Abstract

Fischerella sp. is a valuable source of active metabolites, including UV-protecting compounds, among which mycosporin-like amino acids (MAAs) can be mentioned. Mycosporine-like amino acids are attractive secondary metabolites of a wide range of microorganisms, including microalgae and cyanobacteria. Enhanced production of MAAs has been studied in different sources. This study aimed to optimize the phosphate and nitrate concentrations of the culture medium on BG11 to maximize MAAs production from Fischerella sp. F5, using response surface methodology. The extraction process from the cultures, grown in adjusted conditions, was also optimized. The results confirmed that increasing both, nitrate and phosphate concentration, in the culture medium had a positive effect on the MAAs production by Fischerella sp. F5. While, optimization of the extraction process was not led to a highly accurate predictive model; temperature, sonication time, methanol ratio, and solvent/biomass ratio exhibited significant effects on the final MAAs’ concentration in partially purified extracts. In general, more optimization cultures studies need to complete these findings in reference to MAAs production and extraction from Fischerella sp. F5, for commercial-scale applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mycosporin-like amino acids (MAAs) are bioactive secondary metabolites of a wide range of organisms, including macro- and micro-algae and cyanobacteria to show ultraviolet (UV)-absorbing properties. MAAs can be specially produced in highly UV-irradiated environments [1]. These natural protective compounds are low molecular weight chemicals and they commonly are less than 400 Da, water-soluble, and colorless. Meanwhile, cyanobacteria have been recognized as a significant source of MAAs, and initially in 1969 was reported as high production of MAAs in cyanobacteria for Microcoleus [2].

Nowadays, eco-friendly and eco-sustainable products have become more attractively well-known to consumers [3]. As for sunscreens, a growing number of consumers are becoming aware of the harmful effects of synthetic UV filters on ecosystems [4, 5]. Accordingly, requests for cosmetic products with biocompatible ingredients are increasing every single day; and MAAs have been introduced as the most-studied natural UV-absorbing agents with many beneficial effects on the skin [6, 7]. They are considered a promising alternative active ingredient for synthetic chemical sunscreens [3, 8]. In that, this growing global demand is driving the cosmetics industry to invest more in the research and development of natural algae-based products [9]. As a consequence, it seems as an essential to detect the parameters that increase the production yield of MAAs. Interestingly, MAAs have been used in emulsions for protecting plant organs, fruits, and vegetables against sunscald while they are safe and biodegradable [10]. Optimizing the culture conditions for better growth of MAA-producing microorganisms and enhancing MAA production are the preliminary steps toward expanding the market for MAAs, as natural UV-absorbing agents.

Previous studies have indicated that various Fischerella species can generate a remarkable variety of natural products, including antifungal alkaloids, algicidal fischerellins, and ambigols, which are used as antimicrobial agent [11]. A few studies only have demonstrated MAA biosynthesis or the presence of MAA gene clusters in certain Fischerella species. In one of these studies, Rastogi and Incharoensakdi (2015) revealed the production of MAA in Fischerella muscicola under UVR induction and it was shown that the produced MAA might be shinorine methyl ester, regarding its mass spectra and other physicochemical properties [12]. Yang et al. (2018) reported a functional shinorine gene cluster in Fischerella sp. PCC9339 and it has been used for heterologous expression in a genetically engineered strain of Synechocystis sp., to improve MAA biosynthesis [13]. Recently, Geraldes et al. (2020) screened 69 Brazilian cyanobacterial strains for their capability to produce MAAs, and among them, Fischerella sp. (CENA161) was reported as a promising source that produced shinorine [14]. Similarly, the previous study proved that two Fischerella species (collected in Iran) could produce MAAs [15].

Moreover, it has been approved that different conditions can affect MAAs production by microalgae and cyanobacteria, e.g., the effect of UV irradiation on MAA production. A recent study showed that enhanced irradiation could augment the production of MAAs in the sun-type red algal genus Porphyra [16]. Similarly, Guihéneuf et al. (2018) reported that increasing the daily light doses and irradiance levels, such as what happened in season changes from winter to spring, could result in the improvement of total MAA contents in Palmaria palmata, Chondrus crispus, and Porphyra dioica; however, there were not significant correlations between light and/or temperature and MAAs production [17]. Similarly, UVB irradiation could stimulate greater production of MAAs in Lyngbya purpurem UTEX LB 2716 [18].

Culture nutrients also affect the production level of MAAs. This was shown in various microalgae and cyanobacteria, including the green microalga Desmodesmus sp. that produced MAAs only after the addition of sodium chloride to its culture medium [19]. Moreover, optimization of nitrate and phosphate concentration could also improve the production level of MAAs in Chlorella Vulgaris [20], the red agarophyte Gracilaria tenuistipitata [21], or some types of Brazilian red marine algae [22].

Fischerella sp. F5 has been previously verified by our previous research study as an expected source of MAAs [15]. Hence, this experimental study aimed to optimize the effect of nitrate and phosphate concentrations on the production of MAAs, and also determine the optimum purification method towards increasing the MAAs purification yield.

Materials and Methods

Cultivation of Fischerella sp. F5

Fischerella sp. F5 as a strain of Fischerella spp. was genetically identified at Protein Technology Research Center of Shahid Beheshti University of Medical Silences, Iran (Accession No. OR228690) [15]. 2 mL of stocked culture were cultivated in 20 mL of BG-11 culture medium with different concentrations of nitrate and phosphate, based on experimental design. The chemical ingredients of BG11 medium were supplied from Merck Chemicals (Germany). All samples were cultured in BG11 medium [23] for 28 days at room temperature and natural sunlight UV irradiation and then, MAA content was extracted. The details of BG11 composition were presented in Table 1.

Extraction and Partial Purification of MAA

MAA extraction was conducted following Rastogi et al. (2016) [24]’s method with minor modifications to the procedure [19]. The culture medium was centrifuged for 10 min at 6700×g and then, the supernatant was removed. The precipitated biomass was suspended in a small amount of deionized water (DW) and lyophilized. In the next phase, 10 mg of dried biomass, which per-moisturized with one mL DW, was extracted overnight by 10 mL of absolute methanol (HPLC grade) at 4 °C and in dark condition. Before overnight incubation, a sonication step at 35 °C for 15 min was applied using an ultrasound bath (S 60 H, Elma, Germany). Right the next day, the mixture was centrifuged for 10 min at 6700×g. The supernatant was collected and dried. Subsequently, it was dissolved in distilled water and centrifuged at 13,200×g to remove the insoluble impurities in the water. The supernatant was decanted against 500 µL of chloroform and centrifuged again at 13,200×g. Finally, the upper aquatic phase was collected and filtered using a 0.22 μm syringe filter (MS® PTFE Syringe Filter), before being injected into the HPLC column.

Characterization of MAAs

HPLC was performed on a C18 HPLC column (5 μm, 25 × 4.6 mm), equipped with a photodiode array (PDA) detector, which scanned 200–800 nm (SPD-M10A-Shimadzu, Kyoto, Japan). The isocratic mobile phase contained 25% aqueous methanol plus 0.1% acetic acid (HPLC grade) at a flow rate of 1 mL/min. MAAs compounds were detected at 330 nm.

Experimental Design

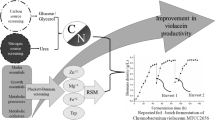

The response surface methodology, using Design-Expert software version 2.0.1.0, was used to simultaneously optimize nitrate and phosphate (quantitative) concentrations. The central composite design (CCD) was applied to maximize MAAs production by Fischerella sp. F5. The characteristics of study factors, are shown in Table 2.

Fourteen runs of 30-day cultures, in two blocks, were designed to optimize the range and levels of nitrate and phosphate concentrations. The MAAs content, as the primary response, was calculated based on the area under the curve (AUC) of associated peaks, extracted from the MAAs HPLC chromatograms. Additionally, dried biomass weight was measured and applied as the second response for the optimization process. For the optimization of MAAs extraction process, five factors including the solvent type and volume (solvent/biomass ratio), sonication time, extraction temperature, and duration were considered. Quantitative measures were used to measure all factors. The central composite design (CCD) method was applied. A total number of 32 experiments in two blocks were run. Lastly, 2FI was the best model to predict the fractional effects of factors. The factors’ features are presented in Table 2.

Validation of the Model

To validate the predicted model, two optimum cultures were run and analyzed. These runs were 30-day cultures, and the purification of MAAs was performed similar to the previous runs. The growth curves of Fischerella sp. F5 under both conditions (normal and optimized) were derived using two series of thirty falcons containing 10 mL cultures of Fischerella sp. F5, which were sampled on a daily basis. The initial inoculum consist of 1 mL of a 25-day culture of Fischerella sp. F5 was applied.

Statistical Analysis

The experiments were designed by Design Expert software using Response Surface Methodology. Experiments were run in two blocks. The value of correlation (R2) indicated the quality of the developed model; and the analysis of variance (ANOVA) was conducted to evaluate the statistical significance of the model. The significant level was considered at p ≤ 0.05.

Results

Optimization of Culture Nutrients

HPLC Analysis of Partially Purified MAAs from each Experiment

A total of 14 samples including partially purified extracts of the cultures that had grown under predetermined conditions were analyzed by HPLC and the data regarding retention times (Rt) and the AUC of MAAs peaks were shown in Table 3.

The HPLC chromatogram of run 1 was seen in Fig. 1. The main peak, with a retention time (Rt) of 2.929 min, had a maximum absorption at 330–340 nm, which earlier reported in a preliminary study of MAA production of this species [15]. However, in run 3, which contained none of phosphate and nitrate ingredients, the amount of MAAs content and purity identified in extracted samples were at the lowest value. The HPLC chromatogram of 3rd run was shown in Fig. 2. The peaks numbers, with maximum absorption between 300 and 400 nm, were increased that might indicate the presence of several MAA structures with close physicochemical characteristics.

Modeling of the Culture Nutrients and Optimization of MAAs Production

All AUCs of the peaks with maximum absorption between 300 and 400 nm were accumulated and considered as the total MAAs content. The best model [1] with Adjusted R2 equal to 0.81 was calculated. The Model F value was 17.50, which implied that the model was significant. The results revealed the model was significant (p = 0.0004). In this case, A, B, and AB were significant model terms as Eq. 1 shows.

For maximizing the biomass, another model was predicted (Eq. 2). The Model F value was 16.77, which implied that the model was significant. P values of 0.0009 indicated the model was significant. In this case, A, B, A2, and B2 were significant model terms [2].

In Eqs. 1 and 2, A and B were phosphate and nitrate concentrations, respectively.

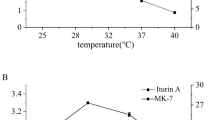

The best culture condition for maximum production of MAAs was reported in Table 4. The 3D surface model for the maximum production of MAAs was presented in Fig. 3.

The Optimized Culture Validation

The culture under the optimum condition (including 0.235 g/L of phosphate salt and 4.622 g/L of nitrate salt) and extraction process were performed. HPLC analysis of partially extracted MAAs showed a different pattern (Fig. 4). The main peak was seen around 3 min and there were at least four compounds with maximum absorption at 330–340 nm, although, all of them had similar maximum absorption wavelengths. Comparison of the growth curves of Fischerella sp. F5 cultured in normal and optimized conditions revealed a relatively increase in the growth and biomass production (Fig. 5).

Optimization of MAAs Extraction Process

HPLC Analysis of Partially Purified MAAs from each Experiment

The culture under the optimum condition was performed and the extraction process was optimized by running 32 experiments, which were designed by 1/2 factorial design, considering five factors of time, temperature, sonication time, methanol ratio, and solvent volume. HPLC analysis of extracted samples was performed similar to the previous optimization process on the culture condition. Experiment features and results obtained from HPLC analysis were reported in Table 5.

Modeling of the Extraction Process and Optimization of MAA Partial Purification

The best model (Eq. 3) with Adjusted R2 equal to 0.72 was calculated. The Model F value was 6.05, which implied the significance of the model. A P value of 0.0006 indicated that the model was significant. In this case, B, C, D, E, AC, AE, BE, and CD were significant model terms.

In Eq. 3, A, B, C, D, and E were the time of extraction process, temperature, sonication time, methanol ratio, and solvent volume in the extraction process, respectively.

The best model had R2 around 0.7 for MAA% and the numbers of MAA compounds and a significant model could not be adopted to data. The best predicted extraction process and the anticipated values for each factor were reported in Table 6.

Discussion

This study aimed to optimize the MAAs production and extraction as a natural sun-protective agent. Different organisms have developed unique chemical adaptations to confront the detrimental effects of the sun's ultraviolet radiation. Melanin in animals and humans, flavonoids in higher plants, and scytonemin and mycosporine-like amino acids (MAAs) in organisms dwelling in the marine environment; all are secondary metabolites produced to act as UV-absorbing agents in these species [25]. Using these natural UV protectants has been expanding in recent years. Therefore, finding new sources and optimizing the production and extraction of effective ingredients are attractive fields of study. In the current study, MAAs were considered as potent natural UV protectants, which used in sunscreens, and their production and extraction in Fischerella sp. F5, as one of MAAs source, was optimized using response surface methodology.

Regarding nutrient availability, nitrogen and phosphorus as the macronutrient, and iron as the micronutrient, are considered to be the most important resources affecting cyanobacterial growth. In a recent study on two N2-fixing cyanobacteria, it was observed that in Halothece sp., nitrate is the limiting factor, and a decreasing concentration of nitrate had a negative effect on its growth, while it was less influenced by phosphate or iron concentrations. On the contrary, Fischerella muscicola’s growth, was unaffected by the decrease in nitrate concentration, but phosphate and iron were more restrictive components in its growth [26].While increasing the initial nitrate concentration resulted in enhanced MAA biosynthesis by Glenodinium foliaceum, it had opposite effect on increasing the initial phosphate concentration.. It should be mentioned that the nitrate and phosphate content of algal culture media had various effects on MAAs production and the composition of accumulated MAAs [27].

The findings revealed that increasing nitrate and phosphate concentrations had a positive effect on the MAAs production by Fischerella sp. F5. Concerning the best model fitted to data, increasing two-fold of nitrate and phosphate concentration resulted in a 2.64 and 2.28-fold increase in MAAs content, respectively. However, there was a superior effect of nitrate on the MAAs production compared to phosphate. Both nitrate and phosphate optimum concentrations were higher than their concentration in common BG11 culture medium composition (in which NaNO3 is 1.5 g/L and K2HPO4 is 0.04 g/L). Similarly, Saadatmand and Zamani (2015) found that increasing of nitrate and phosphate concentrations could significantly enhance MAAs production by Spirulina platensis. They clarified that optimizing the macronutrients of culture medium, like nitrate and phosphate, could change the photosynthesis pathways and stimulating shikimate pathway in increment of the UV absorbing metabolites such as MAAs [28]. Moreover, the characterization of MAAs from red marine algae of the Brazilian coast exhibited that high concentrations of phosphate and nitrate could enhance MAA contents [22].

Indeed, in certain cyanobacterial strains, phosphate-limited conditions are in favor of higher MAAs production. However, the increased nutrient availability caused better growth, in general [29]. In contrast to Glenodinium sp., Lyngbya purpureum was shown to produce more MAAs in a lower nitrogen concentration (0.3 mM compared to 1 mM) [30]. Therefore, it can be concluded that various microalgae and cyanobacteria species have responded different nutrient availability which resulted in varieties in growth patterns. In that, some cyanobacteria demand high concentrations of nitrogen and phosphate to grow better, while others prefer low-nutrient conditions [31].

Volkmann and Gorbushina developed a universal method for the extraction and characterization of mycosporines and mycosporine-like amino acids of terrestrial, marine, and freshwater origin. The process included 20 mg of dried microorganism biomass suspended in 1 mL of 0.2% aqueous acetic acid with 0.5% methanol (v/v), followed by 10 s vortexing, and incubation at 4 °C for 12 h on a vertical shaker. The extracted samples were then centrifuged at 14,000×g, 5 min and the supernatants were filtered through 0.2 μm syringe filters. Final extracts were analyzed by HPLC and LC/MS/MS. The study approach was used for simultaneous extraction and analysis of MAAs. They could efficiently extract and detect glycosylated MAAs by HPLC, which were identified at the retention times of upper than 10 min [32]. However, in current study, MAAs extraction was performed followed the Rastogi et al. (2016) method [24, 33] with minor modifications including using methanol as extraction solvent, followed by chloroform decanting to remove impurities, such as proteins, from MAAs partially purified extract. The structural analysis was performed by HPLC using 25% aqueous methanol and 0.1% acetic acid as mobile phase.

Generally, a typical MAAs extraction was performed using absolute ethanol, up to ethanol 50%, or absolute methanol up to 20% in aquatic solution [1]. Ngoennet et al. (2018) reported a simple method for the MAAs extraction from the halotolerant cyanobacterium Aphanothece halophytica. They suspended the organism's cells in methanol and sonicated them using an ultrasound probe homogenizer. Then, the extraction mixture was centrifuged and the supernatant was dried using a rotary evaporator. Then, dried extract was solved in water, and decanted against chloroform to remove coloring compounds [34]. Another study reported that the extraction with water could increase the MAAs yields by twofold compared to absolute methanol. This study showed that 6 h extraction with water could lead to the best yield of MAAs extraction [35].

Here, we considered a similar strategy, and the factors involved in the extraction, including time, temperature, sonication time, methanol concentration, and solvent volume, were optimized. Results confirmed, except the time, all other factors could significantly affect the MAAs extraction yield. The best-predicted process would include extraction in 30 mL of 80% methanolic solution for 41 h at 50 °C, after 30 min sonication. In a similar study, Sultani et al. investigated the effect of different solvent including 100% and 20% methanol, 70% ethanol, distilled water and 100% ethyl acetate and the temperatures of 4 °C and 45 °C on the MAAs extraction from the cyanobacterium Leptolyngbya fragilis and red algae Hypnea musciformis. They found the best extraction form the cyanobacterium L. fragilis was when using the 100% ethyl acetate at 4 °C, and for red algae H. musciformis was in the 20% methanol extract at 45 °C [36].

It seemed that increasing the sonication time followed by incubation at higher temperature decreased the MAAs yield in the final extract, which probably resulted in MAAs instabilities against long time ultrasound exposure. Nevertheless, it was reported that MAAs were highly stable structures, such as MAAs extracted from the cyanobacterium Gloeocapsa sp. CU-2556. [37], Nostoc sp. R76DM [24], or cyanobacterium Lyngbya sp. [33], which all were stable against physicochemical stressors, including UV radiation, pH, heat, and a strong oxidizing agent.

Conclusion

The differences between cyanobacterial species should be considered for the optimization of their growth, as well as, the optimization of MAAs production, particularly for industrial scale. In this study, MAAs production by Fischerella sp. F5 was optimized, considering nitrate and phosphate concentrations in the culture medium, using response surface methodology. The optimized culture condition exhibited a slightly different HPLC pattern of partially purified MAAs compared to the culture in common BG11 medium. It should be well-thought-out that only the concentrations of two main macronutrients of cyanobacterial culture medium were optimized in present study, and the concentrations of other macro or micronutrients may also have partial effect on cyanobacterium growth or its MAA production. Further studies are needed to determine all influential factors in MAAs production, also. Subsequently the optimization of extraction process, based on the most important parameters in MAA extraction revealed that the optimum features to maximize the extraction yield are temperature, sonication time, and solvent type and volume. These factors significantly could affect the yield of MAAs extraction.

Data Availability

The data that support the findings of this study are available on request from the corresponding author.

References

Geraldes, V., & Pinto, E. (2021). Mycosporine-like amino acids (MAAs): biology, chemistry and identification features. Pharmaceuticals, 14(1), 63. https://doi.org/10.3390/ph14010063

Jain, S., Prajapat, G., Abrar, M., Ledwani, L., Singh, A., & Agrawal, A. (2017). Cyanobacteria as efficient producers of mycosporine-like amino acids. Journal of Basic Microbiology, 57, 715–727. https://doi.org/10.1002/jobm.201700044

Santiesteban-Romero, B., Martínez-Ruiz, M., Sosa-Hernández, J. E., Parra-Saldívar, R., & Iqbal, H. M. (2022). Microalgae photo-protectants and related bio-carriers loaded with bioactive entities for skin applications—An insight of microalgae biotechnology. Marine Drugs, 20, 487. https://doi.org/10.3390/md20080487

Galamgam, J., Linou, N., & Linos, E. (2018). Sunscreens, cancer, and protecting our planet. The Lancet Planetary Health, 2, e465–e466. https://doi.org/10.1016/S2542-5196(18)30224-9

Schneider, S. L., & Lim, H. W. (2019). Review of environmental effects of oxybenzone and other sunscreen active ingredients. Journal of the American Academy of Dermatology, 80, 266–271. https://doi.org/10.1016/j.jaad.2018.06.033

Suh, S.-S., Hwang, J., Park, M., Seo, H. H., Kim, H.-S., Lee, J. H., Moh, S. H., & Lee, T.-K. (2014). Anti-inflammation activities of mycosporine-like amino acids (MAAs) in response to UV radiation suggest potential anti-skin aging activity. Marine Drugs, 12, 5174–5187. https://doi.org/10.3390/md12105174

Hartmann, A., Gostner, J., Fuchs, J. E., Chaita, E., Aligiannis, N., Skaltsounis, L., & Ganzera, M. (2015). Inhibition of collagenase by mycosporine-like amino acids from marine sources. Planta Medica, 81, 813–820. https://doi.org/10.1055/s-0035-1546105

Sen, S., & Mallick, N. (2021). Mycosporine-like amino acids: Algal metabolites shaping the safety and sustainability profiles of commercial sunscreens. Algal Research, 58, 102425. https://doi.org/10.1016/j.algal.2021.102425

Ariede, M. B., Candido, T. M., Jacome, A. L. M., Velasco, M. V. R., de Carvalho, J. C. M., & Baby, A. R. (2017). Cosmetic attributes of algae—A review. Algal Research, 25, 483–487. https://doi.org/10.1016/j.algal.2017.05.019

Pedrosa, V. M., Sanches, A. G., da Silva, M. B., Gratão, P. L., Isaac, V. L., Gindri, M., & Teixeira, G. H. (2022). Production of mycosporine-like amino acid (MAA)-loaded emulsions as chemical barriers to control sunscald in fruits and vegetables. Journal of the Science of Food and Agriculture, 102, 801–812. https://doi.org/10.1002/jsfa.11415

Wright, A. D., Papendorf, O., & König, G. M. (2005). Ambigol C and 2, 4-dichlorobenzoic acid, natural products produced by the terrestrial cyanobacterium Fischerella ambigua. Journal of Natural Products, 68, 459–461. https://doi.org/10.1021/np049640w

Rastogi, R. P., & Incharoensakdi, A. (2015). Occurrence and induction of a ultraviolet-absorbing substance in the cyanobacterium Fischerella muscicola TISTR8215. Phycological Research, 63, 51–55. https://doi.org/10.1111/pre.12069

Yang, G., Cozad, M. A., Holland, D. A., Zhang, Y., Luesch, H., & Ding, Y. (2018). Photosynthetic production of sunscreen shinorine using an engineered cyanobacterium. ACS Synthetic Biology, 7, 664–671. https://doi.org/10.1021/acssynbio.7b00397

Geraldes, V., Jacinavicius, F. R., Genuário, D. B., & Pinto, E. (2020). Identification and distribution of mycosporine-like amino acids in Brazilian cyanobacteria using ultrahigh-performance liquid chromatography with diode array detection coupled to quadrupole time-of-flight mass spectrometry. Rapid Communications in Mass Spectrometry, 34, e8634. https://doi.org/10.1002/rcm.8634

Tabarzad, M., Baktash, S., Atabaki, V., & Hosseinabadi, T. (2021). Primary assessment of mycosporine-like amino acids production by two species of Fischerella sp. Iranian Journal of Pharmaceutical Research, 20, 405–414. https://doi.org/10.22037/ijpr.2021.115100.15194

Figueroa, F. L., Escassi, L., Pérez-Rodrı́guez, E., Korbee, N., Delia Giles, A., & Johnsen, G. (2003). Effects of short-term irradiation on photoinhibition and accumulation of mycosporine-like amino acids in sun and shade species of the red algal genus Porphyra. Journal of Photochemistry and Photobiology B: Biology, 69, 21–30. https://doi.org/10.1016/S1011-1344(02)00388-3

Guihéneuf, F., Gietl, A., & Stengel, D. B. (2018). Temporal and spatial variability of mycosporine-like amino acids and pigments in three edible red seaweeds from western Ireland. Journal of Applied Phycology, 30, 2573–2586. https://doi.org/10.1007/s10811-018-1436-z

Chandra, R., Pons-Faudoa, F. P., Parraaldívar, R., & Rittmann, B. E. (2020). Effect of ultra-violet exposure on production of mycosporine-like amino acids and lipids by Lyngbya purpurem. Biomass and Bioenergy, 134, 105475. https://doi.org/10.1016/j.biombioe.2020.105475

Gharib, R., Tabarzad, M., & Hosseinabadi, T. (2020). Effect of high salinity on mycosporine-like amino acid production in Desmodesmus sp. trends pept. Protein Science, 5, 1–6. https://doi.org/10.22037/tpps.v5i0.28876

Hosseinabadi, T., Gharib, R., Salehian, S., & Tabarzad, M. (2022). A study on the effect of nitrate and phosphate concentrations on the production of mycosporine-like amino acids by Chlorella vulgaris. Iranian Journal of Biotechnology, 20, 66–76. https://doi.org/10.30498/ijb.2022.313739.3194

Barufi, J. B., Korbee, N., Oliveira, M. C., & Figueroa, F. L. (2011). Effects of N supply on the accumulation of photosynthetic pigments and photoprotectors in Gracilaria tenuistipitata (Rhodophyta) cultured under UV radiation. Journal of Applied Phycology, 23, 457–466. https://doi.org/10.1007/s10811-010-9603-x

Briani, B., Sissini, M. N., Lucena, L. A., Batista, M. B., Costa, I. O., Nunes, J. M., Schmitz, C., Ramlov, F., Maraschin, M., & Korbee, N. (2018). The influence of environmental features in the content of mycosporine-like amino acids in red marine algae along the Brazilian coast. Journal of Phycology, 54, 380–390. https://doi.org/10.1111/jpy.12640

Vaulot, D. (2019). BG11 medium. CNRS-Sorbonne Université, Station Biologique, Place G. Tessier 29680 Roscoff FRANCE. https://doi.org/10.17504/protocols.io.s2pegdn.

Rastogi, R. P., Sonani, R. R., Madamwar, D., & Incharoensakdi, A. (2016). Characterization and antioxidant functions of mycosporine-like amino acids in the cyanobacterium Nostoc sp. R76DM. Algal Research, 16, 110–118. https://doi.org/10.1016/j.algal.2016.03.009

Alves, A., Sousa, E., Kijjoa, A., & Pinto, M. (2020). Marine-derived compounds with potential use as cosmeceuticals and nutricosmetics. Molecules, 25, 2536. https://doi.org/10.3390/molecules25112536

Fernández-Juárez, V., Bennasar-Figueras, A., Sureda-Gomila, A., Ramis-Munar, G., & Agawin, N. S. (2020). Differential effects of varying concentrations of phosphorus, iron, and nitrogen in N2-fixing cyanobacteria. Frontiers in Microbiology, 11, 541558. https://doi.org/10.3389/fmicb.2020.541558

White, D. A., Polimene, L., & Llewellyn, C. A. (2011). Effects of ultraviolet-a radiation and nutrient availability on the cellular composition of photoprotective compounds in Glenodinium foliaceum (dinophyceae). Journal of Phycology, 47, 1078–1088. https://doi.org/10.1111/j.1529-8817.2011.01046.x

Saadatmand, S., & Zamani, M. (2015). Investigating the effect of different concentrations of nitrate and phosphate on the quantity of mycosporine like amino acids production and growth in Spirulina platensis. International Journal of Biosciences, 6, 63–69. https://doi.org/10.12692/ijb/6.5.63-69

Mohlin, M., & Wulff, A. (2009). Interaction effects of ambient UV radiation and nutrient limitation on the toxic cyanobacterium Nodularia spumigena. Microbial Ecology, 57, 675–686. https://doi.org/10.1007/s00248-008-9427-2

Chandra, R., Das, P., Vishal, G., & Nagra, S. (2019). Factors affecting the induction of UV protectant and lipid productivity in Lyngbya for sequential biorefinery product recovery. Bioresource Technology, 278, 303–310. https://doi.org/10.1016/j.biortech.2019.01.084

Loza, V., Perona, E., & Mateo, P. (2014). Specific responses to nitrogen and phosphorus enrichment in cyanobacteria: Factors influencing changes in species dominance along eutrophic gradients. Water Research, 48, 622–631. https://doi.org/10.1016/j.watres.2013.10.014

Volkmann, M., & Gorbushina, A. A. (2006). A broadly applicable method for extraction and characterization of mycosporines and mycosporine-like amino acids of terrestrial, marine and freshwater origin. FEMS Microbiology Letters, 255, 286–295. https://doi.org/10.1111/j.1574-6968.2006.00088.x

Rastogi, R. P., & Incharoensakdi, A. (2014). Characterization of UV-screening compounds, mycosporine-like amino acids, and scytonemin in the cyanobacterium Lyngbya sp. CU2555. FEMS Microbiology Ecology, 87, 244–256. https://doi.org/10.1111/1574-6941.12220

Ngoennet, S., Nishikawa, Y., Hibino, T., Waditee-Sirisattha, R., & Kageyama, H. (2018). A method for the isolation and characterization of mycosporine-like amino acids from cyanobacteria. Methods and Protocols, 1, 46. https://doi.org/10.3390/mps1040046

Nishida, Y., Kumagai, Y., Michiba, S., Yasui, H., & Kishimura, H. (2020). Efficient extraction and antioxidant capacity of mycosporine-like amino acids from red alga Dulse Palmaria palmata in Japan. Marine Drugs, 18(10), 502. https://doi.org/10.3390/md18100502

Sultani, M., Yousefzadi, M., Samari, F., & Kokabi, M. (2020). Optimization of the extraction of mycosporine-like amino acids (MAAs) from Hypnea musciformis and cyanobacteria isolated from the Geno hot springs. Journal of Aquatic Physiology and Biotechnology, 7, 19–40. https://doi.org/10.22124/japb.2020.11747.1283

Rastogi, R. P., & Incharoensakdi, A. (2014). UV radiation-induced biosynthesis, stability and antioxidant activity of mycosporine-like amino acids (MAAs) in a unicellular cyanobacterium Gloeocapsa sp. CU2556. Journal of Photochemistry and Photobiology B: Biology, 130, 287–292. https://doi.org/10.1016/j.jphotobiol.2013.12.001

Acknowledgements

Authors greatly thank Dr. Mohammad Ali Faramarzi for supplying the Fischerella sp. source and his valuable advising.

Funding

The research deputy of School of Pharmacy, Shahid Beheshti University of Medical sciences, Tehran, Iran, financially supported this study.

Author information

Authors and Affiliations

Contributions

MT and TH designed the methods and supervised the molecular studies. SS and MS. performed the experiments and data analysis and MT and SS wrote the manuscript draft and check result data and analysis. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing Interests

All authors declare that they have no conflicts of interest.

Ethical Approval

The work did not contain any human or animal stucy and it was approved by the Ethical committee of Shahid Beheshti University of Medical Sciences, Tran, Iran (IR.SBMU.PHARMACY.REC.1400.231).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Salehian, S., Saadatbakht, M., Tabarzad, M. et al. Culture Optimization to Produce High Yields of Mycosporine-Like Amino Acids by Fischerella sp. F5. Mol Biotechnol (2023). https://doi.org/10.1007/s12033-023-00854-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12033-023-00854-4