Abstract

Until now, researchers have conducted many studies about diamond-like carbon materials. We saw some shortcomings of a well-known method, and we decided to improve it. First, we performed the electrolysis stage of poly(hydridocarbyne) production. We continued with a pericyclic reaction by adding benzoyl peroxide or 2,2′-azobis(isobutyronitrile). Then, we heated the obtained poly(hydridocarbyne) powders at high temperatures in an argon atmosphere. The product produced according to the literature was the control group, and the others were test groups (E1 and E2). The samples were compared through X-ray diffraction (XRD), Fourier transform infrared (FTIR) and scanning electron microscopy analysis. According to the results, diamond-like carbon powders can be produced in smaller particle sizes. They can be crystallized better by adding a new pericyclic reaction to the production method in the literature. The strength of the XRD peak of the diamond-like material produced with benzoyl peroxide was almost twice the other. The crystalline sizes were 13, 11, and 17 nm for the control group, E1 and E2, respectively. The vibration peaks of diamond-like materials were observed in the FTIR spectrum. In tunnelling electron microscope images, particle sizes of the control group, E1 and E2 were 135, 125 and 88 nm, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent days, many studies have been conducted about diamonds or the production of diamond-like materials. Diamond-like materials are quite useful in many fields of the industry, such as metal coating, cookware, enamel, thermal insulation and automobile pistons with their low electrical conductivity, high thermal conductivity, hardness, and chemical inertness. They are either directly used or through coating [1,2,3,4,5,6]. Diamond could be obtained by squeezing carbon-based material at 4000 K, under 200 kbar pressure. Researchers have first used nickel as a catalyst, and they have produced carbon or carbon-based amorphous powders at 2000 K, under 150 kbar pressure. However, it was much costly. In addition to that, scientists have started to use different methods to reduce the cost of producing diamond and diamond-like materials. In shock loading, high temperature and pressure trials, they have used graphite, carbon black, fullerenes and organic materials. Their cost-reducing efforts have been continued. In order to increase efficiency, they have also used catalysts, such as copper-cobalt [7]. The most important field of study about this topic is perhaps the studies featuring the synthesis of poly(hydridocarbyne), a polymer of network structure, having carbon-based sp3 hybridization. The generic formula of poly(hydridocarbyne) is [CH]n, and it was first produced from bromoform and halocarbon. Poly(hydridocarbyne), a brown powder at room temperature, was transformed to a diamond at 1000°C in an argon atmosphere. Poly(hydridocarbyne) was produced by the electrolysis of the chemicals such as chloroform and hexachloroethane in a salty medium [8,9,10,11]. Again, it was transformed into a diamond at 1000°C in an argon atmosphere. We can show this process in two stages:

Process 1:

Process 2:

During Process 1, chloroform was dissolved in acetonitrile mixed with NaCl dissolved in water or tetrabutylammonium tetrafluoroborate dissolved in acetonitrile. It was electrolysed under 6 V for 4 h in a nitrogen atmosphere. Afterwards, it was boiled with LiAlH4 and tetrahydrofuran (THF) in a condenser for 12 h to eliminate impurities and then washed with organic solvents, such as dichloromethane, hexane, and dried. The obtained brown solid powder was oven-dried in an argon atmosphere, at 1000°C, for 24 h [9]. Nevertheless, after numerous operations following these steps, we could not obtain good crystallization, particularly in XRD data. Therefore, we added a wet chemical radical reaction with pericyclic reaction starters (benzoyl chloride or 2,2′-azobis(isobutyronitrile) (AIBN)) after the pericyclic electrolysis reaction. Afterwards, we oven-dried it at 1000°C for 24 h. Fourier transform infrared (FTIR) analysis of poly(hydridocarbyne) and carbon-based diamond powders was performed. The average particle size and dislocation density of diamond powders, which are the indicators of crystallization, were calculated from their XRD patterns. At the same time, we compared particle sizes through scanning electron microscopy images.

2 Experimental

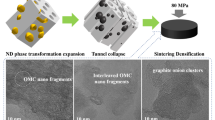

All chemicals were purchased from Sigma-Aldrich (Germany). As mentioned in the introduction, we synthesized typical diamond powder as described in the literature for comparison purposes (Control group). A part of the synthesized poly(hydridocarbyne) was reacted with AIBN in THF solvent and another part with benzoyl peroxide in 1,4 dioxane for the experimental groups. Afterwards, we heated all solid powders at 1000°C, in an argon atmosphere, for 24 h. As shown in figure 1, all samples were washed with the same solvents (n-hexane, ethanol, 1,4 dioxane, THF) and purified with the same reagents (LiAlH4, THF (1 M acetonitrile in chloroform and 1 g NaCl, 1 g LiAlH4 in THF, 1:10 AIBN and benzoyl peroxide of poly(hydridocarbyne)).

The structural properties of diamond powders were measured by X-ray diffraction (XRD) with a CuKα1 radiation source (Rikagu RadB model, λ = 1.5406 Å) over the range of 10° < 2θ < 90o at a speed of 1° min–1 with a step size of 0.02°. The surface properties of the powders were examined using an EVO40-LEO computer-controlled digital tunnelling electron microscope (TEM). Quantitative elemental analysis was performed with an EDX spectrometer attached to TEM. The infrared spectrum of powders was recorded by a Perkin Elmer Spectrum 400 spectrometer with a resolution of 4 cm–1 using a DTGS detector and 10 scans for each spectrum.

3 Result and discussion

XRD patterns of diamond-like powders are shown in figure 2. The most prominent peaks were observed in all samples around 31.88, 37.41, 45.69 and 66.63 degrees (table 1).

In our study, the strength of the peak observed around 41° in the literature was relatively low compared to the others. As it was located inside the amorphous structure, we did not consider it in the evaluation. Besides, nearly all peaks were in line with the literature. In most of the studies in the literature, tetrabutylammonium tetrafluoroborate, which is an organic salt, was used instead of NaCl. Using this salt instead of NaCl effectively produces better quality diamond and diamond-like powder. However, since our objective is to determine how to obtain diamond and diamond-like materials in a best-crystallized way, we continued using NaCl. The strength of the XRD peak belonging to diamond-like carbon powder produced with benzoyl peroxide is almost twice that of the others, which indicates that the solid powder produced through this method was better crystalized. We observed these peaks at 30.86º, 31.87º, 37.41º, 45.54º, 66.19º in the Control group; 31.74º, 37.26º, 45.54º, 56.60º, 60.27º, 66.35º in E1 and 31.88º, 37.56º, 45.69º, 56.60º, 60.52º, 66.63º in E2. The XRD pattern of E2 results was almost in line with the theoretical values of the diamond.

Dislocation density (δ) and grain size (D) are critical parameters, and they can provide valuable information about the structure. These can be easily calculated from XRD patterns using Debye Scherrer formulas. In this regard, for each sample, we selected the strongest 6 peaks observed in their XRD patterns, and we calculated the average crystalline size using them. Moreover, these 6 peaks are clearly observed; they are not lost in the amorphous structure.

where D is the grain size, λ the X-ray wavelength used, β the angular line width at the half-maximum intensity in radians, and θ is the Bragg angle.

Smaller D and bigger δ values mean better crystallization of the material.

As shown in figure 3, crystalline size was reduced when pericyclic reactions were added after electrolysis. The difference between carbon powders produced with AIBN and benzoyl peroxide is due to the reaction temperature, which depends on the solvent. The reaction with benzoyl peroxide could go up to 101°C in 1-4 dioxane, increasing the reaction speed and prolonging the poly(hydridocarbyne) chain. The polymer with a longer chain caused the formation of smaller particles or crystals in the argon atmosphere at high temperatures. As can be understood from formulas 3 and 4, average crystalline size and dislocation density are inversely correlated. The dislocation density of the carbon-based diamond powder produced with benzoyl peroxide was higher because the holes between the particles increase as crystalline get smaller, which causes the increase of dislocation density.

Figure 4 displays the FTIR spectrum of the poly(hydridocarbyne) types obtained by electrolysis and wet chemical method using AIBN or benzoyl peroxide.

Regarding the characteristic peaks of poly(hydridocarbyne) reported in the literature [10,11,12], we have observed the following in the compounds that we have produced:

Poly(hydridocarbyne) produced by electrolysis (only): C−C symmetrical vibrations were observed at 976–1366 cm–1 and vibrations peaks of the water at 3416 cm–1.

Poly(hydridocarbyne) produced using pericyclic reaction with AIBN after electrolysis: C−C symmetrical vibrations were observed at 981–1380 cm–1, aliphatic C–H in-plane bending at 1450–1500 cm–1, aliphatic C–H vibration peaks at 2900 cm−1 and vibrations peaks of the water at 3430 cm–1.

Poly(hydridocarbyne) produced using pericyclic reaction with benzoyl peroxide after electrolysis: C−C symmetrical vibrations were observed at 981–1360 cm–1, aliphatic C-H in-plane bending at 1450–1500 cm–1, aliphatic C-H vibration peaks at 2970 cm–1 and vibrations peaks of the water at 3392 cm–1. Moreover, we observed the peak of 3416 cm–1 attributed to the water.

Figure 5 displays the FTIR spectrum of the carbon-based diamond powder produced by oven-drying the poly(hydridocarbyne) types obtained by electrolysis and wet chemical method using AIBN or benzoyl peroxide, in an argon atmosphere at 1000°C, for 24 h.

Regarding the characteristic peaks of the diamond powder reported in the literature [10,11,12], we have observed the following in the carbon-based products that we have produced:

Diamond-like carbon powder produced from poly(hydridocarbyne) produced by electrolysis (only): Symmetrical vibrations of the C−C bond were observed at 976–1390 cm–1.

Diamond-like carbon powder produced from poly(hydridocarbyne) using pericyclic reaction with AIBN after electrolysis: C−C vibration peaks were observed at 1054–1380 cm–1.

Diamond-like carbon powder produced from poly(hydridocarbyne) using pericyclic reaction with benzoyl peroxide after electrolysis: C−C vibration peaks were observed at 1054–1360 cm–1.

In all spectrums, complex vibrations were observed under 1000 cm–1; thus, they were not considered during evaluation. All results are in line with the literature [10,11,12].

As shown in TEM images presented in figure 6, grain sizes are similar to the outcomes obtained from the crystalline size of XRD patterns. Regarding the computations made from the XRD pattern, average grain sizes were 13, 11 and 17 nm for the control group, E1 and E2, respectively. On the other hand, particle sizes of diamond-like carbon powders, which were automatically given by the program of the TEM device, were 135, 125 and 88 nm for the control group, E1 and E2, respectively.

Figure 7 shows XPS analysis of diamond-like carbon material. XPS was performed using the Mg K-α-line, which was analysed with solid powder. According to the literature, diamond-like carbon materials give C (1s) peak around 284–285 eV depending on the impact of the chemical environment. Studies have shown that samples whose peak is at 285 eV and around have more diamond properties. In this study, the C 1s peak was determined at 284.6 eV. It is known that the C 1s peak detected at 284 eV and below belongs to graphite [13].

Raman spectrum of diamond-like carbon powder produced by AIBN radical reaction is given in figure 8. Accordingly, a very clear and sharp peak appeared at 741 cm–1, a specific peak of C−C bonds seen in high-molecular-weight polymers. It shows that the diamond-like carbon powder produced with the AIBN reagent contains nothing but C−C bonds and has a structure very close to the diamond, which is only a Raman-active molecule.

In the introduction, we have given the synthesis mechanism of polyhydrocarbons by electrolysis in equilibrium 1. As can be seen from these results, the polymer chain can then be extended with AIBN and benzoyl peroxide, and better-quality diamond-like carbon materials can be produced. For this mechanism, the example of benzoyl peroxide is given below.

The resulting benzoyl peroxide radical continues to polymerize polyhydrocarbons.

In equation (4), the number of radicals will increase first. Then, the polymer forming complex with the radical initiator is separated and reacts with the other polymer, and the polymer chain is extended. Moreover, many studies in the literature about carbon nanomaterials are in line with our results [14,15,16,17].

4 Conclusion

In this study, carbon-based or diamond-like carbon powders were produced via the method known in the literature by adding additional processes designed by us; their XRD, FTIR analysis and TEM images were compared. According to the XRD pattern, the strongest peak was observed in the diamond-like carbon material that has been produced by oven-drying the poly(hydridocarbyne) produced by using pericyclic reaction with benzoyl peroxide after electrolysis in argon atmosphere, at high temperature. This also indicates that this material had a smaller crystalline size, and it was crystallized better than the others. Of course, we would probably see a similar result if the solvent, in which we have added AIBN, was 1-4 dioxane instead of THF. Here, we tested both pericyclic initiator reagent and solvent media. As reported in the literature, it is possible to use tetrabutylammonium tetrafluoroborate instead of NaCl. According to these results, better quality, well-crystallized, and even nano-dimension diamond-like carbon powders can be produced using this process. In the future, these results can help researchers who study in this field to produce diamond-like crystals.

References

Isberg J, Hammersberg J, Johansson E, Wikstrom T, Twitchen D J, Whitehead A J et al 2002 Science 297 1670

Nebel C E, Yang N, Uetsuka H, Yamada T and Watanabe H 2008 J. Appl. Phys. 103 013711

Luo J K, Fu Y Q, Le H R, Williams J A, Spearing S M and Milne W I 2007 Micromech. Microengin. 17 S147

Chao J I, Perevedentseva E, Chung P H, Liu K K, Cheng C Y, Chang C C et al 2007 Biophys. J. 93 2199

Robertson J 2006 Diam. Relat. Mater. 15 898

Zhang L, Chen M, Li Z Y, Chen D H and Pan S R 2008 Mater. Lett. 62 1040

Donnet J B, Fousson E, Wang T K, Samirant M, Baras C and Johnson M P 2000 Diam. Relat. Mater. 9 882

Bianconi P A, Joray S J, Aldrich B L, Sumranjit J, Duffy D J, Long D P et al 2004 J. Am. Chem. Soc. 126 3191

Nur Y, Pitcher M W, Seyyidoğlu S and Toppare L 2008 J. Macro. Sci. Part A: Pure Appl. Chem. 45 358

Nur Y, Cengiz H M, Pitcher M W and Toppare L T 2009 J. Mater. Sci. 44 2774

Sizov A I, Zvukova T M and Bulychev B M 2012 Rus. Chem. Bull. 61 668

Katzenmeyer A M, Bayam Y, Logeeswaran V J, Pitcher M W, Nur Y, Seyyidoğlu S et al 2009 J. Nanomater. 2009 832327

Filik J, May P W, Pearce S R J, Wild R K and Hallam K R 2003 Diam. Relat. Mater. 12 974

Reddy K R, Sin B C, Ryu K S, Noh J and Lee Y 2019 Synt. Met. 159 1934

Shetti N P, Malode S J, Nayak D S, Bagihalli G B, Reddy K R, Ravindnaradh K et al 2019 Microchem. J. 149 103985

Reddy K R, Sin B C, Yoo C H, Park W, Ryu K S, Lee J S et al 2008 Scr. Mater. 58 1010

Mehta A, Misha A, Basu S, Shetti N P, Reddy K R, Saleh T A et al 2019 J. Environ. Manage. 250 109486

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kariper, İ.A. Production of diamond-like carbon powder in nano size. Bull Mater Sci 45, 210 (2022). https://doi.org/10.1007/s12034-022-02792-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02792-4