Abstract

Bacterial cellulose (BC) is a biopolymer mainly produced by acetic acid bacteria (AAB) that has several applications in the medical, pharmaceutical, and food industries. As other living organisms, AAB require sources of chemical elements and nutrients, which are essential for their multiplication and metabolite production. So, the knowledge of the nutritional needs of microorganisms that have important industrial applications is necessary for the nutrients to be supplied in the appropriate form and amount. Considering that the choice of different nutrients as nitrogen source can result in different metabolic effects, this work aimed to verify the effects of amino acid supplementation in the culture media for BC production by an AAB strain (Komagataeibacter intermedius V-05). For this, nineteen amino acids were tested, selected, and optimized through a Plackett and Burman factorial design and central composite design to determine the optimal concentrations of each required amino acid. Membranes produced under optimal conditions were characterized in relation to chemical structure and properties by X-ray diffraction (XRD), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), infrared spectroscopy (FT-IR), and hydrophilic properties. Three amino acids had a significant positive effect and were required: aspartic acid (1.5 g L−1), phenylalanine (1.5 g L−1), and serine (3.0 g L−1). Conversely, all sulfur and positively charged amino acids had a negative effect and reduced the production yield. After optimization and validation steps, a production level of 3.02 g L−1 was achieved. Membranes produced from optimized media by this strain presented lower crystallinity index but greater thermal and hydrophilic properties than those produced from standard HS medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most abundant renewable biopolymer on Earth. It is the main structural component of the primary cell wall in plants. However, cellulose may also be produced by some algae and bacterial strains [1, 2]. Bacterial cellulose (BC) is mainly synthesized by acetic acid bacteria from the genus Komagataeibacter [3]. In the static cultivation method, a white gelatinous membrane is formed on the surface of the culture medium consisting of a nanofibrillated arrangement of pure cellulosic fibers that increases in thickness with increasing cultivation time. Unlike cellulose of plant origin, BC is free of lignin, pectin, and hemicellulose. Thus, its purification process is relatively simpler and cheaper and has reduced environmental damage [4, 5]. BC has high purity and crystallinity, good thermal and mechanical properties, and excellent biocompatibility and biodegradability. Due to these intrinsic properties, BC has widespread applications in various industrial sectors such as food, pharmaceutical, and bio-medical industries [6].

The optimization of productive conditions is a very important step in fermentative processes due to their high complexity and influence by many variables, including physical parameters (pH and temperature) and the nutritional composition of culture media [7]. The classical method usually employed uses “one-factor-at-a-time,” in which the level of one factor is changed while keeping the other factors constant. It has the advantage of being simple and easy. However, the combined effect of all involved factors and their possible interactions is not considered. Conversely, statistical methods are generally preferred due to their advantages since they could minimize errors in determining the effect of parameters in a more economical manner [8, 9]. In a process that involves a large number of variables, the first step is to identify significant factors with positive or negative effects on the response of interest. Then, critical components can be eliminated or selected for further optimization. The Plackett and Burman factorial design is a suitable method for this purpose, especially when there are many factors involved, since it allows estimating the main effects with a reduced number of experiments [10, 11].

Following the selection of the main factors, the next step is to identify the optimal concentrations of selected parameters through optimization by response surface methodology (RSM). RSM is a collection of tools developed for the purpose of determining optimum operating conditions. It has been applied in several sectors such as chemical [12], biotechnological [13], and food industries [14]. RSM utilizes mathematical and statistical techniques to design experiments, build models, identify relevant factors, study interactions, and search for optimal conditions. As a result, the generated experimental model gives a relationship between the predicted values of independent variables and response variables, which are used to construct contour and surface plots [14, 15]. It has been proven that experimental designs are more efficient than traditional methods, especially in multivariable selection. The statistical approaches applied in fermentative processes can result in improved production yields, reduced process variability, closer confirmation of the interest response to the expected requirements, and reduced development time and overall cost [16, 17].

The production of cellulose using microorganisms is performed through the inoculation of viable cells in a nutrient solution, which has the purpose of promoting microbial development and favoring product formation. There are several factors that strongly influence bacterial growth and the accumulation of metabolic products. In the cultivation media, carbon and nitrogen sources play important roles because microbial biomass is mainly composed of these elements; they are a fundamental energy source for microorganisms and are still directly linked with product formation [18]. Microorganisms can utilize both inorganic and/or organic nitrogen sources. When utilizing organic nitrogen, the use of some specific amino acids can increase productivity, while unsuitable amino acids may inhibit the synthesis of metabolites. The choice of organic nitrogen source may also significantly influence cell growth and polysaccharide formation compared to inorganic nitrogen because they are present in important cellular biomolecules such as proteins and nucleic acids [19, 20]. Proteins formed by amino acids are vital biomolecules that include enzymes. These biomolecules are responsible for catalyzing many biochemical reactions in a variety of biological processes in all living cells.

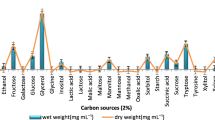

Some studies reported that different carbon sources including monosaccharides, disaccharides, and sugar alcohols had different effects on the efficiency of BC production [21, 22]. In the same way, the investigation of different types of nitrogen sources used in the culture media like amino acids could increase the knowledge about the factors that influence BC production by AAB strains. However, no studies were found reporting this topic, mainly by using statistical tools for analysis of effects and optimization of variables. Thus, this work aimed to evaluate the effects of medium supplementation with several amino acids on BC production by an acetic acid bacterium from the genus Komagataeibacter. Amino acids with positive effects were selected for optimization by RSM, and the samples obtained under optimal conditions were characterized in relation to their structure and properties.

Material and Methods

Material

All experiments were carried out by using an acetic acid bacterium named Komagataeibacter intermedius V-05, previously isolated from the vinegar industry [23]. The amino acids were purchased from Dinâmica (Indaiatuba, SP, Brazil), Sigma-Aldrich (St. Louis, MO, USA), Synth (Diadema, SP, Brazil), and Thermo Fisher Scientific (Waltham, MA, USA). Other reagents and chemical products were of analytical grade and purchased from different companies: Himedia (Mumbai, India), Anidrol (Diadema, SP, Brazil), Inlab (Diadema, SP, Brazil), Nuclear (Diadema, SP, Brazil), and Vetec Química (Rio de Janeiro, RJ, Brazil).

Activation of Microorganisms and Preparation of Inoculum

Bacterial colonies of K. intermedius V-05 previously grown on mannitol-yeast extract-peptone (MYP) agar (25 g L−1 mannitol, 5 g L−1 yeast extract, 3 g L−1 peptone, and 10 g L−1 agar) were cultivated in tubes containing 10 mL Hestrin-Schramm (HS) medium composed of 20 g L−1 glucose, 5 g L−1 peptone, 5 g L−1 yeast extract, 2.7 g L−1 Na2HPO4, and 1.15 g L−1 citric acid. After microbial growth under static conditions (30 ± 0.5 °C), the cultivated broth was transferred to new flasks containing 100 mL HS medium. This newly cultivated broth was used as inoculum after an incubation period (30 °C for 5 days) in a microbiological incubator (Tecnal TE-391) under static conditions. Then, the hydrolysis of BC formed on the surface of the medium was carried out using 0.02% cellulase enzyme (1–2 days at 30 ± 0.5 °C) to obtain a high amount of cells per milliliter.

Basal Medium and Inoculation of the Microorganisms

To analyze the effects on BC production by adding several amino acids, a yeast extract and peptone-free synthetic culture medium containing only selected macronutrients (50 g L−1 sucrose, 10 g L−1 (NH4)2SO4), 2 g L−1 NaH2PO4, 1 g L−1 MgSO4.7H2O, and 10 mL L−1 ethanol) was prepared. The pH of the medium was adjusted to 6.00 ± 0.10 with 1 M KOH. After hydrolysis of the inoculum, the cells were centrifuged (Eppendorf Centrifuge 5804R, Germany) for 15 min at 5000 rpm (5 °C) to remove culture medium interferers. A cell suspension containing 108 colony-forming units (CFU) per milliliter was transferred to flasks containing basal medium (100 mL) supplemented with varying concentrations of amino acids, according to the screening and optimization experiments.

Experimental Design for the Selection of Amino Acids

To select amino acids that influence BC production by the strain K. intermedius V-05, the Plackett and Burman design was employed. The amino acids used were alanine, arginine, asparagine, aspartic acid, cysteine, glutamine, glutamic acid, glycine, histidine, isoleucine, leucine, lysine, methionine, phenylalanine, proline, serine, threonine, tryptophan, and valine. An experimental design composed of 28 runs was generated for nineteen variables (amino acids), five dummy variables, and four central points. The actual values of the variables are given in Table 1, where each factor is represented at three levels: high (+ 1), middle (0), and low (− 1). The incorporation of a dummy variable made it possible to estimate the variance of an effect (experimental error), while the addition of a central point allowed us to verify the repeatability of the process [24]. The experimental design was generated and analyzed by using R® statistical software (R Core Team, Version 3.6.3). The response variable was the mass of BC produced and expressed in dry weight (g L−1). The effect of each variable was equal to the difference between the average of the response variable made at a high concentration level of the factor and the average of the response variable made at a low concentration level of the same factor. The resultant effect of each variable was determined by the following equation [25]:

where \(E\left({\text{X}}i\right)\) is the concentration effect of the tested variable; \({{\text{M}}i}^{+}\) and \({{\text{M}}i}^{-}\) represent BC production from the runs where the measured variables \({\text{X}}i\) were present at high and low concentrations, respectively; and \(N\) is the total number of runs that was equal to 24. The significance level of each variable was determined via their p values using Student’s t test [19]:

where \(E\left({\text{X}}i\right)\) is the effect of variable \({\text{X}}i\) and SE is the standard error of the concentration effect that was equal to the square root of the variance of an effect.

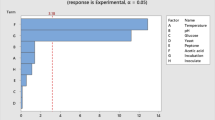

Variables with confidence levels greater than 90% were considered to significantly influence BC production. From the analysis of the results, the three most relevant variables with significant and positive effects were selected.

Central Composite Design

A 23 central composite design (CCD) was used to obtain the optimal levels of the three selected variables. Independent variables were X1 = aspartic acid (g L−1), X2 = phenylalanine (g L−1), and X3 = serine (g L−1) at five fixed levels (− α, − 1, 0, + 1, and + α). The full factorial design consisted of 18 experiments performed with different combinations of the three independent variables, six axial points, and four replicates at the center point (Table 2). The response variable was the mass of BC produced and expressed in dry weight (g L−1). The experimental design was generated and analyzed by using the statistical software R® (R Core Team, Version 3.6.3), and the estimated effects, regression coefficients, analysis of variance (ANOVA), and optimal conditions of the essential amino acids were determined. The second-order polynomial model was represented by the following quadratic equation [26]:

where \({\text{Y}}\) is the predicted response variable; β0 is the intercept coefficient; βi is the coefficient of the linear effect; βii is the coefficient of the squared effect; βij is the coefficient of interaction; and \({X}_{i}\) is the coded value of the independent variables.

An experiment was run using the optimal values given by a polynomial equation to confirm the predicted values. The mathematical model was validated using Student’s t test (α = 0.05), where the average of the experimental values (n = 5) was compared with the predicted values of BC given by a polynomial equation. Another experiment was carried out in HS medium to compare BC production in optimized synthetic medium supplemented with amino acids and in a standard complex medium.

Quantification of Bacterial Cellulose Produced

After 10 days, the bacterial cellulose produced on the surface of each medium was collected and heated in 2% (w/v) NaOH solution for 1 h at 80 °C and then washed with distilled water until neutral pH was reached [27]. BC membranes obtained after the alkaline treatment were dried until constant weight to determine the respective yields expressed in dry weight (g L−1).

Characterization of Bacterial Cellulose Produced

Bacterial cellulose produced under optimal conditions and in standard HS medium was dried in an oven at 60 °C to be characterized as follows:

Fourier Transform Infrared Spectroscopy (FT-IR)

Infrared spectra were recorded using a spectrometer (Shimadzu, Prestige-21, Japan) over the 4000–400 cm−1 range. Dried BC samples were mixed with potassium bromide (KBr) powder, and their spectra were collected in transmission mode with a resolution of 1 cm−1 [28].

X-Ray Diffraction (XRD)

XRD patterns of the samples were obtained using an X-ray diffractometer (Malvern Panalytical X’Pert PRO MPD, Almelo, Netherlands) with Cu-Kα radiation (λ = 1.5418 Å) in the method known as θ–2θ, Bragg–Brentano geometry. The radiation source voltage and electric current were 40 kV and 40 mA, respectively. The 2θ scans were made in the range between 5 and 70° with an angular step of 0.04°. The counting time per point was 3.0 s. The degree of crystallinity was determined for cellulose I as described by Segal et al. [29]:

where I002 is the maximum peak intensity corresponding to the 002 lattice diffraction at angle 2θ = 22.8° and \({\text{Iam}}\) is the intensity of diffraction corresponding to the amorphous background at angle 2θ = 18°.

Differential Scanning Calorimetry (DSC)

DSC curves of the samples were obtained using a differential scanning calorimeter (Shimadzu DSC-60, Tokyo, Japan). The scans were started at room temperature and completed at 400 °C under a nitrogen atmosphere (50 mL min−1) and a heating rate of 10 °C min−1. The calorimeter was calibrated with indium standard [30].

Thermogravimetric Analysis (TGA)

Thermal analysis of the samples (approximately 5 mg) was performed using a thermal analyzer (Shimadzu TGA-50, Tokyo, Japan). The temperatures of scans were ramped from room temperature to 600 °C at a heating rate of 10 °C min−1 under a nitrogen atmosphere (50 mL min−1). The derivative form of TG curves (DTG) was obtained using differential TGA values. The TGA and DTG curves were expressed as the mass variation as a function of temperature [30].

Hydrophilic Properties

To determine the water holding capacity (WHC), rehydration capacity (RC), and moisture content, never-dried samples were shaken quickly and weighed after being removed from the storage recipient (BCwet). Then, the samples were dried in an oven until the water was completely removed and weighed again (BCdry). WHC was calculated by the following formula [31]:

Reabsorption capacity was determined by immersion of dried membranes (BCdry) in distilled water until rehydrated samples (BCr) reached constant weight. RC was calculated by the following formula [32]:

The moisture content of BC was determined according to the following equation [33]:

Results and Discussion

Effect Analysis of Amino Acids on Bacterial Cellulose Production by Acetic Acid Bacteria

Table 1 shows the Plackett and Burman experimental design containing actual values of independent variables and the response variable corresponding to the mass of BC obtained in each of the 28 experimental runs. The 19 amino acids evaluated in this assay produced BC with dry weights varying between 0.72 and 1.40 g.L−1. Table S1 presents the estimated effects and confidence level (p value) of each variable on BC production. The coefficient of determination (R2) was equal to 0.9468, indicating that 94.68% of the variability in the results can be explained by the model. Adjusted R2 was equal to 0.8206. The Plackett and Burman design was useful to select the most significant variables. Among the 19 amino acids tested, aspartic acid, phenylalanine, and serine had more significant positive effects and were required for the biosynthesis of BC.

Aspartic acid (also known as aspartate) is a negatively charged polar amino acid constituent of most proteins and peptides. It is also used for the synthesis of asparagine, pyrimidine, and purine nucleotides [34, 35]. Furthermore, aspartate is a precursor of β-alanine. It has been suggested that some bacteria and fungi are capable of converting β-alanine to pantothenic acid in vivo. The originated pantothenate is either released from the cell or used for coenzyme A (CoA) biosynthesis. CoA is an essential cofactor for the growth of microorganisms. It is involved in many metabolic reactions, including the synthesis of phospholipids, synthesis and degradation of fatty acids, and the operation of the tricarboxylic acid cycle (TCA), which is one of the stages of cellular respiration to produce energy from carbohydrate catabolism [35,36,37,38]. In addition to CoA, aspartate may be a key precursor for nicotinamide adenine dinucleotide (NAD+) synthesis, which is an important cofactor for several cellular enzymes. NAD and its phosphorylated form NADP can originate via quinolinic acid via several routes depending on the organism and the precursors used. The major biosynthetic pathways used for quinolinate production in vivo are aspartate in most prokaryotes and tryptophan in eukaryotic cells [39,40,41].

The aromatic amino acid phenylalanine is needed for the synthesis of proteins and is also an important precursor of the amino acid tyrosine. Catabolism of tyrosine generates fumarate, which is a glucogenic intermediate utilized directly through the Krebs cycle [34]. Tyrosine was the only proteinogenic amino acid not used in this study due to its low solubility in water.

Serine is a neutral amino acid needed for the synthesis of proteins, selenocysteine, and other amino acids, such as glycine, cysteine, and alanine. Serine can also be a precursor for the synthesis of several types of phospholipids, including phosphatidylcholine (PC), phosphatidylethanolamine (PE), and phosphatidylserine (PS) [34]. Phospholipids are the molecules that build cell membranes. The plasma membrane of prokaryotes consists primarily of phospholipids, which are arranged in two parallel rows, named the lipid bilayer. PC is predominantly found in the outer leaflet of the cell membrane, while PE and PS predominate in the inner leaflet phospholipid. Phospholipids are essential components of cell survival because they act as a barrier of the membrane that separates the cell content from the water-based environment in which it lives [38, 42].

Significant negative effects were observed for seven amino acids: methionine (p < 0.001), cysteine (p < 0.001), arginine (p < 0.05), tryptophan (p < 0.05), alanine (p < 0.05), leucine (p < 0.05), and histidine (p < 0.10). If the effect found was negative and showed a significance level equal to or above 90%, it was considered effective, but the concentration required may be lower than the indicated low level (− 1). Therefore, they were removed from the optimization experiments. Remaining components, i.e., asparagine, glycine, glutamine, glutamic acid, isoleucine, proline, lysine, threonine, and valine, showed low positive or negative confidence levels and were considered insignificant in this study. In general, all sulfur and positively charged amino acids were rejected. This fact demonstrates that the most suitable amino acids for BC production by this strain are nonsulfurized and not positively charged polar amino acids. Aspartic acid, phenylalanine, and serine were selected to optimize their response, and their optimum levels were found through RSM.

Heo and Son [43] investigated BC production by Acetobacter sp. A9 in a defined medium by omission of a single component. The single omission of arginine or threonine affected BC production, causing a slight decrease. In the same way, Son et al. [44] verified that among 18 amino acids tested (except glutamine and phenylalanine), the single addition of tyrosine, valine, methionine, isoleucine, or glycine reduced the level of BC by Acetobacter sp. V6. However, BC production by the addition of the other amino acids slightly increased. Another study on the effects of 14 amino acids (except asparagine, glutamine, histidine, cysteine, tyrosine, and tryptophan) found that methionine stimulated the growth rate during the early stage of the culture period and increased cellulose production by Acetobacter xylinum subsp. sucrofermentans. This study suggested that amino acid methionine would be essential to obtain high cellulose yields and stimulate cell growth for this strain [45]. These facts demonstrate that possibly due to structural similarities of amino acids, the requirements of these compounds for cellulose production by AAB may vary significantly and is strongly dependent on the strain and methodology of the study used.

Analysis of Central Composite Design

Table 2 shows the central composite design involving three independent variables and the response variable expressed as the mass of BC obtained in each of the 18 experimental runs. The dry weight of BC varied from 1.21 to 3.09 g L−1. Analysis of variance (Table S2) showed that all quadratic effects were negative and significant (p < 0.10), which indicated that an optimal region was reached. Moreover, no interaction term had a significant positive or negative effect, indicating that there was no interaction among these parameters that positively or negatively influenced BC production. The coefficient of determination (R2 = 0.9091) was satisfactory, indicating that 90.91% of the data variability can be explained by the predicted model. Adjusted R2 was slightly lower than regular R2 (0.8069). This parameter is similar to regular coefficient of determination but the R2 always increases or at least stays constant when adding new variables in the model. On the contrary, adjusted R2 can decrease especially if the added independent variables have little explanatory power of if the degrees of freedom become too small, thus indicating if the new variable really improves the model [46, 47]. The lack-of-fit test was not significant (p > 0.10), indicating that the predicted model was well adjusted to the data.

From the results achieved by central composite design, a second-order regression model was obtained that explains the dependence of independent variables on the response variable and provided the levels of BC as a function of the concentration of the amino acids aspartic acid, phenylalanine, and serine. Therefore, the levels of BC produced by K. intermedius V-05 could be predicted by the following quadratic polynomial equation, in which terms in bold are considered significant at the 90% confidence level:

where \({\text{Y}}{\text{BC}}\) is the response variable (BC production), \({{\varvec{x}}}_{1}\) is the coded value of variable X1 (aspartic acid), \({{\varvec{x}}}_{2}\) is the coded value of variable X2 (phenylalanine), and \({{\varvec{x}}}_{3}\) is the coded value of variable X3 (serine).

The three-dimensional (3D) response surface graphs and contour curves were plotted from the second-order regression model. Figure 1 shows the dependency of BC production on the variables studied at different concentration levels and the regions of maximum production. According to Fig. 1a, b, and c, the increase or decrease in aspartic acid, phenylalanine, and serine concentrations resulted in decreased BC production levels. From the quadratic polynomial Eq. (8) and the response surface plots, the optimal concentration of the variables was found to be closer to the (0) level, i.e., 1.50 g L−1 aspartic acid, 1.50 g L−1 phenylalanine, and 3.00 g L−1 serine.

Validation of the Experimental Model

Verification of the calculated optimal conditions for BC production was performed by performing the experiment at predicted optimized conditions. In this study, the maximum predicted BC production that could be reached using the optimal concentrations of variables (1.50 g L−1 aspartic acid, 1.50 g L−1 phenylalanine, and 3.00 g L−1 serine) was 2.94 g L−1. The observed value obtained experimentally under these conditions by K. intermedius V-05 (3.02 ± 0.16 g L−1) was very close to the value estimated by the predictive model (p < 0.05) and the production obtained in HS medium (3.43 ± 0.19 g L−1).

As performed in this work, RSM has been successfully applied to optimize the production of several biomolecules, such as microbial enzymes [48], bacteriocins [49], bioethanol [13], and to improve biotechnological processes, such as for removal of biofilms formed by pathogenic organisms [50].

FT-IR Analysis

Chemical characterization of functional groups of BC produced from optimized medium supplemented with amino acids was performed by FT-IR spectroscopy and compared to samples produced from standard HS medium. Figure 2 presents the obtained FT-IR spectra of the characterized samples, which shows that optimized synthetic media supplemented with amino acids did not change the profile of BC spectra compared to the standard complex media.

According to Table 3, the produced samples presented the main bands that characterize cellulose polymers, such as strong transmission of O–H stretching vibrations at 3400–3500 cm−1; alkane C-H stretching and CH2 asymmetric stretching vibration at 2900 cm−1; CH2 symmetric stretching vibration at 2700 cm−1; O–H deformation vibration at 1600 cm−1; CH2 deformation vibration at 1400 cm−1; CH3 deformation vibration at 1370 cm−1; and C-O deformation vibration in the range of 1320–1030 cm−1, as previously described for cellulose [23, 28]. Bands observed at 1640 cm−1 (H–O-H) and 3500 cm−1 (O–H) were attributed to water absorption by the samples. The absence of bands at 1735 cm−1 associated with functional groups present in proteins (C = O) and other bands of nitrogenous organic compounds at 1538 cm−1 indicated that the purification process was efficient. The results of FT-IR analysis are in agreement with studies of BC biopolymers carried out previously [23], also indicating that the substances produced were chemically pure bacterial cellulose.

XRD Analysis

The XRD patterns of BC samples produced in both optimized synthetic and standard complex media (Fig. 3) demonstrated that the culture medium did not significantly influence the crystal organization of the BC membranes since they showed similar crystalline profiles. Both samples present two major peaks at 14.8° and 22.5° and a low-intensity peak at 16.8°. These diffraction peaks corresponded to the primary diffraction of the crystal planes (1–10), (200), and (110) [51]. The two main peaks observed at 14.8° and 22.5° demonstrated that these samples possess typical crystalline forms of cellulose I. According to the calculated parameters from the related peak intensity, BC membranes obtained from optimized medium supplemented with amino acids showed crystallinity indices slightly lower than those from HS medium (Table 4). This fact may be related to the higher yield reached by the strain in HS complex medium compared to optimized synthetic medium. The crystallinity index of the samples produced in both media was similar to those described by Güzel and Akpınar [52], in which they found values between 80.3 and 93.0% for BC produced from different fruit and vegetal peels.

The high crystallinity index of the samples produced by K. intermedius V-05 (> 85.0%) may indicate an increase in crystalline regions and hydrophobic interactions, making these samples interesting sources for use to stabilize water/oil (W/O) emulsions [53].

DSC Analysis

DSC was used to measure the thermal stability behavior of BC membranes produced in both optimized synthetic and standard complex media. Figure 4 shows the heat absorbed or released by BC membranes as a function of temperature. The DSC curves of both samples presented two main peaks in their spectra. The endothermic peak was observed at approximately 50–65 °C and attributed to evaporation of residual water from the polymers. The exothermic peak was observed at approximately 370 °C and attributed to the thermal decomposition (pyrolysis) of cellulose due to fragmentation of carbonyl and carboxylic bonds [30]. The observed results were in accordance with other results obtained from DSC analysis of pure, acetylated, and phosphorylated BC membranes reported by Barud et al. [30, 54]. As reported by George et al. [55], the glass transition temperature (Tg) of macromolecules like cellulose is difficult to detect properly using DSC technique due to the overlap of the broad heat flow curves. Moreover, no additional peak was observed at temperature of 150 °C due to the melting and degradation of proteinaceous matter. This absence indicated the effectiveness of the alkaline chemical treatment to remove unwanted materials from the culture media [55]. The degradation peaks were found to be approximately 369.0 °C and 374.0 °C for BC produced in complex HS and optimized synthetic media, respectively, indicating improved thermal stability for the samples produced from synthetic medium supplemented with amino acids. The thermal stability of the samples was consistent with the observed degradation profile obtained in TG and DTG analysis.

TG and DTG Analysis

The thermal decomposition and the respective DTG curves of BC membranes are shown in Fig. 5. The TG curves of the samples produced in both optimized synthetic and standard complex media presented similar profiles. The samples presented three distinct mass-loss events, which are characteristic of pure BC. The first event was observed from room temperature (approximately 30 °C) to approximately 150 °C and attributed to mass loss due to evaporation of residual water from the polymeric matrix. The second event was observed between the temperature ranges from 300 to 400 °C and attributed to degradation of cellulose due to dehydration and decomposition of the glycosidic units. Finally, the third event occurred up to 600 °C, corresponding to the thermooxidative degradation (pyrolysis) of cellulose resulting in carbon monoxide liberation [56].

From the plotted curves, the temperatures (parameters) of initial thermal decomposition (Tonset), final thermal decomposition (Tendset), and maximum weight loss rate (Tmax) were determined, as shown in Table 4. Production in optimized medium supplemented with amino acids slightly increased the temperatures of maximum weight loss (364.9 °C) and final thermal degradation (389.8 °C) compared to production in HS complex medium (Tmax = 358.5 °C and Tendset = 375.0 °C). These facts demonstrate a higher energy necessary for the degradation of membranes produced from optimized synthetic media. The thermal stability and degradation temperature profiles of BC observed in this work were similar to those observed by Souza et al. [57]. The values of Tonset were similar to those reported by Rojo et al. [58], in which they found values at approximately 330 °C for pure BC. The maximum weight loss occurred between 300 and 400 °C, indicating that the samples were stable up to this temperature, similar to those reported in other studies of thermal characterization of BC [59]. The improvement in thermal stability makes BC produced in this work a very attractive raw material for food packaging applications.

Hydrophilic Properties

The characterization of the BC membranes regarding water holding capacity (WHC) and rehydration capacity (RC) is shown in Table 4. All the samples had moisture contents greater than 99.0% (w/w). Membranes produced in optimized medium supplemented with amino acids exhibited higher WHC and RC than those produced in HS medium. WHC represents the water mass retained per unit of cellulose dry weight and is mainly related to never-dried BC. Conversely, RC represents the degree to which removed water was recovered by the samples. Both parameters have a direct relation with the porosity and surface area of the BC matrix, which means that a high WHC and RC indicate a more porous membrane [60]. The drying process improves the storage and sell-life of BC, but poor rehydration capacity reduces the utility of dried BC [61, 62].

Because membranes obtained from optimized media supplemented with amino acids presented lower dry weight and crystallinity compared to those from standard medium, the observed increase in hydrophilic properties may be correlated with the increase in empty spaces among BC fibrils caused by the lower density of the membranes. These facts caused an increase in porosity and provided more space for water accommodation. Consequently, more water could penetrate and adsorb onto the material [60]. The high water holding capacity makes BC an excellent wound healing material by maintaining a moist environment and helping to eliminate exudates [63]. The WHC values of BC generally vary between 100 and 200 times its dry weight. However, values reaching up to 400 times dry weight were described by Mohite and Patil [64]. The values observed in this work were similar to those observed by Bandyopadhyay et al. [65] for BC produced from waste apple juice, in which they achieved values between 100 and 250 times dry weight.

Conclusion

The Plackett and Burman factorial design followed by response surface methodology was effective in selecting and determining the best concentration of required amino acids that affect BC production by the strain K. intermedius V-05. Additionally, the different amino acids had distinct effects on the biosynthesis of BC. Aspartic acid, phenylalanine, and serine presented more significant positive effects and improved production. Conversely, others, such as those containing sulfur or positively charged amino acids, presented a significant negative effect and reduced the production yield.

The response surface methodology was also a useful tool that made it possible to elaborate a synthetic growth medium capable of supplying essential amino acids required for the biosynthesis of BC. A maximum production of 3.02 g L−1 was reached in the optimized medium supplemented with amino acids aspartic acid (1.5 g L−1), phenylalanine (1.5 g L−1), and serine (3.0 g L−1). The use of this medium could provide membranes with greater characteristics than those observed by using the standard complex medium, such as some thermal and hydrophilic properties.

Data Availability

All data supporting the conclusions of this study are included within the article and its supplementary materials file.

References

Chen, S. Q., Meldrum, O. W., Liao, Q., Li, Z., Cao, X., Guo, L., Zhang, S., Zhu, J., & Li, L. (2021). The influence of alkaline treatment on the mechanical and structural properties of bacterial cellulose. Carbohydrate Polymers, 271, 118431.

Islam, M. U., Ullah, M. W., Khan, S., Shah, N., & Park, J. K. (2017). Strategies for cost-effective and enhanced production of bacterial cellulose. International Journal of Biological Macromolecules, 102, 1166–1173.

Gomes, R. J., Borges, M. F., Rosa, M. F., Castro-Gómez, R. J. H., & Spinosa, W. A. (2018). Acetic acid bacteria in the food industry: Systematics, characteristics and applications. Food Technology and Biotechnology, 56, 139–151.

Lin, D., Liu, Z., Shen, R., Chen, S., & Yang, X. (2020). Bacterial cellulose in food industry: Current research and future prospects. International Journal of Biological Macromolecules, 158, 1007–1019.

Wang, J., Tavakoli, J., & Tang, Y. (2019). Bacterial cellulose production, properties and applications with different culture methods–A review. Carbohydrate Polymers, 219, 63–76.

Lahiri, D., Nag, M., Dutta, B., Dey, A., Sarkar, T., Pati, S., Edinur, H. A., Kari, Z. A., Noor, N. H. M., & Ray, R. R. (2021). Bacterial cellulose: Production, characterization and application as antimicrobial agent. International Journal of Molecular Sciences, 22, 12984.

Jawan, R., Abbasiliasi, S., Tan, J. S., Mustafa, S., Halim, M., & Ariff, A. B. (2020). Influence of culture conditions and medium compositions on the production of bacteriocin-like inhibitory substances by Lactococcus lactis Gh1. Microorganisms, 8, 1454.

Dinarvand, M., Rezaee, M., & Foroughi, M. (2017). Optimizing culture conditions for production of intra and extracellular inulinase and invertase from Aspergillus niger ATCC 20611 by response surface methodology (RSM). Brazilian Journal of Microbiology, 48, 427–441.

Kumar, S., Pakshirajan, K., & Dasu, V. V. (2009). Development of medium for enhanced production of glutaminase-free L-asparaginase from Pectobacterium carotovorum MTCC 1428. Applied Microbiology and Biotechnology, 84, 477–486.

Ferreira, S. L., Caires, A. O., Borges, T. D. S., Lima, A. M., Silva, L. O., & Santos, W. N. (2017). Robustness evaluation in analytical methods optimized using experimental designs. Microchemical Journal, 131, 163–169.

Wang, J., & Wan, W. (2009). Experimental design methods for fermentative hydrogen production: A review. International Journal of Hydrogen Energy, 34, 235–244.

Myers, R. H., Khuri, A. I., & Carter, W. H. (1989). Response surface methodology: 1966–l988. Technometrics, 31, 137–157.

Pereira, L. M. S., Milan, T. M., & Tapia-Blácido, D. R. (2021). Using response surface methodology (RSM) to optimize 2G bioethanol production: A review. Biomass and Bioenergy, 151, 106166.

Yolmeh, M., & Jafari, S. M. (2017). Applications of response surface methodology in the food industry processes. Food and Bioprocess Technology, 10, 413–433.

Qiu, J., Song, F., Qiu, Y., Li, X., & Guan, X. (2013). Optimization of the medium composition of a biphasic production system for mycelial growth and spore production of Aschersonia placenta using response surface methodology. Journal of Invertebrate Pathology, 112, 108–115.

Luthra, U., Singh, N., Tripathi, A., Vora, S., & Bhosle, V. (2015). Media optimization for lovastatin production by statistical approach using Aspergillus terreus by submerged fermentation. Journal of Medical Science and Clinical Research, 3, 4520–4528.

Boudrahem, F., Ziani, S., & Aissani-Benissad, F. (2019). Application of response surface methodology based on central composite design for optimization of yellow bezacryl sorption on shoe soles waste. Environmental Progress & Sustainable Energy, 38, S412–S421.

Grahovac, J., Grahovac, M., Dodić, J., Bajić, B., & Balaž, J. (2014). Optimization of cultivation medium for enhanced production of antifungal metabolites by Streptomyces hygroscopicus. Crop Protection, 65, 143–152.

Singh, V., Haque, S., Niwas, R., Srivastava, A., Pasupuleti, M., & Tripathi, C. (2017). Strategies for fermentation medium optimization: An in-depth review. Frontiers in Microbiology, 7, 2087.

Nurfarahin, A. H., Mohamed, M. S., & Phang, L. Y. (2018). Culture medium development for microbial-derived surfactants production—An overview. Molecules, 23, 1049.

Keshk, S. M., & Sameshima, K. (2005). Evaluation of different carbon sources for bacterial cellulose production. African Journal of Biotechnology, 4, 478–482.

Mikkelsen, D., Flanagan, B. M., Dykes, G. A., & Gidley, M. J. (2009). Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524. Journal of Applied Microbiology, 107, 576–583.

Gomes, R. J., Faria-Tischer, P. C. S., Tischer, C. A., Constantino, L. V., Rosa, M. F., Chideroli, R. T., Pereira, U. P., & Spinosa, W. A. (2021). Komagataeibacter intermedius V-05: An acetic acid bacterium isolated from vinegar industry, with high capacity for bacterial cellulose production in soybean molasses medium. Food Technology and Biotechnology, 59, 432–442.

Rajput, K. N., Patel, K. C., & Trivedi, U. B. (2016). Screening and selection of medium components for cyclodextrin glucanotransferase production by new alkaliphile Microbacterium terrae KNR 9 using Plackett-Burman design. Biotechnology Research International, 2016, 3584807.

Du, L., Liu, S., Hao, G., Zhang, L., Zhou, M., Bao, Y., Ding, B., Sun, Q., & Zhang, G. (2021). Preparation and release profiles in vitro/vivo of galantamine pamoate loaded poly (Lactideco-Glycolide)(PLGA) microspheres. Frontiers in Pharmacology, 11, 2392.

Zhang, Q., Li, Y., Xu, F., Zheng, M., Xi, X., Zhang, X., & Han, C. (2017). Optimization of submerged fermentation medium for matrine production by Aspergillus terreus, an endophytic fungus harboring seeds of Sophora flavescens, using response surface methodology. Mycobiology, 45, 90–96.

Núñez, D., Cáceres, R., Ide, W., Varaprasad, K., & Oyarzún, P. (2020). An ecofriendly nanocomposite of bacterial cellulose and hydroxyapatite efficiently removes lead from water. International Journal of Biological Macromolecules, 165, 2711–2720.

Kačuráková, M., Smith, A. C., Gidley, M. J., & Wilson, R. H. (2002). Molecular interactions in bacterial cellulose composites studied by 1D FT-IR and dynamic 2D FT-IR spectroscopy. Carbohydrate Research, 337, 1145–1153.

Segal, L. G. J. M. A., Creely, J. J., Martin, A. E., Jr., & Conrad, C. M. (1959). An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Textile Research Journal, 29, 786–794.

Barud, H., Ribeiro, C., Crespi, M., Martines, M., Dexpert-Ghys, J., Marques, R., Messaddeq, Y., & Ribeiro, S. (2007). Thermal characterization of bacterial cellulose–phosphate composite membranes. Journal of Thermal Analysis and Calorimetry, 87, 815–818.

Feng, X., Ullah, N., Wang, X., Sun, X., Li, C., Bai, Y., Chen, L., & Li, Z. (2015). Characterization of bacterial cellulose by Gluconacetobacter hansenii CGMCC 3917. Journal of Food Science, 80, E2217–E2227.

Teixeira, S. R. Z., Reis, E. M. D., Apati, G. P., Meier, M. M., Nogueira, A. L., Garcia, M. C. F., Schneider, A. L. S., Pezzin, A. P. T., & Porto, L. M. (2019). Biosynthesis and functionalization of bacterial cellulose membranes with cerium nitrate and silver nanoparticles. Materials Research, 22, e20190054.

Chandrasekaran, P. T., Bari, N. K., & Sinha, S. (2017). Enhanced bacterial cellulose production from Gluconobacter xylinus using super optimal broth. Cellulose, 24, 4367–4381.

Kohlmeier, M. (2015). Nutrient metabolism: Structures, functions, and genes (2nd ed.). Academic Press.

Wu, G. (2009). Amino acids: Metabolism, functions, and nutrition. Amino Acids, 37, 1–17.

Leonardi, R., & Jackowski, S. (2007). Biosynthesis of pantothenic acid and coenzyme A. EcoSal Plus, 2, 1–17.

Spry, C., Kirk, K., & Saliba, K. J. (2008). Coenzyme A biosynthesis: An antimicrobial drug target. FEMS Microbiology Reviews, 32, 56–106.

Tortora, G. J., Funke, B. R., & Case, C. L. (2019). Microbiology: An introduction (13th ed.). Pearson Education.

Sahm, F., Oezen, I., Opitz, C. A., Radlwimmer, B., Von Deimling, A., Ahrendt, T., Adams, S., Bode, H. B., Guillemin, G. J., Wick, W., & Platten, M. (2013). The endogenous tryptophan metabolite and NAD+ precursor quinolinic acid confers resistance of gliomas to oxidative stress. Cancer Research, 73, 3225–3234.

VanLinden, M. R., Skoge, R. H., & Ziegler, M. (2015). Discovery, metabolism and functions of NAD and NADP. Biochem., 37, 9–13.

Zhu, F., Peña, M., & Bennett, G. N. (2021). Metabolic engineering of Escherichia coli for quinolinic acid production by assembling L-aspartate oxidase and quinolinate synthase as an enzyme complex. Metabolic Engineering, 67, 164–172.

Pereira, L., Girardi, J. P., & Bakovic, M. (2012). Forms, crosstalks, and the role of phospholipid biosynthesis in autophagy. International Journal of Cell Biology, 2012, 931956.

Heo, M. S., & Son, H. J. (2002). Development of an optimized, simple chemically defined medium for bacterial cellulose production by Acetobacter sp. A9 in shaking cultures. Biotechnology and Applied Biochemistry, 36, 41–45.

Son, H. J., Kim, H. G., Kim, K. K., Kim, H. S., Kim, Y. G., & Lee, S. J. (2003). Increased production of bacterial cellulose by Acetobacter sp. V6 in synthetic media under shaking culture conditions. Bioresource Technology, 86, 215–219.

Matsuoka, M., Tsuchida, T., Matsushita, K., Adachi, O., & Yoshinaga, F. (1996). A synthetic medium for bacterial cellulose production by Acetobacter xylinum subsp. sucrofermentans. Bioscience, Biotechnology, and Biochemistry, 60, 575–579.

Kalam, M. A., Humayun, M., Parvez, N., Yadav, S., Garg, A., Amin, S., Sultana, Y., & Ali, A. (2007). Release kinetics of modified pharmaceutical dosage forms: A review. Continental Journal of Pharmaceutical Sciences, 1, 30–35.

Figueiredo Filho, D. B., Júnior, J. A. S., & Rocha, E. C. (2011). What is R2 all about? Leviathan, 3, 60–68.

Lahiri, D., Nag, M., Mukherjee, D., Garai, S., Banerjee, R., & Ray, R. R. (2021). Recent trends in approaches for optimization of process parameters for the production of microbial cellulase from wastes. Journal of Environmental Sustainability, 4, 273–284.

Lahiri, D., Nag, M., Dutta, B., Sarkar, T., & Ray, R. R. (2021). Artificial neural network and response surface methodology-mediated optimization of bacteriocin production by Rhizobium leguminosarum. Iranian Journal of Science and Technology, Transactions A: Science, 45, 1509–1517.

Lahiri, D., Nag, M., Sarkar, T., Dutta, B., & Ray, R. R. (2021). Antibiofilm activity of α-amylase from Bacillus subtilis and prediction of the optimized conditions for biofilm removal by response surface methodology (RSM) and artificial neural network (ANN). Applied Biochemistry and Biotechnology, 193, 1853–1872.

Peng, S., Zheng, Y., Wu, J., Wu, Y., Ma, Y., Song, W., & Xi, T. (2012). Preparation and characterization of degradable oxidized bacterial cellulose reacted with nitrogen dioxide. Polymer Bulletin, 68, 415–423.

Güzel, M., & Akpınar, Ö. (2020). Preparation and characterization of bacterial cellulose produced from fruit and vegetable peels by Komagataeibacter hansenii GA2016. International Journal of Biological Macromolecules, 162, 1597–1604.

Li, X., Li, J., Gong, J., Kuang, Y., Mo, L., & Song, T. (2018). Cellulose nanocrystals (CNCs) with different crystalline allomorph for oil in water Pickering emulsions. Carbohydrate Polymers, 183, 303–310.

Barud, H. S., Araújo Júnior, A. M., Santos, D. B., Assunção, R. M., Meireles, C. S., Cerqueira, D. A., Rodrigues Filho, G., Ribeiro, C. A., Messaddeq, Y., & Ribeiro, S. J. (2008). Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochimica Acta, 471, 61–69.

George, J., Ramana, K. V., Sabapathy, S. N., Jagannath, J. H., & Bawa, A. S. (2005). Characterization of chemically treated bacterial (Acetobacter xylinum) biopolymer: Some thermo-mechanical properties. International Journal of Biological Macromolecules, 37, 189–194.

Vasconcelos, N. F., Feitosa, J. P. A., Gama, F. M. P., Morais, J. P. S., Andrade, F. K., Souza, M. D. S. M., & Rosa, M. F. (2017). Bacterial cellulose nanocrystals produced under different hydrolysis conditions: Properties and morphological features. Carbohydrate Polymers, 155, 425–431.

Souza, E. F., Furtado, M. R., Carvalho, C. W., Freitas-Silva, O., & Gottschalk, L. M. (2020). Production and characterization of Gluconacetobacter xylinus bacterial cellulose using cashew apple juice and soybean molasses. International Journal of Biological Macromolecules, 146, 285–289.

Rojo, Ú. M., Rossi, E., Cerrutti, P., Errea, M. I., & Foresti, M. L. (2021). Preparation of water insoluble carboxymethylated bacterial cellulose with maximum lead retention capacity. Journal of Polymer Research, 28, 1–7.

Molina-Ramírez, C., Cañas-Gutiérrez, A., Castro, C., Zuluaga, R., & Gañán, P. (2020). Effect of production process scale-up on the characteristics and properties of bacterial nanocellulose obtained from overripe Banana culture medium. Carbohydrate Polymers, 240, 116341.

Ul-Islam, M., Khan, T., & Park, J. K. (2012). Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohydrate Polymers, 88, 596–603.

Huang, H. C., Chen, L. C., Lin, S. B., Hsu, C. P., & Chen, H. H. (2010). In situ modification of bacterial cellulose network structure by adding interfering substances during fermentation. Bioresource Technology, 101, 6084–6091.

Lin, S. B., Hsu, C. P., Chen, L. C., & Chen, H. H. (2009). Adding enzymatically modified gelatin to enhance the rehydration abilities and mechanical properties of bacterial cellulose. Food Hydrocoll., 23, 2195–2203.

Eslahi, N., Mahmoodi, A., Mahmoudi, N., Zandi, N., & Simchi, A. (2020). Processing and properties of nanofibrous bacterial cellulose-containing polymer composites: A review of recent advances for biomedical applications. Polymer Reviews, 60, 144–170.

Mohite, B. V., & Patil, S. V. (2014). Physical, structural, mechanical and thermal characterization of bacterial cellulose by G. hansenii NCIM 2529. Carbohydrate Polymers, 106, 132–141.

Bandyopadhyay, S., Saha, N., & Sáha, P. (2018). Characterization of bacterial cellulose produced using media containing waste apple juice. Applied Biochemistry and Microbiology, 54, 649–657.

Acknowledgements

We would like to thank “Laboratório de Espectroscopia (ESPEC)” and “Laboratório de Difração de Raios X (LabDRX)” of the State University of Londrina for providing equipment and assistance in the chemical characterization analyses.

Funding

We thank “Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq)” for providing scholarship to Rodrigo J. Gomes (grant number: 142380/2017–2) and research fellowship to Wilma A. Spinosa (grant number: 307846/2020–2).

Author information

Authors and Affiliations

Contributions

Rodrigo J. Gomes: methodology, formal analysis and investigation, writing (original draft preparation); Elza I. Ida: writing (review and editing); Wilma A. Spinosa: conceptualization, funding acquisition, supervision.

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Tables S1 and S2 can be obtained as supplementary material in the online version of this article.

Rights and permissions

About this article

Cite this article

Gomes, R.J., Ida, E.I. & Spinosa, W.A. Nutritional Supplementation with Amino Acids on Bacterial Cellulose Production by Komagataeibacter intermedius: Effect Analysis and Application of Response Surface Methodology. Appl Biochem Biotechnol 194, 5017–5036 (2022). https://doi.org/10.1007/s12010-022-04013-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-04013-4