Abstract

Substantial progress has been made in ethanol fermentation technology under high gravity (HG) and very high gravity (VHG), which offer environmental and economic benefits. HG and VHG processes increase the productivity of ethanol, reduce distillation costs, and enable higher yields. The aim of the present study was to evaluate the use of sugarcane molasses as the medium component along with flocculating yeasts for fermentation in a fed-batch process employing this promising technology. We evaluated fed-batch fermentation, HG, and VHG involving a molasses-based medium with high concentrations of reducing sugars (209, 222, and 250 g/L). Fermentation of 222 g/L of total reducing sugars achieved 89.45% efficiency, with a final ethanol concentration of 104.4 g/L, whereas the highest productivity (2.98 g/(L.h)) was achieved with the fermentation of 209 g/L of total reducing sugars. The ethanol concentration achieved with the fermentation of 222 g/L of total reducing sugars was close to the value obtained for P’max (105.35 g/L). The kinetic model provided a good fit to the experimental data regarding the fermentation of 222 g/L. The results revealed that sugarcane molasses and flocculating yeasts can be efficiently used in HG fermentation to reduce the costs of the process and achieve high ethanol titers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the rising oil prices, concerns regarding fossil fuel emissions, and the need for energy security, biofuels have attracted the attention of both the public and scientific community. Brazil, France, England, Austria, Norway, and Holland plan to ban the sale of cars run on diesel and gasoline in the near future, which will lead to an increased demand for biofuels and the need for greater global biofuel production. In the last three decades, substantial progress has been made in ethanol fermentation technology under high gravity (HG) and very high gravity (VHG), which offer environmental and economic benefits [1, 2].

Brazil is one of the largest and most competitive ethanol producers. The country’s current bioethanol plants have high yields and preserve cell viability. They also use a low concentration of sugars, from X to Y g/L of sugars, to ensure the completion of fermentation within a short period (8 to 12 h). The process produces wines with ethanol concentration of 7 to 12% v/v, and, therefore, a large volume of residual vinasse is produced, which also increases energy expenditure during distillation [3, 4].

Fermentation technology under high gravity (180 to 240 g/L of sugars) and very high gravity (≥ 250 g/L of sugars) constitutes an option for reducing distillation costs. The VHG process leads to wines with a higher alcohol content, enabling the obtainment of more ethanol from the same volume of wine, thereby generating fewer expenses with subsequent treatments [5, 6]. It is therefore possible to save water, capital, and energy per liter of alcohol, while reducing the risk of bacterial contamination. This technology also enables an increase of ethanol production without changing the capacity of the plant or number of employees. VHG fermentation is also expected to achieve gains in yield due to the reduction in the amount of residual ethanol entrained in the vinasse and the amount of residual total reducing sugars (TRS) entrained in the wine [5, 7, 8].

However, the high concentration of ethanol achieved with this process causes the loss of cell membrane integrity [9]. Another disadvantage of the HG and VHG processes is the occurrence of adverse effects on yeast metabolism due to high osmotic pressures, resulting in the loss of cell viability and a consequent reduction in the ethanol production rate [5, 10] as well as incomplete substrate utilization at the end of fermentation [11]. Thus, one of the challenges of VHG technology applied to alcoholic fermentation is the maintenance of yeast activity and viability throughout the entire harvest [8].

The tolerance of yeast to ethanol depends on two factors: the resistance of the yeast strain and the composition of the growth medium [12]. Thus, the osmotic stress caused by high gravity fermentation technology can be overcome by the addition of nutrients to the fermentation medium. To obtain high concentrations of ethanol using HG and VHG technology, several types of supplementation have been studied, such as fruit pulps, nitrogen, urea, dry yeast, yeast extract, corn steep liquor, trace elements, and vitamins; some studies have also evaluated aeration along with supplementation [11, 13,14,15,16,17]. In HG fermentation, some studies have recommended to perform hydrolysis of raw material components using enzymes as proteases, cellulases, and phytases, in order to reduce medium viscosity and increase starch availability. These strategies have resulted in an increase of ethanol production [2].

Another option for reducing production costs is the combination of different raw materials in VHG fermentation with the addition of molasses [18]. Sugarcane molasses is the liquid residue obtained during the manufacturing of crystallized sugar and contains 25 to 35% sucrose, 20 to 35% reducing sugars (glucose and fructose), and a high nutrient content, making it a potential raw material for bioethanol production [19]. Brazil is the world’s largest producer of sugarcane and produces large amounts of sugar [20], which consequently leads to the generation of molasses. Therefore, research has been conducted to determine uses for this industrial byproduct.

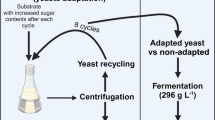

Flocculating yeasts are selected yeast strains that play a distinct role in the process of obtaining alcohol due to their ability to adhere to each other and form cellular aggregates, while also exhibiting both osmotolerance and high ethanol yielding capabilities under VHG conditions (2). Zhao et al. (2012) [21] demonstrated that industrial flocculating yeast strains improved the production efficiency of ethanol fuel. The use of flocculating yeasts in the production of bioethanol enables the elimination of the centrifugation step, as the yeasts aggregate in the form of flakes and concentrate at the bottom of the reactor after sugar consumption [5]. Liu et al. [22] found that yeast flocculation protected cells from the rapid change in environment after inoculation in HG and VHG media. Moreover, the metabolites are occluded within the flakes, which avoid their release into the fermentation broth and benefit the process. In a comparative study of flocculating and non-flocculating yeast strains, Tofalo et al. [23] found that flocculation conferred greater resistance to stress by ethanol. Santos et al. [24] demonstrated that the continuous process with flocculating yeast is efficient and promising, with the nearly complete conversion of sucrose at a feed rate of 200 g/L.

As discussed above, HG and VHG processes, agro-industrial byproducts, and flocculating yeasts are effective strategies for improving economic efficiency and reducing the environmental impact of ethanol production. To the best of our knowledge, however, no previous studies have evaluated the use of these three strategies together. Therefore, the aims of the present study were to evaluate HG and VHG fermentation conducted in a fed-batch process with different concentrations of sugarcane molasses using Saccharomyces cerevisiae with flocculating characteristics, determine the maximum ethanol concentration produced by the yeast, and model the fermentative kinetics by simulating real process conditions.

Materials and Methods

Microorganism and Fermentation Media

The flocculating yeast S. cerevisiae C2/00 was donated by the Center for Chemical, Biological, and Agricultural Research (CPQBA), Campinas, SP, Brazil. Fermentations were conducted using sugarcane molasses donated by the Usina Uberaba S.A. company located in Uberaba, MG, Brazil. Fermentation media prepared diluting molasses in distilled water in order to obtain 84°Brix.

Molasses Characterization

The composition of the molasses is displayed in Table 1. The metals, calcium, iron, magnesium, manganese, potassium, sodium, and zinc, present in the samples of sugarcane molasses were quantified using the atomic absorption spectrophotometer, brand Shimadzu, model AA-7000. The total nitrogen was quantified using the catalytic combustion technique with the Shimadzu Total Organic Carbon Analyzer TOC-L CPH/CPN analyzer.

Total soluble solids in the molasses were quantified using the refractometer and expressed as °Brix. The sucrose, glucose, and fructose sugars and organic acids were quantified by high-performance liquid chromatography (ESTD), Shimadzu, model LC-20A Prominence, with Supelcogel C-610H column, equipped with a refractive index and ultraviolet detector. The reading of organic acids occurred at a wavelength of 210 nm. Sugars were detected by the refractive index detector and organic acids by the ultraviolet detector at a wavelength of 210 nm. The mobile phase used was phosphoric acid (H3PO4) 0.1% at a flow rate of 0.5 mL/min and the oven temperature was 32 °C. The column used was a Supelcogel C-610H (Sigma-Aldrich), and the mobile phase was phosphoric acid (H3PO4) 0.1% at a flow rate of 0.5 mL/min and the oven temperature was 32 °C.

Sugar concentrations determined by HPLC were converted into total reducing sugar concentration (TRS).

Fed-Batch Fermentation with Molasses-Based Medium

The HG and VHG fermentations with molasses were conducted in a fed-batch system with the flocculating strain C2/00; the experiments were performed in triplicate. It is known that pH and temperature influence flocculating capacity of yeast cells, and studies have shown that it is strain dependent. Therefore, fermentation conditions and inoculum preparation were based on the study carried out by Guidini et al. [25], with some modifications based on preliminary experiments. Fed-batch fermentations were conducted in the biofermenter (TECNAL TEC BIO PLUS; 1200 mL working volume) with the temperature maintained at 32 ± 0.5 °C and an initial medium pH of 4.5. The inoculum consisted of 220 mL of decanted cells plus 140 mL of molasses solution containing 155 g/L TRS. The cell concentration was around 1.8 × 109 cell/mL. The inoculum concentration in the reactor was 30% v/v. For 6 h, the reactor was fed into the molasses-based medium at a flow rate of 0.140 L/h. The operating conditions of the three types of fed-batch fermentations (FB 1–FB 3) are specified in Table 2.

Study of Maximum Ethanol Production in Alcoholic Fermentation (P’max)

The P’max was determined to quantify the maximum ethanol concentration that the C2/00 strain would be able to endure during the fermentative process until inhibition by the product. The assay was carried out in a reactor with a working volume of 1200 mL, starting in a batch with a volume of 800 mL, cell concentration of 18% (v/v), and molasses solution with 189.6 g/L TRS [25]. When the concentration of total reducing sugars (TRS) reached less than 10 g/L (13.35 h), 100 mL of molasses solution with a concentration of 450 g/L TRS were added to the reactor at 22.5 h of fermentation. With a concentration of 500 g/L TRS, 100 mL of molasses solution were also added.

Analytical Methods

Glucose, fructose, sucrose, and ethanol concentrations were analyzed using high-performance liquid chromatography (HPLC) (model: LC-20ª Prominence, Shimadzu) with a Supelcogel K column and refractive index detector. The mobile phase was potassium phosphate dibasic (K2HPO4) 15 mM at a flow rate of 0.5 mL/min and the oven temperature was 85 °C.

Cell concentration and cell viability were determined in a Neubauer chamber following dilution in a 5 mM EDTA solution in citrate buffer, pH 3, for cell deflocculation.

Mathematical Modeling of Fed-Batch Fermentation

Fed-batch fermentations were conducted in two steps. The mathematical model describing ethanol fermentation was obtained from the mass balance for cells in batch and fed-batch fermentation. The model used in this study considered cell maintenance, by which a portion of the energy obtained from substrate metabolism is used for support. The must feed and the reactor volume (V) varied according to the feed flow (F). To produce ethanol, the cells meet their energy needs for growth and maintenance. Cell maintenance is the energy required to support cellular functions, such as repair, protein synthesis, etc. [26]. Cell maintenance was included in the model due to the high ethanol concentrations achieved in HG and VHG fermentations, which can cause damage to the cell structure and alter the cell metabolism. Under this stressful condition, yeasts may use some of the cellular energy to repair cell structures. Moreover, as part of the ATP produced in the ethanol fermentation pathway was used only for cell maintenance, nongrowth-associated ethanol production was also included in the model.

Considering product generation associated and not associated with cell growth and the contribution of the substrate to cell growth and maintenance, the mass balance for cells (X), substrate (S), and ethanol (P) in fed-batch fermentation can be described by the Eqs. (1)–(3).

in which X is the cell concentration (number of viable cells/L), μ denotes the specific cell growth rate (h−1), S is the concentration of total reducing sugars in the reactor (g/L), Sa is the concentration of total reducing sugars in the must feed (g/L), Yx/s is the cell yield coefficient (cel/gs), YP/s is the ethanol yield coefficient concerning sugar consumed (ge/gs), ms denotes cell maintenance parameter (g/(cel.h)), mp denotes nongrowth-associated constant for ethanol production (g/(cel.h)), and P is the ethanol concentration (g/L).

After the feed, the second stage consisted of the continuation of the fermentation process until all sugars were consumed or no further formation of ethanol occurred. Thus, F equals zero and the mass balance of cells (X), substrate (S), and ethanol (E) are described for a conventional batch according to the Eqs. (4)–(6).

The hybrid Andrews-Levenspiel Kinetic model [27] was used to describe cell growth, which considers inhibition by both substrate and product (Eq. 7).

in which μmax denotes the maximum specific cell growth rate (h−1), Ks is the saturation constant for cell growth (g/L), KIS is the substrate inhibition constant (g/L), Pmax is the maximum concentration of ethanol when cell growth ceases (g/L), and n is a dimensionless constant (potency of the inhibition term by the product).

Cellular and ethanol yield coefficients were determined using Eqs. 8 and 9.

in which the subscripts “0” and “f” refer to the initial and final times, respectively.

Mathematical Adjustment of Kinetic Variables

After determining the parameters Y(X/S), Y(P/S), and P’max, the kinetic variables (μmax, n, KS, KIS, ms, mp) were estimated using the nonlinear regression method proposed by Nelder and Mead (1965) [28]. The numerical method used for solving the differential equations of the model was the Runge-Kutta algorithm [29]. The minimization of the sum of squared residuals was used as a criterion for the best fit and optimization of the variables. Numerical resolutions were implemented in Scilab-6.0.1.

Yield, Productivity, and Efficiency

Ethanol yield was calculated relative to the ethanol produced by the total reducing sugars (TRS) added. The efficiency of alcoholic fermentation was calculated as the ethanol produced by the total TRS consumed. To express the yield and efficiency of ethanol production in percentage, the theoretical yield of 0.511 getanol/gART was considered to be 100%. Productivity was calculated as ethanol produced by total fermentation time.

Results and Discussion

HG and VHG Fermentation in Fed-Batch Process

In preliminary studies, the increase in molasses concentration in the fermentation media achieved satisfactory results regarding ethanol production efficiency and the cell viability of flocculating S. cerevisiae. Thus, further experiments were conducted to evaluate fermentation behavior when scaling up to reactors in a fed-batch process.

The comparative profiles of ethanol, TRS, and cell concentration for the FB 1, FB 2, and FB 3 fermentations are shown in Figs. 1, 2, and 3. Figure 1 shows variable concentrations of ethanol up to 6 h due to the combined influence of the must dilution by the feed and ethanol production by the yeast. Between 6 to 18 h, the three fermentation conditions exhibited similar ethanol concentrations. The ethanol production rate in FB 3 dropped after 18 h, whereas this drop only occurred after 24 h in the FB 1 and FB 2 fermentations. Ethanol production ceased in FB 1 due to sugar depletion. The highest final ethanol concentration (104.40 g/L) was achieved in FB 2 and was very close to P’max (105.35 g/L). Figure 2 shows the same behavior over time regarding the concentration of TRS for the three fermentations. The fermentations with higher concentrations of TRS in the process required more time and the residual sugars were higher. FB 2 and FB 3 exhibited maximum TRS concentrations in the reactor at 6 h (131 and 170.4 g/L, respectively), whereas FB 1 exhibited a maximum TRS concentration of 119.2 g/L at 4.5 h of fermentation. Nearly all reducing sugars were consumed within 30 h in FB 1, whereas FB 3 had the highest concentration of residual sugars after 36 h.

Cell concentrations of the three fermentations exhibited similar behavior up to 12 h (Fig. 3). From 12 h onwards, an increase in the cell concentration occurred in FB 1 and a progressive reduction in the viable cell concentration was found in FB 3, indicating cell death. In FB 2, a drop in viable cell concentration was found between 18 and 24 h, but ethanol production continued. Joannis-Cassan and colleagues [30] describe a similar finding in the fed-batch fermentation of 255 g/L of sucrose from beet syrup, reporting a reduction in the cell concentration with no effect on ethanol production. Cell reduction may be a response of the yeast to inhibition by ethanol.

The exposure time to higher concentrations of reducing sugars was much longer in FB 3 compared to FB 1 and FB 2 (Fig. 2). Thus, the yeast in FB 3 may have been submitted to greater stress due to the concentration of TRS in addition to the increased concentration of ethanol. This combination may have had a synergistic effect, exerting a greater impact on the yeast and leading to a lower ethanol yield [5]. Another possibility is that the additional stress of the sugar concentration reduced the latency time in the response of the yeast to stress. Joannis-Cassan et al. [30] were able to increase the final ethanol concentration by controlling the feed rate to maintain a sucrose concentration of less than 100 g/L within the reactor and modifying the duration of the feed time. According to the authors, the feed phase should be controlled to avoid the prolonged exposure of yeast to high concentrations of ethanol (above 10% v/v) and sugars simultaneously, thereby limiting the synergistic inhibition effect. Therefore, the shorter feed time in FB 3 negatively affected ethanol production.

Analyzing batch fermentation with glucose concentrations ranging 10 to 260 g/L, Chand et al. [31] found substrate inhibition at concentrations above 180 g/L, which considerably affected cell growth, the final ethanol concentration, and yield, similar to what occurred in the present investigation. Sonego et al. [27] evaluated feed times of 3 and 5 h for alcoholic fermentation in a conventional fed-batch system. Feeding was performed with 180 g/L sucrose solution. The accumulated substrate concentration reached about 120 g/L at the end of the 3-h feed time compared to 75 g/L at the end of the 5-h feed time. The researchers concluded that longer feed times controlled the substrate concentration in the must, which helped minimize substrate inhibition in the first hours of fermentation.

Table 3 displays the variables analyzed in the three types of fed-batch fermentations with a sugarcane molasses-based medium and flocculating yeasts. FB 2 achieved the highest ethanol concentration and, consequently, the highest yield and greatest efficiency, with values close to those considered optimal in the sugar-energy sector [19, 24]. FB 1 and FB 2 had the best productivity values.

Evaluating industrial scale fed-batch fermentation with cell recirculation using molasses with 32, 36, and 40°Brix, Arshad et al. [4] obtained final ethanol concentrations of 70.22, 73.38, and 75.74 g/L, respectively, after 60 h of fermentation, with residual TRS concentrations of 35.41, 41.00, and 60.40 g/L. The researchers were able to increase the final ethanol concentration using aeration at 0.2 vvm, obtaining 12.2% (v/v) ethanol with fermentation of the 40°Brix medium and reducing the residual TRS content to 18.7 g/L. Pattanakittivorakul et al. [32] obtained 72.4 g/L of ethanol after 60 h in a batch at 40 °C with the fermentation of molasses (200 g/L total fermentable sugar). Comparing these results with FB 2, in which the total used TRS concentration of 222 g/L corresponded to 33°Brix, the final ethanol concentration obtained in the present study of 104.4 g/L (13.2% v/v) was higher than that obtained by Arshad et al. [4]. Moreover, the residual TRS content (8.68 g/L) was lower and the fermentation time was considerably shorter.

Rivera et al. [26] performed fed-batch fermentation of a medium composed of a mixture of sugarcane juice and molasses with 400 g/L TRS (if a simple batch is considered), achieving a maximum ethanol concentration of 120 g/L in just 11.5 h of fermentation. To achieve the high productivity of 10.2 g/L.h, the researchers used an adequate temperature and micro-aeration of 0.2 vvm when the ethanol concentration was approximately equal to Pmax. However, part of the sugars was destined for the formation of byproducts, such as glycerol, lactic acid, and acetic acid.

Maximum Ethanol Production (P’max)

Figure 4 displays the results of maximum ethanol production (P’max) with the profiles of ethanol and TRS concentrations during the experiment using the aqueous molasses solution as substrate. No substrate consumption by the yeast occurred after 40 h due to product inhibition. The maximum ethanol production was 105.35 g/L, which corresponds to 13.35% v/v.

Guidini et al. [25] evaluated ethanol production by S. cerevisiae C2/00 in a synthetic medium, obtaining maximum production close to that found in the present investigation after 30 h of fermentation (110 g/L). Using molasses as the sugar source, the behavior of the yeast did not change significantly. As molasses is a byproduct of the sugar production industry, it has components that act as inhibitors to the fermentation process, such as acetic and lactic acid, among others, presented in Table 3. Moreover, osmotic pressure interferes with the process [33, 34]. Nonetheless, the present experiment shows that it is possible to obtain final concentrations of ethanol from molasses fermentation close to those obtained using a synthetic medium, approximating industrial conditions.

Cruz [25] evaluated the maximum ethanol production of an industrial strain (Y904) using a central composite design with a fermentation temperature of 24 to 34 °C, an initial cell concentration of 10 to 35 g/L, and an initial total reducing sugar concentration of 179.6 to 280.5 g/L. Maximum ethanol productivity and yield were achieved with an initial total reducing sugar concentration of 240 g/L, an inoculum cell concentration of 35 g/L, and a temperature of 26 °C. This study indicates that temperature exerts an influence of the tolerance of the strain to ethanol and that higher concentrations of ethanol can be obtained at lower temperatures, which was also reported by Rivera et al. [26] and Veloso et al. [35].

Phukoetphim et al. [12] studied the ethanol tolerance of S. cerevisiae strains NP01 and ATCC 4132. For such, the cells were inoculated into sweet sorghum juice (100 g/L), together with different ethanol concentrations (0, 6, 9, 12, 15, and 18% (v/v)). As the ethanol concentration increased, the μ decreased sharply. Thus, inhibition was complete at 9 to 12% ethanol after 24 h. The study demonstrates another way to determine the tolerance of a strain to ethanol. However, the method does not consider other metabolites that may be formed and cause inhibition during the fermentation process.

Kinetics of Alcoholic Fermentation

The variables of the hybrid Andrews-Levenspiel kinetic model were estimated from the results obtained in the FB 2 fermentation. The cell and ethanol yield coefficients were calculated from the experimental results. The Pmax value used in the adjustment was obtained experimentally, and the other variables displayed in Table 4 were obtained by adjusting the model to the experimental data.

Figure 5 compares the simulated data from the model and the experimental data from the FB 2 fermentation (feed, 290 g/L of TRS; total fermentation time, 33 h) regarding the concentration of TRS, ethanol, and cells during the process. The proposed model exhibited a good fit to the experimental data, with a greater variation in the cell concentration values, which also had the largest deviations.

Comparison of simulated and experimental data for reducing sugars, ethanol, and cell concentrations during fermentation FB 2. Where: (  ), TRS concentration (g/L); (▲), cell concentration (cells × 108/mL); (

), TRS concentration (g/L); (▲), cell concentration (cells × 108/mL); (  ), ethanol concentration (g/L) experimental. The lines represent the simulated data. Black for cell concentration, red for ethanol concentration, and blue for TRS concentration

), ethanol concentration (g/L) experimental. The lines represent the simulated data. Black for cell concentration, red for ethanol concentration, and blue for TRS concentration

Guidini et al. [25] used model similar to the hybrid Andrews-Levenspiel kinetic model to describe the alcoholic fermentation kinetics of a synthetic medium by S. cerevisiae C2/00. Modeling was performed for a fed-batch process with cell recirculation. The maximum growth rate (μmax) was 0.182 h−1. The saturation (KS) and inhibition constant (KIS) were 30.24 g/L and 109.86 g/L, respectively, obtaining a good fit. Sonego et al. [27] also obtained an excellent fit using the hybrid Andrews-Levenspiel kinetic model to describe the kinetic behavior in the fed-batch fermentation of sucrose. The kinetic variables determined by the model were μmax, KS, and KIS of 0.125 h−1, 25.1 g/L, and 131.8 g/L, respectively. From the model proposed by Atala et al. [36], Rivera et al. [26] developed a temperature-dependent kinetic model to be used in the simulation of the VHG fermentation process in a fed-batch system. Among the kinetic variables, some were set at a certain temperature, such as a KS of 4.1 g/L, and the others were estimated. Kinetic parameters were estimated at temperatures ranging from 24 to 36 °C, obtaining KIS values ranging from 0.0033 to 0.0048 g/L.

By definition, KS is the limiting substrate concentration value at which the growth rate is half the maximum value and KIS is the substrate concentration at which the onset of inhibition occurs [37]. Values for the saturation and substrate inhibition constants reported in the literature are highly variable, demonstrating that these constants can be influenced by the model selected and the fermentation conditions.

Conclusion

The results obtained in this work revealed the efficiency of HG fermentation using only sugarcane molasses and a flocculating strain of S. cerevisiae, enabling maximum ethanol production of 13.2% v/v, which is higher than the values obtained in traditional ethanol production processes. VHG fermentation did not yield good results, likely due to inhibition by substrate concentration and/or the fact that sugarcane molasses has components that act as inhibitors to the process. The P’max value revealed the need for other strategies so that the S. cerevisiae C2/00 strain can support higher ethanol concentrations and an increase in the final ethanol concentration can be achieved. In summary, this study shows that it is possible to obtain high concentrations of ethanol from the fermentation of a byproduct of the sugar industry using flocculating yeasts, which reduces the cost of the process.

References

Shalaby, E. A. (2013). Biofuel: sources, extraction and determination. In Liquid, gaseous and solid biofuels - conversion techniques (pp. 451–478). https://doi.org/10.5772/51943.

Puligundla, P., Smogrovicova, D., Mok, C., & Obulam, V. S. R. (2019). A review of recent advances in high gravity ethanol fermentation. Renewable Energy, 133, 1366–1379. https://doi.org/10.1016/j.renene.2018.06.062.

Barbosa, H. S., Silveira, E. A., Miranda, M., & Ernandes, J. R. (2016). Efficient very-high-gravity fermentation of sugarcane molasses by industrial yeast strains. Institute of Brewing and Distilling, 122(2), 329–333. https://doi.org/10.1002/jib.317.

Arshad, M., Hussain, T., Iqbal, M., & Abbas, M. (2017). Enhanced ethanol production at commercial scale from molasses using high gravity technology by mutant S. cerevisiae. Brazilian Journal of Microbiology, 48(3), 403–409. https://doi.org/10.1016/j.bjm.2017.02.003.

Bai, F. W., Anderson, W. A., & Moo-Young, M. (2008). Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnology Advances, 26(2008), 89–105. https://doi.org/10.1016/j.biotechadv.2007.09.002.

Lopes, M. L., Paulillo, S. C. L., Godoy, A., Cherubin, R. A., Lorenzi, M. S., Giometti, F. H. C., Bernardino, C. D., Amorim Neto, H. B., & Amorim, H. V. (2016). Ethanol production in Brazil: a bridge between science and industry. Brazilian Journal of Microbiology, 47(Supp 1), 64–76. https://doi.org/10.1016/j.bjm.2016.10.003.

Thomas, K. C., Dhas, A., Rossnagel, B. G., & Ingledew, W. M. (1995). Production of fuel alcohol from hull-less barley by very high gravity technology. Cereal Chemistry, 72, 360–364.

Rossell, C. E. V., Nolasco Junior, J., & Yamakawa, C. K., (2014). Patent WO2014078924-A1.

Cot, M., Loret, M. O., François, J., & Benbadis, L. (2007). Physiological behaviour of Saccharomyces cerevisiae in aerated fed-batch fermentation for high level production of bioethanol. FEMS Yeast Research, 7(1), 22–32. https://doi.org/10.1111/j.1567-1364.2006.00152.x.

Kawa-Rygielska, J., & Pietrzak, W. (2014). Ethanol fermentation of very high gravity (VHG) maize mashes by Saccharomyces cerevisiae with spent brewer’s yeast supplementation. Biomass and Bioenergy, 60, 50–57. https://doi.org/10.1016/j.biombioe.2013.10.028.C.G.

Liu, C. G., Hao, X. M., Lin, Y. H., & Bai, F. W. (2016). Redox potential driven aeration during very-high-gravity ethanol fermentation by using flocculating yeast. Scientific Reports, 6, 25763. https://doi.org/10.1038/srep30995.

Phukoetphim, N., Salakkam, A., Laopaiboon, P., & Laopaiboon, L. (2017). Improvement of ethanol production from sweet sorghum juice under batch and fed-batch fermentations: effects of sugar levels, nitrogen supplementation, and feeding regimes. Electronic Journal of Biotechnology, 26, 84–92. https://doi.org/10.1016/j.ejbt.2017.01.005.

Pereira, F. B., Guimarães, P. M. R., Teixeira, A., & Domingues, L. (2010). Optimization of low-cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Bioresource Technology, 101(20), 7856–7863. https://doi.org/10.1016/j.biortech.2010.04.082.

Monteiro, B., Ferraz, P., Barroca, M., Cruz, S. H., Collins, T., & Lucas, C. (2018). Conditions promoting effective very high gravity sugarcane juice fermentation. Biotechnology for Biofuels, 11, 251. https://doi.org/10.1186/s13068-018-1239-0.

Lebaka, V. R., Ryu, H. W., & Wee, Y. J. (2014). Effect of fruit pulp supplementation on rapid and enhanced ethanol production in very high gravity (VHG) fermentation. Bioresources and Bioprocessing, 1, 22. https://doi.org/10.1186/s40643-014-0022-8.

Deesuth, O., Laopaiboon, P., Klanrit, P., & Laopaiboon, L. (2015). Improvement of ethanol production from sweet sorghum juice under high gravity and very high gravity conditions: effects of nutrient supplementation and aeration. Industrial Crops and Products, 74, 95–105. https://doi.org/10.1016/j.indcrop.2015.04.068.

Li, Z., Wang, D., & Shi, Y. C. (2017). Effects of nitrogen source on ethanol production in very high gravity fermentation of corn starch. Journal of the Taiwan Institute of Chemical Engineers, 70, 229–235. https://doi.org/10.1016/j.jtice.2016.10.055.

Kłosowski, G., & Mikulski, D. (2018). Complementarity of the raw material composition of Very High Gravity (VHG) mashes as a method to improve efficiency of the alcoholic fermentation process. Process Biochemistry, 74, 1–9. https://doi.org/10.1016/j.procbio.2018.08.028.

Yamakawa CK. (2016) Avaliação da fermentação alcoólica com reciclo de células de hidrolisado celulósico de bagaço de cana-de-açúcar em unidade integrada e autônoma. In Brazil: Faculty of Chemical Engineering, State University of Campinas; Thesis, (p. 269).

CONAB – (2019) Companhia Nacional de Abastecimento. Acompanhamento da Safra Brasileira de Cana de açúcar. - Safra 2018/19. https://www.conab.gov.br. Accessed 6 Jun 2019.

Zhao, X. Q., Li, Q., He, L. Y., Li, F., Que, W. W., & Bai, F. W. (2012). Exploration of a natural reservoir of flocculating genes from various Saccharomyces cerevisiae strains and improved ethanol fermentation using stable genetically engineered flocculating yeast strains. Process Biochemistry, 47(11), 1612–1619. https://doi.org/10.1016/j.procbio.2011.06.009.

Liu, C. G., Wang, N., Lin, Y. H., & Bai, F. W. (2012). Very high gravity ethanol fermentation by flocculating yeast under redox potential-controlled conditions. Biotechnology for Biofuels, 191, 45–52. https://doi.org/10.1186/1754-6834-5-61.

Tofalo, R., Perpetuini, G., Gianvito, P. D., Schirone, M., Corsetti, A., & Suzzi, G. (2014). Genetic diversity of FLO1 and FLO5 genes in wine flocculent Saccharomyces cerevisiae strains. International Journal of Food Microbiology, 191, 45–52. https://doi.org/10.1016/j.ijfoodmicro.2014.08.028.

Santos, L. D., Sousa, M. D. B., Guidini, C. Z., Resende, M. M., Cardoso, V. L., & Ribeiro, E. J. (2015). Continuous ethanol fermentation in tower reactors with cell recycling using flocculent Saccharomyces cerevisiae. Process Biochemistry, 50(11), 1725–1729. https://doi.org/10.1016/j.procbio.2015.07.020.

Guidini, C. Z., Santos, L. D., Silva, H. A., Resende, M. M., Cardoso, V. L., & Ribeiro, E. J. (2014). Alcoholic fermentation with flocculant Saccharomyces cerevisiae in fed-batch process. Applied Biochemistry and Biotechnology, 172(3), 1623–1638. https://doi.org/10.1007/s12010-013-0646-8.

Rivera, E. C., Yamakawa, C. K., Saad, M. B. W., Atala, D. I. P., Ambrosio, W. B., Bonomi, A., Nolasco Junior, J., & Rossell, C. E. V. (2017). Effect of temperature on sugarcane ethanol fermentation: kinetic modeling and validation under very-high-gravity fermentation conditions. Biochemical Engineering Journal, 119, 42–51. https://doi.org/10.1016/j.bej.2016.12.002.

Sonego, J. L. S., Lemos, D. A., Pinto, C. E. M., Cruz, A. J. G., & Badino, A. C. (2016). Extractive fed-batch ethanol fermentation with CO2 stripping in a bubble column bioreactor: experiment and modeling. Energy and Fuels, 30, 748–757. https://doi.org/10.1021/acs.energyfuels.5b02320.

Nelder, J. A., & Mead, R. A. (1965). Simplex method for function minimization. Computer Journal, 7, 308–313. https://doi.org/10.1093/comjnl/7.4.308.

Gill, S. (1951). A process for the step-by-step integration of differential equations in an automatic digital computing machine. Proceedings of the Cambridge Philological Society, 47(1), 96–108. https://doi.org/10.1017/S0305004100026414.

Joannis-Cassan, C., Riess, J., Jolibert, F., & Taillandier, P. (2014). Optimization of very high gravity fermentation process for ethanol production from industrial sugar beet syrup. Biomass and Bioenergy, 70, 165–173. https://doi.org/10.1016/j.biombioe.2014.07.027.

Chang, Y. H., Chang, K. S., Chen, C. Y., Hsu, C. L., Chang, T. C., & Jang, H. D. (2018). Enhancement of the efficiency of bioethanol production by Saccharomyces cerevisiae via gradually batch-wise and fed-batch increasing the glucose concentration. Fermentation, 4(2), 45. https://doi.org/10.3390/fermentation4020045.

Pattanakittivorakul, S., Lertwattanasakul, N., Yamada, M., & Limtong, S. (2019). Selection of thermotolerant Saccharomyces cerevisiae for high temperature ethanol production from molasses and increasing ethanol production by strain improvement. Antonie Van Leeuwenhoek, 112(7), 975–990. https://doi.org/10.1007/s10482-019-01230-6.

Andrietta, M. G. S., Andrietta, S. R., & Stupiello, E. N. A. (2011). Bioethanol – What has Brazil learned about yeasts inhabiting the ethanol production processes from sugar cane? In Biofuel production – recent developments and prospects (pp. 67–84). https://doi.org/10.5772/16572.

Cao, D., Tu, M., Xie, R., Li, J., Wu, Y., & Adhikari, S. (2014). Inhibitory activity of carbonyl compounds on alcoholic fermentation by Saccharomyces cerevisiae. Journal of Agricultural and Food Chemistry, 62(4), 918–926. https://doi.org/10.1021/jf405711f.

Veloso, I. I. K., Rodrigues, K. C. S., Sonego, J. L. S., Cruz, A. J. G., & Badino, A. C. (2019). Fed-batch ethanol fermentation at low temperature as a way to obtain highly concentrated alcoholic wines: Modeling and optimization. Biochemical Engineering Journal, 41, 60–70. https://doi.org/10.1016/j.bej.2018.10.005.

Atala, D. I. P., Costa, A. C., Maciel, R., & Maugeri, F. (2001). Kinetics of ethanol fermentation with high biomass concentration considering the effect of temperature. Applied Biochemistry and Biotechnology, 91-93, 353–365. https://doi.org/10.1385/ABAB:91-93:1-9:353.

Pinheiro, A. D. T., Pereira, A. S., Barros, E. M., Antonini, S. R. C., Cartaxo, S. J. M., Rocha, M. V. P., & Gonçalves, L. R. B. (2017). Mathematical modeling of the ethanol fermentation of cashew apple juice by a flocculent yeast: the effect of initial substrate concentration and temperature. Bioprocess and Biosystems Engineering, 40(8), 1221–1235. https://doi.org/10.1007/s00449-017-1782-2.

Funding

The authors would like to acknowledge the Brazilian fostering agencies CAPES, CNPq, and FAPEMIG (TEC-APQ-02079-16 and TEC-APQ-02489-16) for financial support to this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Camargos, C.V., Moraes, V.D., de Oliveira, L.M. et al. High Gravity and Very High Gravity Fermentation of Sugarcane Molasses by Flocculating Saccharomyces cerevisiae: Experimental Investigation and Kinetic Modeling. Appl Biochem Biotechnol 193, 807–821 (2021). https://doi.org/10.1007/s12010-020-03466-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03466-9