinning

A syringe of plastic tube (5 ml) with a needle of 0.5 mm internal diameter was filled with the desired percentage of PCL–CS–PEC solution. A power source of high-voltage was attached to the needle. A 17 kV was employed to electrospun the solution with a flow rate of 1 ml h–1 using an electrospinning machine, following which fibres were retrieved at a distance of 10 cm by spinning of the drum through 450 rpm. Electrospun of the same settings were kept for other percentages of PCL–CS–PEC mixes. All of the tests were carried out at 25°C with a relative humidity of 30–50 weight percent.

2.3 FT-IR, SEM and TGA analysis

By convention, FT-IR is used to obtain the absorption and emission of infrared spectra. Moreover, it gathers spectral resolution of high intensity through a broad spectral range and hence, proved to be better than a dispersive spectrometer. 5 mg of sample was collected and evaluated using a spectrophotometer at the University of Madras, India. The morphological characterization of electrospun PCL nanofibres, which include the scanning coils needed to raster the beam onto the material, was studied using a Quanta 200 FEG SEM. From the synthesized nanofibres, a tiny portion of 10 mm diameter was cut and put on an aluminium foil sheet, which was then pierced on the stub. To produce a vacuum, a suction pump is employed, and the sample is then exposed to SEM examination. A thermal gravimetric analyzer was used to measure phase transitions, absorption, adsorption and desorption (physical phenomena) as well as chemisorption, thermal decomposition and solid–gas reactions (chemical phenomena) in the series of 30–1000ºC with a flow rate of 20 ml min–1 through nitrogen atmosphere. Weight (%) vs. temperature (ºC) was displayed on the graph.

2.4 Tensile strength testing

The electrospun of PCL–CS–PEC’s Young’s modulus was measured using universal testing equipment at 23°C and 50% relative humidity. To evaluate the ultimate testing strength, breaking strength, maximum elongation and decrease in area, an increasing load was given to the nanofibres up to the point of failure, i.e., until the fibres reached their breaking point.

2.5 Antibacterial assay

Through a nutrient agar slant, microbial stock cultures were preserved at 4°C. For experiments, active cultures were prepared by transferring a loop full of culture from the stock cultures into the nutrient broth test tubes that were incubated for 24 h and maintained at 37ºC. The agar disc diffusion method was used as per the standard procedure with ampicillin as standard.

Nanofibre antibacterial properties were performed using a disc diffusion technique through a medium of MHA. A Petri dish is filled with MHA medium. A sterile swab with a suspension of bacteria was dispersed onto the hardened medium. The antibacterial (Ampicillin) discs were placed in the centre of MHA plates in controls whereas, in other plates, the desired percentage of PCL–CS–PEC to be analysed was kept. At 37°C for 24 h, plates were incubated. The zone of inhibition diameter was then noted to evaluate the antibacterial activity in cm.

2.6 Statistical analysis

The investigated parameters were assessed using SPSS version 23. A Student’s t-test was used to assess the significance of the compared parameters. A p-value of 0.05 was regarded as significant.

3 Results

Under the influence of a high electric field, a solution of polymer was ejected through a syringe during electrospinning (involving voltages of up to several tens of kV). This is an accelerated and extended surface-charged jet. The solvent evaporated in the first few centimetres of the jet’s flight through the air, making room for a nanometric fibre polymer to settle on the metallic support. The solvent choice was critical in this procedure and had a significant impact on the dried fibre shape.

3.1 Electrospinning pure PCL nanofibre

PCL is not able to be processed directly by electrospinning, hence a solvent system (formic and glacial acetic acid) was added in different percentages of PCL to synthesize nanofibres at particular PCL/solvent ratios. And nanofibre formation was observed as represented in table 1.

When formic and glacial acetic acid is in 3:7 proportion, 15% PCL nanofibre formation was established than in other ratios of the solvent. Similarly, 17% of PCL nanofibres formed when formic and glacial acetic acids are supplemented in 3:7 and 5:5 ratios individually. The maximum frequency of nanofibres is synthesized in 19% PCL when formic acid and glacial acetic acid are mixed in different ratios of 3:7, 5.5 and 7:3 separately, except for 1:9 and 9:1 ratios of solvent. In other ratios of formic and glacial acetic acids with PCL percentages, nanofibres were not formed. Hence, PCL of 15%, 17% and 19% was selected for forming a blend with CS and PEC combined together. Hence, the desired percentage of 15%, 17% and 19% PCL nanofibres in the ratio of 3:7 of formic and glacial acetic acids was taken.

Chitosan readily dissolves by binding to hydrogen ions with weak organic acids (formic and glacial acetic acids) and hence, chitosan-bound hydrogen ions undergo greater tension under electric force during electrospinning [58]. Moreover, as the concentration of chitosan increases in the formic and glacial acetic acids, conductivity linear behaviour can be observed. The conductivity of samples may be adjusted by combining natural and synthetic polymers. The process of electrospinning and, the subsequent nanofibre was also impacted by the viscosity of polymer solutions. Nanofibre cannot form with low viscous polymer solution. Conversely, if the thickness is too high, propelling the polymer solution through the needle remains challenging. As a result, the concentration of PCL in the current study was chosen as 15, 17 and 19 wt%, and the ratio of PCL to CS–PEC was in the ratio of 7:3, as indicated in table 2, with the value of conductance and viscosity, since the success of nanofibre manufacturing using the process of electrospinning is determined by polymer solution conductivity.

The study result demonstrated that nanofibre may be successfully spun through 70cp viscous polymer solution or higher polymer solution may improve when the amount of PCL–CS–PEC is increased, but still, the conductivity of the polymer solution would diminish. This could be explained by the fact that reducing the amount of PCL–CS–PEC in the mixture tends to decrease the amount of ions present. Additionally, the PCL–CS–longer PEC’s polymer chain limits molecular mobility and prone to increase the mixture’s viscosity. Hence, the preliminary result indicated that the concentration of PCL with 15, 17, and 19 weight %, and the ratio of PCL to CS–PEC selected in 7:3 ratios individually were determined to be optimal and ideal for nanofibre formation for assessing the morphological characterization using the process of electrospinning.

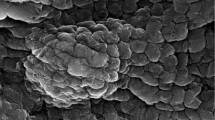

3.2 Morphological description

Figure 1 showed the nanofibre sample morphology of various PCL–CS–PEC concentrations in SEM. It demonstrated that when the concentration of PCL–CS–PEC increases, the diameter of the nanofibre increases. In comparison to nanofibres with lower PCL–CS–PEC concentrations, it also produces more voids, increasing porosity. In comparison to lower PCL–CS–PEC concentration nanofibre samples, the higher PCL–CS–PEC concentration nanofibre diameter distribution of samples is likewise further homogeneous. Samples with varying PCL–CS–PEC concentrations, on the other hand, revealed that beads formed as well observed with 15% and 17% and not with 19%, and the beads might be related to the concentration of CS and PEC of PCL–CS–PEC in all samples, as perceived in figure 1. It illustrated that adding PCL to a CS and PEC solution changes the structure of the generated nanofibre. Because the addition of PCL lowers the CS and PEC concentration in the mixture, the high surface tension is reduced [59]. As a result, the formed nanofibres can be more uniform.

Figure 2 demonstrates the sample’s average diameter that was estimated using Image software from a higher magnification SEM image [60]. Table 3 shows the ranges of novel PCL–CS–PEC nanofibres with different percentages of PCL. It indicated that once the proportion of PCL in the mixture improved, nanofibre diameter also increased. PCL addition to CS–PEC polymer might have increased the mixture viscosity, causing large diameter nanofibres to form [61].

3.3 FT-IR data

Spectrum of FT-IR samples with different percentages of PCL–CS–PEC blend are shown in figure 3. It is observed at 399 to 6000nm wavelength, all the samples of different percentages of PCL–CS–PEC showed similar peaks at a different wavelength. The presence of the C=O functional group in PCL is denoted by the observed peak at 1700 nm in all the three percentages of PCL–CS–PEC [59]. The peak at 2900 to 2800 nm indicated the presence of functional group (N‒H and O‒H) of CS due to hydrogen bond, whereas the peak at 1120 to 990 nm indicated the presence of galacturonic acid in pectin molecules [59]. Hence, the presence of PCL–CS–PEC blend composition is confirmed through FT-IR analysis. The maximum peak absorbance of 2.35 to 4.1 at 1399 and 1899 nm was an indicative of PCL–CS–PEC presence in the nanofibre.

3.4 Thermogravimetric analysis

PCL–CS–PEC blend under nitrogen atmosphere can be observed in figure 4. The degradation of PCL–CS–PEC initiated at 235.03°C with an initial weight of 99.02%, reaching a maximum degradation at 696.9°C with 1.3% weight and leaving a residue at 800°C (0.9%) in 15% PCL–CS–PEC blend. Similarly, 17 and 19% also showed an initial melting temperature and maximum degradation temperature at 280°C (99.24%), 186°C (99.71%) and 536.2°C (1.9%), 539.2°C (2.6%).

3.5 Tensile strength testing

The tensile properties of scaffolds must be determined since they must be robust, stress-resistant, flexible, and pliable in order to withstand the stresses imposed by various regions of the body and their diverse forms [62]. The nanofibrous scaffold’s Young’s modulus and strain at break of PCL–CS–PEC were measured, and the results are displayed in figure 5.

Sample 19% PCL–CS–PEC showed higher Young’s modulus and elongation at break (%) of 4.71 megapascal (MPa) and 54.7% than 15% and 17% PCL–CS–PEC with nil level of statistical significance (p > 0.05) between them. Studies had already established that the addition of pectin in nanofibres is always associated with stronger and increased elastic stiffness in a similar study [63]. In our study, a higher percentage of PEC may be responsible for stronger and higher elastic stiffness properties. Table 4 represents the thickness of different percentages of PCL–CS–PEC blend nanofibres and shows that the least thickness was observed with 19% of PCL–CS–PEC blends followed by 17% and then 15% with no statistical significance between them (p > 0.05).

3.6 Antibacterial activity of nanofibres

Antibacterial activity was found to be good with all pathogenic bacteria in different percentages of PCL–CS–PEC. It was determined that the antibacterial activity was based on concentration. In positive controls, no zone of inhibition activity was observed. In 19% PCL–CS–PEC, the maximum zone of inhibition with a 2.1 cm diameter clear zone was observed in E. coli, 1.9 cm against Pseudomonas aeruginosa, and 2 cm in Staphylococcus aureus and Bacillus subtilis individually, as shown in figure 6.

The uppermost microbial inhibition zone was found in E. coli and S. aureus (1.9 cm) with 17% PCL–CS–PEC blend, followed by 1.8 cm for B. subtilis and 1.7 cm for P. aeruginosa. E. coli and S. aureus were maximally suppressed by 1.7 cm and B. subtilis and S. aureus by 1.6 cm, respectively, in the presence of 15% PCL–CS–PEC nanofibres. The overall mean zone of antimicrobial inhibition was 1.5 ± 0.8 cm in control, but the mean of 15%, 17%, and 19% PCL–CSPEC was 1.65 ± 0.06, 1.8 ± 0.1 and 2.0 ± 0.08 cm, respectively. As a result, antibacterial activity was shown to be highest in 19% PCL–CS–PEC.

4 Discussion

Literature has already documented the application of benign solvents in electrospinning [64,65,66,67], hence more research into the fibre qualities generated by associating diverse benign solvents with normal solvents is required. Several research investigated the electrospinning of PCL using various solvent systems, and diverse nanofibres were generated from conventional organic solvents, while with specific benign solvents also. Either a single or mixtures of multiple solvents have been used to dissolve PCL [68]. PCL solubility with benign solvents including water, acetic acid, formic acid, acetone and ethanol has been well described in the literature [66,67,68,69,70]. Hence, this study employed formic acid and glacial acetic acid for dissolving PCL and identified that 15%, 17% and 19% of PCL dissolved well with 3:7 ratios.

Electrospinning was used to create a composite PCL/chitosan/pectin nanofibrous scaffold. Different parameters were modified to generate bead-free smooth fibres, including voltage, needle distance (spinneret) and collector, rate of flow of polymer solution, and PCL/CS/PEC solution proportion according to the study [71]. The above-mentioned parameters have been found to influence the shape of electrospun nanofibres. Nanofibrous scaffolds were created with different parameters to study cell survival, degradation and other factors. This study observed beads formation predominantly in 15 and 17% PCL–CS–PEC and Gautam et al [71] defined the underlying principle behind the bead formation in PCL blends and suggested that beaded structure morphology could be converted to smooth fibre morphology through altering or decreasing the concentration of ionic polymers (PEC and CS). Moreover, the study proved that PCL when dissolved in the proportion of 3:1 volume/volume of chloroform and methanol cannot generate any ions in the solution is a non-ionic synthetic polymer, whereas PEC and CS are ionic polymers with various ionizable groups. Henceforth, this study ignored the bead formation in 15% and 17% PCL–CS–PEC, as reducing the ionic polymers concentrations of CS and PEC will offer the advantage of producing bead-free nanofibres. Moreover, the present investigation had not identified any bead formation in 19% PCL–CS–PEC. Hence, the study has considered 15, 17 and 19% PCL–CSPEC for the analysis of antimicrobial activity.

It is well known that the diameter of nanofibres and the size of pores play a role in cell proliferation over the scaffold [72,73]. It was proved that human skin fibroblast proliferation was regulated by the diameter of fibre according to Kumbar et al [72]. The study established that with 250–1,200 nm fibre diameter range of nanofibrous scaffold had a well-defined fibroblast morphology. The interaction between the scaffolds and their environment depends on the pore size scaffolds since excellent cell proliferation would occur only when there is an effective metabolic exchange between the scaffold and its surroundings. Another study showed that PCL/CS/PEC indicated that 6.6 ± 1.9 µm of average pore size ranging from 3.6 to 10.6 µm showed better results for cell proliferation [71]. The current investigation had projected that 0.16, 0.18, 0.19 µm for 15, 17 and 19% PCL–CS–PEC nanofibres coincide with the earlier reports, which had defined the <5 µm pore size to be the lower cutoff limit for ideal cell penetration and migration, which would result in the wound healing process [71,74]. Hence, the pore size obtained in the present investigation was found to be ideal for cell proliferation to be investigated in future studies. The result of the pore sizes identified in this study was almost inconsistent with the previous studies [59]. In all three PCL–CS–PEC percentages tested, two weight loss drifts were found in PCL–CS–PEC nanofibres. The initial step of nanofibre disintegration occurred at roughly 186 to 286°C on PCL–CS–PEC polymers of various percentages. After the loss of water, the second breakdown stage took place at temperatures ranging from 536 to 696°C. When the test was completed at 700 to 800°C, the sample lost its moisture content and had a residual mass of 0.86 to 2.2%. Santos et al [75] recorded a residual mass of 29.7 ± 0.5% in literature for polysaccharides/polyvinyl alcohol blend nanofibrous, but the present investigation was a novel fabrication of nanofibres with PCL, CS and PEC and hence, there would be a disparity. Moreover, there was a complete degradation of nanofibre witnessed in the present study.

On the permeability of bacterial membranes, PCL, CS and PEC based nanofibres generated by electrospinning have been well established to possess an antimicrobial effect [76,77]. Therefore, our study also proved to have an antibacterial activity, which might be attributable to a synergistic effect. The significance of each individual PCL–CS–PEC nanofibres with concern to its clinical role for suitability in human use has been presented in table 5. In addition, the previous literature had already discussed each component of PCL–CS–PEC nanofibres with regard to the nanofibre’s properties and suitability for electrospinning [78,79,80].

5 Conclusion

The present work used CS–PEC, a biocompatible and non-toxic polysaccharide. Electrospinning was used to successfully produce CS–PEC nanofibres coupled with PCL polymer. The structural morphology of the PCL–CS–PEC nanofibres clearly displays the presence of nanofibres. The distinct peaks for the corresponding primary functional groups were clearly identified in the FT-IR characterization of PCL–CS–PEC nanofibres, as well. TGA confirmed that PCL–CS–PEC nanofibres have greater thermal stability. The antibacterial activity of the studied nanofibre proved to be effective against a wide range of microbial organisms, which aids in wound healing. Sample 19% PCL–CS–PEC demonstrated better antimicrobial activity against control than 15% and 17%, which might be attributable to concentration. Future studies will be conducted for the validation of the analysed nanofibres using in vivo investigations for the purpose of a wound dressing.

References

Yao Y, Wang J, Cui Y, Xu R, Wang Z, Zhang J et al 2014 Acta Biomater. 10 2739

Dias J R, Baptista-Silva S, Sousa A, Oliveira A L, Bartolo P J and Granja P L 2018 Mater. Sci. Eng. C 93 816

Avsar G, Agirbasli D, Agirbasli M A, Gunduz O and Oner E T 2018 Carbohydr. Polym. 193 316

Surucu S and Sasmazel H T 2016 Int. J. Biol. Macromol. 92 321

Pakravan M, Heuzey M-C and Ajji A 2011 Polymer 52 4813

Narayanan G, Gupta B S and Tonelli A E 2015 Polymer 73 321

Yang X, Fan L, Ma L, Wang Y, Lin S, Yu F et al 2017 Mater. Des. 119 76

Lin L, Zhu Y, Li C, Liu L, Surendhiran D and Cui H 2018 Carbohydr. Polym. 198 225

Ahmed R, Tariq M, Ali I, Asghar R, Khanam P N, Augustine R et al 2018 Int. J. Biol. Macromol. 120 385

Zhang D, Karki A B, Rutman D, Young D P, Wang A, Cocke D et al 2009 Polymer 50 4189

Zhu J, Wei S, Patil R, Rutman D, Kucknoor A S, Wang A et al 2011 Polymer 52 1954

Aslan T, Arslan S, Eyvaz M, Guçlu S, Yuksel E and Koyuncu I 2016 J. Membr. Sci. 520 616

Jiang L, Tu H, Lu Y, Wu Y, Tian J, Shi X et al 2016 Chem. Phys. Lett. 650 82

Yao Y, Wei H, Wang J, Lu H, Leng J and Hui D 2015 Compos. B Eng. 83 264

Rao M, Geng X, Liao Y, Hu S and Li W 2012 J. Membr. Sci. 399–400 37

Narayanan G, Tekbudak M Y, Caydamli Y, Dong J and Krause W E 2017 Polym. Test. 61 240

Yu W J, Xu S M, Zhang L and Fu Q 2017 Chinese J. Polym. Sci. 35 1132

Park Y R, Ju H W, Lee J M, Kim D K, Lee O J, Moon B M et al 2016 Int. J. Biol. Macromol. 93 1567

Guler Z, Erkoc P and Sarac A S 2015 Mater. Express. 5 269

Shahrifi B H, Mohammadi M, Manoochehri M and Atashi A 2020 Bull. Mater. Sci. 43 135

Lin W C, Yeh I T, Niyama E, Huang W R, Ebara M and Wu C S 2018 Polymers 10 231

Manavitehrani I, Fathi A, Badr H, Daly S, Negahi Shirazi A and Dehghani F 2016 Polymers 8 20

Duque Sanchez L, Brack N, Postma A, Pigram P J and Meagher L 2016 Biomaterials 106 24

Mao W and Yoo H S 2017 Macromol. Biosci. 17 1700057

Shahmoradi S, Yazdian F, Tabandeh F, Soheili Z S, Hatamian Zarami A S and Navaei- Nigjeh M 2017 Mater. Sci. Eng. C 73 300

Asadian M, Rashidi A, Majidi M, Mehrjoo M, Emami B A, Tavassoli H et al 2015 J. Iran. Chem. 12 1089

Chan S Y, Choo W S, Young D J and Loh X J 2017 Carbohydr. Polym. 161 118

Chan S Y, Choo W S, Young D J and Loh X J 2016 Polymers 8 404

Chan S Y and Choo W S 2013 Food Chem. 141 3752

Kai D, Chua Y K, Jiang L, Owh C, Chan S Y and Loh X J 2016 RSC Adv. 6 86420

Kai D, Ren W, Tian L, Chee P L, Liu Y, Ramakrishna S et al 2016 ACS Sustain. Chem. Eng. 4 5268

Kai D, Zhang K, Jiang L, Wong H Z, Li Z, Zhang Z et al 2017 ACS Sustain. Chem. Eng. https://doi.org/10.1021/acssuschemeng.7b00850

Yanamala N, Farcas M T, Hatfield M K, Kisin E R, Kagan V E, Geraci C L et al 2014 ACS Sustain. Chem. Eng. 2 1691

Dekamin M G, Azimoshan M and Ramezani L 2013 Green Chem. 15 811

Kucharska M, Walenko K, Butruk B, Brynk T, Heljak M and Ciach T 2010 Mater. Lett. 64 1059

Park S, Marsh K and Rhim J 2002 J. Food Sci. Chic. 67 194

Pandima Devi M, Sekar M, Chamundeswari M, Moorthy A, Krithiga G, Selva Murugan N et al 2012 Bull. Mater. Sci. 35 1157

Cunha-Reis C, TuzlaKoglu K, Baas E, Yang Y, El Haj A and Reis R L 2007 J. Mater. Sci. Mater. Med. 18 195

Raftery R, O’Brien F J and Cryan S A 2013 Molecules 18 5611

Duarte A R, Mano J F and Reis R L 2009 Eur. Polym. J. 45 141

Nishikawa H, Ueno A, Nishikawa S, Kido J, Ohishi M, Inoue H et al 2000 J. Endod. 26 169

Correia C R, Moreira-Teixeira L S, Moroni L, Reis R L, van Blitterswijk C A, Karperien M et al 2011 Tissue Eng. Part C Methods 17 717

Hutmacher D W, Goh J C and Teoh S H 2001 Ann. Acad. Med. Singapore 30 183

Han J, Zhou Z, Yin R, Yang D and Nie J 2010 Int. J. Biol. Macromol. 46 199

Anitha T and Kannaiyan S 2021 Bull. Mater. Sci. 44 119

Kumar P T, Praveen G, Raj M, Chennazhi K P and Jayakumar R 2014 RSC Adv. 4 65081

Mezzana P 2008 Acta Chir. Plast. 50 81

Chan S Y, Choo W S, Young D J and Loh X J 2016 in X J Loh (ed) Polymers for personal care products and cosmetics (The Royal Society of Chemistry) p 205

Rosenbohm C, Lundt I, Christensen T I E and Young N G 2003 Carbohydr. Res. 338 637

Mishra R K, Datt M, Pal K and Banthia A K 2008 J. Mater. Sci. Mater. Med. 19 2275

Fan L, Cao M, Gao S, Wang W, Peng K, Tan C et al 2012 Carbohydr. Polym. 88 707

Coimbra P, Ferreira P, de Sousa H C, Batista P, Rodrigues M A, Correia I J et al 2011 Int. J. Biol. Macromol. 48 112

Luppi B, Bigucci F, Abruzzo A, Corace G, Cerchiara T and Zecchi V 2010 Eur. J. Pharm. Biopharm. 75 381

Meshali M M and Gabr K E 1993 Int. J. Pharm. 89 177

Macleod G S, Collett J H and Fell J T 1999 J. Control. Release 58 303

Croisier F, Sibret P, Dupont-Gillain C C, Genet M J, Detrembleur C and Jerome C 2015 J. Mater. Chem. B 3 3508

Safari J, Esteghlal S, Keramat M and Khalesi M 2020 Nanosci. Nanotechnol. -Asia 10 134

Kusumastuti Y, Putri N R E and Dary A R 2016 AIP Conf. Proc. 1755 1500071

Shalumon K T, Anulekha K H, Girish C M, Prasanth R, Nair S V and Jayakumar R 2020 Carbohydr. Polym. 80 413

Hotaling N A, Bharti K, Kriel H and Simon C G Jr 2015 Biomaterials 61 327

Bhardwaj N and Kundu S C 2010 Biotechnol. Adv. 28 325

Peh K, Khan T and Ch’ng H 2000 J. Pharm. Pharm. Sci. 3 303

Lin H Y, Chen H H, Chang S H and Ni T S 2013 J. Biomater. Sci. Polym. Ed. 24 470

Liverani L, Boccardi E, Beltran A and Boccaccini A R 2017 Polymers 9 487

Liverani L, Vester L and Boccaccini A R 2017 in J Almodovar (ed) Electrospun Biomaterials and Related Technologies (Springer) https://doi.org/10.1007/978-3-319-70049-6_5

Dippold D, Cai A, Hardt M, Boccaccini A R, Horch R, Beier J et al 2017 Mat. Sci. Eng. C Mater. Biol. Appl. 72 278

Liverani L, Lacina J, Roether J, Boccardi E, Killian M, Schmuki P et al 2018 Bioact. Mater. 3 55

Luo C, Stride E and Edirisinghe M 2012 Macromolecules 45 4669

Augustine R, Kalarikkal N and Thomas S 2016 Polym-Plast. Tech. Eng. 55 518

Liverani L and Boccaccini A R 2016 Nanomaterials 6 75

Gautam S, Dinda A K and Mishra N C 2013 Mater. Sci. Eng. C Mater. Biol. Appl. 33 1228

Kumbar S G, Nukavarapu S P, James R, Nair L S and Laurencin C T 2008 Biomaterials 29 4100

Li W J, Laurencin C T, Caterson E J, Tuan R S and Ko F K 2002 J. Biomed. Mater. Res. 60 613

Xu W, Chen Q, Hadim H and Shi Y 2011 Nanotechnology 21 395303

Santos Carla, Silva C J, Buttel Z, Guimaraes R, Pereira S B, Tamagnini P et al 2014 Carbohydr. Polym. 99 584

Ruckh T T, Oldinski R A, Carroll D A, Mikhova K, Bryers J D and Popat K C 2012 J. Mater. Sci. Mater. Med. 23 1411

Arkoun M, Daigle F, Heuzey M C and Ajji A 2017 Food Sci. Nutr. 5 865

Azari A, Golchin A, Mahmoodinia Maymand M, Mansouri F and Ardeshirylajimi A 2022 Adv. Pharm. Bull. p 658. https://doi.org/10.34172/apb.2022.070

Al-Jbour N D, Beg M D, Gimbun J and Alam A K M M 2019 Curr. Drug Deliv. 16 272

McCune D, Guo X, Shi T, Stealey S, Antrobus R, Kaltchev M et al 2018 Appl. Nanosci. 8 33

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaliaperumal, C., Thulasisingh, A. Electrospun polycaprolactone/chitosan/pectin composite nanofibre: a novel wound dressing scaffold. Bull Mater Sci 46, 23 (2023). https://doi.org/10.1007/s12034-022-02859-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02859-2