Abstract

We present a comparative study on phase co-existence in \(\hbox {La}_{1/4}\hbox {Pr}_{3/8}\hbox {Ca}_{3/8}\hbox {MnO}_{3}\) (LPCMO) in a polycrystalline bulk and thin film form. The X-ray diffraction results confirm the formation of single-phase polycrystalline bulk and c-axis-oriented strained epitaxial thin films on a \(\hbox {LaAlO}_{3}\) substrate. Scanning electron microscopy images show a homogeneous microstructure growth for both the bulk as well as thin film samples. The temperature dependent magnetization curves for bulk and thin film show remarkably different features indicating the presence of very different phase separation scenarios. A two-step rise and a large thermal hysteresis are observed between zero-field cooled and field-cooled magnetization plots in the bulk sample. However, the magnetization of the film shows a very small hysteresis and a negligible signature of the CO-AFM state for the same composition. The field dependent magnetization plots indicate that in a bulk form LPCMO is a soft magnet and shows a metamagnetic behaviour while in a thin film form it acts as a hard magnet and the metamagnetic behaviour is completely lost.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pr, Ca co-doped \(\hbox {LaMnO}_{3}\) exhibits a variety of complex physical properties owing to the co-existence and competition of different structural, magnetic and electronic degrees of freedom [1,2,3,4]. The complex interplay of lattice, orbital, spin and charge interactions in \(\hbox {La}_{1/4}\hbox {Pr}_{3/8}\hbox {Ca}_{3/8}\hbox {MnO}_{3}\) (LPCMO) gives rise to a very rich phase diagram. This results in various intriguing properties like colossal magnetoresistance, metal to insulator transition and co-existence of various phases with very different properties such as metallic ferromagnetic (FM), insulating charge ordered (CO) and paramagnetic (PM) [3,4,5,6,7]. The relative fraction of these different phases is known to be sensitive to several parameters which include temperature, external magnetic and electric fields, strain and composition. Even a small change in any of these mentioned parameters can remarkably alter the properties of this strongly co-related manganite [8,9,10,11].

The sensitivity of phase separation towards external parameters inspires a possibility to tailor the physical properties of LPCMO, hence making it a technologically important material. Some external stimuli such as temperature can cause temporary reversible changes in phase separation, whereas, parameters such as composition and structural distortion can lead to permanent changes [12,13,14]. Most technological applications use materials in the form of thin films, which may have very different structural and electronic properties as compared to bulk forms. The physical properties of manganite systems are known to be affected by \(\hbox {MnO}_{6}\) octahedral tilting and distortions [1, 2, 15], which can get modified due to the lattice induced strain in the thin film. The changes in the structure and reduced symmetry in the thin film form can have a remarkable impact on the phase separation scenario and hence on the physical properties of the LPCMO system.

Here, we present a comparative study of phase separation in a polycrystalline LPCMO powder and highly c-axis oriented thin films of LPCMO deposited on the \(\hbox {LaAlO}_{3}\) (LAO) substrate using pulsed laser deposition (PLD). Since the material to be deposited has a complex composition with multiple components, PLD is the preferred technique of deposition to maintain the desired stoichiometry of the thin films. Henceforth, the polycrystalline LPCMO powder is referred to as bulk LPCMO while the LPCMO thin film on the LAO substrate is referred to as LPCMO/LAO. The structural characterization reveals that both the bulk and thin film samples have single phase and homogeneous growth. However, the temperature and field dependent magnetization measurements show major differences. The bulk LPCMO shows clear signs of phase co-existence and first order transition, while such signatures are highly diminished in the LPCMO/LAO film.

2 Experimental

The single-phase polycrystalline powder sample and bulk target (used for thin film deposition) of LPCMO were prepared using a conventional solid state reaction technique. High purity (>99.99%) powders of \(\hbox {La}_{2}\hbox {O}_{3}\), \(\hbox {Pr}_{6}\hbox {O}_{11}\), \(\hbox {CaCO}_{3}\) and MnO mixed in stoichiometric amounts were ground properly in an agate mortar to make a fine powder. The powder was first calcined at \(850^{\circ }\hbox {C}\) for 24 h and then ground again. This process of heat treatment and grinding was repeated again at temperatures of 1050 and \(1150^{\circ }\hbox {C}\) for 30 h each to obtain a single-phase polycrystalline LPCMO sample. The thin films of LPCMO (\({\sim }250\) Å) were deposited from the high density bulk targets on LAO (001) substrates using a PLD technique. The targets used for thin film deposition were prepared under the same conditions as the bulk LPCMO. A KrF excimer laser (\(\lambda = 248\ \hbox {nm}\), pulse width \(= 20\ \hbox {ns}\)) was used to ablate the bulk target with a laser energy density of \({\sim }4\ \hbox {J cm}^{-2}\). The PLD chamber was evacuated to a pressure of \(10^{-6}\) mbar before the deposition to remove any unwanted impurities. An oxygen partial pressure of 0.2 mbar and a substrate temperature of \(750^{\circ }\hbox {C}\) were maintained during the deposition. Post deposition annealing of the thin film was carried out at the same substrate temperature for 30 min in a 1000 mbar \(\mathrm{O}_{2}\) environment after which the film was allowed to cool naturally in the oxygen environment. To study the crystalline nature of the synthesized bulk and thin film samples, X-ray diffraction (XRD) measurements were performed using \(\hbox {Cu} \hbox {K}{\upalpha }\) (1.5406 Å) radiation at 8 KW on a rotating anode-based X-ray diffractometer operating in the Bragg–Brentano focussing geometry. Data were collected in the continuous scan mode at a scan speed of \(2^{\circ }\ \hbox {min}^{-1}\) and a step interval of \(0.02^{\circ }\). The microstructure of the samples was observed using scanning electron microscopy (SEM) on a FEG-SEM, Ziess instrument. Temperature and field dependent magnetizations of the samples were measured using the Oxford MPMS SQUID magnetometer.

3 Results and discussion

3.1 Structural properties

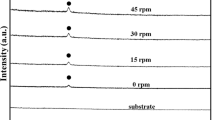

Figure 1a and b show room temperature XRD spectra of the LPCMO bulk and LPCMO/LAO thin film, respectively. All the peaks observed in the bulk XRD pattern can be indexed to PDF no. 01-072-7022 of the ICSD database. This confirms a single-phase polycrystalline growth with an orthorhombic unit cell. The lattice parameters calculated from the XRD pattern are found to be: \(a = 5.4417\) Å, \(b = 7.6783\) Å and \(c = 5.4391\) Å. In contrast, we observe a c-axis oriented epitaxial growth of the LPCMO thin film on the LAO substrate. The out-of-plane lattice parameter for the film obtained from the XRD measurements is found to be 3.912 Å. The equivalent pseudo-cubic lattice parameter for the bulk sample is \(\sim 3.84\) Å which clearly indicates an out-of-plane tensile strain in the thin film.

The surface microstructure and morphology for both the bulk and thin film samples were studied using SEM. Figure 2 shows the recorded SEM images of (a) the LPCMO bulk and (b) LPCMO/LAO thin film. A homogeneous distribution of irregularly shaped particles (see figure 2a) is observed in bulk LPCMO. A majority of small particles have agglomerated to form bigger particles and the particle size ranges from 2.5 to \(10\ \upmu \hbox {m}\). In the case of the LPCMO film on LAO, it is observed that the morphology is homogeneous but grainy. This is a typical feature of the LPCMO film grown on the LAO substrate and is well reported in the literature [16, 17]. Such an island growth mechanism is attributed to the deposition of a homogeneous wetting layer on the substrate which is topped by the growth of grains at evenly distributed nucleation sites.

3.2 Magnetic properties

The magnetic properties of both the samples were investigated using temperature (M–T) as well as field (M–H) dependent magnetization measurements. Figure 3 shows the temperature dependent magnetization plots recorded in zero-field cooling (ZFC), field cooled cooling (FCC) and field cooled warming (FCW) modes in a temperature range of 5–300 K. In the high temperature region (\({>}220\ \hbox {K}\)), both samples show a similar PM behaviour. As the temperature is reduced the M–T plots of the two samples show remarkable differences. A significant thermal hysteresis is visible between the FCC and FCW/ZFC curves in the M–T plot for the LPCMO bulk sample in the temperature range of 30–200 K, which indicates the presence of a first order phase transition and co-existence of insulating CO and metallic FM phases in this temperature range [6, 8, 12]. Moreover, the magnetization of bulk sample shows a two-step rise with a broad feature around 200 K followed by a plateau which indicates the onset and dominance of the CO-AFM phase. However, in the M–T plot of the LPCMO thin film on the LAO substrate (figure 3b) no thermal hysteresis is observed which indicates that the transition is of a higher order. Also, unlike the bulk case there is no indication of existence and dominance of different magnetic phases in different temperature ranges. A monotonic rise in magnetization is observed from around 170 K for the thin film case. In the low temperature region (\({<}50\ \hbox {K}\)) the FCW curve follows the FCC curve in both cases, while the ZFC curve shows an increase in magnetization with rise in temperature. This feature in the ZFC curve of both the samples is attributed to the unblocking of moments which get blocked in a metastable state on reduction of the temperature in the absence of magnetic field [18, 19].

Figure 4 presents the M–H isotherms for both the samples recorded at 5 K where the field is ramped up from 0 to 5 T and then reduced. It is to be noted that the samples were cooled from room temperature to 5 K in the absence of magnetic field. The saturation magnetization for the bulk sample is found to be \({\sim }3.7\ \upmu _{\mathrm{b}}\ \mathrm{per~Mn}\) while the thin film sample is not saturated even up to 5 T applied field. The major difference between the M–H plots of the bulk and thin film is the metamagnetic behaviour observed in the case of the bulk sample. While increasing the magnetic field, the magnetization first saturates around 1.6 T which corresponds to the alignment of all the FM moments in the sample [12, 20]. As the field is further increased, another rise in magnetization is observed which corresponds to the melting of the CO state into the FM state. The magnetization finally saturates at about 5 T. Once this transition takes place, the FM state continues to stay even when the external magnetic field is reduced. A similar two step rise in field dependent magnetization has been observed for \(\hbox {La}_{0.7-x}\hbox {Dy}_{x}\hbox {Ca}_{0.3}\hbox {Mn}_{0.97}\hbox {Fe}_{0.03}\hbox {O}_{3}\) which is also known to show phase co-existence [21]. The M–H plot for the LPCMO thin film on the LAO substrate shows no sign of stepwise transition and the metamagnetic behaviour. The magnetization here, unlike the bulk case, does not saturate even up to a 5 T field. The substrate induced strain in the thin film may be the reason for the observation of such a magnetic behaviour.

4 Conclusion

We have studied the structural and magnetic properties of LPCMO in its thin film and bulk form. XRD a confirmed single-phase polycrystalline nature of bulk sample and highly c-axis-oriented growth of thin film. We observe that reduction in dimensionality of LPCMO remarkably changes its surface morphology and magnetic properties. Both the samples show homogeneous growth with agglomerated particles of a micrometre range in the bulk sample and grainy island growth in the case of thin films. The temperature dependent magnetization measurements show a two-step rise and large thermal hysteresis in the magnetization which indicates the co-existence of FM and CO phase, while such signs cease to exist in the case of the thin film. The field dependent magnetization also shows significant variations, where again, a two-step metamagnetic behaviour is observed in bulk samples, indicating the presence of phase co-existence, while no such feature is observed for the thin film samples. The thin films deposited on LAO substrates are found to be highly strained, which may be one of the major factors contributing to such a huge variation in physical properties of thin film and bulk samples.

References

Salamon M B and Jaime M 2001 Rev. Mod. Phys.73 583

Dagotto E, Hotta T and Moreo A 2001 Phys. Rep.344 1

Uehara M, Mori S, Chen C H and Cheong S W 1999 Nature 399 560

Casa D, Kiryukhin V, Saleh O A, Keimer B, Hill J P, Tomioka Y et al 1999 Europhys. Lett.47 90

Kim K, Uehara M, Hess C, Sharma P and Cheong S-W 2000 Phys. Rev. Lett.84 2961

Uehara M and Cheong S W 2000 Europhys. Lett.52 674

Israel C, Wu W and De Lozanne A 2006 Appl. Phys. Lett.89 032502

Ghivelder L and Parisi F 2005 Phys. Rev. B–Condens. Matter Mater. Phys.71 1

Moritomo Y, Kuwahara H, Tomioka Y and Tokura Y 1997 Phys. Rev. B 55 7549

Kiryukhin V, Casa D, Hill J P, Keimer B, Vigliante A, Tomioka Y et al 1997 Nature 386 813

Sharma H, Lees M, Balakrishnan G, Paul D M, Tulapurkar A and Tomy C 2017 Mater. Chem. Phys.194 142

Kiryukhin V, Kim B G, Podzorov V, Cheong S-W, Koo T Y, Hill J P et al 2000 Phys. Rev. B 63 024420

Deac I G, Diaz S V, Kim B G, Cheong S-W and Schier P 2002 Phys. Rev. B 65 174426

Dwivedi G D, Kumar S, Joshi A G, Kumar S, Ghosh A K, Chou H et al 2017 J. Alloys Compd.699 31

Rao C N R and Raveau B 1998 Colossal Magnetoresistance Charge ordering and related properties of manganese oxides (Singapore: WorldScientic) ISBN: 978-981-02-3276-4

Nelson C S, Hill J P, Gibbs D, Rajeswari M, Biswas A, Shinde S et al 2004 J. Phys.: Condens. Matter 1 16

Zhang C, Su F, Dai J, Pi L, Mei H, Zhang P et al 2016 Jpn. J. Appl. Phys.3 55

Sharma P A, Kim S B, Koo T Y, Guha S and Cheong S W 2005 Phys. Rev. B 71 1

Singh S, Sharma G, Thakur M K, Siwach P K, Kumar Tyagi P, Maurya K K et al 2015 AIP Adv.5 027131

Bingham N S, Lampen P, Phan M H, Hoang T D, Chinh H D, Zhang C L et al 2012 Phys. Rev. B 86 1

Bhargava S C, Kunkel H P, Singh S, Malik S K, Buddhikot D D and Morrish A H 2005 Phys. Rev. B 71 104419

Acknowledgements

We would like to thank Mr V B Jayakrishnan from BARC, Mumbai for his help in recording the X-ray diffraction patterns. This work is partially supported by the Department of Science and Technology (DST), India via the DST INSPIRE Faculty research grant (DST/INSPIRE/04/2015/002938).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhatt, H., Kumar, Y., Prajapat, C.L. et al. A comparative study on phase co-existence of \(\hbox {La}_{1/4}\hbox {Pr}_{3/8}\hbox {Ca}_{3/8}\hbox {MnO}_{3}\) in a polycrystalline bulk and thin film. Bull Mater Sci 42, 267 (2019). https://doi.org/10.1007/s12034-019-1941-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1941-y