Abstract

Genetic modifications are considered as one of the most important technologies for improving fermentative hydrogen yield. Herein, we overexpress fhlA and pncB genes from Klebsiella HQ-3 independently to enhance hydrogen molar yield. HQ-3-fhlA/pncB strain is developed by manipulation of pET28-Pkan/fhlA Kanr and pBBR1-MCS5/pncB Gmr as expression vectors to examine the synchronous effects of fhlA and pncB. Optimization of anaerobic batch fermentations is achieved and the maximum yield of biohydrogen (1.42 mol H2/mol of glucose) is produced in the range of pH 6.5–7.0 at 33–37 °C. Whole cell H2 yield is increased up to 40 % from HQ-3-fhlA/pncB, as compared with HQ-3-fhlA 20 % and HQ-3-pncB 12 % keeping HQ-3-C as a control. Mechanism of improved H2 yield is studied in combination with metabolic flux analysis by measuring glucose consumption and other metabolites including formate, succinate, 2,3 butanediol, lactate, acetate, ethanol, and hydrogen. The results suggest that under transient conditions, the increase in the total level of NAD by NAPRTase can enhance the rate of NADH-dependent pathways, and therefore, final distribution of metabolites is changed. Combined overexpression of fhlA and pncB eventually modifies the energy and carbon balance leading to enhanced H2 production from FHL as well as by NADH pathway.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, the world is going in a phase of ever-depleting fossil fuel reserves and continuous growing of fuel demand. Mankind is in the hunt for alternate safe and environment-friendly fuel production. Hitherto, a number of biofuels, notably bioethanol and biodiesel are already being produced on a large scale and numerous other alternatives are also under consideration.

Biohydrogen appears to have several advantages over other fuel alternatives. Hydrogen is an ideal, clean, and potentially sustainable energy source in the future perspective owing to its abundance and non-polluting nature [1]. Molecular hydrogen generates only pure water as a by-product, making it an attractive non-polluting energy source. Hydrogen possesses the largest energy content as per weight of any known fuel and can be produced by various means [2, 3]. A variety of bacteria, cyanobacteria, and algae are accomplished of producing hydrogen from water, solar energy, and a variety of organic substrates. However, improvement of these diverse biochemical pathways is desired so as to make biohydrogen production competitive in comparison with current methods.

There are several kinds of approaches of biohydrogen production including direct biophotolysis, indirect biophotolysis, photofermentation, and dark fermentation. The biophotolysis of water is mostly carried out by green microalgae and cyanobacteria [4, 5], but there are some limitations like low photochemical efficiency and evolution of O2, which constrain the activity of hydrogenase enzymes and in turn reduce H2 production [6]. In case of photo fermentation where O2 is not produced, but there are yet some limitations needed to be addressed in this route, such as suppression of nitrogenase by ammonium ion (NH4 +), low hydrogen productivity, competition of the presence of many reactions for electron transfer, and low photochemical efficiency [7].

In contrast of biophotolysis and photofermentation, dark fermentation displays significantly high hydrogen production level. It is carried out by many facultative and obligate anaerobic bacteria through utilization of a variety of organic compounds. Genetic manipulations have been ascertained to be a competent way to improve desired targets [8–10]. By this approach, metabolism of hydrogen production can be improved to achieve a more efficient way of producing hydrogen as a biofuel. Overexpression of certain genes relating to the metabolism is a potential technique to enhance hydrogen production [9, 11, 12].

In facultative anaerobes like Klebsiella, a multi-enzyme complex known as formate hydrogen lyase (FHL) system is responsible for hydrogen production via formate cleavage. FHL contains two enzymes, formate dehydrogenase H (FdhH) and hydrogenase (Hyd) along with electron carriers. These components of FHL are the products of various genes including fdh gene, hyc gene, and hyp operon, which are involved in the maturation of FHL complex. So far, facultative anaerobes FHL system has been broadly explored in Escherichia coli; its chromosome is identified to harbor four transcriptional units. The expression of these genes is under regulation by intracellular formate concentration. The FHL complex has at least two regulators, fhlA and hycA. The transcription of the FHL complex is controlled by many different genes including fhlA, which transcribes the FHL activator protein FHLA. FHLA, a tetramer that binds to the upstream region of the DNA, encodes the FHL complex, and acts as the transcriptional activator of the fdhF gene and the hyc, hyp, and hydN-hypF operons, which form the formate regulon [13–15]. Furthermore, hycA codes for the FHL repressor protein HYCA, which couples with FHLA or to the FHLA-formate complex. The FHLA-HYCA complex represses the transcription of the FHLA complex [16, 17]. When fhlA and hycA control transcription of the FHL complex, it is theoretically possible to control the specific FHL activity and the specific hydrogen production rate by overexpressing the transcriptional activator fhlA gene or by modification of their genetic control.

In contrast, mutant strains with overexpression of pncB gene, encoding nicotinic acid phosphoribosyltransferase (NAPRTase, EC 2.4.2.11), has been proven to be rate limiting in the salvage pathway [18]. Nicotinic acid (NA) and α-d-5-phosphoribosyl-1-pyrophosphate (PRPP) are used as substrates by NAPRTase, and the regulation of nicotinate mononucleotide (NAMN) is increased, which is the direct precursor of NAD. It has been studied by many researchers that the enhanced NAPRTase activity in cell metabolism plays a significant role in increasing NAD(H) pool size [19–21]. Overexpression of the pncB gene in organisms used in chemostat experiments are evidenced to enhance the total NAD(H) level and decrease NADH/NAD+ ratio [20–22] and in turn increases the intracellular concentrations of NAD(H) [23]. All these above studies are appreciated but facile, rapid, and low-cost production of biohydrogen is still a continuous demand of modern world.

In this approach, metabolic changes over Klebsiella HQ-3 strain are addressed to improve hydrogen production by dark fermentation. Three genetically modified strains have been designed for the improvement in the regulation of formate pathway in Klebsiella HQ-3; one of them, termed as HQ-3-A, was used for the expression system of the FHL activator protein FHLA encoded by fhlA. The second one, named as HQ-3-B, was used for overexpression of pncB encodes the nicotinic acid phosphoribosyltransferase (NAPRTase) and acts as a direct precursor of NAD. While a third mutant, termed as HQ-3-AB, was constructed to synchronize homologous overexpression of fhlA and pncB. The distribution of carbon sources was further analyzed under chemostat and anaerobic batch fermentation. During the batch fermentations, metabolic flux analyses and specific enzymatic activities have also been measured in order to investigate the effects of multi-gene manipulations on hydrogen production and to understand the mechanism of multiple metabolic engineering.

Materials and Methods

Strains, Vectors, and Culture Media

The microorganism used for biohydrogen production in this approach was Klebsiella HQ-3. It was isolated from soil sludge for anaerobic dark fermentation and developed in the laboratory [12]. All strain cultures were maintained in 15 % glycerol at −80 °C. The fermentation medium composition (w/v%) for the hydrogen production was glucose, 1.5; tryptone, 0.5; yeast extract, 0.2; NaCl, 0.2; K2HPO4, 0.15; MgCl2·6H2O, 0.06; FeSO4·7H2O, 0.02; and 1 % trace elements contained (g/L) ZnSO4·7H2O, 0.06 g; AlK(SO4)2, 0.01 g; N(CH2COOH)3, 0.03 g; H3BO3, 0.02 g; CaCl2, 0.02 g; Na2MoO4, 0.02 g; MnSO4·7H2O, 0.03 g; and CoCl2, 0.1 g. Medium used for screening was (%) yeast extract, 0.5; tryptone, 1; and NaCl, 1 (Luria-Bertani medium, LB). Preferred transformants and recombinants were selected by adding kanamycin (50 μg/mL) and gentamycin (50 μg/mL). The strains and plasmids used in this study are listed in Table 1, while the primers for PCR amplification are given in Table 2.

Respective Overexpression of fhlA and pncB

The plasmid pET-28kan was designed to express homologous protein in Klebsiella HQ-3 using the method according to the previous study with some modifications [24]. The promoter T7 was replaced by Pkan which was replicated from the kanamycin-resistant gene in the plasmid pET28a. The promoter Pkan is a constitutive promoter, and the activity of Pkan in HQ-3 was confirmed through resistance test by kanamycin addition. The gene fhlA was manipulated into plasmid pET-28kan as per below procedure. The gene fhlA was amplified with primers fhlA-Fw and fhlA-Rv by using PCR from the genomic DNA of HQ-3. In each primer, 1 μL (synthesized by Tianyi Biotech, Wuhan, China) was mixed with 2 μL of 10 μmol purified genomic DNA, 25 μL 2× Es Taq Master Mix (obtained from CWBiotech, Wuhan, China) and sterile water to produce a 50-μL PCR reaction mixture. The PCR conditions were 94 °C for 10 min, followed by 30 cycles of 94 °C for 45 s, 51 °C for 30 s, and 72 °C for 1.5 min with a final step of 72 °C for 10 min. The SacI/Hind III fragment of the fhlA gene from the chromosome was ligated into the SacI and HindIII sites of vector pET-28kan to generate pET-28kan-fhlA, and the recombinant plasmid was confirmed by double digestion with sacI and HindIII. The fhlA gene fragment was positioned under the control of Pkan. The plasmid pET-28kan-fhlA was initially transformed into E. coli DH5-α for amplification and mutant strain, and E. coli/pET28kan-fhlA was selected by addition of 50 μg/mL kanamycin in LB media. Then, amplified plasmid pET-28kan-fhlA was electro-transformed into HQ-3. Electric pulse was performed on BIORAD Gene Pulser Xcell, under these parameters: voltage 2500 V, capacitance 25 μF, resistance 200 Ω, and 2 mm cuvette was used to construct HQ-3/pET-28Pkan-fhlA (HQ-3-A). By using the same approach, another expression vector pET-28Pkan-pncB was constructed using primers pncB-Fw and pncB-Rv and genomic DNA of HQ-3 used as a template for the overexpression. The plasmid amplification was achieved by transferring into DH5-α and then the amplified plasmid was electro-transformed into HQ-3 to obtain Klebsiella HQ-3/pET-28Pkan-pncB (HQ-3-B). Finally, the transformants were selected by addition of kanamycin into the screening media.

Co-overexpression of fhlA and pncB

For the synchronized overexpression of fhlA and pncB in Klebsiella HQ-3, the pncB gene was amplified by PCR using primers pncB2-Fw and pncB2-Rv from the chromosome of Klebsiella HQ-3. The PCR conditions were 94 °C for 10 min, followed by 30 cycles of 94 °C for 45 s, 53 °C for 30 s, and 72 °C for 1 min with a final step of 72 °C for 10 min. The XhoI/EcoRI fragment of the pncB gene obtained from the chromosome was inserted into the XhoI and EcoRI site of vector pBBR1MCS5 to produce pBBR1MCS5-pncB Gmr. The pncB gene fragment was kept under the control of lacZ promoter [25]. The newly constructed expression vector pBBR1-MCS5-pncB was first transformed into E. coli for amplification, analyzed for the correct insert by restriction analysis, and then electro-transformed into Klebsiella HQ-3/pET-28kan-fhlA (HQ-3-A) by electroporation, and the recombinant strain HQ-3-fhlA/pncB (HQ-3-AB) was selected as per kanamycin and gentamycin resistance. Similarly, another strain was developed with electro-transformation of empty plasmids (without insertion of the genes of interest), pET28-Pkan Kanr, and pBBR1-MCS5 Gmr into the HQ-3 wild strain named as HQ-3-C used as a control.

Anaerobic Batch Fermentation Experiments

The anaerobic batch fermentation experiments were performed using 150-mL flat bottomed flasks tightly covered with rubber stoppers. Each flask was filled with 70 mL fermentation medium and 10 % (v/v) LB overnight seeding culture was added as an inoculum to start the fermentation. The headspace air and trace amounts of oxygen in the fermentation medium was displaced by nitrogen gas to ensure anaerobic conditions, and the batch fermentations were carried out in a magnetic stirring thermostatic water bath under 250 rpm for 16 h at 37 °C.

SDS-PAGE Analysis

The recombinant strains HQ-3-C, HQ-3-A, HQ-3-B, and HQ-3-AB were cultured overnight in 20 mL seed LB medium containing corresponding antibiotics in an anaerobic environment. Harvested bacteria were all inoculated into 1 L of LB medium without antibiotics at 16 °C, when OD600 reached between 0.5 to 0.6 nm, 0.4 mmol/L isopropyl β-d-1-thiogalactopyranoside (IPTG) was added into engineered and control strains to induce protein expression. After 20 h shaking culture, the cells were centrifuged at 12,000×g under 4 °C for 10 min and lysed in a high-pressure cell disruption system (One Shot Model, Constant Systems, UK). The lysates were centrifuged at 12,000×g for 10 min at 4 °C and the cell free extracts were separated by 10 % SDS-PAGE.

Measurement of Gas Composition

Spectrophotometer (Mapada UV-1800PC, China) was used to measure the cell density during cultivation at 600 nm (OD600). The total volume of the gas produced by the anaerobic shaking flask culture was measured via measuring cylinders and the total gas was collected by water displacement method. The composition of the gas was measured by using a gas chromatography (FULI GC-9750, China) with a packed column (2.0 mml, D. 200 mml, carboxen-1004, 80–100 mesh) and a TCD detector. The working temperatures of the detector and the column were 60 and 110 °C, respectively.

Metabolites Analyses

The analyses of glucose, formate, lactate, succinate, 2,3-butanediol, acetate, and ethanol were performed using a high-performance liquid chromatography (HPLC) (SSI Model 2300-525, USA) equipped with a sulfonated polystyrene divinyl benzene column (BioRad Aminex HPX-87H, USA) and a refractive index detector. Sulfuric acid of 10 mmol/L was used as a mobile phase. The column temperature was 55 °C and the flow rate was 0.5 mL/min.

Enzyme Activity Assay

In order to perform the enzyme activity assay, the cells were cultured for 4 h in fermentation media under anaerobic conditions and harvested by centrifugation (12,000×g for 10 min at 4 °C). Cell extracts and supernatants were obtained by the same method as mentioned in “SDS-PAGE analysis” previously. NADH-dependent enzymes catalyze NADH to NAD+; this approach allows the enzyme activities to be measured by monitoring the decrease in absorbance of NADH at 340 nm via a spectrophotometer as per our previous study [22]. Alcohol dehydrogenase (ADH, EC 1.1.1.1) activity was measured through a reaction containing 1.0 mL of 0.1 M imidazol-HCl (pH 6.7), 0.1 mL of 10 mM NADH, 1.5 mL of 0.5 mM acetaldehyde, and 0.5 mL of cell free extract at 30 °C [26]. The assays of lactate dehydrogenase (LDH, EC1.1.127) and 2,3-butanediol dehydrogenase (BDDH, EC 1.1.1.76) activities were similar as that of ADH, except that 0.5 mM acetaldehyde was substituted by 0.5 mM sodium pyruvate and 10 mM acetoin, respectively. One unit of enzyme activity was defined as the amount of enzyme catalyzing the conversion of 1 μmol of substrate/min. All steps were performed under anaerobic conditions.

Results

Synchronized Overexpression of fhlA and pncB in Klebsiella HQ-3

In this approach, the fhlA and pncB genes from Klebsiella HQ-3 were cloned in the expression vector pET-28kan individually. Correspondingly, another plasmid pBBR1-MCS5-pncB was designed under the control of lacZ promoter, in the presence of gentamycin (Gm)-resistant gene. The modified plasmid was confirmed by PCR and XhoI/EcoRI double digestion and then transformed into HQ-3-A by electroporation. SDS-PAGE analysis showed that there were marked bands with similar molecular masses, respectively, corresponding to FHL activator protein FHLA encoded by fhlA and NAPRTase encoded by pncB in the mutant strains. Furthermore, SDS-PAGE analyses for the cell extracts of the IPTG-induced overexpressed single gene or co-overexpressed coupled genes revealed the existence of an abundant protein (molecular weight, approximately 78 kDa) in HQ-3-A and HQ-3-AB and the most abundant protein (molecular weight, approximately 46 kDa) in HQ-3-B and HQ-3-AB while these proteins were not found in large excess in IPTG-induced HQ-3-C (Fig. 1).

SDS-PAGE analysis of cell free extracts of HQ-3-C strain and mutants. Lane M is molecular weight marker for proteins, Lane 1 is the cell free extract of HQ-3-C (control); Lane 2 is the cell free extract of HQ-3-A showing FHLA induction encoded by fhlA gene; Lane 3 is the HQ-3-B, showing overexpression of NAPRTase by pncB gene; and Lane 4 is HQ-3-AB, showing overexpression of both FHLA and NAPRTase. All strains including the control strain were induced by IPTG for overexpression of the desired proteins

Improvement of Specific Hydrogen Production Rate by Genetic Modifications

In order to improve volumetric biohydrogen production, the fhlA-overexpressed strain (HQ-3-A), the pncB-overexpressed strain (HQ-3-B), and the combined fhlA- and pncB-overexpressed strain (HQ-3-AB) were successfully constructed for the purpose of enhanced expression of FHL enzymes to improve an alternate hydrogen-producing pathways. Strain HQ-3-AB showed the maximum H2 yield of 1.42 mol/mol-glucose as compared to the control strain HQ-3-C which was only 1.016 mol/mol-glucose (see Table 3). In contrast, strain HQ-3-A and HQ-3-B yielded 1.21 and 1.15 mol/mol-glucose, which was 21 and 13 %, respectively, more than that of the control strain HQ-3-C (Fig. 2).

pH and Temperature Effects on H2 Production Activity

pH effects were studied in the pH range 5.0–8.0 at 37 °C initially using 15 g/L glucose as a substrate in the fermentation media. Optimum activity was shown by all strains in the pH range 6.5–7.0. Temperature effect was monitored in the range 25–40 °C at constant pH 7.0. The maximum hydrogen molar yield (mol/mol-glucose) obtained at 37 °C and pH 7.0 was, respectivel,y 1.232, 1.155 and 1.426 for the mutant strains HQ-3-A, HQ-3-B, and HQ-3-AB in comparison with HQ-3-C which was only 1.017 mol H2/mol-glucose (Fig. 3).

Anaerobic Batch Fermentation

To study the change of hydrogen production rate and yield, metabolic flux, and carbon balance, batch fermentation experiments were performed anaerobically with the strains HQ-3-C as a control, and genetically engineered strains HQ-3-A, HQ-3-B, and HQ-3-AB in 150-mL flat bottomed flasks after removal of oxygen by N2 sparging independently and simultaneously. The cell densities, consumption of glucose, and the concentrations of important metabolites produced after anaerobic fermentation, including formate, succinate, 2,3 butanediol, lactate, acetate, ethanol, Et/Ac ratio, and hydrogen were analyzed (Fig. 4).

Measurements of hydrogen from two distinct pathways, formate hydrogen lyase (FHL) and NADH, were also performed. In the control strain HQ-3-C, 43.64 mmol/L of hydrogen was produced (see Fig. 5), among which, 68 % was produced through FHL pathway and the rest by NADH pathway. HQ-3-A produced 70.83 mmol/L of hydrogen, out of which 66 % was produced through FHL pathway. HQ-3-B emitted 58.61 mmol/L of hydrogen, where the proportion of FHL and NADH was 4:1. However, the highest concentration of H2 was achieved in HQ-3-AB that was 86.1 mmol/L of hydrogen, and almost 70 % was produced through FHL pathway (Fig. 5).

Specific Enzyme Activities and Redirection of Metabolic Flux

Overexpression of fhlA and pncB led to a significant change in the hydrogen yield per mole of glucose consumed, which were increased by 21, 13, and 40 % in HQ-3-A, HQ-3-B, and HQ-3-AB, respectively, Two-way ANOVA in Origin Pro8 was performed at 0.05 level; the means of metabolites from all mutants when compared with the means of all metabolites from the control were found to be significantly different (see Tables 4, 5, and 6). Moreover, a significant increase in succinic acid (34, 42, and 41 %) and ethanol (36, 31, and 50 %) in HQ-3-A, HQ-3-B, and HQ-3-AB was also observed. In contrast, a significant decrease in formate (43, 30, and 52 %) and lactate (16, 9, and 20 %) was, respectively, detected in HQ-3-A, HQ-3-B, and HQ-3-AB, as compared with the control strain HQ-3-C (Tables 4, 5, and 6). Additionally, the glucose uptake was improved by 33, 18, and 40 %, and the cell densities were also improved by 9, 3, and 12 % in HQ-3-A, HQ-3-B, and HQ-3-AB, respectively.

NADH-dependent specific enzyme activities of alcohol dehydrogenase (ADH), lactate dehydrogenase (LDH), and 2,3-butanediol dehydrogenase (BDDH) of HQ-3-A were increased by 2.2-, 1.3-, and 2.7-fold, respectively (see Fig. 6). At the same time, specific enzyme activities of ADH, LDH, and BDDH of HQ-3-B was also improved by 2.9-, 1.6-, and 1.6-fold, respectively, as compared with the control strain. They are accompanied with an increase in succinate concentration of 42 % in pncB-overexpressed strain (HQ-3-B), and ethanol and acetate were also increased up to 31 and 56 %, respectively, while formate and lactate decreased by 30 and 9 %, yet no significant change in the concentration of 2,3-butanediol was detected. This change in the pattern of carbon balance led to an increase in the total hydrogen yield of 13 % (1.15 mol-H2/mol-glucose); the H2 yield was mainly increased by formate pathway and partly through NADH pathway as compared with the wild strain (see Fig. 6).

The most significant results obtained in HQ-3-AB were that the NADH-dependent enzyme activity of BDDH was increased by 19 %, while LDH by 15 % and ADH had no significant change. These led to increases of succinate, 2,3-butanediol, ethanol, and acetate by 41, 6, 50, and 62 % and decreases of formate and lactate by 52 and 20 %, as compared with HQ-3-C with a maximum yield of 1.42 mol-H2/mol-glucose, 40 % greater than control strain.

Discussion

To improve hydrogen production activity and enhance the rate of metabolism by Klebsiella HQ-3, two different genetically modified strains were developed. One was to increase the specific FHL activity by overexpressing fhlA gene, and the other was to increase the NAD(H) pool size via overexpression of pncB gene (encoding NAPRTase). Significantly positive results were obtained in recombinants HQ-3-A and HQ-3-B, respectively, overexpressing fhlA and pncB. Therefore, these two modifications were synchronized in HQ-3-AB. For this purpose, two different expression vectors with dissimilar origins of replication, pET28-Pkan Kanr for fhlA and pBBR1-MCS5 Gmr for pncB were chosen to facilitate the replication of the plasmids and to ensure the transcription of the genes of interest. SDS-PAGE analysis revealed the existence of proteins with molecular weights of 78 KDa translated from fhlA [27] in HQ-3-A and 46 KDa protein from pncB [18] in HQ-3-B, while co-existence of both 46 and 78 KDa proteins were found in HQ-3-AB. In contrast, all these proteins were not present in significant amounts in HQ-3-C (the control).

H2 is usually produced from formate hydrogen lyase, while acetyl-CoA plays vital role in the production of ethanol and acetate. Formate shows a signature molecule in fermenting HQ-3 cells and features that regulate formate metabolism control FHL synthesis and subsequently H2 production [28]. An increase in the production of ethanol and acetate is essential to increase the H2 yield if FHL is hyper-activated to break the formate into H2 and CO2 [26, 29]. Thus, the difference in H2 yields of the mutant strains (Fig. 2) can be explained by their metabolic flux distribution (Table 3).

pH effects on the H2 production activity of the control strain HQ-3-C and its mutant strains HQ-3-A, HQ-3-B, and HQ-3-AB were studied in the pH range 5.0–8.0 at 37 °C . Increase in H2 production in HQ-3-C was observed with rise of temperature. While all recombinant strains exhibited maximum activity in 33–37 °C temperature range and decreased slightly when temperature increased beyond 40 °C. It was observed that H2 production activity was less stable in recombinant strains at high temperature. It may be due to it that some enzymes and proteins essential for the growth of bacteria and hydrogen production become non-functionalized when the temperature excels the optimum level (37 °C) [30]. When fermentation process got start, cell densities of all strains were increased and appositively pH was decreased with the lasting of time (Fig. 3). This change in pH may be due to the accumulation of acidic metabolites, mainly acetate and lactate in fermentation media [31].

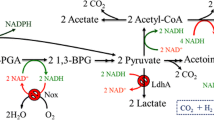

The mechanism for the improved hydrogen production by the wild and mutant strains was investigated through metabolic flux analysis. It was observed that most of the formate was converted into H2 and CO2 during anaerobic batch fermentation by mutants of HQ-3 (shown in Table 3). Hydrogen production from formate pathway can be calculated as follows: ethanol + acetate = H2 (FHL) + formate. The hydrogen through NADH pathway was calculated by the following equation:

Hence, we can positively correlate the hydrogen yield from formate pathway with the production of ethanol and in contrast with overstimulation of NAPRTase, which plays a positive role in the availability of NAD(H) during the metabolism of hydrogen-producing pathways (Fig. 5).

As given in Table 3, hydrogen molar yield, succinic acid, ethanol, glucose consumption, and cell densities were significantly increased in mutant strains, while formate and lactate were catalyzed and reduction in amounts were observed in engineered strains as compared with HQ-3-C. This alteration in metabolic patterns is indicative of an increase in NAD(H) and decrease in NADH/NAD+ ratio by overexpression of pncB, which enhanced the utilization of glucose and increased the cell mass [18, 32]. The synchronous overexpression of two genes in HQ-3-AB facilitated to efficiently produce hydrogen by FHL as well as by NADH pathway (Fig. 5). It has already been quoted that NAD+ regeneration has ability to speed up the metabolic pathways when reducing agents are excessive [21]. The results of these experiments also suggest that the rate of reaction of hydrogen-producing pathways can be accelerated by increasing or regenerating the concentrations of NADH.

Synthesis of succinate and ethanol require two NADH molecules, while 2,3-butanediol need only one NADH molecule [22]. Hence, all these pathways increase the rate of reaction in pncB-overexpressed strain of HQ-3, while 2,3-butanediol, ethanol, lactate, and succinate are formed via re-oxidation of NADH to maintain the intracellular redox balance. The results of anaerobic batch fermentation proved that hydrogen production from formate pathway was increased by 1.5-fold in HQ-3-A (Fig. 5) with overall hydrogen yield of 1.23 mol-H2/mol-glucose. Furthermore, succinate synthesis, which comprises another branch route for hydrogen production, was increased the maximum (42 %) by pncB-overexpressing strain. Synthesis of succinate might be facilitated by regeneration of NAD(H) and by decrease of NADH/NAD+ ratio by NAPRTase. This mechanism employed positive impact on redirection of carbon flux over enhancing the hydrogen production. HQ-3-AB showed the minimum concentration of formate and the maximum of ethanol and acetate, which revealed that formate and alternate hydrogen-producing pathways were efficiently utilized.

HQ-3-A, fhlA-overexpressed strain, showed maximum activity of 2,3-butanediol dehydrogenase (BDDH) (Fig. 6a), which is a key enzyme in the production of 2,3-butanediol in microorganisms. BDDH can be used as valuable building block in asymmetric synthesis of chiral compounds [33]. HQ-3-B showed uppermost alcohol dehydrogenase (ADH) activity (Fig. 6b). ADH participates in metabolizing a wide variety of alcohols and aldehydes and catalyzes the first step of alcoholic oxidation using NAD+ as a cofactor and producing NADH and the corresponding carbonyl compounds. Various studies have suggested that ADH activity is a major rate-limiting factor in ethanol metabolism [34]. HQ-3-AB showed the most significant results for specific enzymatic activities, a decrease of 15 % in LDH activity and almost equal ADH activity as compared to the control strain were observed. As reported by Yoshida et al. (2006), ldh- and frd-inactivated E. coli strain produced 1.8 mol H2/mol-glucose, which is equal to 90 % of the theoretical maximum value for E. coli [35, 36]. Hence, we can positively correlate the decrease of LDH and ADH activities with enhanced hydrogen and ethanol production from HQ-3-AB (Fig. 6c). These results indicate that simultaneously synchronized overexpression of fhlA and pncB does affect on the production rate and yield of hydrogen.

In conclusion, we have successfully constructed three recombinants of Klebsiella HQ-3, HQ-3-A, HQ-3-B, and HQ-3-AB, for single overexpression of fhlA and pncB and simultaneously synchronized overexpression of fhlA and pncB. Their activity of FHL complex has been enhanced by overexpressing transcriptional activator FHLA. Overexpression of NAPRTase-encoding pncB gene increased NADH pool size inside the cell so as to speed up the metabolic rate of NADH-dependent pathways and eventually enhanced the uptake of glucose. Thus, the whole cell hydrogen yield per mole of glucose increased up to 40 % (1.402 mol H2/mol-glucose) in HQ-3-AB, which was only 21 and 13 % in HQ-3-A and HQ-3-B. This increase might be due to the enhanced activation of FHL complex and more availability of NADH to speed up metabolism by overexpression of fhlA and pncB. Formate and lactate were catabolized and ultimately increased the production of succinate as well as ethanol, which consequently affected the cellular redox level and energy balance that would lead to enhanced H2 production from both FHL and NADH pathways.

References

Mathews, J., & Wang, G. (2009). Metabolic pathway engineering for enhanced biohydrogen production. Int J Hydrog Energy, 34, 7404–16.

Lin, C. Y., & Lay, C. H. (2004). Effects of carbonate and phosphate concentrations on hydrogen production using anaerobic sewage sludge microflora. Int J Hydrog Energy, 29, 275–81.

Oh, S. E., Van Ginkel, S., & Logan, B. E. (2003). The relative effectiveness of pH control and heat treatment for enhancing biohydrogen gas production. Environ Sci Technol, 37, 5186–90.

Kheshgi, H. S., & Prince, R. C. (2005). Sequestration of fermentation CO2 from ethanol production. Energy, 30, 1865–71.

Levin, D. B., Pitt, L., & Love, M. (2004). Biohydrogen production: prospects and limitations to practical application. Int J Hydrog Energy, 29, 173–85.

Brentner, L. B., Peccia, J., & Zimmerman, J. B. (2010). Challenges in developing biohydrogen as a sustainable energy source: implications for a research agenda. Environ Sci Technol, 44, 2243–54.

Koku, H., Eroğlu Gündüz, U., Yücel, M., & Türker, L. (2002). Aspects of the metabolism of hydrogen production by Rhodobacter sphaeroides. Int J Hydrog Energy, 27, 1315–29.

Dubini, A., & Ghirardi, M. L. (2015). Engineering photosynthetic organisms for the production of biohydrogen. Photosynth Res, 123, 241–53.

Maeda, T., Sanchez‐Torres, V., & Wood, T. K. (2012). Hydrogen production by recombinant Escherichia coli strains. J Microbial Biotechnol, 5, 214–25.

Sinha, P., & Pandey, A. (2011). An evaluative report and challenges for fermentative biohydrogen production. Int J Hydrog Energy, 36, 7460–78.

Seol, E., Jang, Y., Kim, S., Oh, Y. K., & Park, S. (2012). Engineering of formate-hydrogen lyase gene cluster for improved hydrogen production in Escherichia coli. Int J Hydrog Energy, 37, 15045–51.

Wang, S., Wang, J., Xu, L., Pi, J., Zhang, H., & Yan, Y. (2013). Enhanced biohydrogen production by homologous over-expression of fnr, pncB, fdhF in Klebsiella sp. HQ-3. Sheng Wu Gong Cheng Xue Bao, 29, 1278–89.

Leonhartsberger, S., Ehrenreich, A., & Böck, A. (2000). Analysis of the domain structure and the DNA binding site of the transcriptional activator FhlA. Eur J Biochem, 267, 3672–84.

Schlensog, V., & Böck, A. (1990). Identification and sequence analysis of the gene encoding the transcriptional activator of the formate hydrogenlyase system of Escherichia coli. Mol Microbiol, 4, 1319–27.

Sanchez-Torres, V., Maeda, T., & Wood, T. K. (2009). Protein engineering of the transcriptional activator FhlA to enhance hydrogen production in Escherichia coli. Appl Environ Microbiol, 75, 5639–46.

Leonhartsberger, S., Korsa, I., & Bock, A. (2002). The molecular biology of formate metabolism in Enterobacteria. J Mol Microbiol Biotechnol, 4, 269–76.

Sauter, M., Bohm, R., & Bock, A. (1992). Mutational analysis of the operon (hyc) determining hydrogenase 3 formation in Escherichia coli. Mol Microbiol, 6, 1523–32.

Liang, L., Liu, R., Wang, G., Gou, D., Ma, J., Chen, K., Jiang, M., Wei, P., & Ouyang, P. (2012). Regulation of NAD(H) pool and NADH/NAD+ ratio by overexpression of nicotinic acid phosphoribosyltransferase for succinic acid production in Escherichia coli NZN111. Enzyme Microb Technol, 51, 286–93.

Wu, H., Li, Z., Zhou, L., & Ye, Q. (2007). Improved succinic acid production in the anaerobic culture of an Escherichia coli pflB ldhA double mutant as a result of enhanced anaplerotic activities in the preceding aerobic culture. Appl Environ Microbiol, 73, 7837–43.

San, K. Y., Bennett, G. N., Berrios-Rivera, S. J., Vadali, R. V., Yang, Y. T., Horton, E., Rudolph, F. B., Sariyar, B., & Blackwood, K. (2002). Metabolic engineering through cofactor manipulation and its effects on metabolic flux redistribution in Escherichia coli. Metab Eng, 4, 182–92.

Berrı, X., Os-Rivera, S. J., San, K. Y., & Bennett, G. N. (2002). The effect of NAPRTase overexpression on the total levels of NAD, the NADH/NAD+ ratio, and the distribution of metabolites in Escherichia coli. Metab Eng, 4, 238–47.

Wang, J., Yu, W., Xu, L., Wang, S., & Yan, Y. (2013). Effects of increasing the NAD(H) pool on hydrogen production and metabolic flux distribution in Enterobacter aerogenes mutants. Int J Hydrog Energy, 38, 13204–15.

Heuser, F., Schroer, K., Lütz, S., Bringer-Meyer, S., & Sahm, H. (2007). Enhancement of the NAD(P)(H) pool in Escherichia coli for biotransformation. Eng Life Sci, 7, 343–53.

Ma, Z., Rao, Z., Zhuge, B., Fang, H., Liao, X., & Zhuge, J. (2010). Construction of a novel expression system in Klebsiella pneumoniae and its application for 1,3-propanediol production. Appl Biochem Biotechnol, 162, 399–407.

Kovach, M. E., Elzer, P. H., Hill, D. S., Robertson, G. T., Farris, M. A., Roop, R. M., & Peterson, K. M. (1995). Four new derivatives of the broad-host-range cloning vector pBBR1MCS, carrying different antibiotic-resistance cassettes. Gene, 166, 175–6.

Ito, T., Nakashimada, Y., Kakizono, T., & Nishio, N. (2004). High-yield production of hydrogen by Enterobacter aerogenes mutants with decreased alpha-acetolactate synthase activity. J Biosci Bioeng, 97, 227–32.

Maupin, J. A., & Shanmugam, K. T. (1990). Genetic regulation of formate hydrogenlyase of Escherichia coli: role of the fhlA gene product as a transcriptional activator for a new regulatory gene, fhlB. J Bacteriol, 172, 4798–806.

Sawers, R. G. (2005). Formate and its role in hydrogen production in Escherichia coli. Biochem Soc Trans, 33, 42–6.

Si, B., Liu, Z., Zhang, Y., Li, J., Xing, X.-H., Li, B., Duan, N., & Lu, H. (2015). Effect of reaction mode on biohydrogen production and its microbial diversity. Int J Hydrog Energy, 40, 3191–200.

Lee, K. S., Lin, P. J., & Chang, J. S. (2006). Temperature effects on biohydrogen production in a granular sludge bed induced by activated carbon carriers. Int J Hydrog Energy, 31, 465–72.

Wu, K. J., Saratale, G. D., Lo, Y. C., Chen, W. M., Tseng, Z. J., Chang, M. C., Tsai, B. C., Su, A., & Chang, J. S. (2008). Simultaneous production of 2,3-butanediol, ethanol and hydrogen with a Klebsiella sp. strain isolated from sewage sludge. Bioresour Technol, 99, 7966–70.

Sánchez, A. M., Bennett, G. N., & San, K.-Y. (2005). Effect of different levels of NADH availability on metabolic fluxes of Escherichia coli chemostat cultures in defined medium. J Biotechnol, 117, 395–405.

Yu, M., Huang, M., Song, Q., Shao, J., & Ying, X. (2015). Characterization of a (2R, 3R)-2,3-butanediol dehydrogenase from Rhodococcus erythropolis WZ010. Molecules, 20, 7156–73.

Plapp, B. V., Leidal, K. G., Murch, B., Green, P., & David, W. (2015). Contribution of liver alcohol dehydrogenase to metabolism of alcohols in rats. Chem Biol Interact, 234, 85–95.

Yoshida, A., Nishimura, T., Kawaguchi, H., Inui, M., & Yukawa, H. (2006). Enhanced hydrogen production from glucose using ldh- and frd-inactivated Escherichia coli strains. Appl Microbiol Biotechnol, 73, 67–72.

Lu, Y., Zhao, H., Zhang, C., Lai, Q., & Xing, X. (2009). Perturbation of formate pathway for hydrogen production by expressions of formate hydrogen lyase and its transcriptional activator in wild Enterobacter aerogenes and its mutants. Int J Hydrog Energy, 34, 5072–9.

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities (HUST: 2010MS029) and the National Natural Science Foundation of P. R. China (NSFC) (Nos. 31070089 and 31170078). The authors are deeply indebted to the Analytical and Testing Center of Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Jawed, M., Pi, J., Xu, L. et al. Enhanced H2 Production and Redirected Metabolic Flux via Overexpression of fhlA and pncB in Klebsiella HQ-3 Strain. Appl Biochem Biotechnol 178, 1113–1128 (2016). https://doi.org/10.1007/s12010-015-1932-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1932-4