Abstract

Polyhydroxyalkanoates (PHAs) are a potential substitute for traditional plastics. Synthesis of PHAs using excess sludge without additional domestication as a mixed microbial culture can reduce production costs. PHAs were synthesized using excess sludge (R1) from a continuous flow system performing simultaneous nitrification/denitrification and phosphorus removal. Excess sludge (R2) from a A2O wastewater treatment plant was used as a mixed microflora culture (MMC) and the waste fermentation liquid was used as a carbon source. Results showed that with volatile fatty acid (VFA) concentrations of 430–520 mg/L (COD of 650–750 mg/L), when R1 and R2 were reacted under anaerobic conditions, the maximum generated concentrations of PHAs were 84.41 mg/g and 30.8 mg/g, respectively. When aeration volumes were 5, 10, 15, and 20 L/h, the amounts of PHAs synthesized from R1 and R2 increased by varying degrees, with the highest amount generated at 10 L/h (108.6 mg/g and 58.58 mg/g, respectively). In the process of PHA formation, ORP shows a decreasing trend. When the concentration of PHAs reaches a maximum level, ORP drops to a “valley point.” Lower ORP valley points indicate a higher potential for synthesis of PHAs. Therefore, ORP can be used as a control parameter to reflect the reaction process in the micro-oxygen synthesis of PHAs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

PHAs are intracellular microbial polymers. When microbial growth conditions are not balanced PHAs can be used as storage material for intracellular energy, continuously releasing carbon to support microbial denitrification and phosphorus removal. PHAs are considered to be a non-toxic, non-stimulating polymer materials with physical and chemical properties similar to traditional plastics. In addition, PHAs have properties of biodegradability, biocompatibility, and nonlinear optical properties that traditional plastics do not have [1, 2]. Therefore, PHAs can be used as a substitute for traditional plastics, reducing the environmental impact of production processes and end-of-life disposal [3]. Due to these superior properties, PHAs have attracted widespread research attention, especially in the fields of environmental and material science. The yield of PHAs synthesized by pure microbial strains is reported to account for 80–90% of the dry weight of cells. However, due to the specific substrate requirements, operation mode, and strict disinfection conditions, the cost of synthesis remains high [4]. In addition, the long duration required for the growth of pure bacteria and the recovery of biomass, also increase the costs of PHA synthesis [5]. Therefore, the synthesis of PHAs using widely available and inexpensive domesticated mixed colonies is useful method to solve the problem.

The high cost of synthesis of PHAs from pure bacterial cultures can be reduced by using sludge from sewage plants as a mixed microflora culture (MMC). MMC uses a wide range of carbon sources, does not require complex disinfection processes, and operates in a simpler way [6]. Studies have shown that sewage plant surplus sludge contains bacteria that can synthesize PHAs [3], and therefore, the use of surplus sludge has become a key focus in PHA synthesis [7, 8]. At present, the synthesis of PHAs by MMC mainly adopts three steps [9, 10]. First is the substrate preparation step, where the macromolecular organics in waste are converted into small molecular volatile fatty acids (VFAs) that are easily absorbed by microbes through hydrolysis/fermentation. Second is the PHA producing microbe enrichment stage, using the carbon sources generated in the first step, with ecological selection of microbes. After a period of domestication, the strains exhibiting a relatively strong ability to synthesize PHAs are selected [11, 12]. This enrichment stage before PHAs synthesis can be stabilized at between 50 and 80%. Third is the PHA synthesis step, where the accumulation of PHAs is maximized by exposing microbes to excessive carbon source concentrations for an extended period. This three-step method can solve the problem of high carbon source costs, although the long duration required for microbial domestication in the second step is not conducive to the large-scale production of PHAs in practical applications.

In the process of synthesizing PHAs, the processes usually used include anaerobic-aerobic processes, microaerobic-aerobic processes, or aerobic dynamic feeding (ADF). In anaerobic-aerobic processes (also known as enhanced biological phosphorus removal (EBPR) processes), under anaerobic conditions, polyphosphorous accumulating organisms (PAOs) absorb short-chain fatty acids and other organic compounds, synthesizing PHAs within cells. Satoh et al. [13] reported that when trace oxygen was introduced into the reaction system to form a micro-oxygen environment, PHAs were synthesized using domesticated activated sludge, forming PHAs contents of up to 62% of the MLSS. ADF processes require the addition of all substrates at the start of the reaction with a continuous supply oxygen to the reactor, resulting in a DO content of generally more than 3 mg/L and relatively high energy consumption requirements. Therefore, it is possible to further reduce the energy consumption associated with the synthesis of PHAs by controlling DO levels. Third et al. [14] studied the effects of DO on the accumulation of PHAs in activated sludge, reporting that low DO was conducive to the accumulation of PHAs, while high DO levels lead to a large increase in biomass, the consumption of PHAs, and therefore a decline in PHAs production. Wang et al. [4] compared the use of high DO (3.47 ± 1.12 mg /L) and low DO (0.86 ± 0.50 mg /L) in the satiation stage to explore the influence of DO on the synthesis of PHAs, reporting that low DO is more conducive to the screening and accumulation of mixed PHAs producing flora.

To date, studies on the synthesis of PHAs from activated sludge have largely focused on the use of domesticated activated sludge, while few studies have assessed the synthesis of PHAs from undomesticated activated sludge. The synthesis of PHAs using undomesticated excess sludge mitigates the requirement for the second step of the “three-step” domestication process and compared with the use of domesticated sludge, reduces the duration of synthesis (usually 3 months to 1 year) and the economic costs of the process. However, without domestication, the initial ability of microorganisms to synthesize PHAs is low. Therefore, the purpose of this study was to increase the yield of undomesticated excess sludge synthetic PHAs through micro-aeration, with investigation of the control parameters in a micro-oxygen environment. Excess sludge from secondary sedimentation tanks in two sewage treatment processes (R1, R2) was used to investigate the capacity for PHA synthesis from different types of undomesticated surplus sludge. The excess sludge from an anaerobic/limited oxygen continuous flow reactor, in which stable nitrification and denitrification dephosphorization reactions take place simultaneously (R1), was compared to excess sludge from a municipal wastewater treatment plant, operating an A2O nitrogen and phosphorus removal process (R2). The synthesis of PHAs from R1 and R2 sludge were compared under anaerobic and micro-oxygen conditions. The aim of this study was to provide a regulation method for increasing the yield of undomesticated surplus sludge synthesized PHAs.

Materials and Methods

Materials

Fig. 1 show the Schematic diagram of the reaction device. R1 activated sludge was taken from an anaerobic-limited oxygen continuous flow (A/OLA) reactor used for research purposes for simultaneous nitrification/denitrification and phosphorus removal. The anaerobic zone volume of the reactor was 13.8 L, the oxygen limiting zone was 39 L, and the aeration panel was located in the oxygen limiting zone. The bottom of the second sedimentation tank was connected with a return pipe and the return sludge was transferred back to the anaerobic zone via a peristaltic pump. R2 activated sludge was taken from the secondary sedimentation tank of an A2O process municipal wastewater treatment plant.

The fermentation liquid used in this experiment was supplied by a peanut residue waste fermentation tank being operated for research purposes, with an effective dissolution volume of 10 L. The parameters of the fermentation liquid are shown in Table 1.

The initial MLSS of the R1 and R2 secondary sludge were 10,120 mg/L and 12,829 mg/L, 67% and 97% of SV, 662 mL/g and 756 mL/g of SVI, and 7.20 and 7.56 of PH, respectively.

Experimental Methods

Anaerobic batch tests used an appropriate amount of R1 or R2 sludge to form final concentrations in the two 2L SBR reactors of 3300–3600 mg/L. An appropriate amount of fermentation liquid was added to provide VFA concentrations of 430–520 mg/L and COD levels of 650–750 mg/L. The reaction occurred for 5 h under anaerobic conditions, with continual stirring. Water and sludge samples were collected every 60 min for analysis.

Micro-oxygen batch tests used the same conditions as described for anaerobic batch tests, including VFA concentrations of 430–520 mg/L and a reaction time of 5 h. The whole reaction process was carried out with aeration at 5, 10, 15, and 20 L/h via an air pump. Water and sludge samples were collected every 0.5 h and their ORP was measured.

Test Methods

CODCr, MLSS, MLVSS, TP, and NH4+-N parameters were analyzed using standard methods [15]. CODCr was measured using the closed reflux titrimetric method, while ORP and pH values were continuously monitored using a WTW Multi 340i meter with an ORP electrode and a pH probe. Spectrophotometry was performed using a Beifen-Ruili UV1600 and UV1200.

PHAs (HB, HV) were measured by gas chromatography [16] (Agilent 7980A-5975C GC-MS). First, sludge was separated from the slurry using a high-speed freezing centrifuge at 8000 r/min and then the upper water layer was passed through filter paper and collected in a sampling cup. Samples were mixed with deionized water and centrifuged again, and the supernatant was removed. Samples were then frozen at − 20 °C and transferred to a freeze-dryer and dried for 12 h. The freeze-dried sludge material was then placed in a heat-resistant tube and combined with 2 ml chloroform, 2 ml methanol solution containing 500 mg/L benzoic acid, and 2 ml acidified10% (V:V) methanol. Tubes were sealed and heated in a water bath at 100 °C for 4 h. Following this, 2 ml deionized water was added and tubes were shaken, before the organic compound content was analyzed by gas chromatography.

VFAs (acetic acid, propionic acid, butyrate, and pentanoic acid) were measured by gas chromatography [17]. Samples were centrifuged at 10,000 rpm for 10 min, and the supernatant was removed and filtered through a 0.45-μm filter membrane, before 0.1 ml formic acid was added to each sample. Samples were then analyzed using gas chromatography (GC7900 (CNW, CD-WAX, FID)), with a sample size of 1 μL. The temperature of the detector and the inlet were 250 °C and 220 °C, respectively. The column temperature was increased from 60 to 150 °C at a rate of 7 °C min−1 for 5 min, before increasing to 230 °C at a rate of 20 °C min−1 for 10 min.

Determination of intracellular polyphosphate was performed using sludge samples dissolved in deionized water and treated with an ultrasonic cell pulverizer (Sceintz-IID) at a power of 400 W, a working time of 5 s and a gap time of 5 s, for 20 min. The total phosphorus concentration was measured according to a previously reported method. The Coomassie Brilliant Blue G-250 method was used to measure the protein content [18]. The determination of intracellular glycogen was performed by adding dry sludge to 0.6 mol/L HCl, followed by digestion at 121 °C for 30 min in a high pressure steam cooker. Extracted carbohydrates were measured using phenol sulfuric acid [19].

Calculation Method

The concentration of PHAs is expressed according to the formula shown in Eq. (1):

Results and Discussion

Production of Synthetic PHAs from activated Sludge

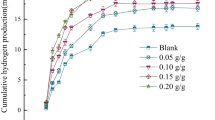

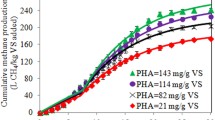

Figures 2 and 3 show the changes in PHA concentrations under anaerobic and micro-oxygen conditions, respectively. The initial PHAs contents of R1 and R2 were 14.91 mg/g and 7.15 mg/g, respectively. After 5 h of anaerobic reaction, the concentration of PHAs generated by R1 and R2, reached 84.41 mg/g and 30.8 mg/g, respectively. When aerated at 5, 10, 15, and 20 L/h, the maximum concentration of PHAs generated using R1 reached 101.4, 108.6, 80.1, and 78.9 mg/g, respectively, while the maximum concentration of PHAs generated using R2 were 41.96, 58.58, 42.59, and 35.98 mg/g, respectively. These results show that R1 itself contained a higher initial content of PHAs, as the R1 activated sludge was taken from a simultaneous nitrifying and denitrifying phosphorus removal system. The denitrifying phosphorus removal process is carried out under oxygen-limited reaction conditions. Compared to the completely aerobic conditions of traditional A2O processes, the PHAs in sludge are slowly consumed in oxygen-limited environments, allowing more PHAs to remain. Under anaerobic conditions, the concentration of PHAs in R1 and R2 sludge show an upward trend, before becoming stable with maximum values of 84.41 mg/g and 30.8 mg/g, respectively. This indicates that the activated sludge from the simultaneous nitrifying/denitrifying phosphorus removal system has a higher capacity to synthesize PHAs under anaerobic conditions. When trace oxygen was injected into the reaction system (Fig. 3), the production of PHAs using both residual sludge types improved to varying degrees. When the aeration amount was 10 L/h, a maximum level of synthesis of PHAs was observed using both R1 and R2 sludge. Moreover, with the increase in micro-oxygen content, the time required for peak concentrations of PHAs to be reached decreased and the reaction rate increased. When concentrations of PHAs reached their peak level, microorganisms start to consume PHAs from the satiation stage to the starvation stage. Therefore, when synthesizing PHAs using micro-oxygen processes, in order to maximize the yield of PHAs, the reaction should be controlled before microorganisms enter the consumption stage. In addition, as shown in Fig. 3, the production of PHAs does not increase with greater aeration levels, as excessive aeration damages the micro-oxygen environment, causing cells to rapidly enter a state of aerobic carbon source consumption. When the system was aerated with micro-oxygen at 10 L/h, a maximum yield of PHAs was achieved, suggesting that this the optimal amount of aeration required for the synthesis of PHAs from activated sludge in micro-oxygen environment.

Changes in Intracellular Glycogen

Intracellular glycogen is an energy storage substance for the further conversion or anabolism of carbon sources. For the synthesis of PHAs, intracellular glycogen provides a reductive force. Figures 4 and 5 show the change in intracellular glycogen under anaerobic and micro-oxygen conditions, respectively. According to Fig. 4, the initial intracellular glycogen concentrations of R1 and R2 sludge were 109.42 mg/g and 70.34 mg/g, respectively. Following the anaerobic reaction, the intracellular glycogen concentrations decreased to 86.06 mg/g and 67.10 mg/g, respectively. According to the Mino model [20], under anaerobic conditions, the hydrolysis of intracellular phosphorus provides energy for the microbial synthesis of PHAs. Meanwhile, intracellular glycogen-based synthesis of NADH2 through EMP or ED pathways provides a reductive force for the synthesis of PHAs. Therefore, intracellular glycogen concentration is an influential factor in the synthesis of PHAs. A higher initial intracellular glycogen content results in a stronger ability to synthesize PHAs. In addition, the intracellular glycogen consumption by R1 during the process of PHAs synthesis was higher than that of R2, with this higher intracellular glycogen utilization rate supporting a stronger PHAs synthesis ability.

According to Fig. 5, when a small amount of oxygen is introduced into the reaction system, intracellular glycogen consumption slows down. For R1, when the aerated gas volume was 5 L/h, the intracellular glycogen concentration decreased from the initial concentration of 117.26 to 102.03 mg/g, with a consumption of 15.03 mg/g. The lowest intracellular glycogen concentration occurred in accordance with the highest concentration of PHAs. As the reaction continued, the intracellular glycogen content increased, indicating that microbes had entered an aerobic state and therefore, began to synthesize intracellular glycogen. When the aerated gas volume was increased to 10 L/h, the intracellular glycogen concentration decreased from 116.93 to 111.28 mg/g, with a consumption of 5.65 mg/g. Intracellular glycogen consumption decreased as compared with aeration at 5 L/h. This indicates that a small amount of oxygen can cause cells to not only consume intracellular glycogen, but also to synthesize intracellular sugar, reducing the total consumption of intracellular glycogen. When the gas volume continued to increase to 15 L/h, the intracellular glycogen content decreased from 114.92 to 111.12 mg/g, with a consumption of 3.79 mg/g. When the gas volume was increased further to 20 L/h, the intracellular glycogen content decreased only slightly from 116.54 to 113.42 mg/g, with a consumption of 3.12 mg/g. For R2, with the increase in aerated gas volume, the intracellular glycogen consumption in the PHAs synthesis phase was 2.03, 1.56, 0.75, and 0.12 mg/g, respectively. After reaching the peak concentration of PHAs, the intracellular glycogen content began to increase. It is of note that under all aeration conditions, the intracellular glycogen consumption of R2 was less than that of R1.

The above phenomenon indicates that the presence of DO causes sludge to not only consume intracellular glycogen but also to synthesize intracellular glycogen. It has been previously been shown in the literature that the energy required for the absorption of extracellular organics and the formation of intracellular polymers is supplied by the metabolic process of partially soluble organic matrices using oxygen as an electron acceptor [21]. High intracellular glycogen concentrations are conducive to the accumulation of PHAs. However, when the aerated gas volume was 20 L/h, although intracellular glycogen was at a maximum level, the maximum amount of accumulated PHAs was not as high as with an aerated gas volume of 10 L/h. This indicates that intracellular glycogen is no longer the influencing factor limiting the synthesis of PHAs at this time. Excessive DO concentrations destroy the micro-oxygen environment, causing microbes to enter the aerobic stage prematurely and consume PHAs.

Comparison of Intracellular Phosphorus Content Between Two Kinds of activated Sludge

Figure 6 shows the initial intracellular phosphorus concentrations of the two activated sludge types. During the satiation phase, intracellular phosphorous is hydrolyzed into phosphate, producing energy to synthesize PHAs. The concentration of intracellular phosphorous in R1 was 46.11 mg/g, which was significantly higher than in R2 (4.13 mg/g). Under anaerobic conditions, the synthesis of PHAs from activated sludge occurred mainly due to the hydrolysis of polyphosphorous by PAOs, with the release of energy from external carbon sources stored in the form of PHAs into the cell. The concentration of intracellular phosphorus becomes a factor affecting the ability to synthesize PHAs. Therefore, from the perspective that R1 contains higher intracellular phosphorous concentrations, this also indicates that R1 has a stronger capacity for PHAs synthesis.

Regulation of Protein and Carbohydrate Absorption

Figure 7 shows the changes in carbohydrate and protein concentrations with time, under anaerobic reaction conditions. The reduction in carbohydrate concentrations in the R1 and R2 reactors under anaerobic conditions were 0.49 mg/L and 1.18 mg/L, respectively, while the protein concentration reduction in the R1 and R2 reactors were 1.90 mg/L and 13.83 mg/L, respectively.

The above experiments show that R1 had a weaker ability to degrade and absorb carbohydrates and proteins than R2. This is because the simultaneous nitrifying/denitrifying phosphorus removal system used artificial simulated sewage with sodium acetate as the sole carbon source, while R2 was taken from the residual sludge of a municipal sewage treatment plant. The carbon sources in the inlet water are therefore more diverse, resulting in a more diverse microbial community which is more adaptable to variable carbon sources. In addition, according to the mechanism of microbial degradation of proteins and carbohydrates [22], after the protein is decomposed into amino acids by microbes, a fraction of the amino acids are used to synthesize the proteins required by the microorganism itself. The remaining fraction of amino acids is metabolized into various intermediate products, such as acetyl coenzyme A, which is the intermediate product required for the synthesis of PHAs. The degradation of carbohydrates occurs partly for use in cell synthesis, while some of them are stored as glycogen in the cell to provide energy for the synthesis of PHAs.

When aerated gas volumes of 5, 10, 15, and 20 L/h were injected to the reaction system, the protein concentration in the R1 SBR decreased by 20.73, 22.274, 24.07, and 27.93 mg/L, respectively, while the carbohydrate concentration decreased by 1.59, 3.09, 3.18, and 3.22 mg/L, respectively (Figs. 8 and 9). The R2 SBR protein concentration decreased by 27.15, 28.86, 28.16, and 33.02 mg/L, respectively, while the carbohydrate concentration decreased by 2.74, 3.67, 4.05, and 3.92 mg/L, respectively.

The above experimental results show that following the introduction of trace oxygen, the degradation capacity of the two residual sludge types on proteins and carbohydrates increased to varying degrees. Proteins are macromolecules that can only be absorbed by microbes in the form of monomers or oligomers, under the action of extracellular hydrolases [23]. This indicates that the existence of DO enhances the hydrolysis capability of extracellular hydrolytic enzymes and with the increase in DO concentrations, the hydrolysis capability also increases. Similarly, carbohydrate macromolecules cannot be directly absorbed by microbial cells and can only pass the cell wall and be utilized by cells in the form of monosaccharides or oligomers with molecular weights of < 1000, under the action of extracellular hydrolytic enzymes. Overall, the presence of trace oxygen increases the level of degradation and absorption of organic matter, which is conducive to the synthesis of more PHAs by microorganisms.

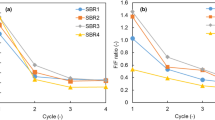

Change in ORP Under Micro-oxygen Conditions

This experiment examined the role of ORP in the progress of the reaction under micro-oxygen conditions. As shown in Fig. 3 and Fig. 10, during the PHA accumulation phase, the ORP exhibited a downward trend. When the PHAs reached a maximum accumulation capacity, the ORP fell to its lowest level (valley point). With the increase in aeration, the ORP valley points advanced and the time when the valley point occurred was consistent with the time when PHAs reached a maximum value. In addition, under optimal aeration conditions of 10 L/h, the ORP of the two residual sludge types exhibited the lowest observed valley point. Therefore, the capacity for synthesis of PHAs can potentially be indicated by the size of ORP valley points, with lower valley points indicating an improved capacity for synthesis of PHAs.

ORP represents the state of oxidation and reduction in the reaction system [24]. When PHAs are accumulating ORP shows a declining trend, which indicates that when the system is in a reductive state, it is more conducive to the synthesis of PHAs. When the system enters an oxidative state, PHAs present in the sludge begin to enter the consumption state. Zhang et al. [24] found that ORP was more sensitive than DO in the detection of a low DO environment. Therefore, ORP can be used as a guiding parameter to judge the PHAs synthesis process.

Conclusions

This study compared PHA production using excess sludge from a simultaneous nitrification and denitrification and phosphorus removal system and from an A2O sewage treatment plant process. Using kitchen waste fermentation broth as the carbon source, the two kinds of surplus sludge were used to synthesize PHAs without domestication. The following conclusions were drawn:

-

1.

R1 exhibited a better PHAs accumulation ability. After aeration with different amounts of air, PHA production by the two kinds of residual sludge increased to varying degrees. Optimal PHA synthesis was observed in both residual sludge types when the applied gas volume was 10 L/h,

-

2.

The presence of DO is conducive to the synthesis of intracellular glycogen by microorganisms. Excessive aeration will damage the micro-oxygen environment, causing microbes to enter the aerobic state in advance, resulting in the consumption of PHAs and a reduction in the PHA yield.

-

3.

Micro-oxygen environments can also increase the absorption of proteins and carbohydrates by microorganisms.

-

4.

ORP can be used as a control parameter in the process of micro-oxygen synthesis of PHAs, with the lowest level of ORP indicating the highest level of PHA production.

References

Basak, B., Ince, O., Artan, N., Yagci, N., & Ince, B. K. (2011). Effect of nitrogen limitation on enrichment of activated sludge for PHA production. Bioprocess and Biosystems Engineering, 34(8), 1007–1016.

Chen, Z., Guo, Z., Wen, Q., Long, H., Bakke, R., & Du, M. (2016). Modeling polyhydroxyalkanoate (PHA) production in a newly developed aerobic dynamic discharge (ADD) culture enrichment process. Chemical Engineering Journal, 298, 36–43.

Li, D., Qian, F., & Dan, Y. (2016). Maximizing the accumulation of poly-β-hydroxybutyrate (PHB) in low-carbon urban sewage. Desalination & Water Treatment, 57, 1–12.

Wang, X., Oehmen, A., Freitas, E. B., Carvalho, G., & Reis, M. A. (2017). The link of feast-phase dissolved oxygen (DO) with substrate competition and microbial selection in PHA production. Water Research, 112, 269–278.

Hand, S., Gill, J., & Chu, K. H. (2016). Phage-based extraction of polyhydroxybutyrate (PHB) produced from synthetic crude glycerol. Science of the Total Environment, 557-558, 317–321.

Cavaillé, L., Albuquerque, M., Grousseau, E., Lepeuple, A. S., Paul, E. (2016) Understanding of polyhydroxybutyrate production under carbon and phosphorus-limited growth conditions in non-axenic continuous culture. Bioresource Technology 201.

Flavigny, R. M., & Cord-Ruwisch, R. (2015). Organic carbon removal from wastewater by a PHA storing biofilm using direct atmospheric air contact as oxygen supply. Bioresource Technology, 187, 182–188.

Valentino, F., Karabegovic, L., Majone, M., Morgan-Sagastume, F., & Werker, A. (2015). Polyhydroxyalkanoate (PHA) storage within a mixed-culture biomass with simultaneous growth as a function of accumulation substrate nitrogen and phosphorus levels. Water Research, 77, 49–63.

Johnson, K., Kleerebezem, R., & Loosdrecht, M. C. M. V. (2010). Influence of the C/N ratio on the performance of polyhydroxybutyrate (PHB) producing sequencing batch reactors at short SRTs. Water Research, 44(7), 2141–2152.

Lee, W. S., Chua, A. S. M., Yeoh, H. K., Nittami, T., & Ngoh, G. C. (2015). Strategy for the biotransformation of fermented palm oil mill effluent into biodegradable polyhydroxyalkanoates by activated sludge. Chemical Engineering Journal, 269, 288–297.

Duque, A. F., Oliveira, C. S. S., Carmo, I. T. D., Gouveia, A. R., Pardelha, F., Ramos, A. M., & Reis, M. A. M. (2014). Response of a three-stage process for PHA production by mixed microbial cultures to feedstock shift: Impact on polymer composition. New Biotechnology, 31(4), 276–288.

Flavigny, R. M.-G., & Cord-Ruwisch, R. (2015). Organic carbon removal from wastewater by a PHA storing biofilm using direct atmospheric air contact as oxygen supply. Bioresource Technology, 187, 182–188.

Satoh, H., Iwamoto, Y., Mino, T., & Matsuo, T. (1998). Activated sludge as a possible source of biodegradable plastic. Water Science & Technology, 38(2), 103–109.

Third, K. A., Newland, M., & Cord-Ruwisch, R. (2003). The effect of dissolved oxygen on PHB accumulation in activated sludge cultures. Biotechnology and Bioengineering, 82(2), 238–250.

Wei, C., ZhiQiang, C., BingNan, L., QinXue, W., YunHai, Z., (2009) Effect of temperature on the polyhydroxyalkanoate synthesis performance of the activated sludge, pp. 515-518.

Wen, Q., Chen, Z., Wang, C., & Ren, N. (2012). Bulking sludge for PHA production: Energy saving and comparative storage capacity with well-settled sludge. Journal of Environmental Sciences, 24(10), 1744–1752.

Wang, Q., Kuninobu, M., Ogawa, H. I., & Kato, Y. (1999). Degradation of volatile fatty acids in highly efficient anaerobic digestion. Biomass & Bioenergy, 16(6), 407–416.

Brasford, M. (1976). A rapid and sensitive method for quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72(1-2), 248–254.

Anat, K., Saha, and, Curtis, F. (n.d.). Brewer Determination of the concentrations of oligosaccharides, complex type carbohydrates, and glycoproteins using the phenol-sulfuric acid method.

Seviour, R. J., Mino, T., & Onuki, M. (2010). The microbiology of biological phosphorus removal in activated sludge systems. FEMS Microbiology Reviews, 27, 99–127.

Majone, M., Massanisso, P., & Ramadori, R. (1998). Comparison of carbon storage under aerobic and anoxic conditions. Water Science and Technology, 38(8-9), 77–84.

Puteh, M., Minekawa, K., Hashimoto, N., & Kawase, Y. (1999). Modeling of activated sludge wastewater treatment processes. Bioprocess Engineering, 21(3), 249–254.

Larsen, T., & Harremoës, A. (1994). Degradation mechanisms of colloidal organic matter in biofilm reactors. Water Research, 28(6), 1443–1452.

Zhang, C., Guo, J., Lian, J., Song, Y., Lu, C., & Li, H. (2018). Bio-mixotrophic perchlorate reduction to control sulfate production in a step-feed sulfur-based reactor: A study of kinetics, ORP and bacterial community structure. Bioresource Technology, 269, 40–49.

Acknowledgments

The authors would like to thank Guangzhou University for its support.

Funding

This project was financially supported by the National Natural Science Foundation of China (Grant No. 21207023) and the Natural Science Foundation of Guangdong Province (Grant No. 2017A030313273).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Undomesticated excess sludge from two sewage treatment processes was used to investigate the capacity for PHA synthesis.

• The yield of synthetic PHAs from undomesticated excess sludge was increased through micro-aeration.

• The presence of DO was conducive to the synthesis of intracellular glycogen by microorganisms.

• ORP can be used as a control parameter in the process of micro-oxygen PHA synthesis.

Rights and permissions

About this article

Cite this article

Fang, Q., Huang, Z., Liu, Y. et al. Micro-oxygen Process Improved Synthesis of PHAs with Undomesticated Excess Sludge. Appl Biochem Biotechnol 192, 367–380 (2020). https://doi.org/10.1007/s12010-020-03322-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03322-w