Abstract

The development of a circular economy (CE) model is increasingly being recognized as a way to improve the performance metrics of Micro, Small, and Medium Enterprises (MSMEs). A CE is an economic model that aims to minimize waste and pollution by maintaining resources in use for long time. This paper provides a comprehensive overview of the benefits of a CE for MSMEs, including reduced costs, increased competitiveness, and improved environmental performance. The paper also outlines the steps that need to be taken to develop a CE model using Industry 4.0’s machine learning algorithms for MSMEs. The paper concludes that the development of a CE model has the potential to significantly improve environmental and other performance metrics of MSMEs and should be a priority for policymakers and stakeholders in the business community.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

A circular economy (CE) model is an economic model where waste and pollution are minimized by maintaining resources in use for long time [1]. This model aims to create a closed loop system where waste is transformed into new resources, leading to reduced environmental impacts and increased economic benefits [2]. Micro, Small, and Medium Enterprises (MSMEs) play a critical role in many economies, accounting for a significant proportion of employment and economic activity [3,4,5]. Despite their importance, MSMEs often struggle to compete with larger organizations, which have greater resources and economies of scale [6,7,8]. In this context, the development of a CE model provides a new way for MSMEs to improve their performance, by decreasing waste and improving efficiency.

The adoption of a CE model can have several benefits for MSMEs, including reduced costs, increased competitiveness, and improved environmental performance. By reducing waste, MSMEs can lower their costs and improve their profitability, as they no longer have to pay for the disposal of waste. Additionally, the development of new products and services based on waste can create new revenue streams and increase competitiveness. Furthermore, the improved environmental performance can help MSMEs to meet increasingly stringent environmental regulations and respond to changing consumer preferences [9]. The development of a CE model for MSMEs requires a systematic approach that considers all stages of the value chain, from the sourcing of raw materials to the disposal of waste. This includes the development of new business models, such as product-as-a-service, and the adoption of new technologies, such as closed-loop supply chains and advanced recycling processes [10].

Recent trends in manufacturing industry shows advances on technologies and digitalization [11, 12]. This uprising is called as era of fourth industrial revolution or Industry 4.0 which involves Industrial Internet of Things (IIoT), Data Analytics and Machine Learning, Automation with artificial intelligence (AI) [10, 13]. These technologies have brought seismYaic change in manufacturing and production systems where machines, material and human are connected over digital internet. Sensor used in the system tracks the data for machine and material which leads to optimization and waste reduction of resources.AI technology can optimize the manufacturing processes to reduce material and energy consumption which leads to increases resource efficacy [3,4,5]. IIoT enabled devices can be used in tracking the product after handed over to users which eases flow of products in circular consumption cycle. Automation and analytics help in sorting, recycling and remanufacturing of product to achieve close loop of product lifecycle. The motivation for this study is grounded in the recognition of the critical need to bridge the gap between the transformative potential of CE, the capabilities offered by Industry 4.0 technologies, and the unique challenges and opportunities faced by MSMEs. By developing CE models tailored to the specific needs of MSMEs and augmented with Machine Learning, we aim to unlock a new era of sustainability and performance improvement within this vital sector. The implementation of these technologies with the principle of circular economy provides a significant advantage to the organization to achieve balance between socio, economic and environmental policies.

In order to be successful, the development of a CE model for MSMEs must also be supported by a favourable policy and regulatory environment. This includes the creation of incentives for MSMEs to adopt circular practices, the provision of financing for circular projects, and the implementation of regulations that support circular practices. The development of a CE model has been increasingly recognized as a way to enhance environmental and other performance metrics of MSMEs [14].

Thus, the development of a CE model has the potential to significantly improve environmental and other performance metrics of MSMEs. By reducing waste and improving resource efficiency, MSMEs can reduce costs, increase competitiveness, and respond to changing consumer preferences. However, the development of a CE model for MSMEs requires a systematic approach that considers all stages of the value chain and must be supported by favourable policies and regulations.The remainder of the article is structured as follows. Based on a comprehensive evaluation of the literature, Sect. 2 proposes a literature review and highlights the research gaps. The research methodology with detailed stages of development of CE model is outlined in Sect. 3. Stages in development of proposed CE model is explained in Sect. 4. Discussion is presented in Sect. 5, while Sect. 6 offers recommendations for a conclusion, limitations, and directions for additional research.

2 Literature review

In the present investigation, a thorough literature study was carried out to find pertinent gaps from earlier investigations.

2.1 Literature search methodology

The concept of CE has acquired significant awareness in these years as a potential solution to the environmental challenges posed by traditional linear models of production and consumption. In the context of MSMEs, the adoption of CE principles has the potential to improve environmental performance while also addressing other key metrics such as economic competitiveness, resource efficiency, and waste reduction. The purpose of this literature review is to provide an overview of the current state of knowledge on the development of CE models for MSMEs, including the drivers and barriers to adoption, the impact on various performance metrics, and the role of stakeholders in facilitating the transition towards a more sustainable CE model. The review is intended to provide a foundation for the subsequent sections of the paper, which will focus on the development and implementation of a CE model for MSMEs.

To understand the many environmental and other performance metrices of MSMEs, the study activity employs a systematic literature review (SLR) technique. As opposed to a generic review, SLR encourages a methodologically rigorous evaluation with an emphasis on evidence-based research criteria. SLR employs an explicit and comprehensive methodology to ensure the validity of the literature review. The research purpose and goal are determined at the initial phase of SLR. The SLR has number of stages, which are explained as follows-

2.1.1 Planning stage

The requirement for review is listed below, along with steps for creating a review protocol. The review process used is given in Table 1, which is in order to identify several elements that serve as catalysts for improvement of environmental and other performance metrices of MSMEs.

2.1.2 Organising literature review

This stage outlines the gathering of research and their data-driven analysis. To provide thorough coverage of the literature, the authors of this study used databases from Science Direct, Web of Science, Emerald, and Scopus. Peer-reviewed articles are included in the study to guarantee the calibre of publications. The study's selection window ran from 2011 to 2023.

In this study, the search parameters of the keywords were applied to further examine phrases associated with CE model, environmental and other performance metrices, and MSMEs. Due to the criteria applied, review articles were included in all 110 papers at the start of the study. In this investigation, articles relating to the issue of interest were filtered using the preferred reporting items for systematic reviews and meta-analysis (PRISMA) technique as shown in Fig. 1. PRISMA is widely used and recognised methodology due to its transparency, rigor, and ability to ensure methodological and credible synthesis existing literature [6, 8, 15]. This systematic approach ensures that step by step methods are followed for identification, screening and synthesizing relevant research content. PRISMA removes the bias from selection of article which ensures no room for arbitrary selection of articles. This approach builds reader and peer reviewer trust that systematic and predefined approach followed through research instead of cherry picking and selective reporting. This approach is important as this study intersect three complex topics like industry 4.0, Circular Economy and MSME. It ensures that our study on development of Circular economy model using Industry 4.0, machine learning technique for MSMEs is built on solid foundation of relevant and reliable academic work contributing to advancement of knowledge in this vital area of sustainable industrial revolution.

To enhance the accuracy and relevance, timeframe of 2011–2023 is decided for PRISMA. This timeframe is relevant as it coincides with technological advancement of IIoT devices and maturation of artificial Intelligence coincides making it critical for our study. Another crucial factor was recent policy and regulatory changes formulated around Circular economy & Industry 4.0. Research inclusion period strikes the balance between historical and recent trends which enhance breadth & depth of input. After further examination of the 60 article abstracts to ensure that they matched the study's integration and framework goals, 22 publications were still excluded from consideration. After that, the articles' full-text accessibility was considered, which resulted in the elimination of 9 further articles. Three articles were excluded from consideration after the substance of the articles was evaluated in light of their relevance to development of CE model to improve environmental and other performance metrices of MSMEs. After thorough analysis of the articles, the final sample consists of 44 articles. The articles were further examined during the reporting phase to identify various aspects that support development of CE model for MSMEs.

2.2 Background of CE models

The CE model is based on the principles of reducing waste and preserving resources by closing material loops and keeping products and materials in use for as long as possible. This contrasts with the traditional linear model of take-make-waste, where resources are extracted, used to create products, and then discarded as waste. The CE model aims to reduce the use of finite resources, minimize waste and emissions, and create economic value by maximizing the use of materials and resources [2].

The concept of the CE has been around for several decades, but it has gained increased attention in recent years as concerns about resource depletion, waste, and environmental impacts have grown. The need for a more sustainable and circular approach to the economy has been recognized by businesses, governments, and international organizations, who are actively exploring ways to transition towards a more CE. This has led to the development of various CE models and initiatives, including product-service systems, closed loop supply chains, and shared economy models, all of which aim to create a more sustainable and resilient economy [16].

2.3 Environmental and other performance metrices of MSMEs

MSMEs play a critical role in the global economy, accounting for a significant proportion of economic activity, employment, and innovation. However, MSMEs often face significant challenges in terms of environmental and other performance metrics, including resource efficiency, waste reduction, and economic competitiveness. The adoption of a CE model has the potential to improve the environmental and other performance metrics of MSMEs by reducing resource use, waste generation, and emissions, and by improving economic competitiveness through increased resource efficiency and reduced costs.

In the context of MSMEs, the environmental benefits of the CE model include reduced greenhouse gas emissions, improved resource efficiency, and reduced waste. The CE model can also help MSMEs to improve their economic competitiveness through reduced costs, increased resource efficiency, and enhanced reputation. Other performance metrics that may be improved through the adoption of a CE model include social and economic sustainability, job creation, and local economic development. By addressing these multiple performance metrics, MSMEs can contribute to a more sustainable and resilient economy and society [17]. The CE concept aims to replace the idea of end-of-life with renovation; however, it is yet uncommon to monitor and assess circularity performances [18]. The CE idea is gaining popularity around the world, but its use must be supported by scientific research and quantification, else it runs the risk of encouraging "circularity for circularity's sake" [19]. The study by [20] examined 30 micro-level CE indicators. These indicators prioritised economic factors over social and environmental implications, which results in suboptimizations and a more constrained vision of sustainability. A production and consumption paradigm known as the "CE" promotes sharing, reusing, repairing, refurbishing, and recycling of pre-existing goods [21].

However, the creation of a CE that is in accordance with environmental protection and sustainable economic growth requires significant investment in recycling infrastructure and cutting-edge resources [22]. MSMEs are important for economic development and growth, but their impact on environmental problems is still underappreciated [23]. To evaluate how industrial activities, affect the environment, the study performed by [24] established 15 essential environmental sustainability indicators, underscoring the need of environmentally friendly product design. Globally, China and Europe prioritised the CE model the most, with Germany taking the lead in bioeconomy-related research [25]. Due to the low HR capabilities of MSMEs in Central Java, the study carried out by [26] intends to develop a Performance Management System-based model to enhance their operational performance. The most crucial insight from the article by [27] is that more study is required to combine the existing approaches and create a more comprehensive framework for evaluating the sustainability effects of CE efforts.

Based on the quality of the waste flow and the benefits to the environment, the Cumulative Exergy Extraction from the Natural Environment (CEENE) indicator is an effective method for directing waste streams towards their best alternative for valorisation [28]. Designing dynamic simulation models and forecasting system behaviour both benefit from multi-method simulation [29]. To identify research gaps and future research priorities, Pangarso et al. [30] analysed the CE-based business model and MSMEs. The study by Busu and Trica [31] looked at the CE model's viability and its effects on the expansion of the European Union’s (EU) economy. An indicator developed by Haupt and Hellweg [32] based on environmental impact quantified the environmental value preserved by recycling, repair, remanufacturing, or reuse. In an effort to make local MSMEs more competitive, the Model of Eco-Friendly Packaging Centre was created [33]. The Circular Economy Index System (CEIS) concept, which communicates environmental management needs along the industrial supply chain, is practical and reasonable [34].

In the study by Palmieri et al. [35] the economic and environmental viability of an energy power plant that generates electricity from olive grove pruning waste was examined. 15 important environmental sustainability indicators were identified by researchers to evaluate the environmental impact of manufacturing activities [24]. By eliminating solid waste, adhering to environmental standards, paying a sufficient wage, and promoting a healthy work-life balance, sustainable manufacturing practises enhance the financial performance of MSMEs [36]. A society built on sustainable production and consumption is what the European Commission's CE Action Plan seeks to promote [37]. Innovation and human resources both have an impact on the competitiveness of MSMEs, with human resources playing a more significant influence than innovation [38]. By developing a fabrication to utilisation whole supply chain that is curative, and reformative, CE seeks to minimise the effects on the environment and the socioeconomic system [39]. A CE model can improve environmental and other performance metrics of MSMEs [40]. To maximise the environmental impact and energy efficiency, the design and manufacturing cycle are rethought in the CE industrial pattern [41]. Users of the RaMa-Scene web platform can visualise the many effects of CE initiatives [42]. With the utilisation of CE, recycling, and reuse during the EOL period of a 3 kW FCH-UPS system, environmental impacts might be cut by 66% [43]. The success of MSMEs in applying the GE idea is gauged by how well they perform in terms of the green economy [44]. By recycling plastic bottles and selling the remaining ones in the city's port, the full plastic fraction can be included into the CE model [45]. The feasibility of the CE in managing municipal solid waste (MSW) is examined from an economic, environmental, and social standpoint in the study [46].

2.4 Summary of research gaps

While there has been significant progress in the development of CE models and initiatives, there are still a number of research gaps that need to be addressed in order to fully understand the impact of the CE on MSMEs. These gaps include a lack of comprehensive data and empirical evidence on the impact of CE models on MSMEs. By conducting empirical study, current study can provide evidence of how CE practices affect various performance metrices such as cost saving, resource efficiency and environmental impact. This will enhance the research outcome. Current studies have limited understanding of the drivers and barriers to adoption of CE models in MSME which can hinder journey of CE Adoption, this study will demonstrate the impact of these factors on CE Metrices and provide practical insight for policymaker. The lack of engagement and participation of MSMEs in CE initiatives necessitates the development of innovative approaches to incentivize and involve MSMEs in CE Practices through tailored CE Model and capacity building programmes. Additionally, there is a need for further research to develop and test innovative and scalable CE models that can be adapted to the specific needs and circumstances of MSMEs. This research can focus on creating adaptable CE framework that consider the resource constraint and operational intricacies of MSME. Also, there is limited literature related to development CE models using machine learning (ML) techniques in Industry 4.0 era. The current study can pioneer in the integration of ML algorithms to optimize CE processes, resource management and decision making in MSME. Innovative approach can enhance the efficiency and effectiveness of CE practices.

By addressing these research gaps, the current research aims to provide a holistic understanding of the impact of CE on MSMEs, offer practical solutions to overcome adoption challenges, and contribute to the development of scalable CE models. Moreover, the incorporation of ML techniques introduces a novel dimension to CE research, potentially revolutionizing how MSMEs can implement and benefit from circular economy principles. This comprehensive approach will lead to more precise research objectives and outcomes with real-world relevance. The urgency of addressing this research gap is further underscored by the global commitment to the United Nations Sustainable Development Goals (SDGs) and the prestigious Paris Agreement, which seek to limit global warming and foster sustainable economic development. The successful integration of CE models with Industry 4.0 and Machine Learning in MSMEs holds the promise of advancing multiple SDGs, including those related to responsible consumption and production (SDG 12), climate action (SDG 13), and industry innovation (SDG 9).

3 Research methodology

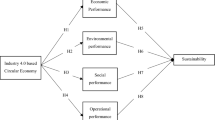

Primary objective of this research is to develop, test and assess Circular Economy model that incorporates Industry 4.0’s Machine Learning technique on the environmental and performance metrices of MSME’s. Conducting case study on a specific MSME is the most effective way to achieve objective. A case study allows you for practical implementation of CE model within real MSME, providing insights into how these principles and technologies can be applied in tangible business setting. MSME sector is very wide in terms of shape, size and operation characteristic, researcher can tailor the CE model to the unique context of that business. A case study allows for in depth analysis including collection of qualitative & quantitative data, interviews with Key stakeholder and detail assessment of performance metrics. While case study focuses on a specific MSME, the findings and lessons learned can contribute to generalise knowledge about CE model with Industry 4.0 and Machine learning in broader MSME sector. Research Methodology for development of CE model to improve environmental and other performance metrics of MSMEs is shown in Fig. 2.

In Sect. 2, SLR is done to identify specific research gaps pertaining to the present study using PRISMA method which conduct an exhaustive search of academic database, online sources and Industrial report to gather relevant literature on CE, Industry 4.0, ML & MSMEs. This section lists out of key theories, frameworks, and existing models which provides the base for development of robust theoretical framework that integrate CE & Industry 4.0 with ML. In Second sub-section, a case study is performed within selected MSME, ensures that CE Model is aligns with operational context, goals and challenges. Further impact assessment is done to evaluate the effect of the CE model on various performance metrics. This step also refine & improve the model based on results, lessons learned and feedback from MSME partners which helps in ease of adoption and effective implementation. In last section, article provide clear and actionable recommendations for MSME interested in CE Model enhanced with Industry 4.0 techniques. Also highlights the avenues for future research in the realm of CE for MSME, identifying specific topic & technologies which enhance business performance.

3.1 Case study analysis

3.1.1 Selection of MSME

The case study will be selected based on specific criteria to ensure its representativeness and relevance to the research topic. The criteria for selection will include the size, sector, location, and potential for replicability and scalability of the MSME. The case study is selected in such a way that it represents the typical challenges and opportunities faced by MSMEs in adopting CE models.

3.1.2 Development and testing of proposed CE model

The proposed CE model will be developed based on the findings of the SLR and the best practices and guidelines for CE models for MSMEs. The model will be adapted and refined based on the specific circumstances and requirements of the case study MSME. The proposed model will be tested and evaluated in practice, and its impact on the environmental and other performance metrics of the MSME will be assessed.

3.1.3 Assessment of impact

The impact of the proposed CE model on the environmental and other performance metrics of the MSME will be assessed using a range of methods and metrics. These may include surveys, interviews, and data analysis, and are focussed on a variety of performance metrics, such as resource efficiency, waste reduction, emissions reduction, and economic competitiveness. The results of the impact assessment are used to refine and improve the proposed model and to make recommendations for future research.

3.1.4 Refinement and improvement of proposed CE model

Based on the results of the impact assessment, the proposed CE model will be refined and improved to ensure that it is effective and sustainable. The refinements and improvements will be based on the lessons learned from the case study and will consider the unique circumstances and requirements of the MSME. The refined model will be used to make recommendations for future research and to guide the development of CE models for other MSMEs.

4 Proposed CE model

Developing a CE model using machine learning techniques can be a complex and multi-step process. Steps for its development are described as follows:

-

1.

Define the scope of the CE model:

-

a.

Introduction to circular economy.

The circular economy is an economic system designed to reduce resource consumption, garbage creation, and environmental impact. The circular economy attempts to establish a closed-loop system in which resources are reused, refurbished, and recycled to maintain their value over time, in contrast to the traditional linear economy (take-make-dispose).

-

b.

Key principles.

Key principles of the circular economy model are defined as follows:

-

1.

Design for Durability and Repairability:

Products are designed to be durable and simple to repair, thereby increasing their longevity.

-

2.

Reuse and Refurbishment:

When possible, emphasise the importance of repurposing products and components to reduce the need for new resources.

-

3.

Recycling and Upcycling:

Describe how recycling and upcycling processes contribute to the extraction of value from garbage materials and the reduction of waste disposal to landfills.

-

4.

Resource Efficiency:

Emphasise the importance of resource efficiency by optimising processes, reducing waste, and utilising materials more effectively.

-

5.

Closed-Loop Systems:

Describe closed-loop systems, in which materials are perpetually cycled back into production, thereby reducing the need for virgin resources.

-

1.

-

c.

Benefits of circular economy:

Consider the environmental and business advantages of adopting a CE model. This could include reduced environmental impact, cost reductions through resource optimization, increased opportunities for innovation, and improved consumer perception due to sustainable practises.

-

d.

Applicability to MSMEs.

Specify the relevance of the CE model to Micro, Small, and Medium-sized Enterprises (MSMEs). Explain that SMBs frequently experience resource constraints and can benefit from the inherent efficiencies and sustainability practises of CE.

-

e.

Transition challenges.

Recognise that the transition to a circular economy model may involve obstacles, such as modifications to business processes and supply chains, and the need for stakeholder buy-in. This demonstrates your comprehension of the complexities involved. Determine which resources or products will be considered in the model and what the desired outcomes are e.g., reducing waste, maximizing resource utilization, etc.

-

a.

-

2.

Gather data:

Collect data on the relevant resources and products. This can include information on their lifecycle, usage patterns, and disposal practices.

-

3.

Pre-process the data:

Clean, normalize, and transform the data so that it can be used for machine learning algorithms.

-

4.

Choose ML algorithms:

Choose ML algorithms that are appropriate for the problem at hand. For example, clustering algorithms can be used to identify patterns in data, while classification algorithms can be used to classify products or materials.

-

5.

Train the model:

Use the collected and pre-processed data to train the ML model.

-

6.

Validate the model:

Test the accuracy of the ML model and validate its performance against the desired outcomes.

-

7.

Implement the model:

Use the ML model to make predictions and recommendations on how to optimize the CE model.

-

8.

Continuously improve the model:

Regularly update and refine the ML based on new data and feedback.

Developing a CE model using ML techniques requires a deep understanding of both CE principles and ML techniques. The process is based on design-science research, which entails putting out a CE model via many stages and sequential tasks for solving a specific issue. The Design of Computational Intelligence Experiments (DCIE) technique has been presented, considering that the proposed CE model should be implemented to confirm its applicability for the present scenario. This technique presents new specifications, models for data analysis, and establishes the synergy between each of the defined stages as well as their implications. Below is a description of the methodology's phase order:

-

Phase 1: created in Sects. 2, this phase proposed a framework for reference. Additionally, the review also enabled the research issue, the research gap, and the research goals to be developed.

-

Phase 2: established in the present Sect. 3, this step entails determining the fundamental traits of environmental practises and environmental management systems, strategies, and knowledge management aspects. To build the CE model and identify the population that needs to be examined, these traits are later categorised according to maturity fulfilment levels.

-

Phase 3: this phase depends upon the outcomes of a survey conducted among MSMEs, was developed in Sect. 4. It entails model validation and data analysis. Data preparation is used to oversee and train a number of algorithms. The optimum algorithm is then chosen at last stage.

The CE model for MSMEs is built with the development of Phase 2 of the present strategy in mind, and three elements are integrated as tabulated in Annexure I. These elements are associated with the environmental, social, and economic considerations that are often included in internal business operations' environmental sustainability studies. Phase 2 also specifies training and validation of the algorithm that aided the reliability categorization and describes the list of businesses examined to apply the CE model.

4.1 Factors and levels

4.1.1 Management of environmental knowledge in MSMEs

By acquiring facts about the topic of environmental protection, employees of businesses may utilise environmental knowledge management to lessen the environmental effects of production and consumption processes. To make changes and enhance goods and corporate operations, it needs technical, human, and financial skills. Employee education and opportunities for information sharing and socialisation are also necessary. In order to provide workers a clear understanding of the procedures required to execute a job or process while reducing the environmental effect, strategic and operational processes must be documented. Knowledge management is a crucial component of company administration since it calls for staff members to comprehend and prioritise environmental best practises.

4.1.2 Techniques and ethical environmental behaviour in MSMEs

Measures and actions performed by businesses to lessen the adverse effects brought on by their productive operations are known as good environmental practises and strategies. Cleaner production, eco-efficiency, and CE are a few of them. Solid waste reduction, energy efficiency, improved air and water quality, noise reduction, and staff devotion to the environment are all examples of performance improvement indicators. The key advantages of applying sound strategies and environmental practises include increased competitiveness, cost savings, adherence to environmental regulations, and dependability in customer relationships. Due to obstacles or internal issues, MSMEs find it difficult to incorporate excellent practises.

4.1.3 Environmental management systems in MSMEs

Companies may structure their management, operational, and support activities using environmental management systems, which also make it easier for employees to follow ethical environmental principles. To accomplish operational, strategic, and tactical objectives, ISO 14001 is a global standard that should be applied. While some of these systems have been modified to meet the requirements of small businesses and are accessible in commercial settings, MSMEs has deficiency the economic resources. A CE model is evaluated on a four-level scale, with level 1 denoting insufficiency, level 2 indicating basic, level 3 denoting developing, and level 4 indicating consolidation.

4.1.4 The studied MSME set

MSMEs from various industries were taken into consideration in this study. MSMEs are dispersed over the country and represent the commerce, service, construction, logistics, and manufacturing sectors. The online database was used to find the contact information for the businesses based in these cities. It serves as a source for corporate data. By utilising database, more than 3500 active MSMEs was created. 1350 MSMEs were removed from the list because their contact information was incorrect or misspelt. To get a sample size of 327 MSMEs, a population estimate of 2150 MSMEs was computed.

The questionnaire was built around traits that each of the elements under study had and that had been evaluated by experts (Annexure II). It had four distinct sections: The purpose of Part 1's six questions regarding general business information was to describe and classify the types of examined firms. Phase 2 of the evaluation had three parts: sustainable integration, which analysed each of the three components separately. 42 questions were included in the questionnaire with the goal of determining the advantages and disadvantages of the industries under review. There were yes/no, open-ended, and multiple-choice items on the survey. With the former, the respondents could choose the solution that met their needs the best from a variety of options. Open questions were utilised to get more data that would have been useful for the study while yes/no questions were added to get quick answers from questions with just two alternatives. Interviews with the managers or people in charge of the production, quality, or environment at the businesses were performed. It was decided to distribute the survey through email along with the study's goals and an invitation to participate in it.

The allocation of the sample among the sectors is shown in Fig. 3. The enterprises were identified as belonging to one of the three major economic sectors. With 36% of the sampled enterprises, the manufacturing sector had the most participation, followed by the service and commerce sectors with 32% and the construction and civil works sectors with 32%. Table 2 lists classification of business sizes based on the number of employees.

4.2 Results

This section covers the outcomes of the survey performed among MSMEs, along with the validation of the model and the analysis of the data, with particular emphasis on Phase 3 of the methodology.

4.2.1 Training and validation method

To analyse data, data analytics use a variety of analytical techniques. ML is a database that analyses information and is one of the most widely utilised techniques. It is a system that can "learn" by expressing data structures and generalising the related behaviours based on a dataset that the user provides [47]. A series of tasks are carried out in Phase 3 of the present research approach to train and verify the employed algorithms.

4.2.2 Dataset

The dataset is a table of the numerical values given by the businesses in response to the survey sent to the number of MSMEs, which are under investigation.

4.2.3 Data pre-processing

The replies to the queries were pre-standardized using a format of numbers to facilitate examination by the classification algorithm. "No" and “Yes” have been assigned numeric values as 0 and 1 respectively. All the responses were converted to logical values by converting them to a binary range using multiple-choice questions of the survey. As a result, the responses "completely disagree," "undecided", and "disagree," get a value of 0. The responses "agree" and "completely agree" are assigned 1, respectively.

In order to produce a homogenous data distribution, the "oversampling" approach of data analysis was used to the levels below the one with the majority of enterprises. To consider the original dataset bias, oversampling entails continually doubling the sampling frequency [48, 49]. This modifies the distribution. When used to classify a sample of organisations, the classification algorithm becomes more accurate in this manner. Therefore, number of level 3 replicates are reproduced proportionally using the level 1, 2 and 4 samples.

4.2.4 Supervised algorithms

Using classification algorithms, supervised learning may identify the category—for example, a level—to which a new instance—for example, a company—belongs based on prior observations. The classification algorithms having multiple classes was used in these processes may deal with many categorization categories. This score in the current research correlated with sustainable maturity levels 1 to 4. It should be noted that the specific management of the training dataset affects how well classification algorithms perform. Pre-processing and standardising the data make up this treatment.

To prevent over adjusting the samples, the Cross-Validation approach is used. In this strategy, k subsets are used to partition the training data. The model is assessed during training using subsets that are sequentially exploited. The accuracy values of each model are computed once the iterations are finished. Finding the matching mean of the k trained models yields further accuracy and final error numbers [50, 51].

The algorithm training and validation processed were conducted using the classification methods such as Support Vector Machine (SVM), Naive Bayes (NB), and Random Forest (RF). These methods were selected because they can tackle classification issues concurrently by measuring the variability of the samples available internally. SVM algorithm is employed to forecast the classification of a novel sample based on a dataset consisting of pre-labelled samples.

Also, RF categorises new samples depending on the properties of past ones, where the prediction is the principal option of a decision tree. To classify a new instance, NB makes the assumption that the predictive variables are independent of one another.

Moreover, to assess the efficacy of algorithms learning models are used using various statistical approaches, in accordance with the DCIE methodology [52]. Common metrics used to evaluate this technique include F1-Score, Accuracy, Recall, and Precision. The training and validation procedure used for the algorithms' categorization is shown in Fig. 4. The data were split into two sets, 30% for validation and 70% for training, for a Cross Validation technique.

4.2.5 Choosing the most effective algorithm

The DCIE technique consists of a number of steps that are used to confirm the applicability and effectiveness of the algorithm’s under-consideration [47, 52]. Based on these considerations, the optimal classification method is chosen to enhance or complete information heterogeneity using data analytics predictions. To ensure the integrity of the conclusions, it is crucial to establish statistical significance by consistently executing the classification algorithm in identical conditions, employing the same dataset, and monitoring error rates. This is accomplished by analysing the standard deviation and mean behaviour of each operation. In this instance, the metrics used in the experiment were subjected to 10 iterations of calculation to get the average and standard deviation values.

The null and alternative hypothesis test is employed to ascertain the statistical superiority of one algorithm over another in terms of performance. The current study employed the parametric student's t-test to assess the independence and significant differences between the average of the samples in training and test. The obtained results indicate that all the algorithms yielded p-values more than 0.05. The F1-score is used to compute a consolidated measure of accuracy and completeness, whereas the null hypothesis is employed to determine the level of precision exhibited by the models. The confusion matrix serves as an adjunct to these assessments, providing a means to assess the efficacy of the algorithms employed in the training phase. Figure 5 shows Machine Learning process for proposed system and Fig. 6 shows training and validation process in selecting the best ML algorithm.

4.2.6 Results of algorithm training and validation

According to the findings, 30% of the 327 MSMEs were employed to evaluate the model, and 70 percent of them were chosen for training and validation. The classification algorithms were trained using the tenfold cross validation approach using training data to guarantee accurate and effective performance. The outcomes of the training and validation process of the model indicated that Random Forests (RF) exhibited superior performance as a classification model, achieving an F1-Score of 94.10%, an Accuracy of 92.20%, a Recall of 92.47%, and a Precision of 93.36%. The "Confusion Matrix" approach was used by data analytics to illustrate and evaluate the performance of the categorization algorithms. A fresh sample of firms' levels were successfully predicted by RF with an accuracy of 93.36%. Figure 7 shows confusion matrix and Table 3 lists results of algorithms.

4.2.7 Evaluation on the test dataset

The 30 percent of the sampled firms that were chosen at random to make up the dataset for the test were included in the sample. In addition, the degree of sustainability maturity as indicated by the model was used to categorise the organisations using the best classification algorithm, i.e., RF.

4.3 Integration of Industry 4.0 with circular economy model

Manufacturing MSME includes various types of component producers, Service providers. Their scope of work varies widely and plays pivotal role in value chain as suppliers to OEMs or end customers. The MSME is striving to improve its resource efficiency and minimize waste through CE practices. Industry 4.0 technologies are aligning with the principles of Circular Economy which promotes optimizing resources and waste reduction [21]. Integration of Industry 4.0 in CE involves following stages-

4.3.1 CE model components

-

1.

Material recovery and reuse: the MSME aims to recover and reuse valuable materials from discarded or defective electronic components. This serves as input material or raw material for other or substitute products.

-

2.

Predictive maintenance: reducing machine downtime is important. Predictive maintenance can help predict equipment failures and schedule maintenance before breakdowns occur. Prediction helps in keeping uptime of the machines, which enable improved efficiency of man, material and machine.

-

3.

Real-time ainventory management: real-time monitoring of inventory levels helps prevent overstocking or stockouts, reducing waste and optimizing resource usage. This is helpful in monitoring shelf life in case of perishable materials.

4.3.2 Integration with Industry 4.0

-

1.

Internet of things (IoT) sensors and data collection: the MSME installs IoT sensors on manufacturing equipment and storage areas to collect real-time data on production processes, equipment performance, and inventory levels.

-

2.

Data analytics and machine learning: collected data is processed using data analytics and machine learning algorithms. These algorithms predict equipment failure patterns and optimize inventory levels based on historical usage and market demand.

-

3.

Closed-loop supply chain: through real-time data, the MSME identifies defective components in the production line. Industry 4.0 technologies enable the identification of reparable materials, which can be reclaimed and used in the production of new components.

MSME CE models integrate Industry 4.0 technologies such as IoT sensors, data analytics, and machine learning. The sensors capture data from various manufacturing process phases, allowing the company to monitor equipment health, production quality, and inventory status in real time. This data is analyzed by data analytics and machine learning algorithms to forecast maintenance requirements, optimize inventory levels, and identify opportunities for material recovery. When a faulty component is identified, the system can determine if any reparable parts or materials can be reclaimed, thereby reducing the need for new materials. By incorporating Industry 4.0 technologies into the CE model, the SME simultaneously accomplishes multiple objectives: it reduces waste through material recovery, optimizes resource utilization through predictive maintenance and inventory management, and improves overall efficiency. This synergy illustrates how Industry 4.0 tools can be utilized to support CE principles and enhance MSME performance metrics. This example demonstrates how Industry 4.0 technologies complement and enhance the CE model, resulting in tangible benefits for MSMEs seeking to enhance resource efficiency and sustainability.

5 Discussion

According to the model, only a few levels 1 enterprises have inadequate maturity of sustainability. 9% of the enterprises are in the service and commerce sector, 6% are in the building and civil works domain, and 3% are in the manufacturing domain. Companies at level 2 have a basic degree of sustainability maturity, while those at level 3 have a growing level of sustainability maturity. Companies in the Level 4 stage of sustainability maturity have established management and sustainability practises that work well. Businesses at level 4 have organised management indicators, environmental practise programmes, and certification in quality management or environmental management. Authors of the present investigation were able to establish that the enterprises were aware of the environmental effects of their activities thanks to the findings of the categorization of the businesses.

It is advised that MSMEs develop technology applications to recognise and classify the components they employ in their internal operations to boost their business relationships and cooperative activities. The system supports decision-making in businesses and governmental organisations. Best model selection is tabulated in Table 4.

6 Conclusion, limitations and future research agenda

MSMEs play a crucial role in the economies of numerous nations, particularly those in the emerging economies. However, apart from the presence of specific structural and organisational vulnerabilities, the absence of readily available strategies and standards to reinforce the adoption of sustainability within the internal operations of firms appears to be a significant concern within the MSME sector. In this context, the existing body of literature exhibits a limited number of studies and models that have thoroughly incorporated the fundamental elements of sustainable development. To assist businesses, identify their environmental sustainability strengths and weaknesses, this study has created a new CE model for MSMEs. The approach is broken down into four tiers that include environmental practises, management systems, and compliance with environmental knowledge management. Using the DSR and DCIE methodologies, the model has been applied to several businesses. The utilised model included data analytics to ascertain the composition of the sampled group of MSMEs. The findings revealed that within this group, 6% of firms exhibited an insufficient degree of sustainability maturity, 31% were classified as being at a basic level, 45% were categorised as being at a developing level, and 18% were identified as being at a consolidated level. The case study demonstrated the need of implementing sustainable strategies in stages for several businesses. MSMEs can enhance their capabilities by using this model, as it enables the evaluation of ecological practices, systems for management, and knowledge retention. Companies will therefore have the chance to develop their internal procedures to define real-time environmental strategies that balance the economic, social, and environmental components of environmental activities. It is recommended that MSMEs use the system via governmental agencies or business groups. In such a situation, the model serves as a flexible instrument that enables corporate decision-making and assessment based on strengths and weaknesses to set up ongoing development methods.

Furthermore, to measure the maturity level of sustainable business on a national scale, future research should encompass not simply the evaluation of outside variables pertaining to corporate environmental concerns, but additionally the broadening of the sample to include additional urban areas. Investigate the incorporation of additional sustainability indicators beyond performance metrics, such as social and economic impacts. This holistic approach aligns with the Paris Agreement's goal of addressing environmental and social aspects of sustainability. Explore how Industry 4.0 technologies and Machine Learning can optimize circular supply chains, promoting sustainable sourcing and reverse logistics. This contributes to reducing emissions and resource consumption. Investigate the policy and regulatory framework required to support the adoption of CE models in MSMEs. Research can focus on how governments and international bodies can incentivize circular practices to align with the Paris Agreement's climate goals. The future research agenda for developing CE models in MSMEs using Industry 4.0 and Machine Learning techniques offers multiple avenues to advance sustainability, circularity, and climate action. By addressing these areas of research, the work can make meaningful contributions to achieving the goals and targets of the prestigious Paris Agreement.

Data availability statement

Data required for the manuscript will be made available if required at different junctures.

References

Rathi, R., Sabale, D.B., Antony, J., Kaswan, M.S., Jayaraman, R.: An analysis of circular economy deployment in developing nations’ manufacturing sector: a systematic state-of-the-art review. Sustainability 14(18), 11354 (2022)

Vásquez, J., et al.: A sustainability maturity model for micro, small and medium-sized enterprises (MSMEs) based on a data analytics evaluation approach. J. Clean. Prod. 311, 127692 (2021). https://doi.org/10.1016/j.jclepro.2021.127692

Jamwal, A., et al.: Developing A sustainability framework for Industry 4.0. Procedia CIRP 98, 430–435 (2021). https://doi.org/10.1016/J.PROCIR.2021.01.129

Kumar, U., Kaswan, M.S., Kumar, R., Chaudhary, R., Garza-Reyes, J.A., Rathi, R., Joshi, R.: A systematic review of Industry 5.0 from main aspects to the execution status. TQM J. (2023). https://doi.org/10.1108/TQM-06-2023-0183

Kumar, N., Singh, A., Gupta, S., Kaswan, M.S., Singh, M.: Integration of lean manufacturing and Industry 4.0: a bibliometric analysis. TQM J (2023). https://doi.org/10.1108/TQM-07-2022-0243

Kaswan, M.S., Rathi, R., Atony, J., Cross, J., Garza-Reyes, J.A., Singh, M., Preet Singh, I., Sony, M.: Integrated Green Lean Six Sigma-Industry 4.0 approach to combat COVID-19: from literature review to framework development. Int. J. Lean Six Sigma, Int (2023). https://doi.org/10.1108/IJLSS-11-2022-0227

Kumar, M., Kaswan, M.S.: Optimization of surface roughness & MRR in end milling on D2 steel using Taguchi method. Optimization 5(1), 4–9 (2016)

Kaswan, M.S., Rathi, R., Cross, J., Garza-Reyes, J.A., Antony, J., Yadav, V.: Integrating green lean six sigma and industry 4.0: a conceptual framework. J. Manuf. Technol. Manag. 34(1), 87–121 (2023). https://doi.org/10.1108/JMTM-03-2022-0115

Mishra, R., Singh, R.K., Govindan, K.: Barriers to the adoption of circular economy practices in micro, small and medium enterprises: instrument development, measurement and validation. J. Clean. Prod. 351, 131389 (2022). https://doi.org/10.1016/j.jclepro.2022.131389

Malik, A., et al.: Circular economy adoption by SMEs in emerging markets: towards a multilevel conceptual framework. J. Bus. Res. 142, 605–619 (2022). https://doi.org/10.1016/j.jbusres.2021.12.076

Yadav, V., Kaswan, M.S., Gahlot, P., Duhan, R.K., Garza-Reyes, J.A., Rathi, R., Chaudhary, R., Yadav, G.: Green Lean Six Sigma for sustainability improvement: a systematic review and future research agenda. Int. J. Lean Six Sigma 14(4), 759–790 (2023). https://doi.org/10.1108/IJLSS-06-2022-0132

Malik, A., Sharma, S., Batra, I., Sharma, C., Kaswan, M.S., Garza-Reyes, J.A.: Industrial revolution and environmental sustainability: an analytical interpretation of research constituents in Industry 4.0. Int. J. Lean Six Sigma (2023). https://doi.org/10.1108/IJLSS-02-2023-0030

Yadav, V., Kumar, V., Gahlot, P., Mittal, A., Kaswan, M.S., Garza-Reyes, J.A., Rathi, R., Antony, J., Kumar, A., Owad, A.A.: Exploration and mitigation of green lean six sigma barriers: a higher education institutions perspective. TQM J. (2023). https://doi.org/10.1108/TQM-03-2023-0069

Akkalatham, W., Taghipour, A.: Pro-environmental behavior model creating circular economy in steel recycling market, empirical study in Thailand. Environ Chall. 4, 100112 (2021). https://doi.org/10.1016/j.envc.2021.100112

Rathi, R., Vakharia, A., Kaswan, M.S.: Grey relational analysis of Green Lean Six Sigma critical success factors for improved organisational performance. Int. J. Six Sigma Compet. Adv. 13(1–3), 55–75 (2021)

Soni, V., et al.: Adaptive distributed leadership and circular economy adoption by emerging SMEs. J. Bus. Res. 156, 113488 (2023). https://doi.org/10.1016/j.jbusres.2022.113488

Priyadarshini, J., et al.: Adoption of additive manufacturing for sustainable operations in the era of circular economy: Self-assessment framework with case illustration. Comput. Ind. Eng. 171, 108514 (2022). https://doi.org/10.1016/j.cie.2022.108514

Sassanelli, C., et al.: Circular economy performance assessment methods: a systematic literature review. J. Clean. Prod. 229, 440–453 (2019). https://doi.org/10.1016/j.jclepro.2019.05.019

Harris, S., Martin, M., Diener, D.: Circularity for circularity’s sake? Scoping review of assessment methods for environmental performance in the circular economy. Sustain. Prod. Consum. 26, 172–186 (2021). https://doi.org/10.1016/J.SPC.2020.09.018

Kristensen, H.S., Mosgaard, M.A.: A review of micro level indicators for a circular economy—moving away from the three dimensions of sustainability? J. Clean. Prod. 243, 118531 (2020). https://doi.org/10.1016/J.JCLEPRO.2019.118531

Mukherjee, S., et al.: ‘Blockchain-based circular economy for achieving environmental sustainability in the Indian electronic MSMEs. Manag Environ Qual: Int J (2022). https://doi.org/10.1108/MEQ-03-2022-0045/FULL/XML

Trica, C., Banacu, C., Busu, M.: Environmental factors and sustainability of the circular economy model at the European Union level. Sustainability 11(4), 1114 (2019). https://doi.org/10.3390/su11041114

Gunawan, M., Asyahira, R., Sidjabat, F.M.: Environmental management system implementation in MSMEs: a literature review. J. Seram. Eng. (2020). https://doi.org/10.32672/JSE.V5I2.1958.

Gani, A., et al.: An integrated DEMATEL-MMDE-ISM approach for analyzing environmental sustainability indicators in MSMEs. Environ. Sci. Pollut. Res. 29(2), 2035–2051 (2022). https://doi.org/10.1007/S11356-021-15194-6/METRICS

Duque-Acevedo, M., et al.: Analysis of the circular economic production models and their approach in agriculture and agricultural waste biomass management. Int. J. Environ. Res. Public Health 17(24), 9549 (2020). https://doi.org/10.3390/IJERPH17249549

Radyanto, M.R., Hayati, E.N.: Design of sustainable production performance systems for MSMEs creative industry sub sector. J. Phys: Confer. Ser. 1517(1), 012016 (2020). https://doi.org/10.1088/1742-6596/1517/1/012016

Walzberg, J., et al.: ‘Do we need a new sustainability assessment method for the circular economy? A critical literature review. Front. Sustain. (2021). https://doi.org/10.3389/frsus.2020.620047

Huysman, S., et al.: Performance indicators for a circular economy: a case study on post-industrial plastic waste. Resour. Conserv. Recycl. 120, 46–54 (2017). https://doi.org/10.1016/J.RESCONREC.2017.01.013

Asif, F.M.A., Lieder, M., Rashid, A.: Multi-method simulation based tool to evaluate economic and environmental performance of circular product systems. J. Clean. Prod. 139, 1261–1281 (2016). https://doi.org/10.1016/j.jclepro.2016.08.122

Pangarso, A., et al.: The long path to achieving green economy performance for micro small medium enterprise. J. Innov. Entrep. 11(1), 16 (2022). https://doi.org/10.1186/s13731-022-00209-4

Busu, M., Trica, C.L.: Sustainability of circular economy indicators and their impact on economic growth of the European Union. Sustainability 11(19), 5481 (2019). https://doi.org/10.3390/su11195481

Haupt, M., Hellweg, S.: Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. (2019). https://doi.org/10.1016/J.INDIC.2019.100005

Suherlan, Y., Widiyanti, E.: The model of eco-friendly packaging center to increase the competitiveness of MSMEs’ local products. IOP Confer. Ser.: Earth Environ. Sci. 905(1), 012072 (2021). https://doi.org/10.1088/1755-1315/905/1/012072

Jiliang, Z., Chen, Z.: Building and application of a circular economy index system frame for manufacturing industrial chain. Res. J. Appl. Sci. Eng. Technol. 5(24), 8646–8651 (2013). https://doi.org/10.19026/RJASET.5.4250

Palmieri, N., et al.: Circular economy model: insights from a case study in South Italy. Sustainability 12(8), 3466 (2020). https://doi.org/10.3390/SU12083466

Kowalski, Z., et al.: Assessment of energy recovery from municipal waste management systems using circular economy quality indicators. Energies 15(22), 8625 (2022). https://doi.org/10.3390/en15228625

Calzolari, T., Genovese, A., Brint, A.: The adoption of circular economy practices in supply chains—an assessment of European Multi-National Enterprises. J. Clean. Prod. 312, 127616 (2021). https://doi.org/10.1016/j.jclepro.2021.127616

Hamdan, H.: Analysis of the sustainability of MSMEs in the Covid-19 pandemic Era. JEJAK 14(1), 183–199 (2021). https://doi.org/10.15294/jejak.v14i1.26342

Avraamidou, S., et al.: Circular economy—a challenge and an opportunity for process systems engineering. Comput. Chem. Eng. 133, 106629 (2020). https://doi.org/10.1016/j.compchemeng.2019.106629

Calzolari, T., Genovese, A., Brint, A.: Circular economy indicators for supply chains: a systematic literature review. Environ. Sustain. Indic. 13, 100160 (2022). https://doi.org/10.1016/j.indic.2021.100160

Gribaudo, M., et al.: Circular economy: a performance evaluation perspective. ACM Int. Confer. Proc. Ser. (2020). https://doi.org/10.1145/3388831.3388858

Donati, F., et al.: Modeling the circular economy in environmentally extended input–output: a web application. J. Ind. Ecol. 25(1), 36–50 (2021). https://doi.org/10.1111/JIEC.13046

Stropnik, R., et al.: Reducing environmental impacts of the ups system based on PEM fuel cell with circular economy. Energy 165, 824–835 (2018). https://doi.org/10.1016/j.energy.2018.09.201

Pangarso, A., Sisilia, K., Peranginangin, Y.: Circular economy business models in the micro, small, and medium enterprises: a review. ETIKONOMI 21(2), 313–334 (2022). https://doi.org/10.15408/etk.v21i2.24052

Salguero-Puerta, L., et al.: Sustainability indicators concerning waste management for implementation of the circular economy model on the University of Lome (Togo) Campus. Int. J. Environ. Res. Public Health 16(12), 2234 (2019). https://doi.org/10.3390/ijerph16122234

Rathore, P., Sarmah, S.P.: Economic, environmental and social optimization of solid waste management in the context of circular economy. Comput. Ind. Eng. 145, 106510 (2020). https://doi.org/10.1016/j.cie.2020.106510

Fernandez-Lozano, C., et al.: A methodology for the design of experiments in computational intelligence with multiple regression models. PeerJ 4, e2721 (2016). https://doi.org/10.7717/peerj.2721

Mukherjee, A., et al.: Utilization of oversampling for multiclass sentiment analysis on Amazon review dataset. In: 2019 IEEE 10th international conference on awareness science and technology (iCAST), pp. 1–6. IEEE (2019). https://doi.org/10.1109/ICAwST.2019.8923260

Patil, S., Sonavane, S.: Minority–majority mix mean oversampling technique: an efficient technique to improve classification of imbalanced data sets, pp. 501–509 (2020). https://doi.org/10.1007/978-981-32-9515-5_48

Fushiki, T.: Estimation of prediction error by using K-fold cross-validation. Stat. Comput. 21(2), 137–146 (2011). https://doi.org/10.1007/s11222-009-9153-8

Klyueva, I.: Improving quality of the multiclass SVM classification based on the feature engineering. In: 2019 1st international conference on control systems, mathematical modelling, automation and energy efficiency (SUMMA), pp. 491–494. IEEE (2019). https://doi.org/10.1109/SUMMA48161.2019.8947599.

Tsiliki, G. et al.: RRegrs: an R package for computer-aided model selection with multiple regression models. J. Cheminformat. 7(1), 46 (2015). https://doi.org/10.1186/s13321-015-0094-2

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have NO affiliations with or involvement in any organization or entity regarding any financial interest (such as honoraria; educational grants; participation in speaker’s bureaus; membership, employment, consultancies, stock ownership, or expert testimony or patent-licensing arrangements), or non-financial interests (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or material discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Annexure

Annexure

Annexure I Classification of the features that describe a factor according to the requirements that must be fulfilled at each maturity level.

Factor | No | Features | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|---|

Environmental knowledge management | 1 | Employees are thought to have extensive understanding about environmental management | 0 | 0 | 0 | 1 |

2 | There are enough human resources to acquire environmental knowledge | 0 | 1 | 1 | 1 | |

3 | Financial resources are sufficient for acquiring environmental knowledge | 0 | 0 | 1 | 1 | |

4 | There are enough technology resources to learn about the environment | 0 | 0 | 0 | 1 | |

5 | The physical resources required to acquire environmental knowledge are there | 0 | 1 | 1 | 1 | |

6 | Employees get environmental care training | 0 | 1 | 1 | 1 | |

7 | Environmental training takes place once a month, twice a month, or three times a month | 0 | 0 | 0 | 1 | |

8 | Every six months, environmental training is performed | 0 | 0 | 1 | 0 | |

9 | Every year, environmental training is held | 1 | 1 | 0 | 0 | |

10 | Employees have access to appropriate channels to share new environmental ideas | 0 | 0 | 1 | 1 | |

11 | Environmental training is used by the staff to enhance industrial procedures | 0 | 0 | 1 | 1 | |

12 | The business has recorded its operational procedures | 0 | 0 | 1 | 1 | |

13 | The staff is knowledgeable of the organization's environmental effects and their remedial actions | 0 | 1 | 1 | 1 | |

14 | The company's primary strategy includes environmental sustainability, which is one of the top goals | 0 | 0 | 0 | 1 | |

15 | Several of the business agenda's priorities are important to environmental sustainability, but not all of them | 0 | 0 | 1 | 0 | |

16 | While it is not a top priority for the organisation, environmental sustainability is nonetheless important | 0 | 1 | 0 | 0 | |

17 | None of the company's activities are related to environmental sustainability | 1 | 0 | 0 | 0 | |

18 | The workforce is knowledgeable with environmental eco-efficiency and greener production | 0 | 0 | 0 | 1 | |

19 | The business has a programme or strategy for environmental practises | 0 | 0 | 1 | 1 | |

20 | The staff is knowledgeable about the issues of the circular economy | 0 | 0 | 0 | 1 | |

21 | The business has set up a method to record outflows, such as spills of liquid substances, gas leaks, gas–liquid mixes, and other instances of inefficiency | 0 | 0 | 1 | 1 | |

22 | Environmentally friendly procedures have been used | 1 | 1 | 1 | 1 | |

23 | There is a scheme in place to use less water and save it | 0 | 1 | 1 | 1 | |

24 | A programme for collecting and classifying solid residues is in place | 1 | 1 | 1 | 1 | |

25 | The business checks how hazardous leftovers are disposed of at the end | 0 | 0 | 0 | 1 | |

26 | Staff members often recycle office supplies | 1 | 1 | 1 | 1 | |

27 | There are procedures in place to increase the usage of industrial resources like oils, lubricants, acids, etc | 0 | 0 | 1 | 1 | |

28 | Recovered are the goods that consumers no longer utilise | 0 | 0 | 0 | 1 | |

29 | A post-sale repair service is now available to prolong the functional life of items | 0 | 0 | 0 | 1 | |

30 | Systems for monitoring noise levels are in use | 0 | 1 | 1 | 1 | |

31 | The business compiles statistics on its water and electricity costs | 0 | 0 | 1 | 1 | |

32 | Environmental factors are taken into consideration while choosing suppliers | 0 | 0 | 0 | 1 | |

33 | The providers abide by the applicable environmental legislation | 0 | 1 | 1 | 1 | |

34 | The workforce is familiar with environmental management systems | 0 | 1 | 1 | 1 | |

35 | There is an environmental management system in place | 0 | 0 | 0 | 1 | |

36 | The business has obtained environmental certification | 0 | 0 | 0 | 1 | |

37 | Nowadays, there is an environmental policy in place | 0 | 1 | 1 | 1 | |

38 | The government's primary environmental laws and regulations that must be followed by the business are obvious | 0 | 0 | 1 | 1 | |

39 | Operating environmental indicators are used by the business | 0 | 0 | 1 | 1 | |

40 | Environmental practises and the procedures used to produce goods or provide services are connected to the support of decision-making | 0 | 0 | 1 | 1 | |

41 | A system for enterprise resource planning (ERP) is in use | 0 | 0 | 1 | 1 | |

42 | The company's ERP systems include an HSEQ (Health, Safety, and Environmental Quality) module for strategic control | 0 | 0 | 1 | 1 |

Annexure II General questions by factors.

Factors | Questions |

|---|---|

Environmental knowledge management | Q1. Does the business believe that its staff have advanced understanding of environmental management? |

Q2. Does the business have enough people resources to acquire environmental knowledge? | |

Q3. Does the business have the financial resources to acquire environmental knowledge? | |

Q4. Does the business have enough technical resources to acquire environmental knowledge? | |

Q5. Does the business have enough physical resources to acquire environmental knowledge? | |

Q6. Have staff received instruction on environmental stewardship? | |

Q7. Do environmental trainings take place every month, every two months, or every three months? | |

Q8. Does environmental training take place every six months? | |

Q9. Are environmental trainings offered annually or more frequently? | |

Q10. Does the business provide employees the tools they need to submit creative environmental ideas? | |

Q11. Do the personnel utilise environmental trainings to increase productive processes? | |

Q12. Has the business recorded all its operational procedures? | |

Q13. Are the workers aware of the organization's environmental implications and the accompanying remedial actions? | |

Q14: Choose the statement that most accurately expresses the importance of environmental sustainability on your company's agenda: It is a key component of the overall strategy and is a high priority | |

Q15: Which statement best describes the importance of environmental sustainability to your company's goals? It is significant for certain operations, but not for all of them | |

Q16: Choose the response that best represents the importance of environmental sustainability on your company's agenda in response to: It is accorded significant prominence despite not being one of the agenda's top priorities | |

Q17: Choose the response that best represents the importance of environmental sustainability on your company's agenda in response to It has no bearing on any of the operations of the business | |

Environmental practices and strategies | Q18. Can you comprehend the terms "cleaner production" and "ecoefficiency"? |

Q19. Do you have an environmental practise programme at your company? | |

Q20. Do you understand what the circular economy is? | |

Q21. Has the business established a procedure for reporting liquid spills, gas leaks, gas–liquid mixes, or any other instances of inefficiency? | |

Q22. Has your business adopted environmental best practises? | |

Q23. Does your business have a programme for water conservation and effective use? | |

Q24. Do you have a solid waste collection and sorting programme at your company? | |

Q25: Does your business inspect the ultimate disposal of hazardous waste (items that are corrosive, reactive, explosive, poisonous, and flammable)? | |

Q26. Does the workforce often recycle office supplies? | |

Q27. To maximise the use of industrial resources like oils, lubricants, acids, etc., does the firm apply any treatments? | |

Q28: Does the business recycle the things that its clients no longer need? | |

Q29. Does the business provide post-sale repairs to extend the life of a product? | |

Q30. Does your business have a mechanism for measuring noise levels? | |

Q31. Does the business keep statistics on its water and electricity bills? | |

Q32: Does the business choose its suppliers based on environmental factors when making purchases? | |

Q33. Do you think that your suppliers abide by the current environmental laws? | |

Management systems | Q34. Do you understand the meaning of an environmental management system? |

Q35. Do you have an environmental management system at your company? | |

Q36. Does the business have any environmental certifications? | |

Q37. Is there an environmental policy at the company? | |

Q38. Is it easy for your business to apply the key environmental policies and laws that have been set by the government? | |

Q39. Do you have any environmental indicators for your business? | |

Q40: Are manufacturing or service delivery methods and environmental practises connected to decision-making support? | |

Q41. Is there an enterprise resource planning (ERP) system at the business? | |

Q42: Does the business' Enterprise Resource Planning (ERP) include a strategy-control HSEQ (Health, Security, Environment, and Quality) module? |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sabale, D.B., Kaswan, M.S. & Rathi, R. Development of circular economy model using Industry 4.0’s machine learning techniques to improve performance metrics of MSMEs. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01782-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01782-6