Abstract

Fermentative protein hydrolysates (FPH) were prepared with a proteolytic bacterium, Bacillus strain exhibiting high proteolytic activity. Three FPH with 1, 2, and 4 % of cod protein hydrolysate (CPH) and 0.5 % of yeast extract in the culture were prepared. The yields achieved varied between 30 and 58 % based on protein content. A general decrease of leucine, isoleucine, valine, alanine, arginine, threonine, proline, and glutamic acid was observed. All FPHs showed higher reducing power and DPPH radical scavenging activity than CPH, but similar ABTS radical scavenging activity. However, FPHs exhibited lower Cu+2-chelating activity than CPH. The ACE inhibitory activity of FPHs was not improved relatively to that recorded in CPH. The fermentative process seems to have potential to obtaining hydrolysates with improved biological activities or even to produce protein hydrolysates from native fish proteins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, much attention has been expressed regarding marine-derived bioactive proteins and peptides due to their various health benefits. Enzymatic hydrolysis of marine-derived proteins is the most common method to prepare hydrolysates and peptides with biological activities. This approach requires two major raw materials: proteins and proteolytic enzymes. Fish processing generate a substantial amount of by-products which are rich in valuable proteins. The use of by-products in the production of protein hydrolysates/bioactive peptides will result in a reduction in production cost with the added advantage of an efficient waste proposal [1]. Proteolytic enzymes from animal, plant, and microorganisms have been extensively used for the hydrolysis process. Microbial proteases secreted by several microorganisms present several advantages over proteases from other sources. These include their low cost of production, less time required for enzyme isolation, possibilities for mass production, and amenability of the organisms to genetic manipulations to improve the enzyme yields [2]. Microbial proteases widely used are those obtained from the Bacillus sp., Bifidobacterium and proteases from lactic acid bacteria [3].

The production of protein hydrolysates by the fermentative process requires natural or added microorganisms that hydrolyze sugars and proteins available in surrounding medium during their growth. Martínez-Alvarez et al. [4] described the preparation of protein hydrolysates by a fermentative process with Saccaromyces cerevisiae live cells and an Alcalase hydrolysate prepared from saithe by-products. The production of protein hydrolysates is influenced by certain growth parameters such as inocula conditions and peptide content of medium [1]. The hydrolysis carried out by these extracellular microbial proteases result in a wide range of peptides with different molecular weight and amino acid sequences with interesting bioactive properties. Thus, the use of microorganisms to produce bioactive peptides via proteolysis has recently been the object of study of many authors. Balakrishnan et al. [5] reported that fermented protein hydrolysates from tannery fleshings using lactic acid bacteria exhibited antioxidant and antimicrobial properties. In another study, Fakhfakh et al. [6] showed that fermented hydrolysates from wool waste by Bacillus pumilus A1 had high antioxidant potential. Similarly, fermented lentils by Bacillus subtilis showed ACE inhibitory activity [7]. More recently, a study by Jemil et al. [8] revealed that protein hydrolysates produced by fermentation using different fish meat have desirable solubility, foaming properties, and emulsification stability. The bioconversion of fish proteins by Bacillus subtilis A26 proteolytic enzymes generated peptides with antioxidant and antibacterial activities [8].

The objective of this work was to prepare and characterize fish protein hydrolysates by a fermentative process using Bacillus sp. previously isolated from the Manila clam Venerupis philippinarum grown in a culture medium added with cod protein hydrolysate. Additionally, the biological activities (antioxidant and ACE inhibitory activity) of these hydrolysates were also measured.

Materials and Methods

Materials

Commercial cod protein hydrolysate (CPH) was provided by Danish Fish Protein, Denmark, yeast extract (YE) was purchased from OxoidTM (Oxoid Limited, Basingstoke, UK), and sucrose was provided by AnalaR® (VWR International-Material de Laboratório, Lda., Carnaxide, Portugal). Fluorescein isothiocyanate (FITC), o-phthaldialdehyde (OPA), 2,2-diphenyl-1-picrylhydrazyl (DPPH), 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) (ABTS), pyrocatechol violet (PV) and 3-(2-pyridyl)-5,6-bis(4-phenyl-sulfonic acid)-1,2,4-triazine (ferrozine) were purchased from Sigma-Aldrich® (St Louis, MO, USA). All other chemicals were of analytical grade.

Methods

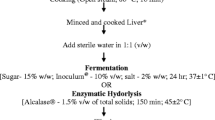

Hydrolysates Production

Preparation of Culture Media and Biomass Estimation

Fish protein hydrolysates were prepared by a fermentation process using a proteolytic strain, Bacillus sp., previously isolated from Manila clam, Venerupis philippinarum. It was selected due to its proteolytic activity detected in plate count agar added with skimmed milk where it exhibited a large clear halo.

Inocula were routinely grown in Tryptic Soy Agar medium at 30 °C for 24 h. For the production of fermentative hydrolysates, three different culture media were used, containing 0.5 % sucrose (w/v), 0.5 % yeast extract (w/v) and 1 %, 2 % and 4 % CPH (w/v). All culture media were sterilized at 121 °C for 15 min. Inocula were added to each culture medium in order to obtain an initial concentration of 104 cfu mL-1. Cultivations were conducted in Erlenmeyer flasks containing 250 mL of each medium and incubations carried out at 30 °C for 72 h with constant agitation (150 rpm). All experiments were performed at least in duplicate. At 24, 50 and 72 h, microbial growth was assessed by duplicate spread plating 0.1 mL of serial tenfold dilutions into Plate Count Agar, followed by incubation at 30 °C for 72 h and the results were expressed in colony forming units per mL.

Obtention of Fish Protein Hydrolysates

Cultures were centrifuged at 10,000 rpm for 5 min, at room temperature in a Kubota 6800 centrifuge (Kubota Corp., Tokyo, Japan), in order to separate the biomass. The supernatant was filtrated using a Millipore filtration system (EMD Millipore Corporation, USA), equipped with a filter with 0.45-μm pore diameter to remove remaining bacteria, and concentrated, using a rotatory evaporator (Rotavapor RE 121, Büchi Laboratory Equipment, Flawil, Switzerland), and a vacuum pump (V - 700, Büchi Laboratory Equipment, Flawil, Switzerland). Samples were freeze-dried (Thermo Scientific Heto Power Dry LL 3000, Labosistema, Portugal) and the resulting powder was identified as FPH_1, FPH_2, and FPH_4, according to the concentration of CPH in the culture medium, and stored at −20 °C until further use.

Hydrolysates Characterization

Determination of Enzymatic Activity

The enzymatic activity was determined following the method described by Twining [9], with slight modifications, using derivatized casein with 1 % (w/v) of FITC as substrate.

After each sampling time (0, 24, 50 and 72 h), 30 μL of Tris buffer 100 mM pH 7.8, 10 μL of casein substrate and 10 μL of FPH were mixed in an Eppendorf tube, homogenized and incubated at 37 °C for 30 min. After the incubation period, 120 μL of trichloroacetic acid (TCA) 5 % (w/v) were added. The samples were centrifuged at 10,000 rpm, for 5 min (Sigma 2K15, B. Braun, Melsungen, Germany), and 100 μL of the supernatant were transferred to a tube with 2.9 mL of Tris buffer 500 mM pH 8.5.

In parallel, two controls were also made, where the FPH was replaced by the same volume (10 μL) of Tris buffer 100 mM pH 7.8. In the positive control the 120 μL TCA 5 % (w/v) were replaced by 120 μL Tris buffer 500 mM pH 8.5. In the negative control, the same volume of TCA 5 % was added. All samples and controls were homogenized and fluorescence measurements were made in a spectrofluorometer (LS 50B, PerkinElmer Inc, Waltham, Massachusetts USA), using an excitation wavelength of 495 nm and an emission wavelength of 525 nm.

The results regarding the enzymatic activity were expressed in relative fluorescence, calculated by the following equation:

where Fs is fluorescence after the enzymatic reaction, F− is the fluorescence of the negative control and F+ is the fluorescence of the positive control. Each measurement was made in quadruplicate.

Gel Filtration and Peptide Profile

In order to characterize the peptide profile of culture medium and the FPH obtained, a gel filtration chromatography was made in a FPLC ÄKTA system (Amersham Biosciences, Uppsala, Sweden) equipped with a UV detector at 280 nm. The column used was a SuperdexTM Peptide 10/300 GL (Amersham Biosciences, Uppsala, Sweden) and the eluent was acetonitrile 30 % with 0.1 % trifluoacetic acid with a 0.5-mL min-1 flow.

The molecular weight (MW) calibration curve was prepared using ribonuclease A (13 700 Da), aprotinin (6500 Da), angiotensin l (1296 Da), triglycine (189 Da) and glycine (75 Da).

Protein Content

The protein content was determined using a FP-528 LECO nitrogen analyzer (LECO; St Joseph, MI, USA) calibrated with ethylenediaminetetraacetic acid (EDTA) according to the Dumas method described by Saint-Denis & Goupy [10]. The determination was performed in triplicate.

Amino Acids

The amino acid profile was determined according to the hydrolysis methods described in AOAC [11, 12]. For the acidic hydrolysis, 10–35 mg of sample (containing 1.5–2.0 mg of nitrogen) was placed in 10-mL ampoules with 3 mL of 6 N HCl with 0.1 % of phenol. The hydrolysis was performed under inert conditions at 110–115 °C for 24 h. Then, the samples were neutralized with NaOH to obtain 0.1 N HCl as final concentration. Samples were filtered (0.2-μm pore size) and stored at −80 °C until amino acid separation.

For the alkaline hydrolysis, 10–35 mg of sample (containing 1.5–2.0 mg of nitrogen) was placed in 10-mL ampoules with 3 mL of 4.2 N NaOH (deaerated by bubbling with N2 for 10 min) and one drop of 1-octanol. The hydrolysis was performed under inert conditions at 110–115 °C for 20 h. Then, the samples were neutralized with HCl to obtain 0.1 N HCl as final concentration. Samples were filtered (0.2-μm pore size) and stored at −80 °C until amino acid separation.

Separation was performed with high-performance liquid chromatography (Agilent 1100 HPLC, Agilent, Palo Alton, CA) using precolumn o-phthalaldehyde (OPA) and 9-fluorenylmethyl chloroformate (FMOC) derivatization, a Phenomenex Gemini ODS C18 guard column (4 × 3 mm), and a Phenomenex Gemini ODS C18 110 Å column (4.6 × 150 mm, 5 μm). The solvents and gradient conditions were as described by Henderson et al. [13]. Detection wavelengths were set at UV (338 and 262 nm) and fluorescence (340/450 and 266/305 nm). The identity and quantity of the amino acids were assessed by comparison with the retention times and peak areas of standard amino acids (Sigma) with the software Agilent ChemStation for LC (Agilent, USA). Norvaline and sarcosine were used as internal standards. All determinations were performed in triplicate.

Protein Recovery Yield

The yield of the different FPH samples was calculated according to the following equation:

where w FPH is the weight in grams of FPH, P FPH is the protein content (%) of FPH, w s is the weight of culture medium in grams and P s is the protein content (%) of culture medium.

Degree of Hydrolysis

Degree of hydrolysis (DH) was measured using OPA following the method referred by Nielsen et al. [14]. An aliquot of the sample (400 μL, 0.4 mg mL-1) was added to 3 mL of OPA solution and homogenized for 5 s. The mixture’s absorbance was measured 2 min later at 340 nm. The same volume of distilled water instead of FPH sample was used as control. In parallel, it was also prepared a serine standard of 0.9516 meqv L-1. The DH of YE and CPH was also determined. Each experiment was made in quadruplicate. The degree of hydrolysis was calculated according to the following formula:

where Abssample is the absorbance of FPH, Absserine is the absorbance of serine, w is the weight in grams of FPH samples (in 100 mL of solution) and N is the total nitrogen (%) of FPH.

Antioxidant Properties of FPH

Antiradical Activity

DPPH Radical Scavenging Activity

DPPH radical scavenging activity was measured according to the procedure described by Shimada et al. [15] and Picot et al. [16]. One milliliter of the sample with different concentrations was added to 1 mL of daily prepared solution of 0.1 mM DPPH in 95 % ethanol. The mixture was homogenized and shaken in the dark at 24 °C for 1 h. After the incubation period, samples were centrifuged at 10 000 × g for 10 min, and the absorbance of the resultant supernatant was measured at 517 nm. The control sample contained a solution of 0.5 % sucrose (w/v), in order to eliminate the effect of sucrose in radical scavenging activity of the sample. DPPH inhibition was also determined for the YE and CPH.

The DPPH radical scavenging activity of the samples was calculated as followed:

where AbsControl is the absorbance of the control sample with 0.5 % sucrose, and AbsSample is the absorbance of the FPH sample.

The DPPH scavenging activity assay was made in quadruplicate and later expressed as EC50, corresponding to the concentration of protein of FPH that is able to scavenge 50 % of DPPH radical.

ABTS Radical Scavenging Activity

ABTS radical scavenging activity was determined using the method described by Re et al. [17]. To prepare the 7 mM ABTS+ · solution, 10 mg of ABTS was dissolved in 2.6 mL of a 2.45-mM potassium persulfate solution. The solution remained for 16 h in the dark at room temperature before use and the ABTS+ · solution was diluted with 5 mM sodium phosphate buffer pH 7.4, to give an absorbance value of 0.7 ± 0.02 at 734 nm. Then, 20 μL of sample solutions at different concentrations were added to 2 mL of the diluted ABTS+ · solution and the mixture was homogenized and incubated in the dark at 30 °C for 6 min. In parallel, a control sample was prepared with 0.5 % sucrose solution (w/v), instead of the FPH samples. ABTS inhibition was also determined for the YE and CPH separately. The absorbance of the samples was measured at 734 nm. The ABTS radical scavenging activity of the samples was expressed in percentage of inhibition:

where AbsControl is the absorbance of the control sample with 0.5 % sucrose, and AbsSample is the absorbance of the FPH. ABTS scavenging activity assay was made in quadruplicate and expressed as EC50, corresponding to the concentration of protein of FPH that is able to scavenge 50 % of ABTS radical.

Reducing Power

The reducing power of culture media and FPH samples was determined according to the method described by Oyaizu [18]. Two milliliters of each sample (0.5 % sucrose solution, for the control) was mixed with 2 mL of 0.2 M phosphate buffer pH 6.6 and 2 mL of 1 % (w/v) potassium ferricyanide. The mixture was homogenized and incubated at 50 °C for 20 min. After the incubation period, 2 mL of 10 % (w/v) TCA was added and the mixture was centrifuged at 1500 × g for 10 min. Then, 2 mL of the supernatant were mixed with 2 mL distilled water and 0.4 mL of 0.1 % ferric chloride. This mixture was incubated for 10 min at room temperature and their absorbance was measured at 700 nm. Reducing power was also determined for the YE and CPH. A standard curve was prepared using ascorbic acid (20–120 μg mL-1) as standard. The results were expressed as ascorbic acid equivalent (μg mL-1). This assay was made in quadruplicate.

Metal Ion Chelating Activity

Copper

Copper-chelating activity was measured according to the procedure described by Saiga et al. [19], with some modifications as described by Torres-Fuentes et al. [20]. Solutions of 0.1 mg mL-1 copper sulfate and 0.3 mM PV were prepared in sodium acetate buffer 50 mM pH 6.0. One milliliter of FPH sample was added to 1 mL of the copper sulfate solution, and the mixture was homogenized. Next, 250 μL of PV 50 mM solution were added and homogenized. Copper-chelating activity was also determined for the YE and CPH. Absorbance was measured at 626 nm and the chelating activity was calculated using the following formula:

where Abs (PV + Cu2+) is the absorbance of the PV + Cu2+ complex in the absence of hydrolysate (0.5 % sucrose) and Abs (PV + Cu2+ + sample) is the absorbance of the PV + Cu2+ complex in the presence of hydrolysate. This assay was made in quadruplicate.

Iron

The chelating activity for iron was determined as mentioned by Decker and Welch [21]. One milliliter of sample was mixed with 3.7 mL of distilled water and 100 μL of ferrous chloride 2 mM, followed by homogenization. Then, 200 μL of ferrozine 5 mM was added to the mixture and it was vigorously shaken. Ten minutes later, the absorbance of samples was measured at 562 nm. Iron-chelating activity of YE and CPH was also determined. Chelating activity was estimated using the equation below:

where AbsControl is the absorbance of the control sample with 0.5 % sucrose and AbsSample is the absorbance of the FPH. This assay was made in quadruplicate.

Angiotensin-Converting Enzyme (ACE) Inhibitory Assays

ACE inhibitory activity of FPH was measured using N-[3-(2-furyl)acryloyl]-Phe-Gly-Gly (FAPGG) as substrate and expressed as percentage of ACE inhibition.

ACE activity against FAPGG was measured according to the spectrophotometric method as described by Geirsdottir et al. [22]. Sample (100 μL, 1 mg mL-1; prepared in buffer 50 mM Tris-HCl containing 300 mM NaCl at pH 7.5), buffer (100 μL, used as blank), or captopril 0.1 mM (100 μL, standard inhibitor) were mixed with 20 μL of 0.2 U mL-1 ACE from rabbit lung and the mixture solution was pre-incubated at 37 °C for 2 min. Subsequently, 900 μL of the substrate solution (0.5 mM N-[3-(2-furyl)acryloyl]-Phe-Gly-Gly prepared in buffer) was added. The reaction was performed in a heated cuvette holder spectrophotometer set at 37 °C and the absorbance was recorded at 340 nm for 5 min.

where slope is the absorbance decrease per minute of reaction.

Statistical Analysis

The results were tested using a general linear model, two-way ANOVA, followed by a multiple comparisons test (Tukey’s honestly significant difference). To identify the differences between the different FPH and CPH, the Dunnett’s test was used after one-way ANOVA. All statistical analyses were tested at a 0.05 level of probability with the software STATISTICA© from StatSoft Inc. (Tulsa, OK, USA, version 5.1, 1996).

Results and Discussion

Microbial Growth and Enzymatic Activity

As shown in Fig. 1 the three media containing 1, 2, and 4 % of CPH provided a biomass production of around 8 log cfu mL-1, after 24 h at 30 °C. Biomass production did not significantly vary with the increase of fermentation period between 50 and 72 h, indicating that the culture was in the stationary phase since biomass production of 4.5, 6.7, and 7.5 log cfu mL-1 were obtained after 3, 6, and 22 h, respectively. Similar biomass concentrations were described for Bacillus species grown in liquid media containing cuttlefish by-products powder or zebra blenny meat flour [8, 23].

The proteolytic activity recorded in the three trials after 24 h was significantly higher than that measured at 50 and 72 h (Fig. 1) which may be associated to the late exponential phase or to the early stationary phase of bacterial growth as mentioned by Priest [24]. Razak et al. [25] also obtained high protease production by Bacillus sp. at this transition of phases. Sousa et al. [26] and Cheng et al. [27] recorded a maximum of enzymatic activity after 24 h of incubation of Bacillus cereus and Bacillus amyloliquefaciens, respectively.

After 24 h, the decline of proteolytic activity recorded in all experiments may result from the lack of Ca2+ in the culture medium. On the other hand, the reaction medium used in the Twining method for the measurement of proteolytic activity had no calcium ions. It was observed that the activity of the protease produced by Bacillus sp. is enhanced by this metal ion (data not shown). Sousa et al. [26] reported that bacteria of the Bacillus genus secrete extracellular metalloproteases which require metal ions, like Ca2+, in order to reach its optimal activity.

The amount of nitrogen in the medium did not seem to affect the bacterial growth, but influenced enzyme production. The differences recorded in the enzymatic activity among the three assays may be related with their different carbon/nitrogen ratio which was 4.4, 4.0, and 3.6, respectively, for FPH_1, FPH_2, and FPH_4. In fact, Beg et al. [28] demonstrated that the C/N ratio strongly influences the production of extracellular proteases by Bacillus mojavensis. In the current work, it seems that the medium with 2 % CPH (FPH_2) had a better C/N ratio for the enzyme production.

Protein Recovery and Degree of Hydrolysis

The evolution of protein recovery yield during the fermentation process is shown in Fig. 2. The highest yield (58 %) was achieved in FPH_4 which may result from the higher initial amount of CPH in the culture medium that was not consumed by bacteria. In the case of hydrolysates FPH_1 and FPH_2, similar protein recovery was obtained. Having in mind that the concentration of CPH in FPH_2 was the double in FPH_1, it indicates that a higher amount of nitrogen was consumed in the preparation of FPH_2.

The extent of hydrolysis by Bacillus sp. was measured by assessing the degree of hydrolysis (DH) and the data obtained during the fermentative process is shown in Table 1. The initial DH of all FPH was higher than that of CPH due to the presence of YE which had a high DH value (45.1 ± 0.6 %). In fact, a decreasing initial value of DH was recorded as the proportion of YE decreased from FPH_1 to FPH_4. The decrease of DH in all FPH after 24 h may result from the consumption of YE. After this period the increase of DH evidenced the hydrolysis of CPH by the bacterial protease. The highest increase of DH was recorded in FPH_2 after 72 h, which had an initial lower proportion of YE than FPH_1. This DH increase is not evidenced in FPH_4, which may be due to the lower proportion of the new peptides formed vs non-hydrolyzed peptides. Effectively, taking into consideration the gel filtration results, the highest ratio between the percentage of peptides with MW < 200 Da and MW > 400 Da was recorded in FPH_2 (7.1) and the lowest (4.2) in FPH_4 as discussed below (Table 2).

Molecular Weight Distribution

In Fig. 3 is shown the gel filtration chromatogram of FPH_2 obtained after different fermentation periods. A clear change of the peptide profile of this hydrolysate over the fermentation period may be observed. The progressive decrease of higher molecular weight peptides and the increasing production of peptides with lower molecular weight are evidenced. The MW distribution of FPH_1, FPH_2 and FPH_4 was very similar, showing a decrease of fractions with a MW higher than 400 Da and the disappearance of peptides with molecular weight between 400 and 200 Da after 24 h.

In Table 2 are shown the percentages of peptide fractions of the FPH samples. The different percentages of peptides in the starting culture medium result from their different amounts of CPH. This hydrolysate had about 70 % of peptides with MW lower than 200 Da (dipeptides and free amino acids) whereas these peptides in YE represented about 45 %. After 72 h of fermentation, a decrease of fractions with a MW higher than 400 Da in all hydrolysates is observed while all FPH samples showed an increase in the fraction of peptides with MW lower than 200 Da.

The highest percentage of peptides with MW > 400 Da in the FPH_4 hydrolysate indicates the presence of non-hydrolyzed peptides which is in accordance with the higher protein recovery achieved (Fig. 3) in the preparation of this hydrolysate. On the other hand, FPH_1 and FPH_2 had similar percentages of both peptide fractions and also identical percentages of protein recovery.

Antioxidant Activity

DPPH Radical Scavenging Activity

The DPPH radical scavenging activity of all FPH as a function of concentration was evaluated and their EC50 values are presented in Fig. 4a. The DPPH radical scavenging activity of the starting culture medium resulted from the antiradicalar activity of CPH (EC50 = 3.9 ± 0.2 mg protein mL-1) and YE (EC50 = 0.7 ± 0.0 mg protein mL-1). The differences between the EC50 values of starting media result from the different proportions of CPH and YE. Thus, the lower EC50 of FPH_1 starting medium reflects the higher proportion of YE. The EC50 of FPH obtained after 24 h of fermentation was higher or similar to the initial value. These changes may result from a lower contribution of YE peptides which would have been consumed during this period. The further decrease of EC50 recorded in FPH_1 and FPH_2 indicates the formation of peptides with higher DPPH scavenging activity. The EC50 of FPH_4 after 72 h was not significantly different from the initial value but new peptides exhibiting higher DPPH scavenging activity were formed because its EC50 was considerably lower than that of CPH. It is higher than those of FPH_1 and FPH_2 because of the dilution of the new peptides formed in a matrix of non-hydrolyzed peptides.

The DPPH radical scavenging activity of fermented protein hydrolysates prepared from different fish meat was reported by Jemil et al. [8] and also showed that their antioxidant activities were dose-dependent. Fermentative protein hydrolysates from different raw materials exhibiting DPPH radical scavenging activity were also reported [5, 6, 29].

ABTS+ Radical Scavenging Activity

In Fig. 4b is shown the evolution of EC50 values of the ABTS radical scavenging activity of each FPH during the fermentation. Similarly to the DPPH radical scavenging activity the EC50 value of each starting culture medium reflects the relative proportions of YE and CPH whose EC50 values were 1.57 ± 0.03 mg protein mL-1 and 2.49 ± 0.07 mg protein mL-1, respectively, i.e., the higher the proportion of YE in the culture medium, the higher activity will be displayed.

A general decrease of EC50 values during the fermentation period suggests the formation of new peptides with higher ABTS+ radical scavenging activity than the former peptides in CPH, particularly FPH_2 and FPH_4.

According to EC50 values of DPPH· and ABTS+ it seems that hydrolysates after 72 h of fermentation had a higher antiradicalar activity against DPPH· than ABTS+. This result may be attributed to differences of the hydrophilicity and lipophilicity of FPH’s. Kim et al. [30] referred that these properties are relevant because the ABTS assay is done in aqueous and organic phases (i.e. hydrophilic and lipophilic antioxidant systems), whereas DPPH assay is performed in organic media. For this reason, ABTS allows a more realistic evaluation of total antiradical activity.

Reducing Power

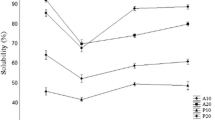

The reducing power of all FPH obtained after each fermentation period increased linearly with hydrolysate concentration (data not shown). In Fig. 5 is shown the evolution of the reducing power of the three hydrolysates at a concentration of 10 mg mL-1 during the fermentation period.

The initial reducing power values of FPHs depend on the YE/CPH ratio of the starting culture medium. Thus, the reducing power of FPH_4 is slightly higher than that of CPH (45.9 μg mL-1) whereas that of FPH_1 is closer to that of YE (87.9 μg mL-1). As it can be seen, the hydrolysates obtained after 72 h of fermentation exhibited higher reducing power than the starting culture medium. It is also noticeable the decrease of this capacity after 24 h in FPH_1 and FPH_2, which was probably caused by the disappearance of YE during the first 24 h of fermentation. This decrease was not observed in FPH_4, may be due to the lowest initial percentage of YE in the culture medium. On the other hand, the increase observed at 50 and 72 h was due to the formation of new hydrolysates with improved reducing power. The lower increase of reducing power recorded in FPH_4 after 72 h may be a result of the dilution of the new peptides formed in the initial intact peptides.

Protein hydrolysates prepared from four fish species fermented by Bacillus subtilis also exhibited a linear relation between reducing power and the concentration of hydrolysates and the results were of the same order of magnitude of those obtained in the current study [8].

Cu2+-Chelating Activity

As it can be seen in Fig. 6a, all FPH prepared after 72 h presented a significantly lower Cu2+-chelating activity than its starting culture medium. The Cu2+-chelating activity of CPH and YE (1 mg mL-1) was, respectively, 27.5 ± 0.4 % and 70.3 ± 0.3 %. The Cu2+-chelating activity of each starting culture medium once again depended on its relative proportions of CPH and YE. The hydrolysates obtained after 72 h showed lower Cu2+-chelating activity than the starting culture medium suggesting that the new peptides formed had lower chelating activity than those of CPH despite the higher activity of FPH_2. The reduction of Cu2+-binding capacity of FPH may result from the decrease of effective sites capable of chelating this metal ion caused by the differences in the structure and length of the peptides as mentioned by Saiga et al. [19] and Ovissipour et al. [31]. It was also reported by Zhu et al. [32] that thiol and carboxylic groups are considered high-affinity metal binding sites, through electrostatic and ionic interactions with copper. On the other hand, Torres-Fuentes et al. [20] stressed the importance of histidine in the chelation of Cu2+ and Carrasco-Castilla et al. [33] related the decrease of Cu2+-binding capacity with the content of negatively charged amino acids, like aspartate and glutamic acid. The high Cu2+-chelating activity of starting culture medium may be related with the level of glutamic acid in YE which was 11.6 g/100 g of sample. On the other hand, glutamic acid was the carboxylic amino acid showing the highest reduction in FPHs after the fermentative process.

Fe2+-Chelating Activity

The Fe2+-chelating activity of FPH’s is presented in Fig. 6b. The chelating activity of the starting culture medium also results from the chelating activity of CPH and the YE which were 32.6 ± 1.7 % and 42.7 ± 3.9 %, respectively. However, the Fe2+-chelating activity of each culture medium was higher than the sum of the individual activity of each component, thus suggesting a synergistic effect between YE and CPH. After 72 h of fermentation, the chelating activity of all FPH obtained was lower than the initial activity. This decrease may be due to the consumption of YE during fermentation and as a consequence a lower interaction between YE constituents and CPH peptides occurs. Moreover, the new peptides formed seemed to exhibit lower chelating activity. It should be highlighted, the higher chelating activity of FPH for Cu2+ than for Fe2+. Kong and Xiong [34] also obtained lower Fe2+-chelating activity when compared to Cu2+, which was related to its greater number coordination sites and requirement of more chelators.

Amino Acids Composition

The amino acid composition of fermented hydrolysates, expressed as grams per 100 g of sample, is presented in Table 3. The major amino acids of fermentative hydrolysates were glycine, glutamic acid, alanine and aspartic acid which were also the same of CPH. As it can be seen, a general decrease of leucine, isoleucine, valine, alanine, arginine, threonine, proline, and glutamic acid was observed after the fermentative period. However, these differences were less accentuated in FPH_4 than in FPH_1 due to a higher amount of CPH in the growth medium. On the other hand, only small differences of the methionine, tyrosine, and hydroxyproline content were recorded. The decrease of amino acids content may be related to the degradative reactions as decarboxylation and deamination [35]. The amino acids are also used by microorganisms in their biosynthetic processes [36].

ACE Inhibitory Activity (%)

The ACE inhibitory activity of CPH was 30.0 ± 8.8 % and that of three FPHs ranged between 24 and 39 %. However, no significant differences among them were observed. These results suggest that the fermentative process did not lead to the formation of new peptides exhibiting higher activity than those previously present in CPH. The inhibitory effect of captopril was tested following the same methodology and an ACE inhibition of 91.6 ± 0.2 % was obtained.

Conclusion

The utilization of Bacillus sp. to prepare fermentative hydrolysates allowed obtaining new peptides which was evidenced by their peptide profile. The yields achieved were around 30 % for FPH_1 and FPH_2 and 58 % for FPH_4. A decrease of some amino acids, particularly proline, leucine, isoleucine, valine, alanine, arginine, threonine, and glutamic acid was recorded for FPHs after 72 h of fermentation. However, the amino acid profile of FPHs was similar to that of the CPH. FPHs exhibited higher reducing power than the starting CPH. They also had higher DPPH radical scavenging activity but similar ABTS radical scavenging activity. FPHs had a lower Cu+2-chelating activity than CPH but in the case of Fe+2-chelating activity no clear trend was observed in all FPHs. All FPHs showed an ACE inhibitory activity similar to that of CPH.

The fermentative process of producing protein hydrolysates seems to be an alternative to improve the biological activities of protein hydrolysates or produce hydrolysates directly from native fish proteins.

References

Agyei, D., & Danquah, M. K. (2011). Industrial-scale manufacturing of pharmaceutical-grade bioactive peptides. Biotechnology Advances, 29, 272–277.

Venugopal, V. (1994). In fisheries processing: biotechnological applications., (Martin, A. M., ed.), Chapman & Hall,, London, UK, pp. 223-243.

Korhonen, H., & Pihlanto, A. (2006). Bioactive peptides: production and functionality. International Dairy Journal, 16, 945–960.

Martínez-Alvarez, O., Guimas, L., Delannoy, C., & Fouchereau-Peron, M. (2008). Use of a commercial protease and yeasts to obtain CGRP-like molecules from saithe protein. Journal of Agricultural and Food Chemistry, 56, 7853–7859.

Balakrishnan, B., Prasad, B., Rai, A., Velappan, S., Subbanna, M., & Narayan, B. (2011). In vitro antioxidant and antibacterial properties of hydrolysed proteins of delimed tannery fleshings: comparison of acid hydrolysis and fermentation methods. Biodegradation, 22, 287–295.

Fakhfakh, N., Ktari, N., Siala, R., & Nasri, M. (2013). Wool-waste valorization: production of protein hydrolysate with high antioxidative potential by fermentation with a new keratinolytic bacterium, Bacillus pumilus A1. Journal of Applied Microbiology, 115, 424–433.

Torino, M. I., Limón, R. I., Martínez-Villaluenga, C., Mäkinen, S., Pihlanto, A., Vidal-Valverde, C., & Frias, J. (2013). Antioxidant and antihypertensive properties of liquid and solid state fermented lentils. Food Chemistry, 136, 1030–1037.

Jemil, I., Jridi, M., Nasri, R., Ktari, N., Ben Slama-Ben Salem, R., Mehiri, M., Hajji, M., & Nasri, M. (2014). Functional, antioxidant and antibacterial properties of protein hydrolysates prepared from fish meat fermented by Bacillus subtilis A26. Process Biochemistry, 49, 963–972.

Twining, S. S. (1984). Fluorescein isothiocyanate-labeled casein assay for proteolytic enzymes. Analytical Biochemistry, 143, 30–34.

Saint-Denis, T., & Goupy, J. (2004). Optimization of a nitrogen analyser based on the Dumas method. Analytica Chimica Acta, 515, 191–198.

AOAC. (1998). Amino acids in feeds - AOAC official method 994.12 (16th ed.). Washington, DC: Association of Official Analytical Chemistry.

AOAC. (1998). Tryptophan in foods and food and feed ingredients - AOAC official method 988.15 (16th ed.). Washington, DC: Association of Official Analytical Chemistry.

Henderson, J. W., Ricker, R. D., Bidlingmeyer, B. A., & Woodward, C. (2000). Rapid, accurate, sensitive and reproducible analysis of amino acids. Palo Alto: Agilent Technologies.

Nielsen, P. M., Petersen, D., & Dambmann, C. (2001). Improved method for determining food protein degree of hydrolysis. Journal of Food Science, 66, 642–646.

Shimada, K., Fujikawa, K., Yahara, K., & Nakamura, T. (1992). Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. Journal of Agricultural and Food Chemistry, 40, 945–948.

Picot, L., Ravallec, R., Fouchereau-Péron, M., Vandanjon, L., Jaouen, P., Chaplain-Derouiniot, M., Guérard, F., Chabeaud, A., LeGal, Y., Alvarez, O. M., Bergé, J.-P., Piot, J.-M., Batista, I., Pires, C., Thorkelsson, G., Delannoy, C., Jakobsen, G., Johansson, I., & Bourseau, P. (2010). Impact of ultrafiltration and nanofiltration of an industrial fish protein hydrolysate on its bioactive properties. Journal of the Science of Food and Agriculture, 90, 1819–1826.

Re, R., Pellegrini, N., Proteggente, A., Pannala, A., Yang, M., & Rice-Evans, C. (1999). Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biology & Medicine, 26, 1231–1237.

Oyaizu, M. (1988). Antioxidative activities of browning products of glucosamine fractionated by organic solvent and thin-layer chromatography. Nippon Shokuhin Kogyo Gakkaishi, 35, 771–775.

Saiga, A., Tanabe, S., & Nishimura, T. (2003). Antioxidant activity of peptides obtained from porcine myofibrillar proteins by protease treatment. Journal of Agricultural and Food Chemistry, 51, 3661–3667.

Torres-Fuentes, C., Alaiz, M., & Vioque, J. (2011). Affinity purification and characterisation of chelating peptides from chickpea protein hydrolysates. Food Chemistry, 129, 485–490.

Decker, E. A., & Welch, B. (1990). Role of ferritin as a lipid oxidation catalyst in muscle food. Journal of Agricultural and Food Chemistry, 38, 674–677.

Geirsdottir, M., Sigurgisladottir, S., Hamaguchi, P. Y., Thorkelsson, G., Johannsson, R., Kristinsson, H. G., & Kristjansson, M. M. (2011). Enzymatic hydrolysis of blue whiting (Micromesistius poutassou); functional and bioactive properties. Journal of Food Science, 76, C14–C20.

Souissi, N., Ellouz-Triki, Y., Bougatef, A., Blibech, M., & Nasri, M. (2008). Preparation and use of media for protease-producing bacterial strains based on by-products from cuttlefish (Sepia officinalis) and wastewaters from marine-products processing factories. Microbiological Research, 163, 473–480.

Priest, F. G. (1977). Extracellular enzyme synthesis in the genus Bacillus. Bacteriological Reviews, 41, 711–753.

Razak, C. N. A., Tang, S. W., Basri, M., & Salleh, A. B. (1997). Preliminary study on the production of extracellular protease from a newly isolated Bacillus sp. (No.1) and the physical factors affecting its production. Pertanika Journal of Science & Technology, 5, 169–177.

Sousa, F., Jus, S., Erbel, A., Kokol, V., Cavaco-Paulo, A., & Gubitz, G. M. (2007). A novel metalloprotease from Bacillus cereus for protein fibre processing. Enzyme and Microbial Technology, 40, 1772–1781.

Cheng, S.-W., Wang, Y.-F., & Wang, M.-L. (2012). Statistical optimization of medium compositions for alkaline protease production by newly isolated Bacillus amyloliquefaciens. Chemical and Biochemical Engineering Quarterly, 26, 225–231.

Beg, Q. K., Sahai, V., & Gupta, R. (2003). Statistical media optimization and alkaline protease production from Bacillus mojavensis in a bioreactor. Process Biochemistry, 39, 203–209.

Fakhfakh, N., Ktari, N., Haddar, A., Mnif, I. H., Dahmen, I., & Nasri, M. (2011). Total solubilisation of the chicken feathers by fermentation with a keratinolytic bacterium, Bacillus pumilus A1, and the production of protein hydrolysate with high antioxidative activity. Process Biochemistry, 46, 1731–1737.

Kim, D.-O., Lee, K. W., Lee, H. J., & Lee, C. Y. (2002). Vitamin C equivalent antioxidant capacity (VCEAC) of phenolic phytochemicals. Journal of Agricultural and Food Chemistry, 50, 3713–3717.

Ovissipour, M., Abedian, A., Motamedzadegan, A., Rasco, B., Safari, R., & Shahiri, H. (2009). The effect of enzymatic hydrolysis time and temperature on the properties of protein hydrolysates from Persian sturgeon (Acipenser persicus) viscera. Food Chemistry, 115, 238–242.

Zhu, L., Chen, J., Tang, X., & Xiong, Y. L. (2008). Reducing, radical scavenging, and chelation properties of in vitro digests of alcalase-treated zein hydrolysate. Journal of Agricultural and Food Chemistry, 56, 2714–2721.

Carrasco-Castilla, J., Hernández-Álvarez, A. J., Jiménez-Martínez, C., Jacinto-Hernández, C., Alaiz, M., Girón-Calle, J., Vioque, J., & Dávila-Ortiz, G. (2012). Antioxidant and metal chelating activities of peptide fractions from phaseolin and bean protein hydrolysates. Food Chemistry, 135, 1789–1795.

Kong, B., & Xiong, Y. L. (2006). Antioxidant activity of zein hydrolysates in a liposome system and the possible mode of action. Journal of Agricultural and Food Chemistry, 54, 6059–6068.

Moat, A. G., Foster, J. W., Spector, M. P. (2003). in microbial physiology, John Wiley & Sons, Inc., pp. 475-502.

Cooper, G. M. (2000) The biosynthesis of cell constituent. In G. M. Cooper (Ed.), The cell: a molecular approach: 2nd edition. Sinauer Associates Inc, Boston University.

Acknowledgments

Bárbara Teixeira acknowledges the project SECUREFISH - “Improving Food Security by Reducing Post Harvest Losses in the Fisheries Sector” FP 7 EU PROJECT THEME: KBBE.2011.2.5-02 (Grant agreement No 289282) for supporting her grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Godinho, I., Pires, C., Pedro, S. et al. Antioxidant Properties of Fish Protein Hydrolysates Prepared from Cod Protein Hydrolysate by Bacillus sp.. Appl Biochem Biotechnol 178, 1095–1112 (2016). https://doi.org/10.1007/s12010-015-1931-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1931-5