Abstract

Cobalt sulphides, including CoS, CoS2, Co3S4 and Co9S8, have been studied as potential anode materials for Li- and Na-ion batteries. However, the mechanical properties of the cobalt sulphides have not been intensively investigated. In this work, density functional theory (DFT) calculation was employed to study the mechanical properties of the cobalt sulphides mentioned above. Besides, the mechanical properties of final products of lithiation/sodiation of Co9S8 have been calculated, including the bulk modulus, shear modulus, Young’s modulus and Poisson’s ratio. This work provides an insight into understanding the electrochemical performance of Co9S8 material as anode material for Li- and Na-storage during the cycling process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Development of new materials for Li-ion batteries (LIBs) has received a great deal of attention in recent years due to the disadvantages of the existing electrode materials [1,2,3]. In the case of anode materials, graphite has been widely used in commercial LIBs. However, the low theoretical capacity of graphite does not meet the consumer’s need for batteries with high energy density [4]. Thus, extensive efforts have been devoted to exploring new anode materials with a high capacity for advanced LIBs [5,6,7,8]. Recently, nanostructured carbon materials including graphene, nanotubes, nanofibres and porous carbon have been intensively investigated [9,10,11,12]. The capacity of these carbonous materials is higher than the theoretical capacity of graphite. The drawbacks of these carbonous anodes include the low charging/discharging efficiency at the first cycle and the poor dispersion stability.

Transition metal sulphides have been considered as promising candidates for graphite anode materials due to their high theoretical capacity [13,14]. However, the application of transition metal sulphides is greatly prohibited by the large volume change during the lithiation process. Many strategies have been carried out to enhance the structural stability of transition metal sulphides, such as morphology modulation, surface coating and combination with carbon nanomaterials. In the family of transition metal sulphides, cobalt sulphides including the forms of CoS, CoS2, Co3S4, and Co9S8 have been considered as potential anode materials for LIBs and sodium-ion batteries owing to their high theoretical capacities and high electrical conductivity [15,16]. However, practical application of cobalt sulphides is limited by severe volume changes during the lithiation process and poor electrochemical kinetics, which causes poor cyclic stability and unsatisfactory rate capability. Several methods have been adopted to improve the electrochemical performance of cobalt sulphides, such as hybridization of cobalt sulphides with carbonaceous materials and construction of hierarchical structures. Although cobalt sulphides have been intensively studied, the structural evolution during the lithiation/sodiation process is still unrevealed from the view of mechanics. The rate capability and cycling performance of the electrode materials greatly depend on the structural stability. The Li insertion caused the lattice distortion of the electrode materials, and further resulted in the changes in bond length and angles. Usually, the bulk modulus is used to characterize a materials resistance to volume deformation against external pressure, while the shear modulus measures a materials ability to resist shear strain. That is, the mechanical properties of the materials often determine their structural stability and the applications.

Up to now, the mechanical properties of the cobalt sulphides have not been intensively investigated. Thus in this work, density functional theory (DFT) calculation was employed to study the mechanical properties of the cobalt sulphides mentioned above. Besides, the structural evolution of the most stable phase Co9S8 during the lithiation/sodiation process has been calculated, including the bulk modulus, shear modulus, Young’s modulus and Poisson’s ratio.

2 Calculation method

Structural optimization and calculation of elastic constants of cobalt sulphides (CoS, CoS2, Co3S4 and Co9S8) have been performed by CASTEP module built in Materials Studio, based on Perdew-Burke-Ernzerhof (PBE) theoretical framework. Electronic wavefunctions are expanded in a plane wave basis set with the kinetic energy cutoff of 600 eV. The k-points 13×13×8, 7×7×7, 7×7×7 and 4×4×4 were adopted for integration in the Brillouin zone. The convergence criterion of energy was set as 5.0×10−7 eV per atom. The maximum number of fully self-consistent field iteration steps is set to 300.

3 Results and discussion

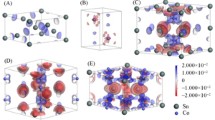

The atomic structures of cobalt sulphides (hexagonal phase CoS, cubic phase CoS2, cubic phase Co3S4 and cubic phase Co9S8) are presented in figure 1. The blue and yellow spheres indicate Co and S atoms, respectively. The crystal structures of the cobalt sulphides mentioned above have been investigated in literatures [17,18,19,20]. The space groups and lattice parameters of the cobalt sulphides are listed in table 1.

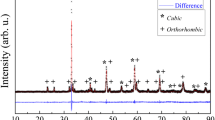

The calculated elastic constants of the cobalt sulphides mentioned above are listed in table 2. The values of elastic constants are all positive and satisfy the condition for mechanical stability. For hexagonal phase CoS, five elastic constants including C11, C12, C13, C33 and C44 besides C66 are independent, which can be employed to evaluate the stability status. The mechanical stability conditions, known as Born’s criteria, can be found in the references [21]. The calculated elastic constants indicate that the CoS, CoS2, Co3S4 and Co9S8 phases are theoretically stable. Due to the symmetry of the crystal structures, the C11 = C22 = C33. For the cubic phase CoS2, Co3S4 and Co9S8, C12 = C13 = C23 and C44 = C55 = C66.

The elastic constants can be further employed to calculate the mechanical properties of CoS, CoS2, Co3S4 and Co9S8 phases. Two approximation methods, namely the Voigt’s and Reuss’s methods, have been widely used to calculate the bulk modulus (K) and shear modulus (G) [22].

For the cubic phase,

For the hexagonal phase,

The calculated results from Voigt’s and Reuss’s methods denote the upper and lower limits of the bulk modulus. Hill [23] proved that the arithmetic average value of Voigt's and Reuss's methods is closer to the real value.

The Young’s modulus E and Poisson’s ratio v can be calculated by the following relationship.

The bulk, shear, Young’s moduli and Poisson’s ratios of the four types of cobalt sulphides have been calculated as listed in table 3. Generally, the mechanical properties affect the electrochemical performance of the cathode materials. Besides the volume variation, Young’s modulus is also an important factor that determines the robustness of the cathode material during the charging/discharging process. Comparisons of the bulk, shear, Young’s moduli and Poisson’s ratios of the four types of cobalt sulphides are presented in figure 2. The cobalt sulphides exhibit different mechanical properties with the change of the stoichiometric ratio of Co/S. The high number of Li atoms incorporated into the cobalt sulphides during lithiation causes large volume changes. From the point of view of mechanics, the insertion of Li atoms induces internal stress. High bulk modulus favours the Li insertion and extraction. From figure 2, it can be found that the CoS2 phase shows the lowest value of bulk modulus (~115.81 GPa). As comparison, the Co9S8 phase exhibits a relatively high bulk modulus of 169.78 GPa. Thus, the Co9S8 phase with the highest value of bulk modulus shows great potential for application in anode materials.

Based on the discussion mentioned above, Co9S8 phase is worth further investigation among the four types of cobalt sulphides. The Co9S8 phase undergoes the electrochemical reaction in the lithiation/sodiation process and forms alloys as follows [11,24].

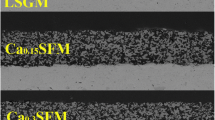

After full lithiation, a huge volume change ~450% was obtained. This is the reason for the capacity fading in the cycling. DFT calculation indicates that the Li3Co (Na3Co) phase is the most stable structure at the lowest energy state [11]. The atomic models of the Li3Co and Na3Co phases are shown in figure 3. As presented in figure 3a, the Li3Co phase possesses a tetragonal crystal structure. The lattice parameters of the Li3Co structure obtained from the theoretical calculation is consistent with the results previously reported [11]. The Na3Co phase shows a cubic crystal structure as shown in figure 3b.

The elastic constants of Li3Co and Na3Co are shown in table 4, which can be employed to calculate the bulk modulus, shear modulus and Poisson’s ratio of cobalt sulphides. For the tetragonal phase, the compliance constants Sij can be expressed as follows [22].

Then,

The obtained bulk moduli, shear moduli and Poisson’s ratios of Li3Co and Na3Co are shown in figure 4. Generally, the Li3Co and Na3Co phases show much lower bulk modulus, shear modulus and Young’s modulus than in the case of Co9S8 phase. It indicates that the lithium/sodiation induces the degradation of the mechanical properties of Co9S8 phase. The low bulk modulus means that the Li3Co and Na3Co phases cannot resist the repeated Li insertion/extraction during the cycling process. The low mechanical stability of Li3Co and Na3Co phases further causes the cracking and pulverization in the electrodes. This is the reason why the raw Co9S8 phase exhibits poor cycling performance. The values of bulk modulus and shear modulus of Li3Co are higher than that of Na3Co. The experimental results indicated that Co9S8 material delivered higher discharge capacity and better cycling performance in the Li-storage than in the case of Na-storage. From this viewpoint, carbon coating technology can improve the electrochemical properties of Co9S8 by enhancing its mechanical stability.

4 Conclusion

In summary, the bulk moduli, shear moduli, Young’s moduli and Poisson’s ratios of the four types of cobalt sulphides have been calculated. Among them, the Co9S8 phase exhibits a relatively high bulk modulus of 169.78 GPa, showing great potential as anode materials for Li and Na storage. After lithiation/sodiation process, Li-Co alloys including Li3Co and Na3Co phases have been formed. The mechanical properties of the Li3Co and Na3Co phases have also been calculated. The low bulk modulus indicates that the Li3Co and Na3Co phases cannot resist the repeated Li insertion/extraction during the cycling process. As comparison, the Li3Co phase shows better mechanical properties than the Na3Co phase.

References

Chen H, Zhang W, Tang X-Q, Ding Y-H, Yin J-R, Jiang Y et al 2018 Appl. Surf. Sci. 427 198

Chibueze T C and Okoye C M I 2019 Physica B 554 165

Ding Y, Jiang Y, Xu F, Yin J, Ren H, Zhuo Q et al 2010 Electrochem. Commun. 12 10

Fuchsbichler B, Stangl C, Kren H, Uhlig F and Koller S 2011 J. Power Sources 196 2889

Hassoun J, Bonaccorso F, Agostini M, Angelucci M, Betti M G, Cingolani R et al 2014 Nano Lett. 14 4901

Jiang T, Yang S, Dai P, Yu X, Bai Z, Wu M et al 2018 Electrochim. Acta 261 143

Jiang W, Han Y, Jiang Y, Xu F, Ouyang D, Sun J et al 2021 Appl. Clay Sci. 203 106020

Jiang W, Jiang Y, Zhao S, Peng J, Qin W, Ouyang D et al 2020 Energy Technol. 8 1901262

Jiang W, Liu Q, Peng J, Jiang Y, Ding Y and Wei Q 2020 Nanotechnol. 31 235713

Liu X, Jiang Y, Li K, Xu F, Zhang P and Ding Y 2019 Mater. Res. Bull. 109 41

Liu Y, Sun K, Jiang J, Zhou W, Shang Y, Du C et al 2021 Green. Energy Environ. 6 91

Qu G, Wu T, Yu Y, Wang Z, Zhou Y, Tang Z et al 2019 Nano Res. 12 2960

Shadike Z, Cao M-H, Ding F, Sang L and Fu Z-W 2015 Chem. Commun. 51 10486

Sun J, Lu C, Tian Q, Mei Y, Peng J and Ding Y 2020 Appl. Surf. Sci. 513 145756

Tan J, Li Y and Ji G 2012 Comput. Mater. Sci. 58 243

Wang Z, Li F, Ding W, Tang X, Xu F and Ding Y 2021 Nanotechnol. 32 315707

Xiao C, Tang X, Peng J and Ding Y 2021 Appl. Surf. Sci. 563 150278

Xiao Q, Fan Y, Wang X, Susantyoko R A and Zhang Q 2014 Energy Environ. Sci. 7 655

Xu X, Liu W, Kim Y and Cho J 2014 Nano Today 9 604

Yang Z, Ding Y, Jiang Y, Zhang P and Jin H 2018 Nanotechnol. 29 405602

Zhang R, Lu C, Shi Z, Liu T, Zhai T and Zhou W 2019 Electrochim. Acta 311 83

Zhang W, Yin J, Zhang P, Tang X and Ding Y 2018 J. Mater. Chem. A 6 12029

Hill R 1952 Proc. Phys. Soc. 65 349

Apostolova R, Shembel’ E, Talyosef I, Grinblat J, Markovsky B and Aurbach D 2009 Russ. J. Electrochem. 45 311

Acknowledgements

This work was financially supported by the Key Laboratory of Intelligent Computing and Information Processing of Ministry of Education and High-level Talent Gathering Project in Hunan Province (No. 2019RS1059).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, Y., Jiang, W. & Tang, X. A DFT study on the mechanical properties of Co9S8 during the lithiation/sodiation process. Bull Mater Sci 45, 253 (2022). https://doi.org/10.1007/s12034-022-02839-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02839-6