Abstract

The transesterification of soybean lecithin with ethyl esters of polyunsaturated fatty acids (eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA)) using immobilized lipase from Rhizomucor miehei was tested in the presence or absence of organic solvent (hexane) and additives (urea with Ca2+ or Mg2+). The reaction was carried out at a water concentration of 4 % and ethyl ester to phospholipid mass ratio of 3:1. After 24 h of reaction without solvent or additive, fatty acid incorporation reached 29.1 % and thereafter increased only slightly. After 48 h, incorporation was highest in the presence of Mg2+, urea, and solvent. After 72 h, it was highest with Mg2+ and urea in the presence or absence of solvent (56.8 and 45.7 %, respectively). Incorporation of EPA and DHA was thus initially fast without solvent and additive, but was increased after prolonged reaction in the presence of Mg2+ and urea with or without solvent. These results are innovative and promising since they show that immobilized Rhizomucor miehei lipase has potential as a biocatalyst for interesterification reactions without solvent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nutraceutical and pharmaceutical products containing the omega-3 polyunsaturated fatty acids eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) have been shifting toward marine phospholipids in recent years [1]. An attractive way of obtaining EPA and DHA as phospholipids is to incorporate the fatty acids into inexpensive natural sources of phospholipids such as soybean lecithin by enzymatic transesterification [2]. Several factors are known to influence the efficiency of transesterification reactions between acyl donors and phospholipids [3–7]. Among these, the enzyme chosen, the water and acyl donor contents, the acyl donor/phospholipid ratio, and the type of solvent in the reaction mixture have been shown to affect the extent of incorporation into phospholipids. Most of these previous studies report negligible or optimal incorporation at water contents below 5 % (wt). Lipase-catalyzed interesterification of fat blends has been achieved in the presence of organic solvents [8, 9] or in solvent-free media [10–12]. The use of organic solvents (hexane and toluene being the most commonly used) is necessary only to improve mass transfer and substrate/product solubility [3–12]. However, it has been reported that solvent-free reactions may be faster under certain conditions and offer many advantages for industrial processes, since they are safer, less expensive, environmentally friendly, and do not inhibit or denature the enzyme [13, 14]. Lipases may be activated by the presence of divalent cations such as calcium or magnesium in the reaction mixture. Calcium binding around the catalytic site promotes polarization of the substrate ester carbonyl group and stabilization of negatively charged intermediates during catalysis via water molecules, which increase thermostability and catalytic activity [15–19].

Among the various industrial lipases available, Rhizomucor miehei lipase (RML) is an important industrial biocatalyst usable in many fields, including oil-fat modification and synthesis of flavor esters, bioenergy, and pharmaceutical applications [20]. Comparing various commercial lipases, Marsaoui et al. [21] reported increased incorporation of ethyl esters of EPA and DHA into soybean phospholipids using immobilized RML in the presence of divalent cations (Ca2+, Mg2+) with or without urea. These results suggested the potential use of this lipase as a biocatalyst for interesterification reactions under conditions of low water content in the presence of organic solvent. However, for nutraceutical and pharmaceutical purposes, a “clean” enzymatic process carried out under solvent-free conditions is preferred.

The purpose of the present work was to compare the effect of presence or absence of organic solvent (hexane) and additives (urea with divalent cation Ca2+or Mg2+) on the incorporation of ethyl esters of EPA and DHA into soybean phospholipids by transesterification using RML. Prior to evaluating these effects, the water concentration and ethyl ester to phospholipid ratio were optimized for maximal enzyme activity.

Materials and Methods

Materials

Oil containing ethyl esters of EPA (52 %) and DHA (20 %) (MEG-3™ Fish Oil) was kindly provided by Ocean Nutrition of Canada Ltd. (Dartmouth, NS). Soybean lecithin (Alcolec® 40P) was kindly provided by American Lecithin Co. (Oxford, CT). This oil-free powdered lecithin contained 98 % acetone-insoluble substances, mainly phosphatidylcholine. Lipase from R. miehei (150 U g1, Lipozyme® RM IM) was obtained from Novozymes A/S (Bagsvaerd, Denmark). All solvents were of HPLC grade, and the remaining chemicals were of analytical grade.

Enzymatic Transesterification Reaction Conditions

Unless otherwise stated, transesterification reactions were carried out in screw-capped Erlenmeyer flasks (50 ml capacity) containing fish oil ethyl esters and soybean lecithin in a mass ratio of 2:1 (i.e., 300 and 150 mg, respectively), lipase (45 mg, i.e., 30 % of the mass of lecithin, corresponding to 150 Units of enzyme activity), water (3 % of total substrate and enzyme combined mass), and hexane (5 ml). Samples were incubated at 50 °C for at least 24 h in an orbital shaker water bath at 250 rpm. The mass of additive (urea, CaCl2, or MgCl2) was 15 % of the mass of the lecithin, that is, 22 mg each. Each experiment was repeated three times.

Separation of Enzymes and Precipitation of Phospholipids

After the transesterification reaction, the enzymes and water were removed from the mixture by filtering on a bed of anhydrous sodium sulfate and glass wool, followed by three successive washes with 5 ml of chloroform. The chloroform was evaporated from the filtrate under vacuum at room temperature. The lipid mixture thus recovered was vortex mixed with 5 ml of acetone at 4 °C for 1 min and then centrifuged at 3000 rpm (5 min, 4 °C) to remove precipitated phospholipids. The phospholipid pellet was washed with another 5 ml of acetone and recovered again in the same manner. The final pellet was dried under vacuum (30 min) and stored at −40 °C under a N2 atmosphere until processing. Before starting analysis of the levels of EPA + DHA incorporation into soybean phospholipids, the lipid profile was tested using thin-layer chromatography coupled to a flame ionization detector (Iatroscan MK-6), as described by Marsaoui et al. [21]. This analysis confirmed that the acetone-precipitated pellets of phospholipid did not contain significant amounts of residual fatty acids or fatty acyl esters.

Analysis of the Fatty Acid Content of the Transesterified Phospholipids

Methylation of Fatty Acids

Fatty acid methyl esters were obtained from phospholipids using the transesterification method of Christie [22]. The sample (5–10 mg) was placed in a 15 ml Pyrex test tube fitted with a PTFE-lined screw cap, along with 5 ml of methanol containing sulfuric acid (2 %, v/v) and 1 ml of hexane containing tricosanoic acid (0.25 mg/ml) as the internal standard. The reaction proceeded overnight at 50 °C under N2 atmosphere. Nanopure water (1 ml) and hexane (2 ml) were then added; the tube contents were mixed by vortex, and the phases were allowed to separate. The upper organic phase was kept, and the lower phase was re-extracted with 1 ml of water and 2 ml of hexane. The combined organic phases were dried over anhydrous sodium sulfate, washed twice with hexane, and finally evaporated using a Titan vapor trap (Jouan, Winchester, VI, USA). The residue was dissolved in 1 ml of hexane containing BHT (50 mg/ml). Samples were stored at −40 °C under a N2 atmosphere until analysis.

Gas Chromatography Analysis (Quantification of % EPA and DHA)

Fatty acid methyl ester analyses were performed using a gas chromatograph connected to a flame ionization detector (Varian, model 3800, Palo Alto, CA, USA). The instrument was equipped with an injector (Varian, model CP-1177) and an autosampler (Varian, model CP-8400) and a 50 % cyanopropyl methylpolysiloxane capillary column (60 and 30 m × 0.25 mm i.d., 0.25 μm film thickness, Varian, model VF-23ms). The carrier gas was helium at a flow rate of 1 ml/min. Both the injector and detector were held at 260 °C. The column temperature profile was programmed as follows: 60 °C initially, ramped to 150 °C at 8 °C/min and held there for 5 min, ramped to 190 °C at 0.7 °C/min, ramped to 230 °C at 1.5 °C/min, ramped to 260 °C at 20 °C/min, and held at this final temperature for 3 min. The temperature program for a single run lasted 105.56 min. Dry hexane-dissolved sample (100 μl) containing 10 μl of methyl nonadecanoate (0.02 mg/ml) as internal standard was transferred to a 250 μl insert. Injection volume was 2 μl with a split ratio of 50 decreasing to 5 after 5 min. Injection temperature was 260 °C. Peak data were collected and integrated using Star Workstation® version 6.2 software (Varian, Palo Alto, CA, USA). Fatty acid methyl esters were identified based on comparison of retention times with standards. Area was quantized using an auxiliary automatic integrator. The response factors of the different fatty acid standards were used to calculate the relative amounts of the various fatty acids in the sample in units of mol%. Results were expressed as % EPA + DHA versus total integrated fatty acid methyl ester peak area. The incorporated omega-3 content, expressed as mol% EPA/(EPA + DHA), was also evaluated.

Statistical Analysis

Comparisons of mean values from each set of experiments were based on ANOVA with the least significant difference (LSD) test at p < 0.05. Analyses were performed using WinSTAT® for Excel® software (R. Fitch, Germany).

Results and Discussion

Before starting analysis, a blank sample without lipase or additive revealed 3.37 % EPA + DHA incorporated into soybean phospholipids under our transesterification conditions. This blank value was subtracted from data obtained in the presence of lipase. It is worth mentioning that this value remained essentially unchanged over 24–72 h of incubation. Thin-layer chromatography coupled to a flame ionization detector (TLC-FID) analysis with the Iatroscan MK-6 confirmed that the acetone-precipitated phospholipid pellets did not contain significant amounts of residual fatty acids or fatty acyl esters (results not shown).

Effect of Water Content

Incorporation of EPA + DHA into soybean lecithin did not differ significantly at water concentrations in the ranges of 0–2 or 2–4 %. However, the values obtained at 0 and 4 % were significantly different, passing from 2.96 % to a maximum of 5.76 % (Fig. 1). Water plays an important role in esterification reactions. Some initial water activity is needed to allow lipases to retain their active three-dimensional conformational form and mobility [23, 24]. However, too high concentrations of water (generally above 4 %) must be avoided since more hydrolysis than esterification could result. Using Pseudomonas cepacia for chiral resolutions of racemic 3-hydroxy esters, Bornscheuer et al. [25] reported loss of enzyme activity beyond 1 % water.

Effect of moisture level (% water) on the incorporation of EPA and DHA into soybean phospholipids by transesterification using the commercial lipase Rhizomucor miehei (RM-IM, see methodology for details). Error bars represent standard deviation based on triplicate experiments (n = 3). Numerical values are written in the respective bars. Differing letters between experimental conditions indicate significant differences (LSD test at p < 0.05)

Effect of Ethyl Ester to Soybean Lecithin Substrate Ratio

The effect of the substrate mass ratio (ethyl ester:phospholipid, ranging from 2:1 to 3:1) was investigated by increasing the quantity of fish oil ethyl esters at a constant quantity of soybean lecithin (Fig. 2). Using 24 h enzymatic reactions at a water concentration of 4 %, substrate ratio was found to have no significant effect, although a tendency for EPA + DHA incorporation to increase (from 4.13 to 5.26 %) was observed at a ratio of 3:1. It is worth mentioning that in preliminary trials in the absence of hexane, the 3:1 ratio appeared to provide a more homogenous mixture than at 2:1, due to better solubility of the soybean phospholipids. Such observation justified the use of a 3:1 ratio for evaluation of EPA + DHA incorporation into soybean lecithin in solvent-free conditions.

Effect of the substrate mass ratio on the incorporation of EPA and DHA into soybean phospholipids by transesterification using the commercial lipase Rhizomucor miehei (RM-IM) at 4 % water (see methodology for details). Error bars represent standard deviation based on triplicate experiments (n = 3). Numerical values are written in the respective bars. Differing letters between experimental conditions indicate significant differences (LSD test at p < 0.05)

Using RML, Vikbjerg et al. [21] reached 49 % incorporation of caprylic acid (CA) into phosphatidylcholine (PC), finding a CA:PC ratio of 6:1 to be optimal. Using phospholipase A1, Kim et al. [26] and Garcia et al. [27] respectively obtained 43 % and 35 % incorporation of n-3 polyunsaturated fatty acid (PUFA) into PC at a substrate molar ratio (n-3 PUFA:PC) of 8:1. Adlercreutz et al. [28] reported increased yields for both esterification and transesterification reactions at increased FFA concentrations. Such increases were also shown to produce changes in polarity or viscosity in the reaction medium [29].

Effect of the Presence or Absence of Organic Solvent (Hexane) and Urea with Ca2+ or Mg2+

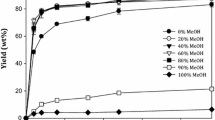

Most of these treatments increased EPA + DHA incorporation during 24–72 h reactions. Without solvent or additives (control condition), incorporation reached the highest incorporation of 29.1 % in 24 h and increased only slightly thereafter, whereas adding hexane + Mg2+ and urea resulted in the highest incorporations of 50.0 and 56.8 % at 48 and 72 h, respectively (Fig. 3). However, the value obtained at 72 h was not significantly different from that obtained by adding Mg2+ and urea without hexane. In the absence of organic solvent, incorporation was greatest under the control condition except at 72 h, although the apparent increase in the presence of Mg2+ and urea was not significant. These results suggest that incorporation of EPA + DHA is faster in the absence of solvent and additives, although the effect of Mg2+ and urea could be beneficial in the presence or absence of solvent when the reaction is prolonged over 24 h. Moreover, after 48 h of reaction, the solvent-free condition reached EPA + DHA levels comparable to or greater than those found in krill oil supplements, which contain about 30 mol% marine-phospholipid-bound EPA + DHA. It is also worth mentioning that for all experimental treatments, the proportions of EPA obtained (%EPA/[EPA + DHA]) remained comparable (72.1–74.5 %), showing no effect of reaction conditions on the composition of the fatty acids bound to the phospholipids. The much lower values shown in Figs. 1 and 2 (in the presence of hexane without additives) reflect the absence of the combined effects of optimal water concentration (4 %) and substrate mass ratio (EE/PL = 3:1). Of course, the effect of reaction time alone was to increase EPA + DHA incorporation from 5.6 % (24 h) to 20.4 % (72 h). It is nevertheless clear that adding Mg2+ and urea improved incorporation substantially to around 20 % within 24 h, an effect that we demonstrated previously to a lesser degree [21]. In the present study, we have shown that using a more suitable water concentration and substrate ratio provided a further improvement. A factorial experiment taking all of these factors into consideration would enable us to understand these effects better and to determine to what extent they are synergistic.

Effect of the presence or absence of solvent or additives (divalent cations, urea) on the incorporation of EPA and DHA into soybean phospholipids by transesterification using commercial lipase Rhizomucor miehei (RM-IM) after 24 to 72 h of incubation at 4 % water and a substrate mass ratio EE/PL of 3:1 (see methodology for details). Error bars represent standard deviation based on triplicate experiments (n = 3). Numerical values are written in the respective bars. Differing letters between experimental conditions indicate significant differences (LSD test at p < 0.05)

In our previous study, EPA + DHA incorporation into soybean lecithin in the presence of RML was increased by adding divalent cations or urea, but no synergistic effect was noted [21]. Among these cations, calcium has been reported to play the most important role as cofactor and activator of lipases [30–32]. Several studies have been reported on the use of immobilized lipases and solvent-free conditions for transesterification reactions (synthesis of various flavor esters) to overcome the problems associated with free enzyme separation and solvent toxicity [33–36]. The present study confirms the advantages of using solvent-free conditions for enzyme interesterification processes, RML being a good choice for food or nutraceutical applications.

Conclusion

Using R. miehei lipase in the presence of a suitable water concentration (4 %) and substrate mass ratio (ethyl ester to phospholipid = 3:1), relatively high levels of EPA + DHA incorporation into soybean phospholipids could be obtained within short times (24 h) without solvent and additives (divalent cations and urea). However, with prolonged reaction, adding Mg2+ and urea generally increased incorporation, in the presence or absence of solvent. The highest level of incorporation obtained in the absence of solvent (45.7 %) suggests that enzymatic production of “marine phospholipid from soybean lecithin” for the food and nutraceutical industries holds promise.

References

Chojnacka, A., Gładkowski, W., Kiełbowicz, G., & Wawrzenczyk, C. (2009). Enzymatic enrichment of egg-yolk phosphatidylcholine with alpha-linolenic acid. Biotechnology Letters, 31, 705–709.

Schuchardt, J. P., Schneider, I., Meyer, H., Neubronner, J., von Schacky, C., & Hahn, A. (2011). Incorporation of EPA and DHA into plasma phospholipids in response to different omega-3 fatty acid formulations a comparative bioavailability study of fish oil vs. krill oil. Lipids in Health and Disease, 10, 145.

Guo, Z., Vikbjerg, A. F., & Xu, X. (2005). Enzymatic modification of phospholipids for functional applications and human nutrition. Biotechnology Advances, 23, 203–259.

Peng, L., Xu, X., Mu, H., Høy, C. E., & Adler-Nissen, J. (2002). Production of structured phospholipids by lipase-catalyzed acidolysis: optimization using response surface methodology. Enzyme and Microbial Technology, 31, 523–532.

Vikbjerg, A. F., Mu, H., & Xu, X. (2005). Lipase-catalyzed acyl exchange of soybean phosphatidylcholine in n-hexane: a critical evaluation of both acyl incorporation and product recovery. Biotechnology Progress, 21, 397–404.

Hita, E., Robles, A., Camacho, B., González, P. A., Esteban, L., Jiménez, M. J., Munío, M. M., & Molina, E. (2009). Production of structured triacylglycerols by acidolysis catalyzed by lipases immobilized in a packed bed reactor. Biochemical Engineering Journal, 46, 257–264.

Totani, Y., & Hara, S. (1991). Preparation of polyunsaturated phospholipids by lipase catalyzed transesterification. Journal of the American Oil Chemists’ Society, 68, 848–851.

Ghazali, H. M., Hamidah, S., & Che Man, Y. B. (1995). Enzymatic transesterification of palm olein with nonspecific and 1,3-specific lipases. Journal of the American Oil Chemists’ Society, 72, 633–639.

Rønne, T. H., Pedersen, L. S., & Xu, X. (2005). Triglyceride selectivity of immobilized Thermomyces lanuginosa lipase in interesterification. Journal of the American Oil Chemists’ Society, 82, 737–743.

Zainal, Z., & Yusoff, M. S. A. (1999). Enzymatic interesterification of palm stearin and palm kernel olein. Journal of the American Oil Chemists’ Society, 76, 1003–1008.

Otero, C., López-Hernandez, A., Garcia, H. S., Hernández-Martín, E., & Hill, C. G., Jr. (2006). Continuous enzymatic transesterification of sesame oil and a fully hydrogenated fat: effects of reaction conditions on product characteristics. Biochemical Engineering Journal, 94, 877–887.

Vikbjerg, A. F., Mu, H., & Xu, X. (2005). Parameters affecting incorporation and byproduct formation during the production of structured phospholipids by lipase-catalyzed acidolysis in solvent-free system. Journal of Molecular Catalysis B: Enzymatic, 36, 14–21.

Otero, C., Arcos, J. A., Berrendero, M. A., & Torres, C. (2001). Emulsifiers from solid and liquid polyols: different strategies for obtaining optimum conversions and selectivities. Journal of Molecular Catalysis B: Enzymatic, 11, 883–892.

Haraldsson, G. G., & Thorarensen, A. (1999). Preparation of phospholipids highly enriched with n-3 polyunsaturated fatty acids by lipase. Journal of the American Oil Chemists’ Society, 76, 1143–1149.

Snijder, H. J., & Dijkstra, B. W. (2000). Bacterial phospholipase A: structure and function of an integral membrane phospholipase. Biochimica et Biophysica Acta, 1488, 91–101.

Arpigny, J. L., & Jaeger, K. E. (1999). Bacterial lipolytic enzymes: classification and properties. Biochemical Journal, 343, 177–183.

Tanaka, A., Sugimoto, H., Muta, Y., Mizuno, T., Senoo, K., & Obata, H. (2003). Differential scanning calorimetry of the effects of Ca2+ on the thermal unfolding of Pseudomonas cepacia lipase. Bioscience Biotechnology and Biochemistry, 67, 207–210.

Kim, H., Choi, H., Kim, M., Sohn, C., & Oh, T. (2002). Expression and characterization of Ca2+ independent lipase from Bacillus pumilus B26. Biochimica et Biophysica Acta, 1583, 205–212.

Hernández, J. A., Aguilar, A. B., Portillo, B., López-Gómez, E., Beneyto, J. M., & Gárcia-Legaz, M. F. (2003). The effect of calcium on the antioxidant enzymes from salt-treated loquat and anger plants. Functional Plant Biology, 30, 1127–1137.

Rodrigues, R. C., & Fernandez-Lafuente, R. (2010). Lipase from Rhizomucor miehei as a biocatalyst in fats and oils modification. Journal of Molecular Catalysis B: Enzymatic, 66, 15–32.

Marsaoui, N., Laplante, S., Raies, A., & Naghmouchi, K. (2013). Incorporation of omega-3 polyunsaturated fatty acids into soybean lecithin: effect of amines and divalent cations on transesterification by lipases. World Journal of Microbiology and Biotechnology, 29, 2233–2338.

Christie, W.W. (2003). Analysis of conjugated linoleic acid—an overview. In: Advances in Conjugated Linoleic Acid Research. 21–12.

Yahya, A. R. M., Anderson, W. A., & Moo-Young, M. (1998). Ester synthesis in lipase catalyzed reactions. Enzyme and Microbial Technology, 23, 438–450.

Pepin, P., & Lortie, R. (1991). Influence of water activity on the enantioselective esterification of (R, S)-ibuprofen by Candida antarctica lipase B in solventless media. Biochemical Engineering Journal, 63, 502–505.

Bornscheuer, U., Herar, A., Kreye, L., Wendel, V., Capewell, A., & Meyer, H. H. (1993). Factors affecting the lipase catalyzed transesterification reactions of 3-hydroxy esters in organic solvents. Tetrahedron: Asymmetry, 4, 1007–1016.

Kim, I. H., Garcia, H. S., & Hill, C. G., Jr. (2010). Synthesis of structured phosphatidylcholine containing n-3 PUFA residues via acidolysis mediated by immobilized phospholipase A1. Journal of the American Oil Chemists’ Society, 87, 1293–1299.

Garcia, H. S., Kim, I., Lopez-Hernandez, A., & Hill, C. G., Jr. (2008). Enrichment of lecithin with n-3 fatty acids by acidolysis using immobilized phospholipase A1. Grasas y Aceites, 59, 368–374.

Adlercreutz, D., Budde, H., & Wehtje, E. (2002). Synthesis of phosphatidylcholine with defined fatty acid in the sn-1 position by lipasecatalyzed esterification and transesterification reaction. Biochemical Engineering Journal, 78, 403–411.

Egger, D., Wehtje, E., & Adlercreutz, P. (1997). Characterization and optimization of phospholipase A2 catalyzed synthesis of phosphatidylcholine. Biochimica et Biophysica Acta, 1343, 76–84.

Dong, H., Gao, S., Han, S., & Cao, S. (1999). Purification and characterization of a Pseudomonas sp. lipase and its properties in non-aqueous media. Biotechnology and Applied Biochemistry, 30, 251–256.

Surinenaite, B., Bendikiene, V., Juodka, B., Bachmatova, I., & Marcinkevichiene, L. (2002). Characterization and physicochemical properties of a lipase from Pseudomonas mendocina 3121–1. Biotechnology and Applied Biochemistry, 36, 47–55.

Pogori, N., Cheikyoussef, A., & Wang, D. (2008). Production and biochemical characterization of an extra cellular lipase from Rhizopus chinensis CCTCC M201021. Journal of Biotechnology, 7, 710–717.

Dave, R., & Madamwar, D. (2006). Esterification in organic solvents by lipase immobilized in polymer of PVA-alginate-boric acid. Process Biochemistry, 41, 951–955.

Silva, J. E. S., & Jesus, P. C. (2003). Evaluation of the catalytic activity of lipases immobilized on chrysotile for esterification. Anais da Academia Brasileira de Ciências, 75, 157–162.

Foresti, M. L., Alimenti, G. A., & Ferreira, M. L. (2005). Interfacial activation and bioimprinting of Candida rugosa lipase immobilized on polypropylene: effect on the enzymatic activity in solvent-free ethyl oleate synthesis. Enzyme and Microbial Technology, 36, 338–349.

Ye, R., Pyo, S. H., & Hayes, D. G. (2010). Lipase-catalyzed synthesis of saccharide-fatty acid esters using suspensions of saccharide crystals in solvent-free media. Journal of the American Oil Chemists’ Society, 87, 281–293.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Marsaoui, N., Naghmouchi, K., Baah, J. et al. Incorportation of Ethyl Esters of EPA and DHA in Soybean Lecithin Using Rhizomucor miehei Lipase: Effect of Additives and Solvent-Free Conditions. Appl Biochem Biotechnol 176, 938–946 (2015). https://doi.org/10.1007/s12010-015-1621-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1621-3