Abstract

In recent years the application of metal nanoparticles is gaining attention in various fields. The present study focuses on the additive effect of ‘green’ synthesized iron nanoparticles (FeNPs) on dark fermentative hydrogen (H2) production by a mesophilic soil bacterium Enterobacter cloacae. The FeNPs were synthesized by a rapid green method from FeSO4 using aqueous leaf extract of Syzygium cumini. The synthesized FeNPs showed a characteristic surface plasmon resonance peak at 267 nm. The transmission electron microscopy images confirm that the formation of FeNPs was mainly porous and irregular in shape, with an average particle size of 20–25 nm. The presence of iron (Fe) in the synthesized FeNPs was confirmed by energy-dispersive X-ray spectroscopy. The comparative effect of FeSO4 and FeNPs on batch fermentative H2 production from glucose was investigated. The fermentation experiments reveal that the percentage and yield of H2 in FeNPs supplementation were increased significantly than the control (no supplementation) and FeSO4 containing media. The maximum H2 yield of 1.9 mol mol−1 glucose utilized was observed in 100 mg l−1 FeNPs supplementation, with two-fold increase in glucose conversion efficiency. Thus, the result suggests that FeNPs supplementation in place of FeSO4 could improve the bioactivity of H2 producing microbes for enhanced H2 yield and glucose consumption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The green method of nanoparticle synthesis has received immense attention, and is a burning area of research since the last decade. Owing to their unique size-dependent physiochemical properties, metal and metal oxide nanoparticles get varied range of applications in biomedical, optics, mechanics and energy science.[1–3]A variety of physical and chemical methods have been reported for the synthesis of metal nanoparticles.[4–7]The necessity of expensive equipment or high energy in physical methods and use of toxic chemicals as well as hazardous by-products formation during chemical synthesis, upsurge the curiosity to find an alternate and safe approach. The green synthesis of nanoparticles using biological materials is considered as a cost-effective, nontoxic and eco-friendly approach.[8] Biological resources like microorganisms and plant extracts can be used as reducing agents.[9–11]The plant extract-mediated synthesis of nanoparticles is potentially advantageous over microorganisms because of simple, cost-effective, readily available and relatively reproducible.[12,13]Plant extracts generally reduce the metal ions in a shorter period of time than microbes. Depending upon the plant type and phytoconstituents concentration, nanoparticles are synthesized within a few minutes to hours.[14] In recent times, green synthesis of iron nanoparticles (FeNPs) of various shapes and sizes have been reported using green tea,[15]Murraya koenigii leaf extract,[16] soya bean sprouts and sorghum bran extract.[17] The above-mentioned nanoparticles were successfully applied in various fields like dye degradation, biohydrogen production and waste water treatment. In recent times, the synthesis of silver nanoparticles using leaf and bark extract of Syzygium cumini as reducing agent has been reported.[18,19]However, there are very few reports on the synthesis of FeNPs using aqueous leaf extract of S. cumini.

Hydrogen (H2) a sustainable energy source, considered as a promising substitute of fossil fuel. It is a clean fuel, as it produces only water instead of green house gases on combustion.[20] Among various methods of H2 production, dark fermentative process has been recognized as the most suitable because of its ecofriendly and energy efficient status.[21] However, the major challenge in this method is the low yield and slow production rate. Therefore, the search for a novel approach is required to accelerate the H2 production rate and enhance the yield. Micronutrients like iron and magnesium are well known for their involvement in the activation or function of many enzymes and co-enzymes, and are also vital for the growth of most microorganisms.[22] Hydrogenases, a group of metalloenzyme catalyses the H2 formation in a variety of microorganisms. They have very unique active sites and are classified based upon the active site metal composition as: [Fe], [Fe–Fe], and [Ni–Fe] hydrogenases.[23] Thus, the supplementation of suitable micronutrients is likely to enhance the activity of these enzymes for high H2 yield. Iron is generally used as a media component in the fermentation medium for H2 production. Mainly, iron is a component of ferredoxin which acts as an electron carrier in hydrogenases.[17] A few studies have reported on improved H2 yield and more substrate utilization by supplementing production media with metal nanoparticles.[2,3,24,25]In the present study a clean method is applied for the synthesis of FeNPs using water extract of the S. cumini leaf. The synthesized FeNPs is used as media supplement to enhance the dark fermentative H2 production by the isolated strain DH-89 in glucose-based batch fermentation.

2 Materials and methods

2.1 H 2 producing bacterial strain

The H2 producing bacterial strain was isolated from soil sample of paddy field from North-East India. For this, 1 g of the soil sample was serially diluted with 0.85% NaCl (w/v) and then plated on nutrient agar plates, incubated at 37∘C for 24 h. Different bacterial colonies based on their colony morphology were obtained and subsequently maintained as pure cultures for screening of potent H2 producers.

2.2 Preparation of leaf extract

Freshly collected S. cumini leaves were washed three times with water and air dried. The dried leaves were then grinded into fine powder. The extract was prepared by mixing 50 g of finely powdered leaf with 1 litre distilled water, followed by boiling for 10 min in boiling water bath. The extract was then filtered through Whatman No. 1 filter paper and the filtrate was used as reducing agent for nanoparticle synthesis.

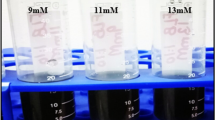

2.3 Synthesis of FeNPs using leaf extract

Different concentrations of leaf extracts and FeSO4 solution were reacted to obtain the optimum concentration for synthesis of FeNPs. In a typical synthesis, 25 ml of plant extract was slowly added to 475 ml of 1 mM FeSO4 solution with constant stirring for 10 min at room temperature. A visible colour change of FeSO4 from light yellow to dark black indicates the formation of FeNPs. The colloidal mixture was then centrifuged (12,000 rpm, 20∘C) for 10 min. The pellet was washed with distilled water and freeze dried for further use.

2.4 Characterization of the synthesized FeNPs

UV–visible spectrophotometer (Thermo Fischer Scientific, Evolution 201) was used to perform optical measurements. The UV–vis spectrum of FeNPs was taken in quartz cuvettes, using distilled water as a reference solvent. UV–visible analysis was carried out by continuous scanning from 200 to 600 nm. X-ray diffraction (XRD) patterns of the FeNPs were obtained by X-ray diffractometer (Miniflex, Rigaku Corporation Japan). The scanning was performed from 10∘ to 70∘ 2 𝜃 with 2 min−1 of scanning rate. For surface morphology study, scanning electron microscopy (SEM-JEOL JSM-6390 LV, Japan) and transmission electron microscopy (TEM–TECNAI G 20 S-TWIN, 200 kV) analysis were done. The elemental composition of the synthesized FeNPs was determined using energy-dispersive X-ray (EDX) spectrophotometer (JEOL-JSM 6390, Japan). Fourier transform infrared (FTIR) spectra of the aqueous leaf extract and FeNPs were analysed by FTIR spectrophotometer (Perkin Elmer 1000 FT-IR spectrometer).

2.5 Experimental procedure for dark fermentative H 2 production

Batch experiments were conducted for dark fermentative H2 production in 125 ml BOD bottle with a working volume of 100 ml under anaerobic condition at 37∘C. The fermentation medium was mineral salt medium (MSM), consisted of macronutrients (g l−1): (NH4)2SO4, 2; Na2HPO4, 2.61; KH2PO4, 4.75; MgSO4, 0.8; glucose, 10; and micronutrients (μg l−1): CaCl2, 500; MnSO4, 100; H3BO3, 10; ZnSO4, 70; and MoO3, 50. The pH of the medium was adjusted to 7.0 before autoclaving. The supplementation of FeSO4 and FeNPs in MSM was done in the range from 0 to 200 mg l−1 to evaluate and compare the effect on H2 production. After bacterial inoculation, the bottles were made air tight using glass stoppers and initial anaerobic condition was established by flushing nitrogen gas. The evolved gases from fermenters were collected by the water displacement method under acidic water. The gas collection and analysis were carried out till the gas production was ceased.[26]

2.6 Analytical methods

The evolved biogas during fermentation was measured through the water displacement method and analysed by gas chromatograph (Nucon GC5765) equipped with Porapak-Q and molecular sieve columns using thermal conductivity detector.[27] The operating temperatures of the oven, injector and the detector were set at 60, 80 and 110∘C, respectively. Argon served as carrier gas at a flow rate of 20 ml min−1. The concentration of glucose was estimated by the DNS method.[28] Cell growth was measured indirectly by measuring the protein content of whole-cell extract at the end of fermentation.[29]

3 Results and discussion

3.1 Screening and identification of H 2 producing bacterial strain

Purified bacterial isolates were screened for H2 production by the method described earlier for fermentation. In this study, strain DH-89 was selected on the basis of maximum biogas production during screening. Identification of the selected strain DH-89 was carried out by 16S rDNA gene sequencing analysis. Finally the sequence was submitted to the NCBI genebank and the strain was named as Enterobacter cloacae DH-89 strain (NCBI Accession no. KP723362).

3.2 Characterization of FeNPs

3.2.1 UV–vis spectroscopy and XRD study

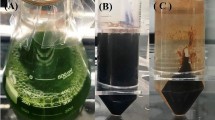

The formation of FeNPs was visually observed by change in colour of the parent precursor and reducing agent mixture (figure 1a) during the synthesis. Figure 1b shows the UV–vis spectra of the aqueous solution of FeSO4 and the synthesized colloidal material. A prominent difference can be observed in the spectra. The synthesized FeNPs showed absorption from 350 nm with a peak at 267 nm, which is typical for iron nanomaterials. The XRD pattern of the FeNPs (figure 2) is complex and shows several small intensity diffraction peaks. The prominent diffraction peaks can beindexed to α-FeOOH (JCPDS no. 29-0713), Fe2O3 (JCPDS no. 33-0664) and Fe3 O 4 (JCPDS no. 19-0629). Most of the peaks from the phases overlap each other. Since the peaks are not intense, it is difficult to determine the crystallite size using the Scherrer formula.

3.2.2 SEM, TEM, EDX and FTIR analysis

The morphology of the FeNPs was investigated by electron microscopy. Figure 3a shows the SEM image. It indicated the formation of random shaped aggregates of micron-sized particles. It can be attributed to uncontrolled nanoparticle agglomeration during the synthesis. This fact is clearly evident from the TEM images (figure 3b). It showed agglomerated clusters of nanoparticles of primary sizes in the range of 20–25 nm. Careful observation of the TEM images indicated that the material is porous. The EDX spectrum (figure 4) shows the elemental profile of FeNPs, primarily composed of C, O, S and Fe. The C and O are mainly from the compounds present in plant extracts, while Fe and S from the FeSO4 precursor. The elemental percentage was observed as 40.54% C, 50.82% O, 2.45% S and 6.19% Fe. The FTIR spectra of the plant extract and FeNPs are shown in figure 5. After comparing the spectra, it was observed that some peaks were shifted and missed. However, few additional peaks were also emerged in case of synthesized FeNPs. The peak positioned at 3428 cm−1 in the plant extract was shifted to 3421 cm−1 in case of FeNPs, similarly peaks at 1739, 1623 1392 and 1052 cm−1 were shifted to 1732, 1630, 1334 and 1020 cm−1, respectively. The peak at 1456 cm−1 in plant extract was found missing in the synthesized FeNPs and emergence of new peaks were observed at 618, 520 and 468 cm−1. The absorption peaks observed in the range of 1800–1500 cm−1 can be assigned as peak due to double bond stretching between C=O and C=C. The peaks observed in the range of 1400–1000 cm−1 can be assigned due to stretching vibration of single bond between C–O and N–H. These stretching’s arises from the organic moieties of the plant extract present in the synthesized FeNPs. The absorption band at 468 and 520 cm−1, in case of FeNPs correspond to the Fe–O stretches of Fe2O3 and Fe3O4.[30,31]

3.3 Effects of FeSO4 and FeNPs on batch fermentative H 2 production

The effects of FeSO4 and FeNPs on fermentative H2 production using E. cloacae DH-89 are shown in figure 6. It was found that the H2 production increases on the addition of both the form of iron. The H2 production in the control (no supplementation) was 950 ml l−1 of fermentation media, which was noticeably increased by supplementation of FeSO4 at a concentration of 25 mg l−1 and then decreased with further increase in the concentration from 50 to 200 mg l−1. With the optimum concentration of 25 mg l−1 FeSO4 supplementation the H2 production was increased to 1600 ml l−1. The addition of high concentration of FeSO4 (above 25 mg l−1) suppressed the activity of bacterium, consequently a low H2 production. A similar kind of result, i.e., the higher concentration of FeSO4 addition decreases the H2 production has been reported.[16] However, supplementation of green synthesized FeNPs in place of FeSO4 was found to further increase the H2 production. The maximum H2 production of 2100 ml was achieved at 100 mg l−1 FeNPs supplementation and it was decreased by increasing the concentration above 100 mg l−1. The present finding suggests that the supplementation of iron can be replaced by iron-based nanoparticles for better H2 production. The fact is that, iron is a fundamental component of ferredoxin, which acts as an electron carrier in the hydrogenases, responsible for H2 production. Hence, at a certain concentration of iron or FeNPs supplementation increases the ferredoxin activity during the fermentation process, which leads to enhanced H2 production.[32,33]

3.4 Effects of FeSO 4 and FeNPs on H 2 yield, glucose conversion efficiency and cell growth

The experimental data for the effects of FeSO4 and FeNPs on H2 yield and glucose consumption efficiency are shown in figure 7a. Without any iron supplementation, the H2 yield was 0.95 mol mol−1 glucose utilized, which was increased to 1.45 mol mol−1 glucose utilized with supplementation of 25 mg l−1 FeSO4. Further it was decreased with increasing the FeSO4 concentration above 25 mg l−1. However, supplementation of FeNPs results into two-fold increase in the H2 yield as compared to control. The yield was observed 1.9 mol mol−1 glucose utilized with 100 mg l−1 FeNPs. The percentage of H2 in the evolved biogas was found maximum (55%) with optimum concentration of FeNPs supplementation (figure 7b). Table 1 shows the experimental data for cell growth and glucose conversion efficiency. The cell growth was observed maximum in case of FeNPs supplementation as compared to control as well as FeSO4 supplementation. The conversion efficiency (%) is a measure of practical conversion of glucose to H2 during fermentation. Theoretically, 1 mol of glucose produce 4 mol of H2, considered as conversion efficiency value of 100%.[34] A two-fold increases in conversion efficiency was observed in FeNPs supplementation as compared to the control. The maximum conversion efficiency of 47.5% was observed at 100 mg l−1 FeNPs supplementation. The results suggest that the FeNPs supplementation also improves the metabolic process of glucose by the bacterial strain resulted into higher carbon flux for H2 production.

4 Conclusions

In this present study, isolation and identification of soil bacterium E. cloacae DH-89 was done for fermentative H2 production. The strain can produce H2 by batch fermentation with a yield of 0.95 mol mol−1 glucose consumed. The efficiency of the strain for H2 production was increased by iron supplementation in the fermentation media. The iron supplementation was done with FeSO4 and FeNPs. The successfully synthesized FeNPs using aqueous leaf extract of S. cumini was characterized and this method can be used for rapid green synthesis of FeNPs. The synthesized FeNPs supplementation with a concentration of 100 mg l−1 was observed to enhance the H2 production potential of the bacterium by two-fold with increasing glucose consumption rate and cell biomass yield.

References

Mody V V, Siwale R, Singh A and Mody H R 2010 J. Pharm. Bioallied Sci. 2 282

Zhao W, Zhang Y, Du B, Wei D, Wei Q and Zhao Y 2013 Bioresour. Technol. 142 240

Mullai P, Yogeswari M K and Sridevi K 2013 Bioresour. Technol. 141 212

Farrell D, Majetich S A and Wilcoxon J P 2003 J. Phys. Chem. B 107 11022

Koltypin Y, Perkas N and Gedanken A 2004 J. Mater. Chem. 14 2975

Choi C J, Tolochko O and Kim B K 2002 Mater. Lett. 56 289

Xiaomin N, Xiaobo S, Huagui Z, Dongen Z, Dandan Y and Qingbiao Z 2005 J. Cryst. Growth 275 548

Mahdavi M, Namvar F, Ahmad M B and Mohamad R 2013 Molecules 18 5954

Ahmad A, Mukherjee P, Mandal D, Senapati S, Khan M I, Kumar R and Sastry M 2002 J. Am. Chem. Soc. 124 12108

Ahmad A, Senapati S, Khan M I, Kumar R and Sastry M 2003 Langmuir 19 3550

Mittala A K, Chisti Y and Banerjee U C 2013 Biotechnol. Adv. 31 346

Iravani S 2011 Green Chem. 13 2638

Gupta K, Hazarika S N, Saikia D, Namsa N D and Mandal M 2014 Mater. Lett. 125 67

Rai M, Yadav A and Gade A 2008 Crit. Rev. Biotechnol. 28 277

Shahwan T, Sirriah S A, Nairat M, Boyaci E, Eroğlu A E, Scott T B and Hallam K R 2011 Chem. Eng. J. 172 258

Mohanraj S, Kodhaiyolii S, Rengasamy M and Pugalenthi V 2014 Appl. Biochem. Biotechnol. 173 318

Cai Y, Shen Y, Xie A, Li S and Wang X 2010 J. Magn. Magn. Mater. 322 2938

Gupta K, Barua S, Hazarika S N, Manhar A K, Nath D, Karak N, Namsa N D, Mukhopadhyay R, Kalia V C and Mandal M 2014 RSC Adv. 4 52845

Prasad R and Swamy V S 2013 J. Nanopart. 2013 1

Patel A K, Debroy A, Sharma S, Saini R, Mathur A, Gupta R and Tuli D K 2015 Bioresour. Technol. 175 291

Patel S K S, Kumar P, Singh M, Lee J K and Kalia V C 2015 Bioresour. Technol. 176 136

Liu B F, Ren N Q, Ding J, Xie G J and Guo W Q 2009 Int. J. Hydrogen Energy 34 721

Kim D H and Kim M S 2011 Bioresour. Technol. 102 8423

Mohanraj S, Anbalagan K, Kodhaiyolii S and Pugalenthi V 2014 J. Biotechnol. 192 87

Zhang Y and Shen J 2007 Int. J. Hydrogen Energy 32 17

Porwal S, Kumar T, Lal S, Rani A, Kumar S, Cheema S, Purohit H J, Sharma R, Patel S K S and Kalia V C 2008 Bioresour. Technol. 99 5444

Patel S K S, Singh M, Kumar P, Purohit H J and Kalia V C 2012 Biomass Bioenergy 36 218

Miller G L 1959 Anal. Chem. 31 426

Sparling R, Islam R, Cicek N, Carere C, Chow H and Levin D B 2006 Can. J. Microbiol. 52 681

Chen Z X, Jin X Y, Chen Z, Megharaj M and Naidu R 2011 J. Colloid Interface Sci. 36 601

Prasad K S, Gandhi P and Selvaraj K 2014 Appl. Surf. Sci. 317 1052

Wang J and Wan W 2008 Int. J. Hydrogen Energy 33 1215

Yang H and Shen J 2006 Int. J. Hydrogen Energy 31 2137

Abdeshahian P, Al-Shorgani N K N, Salih N K M, Shukor H, Kadier A, Hamid A A and Kalil M S 2014 Int. J. Hydrogen Energy 39 12524

Acknowledgements

This research work was financially supported by Department of Biotechnology (Ref. No. BT/212/NE/TBP/2011 dated December 14, 2011), New Delhi, India. Mr D Nath is thankful to CSIR, India, for providing research fellowship (Award no. 09/796/0060/2015-EMR-1). We also acknowledge the help extended by Tezpur University, Assam, India, by providing infrastructure and other necessary facilities to carry out the research work successfully.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

NATH, D., MANHAR, A.K., GUPTA, K. et al. Phytosynthesized iron nanoparticles: effects on fermentative hydrogen production by Enterobacter cloacae DH-89. Bull Mater Sci 38, 1533–1538 (2015). https://doi.org/10.1007/s12034-015-0974-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0974-0