Abstract

Benzene, toluene, ethylbenzene, and xylene (BTEX) removal is one of the most common difficulties in air pollution control. They are emitted from several processes, prejudicial to the environment and humans. BTEX leads to various environmental risks, and there is a significant need for a creating process for the complete removal of BTEX from air streams. This study’s objective is the multi-component adsorption of BTEX pollutants from an air stream, by synthesizing activated carbons (ACs) under several operations. A lignocellulosic waste biomass, Abelmoschus esculentus L. (AE), was utilized as the precursor for synthesizing activated carbons (AE-ACs), and their surface chemical characteristics were investigated. Optimization processes were examined, and the change in the surface area of AE-ACs was investigated as change of some variables results like activation agent, impregnation ratio, temperature, and activation time. The maximum surface area of 968 m2/g and total pore volume of 0.51 cm3/g were attained at 1:2 impregnation ratio, activation time of 110 min, and activation temperature of 800 °C, under N2 atmosphere. A mixture of BTEX pollutants was employed to consider the effect of humidity (0.5, 1, 1.5, and 2 wt%) and initial concentrations (from 5 to 300 mg/m3), using a contact time of 120 min at the temperature of 25 °C. Under the studied conditions, the multi-component and single-component BTEX adsorption capacities by HCl-activated carbon, AE-ACH, were specifically achieved to 6.86–51.36 mg/g and 22–93.62 mg/g, respectively. Overall, Abelmoschus esculentus L. was exploited for the synthesis of AE-ACH which was successfully utilized for efficient BTEX capture from a polluted air stream.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Volatile organic compounds (VOCs) have become quite common air pollutants in industries which apply them as well as in their manufacturing unites [22, 23]. The most common VOCs in the chemical processes are acetaldehyde, acetone, carbon tetrachloride, formaldehyde, heptane, methyl ethyl ketone, monomethyl ether, naphthalene, and styrene [24, 25]. In addition, benzene, toluene, ethylbenzene, and xylene are known as aromatic hydrocarbons, BTEX, which participate in the atmospheric environment and can lead to environmental pollution as toxic or hazardous materials. The BTEX emissions from the indoor or outdoor environment can easily be accelerated with the vapor phase between 50 and 250 °C at atmospheric pressure [8, 11, 26, 27].

Several researchers have mentioned the existence of BTEX in many solvents, cleaning materials [28], degreasers [29], industrial regions [15], the automotive industry [10], aviation fuels [30], cosmetic products [4], wood furniture coatings [16], and cafeterias and volatile gas sources [31, 32]. The presence of BTEX adversely affects the radiation absorption and reactions performed under the influence of sunlight (undergo photochemical oxidation) with various molecules that cause climate change and air pollution (such as photochemical smog and ozone), by releasing into the atmosphere [9, 33]. Also, they prepare the background for PM2.5 and O3 formation in the environment [34,35,36]. The levels of their presence are examined in different environments, and it has been stated that their effects on many other health-related issues are not known yet. Although it has been noted that exposure to these pollutants could occur in various ways, its principal way of entrance to human’s body is inhalation. However, the adverse effects of BTEX on humans are manifested in multiple diseases, including eczema, headaches, dizziness, and injuries to internal systems [37, 38]. Peroxidative damage to protein structures and polyunsaturated fatty acids and DNA damage due to exposure to oxidative stress products in hydrocarbon classes are the beginning of carcinogenic activities [39,40,41]. In fact, due to exposure to high amounts of aromatic hydrocarbons, it has been determined that respiratory diseases, nose-throat damage, and even advanced carcinogenic diseases are seen in humans. Poor air quality, especially indoors; inadequate ventilation in cars, homes, offices, cafeterias, stationery, clothes drying centers, public transportation, museums, and schools; and increased BTEX emission due to insufficient clean air increase possible health problems [12, 42]. Although it seems that the main responsible for indoor air quality (IAQ) is outdoor air, there has been a serious increase in the incidence of industrial-origin BTEX, which has been increased with the frequent use of industrial products in indoor spaces after the 1980s.

Environmental organizations have defined BTEX as a dangerous air pollutant and have proposed to control it with some legislation in various countries [43]. They have agreed to reduce the presence of these materials in the environment via issuing some urgent environmental regulations, such as Directive 1999/13/E.C. and 2004/42/E.C. The US Environmental Protection Agency recommended exposure of maximum hydrocarbon as 1.6×10−4 kg/m3 (0.24 ppm) in 3 h that it should not be exceeded for more than a year [44]. Therefore, in-depth research of BTEX emissions from the gas environment is key to overextending air quality. After seeing that regulations are not completely effective in the control of BTEX, many reduction techniques for improving VOC control were continued to be used, and the main logical manner for BTEX control was considered to be its emission control at the source locale [18]. Although the BTEX elimination methods have been extensively studied, many techniques are infertile because of their unsustainability and high cost. They contain various structural (physical and chemical) limitations [1, 14], and such methods should usually exert restricting policies on the decomposition of BTEX. Methods of BTEX control which need low energy, use materials which are abundant in nature, and need low budget are preferable, like BTEX removal via adsorption process. Successful adsorbents such as organo-silica clay [45], activated carbon [20], activated carbon fiber [46], polymer [47], metal, and organic framework [7] have been applied in the previous adsorption studies. It can be claimed that adsorption is one of the best technologies for removing BTEX, since most adsorbents are often regeneratable, and many adsorbents provide fast and efficient disposal of BTEX.

The removal efficiency reaches high levels for some appropriate adsorbents due to their large specific surface area and good stability. It is aimed to recover BTEX using filtration with the aid of adsorbents with larger volumes, from the air streams with high emitting rates in industry. Numerous types of research have shown that activated carbons show different performance and properties for BTEX adsorption, dependent on the biomass type and/or pyrolysis conditions [17, 21, 48, 49]. However, because the pores of the adsorbents used are tiny and immediately clogged, and due to other limitations, the researchers’ speed for fabrication of suitable adsorbents has accelerated. In search of a new adsorbent, the first goals are the fabrication of an adsorbent with large pores, low-cost production of adsorbent, and reusability of the fabricated adsorbent. At the same time, researchers have been focused on the exploitation of agricultural, lignocellulosic, and forestry wastes for adsorbent production, which are abundant and available at low costs.

The elaborated aims of the present study are, therefore, as follows: (i) development of an adsorbent from the waste biomass of Abelmoschus esculentus L., which has a low-cost, effective, and reusable lignocellulosic structure, for efficient adsorption of gaseous BTEX from air streams; (ii) determination of the removal efficiency and its optimization by changing some variables; and (iii) evaluation of the effects of variables on the removal efficiency. Overall, the results of this investigation provide an enormous basis to support the evolvement of the wondrous BTEX control mechanism. Furthermore, obtaining well-developed pore structure and efficiency with the chemical activation process is foreseen to improve the large specific surface area of the activated carbon which is prepared from agricultural waste.

Materials and Methods

Materials and Chemicals

The agricultural residues of Abelmoschus esculentus L. (AE) were collected from cropland in Kastamonu, Türkiye. All the spent chemicals, including hydrochloric acid (37% purity; HCl) and sodium hydroxide (98% purity; NaOH), were of analytical grade brand, Merck, Germany. Aromatic hydrocarbons were used as received from Sigma-Aldrich. 400 mg/L BTEX solution, in which all compounds had equal concentration, was prepared in distilled water and kept in the refrigerator at 4 °C prior to using in the experiment. BTEX samples were obtained using higher trapping Tenax TA tubes supplied by Millipore/Sigma and stored at −20 °C until analysis.

Preparation of Activated Carbon

The preparation process step was as follows:

-

(i)

Waste residue of Abelmoschus esculentus L. was washed with distilled water to remove undesired surface compounds.

-

(ii)

It was dried at 48 °C for 48 h in an oven.

-

(iii)

Fifty grams of waste was grounded as particles diameter was ≤ 250 μm.

-

(iv)

Ten grams of powdered AE was mixed with 20 g chemical activation agent, dissolved HCl or NaOH, to achieve impregnation ratio of 2:1 (activating agent: biomass waste).

-

(v)

Batch mixer was applied to prepare a paste.

-

(vi)

The stainless steel reactor, which was resistant at high temperatures, was heated from 20 to 900 °C at 10 °C/min under an N2 flow rate of 80 mL/min. The activation temperatures of 500, 600, 700, 800, and 900 °C for 110 min were tested for activation process. After activation process, the mixture was left to cool up to ambient temperature under N2 flow at the rate of 80 mL/min of N2 gas.

-

(vii)

Finally, either 0.01M HCl and 0.01M NaOH solutions were utilized to neutralize the activated carbons and achieving pH of 6–7. Afterward, they were washed several times with boiling distilled water to remove any acid or base remained in the pores. The carbon materials were labeled and kept in polyethylene containers as AE-ACs for subsequent uses.

AE-ACs Characterization

Firstly, the characterization analyses of powdered AE-ACs were performed to evaluate porous structures using BET (Brunauer-Emmett-Teller, Quantachrome Instruments, USA), to obtain information about the morphology of the AE-ACs using SEM (scanning electron microscope, FEI Quanta FEG 250), to identify organic materials and chemical bond on the AE-ACs by FT-IR spectra between 400 and 4000 cm−1 wavelength (using Fourier-transform infrared spectrometer, PerkinElmer, Waltham, MA, USA), to assess elemental comonents (C, H, N, and O) of the AE-ACs and their degree by the elemental analyzer (Eurovector, EA3000-Single), to examine ash amount with ASTM standard test procedures [3], and to determine thermal stability of the AE-ACs using TGA (a thermogravimetric analyzer, STA7300, Hitachi Corp., Japan) under the N2 (80 mL/min) from 50 to 1100 °C at the heating rate of 10 °C/min.

Multi-Component Dynamic Adsorption

The adsorption experiments were executed using AE-ACs in a batch reactor for 120 min at atmospheric pressure in Fig. 1. Benzene (C6H6), toluene (C5H6CH3), ethylbenzene (C6H5C2H5), and xylene (C6H4(CH3)2) were inserted in a stainless-steel tubular reactor as vapor-phase with a length of 210 mm and an internal diameter of 70 mm and maintained until their masses remained steady by a mass flow controller. The initial concentration was injected corresponding to the threshold level in a stock solution under 80 mL/min of N2 flow as the carrier gas. The lowest relative pressure was P/P0 = 0.05.

TD-GC-MS Analysis and System Control

BTEX samples were analyzed through TD-GC/MS (thermal desorber, Markes Unity-gas chromatography-mass spectrometry, Thermo Scientific Trace 1300 - M.S., Thermo Scientific ISQ QD) and using US EPA Method TO-17 [50]. Tenax®TA tubes were analyzed with TG-624; 30.0 m × 0.25 mm × 1.4 μm column for diffusive samples. Their sampling was accomplished via air pump (200 mL/min) AirLite 110–100 (SKC, USA). In order to clean Tenax®TA tubes before sampling, the cleaning process was carried out by providing He flow of 1.5 mL/min at 350 °C, for which heating was started from 50 °C and raised with 30 °C ramps. For detection purposes, temperature scheduling continued from 65 to 170 °C with a steady rise of 5 °C/min, and, after that, it was escalated by 10 °C/min up to 220 °C and kept isothermal at 220 °C for 5 min. The input mass spectra were recorded at 70 eV, 150 °C ion source, and 230 °C interface temperature. An explication of the mass spectrum of GC-MS was made using the National Institute Standard and Technology (NIST) database having more than 62,000 patterns. The method limit of detection (MDL) was calculated, which was ranging from 0.001 to 0.37 ppb depending on the analyte, with less precision to some hydro-compound as an acceptance criterion for analytical curve determination coefficients (R2 for all components was ≥0.99). Quality control of the chromatographic process was provided by comprehensive five-point calibration for BTEX compounds, including routine standard checks using VOC mix gas component standards and periodic duplicates, methods, and field blanks of subsequent values. External standardization was calibrated with a standard BTEX solution (EPA TO-1 Toxic Organic Mix 1A from Sigma-Aldrich).

Adsorption Equilibrium

The BTEX adsorption process was conducted under the isothermal conditions. Samples were collected using 0.2 g of the AE-AC to periodically determine the adsorption behavior (P/P0 = 0–0.2). The system was put into priority operation for the specified temperature for 30 min, and then after running without AE-ACs for 30 min. It stabilized the system and reduced the error rate between fitted and experimental values. The study was carried out in several initial concentrations of 5-10-20-30-50-70-90-100-130-150-250-300 mg/m3 at a temperature of 25 °C and a variety of humidity of 0.5, 1, 1.5, and 2 wt% by a temperature and humidity controller. The humidity and temperature were equilibrated with different levels by extracting the mass increase from the total mass uptake. The BTEX adsorption removal at steady state conditions per gram of AE-AC was evaluated with the differential between the inlet and outlet concentrations for equilibrium in Eq. (1), suggested by Lv et al. [51].

where Ci (mg/L) is the inlet BTEX concentration at equilibrium concentration, Co (mg/L) is the outlet BTEX value, and a feed flow rate (F) of 300 mL/min, along with 200 mg of adsorbent (W), was utilized for each adsorption system. Examination of the rate of adsorption and mechanism for removing volatile compounds was evaluated at 2 mg/mL level of each component in methanol. The AE-ACH and AE-ACN were tested with a contact time of 120 min which was essential for developing a new solid-gas phase equilibrium model based on experimental data under atmospheric pressure. Correlation coefficient values for adsorption of each component on AE-ACH and AE-ACN have changed from 0.991 to 0.999 at reached equilibrium. The measurements were carried out by analytical curves, and no dilution was essential.

Results

Characterization of AE-AC

The physicochemical properties were investigated along with physicochemical functionality to show the difference between lignocellulosic biomass and AE-AC. The surface area and porosity were compared to reveal discrepancies after activating process. The significant change in the AE-ACs was determined with SEM, FT-IR, and TGA, respectively. Furthermore, the pore structure parameters (micro, meso, macro size) were studied by the N2 adsorption-desorption isotherm at −196 °C which is a type I isotherm, based on the International Union of Pure and Applied Chemistry using the non-local density functional theory (NLDFT), shown in Fig. 2. The partial pressure (P/P0) range was from 0.05 to 0.9, and the isotherms became horizontal; N2 adsorption was saturated due to the micropores filling. When P/P0 was close to 1.0, the isotherms rose slightly as N2 condensed in interparticle voids.

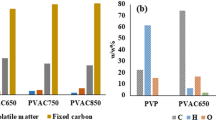

Table 1 shows the ultimate analysis of biomass, AE-ACH and AE-ACN. The carbon content of Abelmoschus esculentus biomass (AEB) was found to be 42.06%, although that of AE-AC increased up to 79.02% under various circumstances. HCl enriched the carbon content in AE-ACH, and it has larger pores and surface area than AE-ACN. The nitrogen content of AE-AC has increased to 1.75% because of the existence of nitrogen-containing moieties in the activated carbons. The main reason that the oxygen element is high in a sample, compared to the others, is the presence of hydroxyl and carboxyl.

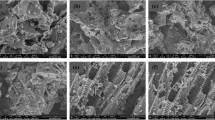

SEM analyses were carried out to appraise the surface morphology of AEB, AE-ACN, and AE-ACH, and the representative micrographs are screened at 5000× magnification in Fig. 3. It can be observed that while AEB is rough and has many clusters in its structure, the surface of AE-ACN and AE-ACH has knurly particles and large pores, including micropores and a less percentage of mesopores and different sizes and shapes due to chemical activation and carbonization. Irregular and spongy pores have emerged from the activation process [13, 52].

The FT-IR spectra of the AEB, AE-ACN, and AE-ACH in Fig. 4 show the functional bonds before and after activating, to compare the effect of chemical activation on the existing functional groups in the adsorbents. Most of the bonds have similar shapes in all three adsorbents. The identified bands are located at 3214 cm−1, assigned to hydroxyl groups’ O–H stretching vibrations, and C–H stretching vibration peak in aliphatic carbon compounds, which appeared at 2899 cm−1. Also, the peaks observed at 2734 and 1978 cm−1 were related to CH2 of CH3 deformation, respectively [2]. In addition, the bonds related to large aromatic skeleton and O–H bending peak were observed at around 1400 cm−1. The region between 800 and 1350 cm−1 contains C=C and C=O stretching vibrations [53]. The peak recorded at 721 cm−1 was due to the bending vibration of the C–H bond which is observed just in AEB.

According to Fig. 5, the TGA thermograms of the AE-ACs show the temperature ranges of gradual mass losses, in the range of temperature 20–670 °C, which were recorded as follows: (i) less weight loss ensues at the beginning with 150 °C; (ii) significant mass drastically decreases in about 440 °C by exothermic peak, and three primary decompositions with CO and CO2 loss between 420 and 630 °C [54]; (iii) a systematic decrease in weight and rate loss after that, from 630 to 670 oC, which was complex in all samples and is due to decomposition of functional groups; and (iv) no remarkable weight loss is located after 670 °C. The main mass losses are due to the loss of a small or a large number of functional groups in AE-ACH and AE-ACN, and such losses represent the functional groups’ decomposition in each ascending temperature step [55, 56]. In fact, the adsorption capacity of the AE-ACH and AE-ACN is exceedingly influenced by their presence.

Table 2 shows the activation agents’ mean, maximum, minimum concentrations, and standard deviations. The maximum concentration of HCl and NaOH led to BET surface areas of 968 cm3/g at 800 °C and 779 cm3/g at 700 °C, respectively, which were labeled as AE-ACH and AE-ACN. Table 2 presents statistical values (mean, standard deviation, minimum and maximum) of BET surface area in terms of several activating agents and temperatures.

Multi-Component BTEX Adsorption

The BTEX adsorption isotherms were described for the low-pressure adsorption of non-polar compounds depending on micropore filling. The adsorption capacities of the multi and single components were calculated when the adsorbents were exposed to P/P0 values from 0.1 to 1. The practical circumstances for adsorption at a temperature of 25 °C were adjusted to analyze the adsorption performance of AE-ACH and AE-ACN. The breakthrough curves are indicated depending on relative pressure in Fig. 6. The AE-ACH and AE-ACN adsorption capacities were reached a plateau at P/P0 of 0.6 in single-component system, while such plateau were reached at P/P0 of 0.4 in multi-component system.

Figure 7 demonstrates the adsorption curves of BTEX at 25 °C against time, in which it can be observed that a more amount is adsorbed onto AE-ACH in single-component system, ranging from 22 to 93.62 mg/g. As a result, a higher adsorbed amount leads to more adsorption capacity in single-BTEX removal with AE-ACH. At the same time, the multi-component system led to lower adsorbed amounts, ranging from 6.86 to 51.36 mg/g, resulting in lower adsorption capacities.

As the temperature increases, even if the humidity ratio remains constant, there is a decrease in the adsorption capacity. Fig. 8 shows removal efficiency values, in which the lowest value was obtained at 71.3% at 300 mg/m3 for AE-ACH, while the highest value was obtained at 92% at 5 mg/m3 in the adsorption experiments. However, the highest capacity of the compared adsorbent, i.e., in AE-ACN, was attained at 84% and at 5 mg/m3, and the lowest value was found at 52.1% and at 300 mg/m3. On both AE-ACN and AE-ACH, xylene and toluene are adsorbed more easily than benzene and ethylbenzene, which can be attributed to both adsorbates properties and the pore structure of AE-ACs.

The interaction of molecules of xylene and toluene are more robust than those of benzene and ethylbenzene, and adsorbed performance of both AE-ACN and AE-ACH reaches the maximum levels at 0.5 wt% humidity. In different studied humidity percentages, the adsorption efficiency for benzene, toluene, ethylbenzene, and xylene in the multi-component system in the case of AE-ACN was from 29.87 to 59.76, 48.77 to 66.92, 21.29 to 62.34, and 41.90 to 91.47 %, and in the case of AE-ACH was from 13.61 to 32.98, 17.49 to 38.65, 18.93 to 36.77, and 23.61 to 52.88, respectively. According to a single or multi-component system, the adsorption amount of BTEX in 0.5 wt% humidity is 1.91–2.62 times greater than that in 2 wt% humidity. These results indicate that the adsorption selectivity of AE-ACH for total BTEX is higher than that of AE-ACN.

Discussion

The gas adsorption process can serve as a technology which causes the removal of unwanted compounds (such as BTEX) from the air streams and effective treatment is achievable by the utilization of suitable adsorbents. Activated carbon is a widely used adsorbent which has the ability to remove many VOCs from multi-component systems [57]. The most effective and promising fundamental approach for BTEX has always been adsorption which is a superior technology in the gas environment [58]. As used in the current work, agricultural wastes and lignocellulosic biomasses have been used by researchers to produce activated carbon. Unused fruits and vegetable pulps, that can be considered waste, and many other lignin-containing biomaterials have been exploited in air pollution control studies [59,60,61]. In particular, various adsorbents used in the removal, purification, or elimination of single BTEX or VOCs have been successfully prepared and applied [62, 63]. However, since the decrease in the multiple removal efficiencies of the adsorbents is significant, in most studies, single gas pollutants have been studied by researchers [6, 64,65,66]. For example, studies on the remediation of BTEX-containing air streams have shown that the used adsorbents are unable to remove all the components effectively. Rajabi et al. [67] reported a char-based adsorbent for the removal of acetone, p-xylene, toluene, and hexane adsorption capacities in single and multi-component systems which were calculated. For all components, the maximum adsorption capacity in the multi-component system was noticeably lower than that of the single-component, despite the agreement of the total adsorption capacity of the adsorbent for multi BTEX with those obtained in previous works [68, 69]. Such studies confirm that the replacement of the adsorbents with new and more suitable adsorbents can be a good solution to this problem.

Huang et al. [19] synthesized carbon adsorbents from several biomass wastes to remove benzene, toluene, and chlorobenzene. They used the adsorbents to examine fixed bed dynamic adsorption systems, in the concentration range of 150–300 ppm. The results showed that the studied adsorbents have different adsorption capacities, and their performance was related to the micropore distribution and adsorbent structure. Among the studied adsorbents, NHPC-CC from corncob displayed a high VOC adsorption performance between 3.92 and 6.25 mmol/g. Batur and Kutluay [5] generated DBCB-AC adsorbent from Nigella sativa L. by ZnCl2 activation for dynamic adsorption of multi-component BTEX. The adsorption capacity was employed as a dependent variable to analyze the efficiency at several initial concentrations (from 10 to 30 mg/L). The maximum adsorption capacity in single-component adsorption was determined as 503 mg/g for benzene, 589 mg/g for toluene, and 692 mg/g for xylene; however, the adsorption capacity of the BTX was observed to be lower, between 83 and 307 mg/g for benzene, between 168 and 451 mg/g for toluene, and between 390 and 621 mg/g for xylene, in the binary- and ternary-component adsorption systems. However, by focusing on this study, the temperature and humidity seem to be the most important parameters which affect BTEX adsorption, and also an inverse correlation between the VOC adsorption capacity and the micropore volume exists, especially for their high concentrations. The highest adsorbed amount onto adsorbents in both single- and multi-component systems at room conditions was obtained when the humidity content was low.

Shin et al. [70] tested the adsorption of some VOCs (including aromatics and chlorinated compounds) by commercially SGA-100 (Samchonli Ltd. Korea) activated carbon, obtained from a landfill area in Korea. They adjusted the initial concentration (at 400 and 600 ppmv) and moisture (at 0, 40, 60, and 90%) by regulating the airflow meter, then maintained it between 24 and 26 °C. The adsorption capacity of aromatics and chlorinated compounds per 1 g activated carbon ranged from 12 to 42 mg/g and 4 to 73 mg/g, respectively. Similarly, BTEX was entirely adsorbed onto the activated carbon surface at the beginning of the sorption process. The weakly bounded BTEX adsorption led to increasing their concentrations in the effluent gas stream. Vikrant et al. [71] studied benzene adsorption with activated carbon and MOFs, using concentrations of 0.1–1 ppm and 5–50 ppm respectively, and determinations were conducted by a TD-GC/MS instrument. They found that the adsorbents had the order of M199 (94.8 mg/g) > A.C. (93.5 mg/g) > U6 (27.1 mg/g) for the adsorption capacities. Similar to our study, perhaps the most critical part, the low amount of adsorbents were used at the presence of high initial concentrations. While each adsorbent readily achieves to high success in the presence of low initial concentrations, these conditions are different when the same amount of adsorbent is used but the initial concentrations have been raised. The AE-ACH studied in the current study had the ability to remove BETEX from the polluted streams at both high and low initial concentrations. Mataji and Khoshandam [72] enquired about benzene removal in the rich amine stream of gas sweetening systems via activated carbon. They prepared it from a walnut shell using ZnCl2 and H3PO4, and ZnCl2 acted as a better-activating agent at 1544 m2/g. Benzene uptake from amine solution was 61.22 mg/g at 300 mg/L, using 0.1 g of activated carbon. Overall, in the current work, AE-ACH was proved to be very good at the sorptive removal of BTEX components, simultaneously, under real-world conditions. The practical applications of AE-ACH must be planned for high initial BTEX loading conditions. In the future, experiments should be conducted under realistic ambient conditions, and suitable performance metrics should be utilized for a meaningful comparison between other VOCs’ uptakes.

Conclusion

The present work deals with producing AE-ACN and AE-ACH from A. esculentus as agricultural waste biomass for reducing gaseous BTEX pollutants from the streams in which such pollutants are present in different concentrations. The adsorption experiments were used to investigate the effect of some parameters like time, humidity, and concentration in both single- and multi-component systems. The prepared adsorbent was successful in the trapping of BTEX pollutants. The physical and chemical characteristics of AE-ACN, AE-ACH, and AEB were studied. The AE-ACH showed a higher success in comparison with AE-ACN. Capture capacities of AE-ACH in a mixture of BTEX compounds were obtained to be between 6.86 and 93.62 mg/g, in tandem with the conditions applied. The overall findings indicate that AE-AC, with a low-cost and high surface area of 968 m2/g, supports future work to develop the progress of gaseous BTEX removal. Adsorption efficiency results indicated that the adsorption performance of multi-BTEX pollutants onto AE-ACH and AE-ACN might be attributed to the useful interaction between the adsorbent surface and the pollutant. Results indicated that the multi-component adsorption system leads to lower adsorption capacities, with stronger adsorption affinities for non-polar molecules. Mono-component adsorption of BTEX has a better performance compared to multi-component adsorption system. In future research, conducting more studies and developing highly productive materials and processes for the preparation of suitable adsorbents will bring about sustainability in the elimination of BTEX compounds from the gas environment.

Data Availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Anjum, H., Johari, K., Gnanasundaram, N., Appusamy, A., & Thanabalan, M. (2019). Impact of surface modification on adsorptive removal of BTX onto activated carbon. Journal of Molecular Liquids, 280, 238–251. https://doi.org/10.1016/j.molliq.2019.02.046

Asadieraghi, M., & Daud, W. M. A. W. (2014). Characterization of lignocellulosic biomass thermal degradation and physiochemical structure: Effects of demineralization by diverse acid solutions. Energy Conversion and Management, 82, 71–82. https://doi.org/10.1016/j.enconman.2014.03.007

ASTM D1102–84 (2013). Standard Test Method for Ash in Wood ASTM International, West Conshohocken

Baghani, A. N., Rostami, R., Arfaeinia, H., Hazrati, S., Fazlzadeh, M., & Delikhoon, M. (2018). BTEX in indoor air of beauty salons: risk assessment, levels and factors influencing their concentrations. Ecotoxicology and Environmental Safety, 159, 102–108. https://doi.org/10.1016/j.ecoenv.2018.04.044

Batur, E., & Kutluay, S. (2022). Dynamic adsorption behavior of benzene, toluene, and xylene VOCs in single-and multi-component systems by activated carbon derived from defatted black cumin (Nigella sativa L.) biowaste. Journal of Environmental. Chemical Engineering, 10(3), 107565. https://doi.org/10.1016/j.jece.2022.107565

Bhandari, P. N., Kumar, A., Bellmer, D. D., & Huhnke, R. L. (2014). Synthesis and evaluation of biochar-derived catalysts for removal of toluene (model tar) from biomass-generated producer gas. Renewable Energy, 66, 346–353.

Bhattarai, D. P., Pant, B., Acharya, J., Park, M., & Ojha, G. P. (2021). Recent progress in metal–organic framework-derived nanostructures in the removal of volatile organic compounds. Molecules, 26(16), 4948. https://doi.org/10.3390/molecules26164948

Bobbitt, N. S., Mendonca, M. L., Howarth, A. J., Islamoglu, T., Hupp, J. T., Farha, O. K., & Snurr, R. Q. (2017). Metal–organic frameworks for the removal of toxic industrial chemicals and chemical warfare agents. Chemical Society Reviews, 46(11), 3357–3385. https://doi.org/10.1039/C7CS00108H

Dutta, C., Som, D., Chatterjee, A., Mukherjee, A. K., Jana, T. K., & Sen, S. (2009). Mixing ratios of carbonyls and BTEX in ambient air of Kolkata, India and their associated health risk. Environmental Monitoring and Assessment, 148(1), 97–107. https://doi.org/10.1007/s10661-007-0142-0

Fedoruk, M. J., & Kerger, B. D. (2003). Measurement of volatile organic compounds inside automobiles. Journal of Exposure Science & Environmental Epidemiology, 13(1), 31–41. https://doi.org/10.1038/sj.jea.7500250

Feng, F., Zheng, Y., Shen, X., Zheng, Q., Dai, S., Zhang, X., & Yan, K. (2015). Characteristics of back corona discharge in a honeycomb catalyst and its application for treatment of volatile organic compounds. Environmental Science & Technology, 49(11), 6831–6837. https://doi.org/10.1021/acs.est.5b00447

Franco, M., Chairez, I., Poznyak, T., & Poznyak, A. (2012). BTEX decomposition by ozone in gaseous phase. Journal of Environmental Management, 95, S55–S60. https://doi.org/10.1016/j.jenvman.2011.09.009

Fu, K., Yue, Q., Gao, B., Sun, Y., & Zhu, L. (2013). Preparation, characterization and application of lignin-based activated carbon from black liquor lignin by steam activation. Chemical Engineering Journal, 228, 1074–1082. https://doi.org/10.1016/j.cej.2013.05.028

Fu, S., Zheng, Y., Zhou, X., Ni, Z., & Xia, S. (2019). Visible light promoted degradation of gaseous volatile organic compounds catalyzed by Au supported layered double hydroxides: Influencing factors, kinetics and mechanism. Journal of Hazardous Materials, 363, 41–54. https://doi.org/10.1016/j.jhazmat.2018.10.009

Ghaffari, H. R., Kamari, Z., Hassanvand, M. S., Fazlzadeh, M., & Heidari, M. (2021). Level of air BTEX in urban, rural and industrial regions of Bandar Abbas, Iran; indoor-outdoor relationships and probabilistic health risk assessment. Environmental Research, 200, 111745. https://doi.org/10.1016/j.envres.2021.111745

Hadei, M., Hopke, P. K., Rafiee, M., Rastkari, N., Yarahmadi, M., Kermani, M., & Shahsavani, A. (2018). Indoor and outdoor concentrations of BTEX and formaldehyde in Tehran, Iran: Effects of building characteristics and health risk assessment. Environmental Science and Pollution Research, 25(27), 27423–27437. https://doi.org/10.1007/s11356-018-2794-4

Huang, B., Lei, C., Wei, C., & Zeng, G. (2014). Chlorinated volatile organic compounds (Cl-VOCs) in environment—sources, potential human health impacts, and current remediation technologies. Environment International, 71, 118–138. https://doi.org/10.1016/j.envint.2014.06.013

Huang, H., Huang, H., Zhan, Y., Liu, G., Wang, X., Lu, H., et al. (2016). Efficient degradation of gaseous benzene by VUV photolysis combined with ozone-assisted catalytic oxidation: Performance and mechanism. Applied Catalysis B: Environmental, 186, 62–68. https://doi.org/10.1016/j.apcatb.2015.12.055

Huang, X., Tang, M., Li, H., Wang, L., & Lu, S. (2023). Adsorption of multi-component VOCs on various biomass-derived hierarchical porous carbon: A study on adsorption mechanism and competitive effect. Chemosphere, 313, 137513. https://doi.org/10.1016/j.chemosphere.2022.137513

Isinkaralar, K. (2022). High-efficiency removal of benzene vapor using activated carbon from Althaea officinalis L. biomass as a lignocellulosic precursor. Environmental Science and Pollution Research, 29(44), 66728–66740. https://doi.org/10.1007/s11356-022-20579-2

Isinkaralar, K. (2023). Experimental evaluation of benzene adsorption in the gas phase using activated carbon from waste biomass. Biomass Conversion and Biorefinery, 1–10. https://doi.org/10.1007/s13399-023-03979-3

Koh, L. H., Kuhn, D. C., Mohseni, M., & Allen, D. G. (2004). Utilizing ultraviolet photooxidation as a pre-treatment of volatile organic compounds upstream of a biological gas cleaning operation. Journal of Chemical Technology & Biotechnology: International Research in Process, Environmental & Clean Technology, 79(6), 619–625. https://doi.org/10.1002/jctb.1030

Tokumura, M., Wada, Y., Usami, Y., Yamaki, T., Mizukoshi, A., Noguchi, M., & Yanagisawa, Y. (2012). Method of removal of volatile organic compounds by using wet scrubber coupled with photo-Fenton reaction–Preventing emission of by-products. Chemosphere, 89(10), 1238–1242. https://doi.org/10.1016/j.chemosphere.2012.07.018

Ruddy, E. N., & Carroll, L. A. (1993). Select the best VOC control strategy. Chemical Engineering Progress; (United States), 89(7).

Shonnard, D. R., & Hiew, D. S. (2000). Comparative environmental assessments of VOC recovery and recycle design alternatives for a gaseous waste stream. Environmental Science & Technology, 34(24), 5222–5228. https://doi.org/10.1021/es0010857

Jia, Z., & Rousseau, A. (2016). Sorbent track: Quantitative monitoring of adsorbed VOCs under in-situ plasma exposure. Scientific Reports, 6(1), 1–11. https://doi.org/10.1038/srep31888

Kuśtrowski, P., Rokicińska, A., & Kondratowicz, T. (2018). Abatement of volatile organic compounds emission as a target for various human activities including energy production. Advances in Inorganic Chemistry, 72, 385–419. https://doi.org/10.1016/bs.adioch.2018.05.004

Nazaroff, W. W., & Weschler, C. J. (2004). Cleaning products and air fresheners: Exposure to primary and secondary air pollutants. Atmospheric Environment, 38(18), 2841–2865. https://doi.org/10.1016/j.atmosenv.2004.02.040

Kuranchie, F. A., Angnunavuri, P. N., Attiogbe, F., & Nerquaye-Tetteh, E. N. (2019). Occupational exposure of benzene, toluene, ethylbenzene and xylene (BTEX) to pump attendants in Ghana: Implications for policy guidance. Cogent Environmental Science, 5(1), 1603418. https://doi.org/10.1080/23311843.2019.1603418

Potter, T. L., & Simmons, K. E. (1998). Composition of petroleum mixtures (Vol. 2). Amherst Scientific Publishers.

Kalenge, S., Lebouf, R. F., Hopke, P. K., Rossner, A., & Benedict-Dunn, A. (2013). Assessment of exposure to outdoor BTEX concentrations on the Saint Regis Mohawk Tribe reservation at Akwesasne New York State. Air Quality, Atmosphere & Health, 6(1), 181–193. https://doi.org/10.1007/s11869-011-0159-y

Kamal, M. S., Razzak, S. A., & Hossain, M. M. (2016). Catalytic oxidation of volatile organic compounds (VOCs)–A review. Atmospheric Environment, 140, 117–134. https://doi.org/10.1016/j.atmosenv.2016.05.031

Słomińska, M., Konieczka, P., & Namieśnik, J. (2014). The fate of BTEX compounds in ambient air. Critical Reviews in Environmental Science and Technology, 44(5), 455–472. https://doi.org/10.1080/10643389.2012.728808

Ramírez, N., Cuadras, A., Rovira, E., Borrull, F., & Marcé, R. M. (2012). Chronic risk assessment of exposure to volatile organic compounds in the atmosphere near the largest Mediterranean industrial site. Environment International, 39(1), 200–209. https://doi.org/10.1016/j.envint.2011.11.002

Xu, J., Tie, X., Gao, W., Lin, Y., & Fu, Q. (2019). Measurement and model analyses of the ozone variation during 2006 to 2015 and its response to emission change in megacity Shanghai, China. Atmospheric Chemistry and Physics, 19(14), 9017–9035. https://doi.org/10.5194/acp-19-9017-2019

Li, Q., Su, G., Li, C., Liu, P., Zhao, X., Zhang, C., et al. (2020). An investigation into the role of VOCs in SOA and ozone production in Beijing, China. Science of the Total Environment, 720, 137536. https://doi.org/10.1016/j.scitotenv.2020.137536

Orellana, G., & Haigh, D. (2008). New trends in fiber-optic chemical and biological sensors. Current Analytical Chemistry, 4(4), 273–295. https://doi.org/10.2174/157341108785914871

Kandyala, R., Raghavendra, S. P. C., & Rajasekharan, S. T. (2010). Xylene: An overview of its health hazards and preventive measures. Journal of Oral and Maxillofacial Pathology: JOMFP, 14(1), 1. https://doi.org/10.4103/0973-029X.64299

Kneepkens, C. F., Lepage, G., & Roy, C. C. (1994). The potential of the hydrocarbon breath test as a measure of lipid peroxidation. Free Radical Biology and Medicine, 17(2), 127–160. https://doi.org/10.1016/0891-5849(94)90110-4

Marnett, L. J. (2000). Oxyradicals and DNA damage. Carcinogenesis, 21(3), 361–370. https://doi.org/10.1093/carcin/21.3.361

Phillips, M., Cataneo, R. N., Greenberg, J., Grodman, R., Gunawardena, R., & Naidu, A. (2003). Effect of oxygen on breath markers of oxidative stress. European Respiratory Journal, 21(1), 48–51. https://doi.org/10.1183/09031936.02.00053402

Nor, N. M., Lau, L. C., Lee, K. T., & Mohamed, A. R. (2013). Synthesis of activated carbon from lignocellulosic biomass and its applications in air pollution control—A review. Journal of Environmental Chemical Engineering, 1(4), 658–666. https://doi.org/10.1016/j.jece.2013.09.017

Wang, R., Wang, X., Cheng, S., Wang, K., Cheng, L., Zhu, J., & Duan, W. (2022). Emission characteristics and reactivity of volatile organic compounds from typical high-energy-consuming industries in North China. Science of The Total Environment, 809, 151134. https://doi.org/10.1016/j.scitotenv.2021.151134

Khan, F. I., & Ghoshal, A. K. (2000). Removal of volatile organic compounds from polluted air. Journal of Loss Prevention in The Process Industries, 13(6), 527–545. https://doi.org/10.1016/S0950-4230(00)00007-3

Nunes, C. D., Pires, J., Carvalho, A. P., Calhorda, M. J., & Ferreira, P. (2008). Synthesis and characterisation of organo-silica hydrophobic clay heterostructures for volatile organic compounds removal. Microporous and Mesoporous Materials, 111(1-3), 612–619. https://doi.org/10.1016/j.micromeso.2007.09.008

Sidheswaran, M. A., Destaillats, H., Sullivan, D. P., Cohn, S., & Fisk, W. J. (2012). Energy efficient indoor VOC air cleaning with activated carbon fiber (ACF) filters. Building and Environment, 47, 357–367. https://doi.org/10.1016/j.buildenv.2011.07.002

Lu, S., Liu, Q., Han, R., Guo, M., Shi, J., Song, C., et al. (2021). Potential applications of porous organic polymers as adsorbent for the adsorption of volatile organic compounds. Journal of Environmental Sciences, 105, 184–203. https://doi.org/10.1016/j.jes.2021.01.007

Yang, C., Qian, H., Li, X., Cheng, Y., He, H., Zeng, G., & Xi, J. (2018). Simultaneous removal of multi-component VOCs in biofilters. Trends in Biotechnology, 36(7), 673–685. https://doi.org/10.1016/j.tibtech.2018.02.004

Rhoderick, G. C., Cecelski, C. E., Miller, W. R., Worton, D. R., Moreno, S., Brewer, P. J., et al. (2019). Stability of gaseous volatile organic compounds contained in gas cylinders with different internal wall treatments. Elementa: Science of the Anthropocene, 7. https://doi.org/10.1525/elementa.366

US EPA. (1999). Determination of volatile organic compounds in ambient air using active sampling onto sorbent tubes, compendium of methods for the determination of toxic organic compounds in ambient air, Second Edition Compendium Method TO-17. U.S. Environmental Protection Agency (US EPA).

Lv, Y., Sun, J., Yu, G., Wang, W., Song, Z., Zhao, X., & Mao, Y. (2020). Hydrophobic design of adsorbent for VOC removal in humid environment and quick regeneration by microwave. Microporous and Mesoporous Materials, 294, 109869. https://doi.org/10.1016/j.micromeso.2019.109869

Ribas, M. C., Adebayo, M. A., Prola, L. D., Lima, E. C., Cataluña, R., Feris, L. A., et al. (2014). Comparison of a homemade cocoa shell activated carbon with commercial activated carbon for the removal of reactive violet 5 dye from aqueous solutions. Chemical Engineering Journal, 248, 315–326. https://doi.org/10.1016/j.cej.2014.03.054

Waghmare, P. R., Kadam, A. A., Saratale, G. D., & Govindwar, S. P. (2014). Enzymatic hydrolysis and characterization of waste lignocellulosic biomass produced after dye bioremediation under solid state fermentation. Bioresource Technology, 168, 136–141. https://doi.org/10.1016/j.biortech.2014.02.099

Jakab, E., & Omastová, M. (2005). Thermal decomposition of polyolefin/carbon black composites. Journal of Analytical and Applied Pyrolysis, 74(1-2), 204–214. https://doi.org/10.1016/j.jaap.2005.02.001

Wu, Z., Wang, S., Zhao, J., Chen, L., & Meng, H. (2014). Synergistic effect on thermal behavior during co-pyrolysis of lignocellulosic biomass model components blend with bituminous coal. Bioresource Technology, 169, 220–228. https://doi.org/10.1016/j.biortech.2014.06.105

Yao, X., Liu, Y., Li, T., Zhang, T., Li, H., Wang, W., & Yao, Z. (2020). Adsorption behavior of multi-component volatile organic compounds on a citric acid residue waste-based activated carbon: Experiment and molecular simulation. Journal of Hazardous Materials, 392, 122323. https://doi.org/10.1016/j.jhazmat.2020.122323

Kim, K. J., Kang, C. S., You, Y. J., Chung, M. C., Woo, M. W., Jeong, W. J., et al. (2006). Adsorption–desorption characteristics of VOCs over impregnated activated carbons. Catalysis Today, 111(3-4), 223–228. https://doi.org/10.1016/j.cattod.2005.10.030

Lillo-Ródenas, M. A., Cazorla-Amorós, D., & Linares-Solano, A. (2005). Behaviour of activated carbons with different pore size distributions and surface oxygen groups for benzene and toluene adsorption at low concentrations. Carbon, 43(8), 1758–1767. https://doi.org/10.1016/j.carbon.2005.02.023

Plaza, M. G., Pevida, C., Martín, C. F., Fermoso, J., Pis, J. J., & Rubiera, F. (2010). Developing almond shell-derived activated carbons as CO2 adsorbents. Separation and Purification Technology, 71(1), 102–106. https://doi.org/10.1016/j.seppur.2009.11.008

Shen, Y. (2022). Biomass-derived porous carbons for sorption of Volatile organic compounds (VOCs). Fuel, 126801. https://doi.org/10.1016/j.fuel.2022.126801

Zeng, Y., Zhu, X., Yuan, Y., Zhang, X., & Ju, S. (2012). Molecular simulations for adsorption and separation of thiophene and benzene in Cu-BTC and IRMOF-1 metal–organic frameworks. Separation and Purification Technology, 95, 149–156. https://doi.org/10.1016/j.seppur.2012.04.032

Vellingiri, K., Szulejko, J. E., Kumar, P., Kwon, E. E., Kim, K. H., Deep, A., & Brown, R. J. (2016). Metal organic frameworks as sorption media for volatile and semi-volatile organic compounds at ambient conditions. Scientific Reports, 6(1), 1–11. https://doi.org/10.1038/srep27813

Tham, Y. J., Latif, P. A., Abdullah, A. M., Shamala-Devi, A., & Taufiq-Yap, Y. H. (2011). Performances of toluene removal by activated carbon derived from durian shell. Bioresource Technology, 102(2), 724–728. https://doi.org/10.1016/j.biortech.2010.08.068

Mohammed, J., Nasri, N. S., Zaini, M. A. A., Hamza, U. D., & Ani, F. N. (2015). Adsorption of benzene and toluene onto KOH activated coconut shell based carbon treated with NH3. International Biodeterioration & Biodegradation, 102, 245–255. https://doi.org/10.1016/j.ibiod.2015.02.012

Liu, H. B., Yang, B., & Xue, N. D. (2016). Enhanced adsorption of benzene vapor on granular activated carbon under humid conditions due to shifts in hydrophobicity and total micropore volume. Journal of Hazardous Materials, 318, 425–432. https://doi.org/10.1016/j.jhazmat.2016.07.026

Sui, H., An, P., Li, X., Cong, S., & He, L. (2017). Removal and recovery of o-xylene by silica gel using vacuum swing adsorption. Chemical Engineering Journal, 316, 232–242. https://doi.org/10.1016/j.cej.2017.01.061

Rajabi, H., Mosleh, M. H., Prakoso, T., Ghaemi, N., Mandal, P., Lea-Langton, A., & Sedighi, M. (2021). Competitive adsorption of multi-component volatile organic compounds on biochar. Chemosphere, 283, 131288. https://doi.org/10.1016/j.chemosphere.2021.131288

Khodwe, M. S., & Ashlesha, M. K. (2022). Adsorption kinetic studies of activated carbon fabric for the removal of volatile organic components. Materials Today: Proceedings, 68, 1051–1056. https://doi.org/10.1016/j.matpr.2022.08.294

Long, Y., Meng, Q., Chen, M., Luo, X., Dai, Q., Lu, H., et al. (2022). Selective Ru adsorption on SnO2/CeO2 mixed oxides for efficient destruction of multi-component volatile organic compounds: From laboratory to practical possibility. Environmental Science & Technology, 56(13), 9762–9772. https://doi.org/10.1021/acs.est.2c02925

Shin, H. C., Park, J. W., Park, K., & Song, H. C. (2002). Removal characteristics of trace compounds of landfill gas by activated carbon adsorption. Environmental Pollution, 119(2), 227–236. https://doi.org/10.1016/S0269-7491(01)00331-1

Vikrant, K., Na, C. J., Younis, S. A., Kim, K. H., & Kumar, S. (2019). Evidence for superiority of conventional adsorbents in the sorptive removal of gaseous benzene under real-world conditions: Test of activated carbon against novel metal-organic frameworks. Journal of Cleaner Production, 235, 1090–1102. https://doi.org/10.1016/j.jclepro.2019.07.038

Mataji, M., & Khoshandam, B. (2014). Benzene adsorption on activated carbon from walnut shell. Chemical Engineering Communications, 201(10), 1294–1313. https://doi.org/10.1080/00986445.2013.808996

Author information

Authors and Affiliations

Contributions

Kaan Isinkaralar: investigation, data curation, writing-original draft, writing—reviewing and editing. Keikimanova Meruyert: data modeling; writing—reviewing and editing.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable

Competing Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Isinkaralar, K., Meruyert, K. Adsorption Behavior of Multi-Component BTEX on the Synthesized Green Adsorbents Derived from Abelmoschus esculentus L. Waste Residue. Appl Biochem Biotechnol 195, 4864–4880 (2023). https://doi.org/10.1007/s12010-023-04556-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04556-0