Abstract

During the pretreatment and hydrolysis of lignocellulosic biomass to obtain a hydrolysate rich in fermentable sugars, furaldehydes (furfural and hydroxymethylfurfural), phenolic compounds, and organic acids are formed and released. These compounds inhibit yeast metabolism, reducing fermentation yields and productivity. This study initially confirmed the ability of Spathaspora passalidarum to ferment xylose and demonstrated its sensibility to the inhibitors present in the hemicellulosic sugarcane bagasse hydrolysate. Then, an adaptive laboratory evolution, with progressive increments of hydrolysate concentration, was employed to select a strain more resistant to hydrolysate inhibitors. Afterward, a central composite design was performed to maximize ethanol production using hydrolysate as substrate. At optimized conditions (initial cell concentration of 30 g/L), S. passalidarum was able to produce 19.4 g/L of ethanol with productivity, yield, and xylose consumption rate of 0.8 g/L.h and 0.4 g/g, respectively, in a sugarcane bagasse hemicellulosic hydrolysate. A kinetic model was developed to describe the inhibition of fermentation by substrate and product. The values obtained for substrate saturation and inhibition constant were Ks = 120.4 g/L and Ki = 1293.4 g/L. Ethanol concentration that stops cell growth was 30.1 g/L. There was an agreement between simulated and experimental results, with a residual standard deviation lower than 6%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lignocellulosic biomass is the main renewable organic matter in nature and one of the most promising alternative feedstocks to produce fuels and chemicals, including bioethanol, with environmental, social, and economic benefits [1]. The lignocellulosic biomass is composed of cellulose, hemicellulose, and lignin polymers, linked through non-covalent and covalent crosslinks to form a complex and recalcitrant structure [2]. Due to the structural properties of lignocellulosic biomass, its use for the production of bioethanol involves several steps, including biomass pretreatment, cellulose and hemicellulose hydrolysis, and fermentation of monosaccharides (mainly glucose and xylose) in ethanol.

Glucose, the main sugar constituent of lignocellulosic biomass, is promptly metabolized and converted into ethanol by microorganisms. On the other hand, there is a reduced number of species capable of converting xylose for ethanol production [3, 4]. As xylose can represent up to 20% of the biomass, efficient xylose conversion processes need to be established to ensure the economics of lignocellulosic ethanol [4]. In this context, it is advantageous to have a process that employs an efficient xylose-fermenting yeast and a fermentation strategy that favors its performance.

During pretreatment and hydrolysis of biomass, cellulose and hemicellulose are deconstructed releasing not only monomeric sugars but also furaldehydes, phenolic compounds, and organic acids. These compounds inhibit microbial metabolism by damaging cellular membranes, reducing intracellular pH, and inhibiting enzymes from central metabolism, which may result in a prolonged lag phase, reduced fermentation rates (sugar consumption and product formation), and reduced tolerance to ethanol concentration, among other effects [5,6,7]. Thus, yeast strains with xylose fermentation capability, even in presence of lignocellulosic derived inhibitors, are desired [8, 9].

The yeast Spathaspora passalidarum shows great potential for production of bioethanol from sugars present in lignocellulosic hydrolysates, being able to co-ferment xylose, glucose, and cellobiose under anaerobic conditions [10,11,12]. These properties make this yeast a candidate for industrial production of bioethanol from the lignocellulosic biomass [10, 11]. However, S. passalidarum has a low tolerance for inhibitors present in the lignocellulosic hydrolysate, as observed by several studies [9, 11, 13,14,15]. Indeed, this yeast is not able to ferment in a medium under synergistic effect of inhibitors such as 2.5 g/L of acetic acid, 2.7 g/L of total phenols, and 1 g/L of formic acid or to grow in presence of 4 g/L of furfural or 4.5 g/L of acetic acid, separately, for example [9, 13, 14]. To overcome this challenge, adaptive evolution and process optimization strategies could be employed to generate strains more tolerant to lignocellulosic inhibitors and more efficient processes.

This study aimed to use the xylose-rich hemicellulose fraction of sugarcane bagasse hydrolysate for ethanol production, since the glucose fermentation rate by Saccharomyces cerevisiae is unlikely to be surpassed by another yeast and an increased production of ethanol per mass of sugarcane bagasse would be achieved if cellulosic and hemicellulosic fractions were separated. This strategy is also advantageous because xylose consumption rate is negatively affected by the presence of hexoses, especially by glucose and mannose [15]. Thus, in this research, S. passalidarum was evolved to improve its tolerance towards inhibitors present in hemicellulosic hydrolysate. Then, a process optimization was performed employing the evolved yeast S. passalidarum A5 to increase the ethanol production from xylose present in sugarcane bagasse hydrolysate. A kinetic model was developed for hemicellulosic hydrolysate fermentation for the yeast S. passalidarum as a way to describe xylose consumption, cell growth, and ethanol production under defined conditions.

Material and Methods

Pretreatment and Preparation of Hemicellulosic Hydrolysate

Sugarcane bagasse, kindly provided by Sugar and Ethanol Plant Jalles Machado (Goianésia, GO, Brazil), was used as lignocellulosic feedstock. Sugarcane bagasse was initially dried in a convection oven at 45 °C for 24 h. Then, it was hydrolyzed with dilute sulfuric acid (1.5% v/v) with a 1:10 solid to liquid ratio (g of bagasse/mL of diluted acid) for 55 min at 121 °C. After the pretreatment, cellulignin (solid fraction) was filtered, and the liquid fraction, called hemicellulosic hydrolysate, which is rich in pentoses, was employed in this research. Carbohydrate content in sugarcane bagasse was performed according to NREL procedure “Determination of Structural Carbohydrates and Lignin in Biomass” [16]. The composition of untreated sugarcane bagasse was determined as follows (% dry weight): cellulose, 38.24 ± 1.39; hemicellulose, 26.31 ± 0.59; lignin, 24.71 ± 0.70; extractives 9.51 ± 0.40; and ashes, 1.45 ± 1.90. After pretreatment, the hemicellulosic hydrolysate composition was (g/L) glucose, 1.93; xylose, 20.50; acetic acid 5.82; furfural, 0.20; and hydroxymethylfurfural, 0.02. Therefore, dilute acid pretreatment resulted in substantial xylan solubilization, close to 90%. The pH of non-diluted hemicellulosic hydrolysate was adjusted to 5.0 with Ca(OH)2. Then, solids were removed by centrifugation. Prior to use, the hydrolysate was supplemented with 6.7 g/L yeast nitrogen base (YNB) without amino acids and with variable xylose concentrations to allow comparison of yeast growth and fermentation capabilities under different substrate concentrations.

Yeast Strain and Preculture Procedure

Spathaspora passalidarum NRRL Y-27907 was used in this study. The strain was stored in 30% glycerol at − 80 °C in “Collection of Microorganisms and Microalgae Applied to Agroenergy and Biorefineries (CMMAABio)” from Embrapa Agroenergy. The culture was first streaked from − 80 °C stock and precultivated in YPX agar medium (1% yeast extract, 2% peptone, 2% xylose, and 1.5% agar) for 3 days at 28 °C.

A starter culture was grown aerobically from single yeast colonies in 500-mL shake flasks containing 100 mL of YPX medium (1% yeast extract, 2% peptone, and 2% xylose). After inoculation, the flasks were incubated at 30 °C and 180 rpm. After 30 h, inoculum volumes were centrifuged at 5600 g for 5 min, washed once, and resuspended in an appropriate volume of sterile water.

Evaluation of the Innate Strain

To confirm the xylose fermentation capacity of the strain, a fermentation using YPX medium with 10% of xylose and 2 g/L of cell dry weight (CDW) was carried out into 250-mL Erlenmeyer flasks containing 90 mL of medium.

In order to evaluate S. passalidarum A5 tolerance to hemicellulosic hydrolysate, the culture was inoculated to an initial cell concentration of 15 g/L into 250-mL Erlenmeyer flasks containing 90 mL of hydrolysate medium (hemicellulosic hydrolysate containing 50 g/L xylose and YNB).

Fermentation assays were performed in triplicate at 30 °C and 140 rpm until complete consumption of xylose for YPX and 120 h for hydrolysate.

Adaptive Laboratory Evolution (ALE)

To improve S. passalidarum performance in hydrolysate fermentation, an adaptive laboratory evolution (ALE) was performed by batch cultivation at progressively increasing hydrolysate concentrations. These experiments were carried out in 80 mL of medium in 250-mL Erlenmeyer flasks. The culture cell was transferred to a fresh medium in a new flask containing a combination of YPX medium and hemicellulosic hydrolysate, with progressive increments of 10% (v/v) hydrolysate in each passage. The xylose concentration was kept constant at 80 g/L for all combinations. Considering viability, a serial transfer of cell mass concentration to 5 g/L to the fresh medium was performed every 48 h. In order to exclude the potential effects of the inhibitors accumulation, in each passage, the culture was centrifuged and resuspended in a small amount of water. Serial adaptation passages were conducted until the medium was composed by hydrolysate only. Throughout the whole course of adaptive evolution, flasks were incubated at 30 °C and 140 rpm. Aliquots of the culture, when the medium was composed of hydrolysate only, were diluted and spread over plates containing YPX medium. The selected evolved yeast was termed S. passalidarum A5 in this study. Thirty-percent glycerol stock cultures were prepared and stored frozen at − 80 °C until required.

Evaluation of Adapted Strain

Fermentation of Hemicellulosic Hydrolysate

After the adaptation process, the fermentation performance of S. passalidarum A5 was evaluated in the same conditions of innate strain, described in “Evaluation of the Innate Strain” section, which is hemicellulosic hydrolysate supplemented to 50 g/L xylose and inoculated to 15 g/L CDW.

Effect of Xylose and Cell Mass Concentration and Agitation Speed on Ethanol Production

Using the adapted strain and hemicellulosic hydrolysate, a central composite design (CCD) with three variables and three replicates at the center point was applied to optimize the ethanol production and productivity, residual xylose concentration, and xylose consumption rate. The independent variables considered were initial xylose concentration (X1) from 40 to 110 g/L, yeast concentration (X2) from 10 to 30 g/L, and agitation speed (X3) from 90 to 200 rpm. The alpha used was 1.68, for orthogonality. The effects of these variables were considered for 24-h fermentation. A quadratic polynomial model was used to estimate the response surface. The experiments were performed in 125-mL flasks containing 40 mL of hemicellulosic hydrolysate at 30 °C. The software Statistica 12.0 (Statsoft™, USA) was used to design experiments, regression, graphical analyses, and analysis of variance. A significant level of 90% (p < 0.1) was considered due to the variability of the bioprocesses [17]. Xylose and ethanol concentration were given by liquid chromatography analysis, ethanol volumetric productivity was defined as the ratio between ethanol concentration produced and time of fermentation, and xylose consumption rate was expressed as xylose consumed per time.

Validation of Proposed CCD Models

To assure the feasibility and accuracy of the models proposed by CCD, an additional fermentation was carried out, in triplicate, under selected conditions. For this experiment, substrate consumption, ethanol production, and cell concentration as a function of time were monitored.

A classical mathematical model was used to describe the behavior of a batch fermentation process and to help in understanding the process. The kinetic model applied was proposed by Ghose & Tyagi [18] and considers limiting substrate, effects of quadratic inhibition by the substrate, and linear inhibition by the product (Eq. 1). An unstructured-unsegregated model was obtained from mass balances for cell, substrate, and product, respectively (Eqs. 2–4), considering a batch system. Assumptions for this model included spatial uniformity, constant density, and negligible cell death.

where S is the xylose concentration, P is the ethanol concentration, X is the cell concentration, μ is the specific growth rate, μm is the maximum specific growth rate, Ks is the saturation constant for substrate, KI is the substrate inhibition constant, Pm is the product concentration that stops cell growth, α is the substrate consumption associated with cell growth, β is the substrate consumption associated with cell maintenance, λ is the product formation associated with cell growth, and δ is the product formation not associated with cell growth.

To make it possible to compare the relative size of the terms in the equations, they were initially dimensionless, in a way that the characteristic scales were the maximum experimental values of the state and time variables (x = X/Xf, s = S/S0, p = P/Pf, τ = t/tm, αA = α.Xf/S0, βA = β.Xf.tm/S0, λA = λ.Xf/Pf, δA = δ.Xf.tm/Pf, KSA = Ks/S0, KIA = KI/S0, μmA = μm.tm). The model was fit using the CCD validation condition and confirmed by the CCD center point condition.

The model parameters were determined by fitting experimental data defined by the CCD validation experiment in a multi-response regression for Eqs. 1–4. Nonlinear regression was performed to get parameters that best fit the model to the experimental data by minimizing the differences between experimental and predicted values. The minimization routine used was a stochastic global optimization named Firefly Algorithm (FA). FA is a bio-inspired method that mimics the patterns of short and rhythmic flashes emitted by fireflies in nature. It was proposed by Yang [19] and, nowadays, is used to solve continuous mathematical functions [20, 21]. The initial parameters were set to attractiveness β0 = 0.7, absorption γ = 1, randomization α = 0.8, population size = 80, and maximum number of generations = 300. Based on the stochastic characteristics of the applied algorithm, a series of 10 runs were performed and the medium values and standard deviations were presented. Scilab 5.5.2 software was used to implement this algorithm and define the model parameters.

The quality of the prediction model was assessed by the residual standard deviation (RSD) proposed by Cleran et al. [22] and presented in Eq. 5.

Metabolite and Biomass Quantification

Samples from fermentation experiments were centrifuged at 16,800g for 10 min and the supernatant was analyzed. Xylose, glucose, acetic acid, ethanol, furfural, and hydroxymethylfurfural were analyzed by high-performance chromatography system HPLC (Agilent 1260 Infinity) coupled with an index detector RID 10-A using a reverse-phase column (Aminex® HPX87H, BioRad). The products were eluted using a solution of 5 mM H2SO4 as mobile phase at 0.6-mL/min flow rate at 45 °C. The concentrations of compounds were determined using calibration curves, and values were calculated from peak areas.

Yeast concentration was monitored by optical density at 600 nm and correlated with dry weight. The cell dry weight was calculated according to optical density using the following linear correlation: concentration (g/L CDW) = dilution × 0.5045 × OD600 nm. Its correlation coefficient R2 was 0.997. Yeast viability was determined by counting cell suspension stained with erythrosine B in a Neubauer chamber using optical microscopy. Cell viability was defined by the ratio of the viable cell number (unstained) to the total cell number.

Results and Discussion

Evaluation of the Innate Strain

The xylose fermentation capacity of S. passalidarum was confirmed by fermentation of YPX medium. The complete consumption of 100 g/L xylose was observed after 40 h, with a production of 30.78 ± 0.966 g/L ethanol and 13.26 ± 0.796 g/L CDW cells, which correspond to ethanol yield of YP/S = 0.313 g/g and biomass yield of YP/S = 0.135 g/g. Ethanol production in absence of inhibitors during fermentation was lower than reported previously [5, 15, 23]. This could be associated with culture conditions and YPX medium employed, which stimulates yeast growth. The performance of the innate S. passalidarum in the hemicellulosic hydrolysate was very poor. When the strain was propagated in YPX medium and inoculated in hemicellulosic hydrolysate, it was unable to ferment xylose to ethanol. In 120 h, only 2.5 g/L xylose had been consumed and ethanol production was not observed. The final cell viability was lower than 30%.

The poor fermentation performance in hydrolysate can be associated with the toxicity of lignocellulose hydrolysate inhibitors. As already known, the inhibitors released in the pretreatment of lignocellulosic biomass reduce the efficiency of the fermentation process. Furfural and hydroxymethylfurfural show high toxicity to the xylose-fermenting yeast S. passalidarum, as 0.5 g/L and 1 g/L, respectively, can cause around 50% inhibition of cell growth and severe inhibition on sugar consumption and ethanol production [7, 13]. Among organic acids, acetic acid is reported as the most important inhibitor present on lignocellulosic hydrolysate. Only 0.6 g/L of acetic acid was sufficient to increase the lag phase of S. passalidarum from 12 to 14 h and to decrease its cell concentration and ethanol production to approximately half that observed in the control synthetic medium without the acid. With the addition of amounts greater than 1.2 g/L of acetic acid, S. passalidarum UFMG-HMD 2.1 was not able to produce ethanol [24]. The inhibition of S. passalidarum observed here is probably caused by the high concentration of acetic acid (5.82 g/L) present in the hydrolysate employed. However, the effects of the low concentrations of furfural (0.20 g/L) and HMF (0.02 g/L) may not be disregarded, since the synergistic inhibitory effects of the lignocellulose derived inhibitors [13, 24, 25].

Adaptive Laboratory Evolution

As S. passalidarum A5 was vigorously affected by the hemicellulosic hydrolysate, a serial culture transfer strategy using gradual 10% increments of hydrolysate concentration in the medium was used to select mutants that fermented xylose in presence of inhibitors. At the end of the adaptive evolution period, the evolved population was plated on YPX medium and five colonies were randomly selected, and the fermentative performance compared on hydrolysate. The ethanol production among the five strains was slightly different among five strains (varying from 2.21 to 19.64 g/L in 48 h) and the best strain, named S. passalidarum A5, was selected for further characterization.

The best fermentation performance of the evolved strain was confirmed in the hemicellulosic hydrolysate. While the control strain was not able to ferment the xylose present in the medium, the evolved strain produced 19.64 ± 0.57 g/L ethanol, corresponding to ethanol yield of 0.40 g/g, ethanol productivity of 0.357 g/L.h, and xylose consumption rate of 0.884 g/h. It was observed 10 h lag phase for starting xylose consumption and ethanol production after inoculation (Fig. 1). Throughout the 48 h of fermentation, there was a loss of cell viability of approximately 12%.

The strain adapted in hydrolysate in this study was capable of maintaining the xylose fermentation capacity even in presence of hydrolysate with a high concentration of inhibitors, mainly acetic acid (5.8 g/L) (Fig. 1). Previous studies have also found positive results in S. passalidarum adaptive evolution [9, 14, 26]; however, tolerance levels varied considerably. An adapted strain of S. passalidarum was obtained by UV mutation followed by adaptation in continuous culture with a gradual increase of acetic acid for 100 days. The mutant strain produced ethanol up to 5.8 g/L from glucose in the presence of 3.5 g/L of acetic acid. Nevertheless, xylose consumption was completely inhibited when the strain was evaluated in media containing 100% of hydrolysate (80 g/L glucose, 12 g/L xylose, 4.7 g/L acetic acid, 1.0 g/L furfural, and 0.35 g/L HMF). It was only able to produce ethanol from glucose [9]. In another study, S. passalidarum U1 was obtained by mutagenesis and it could be confirmed that, in YPX medium containing 100 g/L xylose, it has obtained better performance than the parental strain. However, the xylose conversion efficiency in hemicellulosic hydrolysate obtained through alkali liquor-pretreated corncob was relatively poor, since only 10.5 g/L ethanol was produced from pentoses, which correspond to a yield of 0.17 g/g [26].

Effect of Xylose, Cell Mass Concentration, and Agitation Speed on Ethanol Production

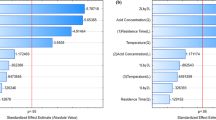

To maximize xylose consumption rate and ethanol production (consequently productivity) and to minimize residual xylose concentration by the evolved S. passalidarum A5 in hemicellulosic hydrolysate, a CCD was carried out with xylose concentration (40 to 110 g/L), initial cell mass concentration (10 to 30 g/L), and agitation speed ranging from 90 to 200 rpm (to achieve different aeration conditions), as independent variables. Table 1 shows the 17 trials carried out in the design and the experimental values obtained for the responses after 24 h of fermentation. The highest ethanol concentration obtained in the experiments was 16.51 g/L, which correlated with the highest xylose consumption rate. This was obtained when employing the lowest substrate (50 g/L) and highest cell (25 g/L) concentrations (Table 1).

The analysis of variance (ANOVA) at 90% of confidence level indicates that the models were statistically significant and the regression could be used for predictive purposes (F ratio is greater than three for all responses). In addition, the good reproducibility of the obtained data was supported by the low value of pure error [25]. Therefore, it is possible to use response optimization techniques in the evaluated ranges to optimize yeast fermentation.

Using response surface methodology and experimental results, a second-order model (with coded variables and considering statistically significant parameters, p < 0.1) was proposed for each analyzed response. The regression equations in coded values and correlation coefficients are presented in Eqs. 6–9. The correlation coefficients (R2) suggest that there is a close agreement between the experimental results and the theoretical values predicted by the polynomial models.

According to Eqs. 6–9, xylose (X1) and initial cell concentration (X2) had strongly contributed to all responses. Agitation speed (X3), despite being significant for all models, has little influence on the responses.

S. passalidarum has specific aeration requirements: an excess of oxygen promotes aerobic cell growth and deficient oxygen supply decreases the substrate consumption rate and ethanol productivity, in addition to induce xylitol accumulation. Oxygen-limited conditions resulted in the best yields for S. passalidarum (0.43 to 0.48 g/g) [12, 23, 26]. Probably the stirring range studied in CCD did not promote a significant difference in the availability of oxygen for different trials.

Canonical analysis and eigenvalues were used to locate the stationary point of the responses and to determine whether it represents a maximum, minimum, or saddle point. In all cases, either the stationary point was not in the experimental range or it was a saddle point (simultaneously positive and negative eigenvalues values). Then, applying models, Eqs. 6–9 individually, as objective functions and the experimental region as constraints, the local maximum for each response (and local minimum for residual xylose concentration) was found by an iterative numerical solution algorithm. The conditions that optimize each model and the response values predicted for its condition are shown in Table 2.

It is possible to notice, by the evaluation of the models, that the combination of the experimental conditions, in the evaluated range, can provide concentrations of ethanol close to 20 g/L in 24 h, which corresponds to productivity higher than 0.8 g/L.h.

To assure the feasibility and accuracy of the proposed models, a CCD validation experiment was performed in X1 = − 0.44, X2 = 1.00, and X3 = 0.75. This condition, in uncoded variables, corresponds to 66 g/L initial xylose concentration, 25.95 g/L yeast concentration, and 170 rpm stirring. Figure 2 shows xylose consumption, ethanol production, and cell growth as a function of time in this experimental condition.

Experimental data fitting to the mathematical model. Xylose consumption, ethanol production, and cell growth in CCD validation experiment (66 g/L initial xylose concentration, 25.95 g/L initial yeast concentration, and 170 rpm stirring). Symbols: experimental variation in xylose (circle), ethanol (triangle), and cell (square), concentrations for CCD validation experiment. Lines: model fit proposed for cell (dot), xylose (solid), and ethanol (dash). Mean values and standard deviations were calculated from three independent experiments

The experimental values are in agreement with the predicted values, which indicate that the models developed from the response surface methodology could reliably predict the dependent variables (Fig. 2 and Table 3). The fitted regression models could explain the observed data and provide a convincing estimate of responses in the evaluated range (Table 3).

The validation experiment was not interrupted in 24 h. Then, after 36 h, 19.17 ± 0.30 g/L of ethanol was produced. From the 36th to the 52nd hour, the produced ethanol concentration increased only 1.58 g/L, which does not justify these additional 16 h of processing. Figure 2 shows that the first 30 h of fermentation had a higher xylose consumption rate and ethanol productivity. The lag phase could be considered less than 6 h.

Although fermentative conditions reported in the literature are usually different, making direct comparison of results not feasible, it is notable that the S. passalidarum A5 can be considered a promising yeast for hemicellulosic hydrolysate fermentation. Ethanol production in this study, both in terms of yield and productivity, obtained after optimization of strain and culture conditions, has not yet been reported in the literature when employing biomass hydrolysate containing a high concentration of inhibitors, especially acetic acid (5.82 g/L). Indeed, the results obtained here are comparable to fermentations that employed S. passalidarum NRRL Y-27907 in a defined medium without inhibitors [5, 12, 15, 23]. When hydrolysate medium is used, the production drops considerably [14, 15].

A fed-batch fermentation with S. passalidarum NRRL Y-27907 cell recycling, using sugarcane bagasse hydrolysate with 43 g/L of glucose and 15 g/L of xylose as carbon source, with no acetic acid, furfural, or HMF, obtained an ethanol concentration, yield (YP/S), and productivity of 23.3 g/L, 0.46 g/g, and 0.81 g/L.h, respectively [15].

For all fermentations carried out in this research, glycerol concentration was found lower than 0.5 g/L. This is similar to what had been reported by Su et al. [23]. In their study, S. passalidarum accumulated more glycerol when the carbon source was glucose or mixed sugars than when cultivated on xylose (concentrations below 0.6 g/L). Veras et al. [25] proposed for the first time a metabolic flux to S. passalidarum and it was not observed flux rate for glycerol formation, an important characteristic in the carbon flux that distinguishes it from other yeasts.

Using this experimental condition and considering Ghose & Tyagi [18] kinetic model and the mass balances of cell, substrate, and product (Eqs. 1–4), a Firefly Algorithm was used to solve coupled differential equations. The parameter values obtained from experimental data and model fitting were substituted into the dimensional substrate and product mass balance equations (Eqs. 10 and 11, respectively). Based on the stochastic characteristics of the applied firefly algorithm, a series of 10 runs was performed and the medium values and standard deviations are presented. The values used to make the parameters dimensionless were S0 = 66.26 g/L, Pf = 20.74 g/L, Xf = 28.46 g/L, and tm = 52 h.

Comparing the magnitude of parameters of xylose and ethanol mass balance, we can suppose that both substrate consumption and product formation were strongly associated with cell growth and weakly associated with cell concentration. However, as the experiments were carried out at high initial cell concentrations with low cell growth rates, both terms in each equation had similar orders of magnitude and importance.

Other kinetic models, which do not simultaneously consider substrate and product inhibition effects, were evaluated but the model proposed by Ghose & Tyagi [18] was the one that best fitted the experimental data. These models, and their modifications, were widely used to describe the kinetics of alcoholic fermentation, usually for S. cerevisiae.

There is a satisfactory agreement between the simulated and the experimental profile to cell, substrate, and product concentrations. Figure 2 shows the model fit proposed. The parameters YX/S = 0.073 ± 0.007 g/g and YP/S = 0.435 ± 0.001 g/g were determined from experimental data, and KS = 120.4 ± 4.1 g/L, KI = 1293.4 ± 96.5 g/L, Pm = 30.1 ± 1.3 g/L, and μm = 0.018 ± 0.003 h−1 were estimated by fitting the model to experimental data. The residual standard deviation (RSD) observed, calculated from Eq. 5, for xylose, ethanol, and cell profile was 3.81, 1.95, and 0.45%, respectively. The kinetic parameters obtained by the model might be incompatible with those found from conventional ethanol-producing microorganisms. The same behavior for parameters was observed by Farias et al. [27].

The high value of saturation constant for substrate (Ks) indicates that fermentation is strongly influenced by the substrate. The high value for substrate inhibition constant (Ki) makes the term (S²/Ki) of the equation have less influence on the specific growth rate than the term Ks. This inhibition of substrate consumption and the consequent production of ethanol and cell growth would be associated not only with the initial substrate concentration but also with the presence of inhibitors, which slow down the substrate consumption rate. The ethanol concentration that interrupts cell growth (Pm) estimated, 30.1 g/L, under the conditions evaluated, can be considered a low value, which may be a negative aspect for the possible use of this strain for industrial ethanol production.

No studies were found reporting effects of inhibition by xylose and ethanol in S. passalidarum fermentation. Rhodrussamee et al. [5] reported that S. passalidarum CMUWF1–2 is tolerant to high glucose and ethanol concentration. This strain was found to grow in presence of 35% (w/v) and 8% (v/v) of glucose and ethanol, respectively, but the authors did not evaluate ethanol production.

It could be confirmed that Ghose & Tyagi [18] model and estimated parameters are adequate to forecast the behavior of S. passalidarum A5 (Fig. 3). To ensure the model quality, the profile of experimental condition defined by center point in CCD (S0 = 75 g/L, X0 = 20 g/L) was used to verify the consistency between model and experimental data that was not used for parameter estimation. The quality of prediction, characterized by RSD value, was 5.01, 0.97, and 1.37% for substrate, product, and cell concentration, respectively.

Validation of Ghose and Tyagi model using center point of CCD (75 g/L initial xylose concentration, 20 g/L yeast concentration, and 145 rpm stirring). Symbols: experimental variation in cell (square), xylose (circle), and ethanol (triangle) concentrations for CCD validation experiment. Lines: model fit proposed for cell (dot), xylose (solid), and ethanol (dash).

Conclusion

An adaptive evolution strategy was successfully employed in this research to improve the fermentation performance of S. passalidarum NRLL Y-27907 in sugarcane biomass hydrolysate. The strain S. passalidarum A5 obtained by consecutive rounds of inoculation and growth in hemicellulosic hydrolysate rich in acetic acid was capable to ferment hydrolysate efficiently, reaching ethanol yield and productivity of 0.404 g/g and 0.357 g/L.h, respectively, when the control strain was not able to ferment. Then, the cultivation conditions were optimized by CCD (initial xylose and inoculum concentration, and agitation speed), and the strain was able to produce 19.42 g/L of ethanol with a productivity of 0.8 g/L.h. These results are among the best reported in the literature for xylose fermentation in lignocellulosic hydrolysate with higher concentrations of inhibitors. In addition, the kinetic model proposed by Ghose and Tyagi was adjusted and showed that the strain was inhibited by substrate and product, with Ks = 120.4 g/L, Ki = 1293.4 g/L, and Pm = 30.1 ± 1.3 g/L. Thus, this study shows that evolutive adaptation and process optimization are powerful tools to increase the fermentative potential of yeasts and that S. passalidarum A5 can be considered a promising yeast for fermentation with xylose as the sole carbon source in presence of inhibitors.

Data Availability

The authors confirm that the data and materials supporting the findings of this article are available within the article and from the corresponding author (S. B. G.) upon reasonable request.

References

Mata, T. M., Tavares, T. F., Meireles, S., & Caetano, N. S. (2015). Bioethanol from brewers’ spent grain: pentose fermentation. Chemical Engineering Transactions, 43, 241–246

Oliva, J. M., Negro, M. J., Manzanares, P., Ballesteros, I., Chamorro, M. A., Sáez, F., Ballesteros, M., & Moreno, A. D. (2017). A sequential steam explosion and reactive extrusion pretreatment for lignocellulosic conversion within a fermentation-based biorefinery perspective. Fermentation, 3(2), 15. https://doi.org/10.3390/fermentation3020015.

Caetano, N. S., Moura, R. F., Meireles, S., Mendes, A. M., & Mata, T. M. (2013). Bioethanol from brewer’s spent grains: acid pretreatment optimization. Chemical Engineering Transactions, 35, 1021–1026

Bergmann, J. C., Trichez, D., Morais Junior, W. G., Ramos, T. G. S., Pacheco, T. F., Carneiro, C. V., Hororato, V. M., Serra, L. A., & Almeida, J. R. M. (2019). Biotechnological application of non-conventional yeasts for xylose valorization. In A. Sibirny (Ed.), Non-conventional yeasts: from basic research to application. Cham: Springer

Rodrussamee, N., Sattayawat, P., & Yamada, M. (2018). Highly efficient conversion of xylose to ethanol without glucose repression by newly isolated thermotolerant Spathaspora passalidarum CMUWF1-2. BMC Microbiology, 18(1), 73.

Kumar, A. K., & Sharma, S. (2017). Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresource and Bioprocessing, 4(7), 7. https://doi.org/10.1186/2017/s40643-017-0137-9.

Almeida, J. R. M., Modig, T., Petersson, A., Hähn-Hägerdal, B., Lidén, G., & Gorwa-Grauslund, M. F. (2007). Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. Journal of Chemistry, Technology and Biotechnology, 82(4), 340–349

Jeffries, T. W. (2006). Engineering yeasts for xylose metabolism. Current Opinion in Biotechnology, 17(3), 320–326

Morales, P., Gentina, J. C., Aroca, G., & Mussatto, S. I. (2017). Development of an acetic acid tolerant Spathaspora passalidarum strain through evolutionary engineering with resistance to inhibitors compounds of autohydrolysate of Eucapyptus globulus. Industrial Crops and Products, 106, 5–11

Nguyen, N. H., Suh, S. O., Marshall, C. J., & Blackwell, M. (2006). Morphological and ecological similarities: wood-boring beetles associated with novel xylose-fermenting yeasts, Spathaspora passalidarum gen. sp. nov. and Candida jeffriesii sp. nov. Mycological Research, 110, 1232–1241

Long, T. M., Su, Y.-K., Higbee, A., Willis, L. B., & Jeffries, T. W. (2012). Co-fermentation of glucose, xylose, and cellobiose by the beetle-associated yeast Spathaspora passalidarum. Applied and Environmental Microbiology, 78(16), 5492–5500

Veras, H. C. T., Parachin, N. S., & Almdeida, J. R. M. (2017). Comparative assessment of fermentative capacity of different xylose-consuming yeasts. Microbial Cell Factories, 16(1), 153

Hou, X., & Yao, S. (2012). Improved inhibitor tolerance in xylose-fermenting yeast Spathaspora passalidarum by mutagenesis and protoplast fusion. Applied Microbiology and Biotechnology, 93(6), 2591–2601

Soares, L. B., Bonan, C. I. D. G., Biazi, L. E., Dionísio, S. R., Bonatelli, M. L., Andrade, A. L. D., Renzano, E. C., Costa, A. C., & Ienczak, J. L. (2020). Investigation of hemicellulosic hydrolysate inhibitor resistance and fermentation strategies to overcome inhibition in non-saccharomyces species. Biomass and Bioenergy, 137, 105549

Nakanishi, S. C., Soares, L. B., Biazi, L. E., Nascimento, V. M., Costa, A. C., Rocha, G. J. M., & Ienezak, J. L. (2017). Fermentation strategy for second generation ethanol production from sugarcane bagasse hydrolysate by Spathaspora passalidarum and Scheffersomyces stipitis. Biotechnology and Bioengineering, 114, 10

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., & Sluiter, J. (2012). Templeton, and D. Crocker, NREL/TP-510-42618 analytical procedure—determination of structural carbohydrates and lignin in biomass. Laboratorial Analysis Procedure, 17. NREL/TP-510-42618

Haaland, P. D. (1989). Experimental design in biotechnology. New York: Marcel Dekker Inc

Ghose, T. K., & Tyagi, R. D. (1979). Rapid ethanol fermentation of cellulose hydrolysate. II Product and substrate inhibition and optimization of fermentor design. Biotechnology and Bioengineering, 21(8), 1401–1420

Yang, X. S. (2008). Nature-inspired metaheuristic algorithms. Luniver Press.

Lobato, F. S., & Steffen Jr., V. (2013). Multi-objective optimization firefly algorithm applied to (bio) chemical engineering system design. American Journal of Applied Mathematics and Statistics, 1(6), 110–116

Roeva, O. (2012). Optimization of E. coli cultivation model parameters using firefly algorithm. International Journal of Bioautomation, 16(1), 23–32

Cleran, Y., Thibault, J., Cheruy, A., & Corrieu, G. (1991). Comparison of prediction performances between models obtained by the group method of data handling and neural networks for the alcoholic fermentation rate in enology. Journal of Fermentation and Bioenginerring, 71(5), 356–362

Su, Y. K., Willis, L. B., & Jeffries, T. W. (2015). Effects of aeration on growth, ethanol and polyol accumulation by Spathaspora passalidarum Y-27907 and Scheffersomyces stipitis NRRL Y-7124. Biotechnology and Bioengineering, 112, 3

Souza, B. R. (2017). Análise da tolerância aos ácidos carboxílicos por leveduras potencialmente utilizadas na produção de etanol de segunda geração. Universidade Federal de Santa Catarina, Ciências Biológicas

Box, G. E. P., Hunter, W. G., & Hunter, J. S. (1978). Statistics for experimenters. An introduction to design, data analysis and model building. Nova York: Wiley

Yu, H., Guo, J., Chen, Y., Fu, G., Li, B., Guo, X., & Xiao, D. (2017). Efficient utilization of hemicellulose in alcali liquor-pretreated corncob for bioethanol production at high solid loading by Spathaspora passalidarum UI-58. Bioresource Technology, 232, 168–175

Farias, D., de Andrade, R. R., & Maugeri-Filho, F. (2014). Kinetic modeling of ethanol production by Scheffersomyces stipitis from xylose. Applied Biochemistry and Biotechnology, 172, 361–379

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors.

Conceived and designed the experiments: TFP, BRCM

Analyzed the data: TFP, WGMJr, JRMA, SBG

Wrote the paper: TFP, WGMJr, JRMA, SBG

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Consent to Participate

All authors have given consent to participate.

Consent to Publish

All authors have given approval of the manuscript to be published.

Competing Interests

The authors confirm that this article content has no conflict of interest. The authors also declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pacheco, T.F., Machado, B.R.C., de Morais Júnior, W.G. et al. Enhanced Tolerance of Spathaspora passalidarum to Sugarcane Bagasse Hydrolysate for Ethanol Production from Xylose. Appl Biochem Biotechnol 193, 2182–2197 (2021). https://doi.org/10.1007/s12010-021-03544-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-021-03544-6