Abstract

Endostar as a specific drug in treatment of the nonsmall cell lung cancer is produced using Escherichia coli expression system. Plackett–Burman design (PBD) and response surface methodology (RSM) are statistical tools for experimental design and optimization of biotechnological processes. This investigation aimed to predict and develop the optimal culture condition and its components for expression and secretion of endostar into the culture medium of E. coli. The synthetic endostar coding sequence was fused with PhoA signal peptide. The nine factors involved in the production of recombinant protein—postinduction temperature, cell density, rotation speed, postinduction time, concentration of glycerol, IPTG, peptone, glycine, and triton X-100—were evaluated using PBD. Four significant factors were selected based on PBD results for optimizing culture condition using RSM. Endostar was purified using cation exchange chromatography and size exclusion chromatography. The maximum level of endostar was obtained under the following condition: 13.57-h postinduction time, 0.76 % glycine, 0.7 % triton X-100, and 4.87 % glycerol. The predicted levels of endostar was significantly correlated with experimental levels (R 2 = 0.982, P = 0.00). The obtained results indicated that PBD and RSM are effective tools for optimization of culture condition and its components for endostar production in E. coli. The most important factors in the enhancement of the protein production are glycerol, glycine, and postinduction time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recombinant human endostatin (rhES) is one of the most common inhibitors of angiogenesis that inhibits different kinds of the tumor. The extended application with its low toxicity and lack of drug resistance in long-term application makes it a broad-spectrum antiangiogenesis and tumor-suppressing agent. However, as a protein, its clinical application has some problems including insolubility, instability, high price, and need for high dosage [1]. To overcome these limitations, several solutions were developed such as selecting a suitable expression vector and suitable expression host and modifying the biochemical properties of endostatin [2–4]. Endostar is a modified rhEs with nine residues (MGGSHHHHH) in the N-terminus that increases its stability. Endostar was approved by the State Pharmaceutical Administration of China (SFDA) as a specific drug in the nonsmall cell lung cancer therapy [5].

Escherichia coli expression system is an alternative method for recombinant protein production [6, 7]. However, in this system, heterologous proteins are often folded incorrectly (especially in proteins with disulfide bonds) and deposited as insoluble inclusion bodies in cytoplasm [8, 9]. Recombinant endostatin is a hydrophobic protein that deposits as insoluble inclusion body in the cytoplasm. Various methods have been developed to get soluble rEs including coexpression with chaperones, fusion with solubility-promoting peptides, fusing with signal peptides, developing purification, and refolding method [10]. The recombinant mouse endostatin was successfully secreted into the media using PhoA signal peptide by Xu et al. [11]. Regarding the advantages of extracellular expression of recombinant proteins and clinical importance of endostar, here for the first time, we reported the expression and secretion of endostar in the culture media of E. coli using PhoA signal peptide.

The composition of the culture medium and culture conditions has an important role in recombinant protein expression [12]. Therefore, in the current study, we aimed to improve the influence of different factors including: postinduction temperature, cell density, rotation speed, postinduction time and concentration of glycerol, inducer concentration, peptone, and glycine and triton X-100.

The one-factor-at-a-time is a conventional approach in optimizing culture condition that a single parameter is evaluated, while all the other parameters are fixed at a given set of conditions. However, this method is time-consuming and ignores the interactions between the influencing parameters. To overcome these drawbacks, other methods such as Plackett–Burman design (PBD) and response surface methodology (RSM) can be used [13]. PBD and RSM could determine the role of individual parameters as well as their collective influence. In addition, RSM is a mathematical and statistical tool that has been successfully used for designing, modeling, and evaluating the effects of several parameters and optimizing biochemical and biotechnological processes [14]. In this study, PBD was used to find the most effective factors, and RSM was applied to optimize and analyze the combined influence of the above-mentioned factors on endostar production.

Materials and Methods

Reagents

Enzymes including NdeI, XhoI, T4DNA ligase, Pfu DNA polymerase, and Gene Ruler DNA Ladder Mix were obtained from Fermentas-Thermo Fisher Scientific (Burlington, USA). Mini Plus™ -Plasmid DNA Extraction kit and Viogene® Gel/PCR DNA Isolation System kit were purchased from Viogene (New Taipei City, Taiwan). PCR reagents were purchased from Cinnagen (Tehran, Iran). Agar, Tryptone, IPTG MTT (3(4, 5-dimethyl thiazol-2-yl) 2, 5-diphenyl-tetrazolium bromide), yeast extract, glycerol, glycine, triton X-100, Ampicillin, penicillin G, streptomycin, and DMSO were obtained from Sigma-Aldrich (St. Louis, MO, USA). Prestained Protein Ladder was from Sinaclon (Tehran, Iran). Fetal bovine serums (FBS) and Trypsin–EDTA were purchased from Invitrogen (Carlsbad, CA, USA). All chemicals used in SDS-PAGE were purchased from Merck (Darmstadt, Germany). Endostatin Human ELISA kit was obtained from Abcam (Cambridge, UK). Rabbit antiendostatin polyclonal antibody (ab3453), Goat Anti-Rabbit IgG H&L (HRP) (ab6721), and ECL Western Blotting Substrate (ab65623) were purchased from Abcam (Cambridge, MA, USA).

Bacterial Strains, Plasmids, Cell Lines, and Media

The E. coli strains DH5α and BL21 (DE3) (Pasteur Institute, Iran), used as cloning and expression hosts, respectively, and pET21a (+) as expression vector, were obtained from Pasteur Institute of Iran. The Human umbilical vein endothelial cell line (HUVEC) was purchased from the National Cell Bank, Pasteur Institute of Iran. DMEM-F12 medium purchased from Invitrogen (Carlsbad, CA, USA). Primers were from Shine Gene Company (Shanghai, China). In addition, the interest synthetic construct was prepared from Shine Gene Company (China) as cloned sequence in pUC57 plasmid.

Construction of Synthetic Gene and Expression Vector

The synthetic construct was supplied in favor of “codon usage” of E. coli by ShineGene Bio-Technologies Company (Shanghai, China). The construct was started with the NdeI site (CATATG) in 5′ end, followed by phoA signal peptide (GenBank: M13763.1), stabilizing sequence (MGGSHHHHH), human endostatin sequence (GenBank accession No. AF184060.1), stop codons (TAATGA), and XhoI site (CTCCAG) in the 3′ end, respectively. This construct was inserted in pUC57 vector (pUC57-phoA sp-hES). In order to obtain the expression vectors, 100 µl of TE buffer was added into the tube containing pUC57-phoA sp-hES. Then, the construct was transformed into E. coli DH5α competent cells by calcium chloride method [15]. Further, the recombinant pUC57 and pET21a were double digested with NdeI and XhoI in separate tubes, and they were run on 1.5 % agarose gel. Then, the interested fragment and linearized pET21a were purified with Viogene® Gel/PCR DNA Isolation kit. Finally, the interested fragment was inserted into pET21a vector to create the corresponding expression vector pET21a-phoA sp-hES. The ligation products were transformed into E. coli BL21 (DE3). The positive clones were checked by PCR and restriction enzyme digestion.

To confirm successful transformation, positive clones were selected on LB agar containing ampicillin (100 µg/ml) and subcloning was confirmed by PCR and restriction analyses. Finally, accuracy of the inserted fragment in positive clone was confirmed by DNA sequencing.

Cultivation Conditions

The screening experiments were carried out in 250 ml Erlenmeyer containing 50 ml culture media. A single clone was inoculated in 5 ml LB containing 100 μg/ml ampicillin and was grown overnight at 37 °C (shaken at 200 rpm) until the OD600 nm reached 1.0 for each experiments, separately. 1 ml of the culture was then diluted 50-fold in a medium. The culture conditions were performed under different conditions as described on PBD and RSM according to the central composite design (CCD) (Tables 1, 2) which is described below.

Optimization of Endostar Production

In the first step of optimization, Plackett–Burman design was used to select most effective factors which are involved in extracellular production of endostar. Nine variables (Table 1) were screened in 12 experimental runs and insignificant ones were excluded in order to obtain a smaller and manageable set of factors. The experiments were designed and analyzed with the statistical software package ‘‘Minitab 17′’ (Minitab Inc., Pennsylvania, USA). Each variable was divided into two levels: −1(low-level) and +1(high-level).

Once the critical factors were recognized by screening, the central composite design (CCD) was employed to develop the optimization more carefully. Therefore, a design with more than two ranges was performed [16]. The independent variables including: glycerol concentration (X 1), postinduction time (X 2), triton X-100 concentration (X 3), and glycine concentration (X 4) were studied at five different levels (Table 3), and a set of 30 experiments was carried out (Table 2). All experiments were done in triplicate, and the average of endostar expression level was calculated as the experimental data. These data were evaluated statistically by regression analysis using the following second-order polynomial:

where Y is the predicted response (endostar expression level); X 1, X 2, X 3 and X 4 are independent variables (glycerol concentration, postinduction time, triton-100 concentration, and glycine concentration, respectively); β 0 is an constant coefficient; β 1, β 2, β 3, and β 4 are linear coefficients; β 12, β 13, β 14, β 23, β 24, and β 34 are the interaction coefficients; and β 11, β 22, β 33, and β 44 are the quadratic coefficients. For analysis of variance (One-Way) and RSM, Minitab™ v 17.1 software (Minitab Inc., Pennsylvania, USA) was used. Also, to understand the optimal culture condition and the interaction of different variables, 3D response surface, contour, and correlation plot were generated. Furthermore, endostar concentration was determined by ELISA following manufacturer’s instructions.

Purification of Endostar

The expression of endostar was carried out in 1000 ml volumetric flask containing 200 ml culture medium consisting of optimal supplemented, based on optimal culture condition which was proposed by RSM. Then the cells were removed by centrifugation (10 min × 5000× g), and the supernatant was subjected to purification. The crude supernatant containing soluble endostar was concentrated using a TFF system (Sartoriu-STEDIM-BIOTECH,17521-002, USA) with ultra-filtration membrane (3051442901, 5-kD cutoff) [3, 17]. Concentrated sample was loaded onto a 1 ml SP-Sepharose (GE Healthcare) column that had been equilibrated with 50 mM PBS, pH 6.5, and at a flow rate of 1 ml/min. The column was washed with 10 ml of the equilibration buffer. The bound endostar eluted sequentially with different concentrations of NaCl (100–1000 mM) in phosphate buffer. The peak fraction containing the endostar was collected, pooled, and desalted by dialyzing overnight at 4 °C against 10 mmol/L PBS (pH 6.5). The dialyzed sample was then loaded onto a HiPrep 16/60 Sephacryl S-100 HR (GE Healthcare) equilibrated with phosphate buffer for further purification. All chromatographic procedures were conducted at 4 °C.

Analysis of the Protein Expression

The chromatographic process was evaluated using SDS-PAGE analysis. Samples were incubated with 5 × Laemmli buffer under reducing condition at 100 °C for 5 min. Then, they were loaded onto SDS-PAGE (12 %) and run until the prestained molecular weight standard revealed a good resolution, followed by staining with Silver nitrate. In addition, Western blot analysis was applied for further analysis of produced endostar. Briefly, after SDS-PAGE electrophoresis, purified endostar was identified by Western blot analysis. Further, proteins were transferred onto a polyvinylidene fluoride (PVDF) membrane. The membranes were blocked with blocking buffer for 2 h at 37 °C and incubated with rabbit antiendostatin polyclonal antibody (ab3453) overnight at 37 °C. After four times washing with phosphate-buffered saline (PBS), the membranes were incubated with Goat Anti-Rabbit IgG H&L (HRP) (ab6721) for 1 h at room temperature followed by three times washing with phosphate-buffered saline (PBS). Proteins were visualized by incubation with ECL Western Blotting Substrate (ab65623).

Analysis of Endostar Bioactivity

The bioactivity of purified endostar produced was evaluated using HUVECs and compared with recombinant human endostatin (Sciencell™ Research laboratories, Cat.No103–12). The cell lines were grown in DMEM/F-12 medium with 10 % FBS and penicillin G–streptomycin 1 % (v/v). Cells were harvested with trypsin (0.25 %) at 37 °C for 5–10 min and seeded into 96-well plates. Cells were incubated in DMEM/F-12 for 24 h at 37 °C with 5 % CO2 and 95 % humidity. The medium was then changed with150 µL fresh DMEM/F-12 containing purified endostar and commercial endostatin at different concentrations, 2 % FBS, and 50 µL PBS. Also, 50 µL PBS was added to the blank control wells. After 72 h of cultivation, the cells were incubated with 100 μg MTT per well for another 4 h. After that the medium was removed, and 100 μl DMSO was added to each well and incubated for 30 min at room temperature. Finally, the surviving endothelial cells were estimated by measuring the absorbance at 570 nm using microplate reader (Bio-Tech Instruments, USA) [3, 17].

Result

Construction of pET21a-phoA sp-Endostar Plasmid

The wild-type hES gene has 31 rare codons including: 3CGG, 3AGG for Arginine, 8CCC for proline, 4 TCC, 2 TCA, 1 AGT, 4TCG for serine, and 6 GGG for glycine. These codons were replaced with preferred E. coli codons in synthetic hES. CAI used to estimate the adaptation of codon optimized hES to E. coli was 0.878. The optimized gene had 75.8 % of identity with respect to the wild-type hES gene. Also PhoA signal peptide and stabilizing sequence (MGGSHHHHH) in this construct was in favor codon usage of E. coli. The synthetic construct was provided by ShineGene Bio-Technologies Company (Shanghai, China) as pUC57-phoA sp-Endostar vector. Further analyzing with Gene Designer (version 2.0) showed that there is no cryptic splice donor, cryptic splice acceptor, prokaryotic ribosome binding site, RNA destabilizes sequence, and shin-dalgarn sequence. Moreover, restriction analyses revealed no restriction sites that may interfere with cloning procedure. In the following step, the plasmid pET21a (+) was used to prepare expression vector. The protein-coding region of the phoA sp and endostar sequences was inserted between the NdeI and XhoI sites of the pET21a. The recombinant pET21a-phoA sp-Endostar contained a T7 promoter, Lac operon, multiple cloning sites, phoA signal peptide sequence, endostar encoding gene, and T7 terminator. The construction of expression vector is presented in Fig. 1.

Following the transformation of E. coli BL21 (DE3), the positive clones were selected on LB agar containing ampicillin (100 µg/ml), and the subcloning was confirmed by PCR and restriction analyses (Fig. 2a, b). Sequencing analysis of the both recombinant plasmids confirmed that there were no amplification errors and frame shift in cloned sequence (data are not shown).

PCR identification and digestion analysis of pET21a-phoA sp-Endostar. Agarose gel electrophoresis of cloned sequence in pET21a; lane 1 DNA molecular weight markers, lane 2 negative control, and lane 3 a 610 bp for PCR product band of cloned sequence (a). pET21a-phoA sp-Endostar Digestion result of pET21a-phoA sp-Endostar was digested with Nde1 and Xho1. Lane 1 DNA marker, lane 2 undigested plasmid and lane 3 digested plasmid (b)

Plackett–Burman Design

As a preliminary study, a PBD (Table 1) was accomplished in two levels of −1 and +1. The goal of this design was to select the most significant factors that affect the expression and secretion of endostar into the media. Evaluation of different culture conditions for the extracellular production of recombinant endostar derived from E. coli BL21 (DE3) was performed in 250 ml shaking flasks containing 50 ml culture medium. Plackett–Burman experiments (Table 4) showed a wide variation in endostar extracellular expression level. This variation revealed the importance of optimization to achieve higher productivity. As a result of PBD analysis, the value for R 2 was 0.9947, indicating that the model was capable of explaining 99.47 % variability of the data, while only a few fractions of the data remained (0.53 %) were unexplained. The regression analysis data of PBD are described in Table 4. From the Pareto chart (Fig. 3), the variables Viz., postinduction time (J), glycine concentration (C), glycerol concentration (D), and triton X-100 concentration (A) were the critical factors that affected the extracellular production of endostar. In addition, Pareto chart revealed that the maximal effect (J: postinduction time) was presented in the upper percentage and then increased to the minimal effect (B: peptone concentration). Also, the lower IPTG concentration, cell density (before induction), postinduction temperature, rotation speed, and the high peptone concentration could stimulate the extracellular expression of soluble proteins. Therefore, four factors (postinduction time, glycine, glycerol, and triton x-100) were selected as main factors for improving the prediction models and optimization procedure in the next step of the optimization.

Pareto chart showing the effect of culture condition and media components on extracellular production of endostar. The significant terms were J (postinduction time), D (glycerol concentration), C (glycine concentration), and A (triton x-100 concentration). The nonsignificant terms were F (cell density prior induction), G (postinduction temperature), E (IPTG concentration), H (rotation speed), and B (peptone concentration) in this study

Central Composite Design

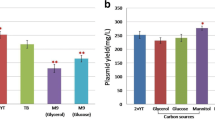

A central composite design (CCD) was employed for further optimization in order to obtain a maximum production of endostar. Thirty experiments consisting of 16 star points, 8 axial points, and six center points were performed in triplicate at different combinations of the factors (Table 3). The predicted and actual results along with design matrix are summarized in Table 2. It could be seen from the results in Table 2 that the highest amount of endostar (1900–2100 µg/L) was obtained in the runs that represent the center points while the lowest level was observed in run 22 (350 µg/L).

The analysis of variance for the adjusted model revealed that the production of endostar was significantly influenced by the linear and quadratic coefficients and their interactions, except the triton X-100(X3) and interaction factors of X2X3 and X2X4 (Table 5). The effects of the postinduction time (125.8, P = 0.01) and glycine concentration (388.3, P = 0.00) were positive, demonstrating that longer postinduction time and high glycine concentration will enhance the production of extracellular soluble protein, respectively, whereas the glycerol concentration was negative (332.5, P = 0.00). In order to estimate the optimal region of endostar production, second-order models were fitted to the endostar results (Table 2). Considering these results, a simplified model is described by Eq. (2), where the variables are specified in their original units as following:

where Y is the response variable (endostar level), and X 1, X 2, X 3, and X 4 are the independent variables (glycerol concentration, postinduction time, triton X-100 concentration, and glycine concentration, respectively). The results showed that the linear coefficients β1 (glycerol concentration), β2 (postinduction time), β3 (triton X-100 concentration), and β4 (glycine concentration) have a significant impact on production of endostar. The statistical significance of the regression quadratic model was represented in the form of analysis of variance (ANOVA). The F value (57.66) and P value (0.00) indicates that the model is significant. The results of analysis of variance and model fitting for the responses of endostar by RSM are given in Table 5. The determination coefficient (R 2) was 0.9818 indicating that 98.18 % of the total variability in the response could be well described by the new model. The adjusted determination coefficient (\(R^{ 2}_{\text{adj}}\)) was 0.9647. Moreover, the lack-of-fit of the model was not statistically significant at 95 % confidence level.

The scatter plots were made for estimating the adequacy of the model (Fig. 4). From the correlation between the experimental and the predicted values of endostar production, it can be concluded that the experimental levels agree well with the predicted levels (Fig. 4b). Also, normal probability plot shows that there was not any problem with normality (Fig. 4a). Therefore, this is a suitable model for predicting production yield in the tested conditions based on the ANOVA results.

In order to understand the interactive effects of variables on production of endostar, the response contour plot (2-dimensional) and their 3-dimensional plots are demonstrated in Fig. 5. These figures show clear information on the relationship between the response and actual levels of each independent variable and help find the optimum conditions. The interactive influence of glycerol concentration and postinduction time on endostar production is shown in Fig. 5a. The optimum condition for endostar production was found to be at glycerol concentration of 5.4 % and postinduction time of 14.48 h. Figure 5b shows the dependency of the endostar production to the glycerol and triton X-100 concentration. The endostar production augmented with increase in glycerol and triton X-100 concentration and thereafter endostar production decreased with further increase in both factors. Figure 5c shows correlation of glycerol and glycine concentration with endostar production. It can be observed that increase in endostar production occurred with both factors. However, an increase in glycerol concentration beyond the optimum region (glycerol concentration: 4.87 % and glycine concentration: 0.76 %) resulted in reduction of the endostar production. Figure 5d indicates the interactive influence of postinduction time and triton X-100 concentration on endostar production level; while the integrated impact of postinduction time and glycine concentration on endostar production is depicted in Fig. 5e. Moreover, Fig. 5g indicates that an increase in glycine and triton X-100 concentration leads to an increased production of Endostar. Maximal endostar production was obtained at glycine concentration of 0.72 % and triton X-100 concentration of 0.69 %. An increase in both factors beyond the optimum region resulted in a decrease in endostar production. Briefly, the contour plot analysis indicated that the central values of the variables were optimal for endostar production. Also, the response surface graphs revealed that the optimum region of endostar production is placed at the peak of the surface.

Response surface and its contour plot of endostar production in supplemented culture medium: a glycerol concentration versus postinduction time at optimum triton X-100 and glycine concentration, b glycerol concentration versus triton X-100 concentration at optimum glycine concentration and postinduction time, c Glycerol concentration versus glycine concentration at optimum triton X-100 concentration and postinduction time, d postinduction time versus triton X-100 concentration at optimum glycine and glycerol concentration, e postinduction time versus glycine concentration at optimum triton X-100 and glycerol concentration, and f glycine versus triton X-100 concentration at optimum glycerol concentration and postinduction time

The mathematical model predicted a maximum endostar production (2088 µg/L) at the condition of 13.57 h of postinduction time, 4.9 % of glycerol concentration, 0.7 % of triton X-100 concentration, and 0.76 % of glycine concentration. In order to validate the predicted results, additional experiments were conducted applying this optimized condition. As a result, the validation yielded 2200 µg/L of endostar into media which was close to the predicted value by model.

Purification and Identification of Endostar

After optimizing expression condition, recombinant endostar was purified from the culture supernatant of E. coli BL21 (pET21a-phoA sp-Endostar) using cation exchange chromatography and size exclusion chromatography. Eluted protein with the 0.4 M NaCl fraction had a maximum amount of endostar but was contaminated with two others, low and high molecular weight proteins (Fig. 6). The amount of endostar after cation exchange chromatography was 1484 µg/L. The protein fractions eluted at 0.4 M NaCl were pooled, concentrated, and dialyzed against PBS; pH 6.5. The purified protein was further separated by size exclusion chromatography using a Sephacryl S-100 column. A final yield of endostar was 1291 µg/L. The purified endostar presented approximately 21 kDa on SDS–PAGE (Fig. 6) compatible with the theoretical molecular weight and was found to be immune-reactive when evaluated through Western blot using rabbit antiendostatin polyclonal antibody (Fig. 7).

SDS–PAGE analysis of expressed and purified endostar in 12 % resolving gel that stained with Silver Nitrate. Lane 1, culture supernatant of E. coli BL21 (pET21a); lane 2–3, culture supernatant of E. coli BL21/pET21a-phoA sp- Endostar; lane 4, protein molecular weight; lane 5, endostar protein purified by Sephacryl S-100; lane 7–9, fractions of 0.4 M NaCl eluted proteins using SP-Sepharose column

Western blot analysis with specific rabbit antiendostatin polyclonal antibody. Panel a is the ponceau s staining of pvdf membrane. Lane 2 is the control sample; lane 3–5 represent the sample related to culture medium proteins after induction, cation exchange purified endostar and size exclusion purified endostar, respectively. Panel b is the immunoblotting image of samples shown in panel a. Lanes 2–5 correspond to the lanes 2–5 in panel a. Lane 1 is protein marker

Determination of Endostatin Bioactivity

To establish the functional integrity of the recombinant endostar produced from E. coli, the inhibition assay of the human umbilical vein cells proliferation was performed. As shown in Fig. 8, the ED50 of purified endostar in inhibiting proliferation of human umbilical vein cells in a dose-dependent manner was approximately 6.2 μg/ml. The results were comparable to that of the commercial endostatin (Sciencell™ Research laboratories, Cat.No103–12) derived from E. coli, which has an ED50 of 5.9 μg/ml.

Representative inhibition curve of human endostatin expressed in E. coli on the cell proliferation of the human umbilical vein cells. Red square and line: purified endostar from current study. Blue diamond and line: commercial human endostatin from Sciencell™ Research laboratories. The experimental procedure was described in the Materials and Methods section

Discussion

Endostar is a modified human endostatin that has been approved by SFDA as a specific drug in nonsmall cell lung cancer therapy [2]. Secretion of recombinant protein into culture medium is one of the common methods for production of soluble recombinant protein in E. coli expression system [11]. In the present study, we have shown that endostar with biological activity can be expressed and secreted into the culture medium by E. coli BL21 (DE3). Experimental conditions for the improvement of recombinant protein expression coupled with experimental design tools serve as a suitable tool for analyzing the influence of cultivation media components and culture conditions on the expression of recombinant protein [18]. This is the first attempt to evaluate the effective factors involved in increasing extracellular production of endostar using PBD and RSM.

The previous reports indicated that rhEs expressed in E. coli was usually accumulated in the cytosol as inclusion bodies, which needs to be converted to the active proteins using refolding process. Thus, its clinical application was limited. Expression of endostar and secretion into the culture medium is an alternative method for overcoming this limitation. Advantage of this system is the expression of protein in soluble form and facilitation of purification. The vector of pET21a harbors a PhoA signal peptide at the protein N-terminal, designed in our laboratory, and led the endostar into the culture media. This finding was compatible with the results of Xu et al. [11]. However, the produced endostar level was very low in comparison with Xu et al. findings. This difference can be due to the following reasons: (1) expression in the lab scale condition instead of fermenter, (2) nine residues in the N-terminus of endostar, and (3) T7 promoter instead of APase promoter.

Researchers have established that the cultivation media components and culture condition significantly affect the recombinant protein expression and its secretion into culture media [16]. To optimize the culture condition of expression, a prior knowledge about effective factors is necessary [19]. Therefore, nine different factors were selected. The PBD was used instead of the conventional method because the latter is time-consuming; able to analyze one variable at a time; and not capable of analyzing the interaction between different factors [13]. PBD helps analyze the large number of factors with the least number of tests and allow determination of the most significant factors [16]. Furthermore, RSM, as a highly effective statistical tool, can validate the interactions between parameters [14]. Therefore, this method based on CCD was applied to achieve the optimal conditions for expected responses and reduce the number of required examinations. The PBD and CCD were performed to predict and improve endostar yield.

In this experiment, the results of PBD revealed that the concentration of endostar in the culture media was significantly correlated with postinduction time (P = 0.007), concentration of glycine (P = 0.01), glycerol (P = 0.011), and triton X-100 (P = 0.034). After selection of the significant factors (four factors in this study), we aimed to optimize these factors for the high production of soluble endostar. Moreover, the other five factors were fixed in their optimum point based on PBD prediction. Because of the existence of several parameters, CCD was employed to obtain a quadratic model, consisting of factorial trials and star points to estimate quadratic effects and central points to assess the pure process variability with endostar production as a response.

The results of CCD revealed that the endostar production was correlated with these factors as an output given by Eq. 2. As it has been proven, a large F value indicates that most of the variation can be described by a regression equation. Also for P value <0.05, the model is considered to be statistically significant [13]. Accordingly, our results of the ANOVA analysis confirmed that the model was adequate for representing the experimental data in the current study. The fit of the model can be confirmed by correlation coefficient (R 2) along with an acceptable agreement with the adjusted correlation coefficient \(R^{ 2}_{\text{adj}}\) and lack of the fit test [20]. Our results showed that the lack-of-fit of the model was not significant which it clearly indicated that the obtained experimental responses adequately fit with the model. Also, the values of R 2 and \(R^{ 2}_{\text{adj}}\) are close to 1 indicating that the obtained experimental responses adequately fit with the model (Fig. 4b). These findings showed that there was a strong correlation between the experimental and the predicted values (Fig. 4a).

In the present study, the endostar level was remarkably enhanced in the optimum point of culture condition and culture components, which are given by PBD and CCD models and also any change in the value of optimized factors, resulted in decreasing of endostar level. As previously reported, any change in the optimum culture components and culture conditions resulted in altering growth rate of E. coli that in turn affects the expression level of the recombinant protein [16, 20]. Aforementioned factors are completely explained in the following.

The results show that glycerol is an effective factor in extracellular production of endostar. The optimum concentration of glycerol was 4.9 % (v/v) that is similar to other results [16, 21]. Cao et al. found that glycerol supports the accumulation of protein in the periplasmic space [16] similar to the results of Du et al. who reported that addition of glycerol (4 % v/v) to the culture medium increased the expression level of soluble scFv2F3 B [22]. Also, it was reported that glycerol protects cells from IPTG’s toxicity [22] and limits the acetate accumulation which has several negative effects on protein expression [16]. In addition, glycerol is an effective stabilizer of protein conformation that has some side effects in high concentration [23]. The results reveal that any change in its optimal concentration caused a decrease in endostar level. Therefore, it is suggested that determination of optimum concentration of glycerol is important in extracellular production of protein.

The other two effective factors in this research were glycine and triton X-100. The addition of glycine and Triton X-100 into the culture medium had a strong promotional effect on extracellular production of endostar. The addition of glycine and Triton-100 increases the cell membrane permeability which in turn facilitates the translocation of proteins out of the cytoplasm and thus enhancing the extracellular secretion efficiency [24]. Bin et al. reported that the extracellular production of the recombinant α-CGTase was strongly promoted with addition of glycine and triton X-100 into the culture. In addition, it was reported that glycine and Triton X-100 in high concentrations have negative effect on E. coli growth. In the present study, the optimized concentration of glycine was 0.76 % (w/v) that is consistent with the report of Bin et al. [25]. However, this finding was higher than that of the previous report (0.3 %). Also, the optimized concentration of triton X-100 was 0.7 % that was higher than that of the latter report which was 0.5 %. The optimal amount of glycine and triton X-100 supplementation may be modified based on the culture medium, host strain, the cultivation condition, and the manner of additive supplementation. Therefore, it is recommended that they should be optimized in each case.

Postinduction time was another effective factor which its optimal point was 13.57 h, in this study. The endostar level was increased with longer postinduction time; however, the higher increase in the postinduction time above the optimum point causes a decrease in endostar level. It has been established that the effects of postinduction time depend on case-specific expression. It is necessary to monitor the postinduction time and amount of recombinant protein that can effectively reduce host cell growth, probably due to its toxicity [26]. Therefore, optimizing the postinduction time is strongly suggested.

Moreover, the other five factors also were able to affect the extracellular production of endostar in PBD. Inducing with IPTG 0.3 mM increased the yield of protein in our experiment. This concentration was lower than that of previous reports for production of endostatin, which was 1 mM. However, this concentration was used for cytoplasmic expression of rhEs [4, 27]. This incompatibility is probably due to the promoted folding rate of protein.

However, it was reported that the concentration of IPTG for induction of gene expression vary from 0.005 to 5 mM [28]. In addition, low IPTG concentration resulted in an ineffective induction as well as high concentration of IPTG resulted in significantly reduced growth rate of E. coli [29, 30]. Additionally, inducing the expression of endostar at low postinduction temperature (16 °C) increased the yield of endostar. This is supported by the findings of Hernandez et al. [31]. The other researchers reported that the large number of proteins with hydrophobic properties were expressed in soluble form in lower postinduction time in E. coli and T7 expression system (used in this research) [32]. The possible reason is that slow rate of protein production allows to proper folding of newly translated recombinant proteins. In addition, temperature affects the plasmid stability which in turn, influences the protein production [33].

The results showed that when peptone was used at the concentration of 10 g/L, the yield of target protein was enhanced, same as the Cao et al. finding. They reported that peptone is an organic nitrogen source for the production of protein [16].

Additionally, the results revealed that the lower speed of rotational speed after induction resulted in the increase of yield. Our findings are consistent with the works of Hartmann et al. that optimized the low rotational speed to increase the yield of recombinant membrane protein UncI in E. coli [34]. The high rotational speed leads to increase in the rate of transcription and, therefore, incorrect folding of newly transcribed recombinant proteins [16]. For the cell density before induction, induction in the lower cell density increased the endostar yield, same as the other results [35, 36]. As it has been reported, induction is usually performed at early or mid-log phase. However, there are some reports recommending induction in late-log phase or even stationary phase [37]. However, Manderson et al. reported that the effects of cell density before induction is case-specific [26]. Therefore, it is recommended that it should be optimized in each case.

In the present study, phoA signal peptide-mediated endostar was cloned, expressed, and secreted into the culture media by E. coli as the first report in this field. The optimization of culture condition and culture supplementation using PBD and RSM remarkably enhanced the yield of soluble endostar in the culture media. As well, the most important factors in enhancement of the protein production are glycerol, glycine, and postinduction time.

References

Ma, Y., Jin, X.-B., Chu, F.-J., Bao, D.-M., & Zhu, J.-Y. (2014). Expression of liver-targeting peptide modified recombinant human endostatin and preliminary study of its biological activities. Applied Microbiology and Biotechnology, 98(18), 7923–7933.

Xu, X., Mao, W., Chen, Q., Zhuang, Q., Wang, L., Dai, J., et al. (2014). Endostar, a modified recombinant human endostatin, suppresses angiogenesis through inhibition of Wnt/β-catenin signaling pathway. PLoS One, 9(9), e107463.

Su, Z., Wu, X., Feng, Y., Ding, C., Xiao, Y., Cai, L., et al. (2007). High level expression of human endostatin in Pichia pastoris using a synthetic gene construct. Applied Microbiology and Biotechnology, 73(6), 1355–1362.

Du, C., Yi, X., & Zhang, Y. (2010). Expression and purification of soluble recombinant human endostatin in Escherichia coli. Biotechnology and Bioprocess Engineering, 15(2), 229–235.

Mohajeri, A., Pilehvar-soltanahmadi, Y., Abdolalizadeh, J., Karimi, P., Zarghami, N. (2016). Effect of Culture Condition Variables on Human Endostatin Gene Expression in Escherichia coli Using Response Surface Methodology. Jundishapur Journal of Microbiology, (In Press), e34091.

Ameghi, A., Baradaran, B., Aghaiypour, K., Barzegar, A., Pilehvar-Soltanahmadi, Y., Moghadampour, M., et al. (2015). Generation of new M2e-HA2 fusion chimeric peptide to development of a recombinant fusion protein vaccine. Advanced pharmaceutical bulletin, 5(Suppl 1), 673.

Niri, N. M., Memarnejadian, A., Hadjati, J., Aghasadeghi, M. R., Shokri, M., Pilehvar-soltanahmadi, Y., et al. (2016). Construction and production of Foxp3-Fc (IgG) DNA vaccine/fusion protein. Avicenna journal of medical biotechnology, 8(2), 57.

Singh, A., Upadhyay, V., Upadhyay, A. K., Singh, S. M., & Panda, A. K. (2015). Protein recovery from inclusion bodies of Escherichia coli using mild solubilization process. Microbial Cell Factories, 14(1), 41.

Mohajeri, A., Pilehvar-Soltanahmadi, Y., Pourhassan-Moghaddam, M., Abdolalizadeh, J., Karimi, P., & Zarghami, N. (2016). Cloning and expression of recombinant human endostatin in periplasm of Escherichia coli expression system. Advanced Pharmaceutical Bulletin, 6(2), 187–194.

Huang, X., Wong, M. K., Zhao, Q., Zhu, Z., Wang, K. Z., Huang, N., et al. (2001). Soluble recombinant endostatin purified from Escherichia coli: antiangiogenic activity and antitumor effect. Cancer Research, 61(2), 478–481.

Xu, R., Du, P., Fan, J.-J., Zhang, Q., Li, T.-P., & Gan, R.-B. (2002). High-level expression and secretion of recombinant mouse endostatin by Escherichia coli. Protein Expression and Purification, 24(3), 453–459.

Vaz, M. R. F., de Sousa Junior, F. C., Costa, L. M. R., dos Santos, E. S., Martins, D. R. A., & de Macedo, G. R. (2015). Optimization of culture medium for cell growth and expression of 648 antigen from Leishmania infantum chagasi in recombinant Escherichia coli M15. Annals of Microbiology, 65(3), 1607–1613.

Maharjan, S., Singh, B., Bok, J.-D., Kim, J.-I., Jiang, T., Cho, C.-S., et al. (2014). Exploring Codon Optimization and Response Surface Methodology to Express Biologically Active Transmembrane RANKL in E. coli. PLoS One, 9(5), e96259.

Lee, M. S., Lin, I. F., Lai, G. H., Lin, Y. C., & Li, K. Y. (2015). Statistical optimization of culture medium for the overproduction of chicken anemia virus immunogen-VP1 protein in a recombinant E. coli for vaccine application. Asia-Pacific Journal of Chemical Engineering, 10(1), 96–104.

Yari, K., Afzali, S., Mozafari, H., Mansouri, K., & Mostafaie, A. (2013). Molecular cloning, expression and purification of recombinant soluble mouse endostatin as an anti-angiogenic protein in Escherichia coli. Molecular Biology Reports, 40(2), 1027–1033.

Cao, W., Li, H., Zhang, J., Li, D., Acheampong, D. O., Chen, Z., & Wang, M. (2013). Periplasmic expression optimization of VEGFR2 D3 adopting response surface methodology: antiangiogenic activity study. Protein Expression and Purification, 90(2), 55–66.

Wu, J., Fu, W., Luo, J., & Zhang, T. (2005). Expression and purification of human endostatin from Hansenula polymorpha A16. Protein Expression and Purification, 42(1), 12–19.

Papaneophytou, C., & Kontopidis, G. (2016). A comparison of statistical approaches used for the optimization of soluble protein expression in Escherichia coli. Protein Expression and Purification, 120, 126–137.

Dilipkumar, M., Rajasimman, M., & Rajamohan, N. (2011). Response surface methodology for the optimization of inulinase production by K. marxianus var. marxianus. Journal of Applied Sciences in Environmental Sanitation, 6(1), 85–95.

Kahyaoglu, T. (2008). Optimization of the pistachio nut roasting process using response surface methodology and gene expression programming. LWT-Food Science and Technology, 41(1), 26–33.

Al-Samarrai, T. H., Jones, W. T., Harvey, D., Kirk, C. A., & Templtone, M. (2013). Effect of 4% glycerol and low aeration on result of expression in Escherichia coli of Cin3 and three Venturia inaequalis EST’s recombinant proteins. American Journal of Molecular Biology, 3, 1–9.

X-b, D. U., Ye, S., Feng, L., K-y, Z. H. E. N. G., K-w, W. A. N. G., T-t, L. I. N., et al. (2007). Chemical chaperones increasing expression level of soluble single-chain Fv antibody (scFv2F3). Chemical Research in Chinese Universities, 23(1), 69–75.

Gekko, K., & Timasheff, S. N. (1981). Mechanism of protein stabilization by glycerol: preferential hydration in glycerol-water mixtures. Biochemistry, 20(16), 4667–4676.

Choi, J., & Lee, S. (2004). Secretory and extracellular production of recombinant proteins using Escherichia coli. Applied Microbiology and Biotechnology, 64(5), 625–635.

Li, B., Wang, L., Su, L., Chen, S., Li, Z., Chen, J., & Wu, J. (2012). Glycine and Triton X-100 enhanced secretion of recombinant α-CGTase mediated by OmpA signal peptide in Escherichia coli. Biotechnology and Bioprocess Engineering, 17(6), 1128–1134.

Manderson, D., Dempster, R., & Chisti, Y. (2006). Production of an active recombinant Aspin antigen in Escherichia coli for identifying animals resistant to nematode infection. Enzyme and microbial technology, 38(5), 591–598.

Wei, D. M., Gao, Y., Cao, X. R., Zhu, N. C., Liang, J. F., Xie, W. P., et al. (2006). Soluble multimer of recombinant endostatin expressed in E. coli has anti-angiogenesis activity. Biochemical and biophysical research communications, 345(4), 1398–1404.

Akbari, H., Jafarian-Dehkordi, A., Chou, C. P., & Abedi, D. V. (2014). Optimization of a single-chain antibody fragment overexpression in Escherichia coli using response surface methodology. Research in Pharmaceutical Sciences, 10(1), 75–83.

Larentis, A. L., Nicolau, J. F., dos Esteves, G., Vareschini, D. T., de Almeida, F. V., dos Reis, M. G., et al. (2014). Evaluation of pre-induction temperature, cell growth at induction and IPTG concentration on the expression of a leptospiral protein in E. coli using shaking flasks and microbioreactor. BMC research notes, 7(1), 671.

Papaneophytou, C. P., & Kontopidis, G. (2014). Statistical approaches to maximize recombinant protein expression in Escherichia coli: a general review. Protein Expression and Purification, 94, 22–32.

Hernández, V. E. B., Maldonado, L. M. P., Rivero, E. M., de la Rosa, A. P. B., Acevedo, L. G. O., & Rodríguez, A. D. L. (2008). Optimization of human interferon gamma production in Escherichia coli by response surface methodology. Biotechnology and Bioprocess Engineering, 13(1), 7–13.

Vera, A., González-Montalbán, N., Arís, A., & Villaverde, A. (2007). The conformational quality of insoluble recombinant proteins is enhanced at low growth temperatures. Biotechnology and Bioengineering, 96(6), 1101–1106.

Wang, Yh, Jing, Cf, Yang, B., Mainda, G., Dong, Ml, & Xu, Al. (2005). Production of a new sea anemone neurotoxin by recombinant Escherichia coli: optimization of culture conditions using response surface methodology. Process Biochemistry, 40(8), 2721–2728.

Hartmann, C., & Engel, A. (2011). Cloning, expression, purification, and characterization of the membrane protein UncI from Escherichia coli. Protein Expression and Purification, 79(2), 187–190.

DeLisa, M., Chae, H., Weigand, W., Valdes, J., Rao, G., & Bentley, W. (2001). Generic model control of induced protein expression in high cell density cultivation of Escherichia coli using on-line GFP-fusion monitoring. Bioprocess and Biosystems Engineering, 24(2), 83–91.

Lim, H. K., & Jung, K. H. (1998). Improvement of heterologous protein productivity by controlling postinduction specific growth rate in recombinant Escherichia coli under control of the PL promoter. Biotechnology Progress, 14(4), 548–553.

Ranjbari, J., Babaeipour, V., Vahidi, H., Moghimi, H., Mofid, M., Namvaran, M., & Jafari, S. (2015). Enhanced Production of Insulin-Like Growth Factor I Protein in Escherichia coli by optimization of five key factors. Iranian Journal of Pharmaceutical Research, 14(3), 907–917.

Acknowledgments

The authors are so thankful to their colleagues at Tuberculosis and Lung Disease Research Center of Tabriz University of Medical Sciences. The authors are thankful to their coworkers in the Drug Applied Research Center of Tabriz University of Medical Sciences. We thank Dr. Sarvin Sanyi for assistance in editing this manuscript.

Authors’ contributions

This work was a part of Ph.D. thesis of Abbas Mohajeri and he wrote the paper. Nosratollah Zarghami was the supervisor of the thesis that edited the manuscript, directed the research, and coordinated the study. Abbas Mohajeri performed plasmid design and molecular works, carried out the analysis, and wrote the manuscript draft. Younes Pilehvar-Soltanahmadi participated in practical activities. Jalal Abdolalizadeh and Farhad Kiafar participated as technical assistance advisor. All the authors read and approved the final manuscript.

Funding/Support

This research was financially supported by a grant (Project Number 5/76/520) from the Tuberculosis and Lung Disease Research Center, Tabriz University of Medical Sciences. Tabriz, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohajeri, A., Abdolalizadeh, J., Pilehvar-Soltanahmadi, Y. et al. Expression and Secretion of Endostar Protein by Escherichia Coli: Optimization of Culture Conditions Using the Response Surface Methodology. Mol Biotechnol 58, 634–647 (2016). https://doi.org/10.1007/s12033-016-9963-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12033-016-9963-9