Abstract

Inulo-oligosaccharides (IOSs), a novel food additive and health product, represent a promising alternative to antibiotics. As prebiotics, IOSs can be obtained from inulin by endo-inulinase-mediated hydrolysis. Nonetheless, enzymatic catalysis is not feasible industrially because of the required catalytic conditions and cost. In this study, a 2331-bp optimized gene inuQ (from Pseudomonas mucidolens) encoding endo-inulinase was cloned into shuttle vector PHY300PLK and transfected into Bacillus subtilis WB800-R, with the simultaneous deletion of gene sacC encoding levanase. The maximal IOS yield after hydrolysis of the crude extract of inulin was 67.84 ± 0.72 g/L for a recombinant strain with the signal peptide nprB from alkaline protease and promoter P43. The conversion rate reached 75.38%. For the major IOSs, the degree of polymerization was between 3 and 5. This study offers a simple and efficient one-step bioprocess for IOS production from inulin through secretion of an extracellular heterologous endo-inulinase by B. subtilis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Historically, sucrose has been considered the most popular sweetener [1]. Nevertheless, in recent years, medical professionals confirmed that excessive sugar intake may lead to obesity, diabetes, and atherosclerosis. Improvements in the standard of living have directed people to use other sweeteners instead of sugar. Oligosaccharides, such as inulo-oligosaccharides (IOSs) and fructo-oligosaccharides (FOSs), which have low thermal and good stability, could retain the pure sweetness and be in common use as functional prebiotics owing to their health-promoting properties [2,3,4,5].

At present, commercial FOSs are predominantly produced from sucrose by the catalysis of fructosyltransferases and β-D-fructofuranosidases [6]. The drawback of this biological process is the simultaneous production of glucose, fructose, and sucrose; this shortcoming increases the separation cost of FOSs, seriously affects the quality of FOSs, and limits their applications [7, 8]. IOSs can be obtained by endo-inulinase-mediated hydrolysis from inulin, which is a naturally occurring storage polysaccharide present in numerous plants, such as Jerusalem artichoke [9, 10]. It contains linear chains of β-2,1-linked-fructofuranose molecules terminated by a glucose residue. The degree of polymerization (DP) of inulin is typically between 2 and 60 [11]. In recent years, inulin-containing materials and inulinases have received greater attention regarding preparation of fructose syrup by means of exo-inulinase and IOSs using endo-inulinase (EC 3.2.1.7), which belongs to the GH32 family [12,13,14,15,16]. As a result, IOSs of DP 3–9 are released as the major products.

Until now, many endo-inulinases have been isolated from various strains and characterized, e.g., from Arthrobacter sp. [17], Penicillium sp. [18], Pseudomonas sp. [19], Aspergillus ficuum [20], and A. niger [21] (Table S1). Nonetheless, commercial endo-inulinases have not been used extensively in scaled up production of IOSs because of the complicated conditions and high cost. Furthermore, most strains can secrete both endo-inulinase and exo-inulinase, and this drawback hampers the development of a process for the production of IOSs by wild-type strains. Therefore, the process of production of IOSs via heterologous expression of endo-inulinase in a recombinant strain has been researched.

Lately, endo-inulinases have been expressed in Escherichia coli and Saccharomyces cerevisiae to prepare IOSs by whole-cell catalysis [22]. The endo-inulinase gene (inu1) of Pseudomonas sp. has been expressed in E. coli HB101, and the resultant strain shows a high yield of IOSs (78%) [23]. On the other hand, E. coli cannot be used as the host for the industrial production of IOSs because of the production of endotoxins. For S. cerevisiae, an endo-inulinase gene from Aspergillus fumigatus was cloned and overexpressed in P. pastoris, then a high concentration of IOSs was obtained via a high cell density fermentation approach [24]. Nonetheless, owing to the presence of undefined enzymes that exert hydrolytic activity on inulin in S. cerevisiae, glucose, fructose, sucrose, and other byproducts are present simultaneously in the one-step bioprocess, thus resulting in the high cost of separation, purification, low quality, and other problems [25]. Among microorganisms with the Generally Regarded as Safe (GRAS) status, Bacillus subtilis can express and secrete foreign proteins efficiently [26]. B. subtilis WB800 has been generated by the knockout of genes such as cwp and vpr encoding a protease. There are no reports on the production of IOSs from inulin by B. subtilis secreting an extracellular endo-inulinase.

In the present study, a recombinant strain—B. subtilis WB800-R with a deletion of the gene sacC encoding levanase—was constructed for endo-inulinase expression. Gene inuQ, encoding an endo-inulinase from Pseudomonas mucidolens [19], was cloned and expressed in B. subtilis WB800-R. To obtain a strain with high expression and secretion of the recombinant endo-inulinase, optimization of the signal peptide and promoter of the producing enzyme was performed. Finally, high yields of IOSs of high quality were achieved in a one-step bioprocess involving inulin and the recombinant B. subtilis secreting the extracellular endo-inulinase.

Materials and Methods

Strains and Media

The strains and plasmids used in this study are listed in Table 1. The host strain B. subtilis WB800 was subjected to engineering. The B. subtilis and E. coli strains were grown in the Luria-Bertani (LB) medium (10.0 g/L tryptone, 5.0 g/L yeast extract, and 10.0 g/L NaCl). Inulin was purchased from Sangon Biotech (Shanghai, China). The starting inulin solution (SI) used in this study consisted of 90.0 g/L pure inulin, 4.02 ± 0.83 g/L glucose, 8.28 ± 0.71 g/L fructose, and 4.25 ± 0.58 g/L sucrose, whereas the crude extract of inulin (CEI) consisted of 90.0 g/L pure inulin, 4.02 ± 0.37 g/L glucose, 8.28 ± 0.62 g/L fructose, 4.25 ± 0.17 g/L sucrose, and some trace elements, which were mainly K, Ca, Na, Mg, Cu, Fe, and Al. The fermentation medium (FM) consisted of 20.0 g/L yeast extract, 15.0 g/L NaCl, 0.5 g/L MgSO4·7H2O, 6.0 g/L K2HPO4·3H2O, 2.0 g/L KH2PO4, and SI or CEI. The SI was replaced by 15.0 g/L sucrose, thus resulting in the enzyme medium (EM) for enzyme analysis. All strains and plasmids were stored at − 80 °C. Ampicillin (Sangon Biotech, China) was used to screen the transformed E. coli strains. Kanamycin, tetracycline, and chloramphenicol (Sangon Biotech, China) were employed separately or in combination to screen B. subtilis transformants. The final concentrations of the antibiotics were 100, 25, 20, and 5 μg/mL respectively. The standards of inulotriose (F3), inulotetraose (F4), and inulopentaose (F5) were purchased from WAKO.

DNA Manipulation Techniques

Gene inuQ (endo-inulinase) was obtained from the P. mucidolens genome, which was discovered in a search of the National Center of Biotechnology Information (NCBI) database. B. subtilis genomic DNA was extracted with the TIANamp Bacteria DNA Kit (Tiangen, China) and PCR amplification was performed with the high-fidelity DNA polymerase KOD mix (Abm, China) [27]. Taq mix DNA polymerase (Vazyme Biotech, China) served for diagnostic PCR amplification. DNA fragments were purified by means of the E.Z.N.A.® Gel Extraction Kit. The plasmids were isolated from E. coli using the plasmid extraction kit (Axygen). One-step cloning ligase was provided by Vazyme Biotech.

Plasmid and Strain Construction Procedures

The recombinant plasmids and constructed strains are presented in Table 2. In recombinant strain B. subtilis WB800-R, gene sacC from B. subtilis WB800 is inactivated through homologous recombination. A 800-bp homologous arm was amplified by PCR with the primer pair PK-sacC-F (5′-agctatgacatgattacgaattcAATCTGAAGCAGTGGACGTA) and PK-sacC-R (5′-tgcaggtcgactctagaggatccTCAACCGAGGAGCGGTCAA) and ligated into thermosensitive plasmid PKSV7 by means of a one-step cloning kit and was transfected into strain B. subtilis WB800. The homologous recombination was triggered by changing the temperature.

Constitutive plasmid PMA05 and shuttle vector PHY300PLK were extracted from E. coli DH5a. Gene inuQ encoding endo-inulinase was amplified by PCR with the primer pair PMA-inuQ-F (5′-aaaaggagcgatttacatatgATGCACAACACAGAAGACACAGG) and PMA-inuQ-R (5′-gagctcgactctagaggatccTTATTTTGTCTGCACGCCATCG). The plasmid backbone and DNA fragments were assembled at 37 °C for 30 min and recombinant plasmid PMA05-inuQ was generated by taking into consideration the signal peptides and endo-inulinase (inuQ) fragments were fused together by overlap-extension PCR. The signal peptides and promoters were amplified from the genome of B. subtilis168.

There were five signal peptides (SPamyQ, SPsacB, SPsacC, SPnprB, and SPbpr) for extracellular secretion. Four promoters were also evaluated for efficient expression of endo-inulinase. P43 and Pamye are constitutive promoters, whereas PxylR and Pglv are inducible promoters. The primers for the signal peptides and promoters are listed in Table S2. The One Step Cloning Kit (Vazyme Biotech) was used in the process of construction of plasmids.

An Endo-Inulinase Activity Assay

One unit of endo-inulinase activity was defined as the amount of enzyme that produces 1 μmol of fructose per minute under the assay conditions [28]. The reaction mixture, containing 200 μL of the supernatant and 800 μL of 2% (w/v) inulin, was dissolved in 0.05 mM phosphate buffer, pH 7.4. The reaction mixture was incubated at 55 °C for 30 min; each experiment was performed in triplicate to obtain more accurate data and reduce experimental error. A separate blank sample containing inactivated enzyme was set up for each sample to correct the results for the nonenzymatic release of sugars [27]. The reaction was terminated at 100 °C for 10 min. The activity was detected in a chromogenic reaction with 3,5-dinitrosalicylic acid (DNS). The reaction products were diluted and the absorbance was measured at 540 nm. For optimization of signal peptides and promoters in recombinant strains, extracellular enzyme activity was measured.

Production of IOSs by Hydrolysis from Inulin Using Recombinant B. subtilis

The recombinant strains for use in fermentation were recovered in glycerol tubes from stocks stored at − 80 °C and were cultivated in 50 mL LB seed culture for 12 h. The seed culture was inoculated at 2% (v/v) into 100 mL of FM loaded into a 500-mL flask. The fermentation was performed at 32 °C with shaking at 200 rpm. Samples were retrieved at intervals of 4 h and centrifuged at 12,000g for 2 min to separate the supernatant for the analysis of IOSs and of sugar consumption. Fermentation was conducted by means of SI or CEI as the carbon source and was scaled up to a 7.5-L bioreactor. The CEI was derived from fresh Jerusalem artichoke tubers [29], which were collected in Yan Cheng, Jiangsu, China.

Analytical Methods

The master standards, CEI, and hydrolysis products of inulin after fermentation were analyzed on a high-performance liquid chromatography (HPLC) system (Chromeleon server monitor, P680 pump, Dionex, USA), which was equipped with an RI detector and an Asahipak NH2P 50 4E column (4.6 mm, 250 mL, Shodex, Japan). Fermentation broth was diluted and passed through a 0.22-μm nylon filter prior to injection into the HPLC system. The mobile phase was a mixture of 70% chromatography-grade acetonitrile and pure water, with 35 min elution, at a mobile phase flow rate of 0.8 mL/min and a column temperature of 30 °C. Under these conditions, the retention time of the RI detector was 36.25 min. Optical density at 600 nm (OD600) was determined by an ultraviolet detection method. For measurement of the dry cell weight (DCW) of the bacteria, 10 mL of fermentation broth was first centrifuged, the pellet was washed twice with deionized water, and then transferred to a centrifuge tube after drying and weighing. The temperature and time of drying were ~ 75 °C and 8 h, respectively. The conversion rate (CR) is defined as follows:

where A (g/L) is the yield of IOSs, and M (g/L) is the concentration of pure inulin.

Results and Discussion

Deletion of Gene sacC in B. subtilis WB800

One study showed that B. subtilis can hydrolyze inulin into fructose and glucose via the secretion of levanase, which is encoded by gene sacC and has exo-inulinase activity. To remove the exo-inulinase activity, gene sacC was disrupted in B. subtilis WB800. In the present study, a knockout plasmid (PKSV7-sacC) was constructed and transfected into strain WB800. The PKSV7 skeleton was 7107 bp, and a 800-bp fragment was selected as the homologous arm for homologous single-crossover. The principle of homologous single exchange is illustrated in Fig. 1. Primers sacC-out-F and sacC-out-R were designed in accordance with the genome sequence flanking the homologous arms and were employed in the screening of transformants for both single-crossover recombinants [30].

Scheme of the temperature-sensitive plasmid PKSV7-based homologous recombination gene deletion method. sacC-up represents homologous arms which were connected to PKSV7-generated PKSV7-sacC. Primers sacC-out-F and sacC-out-R were used to verify whether homologous single exchange has been completed and to block sacC

The single- and double-restriction endonuclease reactions for analysis of recombinant plasmid PKSV7-sacC are shown in Fig. 2a. The results of the single- and double-restriction endonuclease digestion and PCR analysis indicated that the PKSV7-sacC recombinant plasmid was generated successfully. With an extension period of 4 min, PCR was conducted to amplify a DNA fragment of approximately 3500 bp from the genome of B. subtilis WB800 as a template to (lane 8). Thus, the gene sacC was amplified as 3500 bp of B. subtilis WB800 genome. By contrast, in lane 7, the transformant did not yield the 3500-bp amplicon after PCR; it was proven that plasmid PKSV7-sacC got inserted completely and blocked the normal expression of sacC (Fig. 2a).

Confirmation of deletion-carrying mutants. a Nucleic acid gel verification; M, maker; 1, 2: the single- and double-restriction endonuclease of recombinant plasmid PKSV7-sacC; 3, 4, 5, 6: PCR amplification through primers PK-sacC-F/PK-sacC-R; 7, 8: The results of WB800-R and WB800 genome as template PCR, respectively, with primers sacC-out-F/sacC-out-R; b: HPLC analysis fructose in fermentation broth used SI as the sole carbon source. WB800: Bacillus subtilis; WB800-R: recombinant strain blocked the expression of sacC gene

The fermentation results were evaluated continuously. After fermentation for 24 h, the HPLC analysis showed that inulin was hydrolyzed to fructose by strain WB800, but in WB800-R’s fermentation broth, the HPLC analysis did not detect fructose (Fig. 2b). When SI was the carbon source, owing to the blocked expression of levanase, strain WB800-R could not hydrolyze inulin into fructose for cell growth. Nonetheless, in preliminary experiments, SI, which consists of a reducing sugar such as glucose and fructose, could meet the cell growth requirements. These results confirmed that strain WB800-R could serve as the host strain for the heterologous expression of endo-inulinase.

Screening of Signal Peptides for the Best One for Secretion of Endo-Inulinases by Strain WB800-R

To construct a B. subtilis strain for the production of IOSs via inulin hydrolysis, gene inuQ encoding endo-inulinase from P. mucidolens was expressed in B. subtilis WB800-R. The inuQ gene was cloned into shuttle plasmid PMA05 with the PhpaII promoter of S. aureus, and thus recombinant plasmid PMA05-inuQ was generated. The recombinant plasmid was transfected into WB800-R by chemical conversion, thereby generating strain WB800-R-inuQ. Fermentation results revealed a weak intracellular enzymatic activity of 2.12 ± 0.26 U/mL. Unfortunately, the endo-inulinase from P. mucidolens cannot be secreted from cells owing to the absence of a signal peptide.

To achieve the secretion of endo-inulinase, various signal peptides (SPamyQ, SPsacC, SPsacB, SPbpr, and SPnprB) from extracellular enzymes secreted by B. subtilis were screened [17]. The signal peptides were inserted into PMA05-inuQ, thus yielding recombinant plasmids PMA05-SPamyQ-inuQ, PMA05-SPsacC-inuQ, PMA05-SPsacB-inuQ, PMA05-SPbpr-inuQ, and PMA05-SPnprB-inuQ, respectively. Recombinant plasmids were transfected into strain WB800-R, individually. The results are shown in Fig. 3. The expressed amount of the target protein (87 kDa) with signal peptide SPnprB was higher as compared to other signal peptides, as shown by SDS-PAGE. The extracellular secretion was also the highest among all the recombinant strains.

Then, fermentation was carried out with SI as the carbon source. The fermentation findings are listed in Table 2. Compared with other recombinant strains, the recombinant strain with SPnprB showed faster cell growth (in terms of DCW), which reached 9.12 ± 0.08 g/L. The extracellular enzymatic activity was higher in comparison with other strains and reached 22.42 ± 0.95 U/mL. It was 2.56-fold higher than that with SPsacB and 10.52-fold higher than that without a signal peptide. For all recombinant strains, the yield of IOSs with SPnprB was the highest, reaching 45.53 ± 0.71 g/L. For recombinant strains, an important factor in the increase of IOS production was the enzymatic activity. A positive correlation between enzymatic activity and IOS yield was noted. In essence, the enzymatic activity resulted from the different secretory abilities of different signal peptides, which were mainly determined by the amino acid length of the encoded signal peptide and by the type of the −3, −2, and − 1 regions of the amino acids. The frequency of the terminal amino acid sequence Ala, Ser, Ala (ASA) of the signal peptide with a high secretory efficiency was 80%. The terminal amino acid sequence of the nprB signal peptide contains the ASA motif. It can be recognized stably by the specific channel proteins of the general secretion pathway and promote secretion of the target protein to the extracellular environment [31]. By contrast, the last three amino acids of the other four signal peptides were not ASA and did not show a secretory ability as SPnprB did. In addition, this finding was consistent with the results of other researchers who reported that the ASA amino acids of the signal peptide result in high secretory capacity [32].

Screening of Highly Active Promoters of Endo-Inulinase in Strain WB800-R

The endogenous proteins of B. subtilis can be overexpressed effectively [33]. Nonetheless, the secretion of heterologous proteins by B. subtilis is usually low [34]. Thus, efficient production of high-value recombinant proteins in B. subtilis remains a major challenge. To improve the enzymatic activity of endo-inulinase, optimization of the promoter was performed. Promoter regulation is an important factor controlling the expression of enzymes. In this study, four promoters from the genome of B. subtilis were screened. The promoters were PxylR, Pglv, P43, and Pamye: the first two are inducible promoters that initiate transcription and translation during induction by xylose and maltose, respectively, whereas P43 and Pamye are constitutive promoters. Recombinant plasmids PHY-PxylR-SPnprB-inuQ, PHY-Pglv-SPnprB-inuQ, PHY-P43-SPnprB-inuQ, and PHY-Pamye-SPnprB-inuQ were generated. Engineered strains were obtained by transfection of the recombinant plasmids.

There was no significant difference in DCW among the different recombinant strains. The highest extracellular enzymatic activities of the recombinant strains P43, Pamye, PxylR, and Pglv were 50.68 ± 0.52, 43.04 ± 0.93, 39.67 ± 0.74, and 39.43 ± 0.59 U/mL, respectively (Table S3). The endo-inulinase enzymatic activity resulting from the constitutive promoter was better than that corresponding to an inducible promoter. The endo-inulinase enzymatic activity of P43 was optimal, 2.26-fold higher than that of PhpaII.

The recombinant strain with promoter P43 also showed a higher yield of IOSs (up to 50.09 ± 0.62 g/L) than did strains with other promoters. The recombinant strain with Pamye manifested a yield of 43.04 ± 0.93 g/L. As the enzymatic activity increased, higher yields of IOSs were obtained. The difference in IOS amounts was caused by the high expression efficiency of the promoter. In fact, compared with Pamye, P43 is a double promoter: the − 10 region, − 35 region, and the distance between the Shine-Dalgarno (SD) box and the start codon have a strong effect on transcription and translation [35]. Furthermore, induction was not needed, which was beneficial for the expression of the recombinant enzyme.

The recombinant strains that harbored promoter PxylR or Pglv showed lower enzymatic activity than did the strain carrying P43 because the abovementioned two promoters were mainly based on the negative control induced by the repressor protein and activator protein. Owing to the presence of glucose in SI and the Crabtree effect, xylose and maltose cannot be transferred into the cell efficiently, and this problem leads to low expression of endo-inulinase. Removal of this inhibition should improve the efficiency of endo-inulinase expression.

Comparison of SI and CEI Regarding the Production of IOSs

For the recombinant strain WB800-R-inuQ with SPnprB and P43, fermentation was implemented to compare the use of SI and CEI to produce IOSs. DCW of 13.79 ± 0.62 g/L was obtained with CEI, which was 1.48-fold higher than that with SI. The production of IOSs was 62.53 ± 0.74 g/L when CEI was used, but 50.87 ± 0.59 g/L when SI was used (Table S4). The CR of IOSs with CEI was 69.47%, which was 1.22-fold higher than that with SI. Compared with SI fermentation, the production of IOSs was increased significantly by CEI fermentation. The extension of the fermentation period led to a higher concentration of cells and a higher yield of IOSs.

In CEI, there is abundance of natural nutrients such as soluble proteins, amino acids, vitamins, and minerals [36]. In other studies, it was found the amino acid, vitamin, and mineral components can promote the growth of Paenibacillus polymyxa ZJ-9 and help to produce R,R-2,3-butanediol [37]. The citric acid cycle, the Embden–Meyerhof–Parnas pathway, and other basic metabolic pathways are similar in B. subtilis and P. polymyxa. These components may also be important factors favorable for the growth of B. subtilis and may promote the fermentation process, thus enhancing the yield of IOSs. This process here features one-step fermentation of CEI without further purification; this approach greatly decreased the raw-material cost and thus facilitated its practical application.

IOS Production Using CEI in a 7.5-L Bioreactor

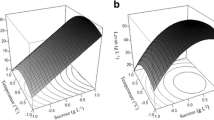

To verify the optimal fermentation conditions for the production of IOSs, strain WB800-R (PHY-P43-SPnprB-inuQ) was incubated in a 7.5-L bioreactor with CEI. As illustrated in Fig. 4, compared with the shake flask fermentation, there was an obvious increase in biomass and consumption of CEI, with a final DCW of 15.37 ± 0.43 g/L, which corresponded to an 11.46% increase. HPLC analysis of CEI fermentation is also shown. The titer of IOSs was 67.84 ± 0.72 g/L, and the CR reached 75.38%. DP3, DP4, and DP5 corresponded to 30.13 ± 0.67, 24.26 ± 0.58, and 13.34 ± 0.49 g/L, respectively. The yield of IOSs and concentration of cells still showed a positive correlation.

Production of IOSs from inulin was reported in another publication, which revealed optimal fermentation yielding 180.2 g/L IOSs, 18.3 g/L sucrose, 0.52 g/L twintose, 0.37 g/L fructose, and 0.14 g/L glucose, and a broad range of DP2 to DP6 produced from 200 g/L chicory inulin by yeast strain JZHΔS-TSC [38]. Glucose, sucrose, twintose, and fructose were by-products, which may have been generated by some unknown extracellular hydrolases secreted during yeast fermentation. An endo-inulinase gene, inu2, was also expressed in E. coli and an IOS yield of 140 g/L was achieved with DP 3 to 7 under the conditions of 15% (w/v) inulin and one-step fermentation by the recombinant strain [39]. Nevertheless, the latter process is seriously limited in practical applications because of the accumulation of exotoxin. In the present study, there were no glucose and sucrose residues, which were consumed for cell growth. At the end of fermentation, the only by-product was 8.52 ± 0.48 g/L fructose. This result may be attributable to the fact that most of the extracellular hydrolase genes in B. subtilis WB800 were knocked out, with a few hydrolases secreted at the later stages. This finding suggested that the one-step bioprocess for production of IOSs from inulin by B. subtilis secreting an extracellular endo-inulinase was highly efficient.

Conclusions

This study offers a simple and efficient one-step bioprocess for the production of a high concentration of IOSs from inulin by recombinant B. subtilis. Host strain WB800-R with a deletion of sacC was obtained. Gene inuQ encoding endo-inulinase from P. mucidolens was cloned and expressed in B. subtilis WB800-R. Through optimization of the signal peptide and promoter, a high yield of IOSs was achieved. The recombinant strain harboring SPnprB and P43 showed an optimal yield of 67.84 g/L and CR of 75.38%, with the main DP values of 3, 4, and 5. The only by-product of this process was fructose. This one-step bioprocess not only realizes the whole value of inulin, but also simplifies the process of purification after IOS production.

References

Pandey, A., Soccol, C. R., Selvakumar, P., Soccol, V. T., Krieger, N., & Fontana, J. D. (1999). Recent developments in microbial inulinases. Applied Biochemistry and Biotechnology, 81(1), 35–52.

Hidaka, H., Eida, T., Takizawa, T., Tokunaga, T., & Tashiro, Y. (1986). Effect of fructooligosaccharides on intestinal flora and human health. Bifidobacterla Microflora, 5(1), 37–50.

Wada, K., Watanabe, J., Mizutani, J., Tomoda, M., Suzuki, H., & Saitoh, Y. (1992). Effect of soybean oligosaccharides in a beverage on human fecal flora and metabolites. Nippon Nogei-kagaku Kaishi, 66(2), 127–135. (in Japanese).

Yun, J. W. (1996). Fructooligosaccharides-occurrence, preparation, and application. Enzyme and Microbial Technology, 19(2), 107–117.

Chen, M., Lei, X., Chen, C., Zhang, S., Xie, J., & Wei, D. (2015). Cloning, overexpression, and characterization of a highly active endoinulinase gene from Aspergillus fumigatus Cl1 for production of inulooligosaccharides. Applied Biochemistry and Biotechnology, 175(2), 1153–1167.

Sangeetha, P. T., Ramesh, M. N., & Prapulla, S. G. (2005). Recent trends in the microbial production: analysis and application of fructooligosaccharides. Trends in Food Science & Technology, 16(10), 442–457.

Uhm, T., Chae, K.-S., Lee, D., Kim, H., Cassart, J., & Vandenhaute, J. (1998). Cloning and nucleotide sequence of the endoinulinase-encoding gene, inu2, from Aspergillus ficuum. Biotechnology Letters, 20(8), 809–812.

Nishizawa, K., Nakajima, M., & Nabetani, H. (2001). Kinetic study on transfructosylation by l-fructofuranosidase from Aspergillus niger ATCC 20611 and availability of a membrane reactor for fructooligosaccharide production. Food Science and Technology Research, 7(1), 39–44.

Chi, Z., Chi, Z., Zhang, T., Liu, G., & Yue, L. (2009). Inulinase-expressing microorganisms and applications of inulinases. Applied Microbiology and Biotechnology, 82(2), 211–220.

Yun, J., Park, J., Song, C., Lee, C., Kim, J., & Song, S. (2000). Continuous production of inulo-oligosaccharides from chicory juice by immobilized endoinulinase. Bioprocess Engineering, 22(3), 189–194.

Ettalibi, M., & Baratti, J. C. (1987). Purification, properties and comparison of invertase, exoinulinases and endoinulinases of Aspergillus ficuum. Applied Microbiology and Biotechnology, 26(1), 13–20.

Xu, Y.-B., Zheng, Z.-J., Xu, Q.-Q., Yong, Q., & Ouyang, J. (2016). Efficient conversion of inulin to inulooligosaccharides through endoinulinase from Aspergillus niger. Journal of Agricultural and Food Chemistry, 64(12), 2612–2618.

Finn, R. D., Tate, J., & Mistry, J. (2008). The pfam protein families database. Nucleic Acids Research, 36, 281–288.

Scigelova, M., Singh, S., & Crout, D. H. (1999). Glycosidases—a great synthetic tool. Journal of Molecular Catalysis B: Enzymatic, 6(5), 483–494.

Davies, G., & Henrissat, B. (1995). Structures and mechanisms of glycosyl hydrolases. Structure, 3(9), 853–859.

Roberfroid, M. B., Van Loo, J. A., & Gibson, G. R. (1998). The bifidogenic nature of chicory inulin and its hydrolysis products. Journal of Nutrition, 128(1), 11–19.

Li, Y., Liu, G.-L., Wang, K., Chi, Z.-M., & Madzak, C. (2012). Overexpression of the endo-inulinase gene from Arthrobacter sp. S37 in Yarrowia lipolytica and characterization of the recombinant endo-inulinase. Journal of Molecular Catalysis B: Enzymatic, 74(1-2), 109–115.

Nakamura, T., Shitara, A., Matsuda, S., Matsuo, T., Suiko, M., & Ohta, K. (1997). Production, purification and properties of an endoinulinase of Penicillium sp. TN-88 that liberates inulotriose. Journal of Fermentation and Bioengineering, 84(4), 313–318.

Kim, D. H., Choi, Y. J., Song, S. K., & Yun, J. W. (1997). Production of inulo-oligosaccharides using endo-inulinase from a Pseudomonas sp. Journal of Fermentation and Bioengineering, 19, 369–372.

Chen, X.-M., Xu, X.-M., Jin, Z.-Y., & Chen, H.-Q. (2012). Expression of an endoinulinase from Aspergillus ficuum JNSP5-06 in Escherichia coli and its characterization. Carbohydrate. Polymers, 88(2), 748–753.

He, M., Wu, D., Wu, J., & Chen, J. (2014). Enhanced expression of endoinulinase from Aspergillus niger by codon optimization in Pichia pastoris and its application in inulooligosaccharide production. Journal of Industrial Microbiology and Biotechnology, 41(1), 105–114.

Jong, W. Y., Yong, J. C., Chii, H. S., & Seung, K. S. (1999). Microbial production of inulo-oligosaccharides by an endoinulinase from Pseudomonas sp. expressed in Escherichia coli. Journal of Bioscience and Bioengineering, (3), 291–295.

Westers, L., Westers, H., & Quax, W. J. (2004). Bacillus subtilis as cell factory for pharmaceutical proteins: a biotechnological approach to optimize the host organism. Biochemica Biophysica Acta, 1694(1-3), 299–310.

Chen, M., Lei, X., Chen, C., Zhang, S., Xie, J., & Wei, D. (2015). Cloning, overexpression, and characterization of a highly active endoinulinase gene from Aspergillus fumigatus Cl1 for production of inulo-oligosaccharides. Applied Biochemistry and Biotechnology, 175(2), 1153–1167.

Gill, P. K., Manhas, R. K., Singh, J., & Singh, P. (2004). Purification and characterization of an exo-inulinase from Aspergillus fumigatus. Applied Biochemistry and Biotechnology, 117(1), 19–32.

Leelasuphakul, W., Hemmanee, P., & Chuenchitt, S. (2008). Growth inhibitory properties of Bacillus subtilis strains and their metabolites against the green mold pathogen (Penicillium digitatum Sacc.) of citrus fruit. Postharvest Biology and Technology, 48(1), 113–121.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Park, S., Jeong, H. Y., Kim, H. S., Yang, M. S., & Chae, K. S. (2001). Enhanced production of Aspergillus ficuum endoinulinase in Saccharomyces cerevisiae by using the SUC2 deletion mutation. Enzyme Microbiology. Technology, 29(2-3), 107–110.

Gao, J., Xu, H., Li, Q. -J., Feng, X.-H., & Li, S. (2010). Optimization of medium for one-step fermentation of inulin extract from Jerusalem artichoke tubers using Paenibacillus polymyxa ZJ-9 to produce R,R-2,3-butanediol. Bioresource Technology, 101(18), 7076–7082.

Zhang, W., Gao, W.-X., Feng, J., Zhang, C., He, Y.-L., Cao, M. F., Li, Q., Sun, Y., Yang, C., Song, C.-J., & Wang, S.-F. (2014). A markerless gene replacement method for B.amyloliquefaciens LL3 and its use in genome reduction and improvement of poly-γ-glutamic acid production. Applied Microbiology and Biotechnology, 98(21), 8963–8973.

Wu, S. C., Ye, R., C, X., Wu, S. C., & Ng, S. L. (1998). Enhanced secretory production of a single-chain antibody fragment from Bacillus subtilis by coproduction of molecular chaperones. Journal of Bacteriology, 180(11), 2830–2835.

Kolkman, M. A. B., van der Ploeg, R., Bertels, M., van Dijk, M., van der Laan, J., van Dijl, J. M., & Ferrari, E. (2008). The twin-arginine signal peptide of Bacillus subtilis YwbN can direct either Tat- or Sec- dependent secretion of different cargo proteins: Secretion of active subtilisin via the B. subtilis Tat pathway. Applied and Environmental Microbiology, 74(24), 7507–7513.

Schumann, W. (2007). Production of recombinant proteins in Bacillus subtilis. Advances in Applied Microbiology, 62, 137–189.

Zhu, F.-M., Ji, S.-Y., Zhang, W.-W., Li, W., & Cao, B.-Y. (2008). Development and application of a novel signal peptide probe vector with PGA as reporter in Bacillus subtilis WB700: twenty-four Tat pathway signal peptides from Bacillus subtilis were monitored. Molecular Biotechnology, 39(3), 225–230.

Aymerich, S. G., Gonzy-Treboul, G., & Steinmetz, M. (1986). 5'-Noncoding region sacR is the target of all identified regulation affecting the levansucrase gene in Bacillus subtilis. Journal of Bacteriology, 166(3), 993–998.

Mullin, W.-J., Modler, H.-W., Farnworth, E.-R., & Payne, A. (1994). The macronutrient content of fractions from Jerusalem artichoke tubers (Helianthus tubersosus). Food Chemistry, 51(3), 263–269.

Cao, C., Zhang, L., Gao, J., Xu, H., Xue, F., Huang, W.-W., & Li, Y. (2017). Research on the solid state fermentation of Jerusalem artichoke pomace for producing R,R-2,3-butanediol by Paenibacillus polymyxa ZJ-9. Applied Biochemistry and Biotechnology, 182(2), 687–696.

Wang, D., Li, F. L., & Wang, S. A. (2016). A one-step bioprocess for production of high-content fructo-oligosaccharides from inulin by yeast. Carbohydrate Polymers, 151, 1220–1226.

Wang, P. P., Ma, J. F., Zhang, Y., Zhang, M., Wu, M. K., Dai, Z. X., & Jiang, M. (2016). Efficient secretory overexpression of endoinulinase in Escherichia coli and the production of inulooligosaccharides. Applied Biochemistry and Biotechnology, 123, 230–234.

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant 21376203), the Promotion Program of Achievements in Scientific Research for Industrial Production of Higher Education of Jiangsu Province (Grant JHB2011-54), Qinglan Project of Higher Education of Jiangsu Province, Overseas Research & Training Program for University Prominent Young & Middle-aged Teachers and Presidents of Jiangsu Province, Jiangsu Agricultural Key Technology Research and Development Program (Grant BE2012394).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic Supplementary Material

ESM 1

(DOCX 82 kb)

Rights and permissions

About this article

Cite this article

Jiang, R., Qiu, Y., Huang, W. et al. One-Step Bioprocess of Inulin to Product Inulo-Oligosaccharides Using Bacillus subtilis Secreting an Extracellular Endo-Inulinase. Appl Biochem Biotechnol 187, 116–128 (2019). https://doi.org/10.1007/s12010-018-2806-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2806-3